Two-Dimensional X-Ray Diffraction (2D-XRD) and Micro-Computed Tomography (Micro-CT) Characterization of Additively Manufactured 316L Stainless Steel

Abstract

1. Introduction

2. Materials and Experimental Methods

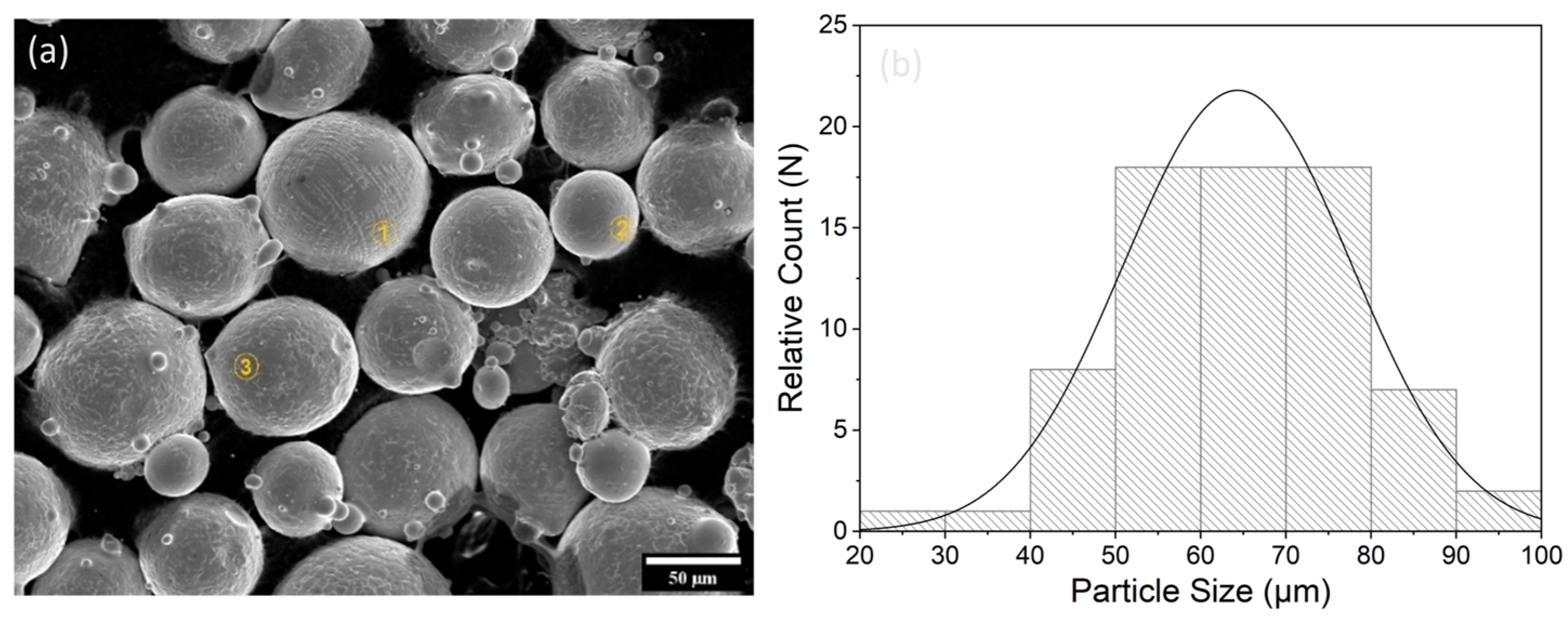

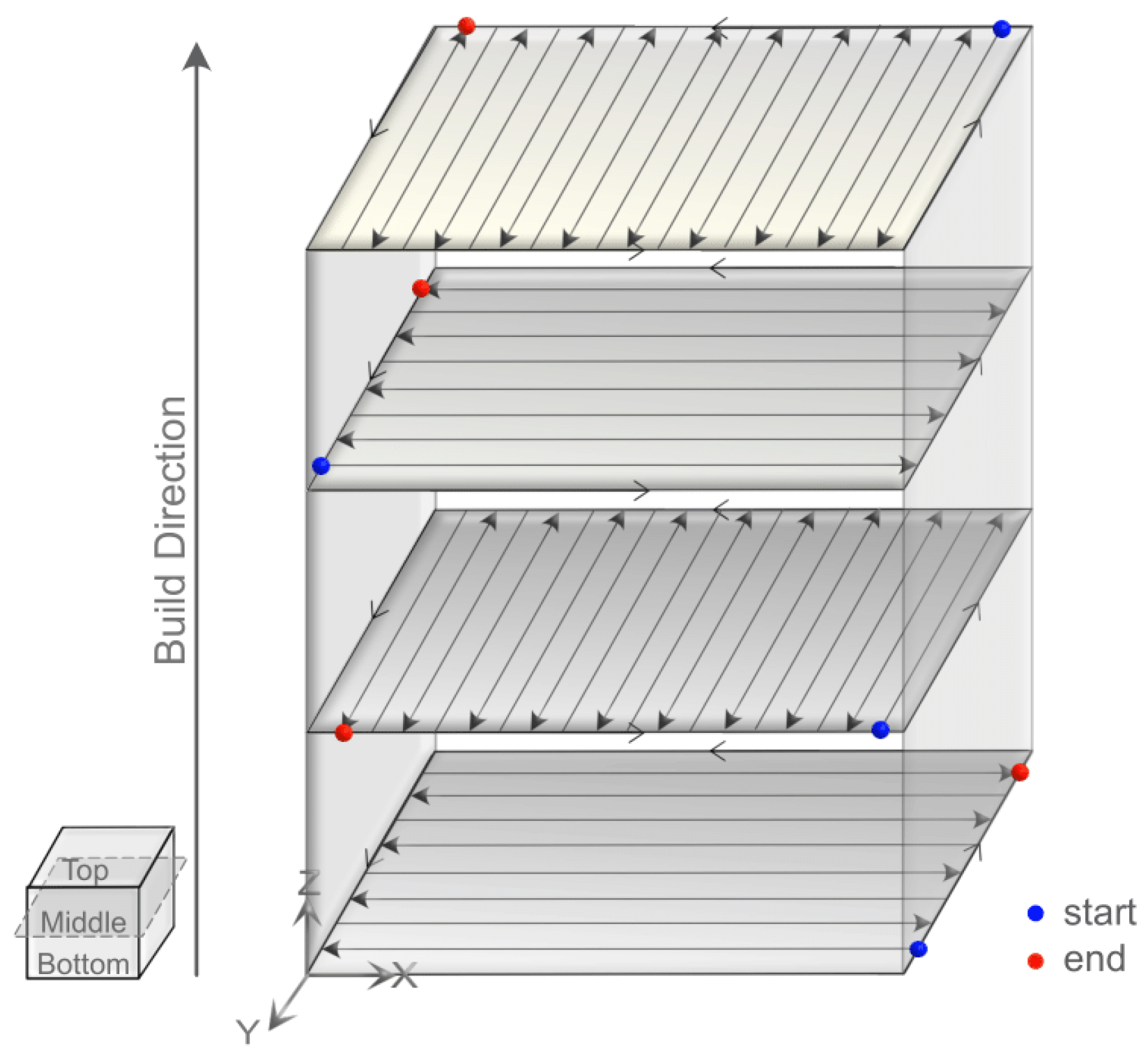

2.1. Materials

2.2. Experimental Methods

3. Results

3.1. Surface Roughness and Density

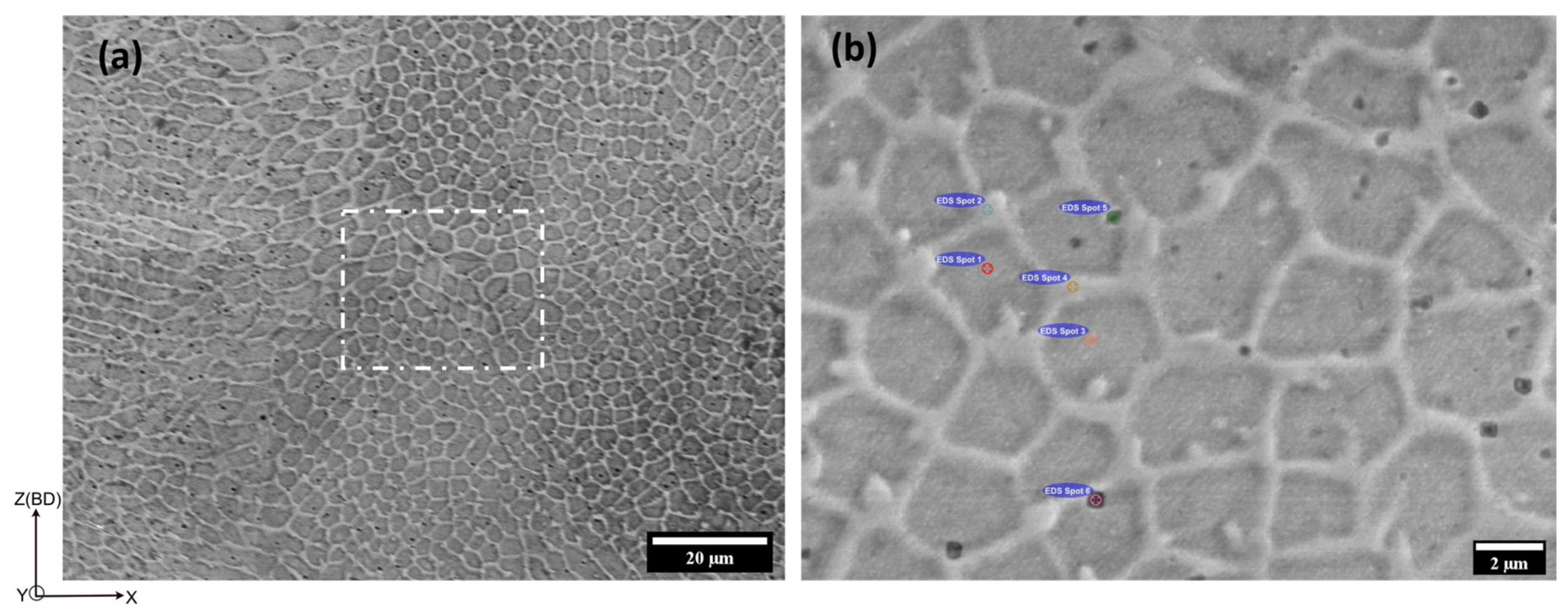

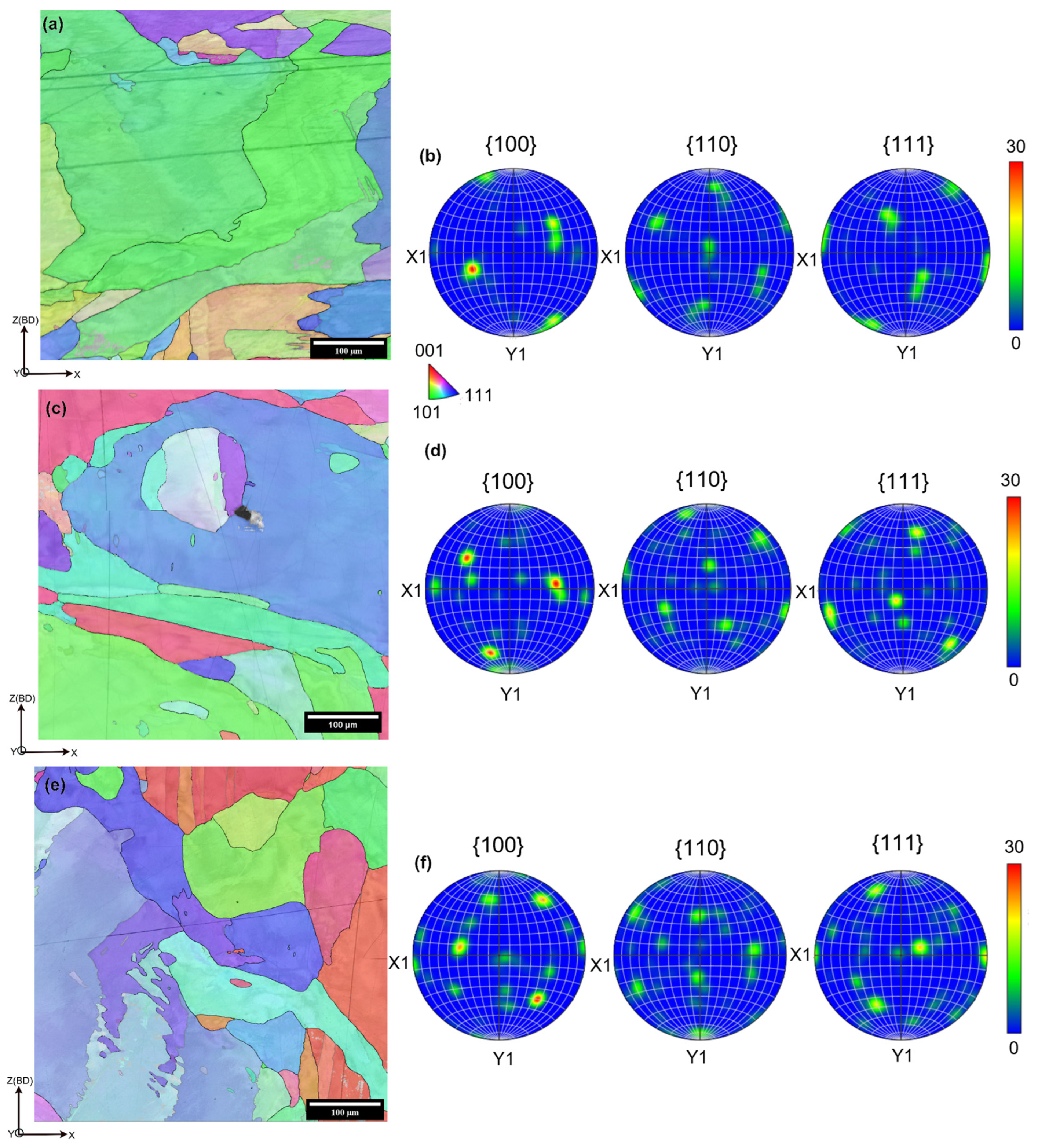

3.2. Microstructure

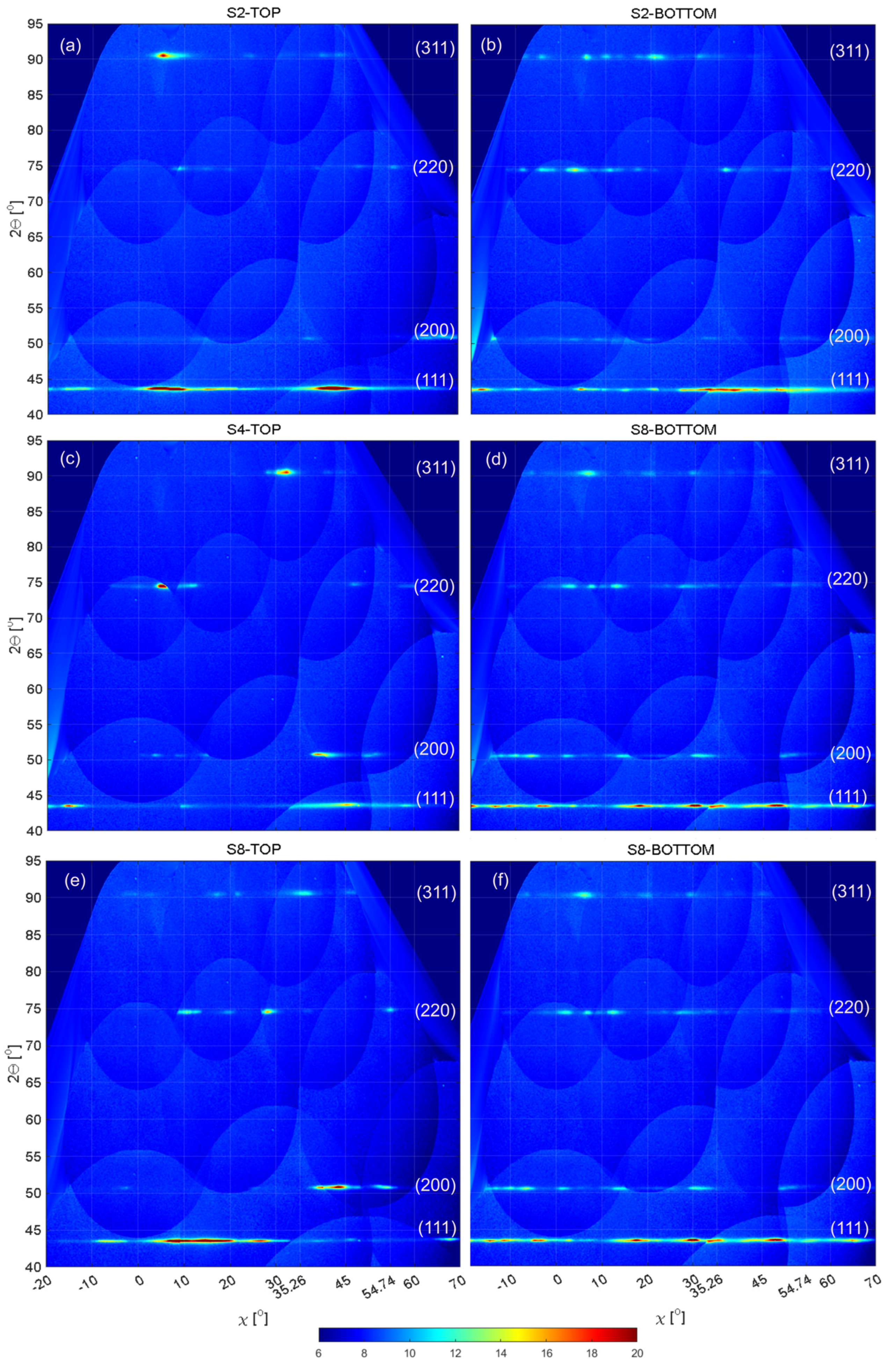

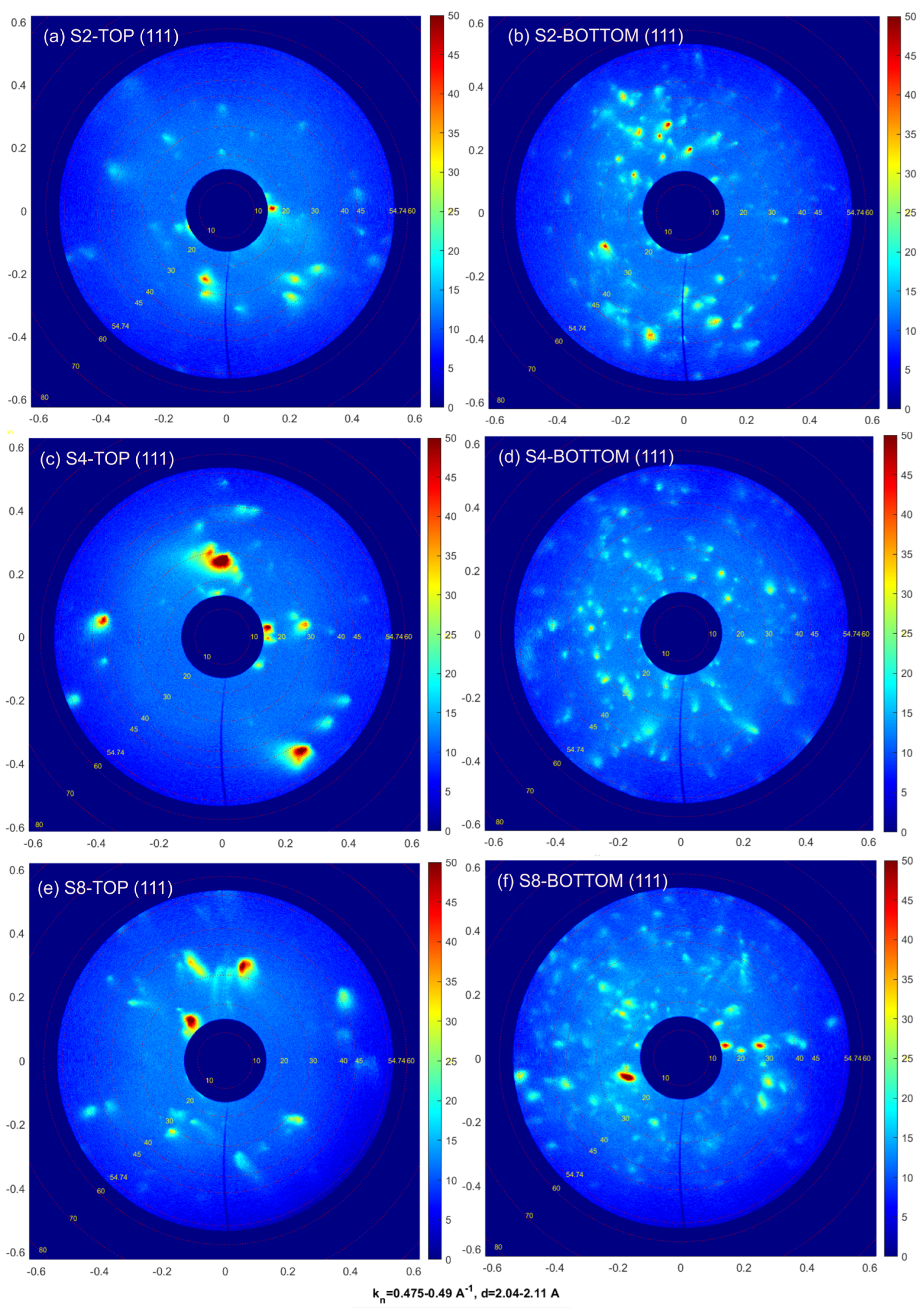

3.3. 2D XRD Analysis

3.4. X-Ray Micro-CT

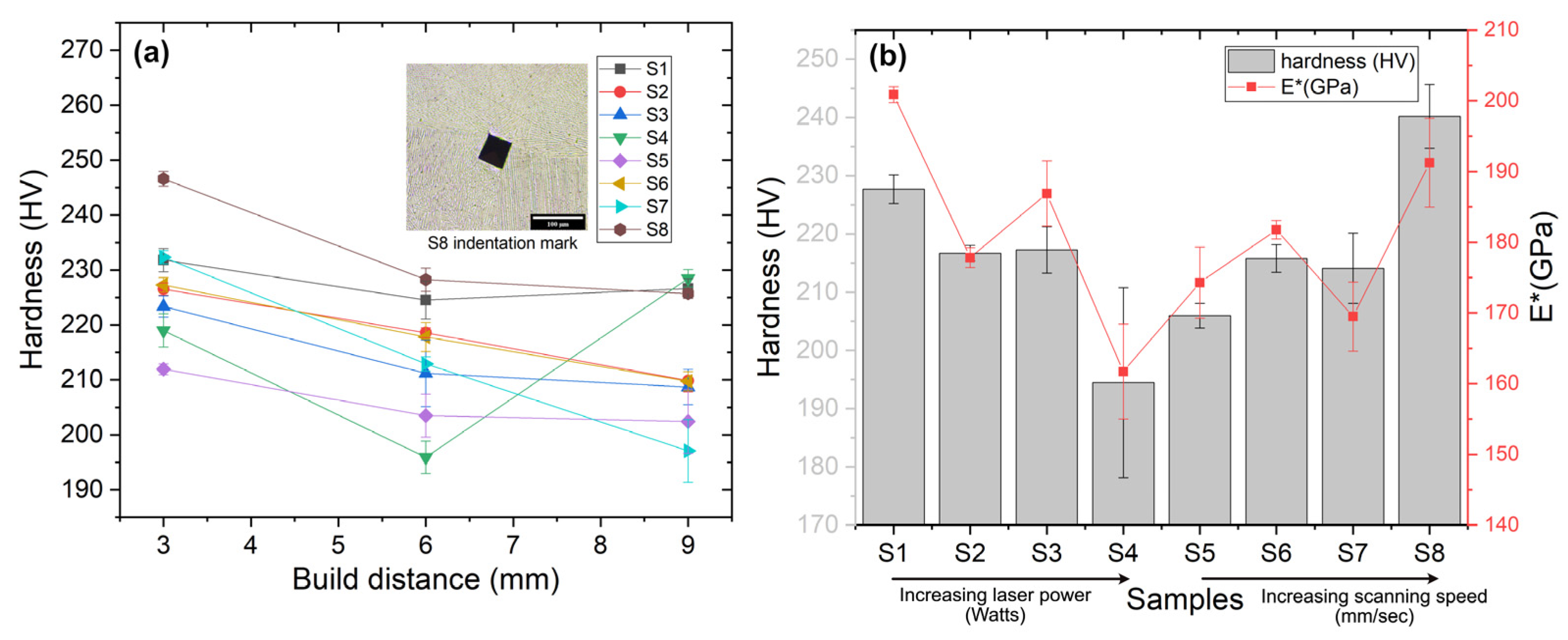

3.5. Micro-Hardness Test

4. Discussion

4.1. Microstructure Analysis Using 2D-XRD and EBSD

4.2. Internal Defect Analysis Using Micro-CT

