A Transition State Theory-Based Continuum Plasticity Model Accounting for the Local Stress Fluctuation

Abstract

1. Introduction

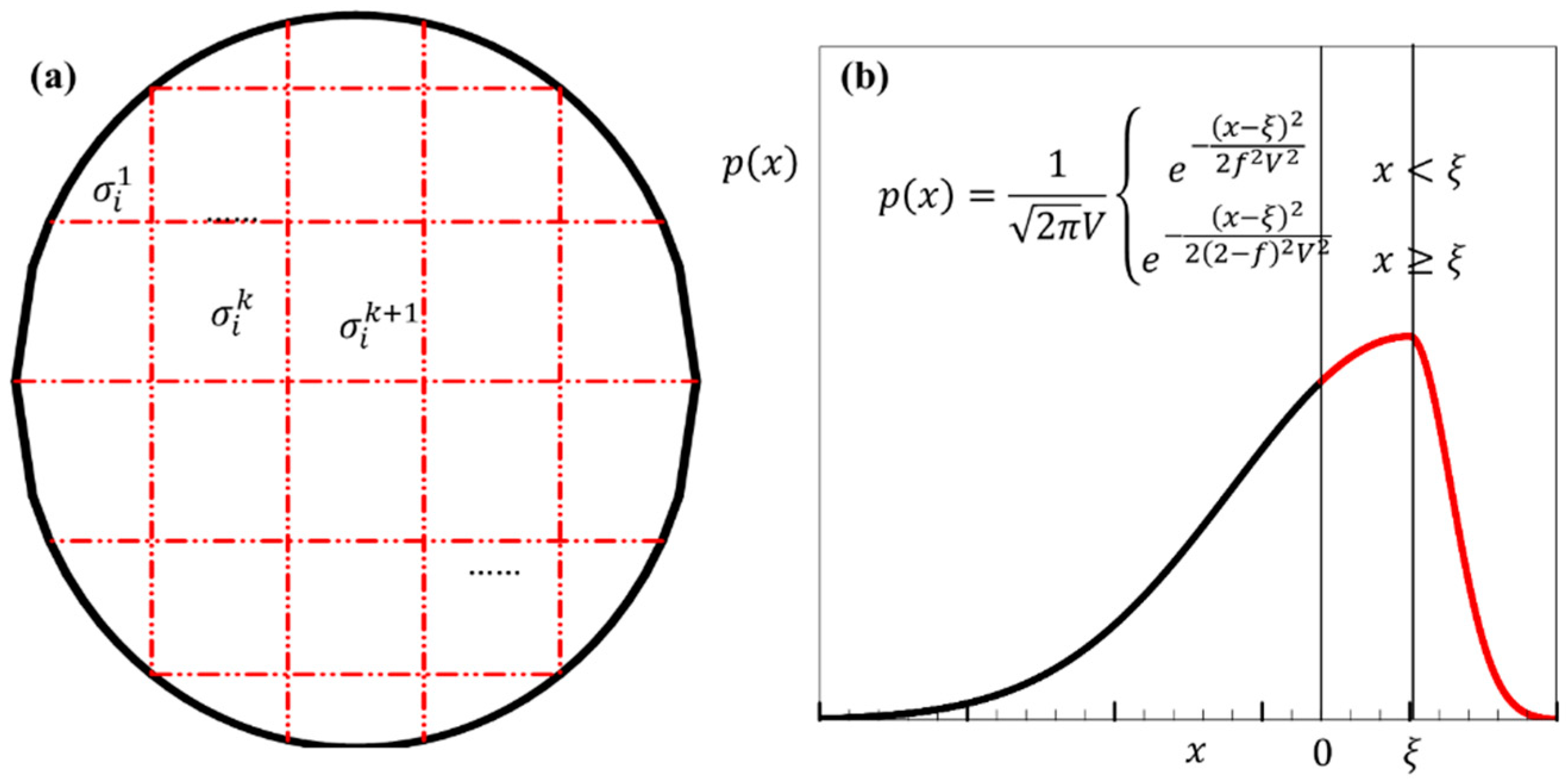

