Investigation of Surface Integrity of Conical Hole in Laser Polishing 440C Stainless Steel

Abstract

1. Introduction

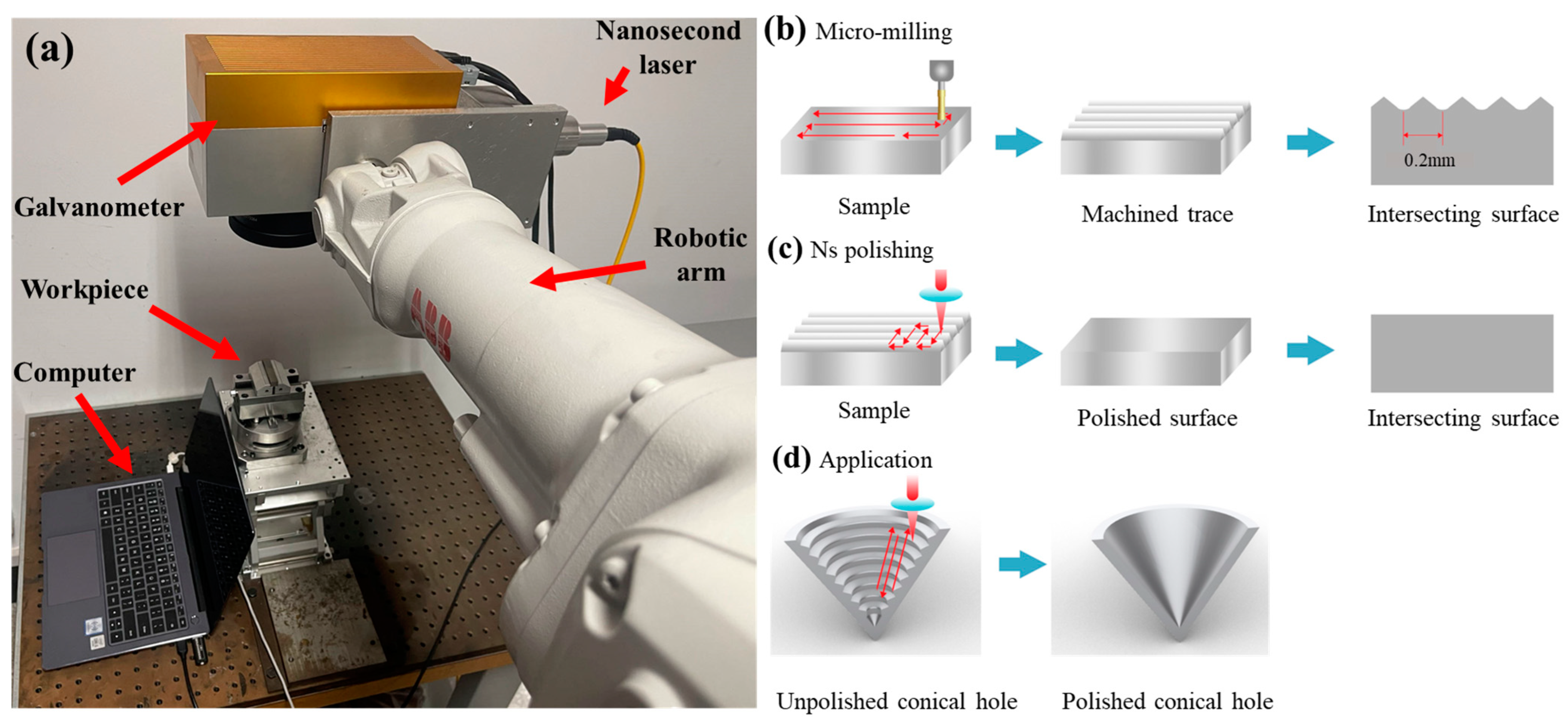

2. Experimental Setup

2.1. Materials and Experimental Procedure

2.2. Laser Polishing Experiment

