Optimized Build Orientation and Laser Scanning Strategies for Reducing Thermal Residual Stress in Topology-Optimized Automotive Components

Abstract

1. Introduction

2. Laser Scan Strategy for Reducing Thermal Stress and Residual Stress

2.1. Material and Equipment

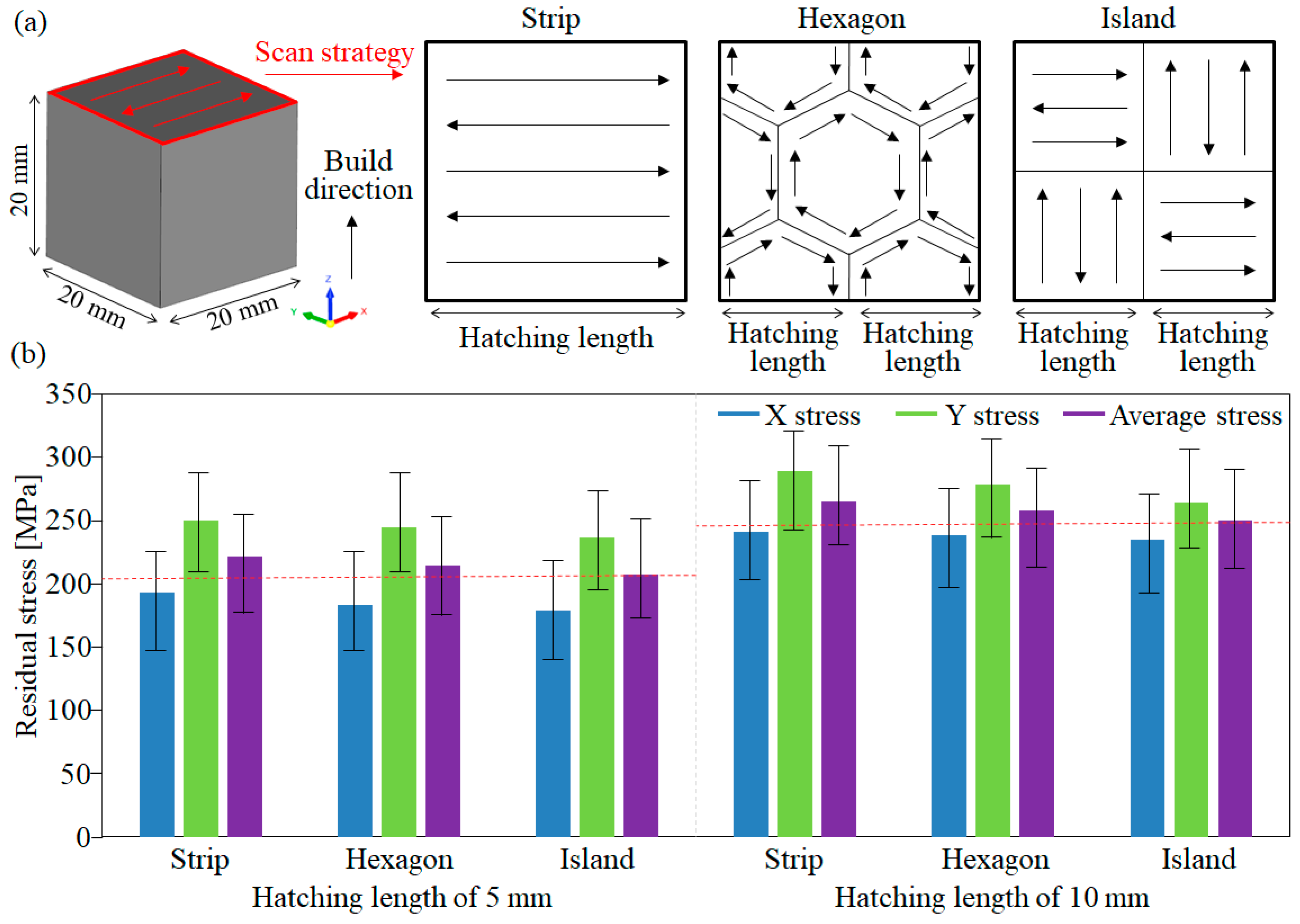

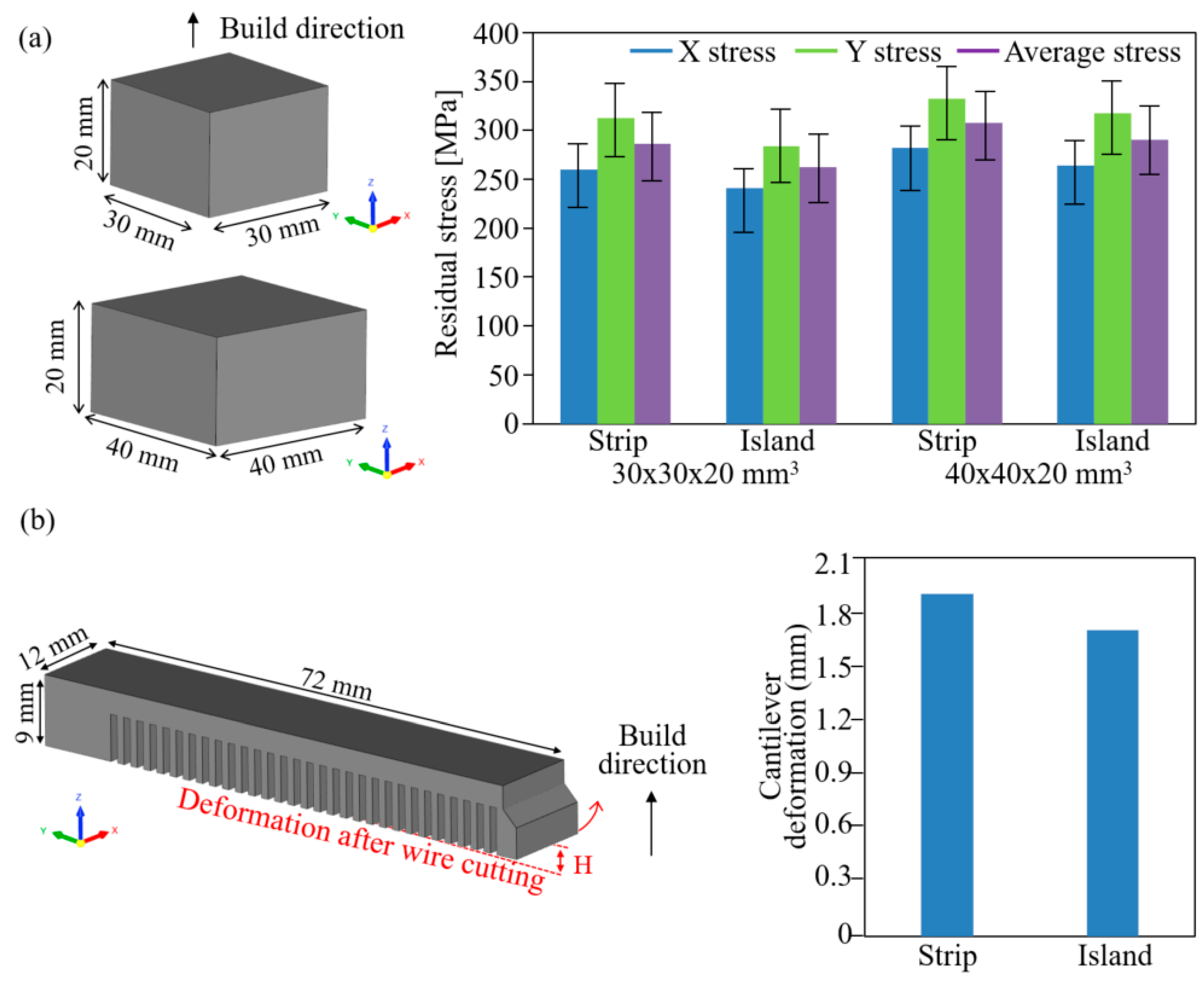

2.2. PBF Scan Strategy Method to Reduce Residual Stress