2. A Continuum Model Accounting for Stress Fluctuation

3. Incorporation of the Stress Distribution

4. Results and Discussion

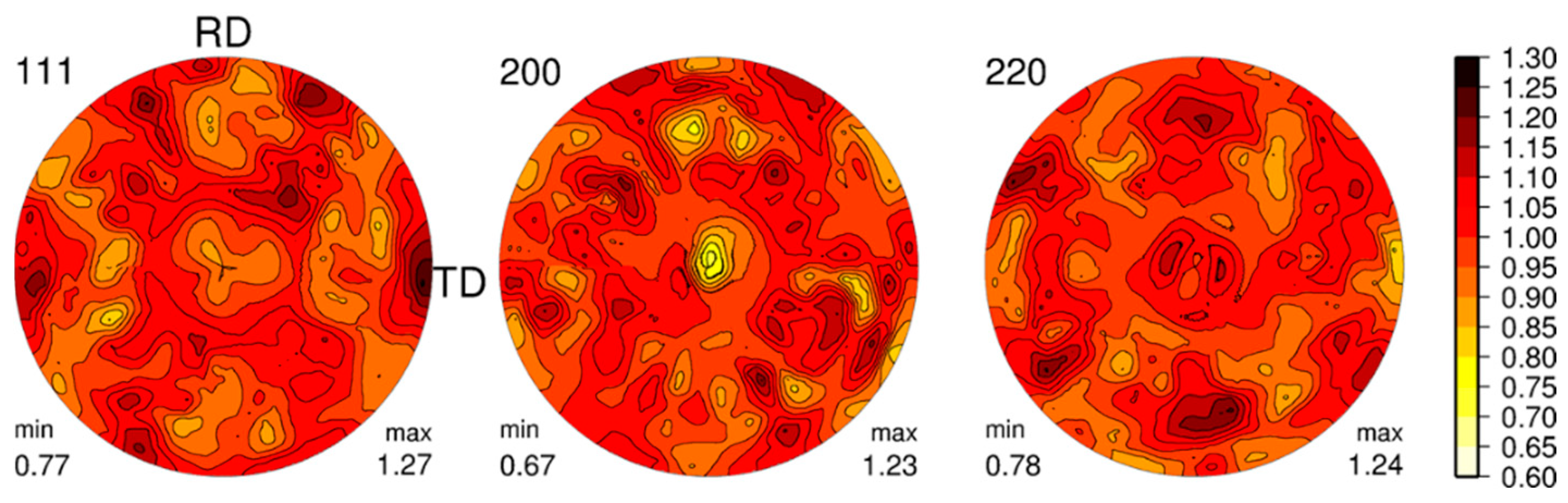