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Izadi, M.; Farzaneh, A.; Mohammed, M.; Gibson, I.; Rolfe, B. A review of laser engineered net shaping (LENS) build and process parameters of metallic parts. Rapid Prototyp. J. 2020, 26, 1059–1078. [Google Scholar] [CrossRef]

- Hassen, A.A.; Noakes, M.; Nandwana, P.; Kim, S.; Kunc, V.; Vaidya, U.; Love, L.; Nycz, A. Scaling Up metal additive manufacturing process to fabricate molds for composite manufacturing. Addit. Manuf. 2020, 32, 101093. [Google Scholar] [CrossRef]

- Svetlizky, D.; Zheng, B.; Vyatskikh, A.; Das, M.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Laser-based directed energy deposition (DED-LB) of advanced materials. Mater. Sci. Eng. A 2022, 840, 142967. [Google Scholar] [CrossRef]

- Aprilia, A.; Wu, N.; Zhou, W. Repair and restoration of engineering components by laser directed energy deposition. Mater. Today Proc. 2022, 70, 206–211. [Google Scholar] [CrossRef]

- Wang, Y.M.; Voisin, T.; McKeown, J.T.; Ye, J.; Calta, N.P.; Li, Z.; Zeng, Z.; Zhang, Y.; Chen, W.; Roehling, T.T.; et al. Additively manufactured hierarchical stainless steels with high strength and ductility. Nat. Mater. 2018, 17, 63–70. [Google Scholar] [CrossRef]

- Casati, R.; Lemke, J.; Vedani, M. Microstructure and Fracture Behavior of 316L Austenitic Stainless Steel Produced by Selective Laser Melting. J. Mater. Sci. Technol. 2016, 32, 738–744. [Google Scholar] [CrossRef]

