Tensile Behavior and Microstructure Evolution of an Extruded 6082 Aluminum Alloy Sheet at High Temperatures

Abstract

:1. Introduction

2. Experimental

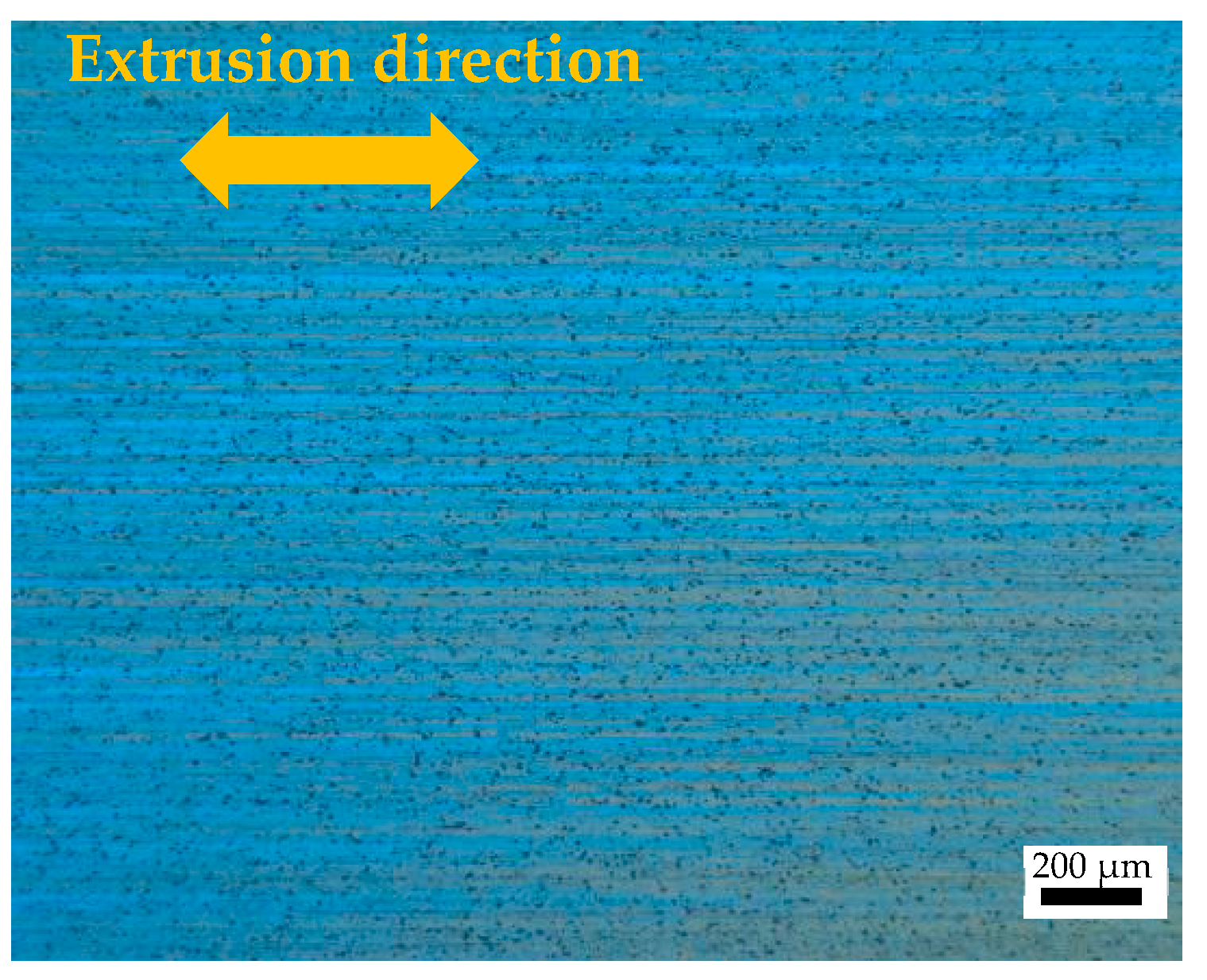

2.1. Materials

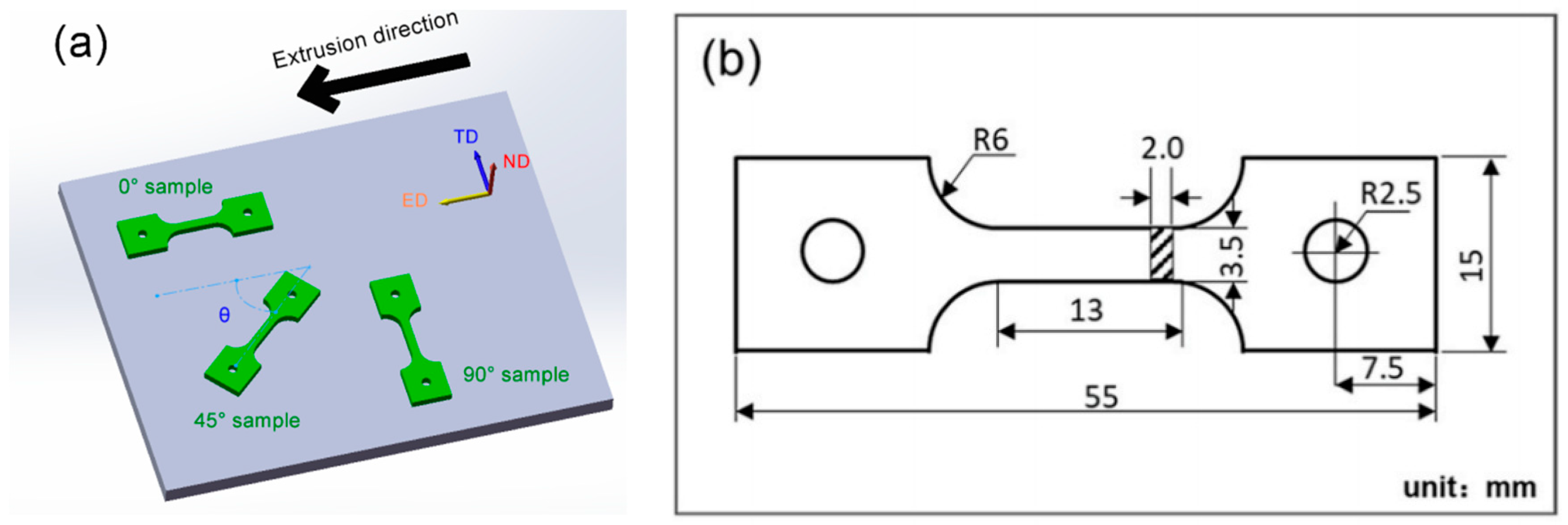

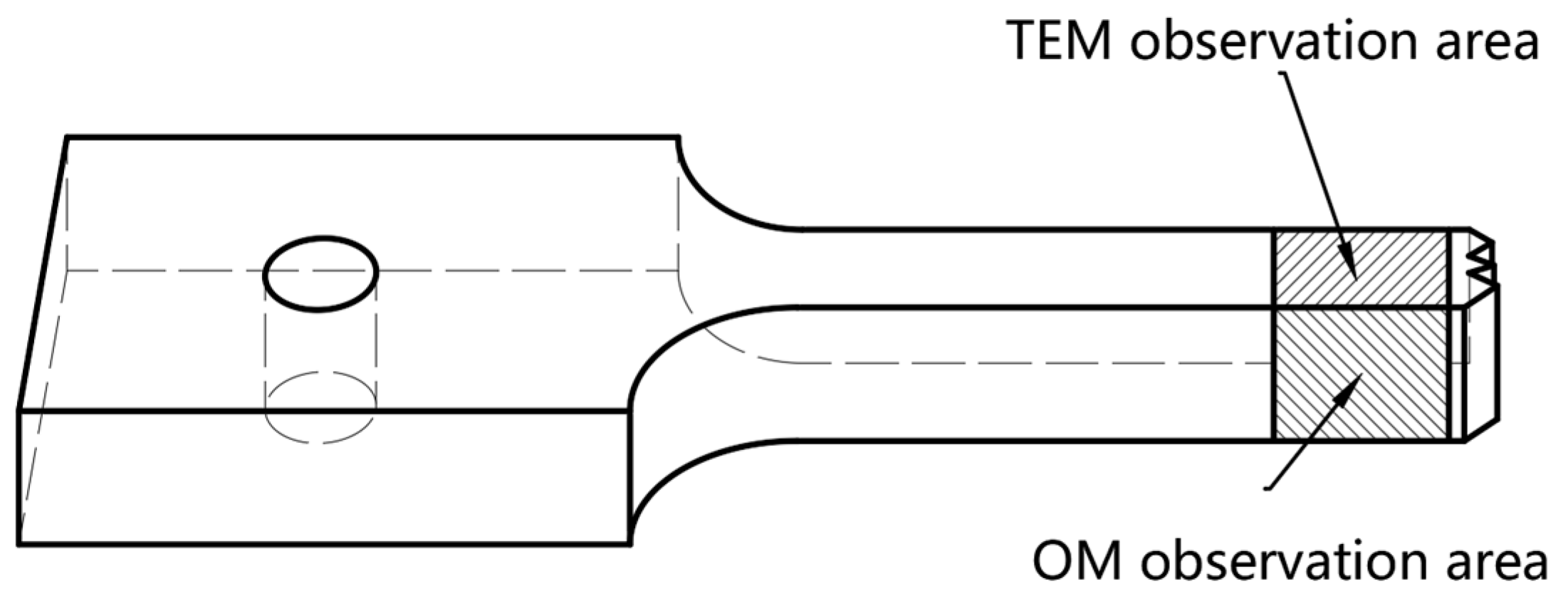