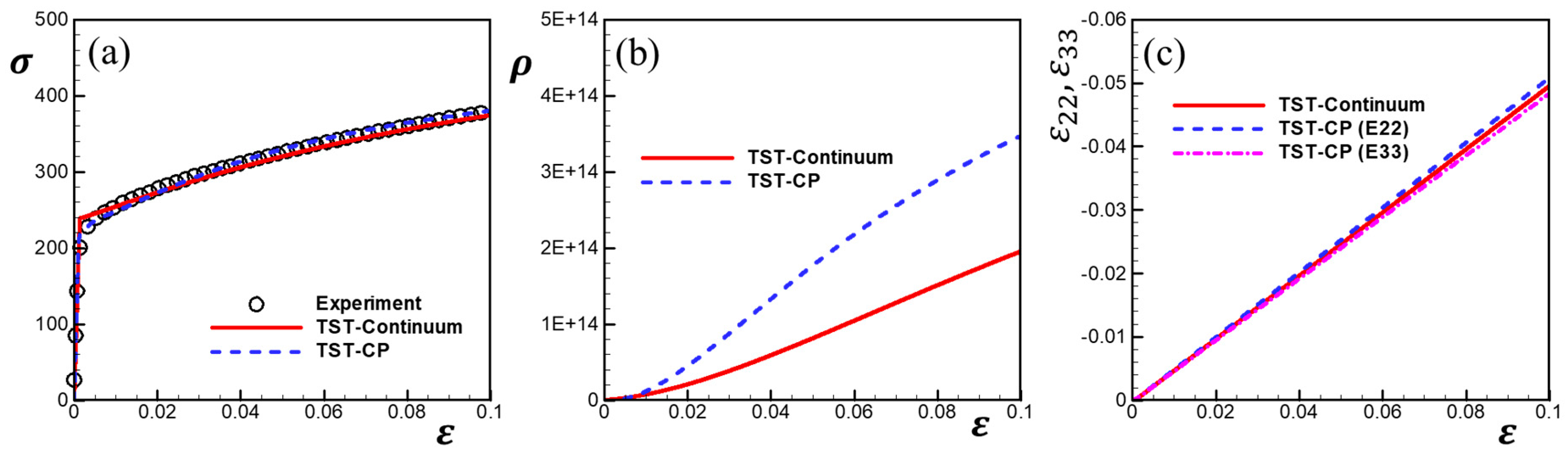

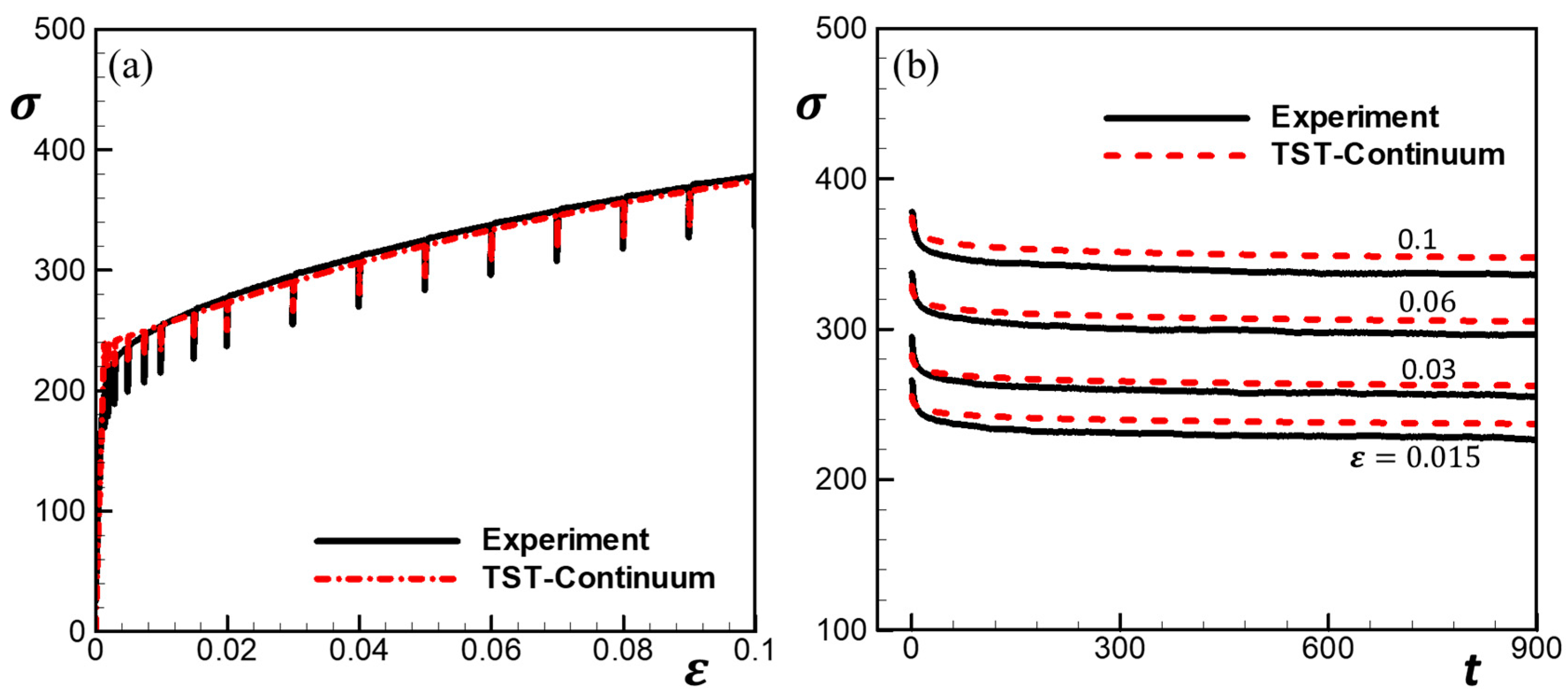

4.1. Unixail Tension

4.2. Loading with Stress Holds

4.3. Loading with Strain Holds

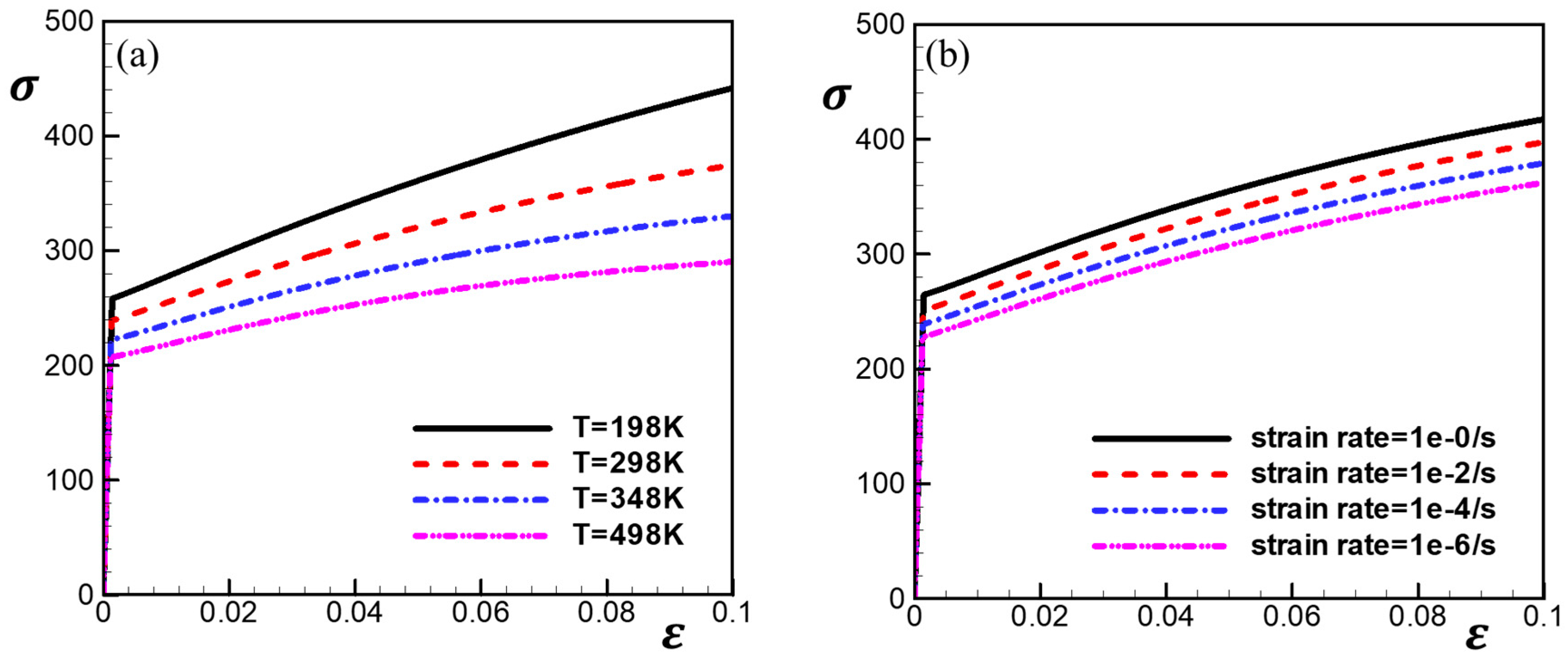