- Fedorenko, A.; Fedulov, B.; Kuzminova, Y.; Evlashin, S.; Staroverov, O.; Tretyakov, M.; Lomakin, E.; Akhatov, I. Anisotropy of mechanical properties and residual stress in additively manufactured 316l specimens. Materials 2021, 14, 7176. [Google Scholar] [CrossRef]

- Zhang, B.; Dembinski, L.; Coddet, C. The study of the laser parameters and environment variables effect on mechanical properties of high compact parts elaborated by selective laser melting 316L powder. Mater. Sci. Eng. A 2013, 584, 21–31. [Google Scholar] [CrossRef]

- Heiden, M.J.; Jensen, S.C.; Koepke, J.R.; Saiz, D.J.; Dickens, S.M.; Jared, B.H. Process and feedstock driven microstructure for laser powder bed fusion of 316L stainless steel. Materialia 2022, 21, 101356. [Google Scholar] [CrossRef]

- Wilson, J.M.; Jones, N.; Jin, L.; Shin, Y.C. Laser deposited coatings of Co-Cr-Mo onto Ti-6Al-4V and SS316L substrates for biomedical applications. J. Biomed. Mater. Res.—Part B Appl. Biomater. 2013, 101, 1124–1132. [Google Scholar] [CrossRef]

- Ahn, D.G. Directed Energy Deposition (DED) Process: State of the Art. Korean Soc. Precis. Eng. 2021, 8, 703–742. [Google Scholar] [CrossRef]

- Jensen, S.C.; Koepke, J.R.; Saiz, D.J.; Heiden, M.; Carroll, J.D.; Boyce, B.L.; Jared, B.H. Optimization of Stochastic Feature Properties in Laser Powder Bed Fusion. Addit. Manuf. 2022, 56, 102943. [Google Scholar] [CrossRef]

- King, W.E.; Barth, H.D.; Castillo, V.M.; Gallegos, G.F.; Gibbs, J.W.; Hahn, D.E.; Kamath, C.; Rubenchik, A.M. Observation of keyhole-mode laser melting in laser powder-bed fusion additive manufacturing. J. Mater. Process. Technol. 2014, 214, 2915–2925. [Google Scholar] [CrossRef]