2.2. High-Temperature Tensile Test

2.3. Characterization

3. Results and Analysis

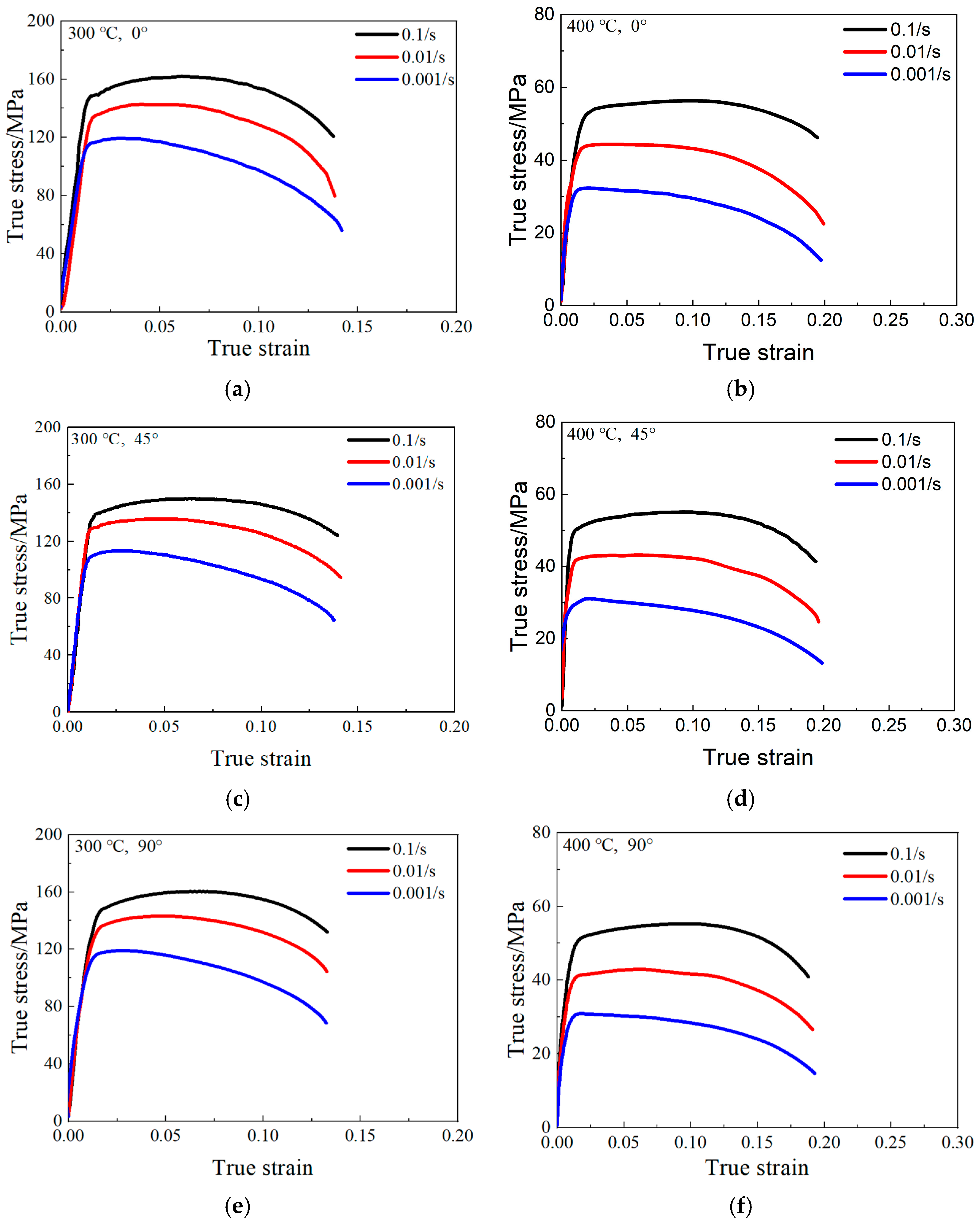

3.1. True Stress–True Strain Curves

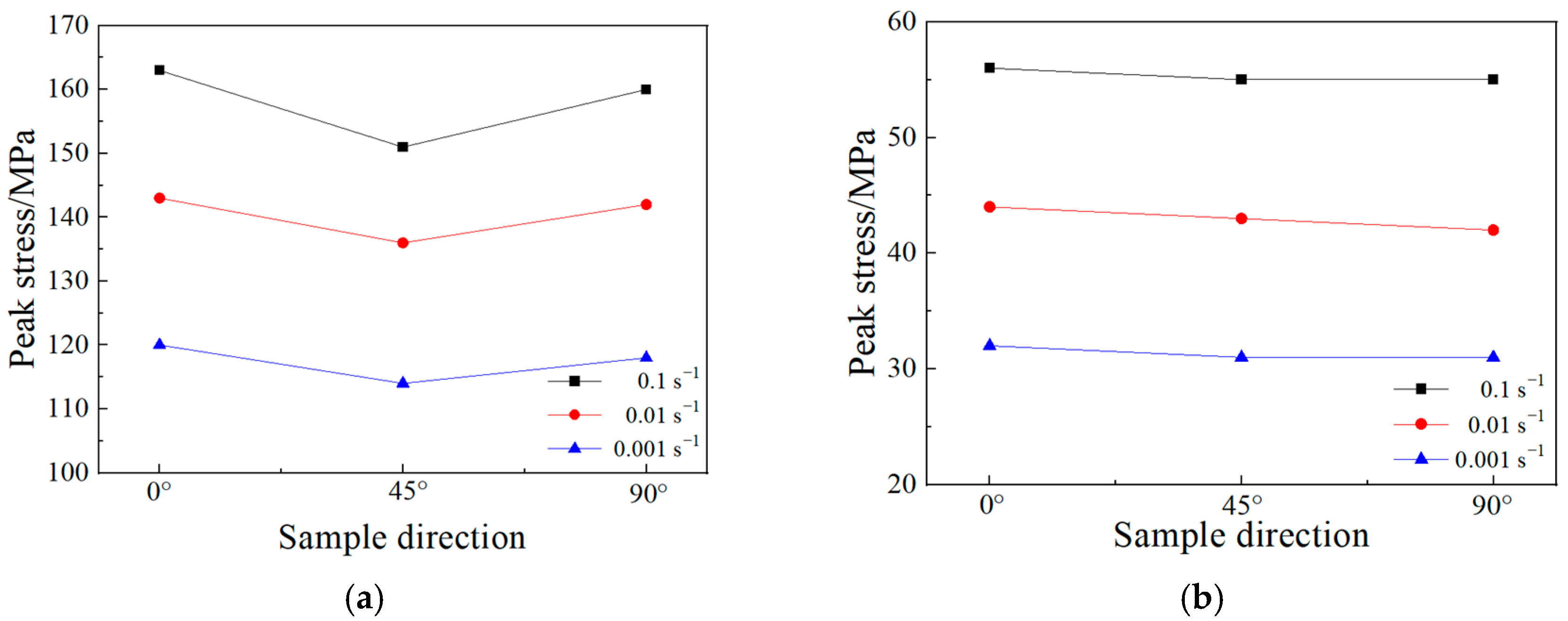

3.2. Anisotropic Mechanical Properties

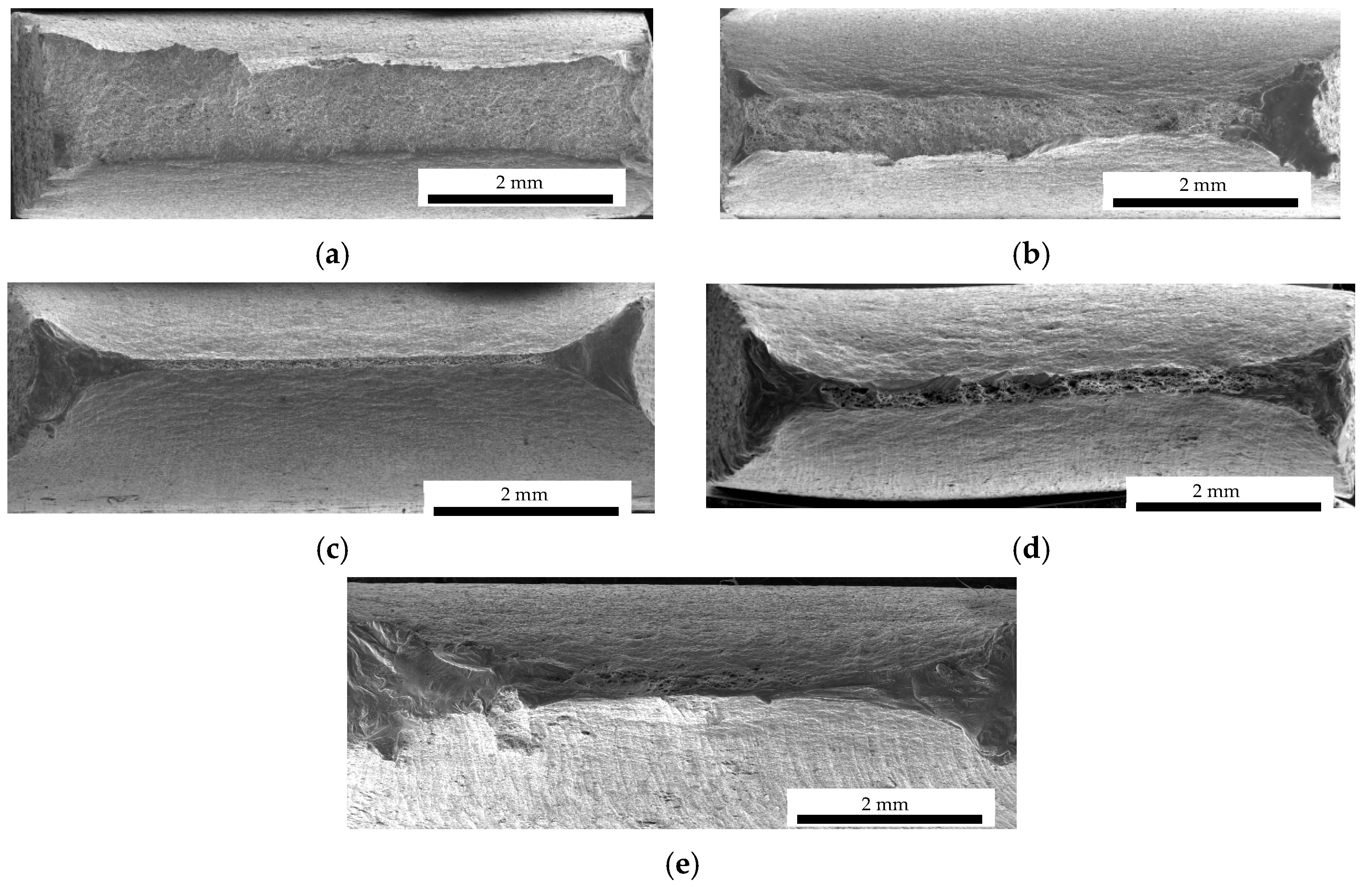