4.4. Dependency of Temperature and Strain Rate

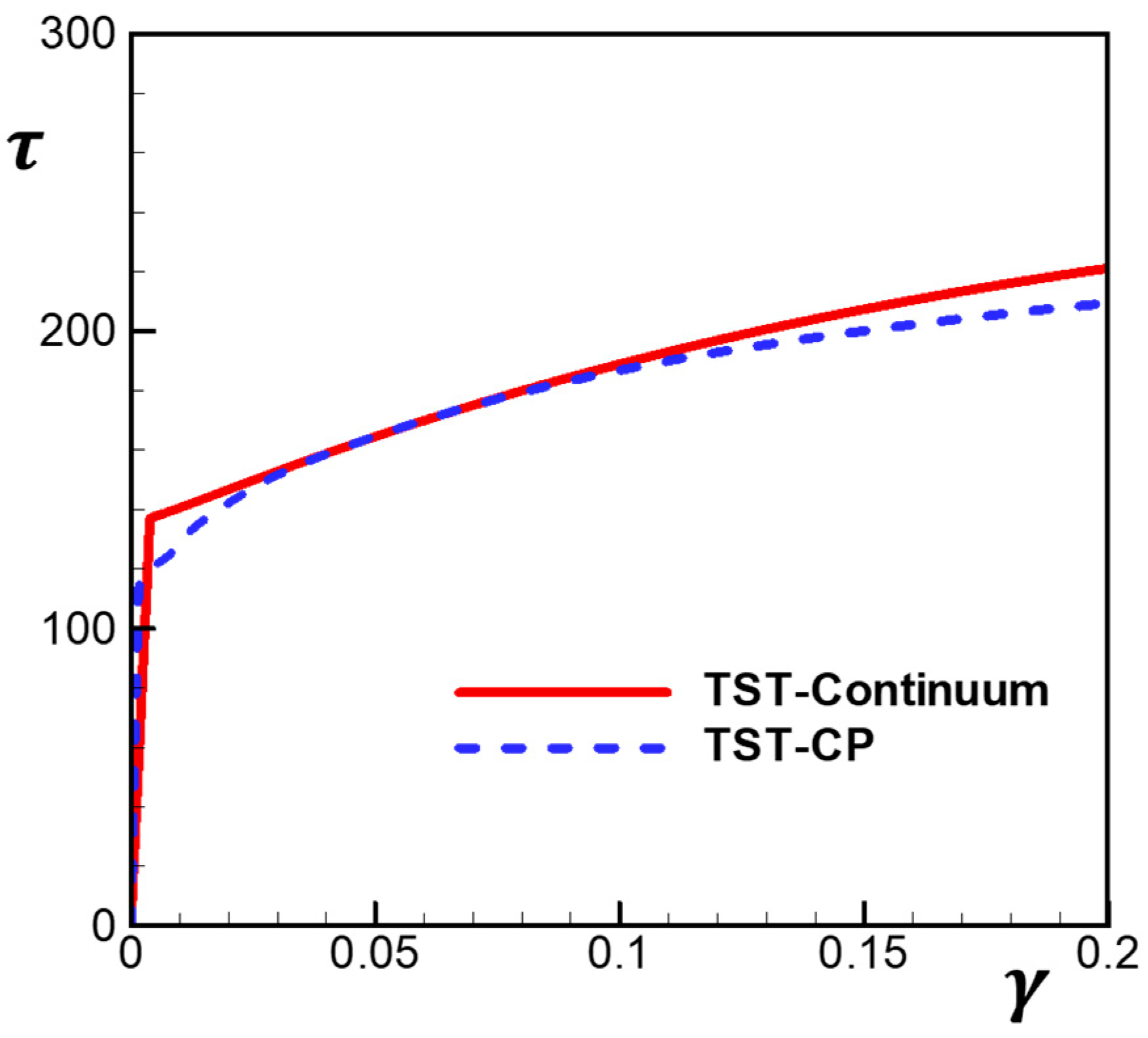

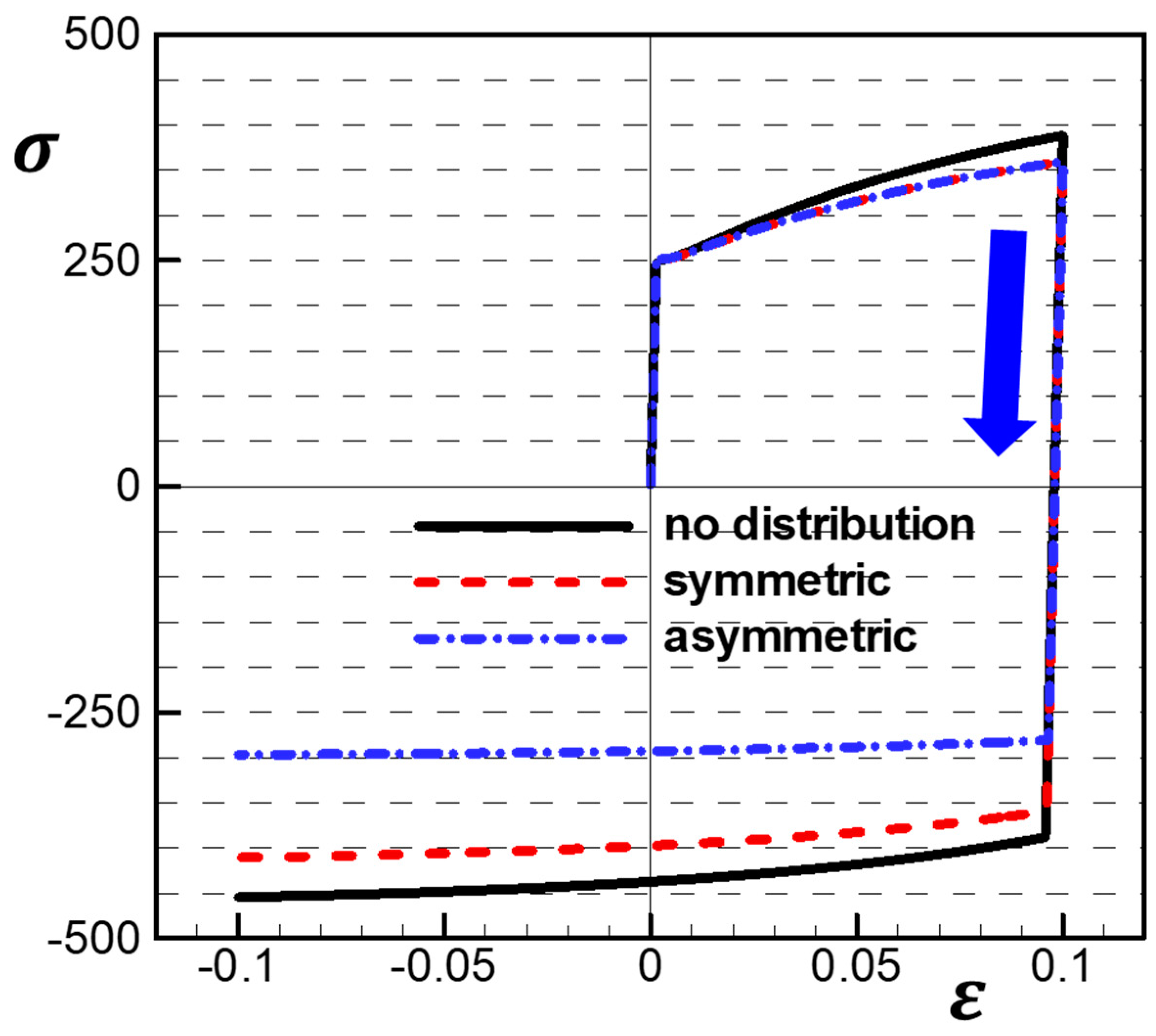

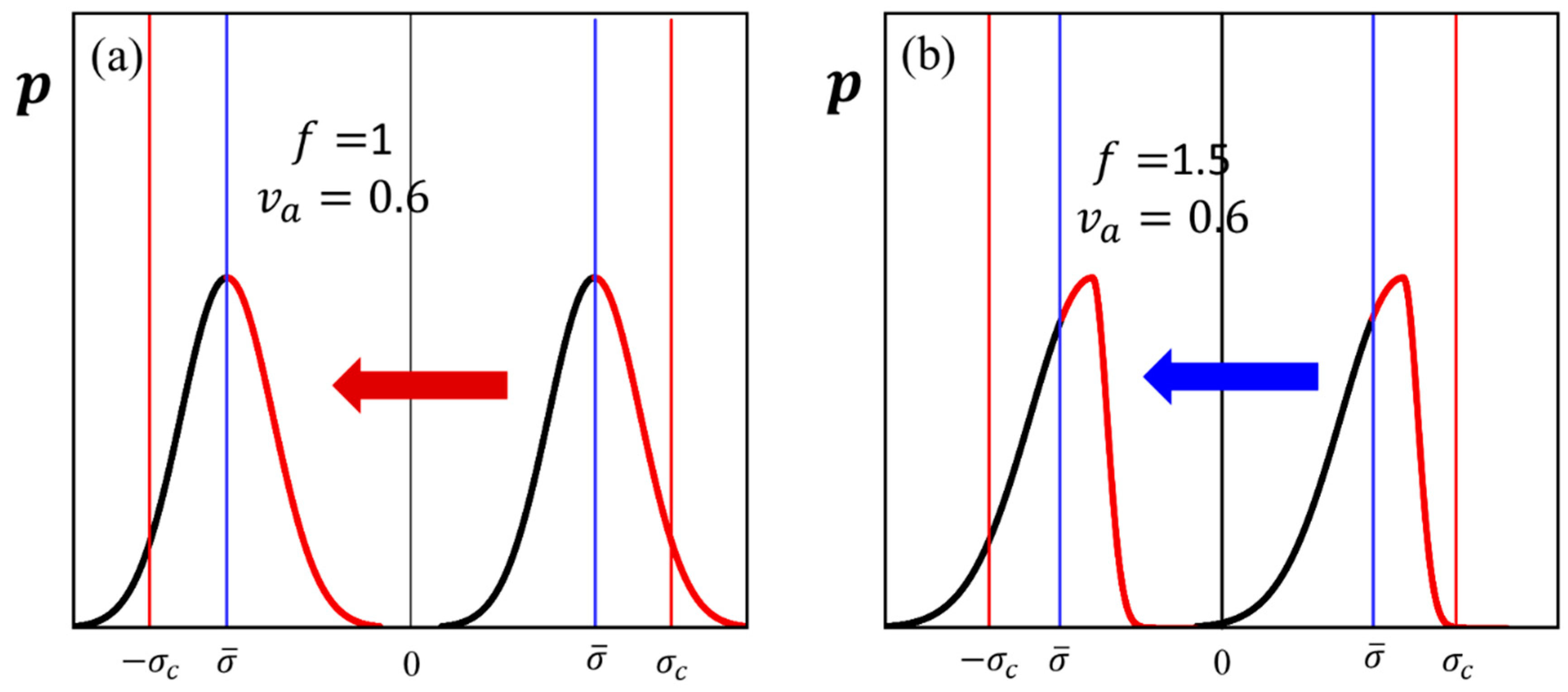