- Roehling, T.T.; Shi, R.; Khairallah, S.A.; Roehling, J.D.; Guss, G.M.; McKeown, J.T.; Matthews, M.J. Controlling grain nucleation and morphology by laser beam shaping in metal additive manufacturing. Mater. Des. 2020, 195, 109071. [Google Scholar] [CrossRef]

- Zheng, B.; Haley, J.C.; Yang, N.; Yee, J.; Terrassa, K.W.; Zhou, Y.; Lavernia, E.J.; Schoenung, J.M. On the evolution of microstructure and defect control in 316L SS components fabricated via directed energy deposition. Mater. Sci. Eng. A 2019, 764, 138243. [Google Scholar] [CrossRef]

- Pathak, P.; Majkic, G.; Selvamanickam, V. Role of customized scan strategies and dwell time on microstructure and properties of additively manufactured 316L stainless steel. Mater. Sci. Addit. Manuf. 2024, 3, 2676. [Google Scholar] [CrossRef]

- Yadollahi, A.; Shamsaei, N.; Thompson, S.M.; Seely, D.W. Effects of process time interval and heat treatment on the mechanical and microstructural properties of direct laser deposited 316L stainless steel. Mater. Sci. Eng. A 2015, 644, 171–183. [Google Scholar] [CrossRef]

- Pacheco, J.T.; Meura, V.H.; Bloemer, P.R.A.; Veiga, M.T.; de Moura Filho, O.C.; Cunha, A.; Teixeira, M.F. Laser directed energy deposition of AISI 316L stainless steel: The effect of build direction on mechanical properties in as-built and heat-treated conditions. Adv. Ind. Manuf. Eng. 2022, 4, 100079. [Google Scholar] [CrossRef]

- Ribeiro, K.S.B.; Mariani, F.E.; Coelho, R.T. A Study of Different Deposition Strategies in Direct Energy Deposition (DED) Processes. Procedia Manuf. 2020, 48, 663–670. [Google Scholar] [CrossRef]

- Lin, P.Y.; Shen, F.C.; Wu, K.T.; Hwang, S.J.; Lee, H.H. Process optimization for directed energy deposition of SS316L components. Int. J. Adv. Manuf. Technol. 2020, 111, 1387–1400. [Google Scholar] [CrossRef]

- Balhara, H.; Botcha, B.; Wolff, S.; Bukkapatnam, S. Ripple formation and its effect on the multi-scale microstructure of Directed Energy Deposition (DED)-printed 316L components. arXiv 2021, arXiv:2111.11601. [Google Scholar]

- Zheng, B.; Zhou, Y.; Smugeresky, J.E.; Schoenung, J.M.; Lavernia, E.J. Thermal behavior and microstructural evolution during laser deposition with laser-engineered net shaping: Part I. Numerical calculations. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2008, 39, 2228–2236. [Google Scholar] [CrossRef]

- Pathak, P.; Dzhurinskiy, D.; Elkin, A.; Shornikov, P.; Dautov, S.; Ivanov, V. Enhanced High-Temperature YSZ-polyester Abradable Honeycomb Seal Structures. J. Therm. Spray Technol. 2022, 31, 307–314. [Google Scholar] [CrossRef] [PubMed]

- Manvatkar, V.D.; Gokhale, A.A.; Reddy, G.J.; Venkataramana, A.; De, A. Estimation of melt pool dimensions, thermal cycle, and hardness distribution in the laser-engineered net shaping process of austenitic stainless steel. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2011, 42, 4080–4087. [Google Scholar] [CrossRef]

- Mukherjee, T.; Zuback, J.S.; De, A.; DebRoy, T. Printability of alloys for additive manufacturing. Sci. Rep. 2016, 6, 19717. [Google Scholar] [CrossRef] [PubMed]

- Mohr, G.; Altenburg, S.J.; Hilgenberg, K. Effects of inter layer time and build height on resulting properties of 316L stainless steel processed by laser powder bed fusion. Addit. Manuf. 2020, 32, 101080. [Google Scholar] [CrossRef]

- Salman, O.O.; Gammer, C.; Chaubey, A.K.; Eckert, J.; Scudino, S. Effect of heat treatment on microstructure and mechanical properties of 316L steel synthesized by selective laser melting. Mater. Sci. Eng. A 2019, 748, 205–212. [Google Scholar] [CrossRef]

- Carminati, M.; Quarto, M.; D’Urso, G.; Giardini, C.; Maccarini, G. Mechanical Characterization of AISI 316L Samples Printed Using Material Extrusion. Appl. Sci. 2022, 12, 1433. [Google Scholar] [CrossRef]

- Kuzminova, Y.O.; Firsov, D.G.; Konev, S.D.; Dudin, A.A.; Dagesyan, S.A.; Akhatov, I.S.; Evlashin, S.A. Structure control of 316L stainless steel through an additive manufacturing. Lett. Mater. 2019, 9, 551–555. [Google Scholar] [CrossRef]

- Chadha, K.; Tian, Y.; Spray, J.G.; Aranas, C. Effect of annealing heat treatment on the microstructural evolution and mechanical properties of hot isostatic pressed 316L stainless steel fabricated by laser powder bed fusion. Metals 2020, 10, 753. [Google Scholar] [CrossRef]

- Mirzababaei, S.; Paul, B.K.; Pasebani, S. Microstructure-property relationship in binder jet produced and vacuum sintered 316 L. Addit. Manuf. 2022, 53, 102720. [Google Scholar] [CrossRef]

- Zhang, G.; Lu, X.; Li, J.; Chen, J.; Lin, X.; Wang, M.; Tan, H.; Huang, W. In-situ grain structure control in directed energy deposition of Ti6Al4V. Addit. Manuf. 2022, 55, 102865. [Google Scholar] [CrossRef]