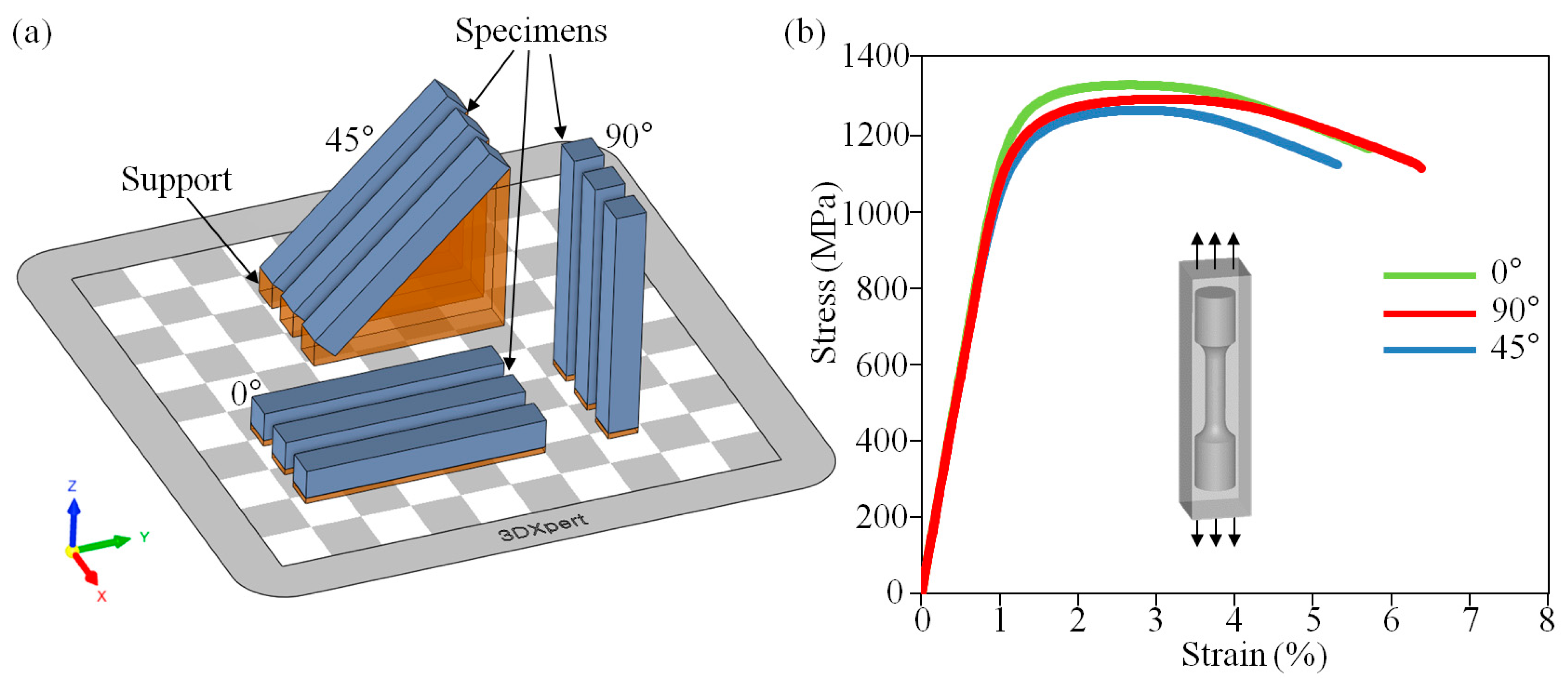

2.3. Mechanical Property According to Build Orientation

3. Additive Manufacturing Strategy of Brake Caliper Model

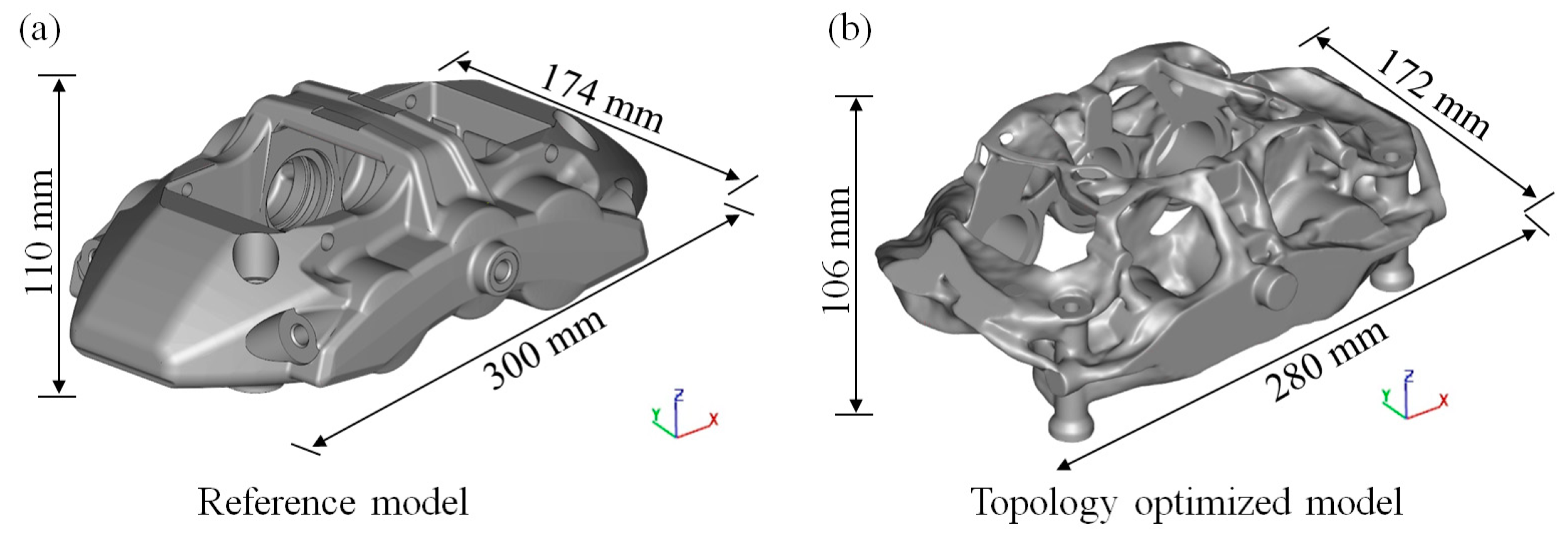

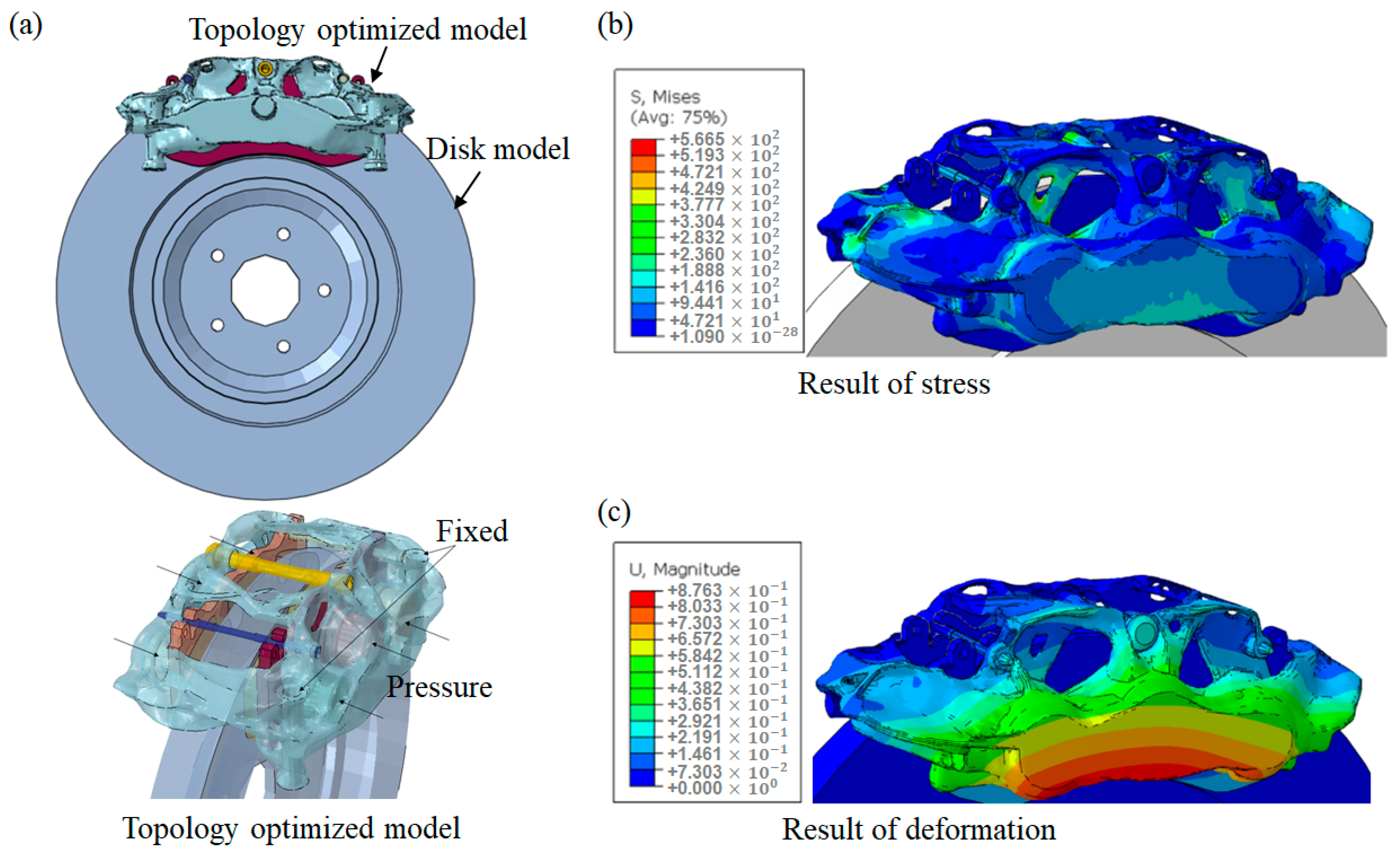

3.1. Topology Optimization of Brake Caliper Model

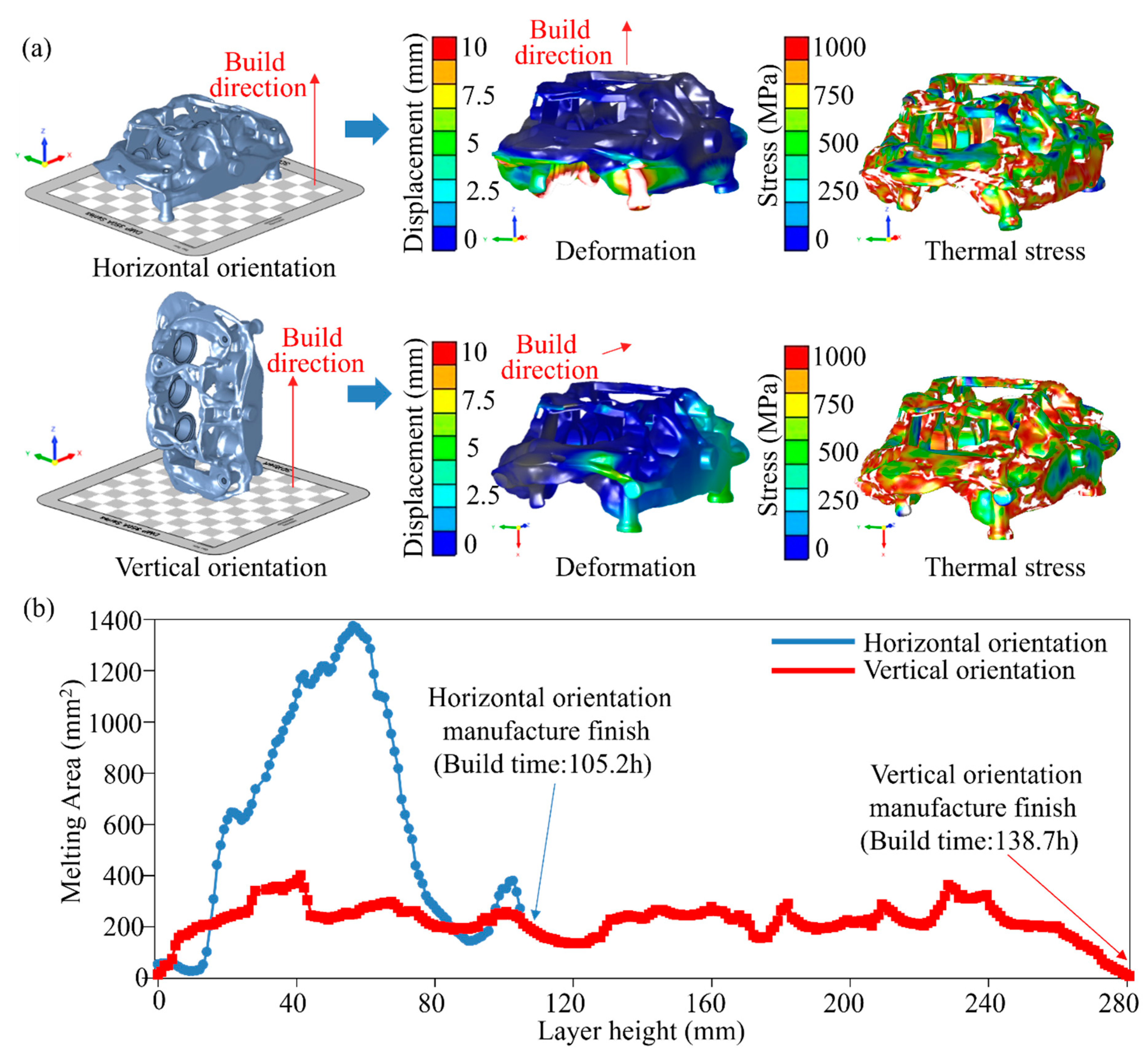

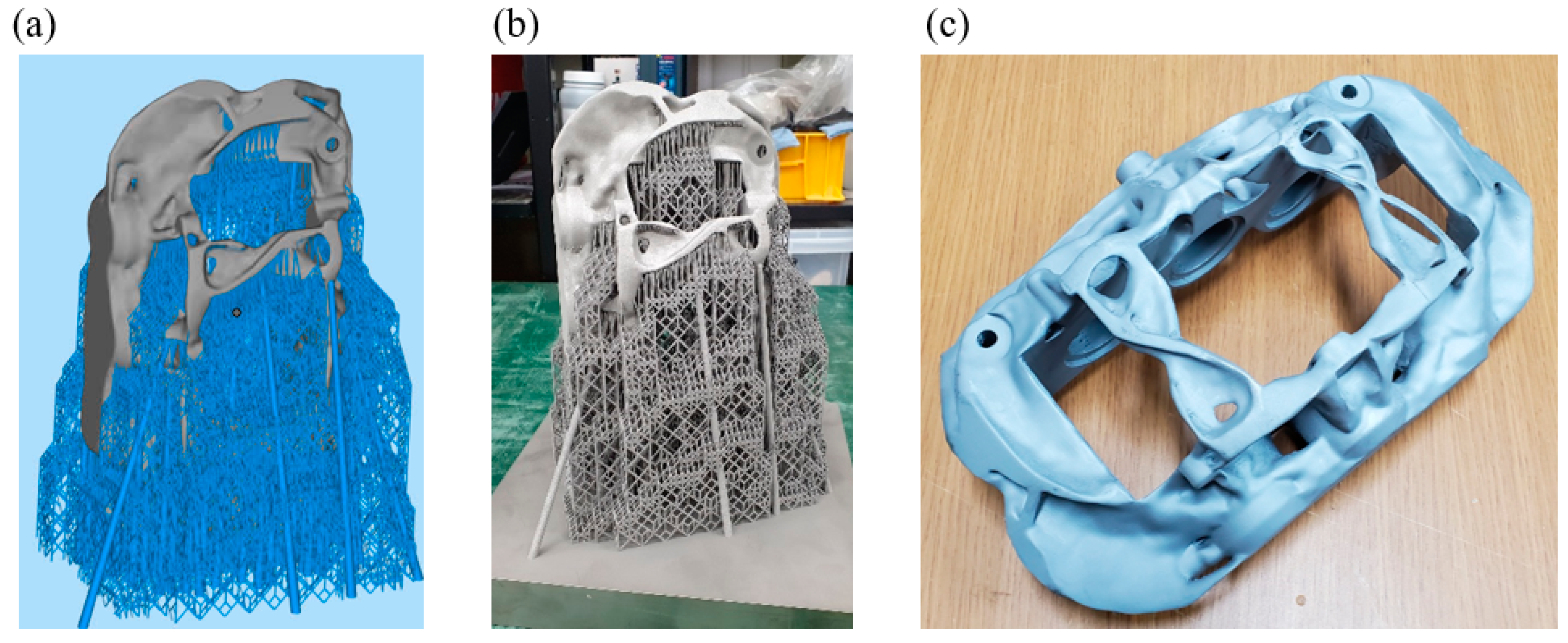