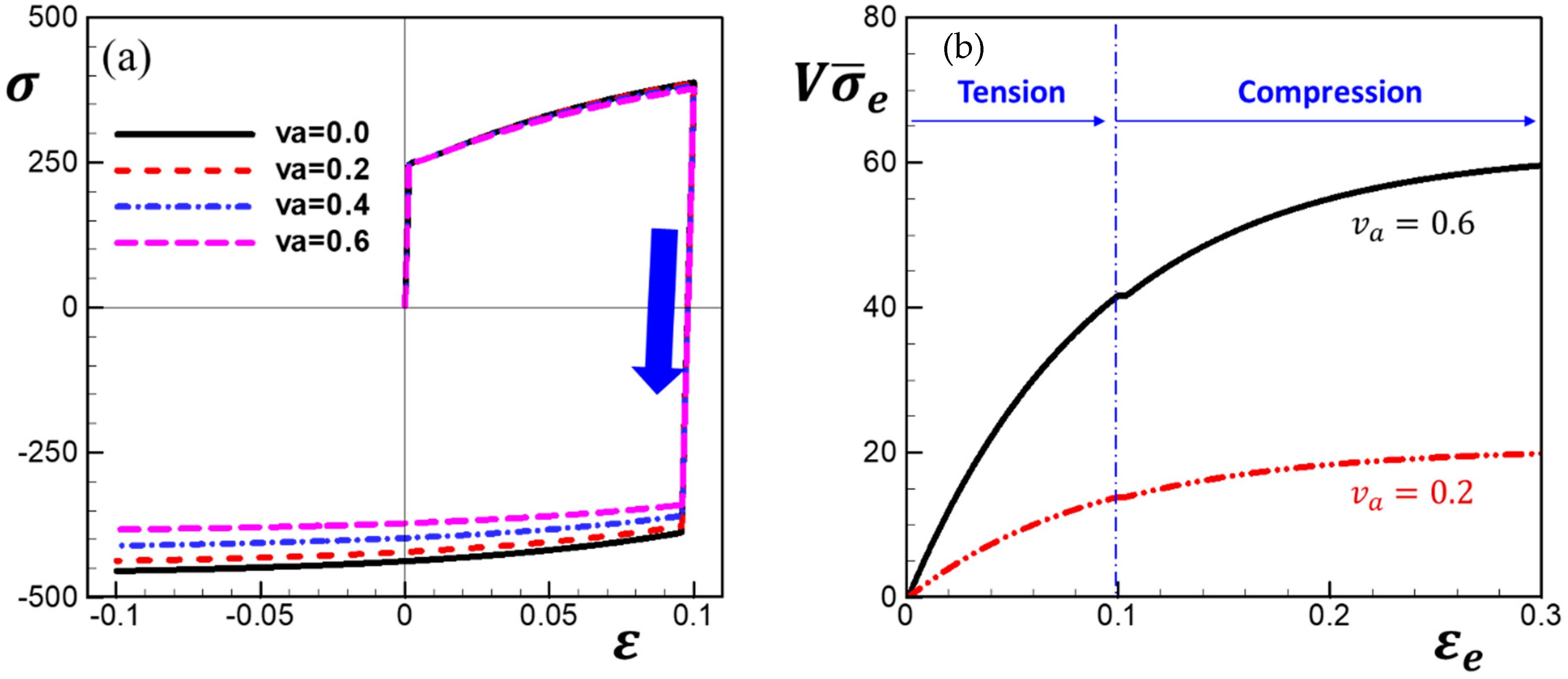

4.5. The Bauschinger Effect

5. Conclusions

- The model adequately describes the mechanical behaviors of materials and reproduces the results obtained by the polycrystal plasticity model. The computational time savings are on the order of the product of the number of grains and the number of systems considered;