- Heigel, J.C.; Michaleris, P.; Reutzel, E.W. Thermo-mechanical model development and validation of directed energy deposition additive manufacturing of Ti-6Al-4V. Addit. Manuf. 2015, 5, 9–19. [Google Scholar] [CrossRef]

- Sciammarella, F.M.; Najafabadi, B.S. Processing parameter doe for 316l using directed energy deposition. J. Manuf. Mater. Process. 2018, 2, 61. [Google Scholar] [CrossRef]

- Gong, H.; Nadimpalli, V.K.; Rafi, K.; Starr, T.; Stucker, B. Micro-CT Evaluation of Defects in Ti-6Al-4V Parts Fabricated by Metal Additive Manufacturing. Technologies 2019, 7, 44. [Google Scholar] [CrossRef]

- Ziętala, M.; Durejko, T.; Polański, M.; Kunce, I.; Płociński, T.; Zieliński, W.; Łazińska, M.; Stępniowski, W.; Czujko, T.; Kurzydłowski, K.J.; et al. The microstructure, mechanical properties and corrosion resistance of 316 L stainless steel fabricated using laser engineered net shaping. Mater. Sci. Eng. A 2016, 677, 1–10. [Google Scholar] [CrossRef]

- Kruth, J.P.; Bartscher, M.; Carmignato, S.; Schmitt, R.; De Chiffre, L.; Weckenmann, A. Computed tomography for dimensional metrology. CIRP Ann.—Manuf. Technol. 2011, 60, 821–842. [Google Scholar] [CrossRef]

- Smith, K.L.; Ortega, K.B. Use of a Two-Dimensional, Position Sensitive Detector for Collecting Pole Figures. Adv. X-Ray Anal. 1992, 36, 641–647. [Google Scholar] [CrossRef]

- He, B.B. Introduction to two-dimensional X-Ray diffraction. Powder Diffr. 2003, 18, 71–85. [Google Scholar] [CrossRef]

- Cho, J.Y.; Xu, W.; Brandt, M.; Qian, M. Selective laser melting-fabricated Ti-6Al-4V alloy: Microstructural inhomogeneity, consequent variations in elastic modulus and implications. Opt. Laser Technol. 2019, 111, 664–670. [Google Scholar] [CrossRef]

- He, B.B.; Preckwinkel, U.; Smith, K.L. Stress and texture analysis with two-dimensional X-Ray diffraction. Mater. Sci. Forum 2002, 404–407, 109–114. [Google Scholar] [CrossRef]

- Thompson, A.; Maskery, I.; Leach, R.K. X-Ray computed tomography for additive manufacturing: A review. Meas. Sci. Technol. 2016, 27, 072001. [Google Scholar] [CrossRef]

- Lopez, E.; Felgueiras, T.; Grunert, C.; Brückner, F.; Riede, M.; Seidel, A.; Marquardt, A.; Leyens, C.; Beyer, E. Evaluation of 3D-printed parts by means of high-performance computer tomography. J. Laser Appl. 2018, 30, 032307. [Google Scholar] [CrossRef]

- Carlton, H.D.; Haboub, A.; Gallegos, G.F.; Parkinson, D.Y.; Macdowell, A.A. Materials Science & Engineering A Damage evolution and failure mechanisms in additively manufactured stainless steel. Mater. Sci. Eng. A 2016, 651, 406–414. [Google Scholar] [CrossRef]

- Mazumder, J.; Schifferer, A.; Choi, J. Direct materials deposition: Designed macro and microstructure. Mater. Res. Innov. 1999, 3, 118–131. [Google Scholar] [CrossRef]

- Bjerregaard, L.; Geels, K.; Ottesen, B.; Rückert, M. Metalog Guide. 2020. Available online: https://www.struers.com/en/Library#brochures (accessed on 2 January 2022).

- Dzhurinskiy, D.; Babu, A.; Pathak, P.; Elkin, A.; Dautov, S.; Shornikov, P. Microstructure and wear properties of atmospheric plasma-sprayed Cr3C2-NiCr composite coatings. Surf. Coat. Technol. 2021, 428, 127904. [Google Scholar] [CrossRef]

- El Awad, S.; Stefaniuk, D.; Krakowiak, K.J. Determination of elastic and flexural strength properties of multi-scale materials via indentation assisted micro-bending experiment and inverse analysis. Mech. Mater. 2021, 158, 103889. [Google Scholar] [CrossRef]

- Joshi, B.; Li, X.; Oz, Y.; Wang, J.; Shan, X.; Mo, Y.L. Effects of fiber dosage, loading orientation and stress on frequency response of enhanced Carbon Nano-Fiber Aggregates. Compos. Part B Eng. 2021, 225, 109257. [Google Scholar] [CrossRef]

- ASTM F3637-23; Standard Guide for Additive Manufacturing of Metal—Finished Part Properties—Methods for Relative Density Measurement. ASTM: West Conshohocken, PA, USA, 2023.

- Puichaud, A.-H.; Flament, C.; Chniouel, A.; Lomello, F.; Rouesne, E.; Giroux, P.-F.; Maskrot, H.; Schuster, F.; Béchade, J.-L. Microstructure and mechanical properties relationship of additively manufactured 316L stainless steel by selective laser melting. EPJ Nucl. Sci. Technol. 2019, 5, 23. [Google Scholar] [CrossRef]

- Rupert, A.N.; McCausland, P.J.A.; Flemming, R.L. Ordinary chondrite shock stage quantification using in situ 2-D X-Ray diffraction of olivine. Meteorit. Planet. Sci. 2020, 55, 2224–2240. [Google Scholar] [CrossRef]

- Kim, F.H.; Moylan, S.P. Literature Review of Metal Additive Manufacturing Defects. NIST Adv. Manuf. Ser. 2018, 1–17. Available online: http://nvlpubs.nist.gov/nistpubs/ams/NIST.AMS.100-16.pdf (accessed on 1 June 2021).