2.3. Surface Integrity Analysis

3. Result and Discussion

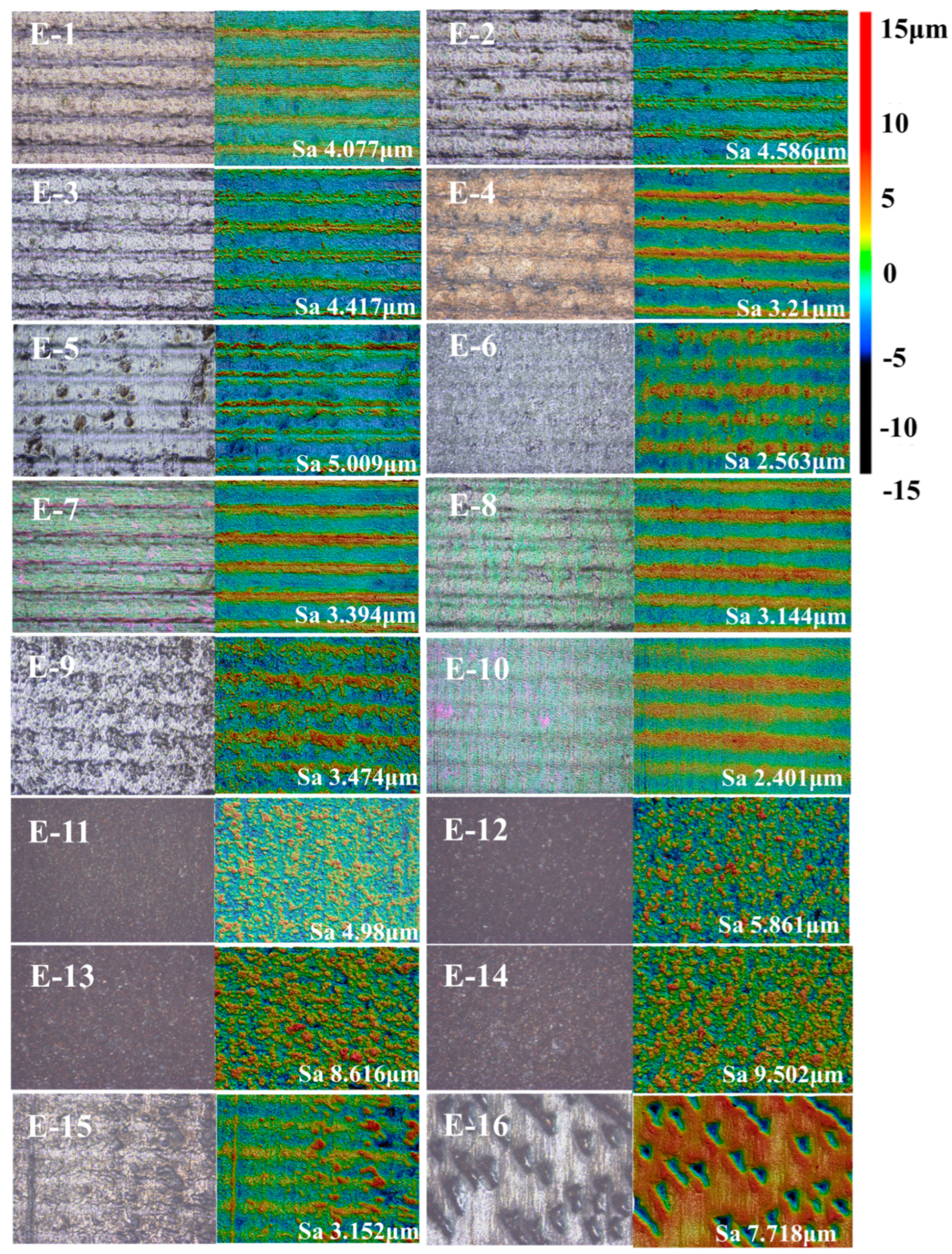

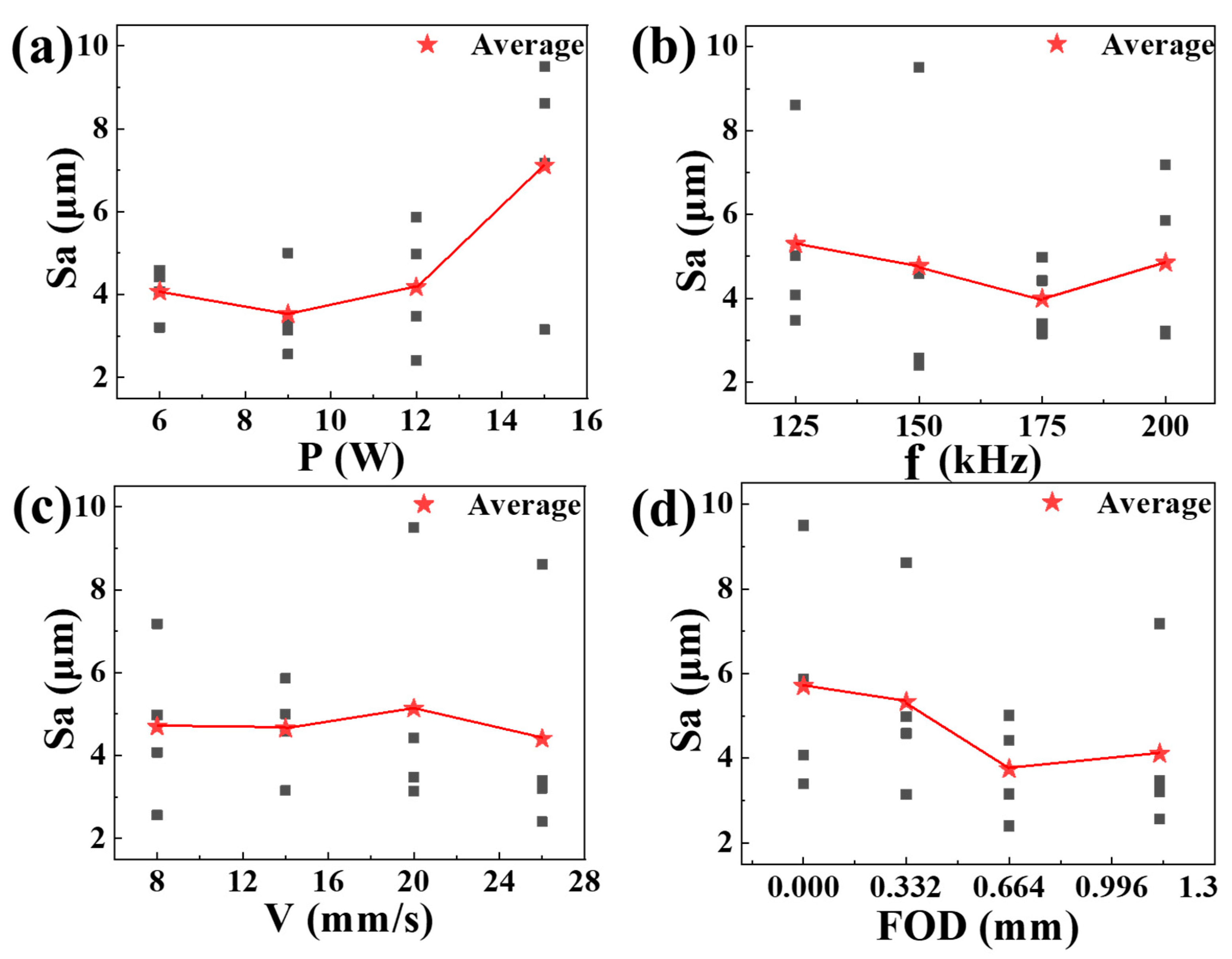