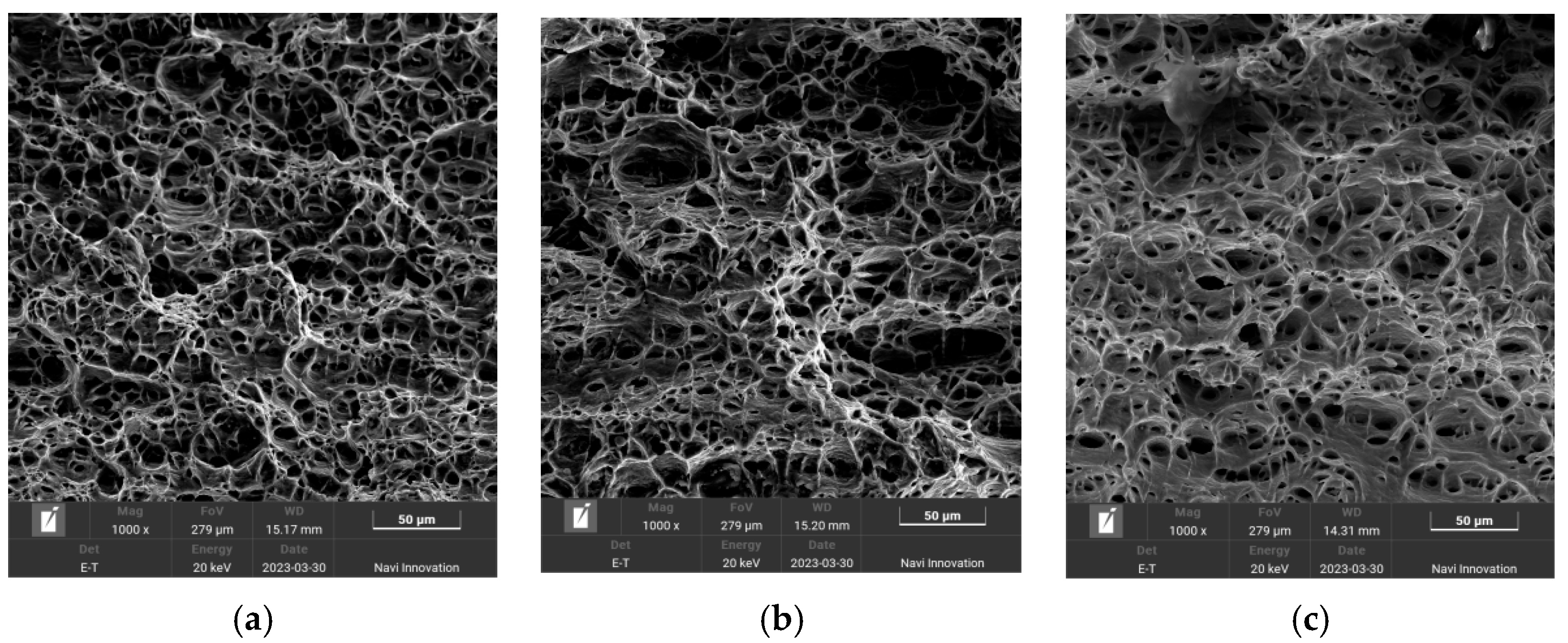

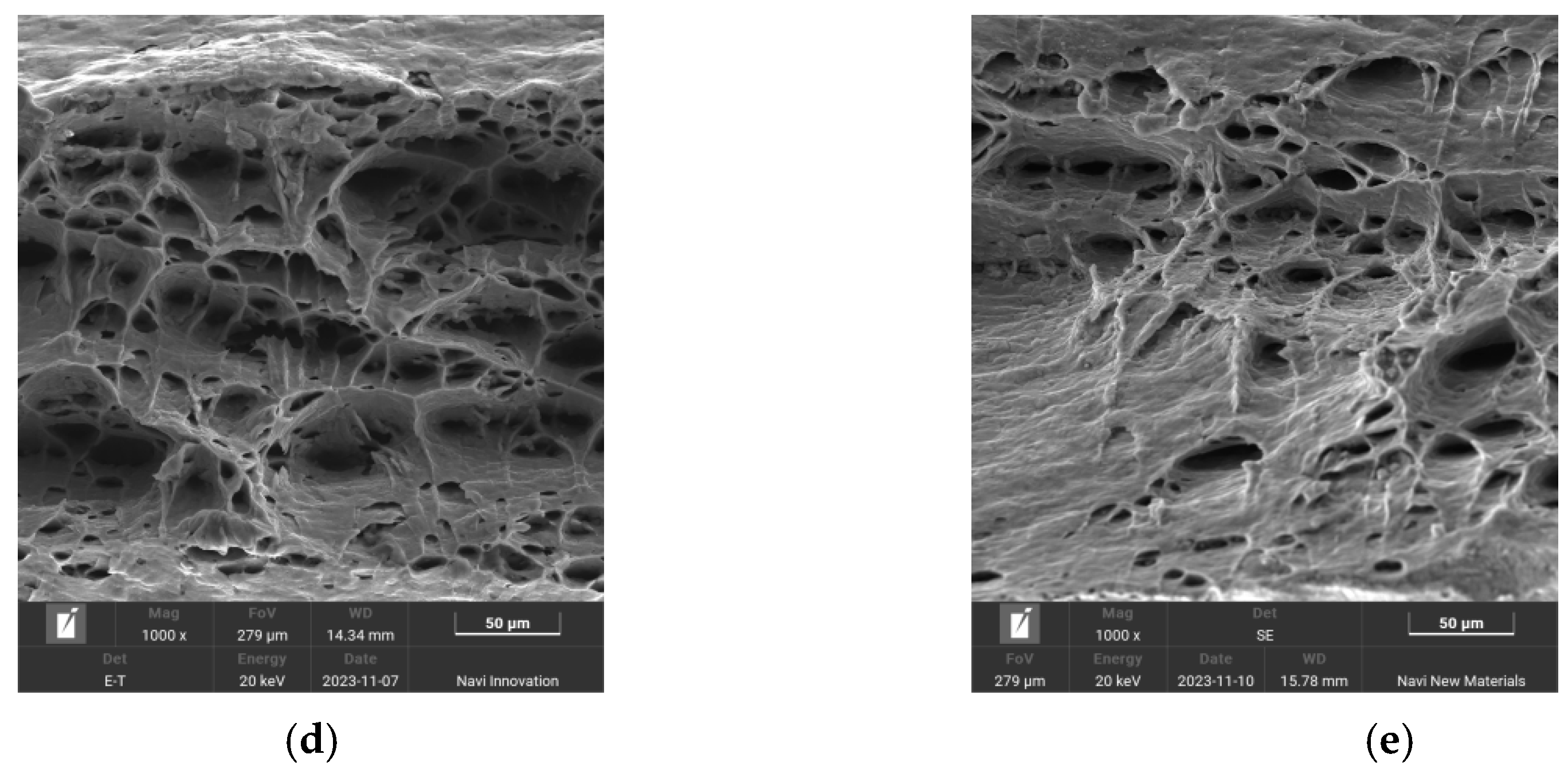

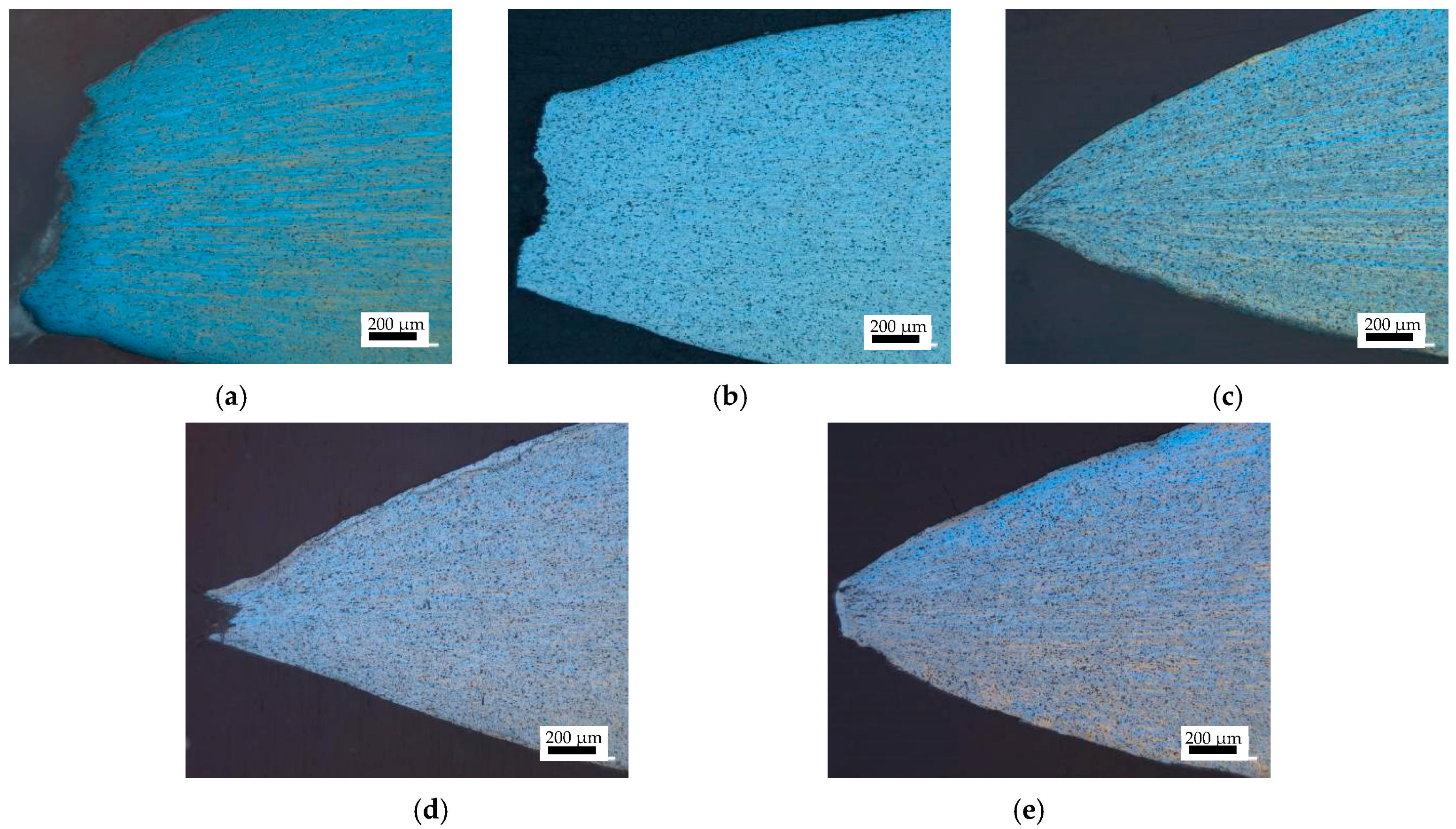

3.3. Fracture Observation

4. Discussion

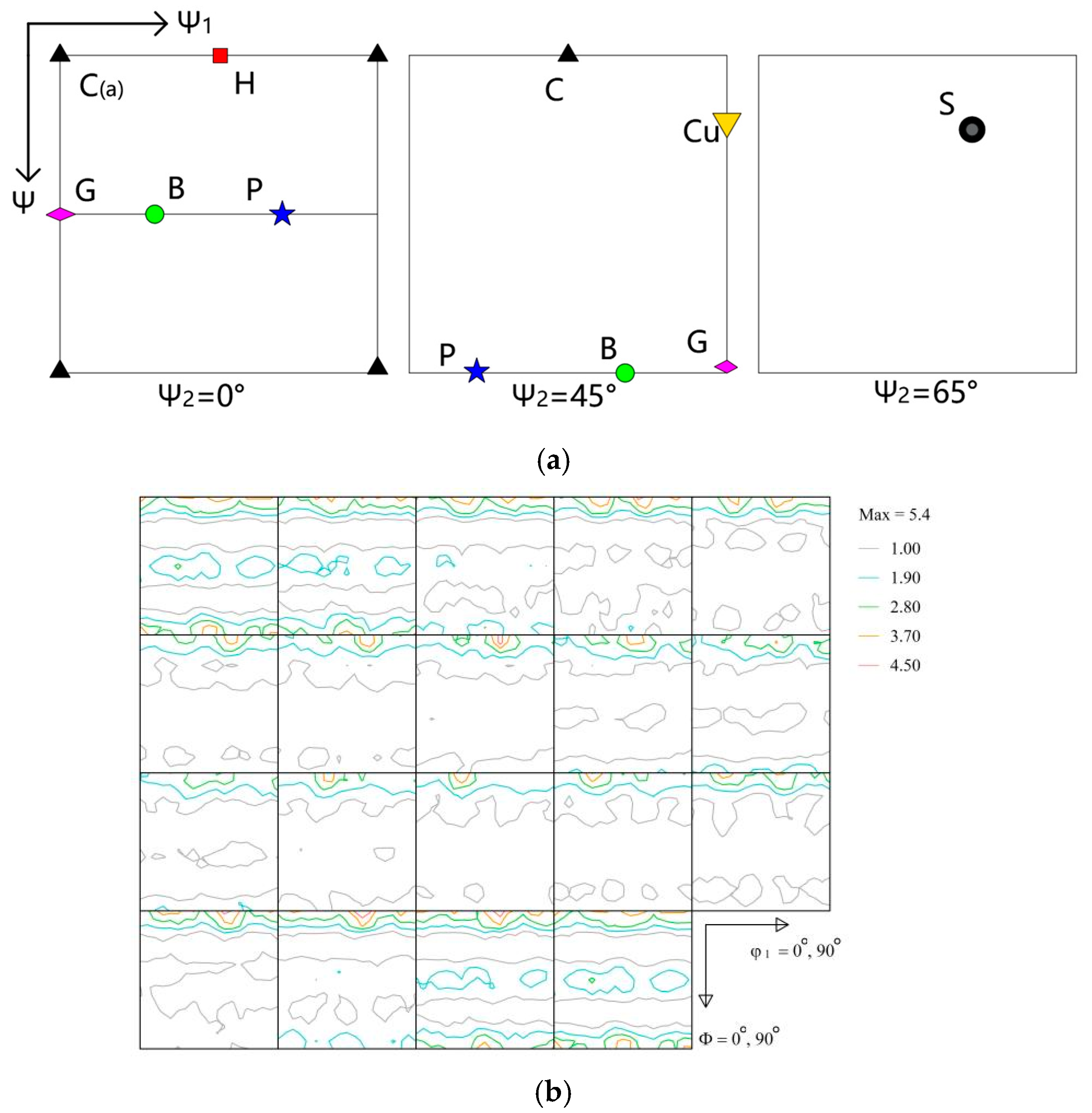

4.1. The Anisotropic Behavior

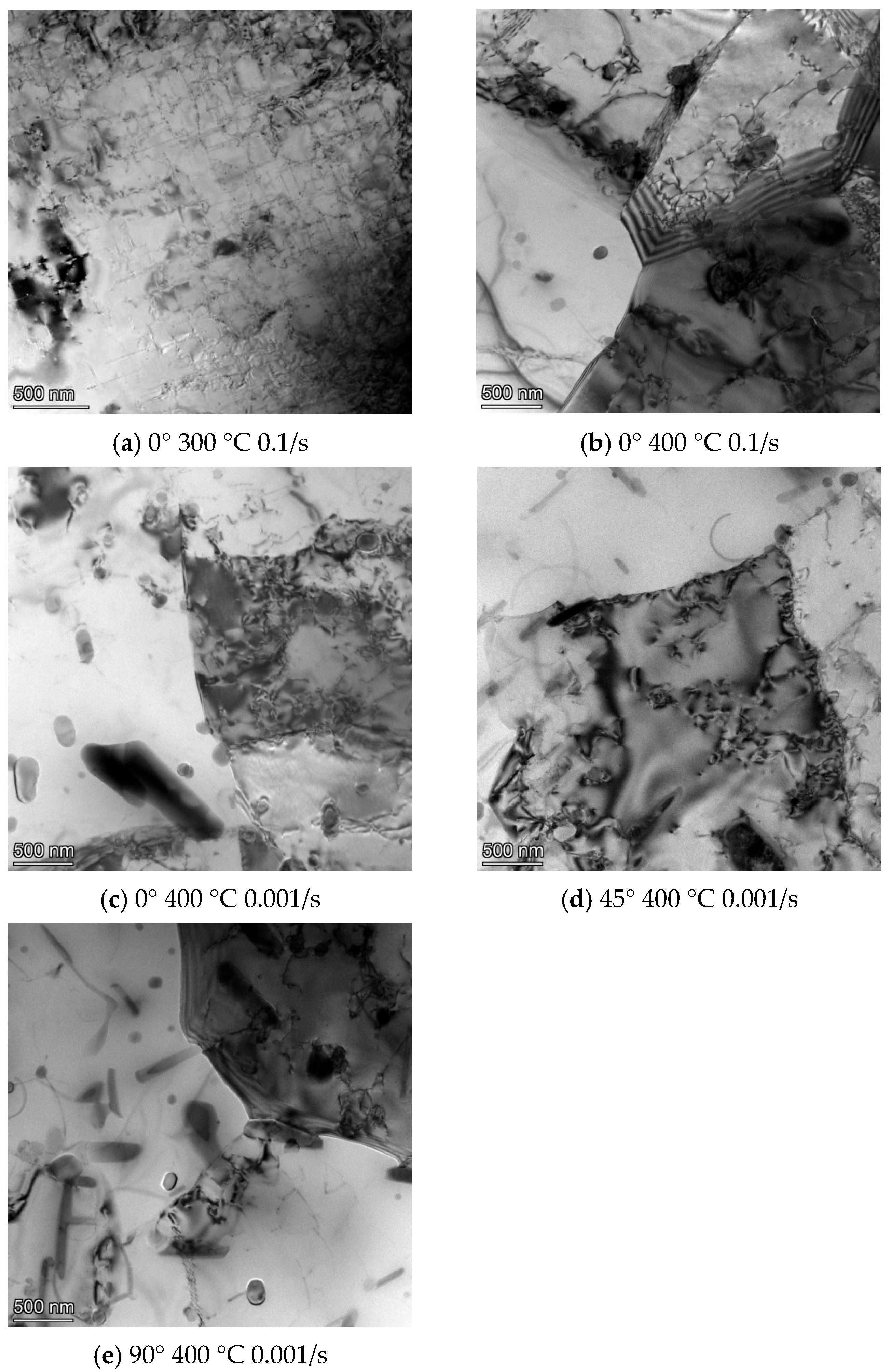

4.2. The Dynamic Softening Effects

5. Conclusions

- (1)

- The strength of the extruded 6082 aluminum alloy declines with increasing tensile temperature and decreasing strain rate. The alloy displays ductile fracture. A certain amount of dimples appear at the fracture surface. When stretched at higher temperatures and lower strain rates, the number of dimples increases. The depth of the dimples became deep, and the plasticity of the alloy was improved.

- (2)

- When deformed at 300 °C, the dynamic recovery occurs. The density of dislocation drops with the increasing temperature and decreasing strain rate. In addition, when deformed at 400 °C, some equiaxed grains are observed, which indicates a dynamic recrystallization. Meanwhile, the phenomenon of precipitate coarsening is observed. The dynamic recovery, dynamic recrystallization and precipitate coarsening result in a decline in the stress level of the alloy.