- Panov, D.; Oreshkin, O.; Voloskov, B.; Petrovskiy, V.; Shishkovsky, I. Pore healing effect of laser polishing and its influence on fatigue properties of SLM manufactured SS316L parts. Opt. Laser Technol. 2022, 156, 108535. [Google Scholar] [CrossRef]

- Terrassa, K.L.; Haley, J.C.; MacDonald, B.E.; Schoenung, J.M. Reuse of powder feedstock for directed energy deposition. Powder Technol. 2018, 338, 819–829. [Google Scholar] [CrossRef]

- Susan, D.F.; Puskar, J.D.; Brooks, J.A.; Robino, C.V. Quantitative characterization of porosity in stainless steel LENS powders and deposits. Mater. Charact. 2006, 57, 36–43. [Google Scholar] [CrossRef]

- Courtois, M.; Carin, M.; Le Masson, P.; Gaied, S. A two-dimensional axially-symmetric model of keyhole and melt pool dynamics during spot laser welding. Metall. Res. Technol. 2013, 110, 165–173. [Google Scholar] [CrossRef]

- Wits, W.W.; Scolaro, E.; Amsterdam, E.; Clare, A.T. The role of scan strategies in fatigue performance for laser powder bed fusion. CIRP Ann. 2022, 71, 185–188. [Google Scholar] [CrossRef]

- Plessis, A.D.; Razavi, S.M.J.; Wan, D.; Berto, F.; Imdaadulah, A.; Beamer, C.; Shipley, J.; MacDonald, E. Fatigue performance of shelled additively manufactured parts subjected to hot isostatic pressing. Addit. Manuf. 2022, 51, 102607. [Google Scholar] [CrossRef]

- Foteinopoulos, P.; Papacharalampopoulos, A.; Angelopoulos, K.; Stavropoulos, P. Development of a simulation approach for laser powder bed fusion based on scanning strategy selection. Int. J. Adv. Manuf. Technol. 2020, 108, 3085–3100. [Google Scholar] [CrossRef]

| First Set (Powder Feed Rate: 7.89 g/min; Scanning Speed: 10 mm/s) | ||

|---|---|---|

| Sample No. | Laser Power (Watts) | Specific Energy (J/mm2) |

| S1 | 280 | 28.00 |

| S2 | 340 | 34.00 |

| S3 | 380 | 38.00 |

| S4 | 420 | 42.00 |

| Second Set (Powder Feed Rate: 7.89 g/min; Laser Power: 340 Watts) | ||

|---|---|---|

| Sample No. | Scanning Speed (mm/s) | Specific Energy (J/mm2) |

| S5 | 8 | 42.50 |

| S6 | 10 | 34.00 |

| S7 | 12 | 28.33 |

| S8 | 16 | 21.25 |

| Elements (wt.%) | ||||||

|---|---|---|---|---|---|---|

| Spot No. | Fe | Cr | Ni | Mo | Si | Mn |

| G1 (spot 1) | 66.9 | 18.8 | 12.0 | 1.3 | 0.3 | 0.7 |

| G2 (spot 3) | 67.1 | 18.6 | 11.9 | 1.3 | 0.3 | 0.7 |

| B1 (spot 2) | 61.7 | 21.4 | 12.1 | 3.2 | 0.6 | 0.7 |

| B2 (spot 4) | 61.9 | 21.1 | 13.1 | 2.5 | 0.8 | 0.7 |

| P1 (spot 5) | 65.7 | 19.6 | 11.8 | 1.3 | 0.8 | 1.4 |

| P2 (spot 6) | 65.7 | 20.2 | 10.9 | 1.7 | 0.3 | 1.3 |

| Grain Size, D (µm) | |||||||

|---|---|---|---|---|---|---|---|

| Samples | Top | Bottom | Average | D(Top)/D(Bottom) | |||

| Max | Min | Max | Min | Top | Bottom | ||

| S2 | 112 | 104 | 62 | 57 | 108 | 59 | 1.8 |

| S4 | 110 | 104 | 54 | 51 | 107 | 53 | 2.0 |

| S8 | 106 | 101 | 54 | 52 | 103 | 53 | 1.9 |

| Peak Count | Grain Size (µm) | ||||

|---|---|---|---|---|---|

| Samples | Top | Bottom | Top | Bottom | Ratio (Top/Bottom) |

| S2 | 7 | 13 | 161 | 118 | 1.4 |

| S4 | 7 | 16 | 161 | 106 | 1.5 |

| S8 | 8 | 15 | 150 | 110 | 1.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pathak, P.; Majkic, G.; Erickson, T.; Chen, T.; Selvamanickam, V. Two-Dimensional X-Ray Diffraction (2D-XRD) and Micro-Computed Tomography (Micro-CT) Characterization of Additively Manufactured 316L Stainless Steel. Metals 2024, 14, 1232. https://doi.org/10.3390/met14111232

Pathak P, Majkic G, Erickson T, Chen T, Selvamanickam V. Two-Dimensional X-Ray Diffraction (2D-XRD) and Micro-Computed Tomography (Micro-CT) Characterization of Additively Manufactured 316L Stainless Steel. Metals. 2024; 14(11):1232. https://doi.org/10.3390/met14111232

Chicago/Turabian StylePathak, Puskar, Goran Majkic, Timmons Erickson, Tian Chen, and Venkat Selvamanickam. 2024. "Two-Dimensional X-Ray Diffraction (2D-XRD) and Micro-Computed Tomography (Micro-CT) Characterization of Additively Manufactured 316L Stainless Steel" Metals 14, no. 11: 1232. https://doi.org/10.3390/met14111232

APA StylePathak, P., Majkic, G., Erickson, T., Chen, T., & Selvamanickam, V. (2024). Two-Dimensional X-Ray Diffraction (2D-XRD) and Micro-Computed Tomography (Micro-CT) Characterization of Additively Manufactured 316L Stainless Steel. Metals, 14(11), 1232. https://doi.org/10.3390/met14111232