3.2. Design and Additive Manufacturing of Brake Caliper

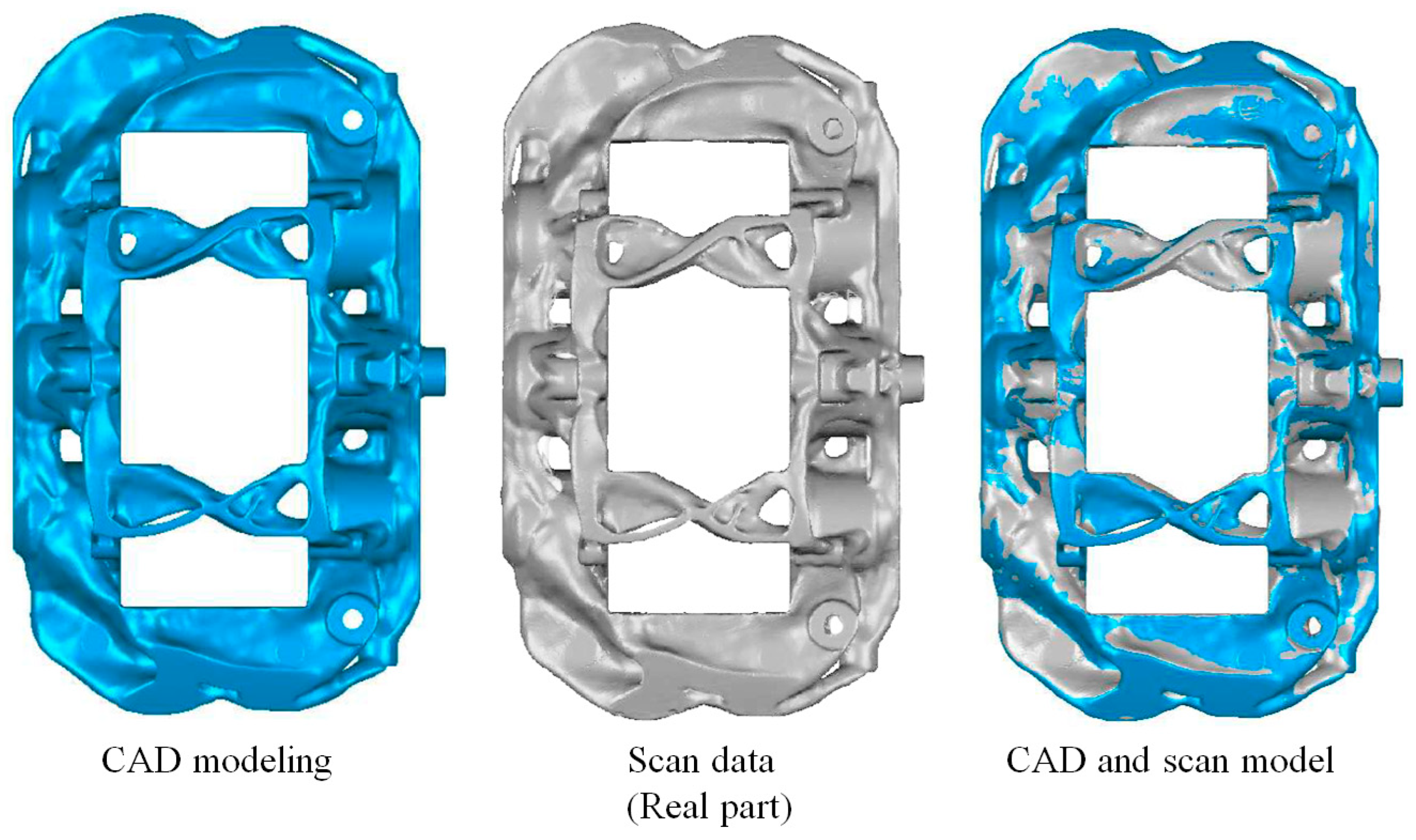

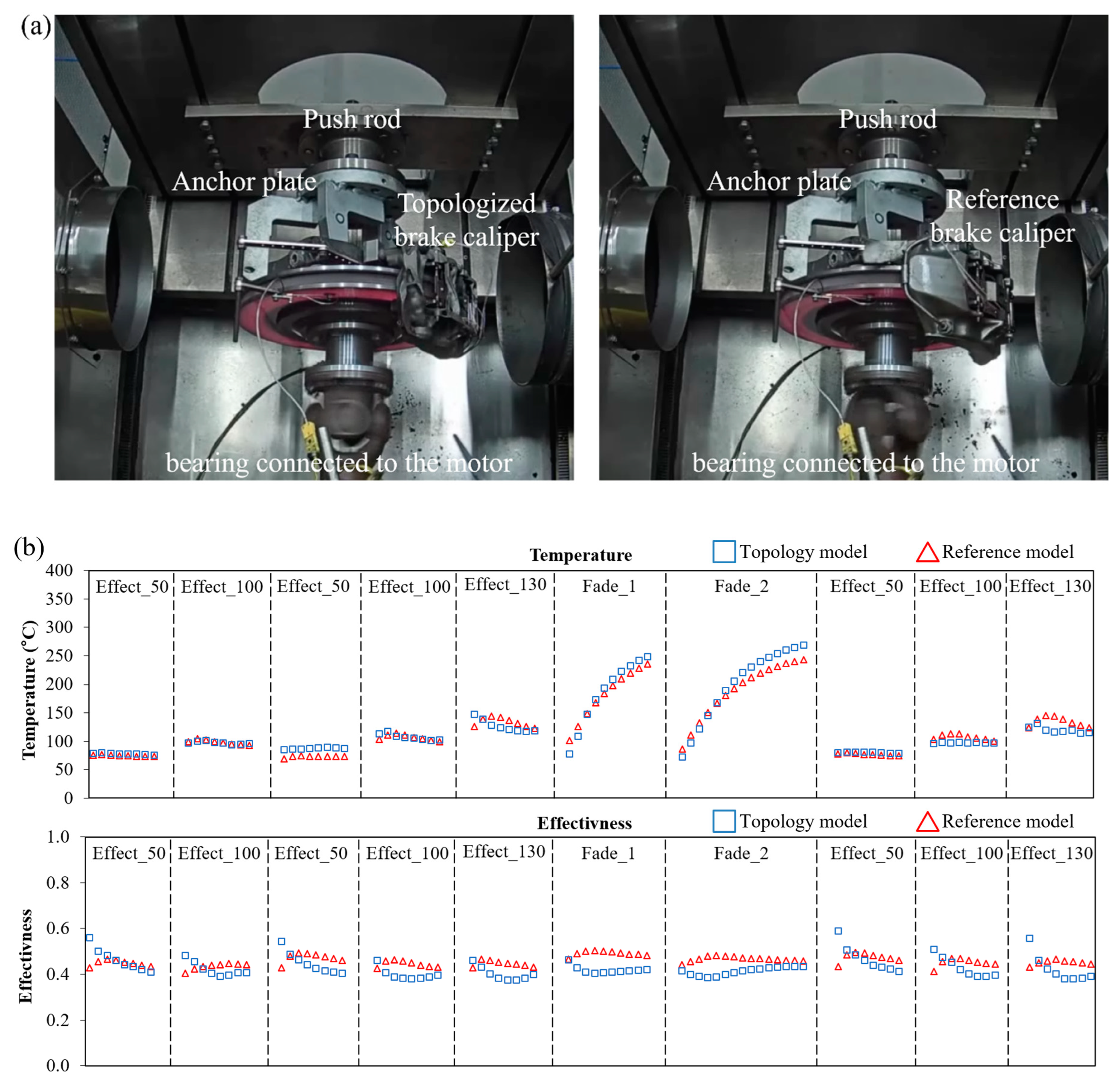

3.3. Evaluation of Topology Optimized Brake Caliper

4. Summary and Conclusions

- The residual stress was reduced by 5.47–8.41% and the thermal deformation of the cantilever by 8.33% compared to the strip process by applying an island pattern with a hatching length of 5 mm.

- The topology-optimized brake caliper is built with a vertical orientation that minimizes the melting area that causes thermal deformation and residual stress. With an effective PBF process, a topology model and a precise brake caliper with an error of up to 97 μm were fabricated.

- The brake performance of the topology-optimized brake caliper was evaluated based on JASO C406. The brake performance of the topology-optimized model equals or surpasses that of the commercial product.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bartlett, J.L.; Li, X. An overview of residual stresses in metal powder bed fusion. Addit. Manuf. 2019, 27, 131–149. [Google Scholar] [CrossRef]

- Seifi, M.; Salem, A.; Beuth, J.; Harrysson, O.; Lewandowski, J.J. Overview of materials qualification needs for metal additive manufacturing. JOM 2016, 68, 747–764. [Google Scholar] [CrossRef]

- Murr, L.E.; Gaytan, S.M.; Ramirez, D.A.; Martinez, E.; Hernandez, J.; Amato, K.N.; Wicker, R.B. Metal fabrication by additive manufacturing using laser and electron beam melting technologies. J. Mater. Sci. Technol. 2012, 28, 1–14. [Google Scholar] [CrossRef]