- The strain rate sensitivity of a material is taken into account in terms of its dependence on the dislocation activation energy. As a consequence, the effects of stress relaxation and strain creep are correctly captured by the model;

- The temperature dependence of material is also taken into account in terms of the harmonic transition state theory. Higher flow stress and higher hardening rate are obtained with lower temperature, which is consistent with the experimental observations;

- The model is further enhanced by accounting for the stress distribution. By incorporating an asymmetric stress distribution, the model captures the Bauschinger effect, which is not accounted for by a conventional continuum model without additional treatment.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Ni, R.; Boehlert, C.J.; Zeng, Y.; Chen, B.; Huang, S.; Zheng, J.; Zhou, H.; Wang, Q.; Yin, D. Automated Analysis Framework of Strain Partitioning and Deformation Mechanisms via Multimodal Fusion and Computer Vision. Int. J. Plast. 2024, 182, 104–119. [Google Scholar] [CrossRef]

- McDowell, D.L. Viscoplasticity of heterogenous metallic materials. Mater. Sci. Emg. R Rep. 2008, 62, 67–123. [Google Scholar] [CrossRef]

- Chaboche, J.L. A review of some plasticity and viscoplasticity constitutive theories. Int. J. Plast. 2008, 24, 1642–1693. [Google Scholar] [CrossRef]

- Drucker, D.C.; Prager, W. Soil mechanics and plastic analysis of limit design. Q. Appl. Math. 1952, 10, 157–162. [Google Scholar] [CrossRef]

- Guo, X.Q.; Wu, P.D.; Wang, H.; Mao, X.B. Study of lattice strain evolution in stainless steel under tension: The role of self-consistent plasticity model. Steel Res. Int. 2015, 86, 894–901. [Google Scholar] [CrossRef]

- Gurson, A.L. Continuum Theory of Ductile Rupture by Void Nucleation and Growth: Part I—Yield Criteria and Flow Rules for Porous Ductile Media. J. Eng. Mater. Technol. 1977, 99, 2. [Google Scholar] [CrossRef]

- Hirth, J.P.; Lothe, J.; Mura, T. Theory of Dislocations. J. Appl. Mech. 1983, 50, 476. [Google Scholar] [CrossRef]

- Huang, Y.; Qu, S.; Hwang, K.C.; Li, M.; Gao, H. A conventional theory of mechanism-based strain gradient plasticity. Int. J. Plast. 2004, 20, 753–782. [Google Scholar] [CrossRef]

- Rahaman, M.M.; Dhas, B.; Roy, D.; Reddy, J.N. A dynamic flow rule for viscoplasticity in polycrystalline solids under high strain rates. Int. J. Non-Linear Mech. 2017, 95, 10–18. [Google Scholar] [CrossRef]

- Orowan, E. Zur Kristallplastizitt. III. Z. Physik 1934, 89, 634–659. [Google Scholar] [CrossRef]

- Taylor, G.I. The mechanism of plastic deformation of crystals, Part I—Theoretical. Proc. R. Soc. Lond. Ser. A 1934, 145, 362–387. [Google Scholar]

- Wenk, H.R.; Lutterotti, L.; Vogel, S. Texture analysis with the new HIPPO TOF diffractometer. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2003, 515, 575–588. [Google Scholar] [CrossRef]

- Wang, H.; Wu, P.D.; Tomé, C.N.; Huang, Y. A finite strain elastic-viscoplastic self-consistent model for polycrystalline materials. J. Mech. Phys. Solids 2010, 58, 594–612. [Google Scholar] [CrossRef]

- Wang, H.; Wu, P.D.; Tomé, C.N.; Wang, J. A crystal plasticity model for hexagonal close packed (HCP) models including twinning and de-twinning mechanisms. Int. J. Plast. 2013, 49, 36–52. [Google Scholar] [CrossRef]

- Wang, H.; Clausen, B.; Capolungo, L.; Beyerlein, I.J.; Wang, J.; Tomé, C.N. Stress and strain relaxation in magnesium AZ31 rolled plate: In-situ neutron measurement and elastic viscoplastic self-consistent polycrystal modeling. Int. J. Plast. 2016, 79, 275–292. [Google Scholar] [CrossRef]

- Wang, H.; Capolungo, L.; Clausen, B.; Tomé, C.N. A crystal plasticity model based on transition state theory. Int. J. Plast. 2017, 93, 251–268. [Google Scholar] [CrossRef]

- Vineyard, G.H. Frequency factors and isotope effects in solid state rate processes. J. Phys. Chem. Solids 1957, 3, 121–127. [Google Scholar] [CrossRef]

- Kocks, U.F.; Argon, A.S.; Ashby, M.F. Thermodynamics and Kinetics of Slip. Prog. Mater. Sci. 1975, 19, 171–229. [Google Scholar]

- Balogh, L.; Ribarik, G.; Ungar, T. Stacking faults and twin boundaries in fcc crystals determined by x-ray diffraction profile analysis. J. Appl. Phys. 2006, 100, 023512. [Google Scholar] [CrossRef]

- Balogh, L.; Capolungo, L.; Tome, C.N. On the measure of dislocation densities from diffraction line profiles: A comparison with discrete dislocation methods. Acta Mater. 2012, 60, 1467–1477. [Google Scholar] [CrossRef]