- (3)

- The extruded 6082 alloy exhibits a mechanical anisotropy at the tensile temperature of 300 °C. This can attributed to the fibrous grains and Brass component. As the temperature rises to a temperature of 400 °C, there is no obvious anisotropy. Because the slip is easier to activate, the dynamic recrystallization leads to the evolution of grain shape and texture.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, W.; Xu, J. Advanced lightweight materials for automobiles: A review. Mater. Design 2022, 221, 110994. [Google Scholar] [CrossRef]

- Georgantzia, E.; Gkantou, M.; Kamaris, G.S. Aluminium alloys as structural material: A review of research. Eng. Struct. 2021, 227, 111372. [Google Scholar] [CrossRef]

- Li, S.S.; Yue, X.; Li, Q.Y.; Peng, H.L.; Dong, B.X.; Liu, T.S.; Jiang, Q.C. Development and applications of aluminum alloys for aerospace industry. J. Mater. Res. Technol. 2023, 27, 944–983. [Google Scholar] [CrossRef]

- Blanco, D.; Rubio, E.M.; Lorente-Pedreille, R.M.; Sáenz-Nuño, M.A. Sustainable processes in aluminium, magnesium, and titanium alloys applied to the transport sector: A review. Metals 2021, 12, 9. [Google Scholar] [CrossRef]

- Berlanga-Labari, C.; Biezma-Moraleda, M.V.; Rivero, P.J. Corrosion of cast aluminum alloys: A review. Metals 2020, 10, 1384. [Google Scholar] [CrossRef]

- Xu, X.; Zhu, W.; Guo, X.; Liang, C.; Deng, Y. Effect of ageing treatment process on the microstructure development and mechanical properties of 6082 Al alloy. J. Alloys Compd. 2023, 935, 167892. [Google Scholar] [CrossRef]

- Kumar, N.; Jayaganthan, R.; Brokmeier, H.G. Effect of deformation temperature on precipitation, microstructural evolution, mechanical and corrosion behavior of 6082 Al alloy. Trans. Nonferrous Metal. Soc. 2017, 27, 475–492. [Google Scholar] [CrossRef]

- Hu, Z.; Zheng, J.; Pang, Q.; Sun, Q.; Zhao, N. Influence of strain rates and aging time on microstructure and hardness of integrally compressed 6082 aluminum alloy. J. Mater. Res. Technol. 2023, 27, 826–838. [Google Scholar] [CrossRef]

- Deng, L.; Zhang, H.D.; Li, G.A.; Tang, X.F.; Yi, P.S.; Liu, Z. Processing map and hot deformation behavior of squeeze cast 6082 aluminum alloy. Trans. Nonferrous Metal. Soc. 2022, 32, 2150–2163. [Google Scholar] [CrossRef]

- Leśniak, D.; Zasadziński, J.; Libura, W.; Żaba, K.; Puchlerska, S.; Madura, J.; Jurczak, H. FEM Numerical and Experimental Study on Dimensional Accuracy of Tubes Extruded from 6082 and 7021 Aluminium Alloys. Materials 2023, 16, 556. [Google Scholar] [CrossRef]

- Noga, P.; Piotrowicz, A.; Skrzekut, T.; Zwoliński, A.; Strzępek, P. Effect of Various Forms of Aluminum 6082 on the Mechanical Properties, Microstructure and Surface Modification of the Profile after Extrusion Process. Materials 2021, 14, 5066. [Google Scholar] [CrossRef] [PubMed]

- Peruš, I.; Kugler, G.; Malej, S.; Terčelj, M. Contour maps for simultaneous increase in yield strength and elongation of hot extruded aluminum alloy 6082. Metals 2022, 12, 461. [Google Scholar] [CrossRef]

- Hua, L.; Yuan, P.G.; Zhan, N.; Hu, Z.L.; Ma, H.J. Microstructure and mechanical properties of 6082 aluminum alloy processed by preaging and hot forging. Trans. Nonferrous Metal. Soc. 2022, 32, 790–800. [Google Scholar] [CrossRef]

- Noga, P.; Skrzekut, T.; Wędrychowicz, M.; Węglowski, M.S.; Węglowska, A. Research of friction stir welding (FSW) and electron beam welding (EBW) process for 6082-T6 aluminum alloy. Materials 2023, 16, 4937. [Google Scholar] [CrossRef] [PubMed]

- Hu, D.; Wang, L.; Wang, H. Dynamic recrystallization behavior and processing map of the 6082 aluminum alloy. Materials 2020, 13, 1042. [Google Scholar] [CrossRef] [PubMed]

- Li, K.; Pan, Q.; Li, R.; Liu, S.; Huang, Z.; He, X. Constitutive modeling of the hot deformation behavior in 6082 aluminum alloy. J. Mater. Eng. Perform. 2019, 28, 981–994. [Google Scholar] [CrossRef]

- Yang, Q.Y.; Yang, D.; Zhang, Z.Q.; Cao, L.F.; Wu, X.D.; Huang, G.J.; Liu, Q. Flow behavior and microstructure evolution of 6A82 aluminium alloy with high copper content during hot compression deformation at elevated temperatures. Trans. Nonferrous Metal. Soc. 2016, 26, 649–657. [Google Scholar] [CrossRef]

- Hidalgo-Manrique, P.; Cao, S.; Shercliff, H.R.; Hunt, R.D.; Robson, J.D. Microstructure and properties of aluminium alloy 6082 formed by the Hot Form Quench process. Mater. Sci. Eng. A 2021, 804, 140751. [Google Scholar] [CrossRef]

- Zheng, J.H.; Pruncu, C.; Zhang, K.; Zheng, K.; Jiang, J. Quantifying geometrically necessary dislocation density during hot deformation in AA6082 Al alloy. Mater. Sci. Eng. A 2021, 814, 141158. [Google Scholar] [CrossRef]

- Zhao, N.; Sun, Q.; Pang, Q.; Hu, Z. Comprehensive study of hot compression behaviors and microstructure evolution of solutionized 6082 aluminum alloy extruded bar. J. Alloys Compd. 2023, 931, 167541. [Google Scholar] [CrossRef]

- Xu, Z.; Ma, H.; Zhao, N.; Hu, Z. Investigation on compressive formability and microstructure evolution of 6082-T6 aluminum alloy. Metals 2020, 10, 469. [Google Scholar] [CrossRef]

- Chen, Y.; Clausen, A.H.; Hopperstad, O.S.; Langseth, M. Stress–strain behaviour of aluminium alloys at a wide range of strain rates. Int. J Solids. Struct. 2009, 46, 3825–3835. [Google Scholar] [CrossRef]

- Chakraborty, P.; Singha, M.K.; Tiwari, V. Anisotropic mechanical response of AA7475-T7351 alloy at different loading rates and temperatures. Thin Wall Struct. 2023, 188, 110842. [Google Scholar] [CrossRef]

- Barnwal, V.K.; Raghavan, R.; Tewari, A.; Narasimhan, K.; Mishra, S.K. Effect of microstructure and texture on forming behaviour of AA-6061 aluminium alloy sheet. Mater. Sci. Eng. A 2017, 679, 56–65. [Google Scholar] [CrossRef]

- Fan, X.; Li, Y.; Xu, C.; Wang, B.; Peng, R.; Chen, J. Improved mechanical anisotropy and texture optimization of a 3xx aluminum alloy by differential temperature rolling. Mater. Sci. Eng. A 2021, 799, 140278. [Google Scholar] [CrossRef]

- Yang, Y.; Xie, Z.P.; Zhang, Z.; Li, X.; Wang, Q.; Zhang, Y. Processing maps for hot deformation of the extruded 7075 aluminum alloy bar: Anisotropy of hot workability. Mater. Sci. Eng. A 2014, 615, 183–190. [Google Scholar] [CrossRef]