- Liu, R.; Wang, Z.; Sparks, T.; Liou, F.; Newkirk, J. Aerospace applications of laser additive manufacturing. In Laser Additive Manufacturing; Woodhead Publishing: Cambridge, UK, 2017; pp. 351–371. [Google Scholar]

- Juechter, V.; Franke, M.M.; Merenda, T.; Stich, A.; Körner, C.; Singer, R.F. Additive manufacturing of Ti-45Al-4Nb-C by selective electron beam melting for automotive applications. Addit. Manuf. 2018, 22, 118–126. [Google Scholar] [CrossRef]

- Li, J.; Hu, J.; Zhu, Y.; Yu, X.; Yu, M.; Yang, H. Surface roughness control of root analogue dental implants fabricated using selective laser melting. Addit. Manuf. 2020, 34, 101283. [Google Scholar] [CrossRef]

- Harzheim, L.; Graf, G.; Klug, S.; Liebers, J. Topologieoptimierung im praktischen Einsatz. ATZ-Automob. Z. 1999, 101, 530–539. [Google Scholar] [CrossRef]

- Kranz, J. Methodik und Richtlinien für Die Konstruktion von Laseradditiv Gefertigten Leichtbaustrukturen; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Dagkolu, A.; Gokdag, I.; Yilmaz, O. Design and additive manufacturing of a fatigue-critical aerospace part using topology optimization and L-PBF process. Procedia Manuf. 2021, 54, 238–243. [Google Scholar] [CrossRef]

- Yıldız, A.R.; Kılıçarpa, U.A.; Demirci, E.; Doğan, M. Topography and topology optimization of diesel engine components for light-weight design in the automotive industry. Mater. Test. 2019, 61, 27–34. [Google Scholar] [CrossRef]

- Bendsoe, M.P.; Sigmund, O. Topology Optimization: Theory, Methods, and Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2003. [Google Scholar]

- Großmann, A.; Weis, P.; Clemen, C.; Mittelstedt, C. Optimization and re-design of a metallic riveting tool for additive manufacturing—A case study. Addit. Manuf. 2020, 31, 100892. [Google Scholar] [CrossRef]

- Kumaran, M.; Senthilkumar, V. Generative design and topology optimization of analysis and repair work of industrial robot arm manufactured using additive manufacturing technology. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1012, 012036. [Google Scholar] [CrossRef]

- Mantovani, S.; Barbieri, S.G.; Giacopini, M.; Croce, A.; Sola, A.; Bassoli, E. Synergy between topology optimization and additive manufacturing in the automotive field. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2021, 235, 555–567. [Google Scholar] [CrossRef]

- Chen, X.; Yin, J.; Wang, W.; Wu, L.; Tang, F. Approaches to diminish large unsprung mass negative effects of wheel side drive electric vehicles. J. Adv. Mech. Des. Syst. Manuf. 2016, 10, JAMDSM0064. [Google Scholar] [CrossRef]

- Kandukuri, S.Y.; Pai, A.; Manikandan, M. Scope of Carbon Fibre-Reinforced Polymer Wheel Rims for Formula Student Racecars: A Finite Element Analytical approach. J. Inst. Eng. (India) Ser. C 2022, 103, 939–948. [Google Scholar] [CrossRef]

- Natarajan, H.K. Study of silicon carbide-reinforced aluminum matrix composite brake rotor for motorcycle application. Int. J. Adv. Manuf. Technol. 2018, 94, 1461–1475. [Google Scholar]

- Jamal, M.H.M.; Saleh, M.K.M. Design and Analysis an Efficient Lightweight Brake Caliper for Kuim Electric Vehicle. J. Eng. Health Sci. 2019, 2, 67–78. [Google Scholar]

- Maijer, D.M.; Gao, Y.X.; Lee, P.D.; Lindley, T.C.; Fukui, T. A through-process model of an A356 brake caliper for fatigue life prediction. Metall. Mater. Trans. A 2004, 35, 3275–3288. [Google Scholar] [CrossRef]

- Merulla, A.; Gatto, A.; Bassoli, E.; Munteanu, S.I.; Gheorghiu, B.; Pop, M.A.; Munteanu, D. Weight reduction by topology optimization of an engine subframe mount, designed for additive manufacturing production. Mater. Today Proc. 2019, 19, 1014–1018. [Google Scholar] [CrossRef]

- Sanaei, N.; Fatemi, A.; Phan, N. Defect characteristics and analysis of their variability in metal L-PBF additive manufacturing. Mater. Des. 2019, 182, 108091. [Google Scholar] [CrossRef]

- Roehling, J.D.; Smith, W.L.; Roehling, T.T.; Vrancken, B.; Guss, G.M.; McKeown, J.T.; Matthews, M.J. Reducing residual stress by selective large-area diode surface heating during laser powder bed fusion additive manufacturing. Addit. Manuf. 2019, 28, 228–235. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, W.; Xie, Y.; Li, H.; Zeng, C.; Xu, M.; Zhang, H. In-situ monitoring plume, spattering behavior and revealing their relationship with melt flow in laser powder bed fusion of nickel-based superalloy. J. Mater. Sci. Technol. 2024, 177, 44–58. [Google Scholar] [CrossRef]

- Guo, Q.; Zhao, C.; Qu, M.; Xiong, L.; Hojjatzadeh, S.M.H.; Escano, L.I.; Parab, N.D.; Fezzaa, K.; Sun, T.; Chen, L. In-situ full-field mapping of melt flow dynamics in laser metal additive manufacturing. Addit. Manuf. 2020, 31, 100939. [Google Scholar] [CrossRef]

- Srivastava, S.; Garg, R.K.; Sharma, V.S.; Alba-Baena, N.G.; Sachdeva, A.; Chand, R.; Singh, S. Multi-physics continuum modelling approaches for metal powder additive manufacturing: A review. Rapid Prototyp. J. 2020, 26, 737–764. [Google Scholar] [CrossRef]