- Ungar, T.; Dragomir, I.; Revesz, A.; Borbely, A. The contrast factors of dislocations in cubic crystals: The dislocation model of strain anisotropy in practice. J. Appl. Crystallogr. 1999, 32, 992–1002. [Google Scholar] [CrossRef]

- Ungar, T.; Gubicza, J.; Ribarik, G.; Borbely, A. Crystallite size distribution and dislocation structure determined by diffraction profile analysis: Principles and practical application to cubic and hexagonal crystals. J. Appl. Crystallogr. 2001, 34, 298–310. [Google Scholar] [CrossRef]

- Ungar, T.; Ribarik, G.; Balogh, L.; Salem, A.A.; Semiatin, S.L.; Vaughan, G.B.M. Burgers vector population, dislocation types and dislocation densities in single grains extracted from a polycrystalline commercial-purity Ti specimen by X-ray line-profile analysis. Scr. Mater. 2010, 63, 69–72. [Google Scholar] [CrossRef]

- Granato, A.; Lücke, K. Theory of mechanical damping due to dislocations. J. Appl. Phys. 1956, 27, 583–593. [Google Scholar] [CrossRef]

- Wilkens, M. Fundamental Aspects of Dislocation Theory; Simmons, J.A., de Wit, R., Bullough, R., Eds.; Naturnal Bureau of Standards; (US) Special Publication No. 317; United States Department of Commerce: Washington, DC, USA, 1970; Volume II, p. 1195. [Google Scholar]

- Beyerlein, I.J.; Tomé, C.N. A dislocation-based constitutive law for pure Zr including temperature effects. Int. J. Plast. 2008, 24, 867–895. [Google Scholar] [CrossRef]

- Besseling, J.F. A theory of elastic, plastic, and creep deformations of an initially isotropic material showing anisotropic strain-hardening, creep recovery, and secondary creep. J. Appl. Mech. 1958, 25, 529–536. [Google Scholar] [CrossRef]

- Picu, R.C. On the function form of non-local elasticity kernels. J. Mech. Phys. Solids 2002, 50, 1923–1939. [Google Scholar] [CrossRef]

- Gurtin, M.E. On the plasticity of single crystals: Free energy, microforce, plastic-strain gradient. J. Mech. Phys. Solids 2000, 48, 989–1036. [Google Scholar] [CrossRef]

- Forest, S. Micromorphic approach for gradient elasticity, viscoplasticity and damage. J. Eng. Mech. 2009, 135, 117–131. [Google Scholar] [CrossRef]

- Talyan, V.; Wagoner, R.H.; Lee, J.K. Formability of stainless steel. Metall. Mater. Trans. A 1998, 29, 2161–2172. [Google Scholar] [CrossRef]

- Wollmershauser, J.A.; Clausen, B.; Agnew, S.R. A slip system-based kinematic hardening model application to in situ neutron diffraction of cyclic deformation of austenitic stainless steel. Int. J. Fatigue 2012, 36, 181–193. [Google Scholar] [CrossRef]

- Cebrian, C.A.; Zaki, W. Fatigue of Shape Memory Alloys with Emphasis on Additively Manufactured NiTi Components. Appl. Mech. Rev. 2022, 74, 040801. [Google Scholar] [CrossRef]

| K1 (m−1) | D (MPa) | g | ΔG (eV) | σ0 (MPa) | E (GPa) | ν | T (°K) |

|---|---|---|---|---|---|---|---|

| 4.4 × 108 | 100 | 0.07 | 7 | 305 | 180 | 0.29 | 298 |

| m | n | νa | ρ0 (m−2) | b (Å) | α | M | vs (m/s) |

| 2/3 | 3/2 | 0 | 1.2 × 1012 | 2.546 | 0.3 | 3.06 | 1500 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, Y.; Wang, H.; Zhou, X.; Tang, D.; Wang, H.; Wang, G.; Wu, P.; Peng, Y.; Jiang, Y. A Transition State Theory-Based Continuum Plasticity Model Accounting for the Local Stress Fluctuation. Metals 2024, 14, 1228. https://doi.org/10.3390/met14111228

Zheng Y, Wang H, Zhou X, Tang D, Wang H, Wang G, Wu P, Peng Y, Jiang Y. A Transition State Theory-Based Continuum Plasticity Model Accounting for the Local Stress Fluctuation. Metals. 2024; 14(11):1228. https://doi.org/10.3390/met14111228

Chicago/Turabian StyleZheng, Yongjia, Hongwei Wang, Xiangyu Zhou, Ding Tang, Huamiao Wang, Guoliang Wang, Peidong Wu, Yinghong Peng, and Yaodong Jiang. 2024. "A Transition State Theory-Based Continuum Plasticity Model Accounting for the Local Stress Fluctuation" Metals 14, no. 11: 1228. https://doi.org/10.3390/met14111228

APA StyleZheng, Y., Wang, H., Zhou, X., Tang, D., Wang, H., Wang, G., Wu, P., Peng, Y., & Jiang, Y. (2024). A Transition State Theory-Based Continuum Plasticity Model Accounting for the Local Stress Fluctuation. Metals, 14(11), 1228. https://doi.org/10.3390/met14111228