- Ye, T.; Li, L.X.; Liu, X.; Liu, W.H.; Guo, P.C.; Tang, X. Anisotropic deformation behavior of as-extruded 6063-T4 alloy under dynamic impact loading. Mater. Sci. Eng. A 2016, 666, 149–155. [Google Scholar] [CrossRef]

- Frodal, B.H.; Thomesen, S.; Børvik, T.; Hopperstad, O.S. On fracture anisotropy in textured aluminium alloys. Int. J. Solids Struct. 2022, 244, 111563. [Google Scholar] [CrossRef]

- Thomesen, S.; Hopperstad, O.S.; Børvik, T. Anisotropic plasticity and fracture of three 6000-series aluminum alloys. Metals 2021, 11, 557. [Google Scholar] [CrossRef]

- Attarilar, S.; Ebrahimi, M.; Hsieh, T.H.; Uan, J.Y.; Göde, C. An insight into the vibration-assisted rolling of AA5052 aluminum alloy: Tensile strength, deformation microstructure, and texture evolution. Mater. Sci. Eng. A 2021, 803, 140489. [Google Scholar] [CrossRef]

- Ye, T.; Xia, E.L.; Qiu, S.; Wang, Y.; Yue, H.Y.; Liu, J.; Wu, Y. High-temperature tensile mechanical properties and microstructure of rolled 6082-T6 aluminum alloy sheets. Materials 2023, 16, 7019. [Google Scholar] [CrossRef] [PubMed]

- Naumenko, K.; Gariboldi, E. Experimental analysis and constitutive modeling of anisotropic creep damage in a wrought age-hardenable Al alloy. Eng. Fract. Mech. 2022, 259, 108119. [Google Scholar] [CrossRef]

- Cho, K.K.; Chung, Y.H.; Lee, C.W.; Kwun, S.I.; Shin, M. Effects of grain shape and texture on the yield strength anisotropy of Al-Li alloy sheet. Scr. Mater. 1999, 40, 651–657. [Google Scholar] [CrossRef]

- Lim, H.; Lee, M.G.; Kim, J.H.; Adams, B.L.; Wagoner, R.H. Simulation of polycrystal deformation with grain and grain boundary effects. Int. J. Plast. 2011, 27, 1328–1354. [Google Scholar] [CrossRef]

- Raabe, D.; Roters, F. Using texture components in crystal plasticity finite element simulations. Int. J. Plast. 2004, 20, 339–361. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, L.; Chen, H.; Liu, J.; Dan, C.; Ma, S.; Chen, Z. Enhancing mechanical properties and improving mechanical anisotropy of rolled 2024 Al sheet by TiB2 nanoparticles. Mater. Sci. Eng. A 2023, 874, 145077. [Google Scholar] [CrossRef]

- Li, Y.; Xu, G.; Liu, S.; Wang, B.; Peng, X. Study on anisotropy of Al-Zn-Mg-Sc-Zr alloy sheet. Mater. Charact. 2021, 172, 110904. [Google Scholar] [CrossRef]

- Fomin, E.V.; Mayer, A.E.; Krasnikov, V.S. Prediction of shear strength of cluster-strengthened aluminum with multi-scale approach describing transition from cutting to bypass of precipitates by dislocations. Int. J. Plast. 2021, 146, 103095. [Google Scholar] [CrossRef]

- Gao, R.; Li, Y.; Li, Z.; Li, X.; Wen, K.; Zhang, Y.; Xiong, B. Quantitative relationship between microstructure and tensile properties of Al-Zn-Mg-Cu alloys with various alloying degrees. J. Mater. Res. Technol. 2022, 18, 5394–5405. [Google Scholar] [CrossRef]

- Zhao, X.; Liu, W.; Xiao, D.; Ma, Y.; Huang, L.; Tang, Y. A critical review: Crystal structure, evolution and interaction mechanism with dislocations of nano precipitates in Al-Li alloys. Mater. Des. 2022, 217, 110629. [Google Scholar] [CrossRef]

| Extrusion Speed | Billet Temperature | Die Temperature | Container Temperature | Extrusion Ratio |

|---|---|---|---|---|

| 2 mm/s | 520 °C | 467 °C | 450 °C | 21.2 |

| Element | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| wt% | 0.89 | 0.2 | 0.1 | 0.43 | 0.75 | 0.1 | 0.02 | 0.09 | Balance |

| Temperature (°C) | Direction (°) | Strain Rate (s−1) | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|---|---|

| 300 | 0 | 0.1 | 146 | 163 | 16.5 |

| 0.01 | 133 | 143 | 17.3 | ||

| 0.001 | 114 | 120 | 18.1 | ||

| 45 | 0.1 | 138 | 151 | 17.2 | |

| 0.01 | 129 | 136 | 17.9 | ||

| 0.001 | 107 | 114 | 18.4 | ||

| 90 | 0.1 | 146 | 160 | 16.6 | |

| 0.01 | 134 | 142 | 17.5 | ||

| 0.001 | 115 | 118 | 18.0 | ||

| 400 | 0 | 0.1 | 53 | 56 | 22.1 |

| 0.01 | 42 | 44 | 23.8 | ||

| 0.001 | 30 | 32 | 24.9 | ||

| 45 | 0.1 | 52 | 55 | 22.5 | |

| 0.01 | 40 | 43 | 24.2 | ||

| 0.001 | 28 | 31 | 24.8 | ||

| 90 | 0.1 | 51 | 55 | 22.3 | |

| 0.01 | 41 | 42 | 23.9 | ||

| 0.001 | 29 | 31 | 24.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiu, S.; Xia, E.; Liu, L.; Ye, T.; Liu, J.; Tang, J.; Liu, W.; Wu, Y. Tensile Behavior and Microstructure Evolution of an Extruded 6082 Aluminum Alloy Sheet at High Temperatures. Metals 2024, 14, 7. https://doi.org/10.3390/met14010007

Qiu S, Xia E, Liu L, Ye T, Liu J, Tang J, Liu W, Wu Y. Tensile Behavior and Microstructure Evolution of an Extruded 6082 Aluminum Alloy Sheet at High Temperatures. Metals. 2024; 14(1):7. https://doi.org/10.3390/met14010007

Chicago/Turabian StyleQiu, Sawei, Erli Xia, Limei Liu, Tuo Ye, Jie Liu, Jian Tang, Wei Liu, and Yuanzhi Wu. 2024. "Tensile Behavior and Microstructure Evolution of an Extruded 6082 Aluminum Alloy Sheet at High Temperatures" Metals 14, no. 1: 7. https://doi.org/10.3390/met14010007

APA StyleQiu, S., Xia, E., Liu, L., Ye, T., Liu, J., Tang, J., Liu, W., & Wu, Y. (2024). Tensile Behavior and Microstructure Evolution of an Extruded 6082 Aluminum Alloy Sheet at High Temperatures. Metals, 14(1), 7. https://doi.org/10.3390/met14010007