- Bian, P.; Shi, J.; Liu, Y.; Xie, Y. Influence of laser power and scanning strategy on residual stress distribution in additively manufactured 316L steel. Opt. Laser Technol. 2020, 132, 106477. [Google Scholar] [CrossRef]

- Nadammal, N.; Mishurova, T.; Fritsch, T.; Serrano-Munoz, I.; Kromm, A.; Haberland, C.; Bruno, G. Critical role of scan strategies on the development of microstructure, texture, and residual stresses during laser powder bed fusion additive manufacturing. Addit. Manuf. 2021, 38, 101792. [Google Scholar] [CrossRef]

- Liu, J.; Li, G.; Sun, Q.; Li, H.; Sun, J.; Wang, X. Understanding the effect of scanning strategies on the microstructure and crystallographic texture of Ti-6Al-4V alloy manufactured by laser powder bed fusion. J. Mater. Process. Technol. 2022, 299, 117366. [Google Scholar] [CrossRef]

- Thompson, S.M.; Bian, L.; Shamsaei, N.; Yadollahi, A. An overview of Direct Laser Deposition for additive manufacturing; Part I: Transport phenomena, modeling and diagnostics. Addit. Manuf. 2015, 8, 36–62. [Google Scholar] [CrossRef]

- Zhang, H.; Li, C.; Xu, M.; Dai, W.; Kumar, P.; Liu, Z.; Li, Z.; Zhang, Y. The fatigue performance evaluation of additively manufactured 304L austenitic stainless steels. Mater. Sci. Eng. A 2021, 802, 140640. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Ganeriwala, R.K.; Strantza, M.; King, W.E.; Clausen, B.; Phan, T.Q.; Levine, L.E.; Hodge, N.E. Evaluation of a thermomechanical model for prediction of residual stress during laser powder bed fusion of Ti-6Al-4V. Addit. Manuf. 2019, 27, 489–502. [Google Scholar] [CrossRef]

- Nguyen, H.D.; Pramanik, A.; Basak, A.K.; Dong, Y.; Prakash, C.; Debnath, S.; Buddhi, D. A critical review on additive manufacturing of Ti-6Al-4V alloy: Microstructure and mechanical properties. J. Mater. Res. Technol. 2022, 18, 4641–4661. [Google Scholar] [CrossRef]

- Kardak, A.A.; Sinclair, G.B. Stress concentration factors for ASTM E8/E8M-16a standard round specimens for tension testing. J. Test. Eval. 2020, 48, 711–719. [Google Scholar] [CrossRef]

- Altair OptiStruct 2016: Users Guide; Altair Engineering, Inc.: Troy, MI, USA, 2016.

- ABAQUS/Standard User’s Manual for Version 6.5.1; Hibbitt, Karlsson and Sorensen Inc.: Pawtucket, RI, USA, 2004.

- Yang, Y.; Li, M.; Li, K.R. Comparison and analysis of main effect elements of machining distortion for aluminum alloy and titanium alloy aircraft monolithic component. Int. J. Adv. Manuf. Technol. 2014, 70, 1803–1811. [Google Scholar] [CrossRef]

- Mugwagwa, L.; Yadroitsava, I.; Makoana, N.W.; Yadroitsev, I. Residual stress in laser powder bed fusion. In Fundamentals of Laser Powder Bed Fusion of Metals; Elsevier: Amsterdam, The Netherlands, 2021; pp. 245–276. [Google Scholar]

- 3Dsystems 3Dxpert. User’s Manual. Available online: https://www.3dsystems.com/software/3dxpert (accessed on 5 November 2024).

- Li, C.; Liu, Z.Y.; Fang, X.Y.; Guo, Y.B. Residual stress in metal additive manufacturing. Procedia Cirp 2018, 71, 348–353. [Google Scholar] [CrossRef]

- Aranganathan, N.; Mahale, V.; Bijwe, J. Effects of aramid fiber concentration on the friction and wear characteristics of non-asbestos organic friction composites using standardized braking tests. Wear 2016, 354, 69–77. [Google Scholar] [CrossRef]

| Parameters | Tensile Stress (MPa) | Elongation (%) |

|---|---|---|

| Horizontal orientation | 1333 ± 23 | 5.8 ± 0.3 |

| Diagonal orientation | 1289 ± 27 | 5.4 ± 0.4 |

| Vertical orientation | 1307 ± 30 | 6.7 ± 0.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, J.; Jung, Y.; Jung, J.; Ock, J.D.; Cho, S.; Park, S.H.; Lee, T.H.; Park, J. Optimized Build Orientation and Laser Scanning Strategies for Reducing Thermal Residual Stress in Topology-Optimized Automotive Components. Metals 2024, 14, 1277. https://doi.org/10.3390/met14111277

Yang J, Jung Y, Jung J, Ock JD, Cho S, Park SH, Lee TH, Park J. Optimized Build Orientation and Laser Scanning Strategies for Reducing Thermal Residual Stress in Topology-Optimized Automotive Components. Metals. 2024; 14(11):1277. https://doi.org/10.3390/met14111277

Chicago/Turabian StyleYang, Jeongho, Youngsuk Jung, Jaewoong Jung, Jae Dong Ock, Shinhu Cho, Sang Hu Park, Tae Hee Lee, and Jiyong Park. 2024. "Optimized Build Orientation and Laser Scanning Strategies for Reducing Thermal Residual Stress in Topology-Optimized Automotive Components" Metals 14, no. 11: 1277. https://doi.org/10.3390/met14111277

APA StyleYang, J., Jung, Y., Jung, J., Ock, J. D., Cho, S., Park, S. H., Lee, T. H., & Park, J. (2024). Optimized Build Orientation and Laser Scanning Strategies for Reducing Thermal Residual Stress in Topology-Optimized Automotive Components. Metals, 14(11), 1277. https://doi.org/10.3390/met14111277