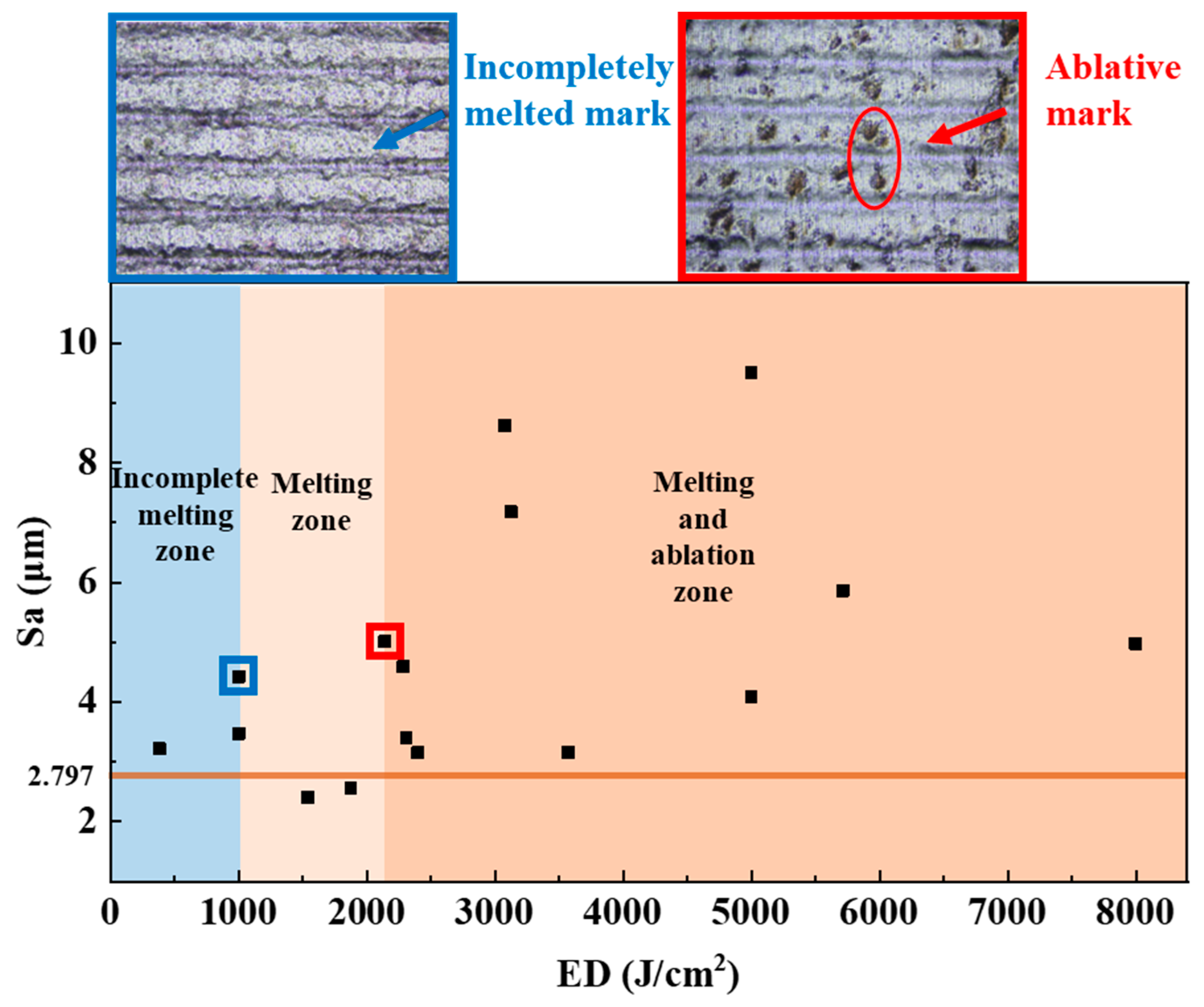

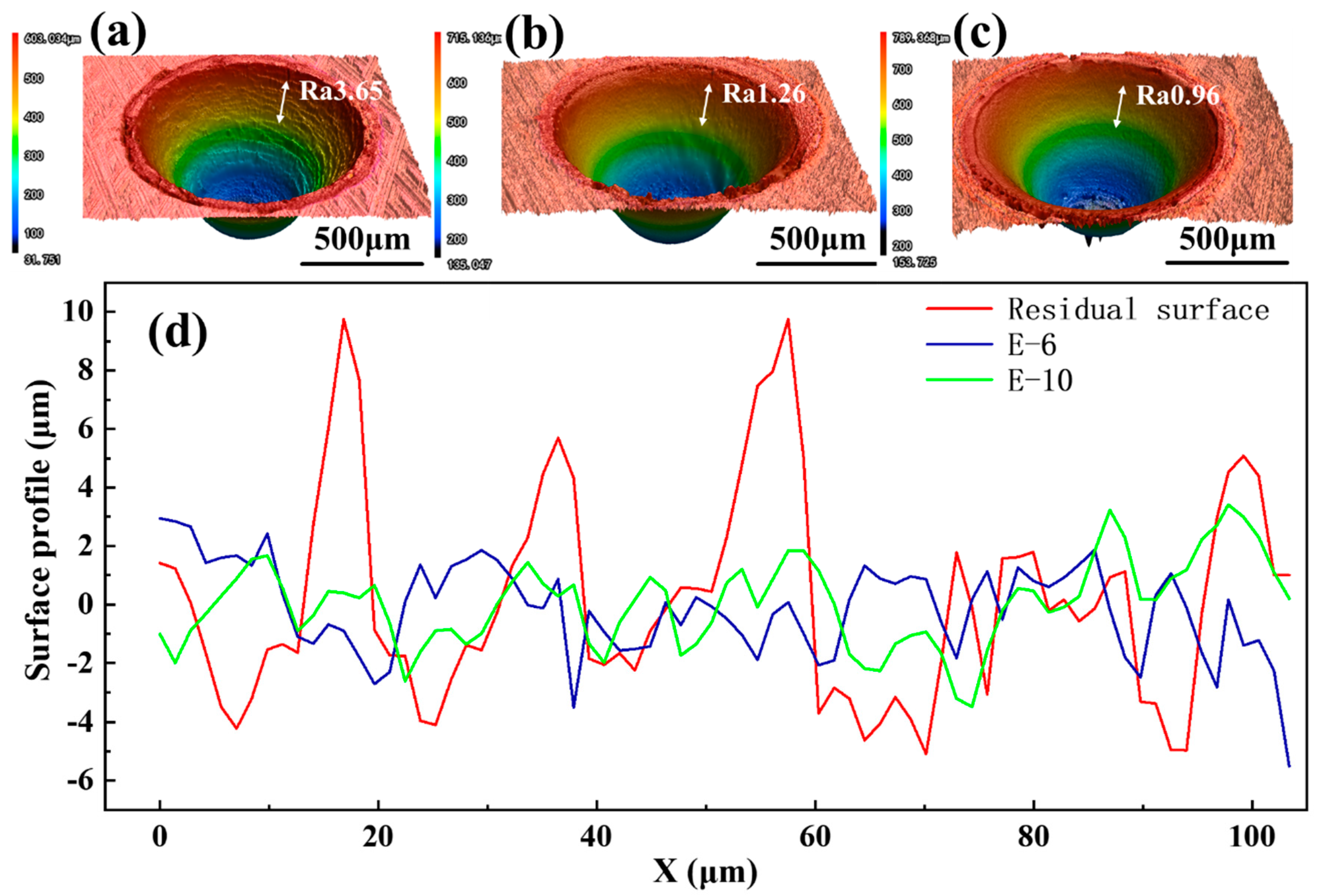

3.1. Effects of Laser Polishing Parameters on Surface Morphology and Roughness

3.1.1. Surface Morphology of Ball-End Milling Surface and Laser-Polished Surface

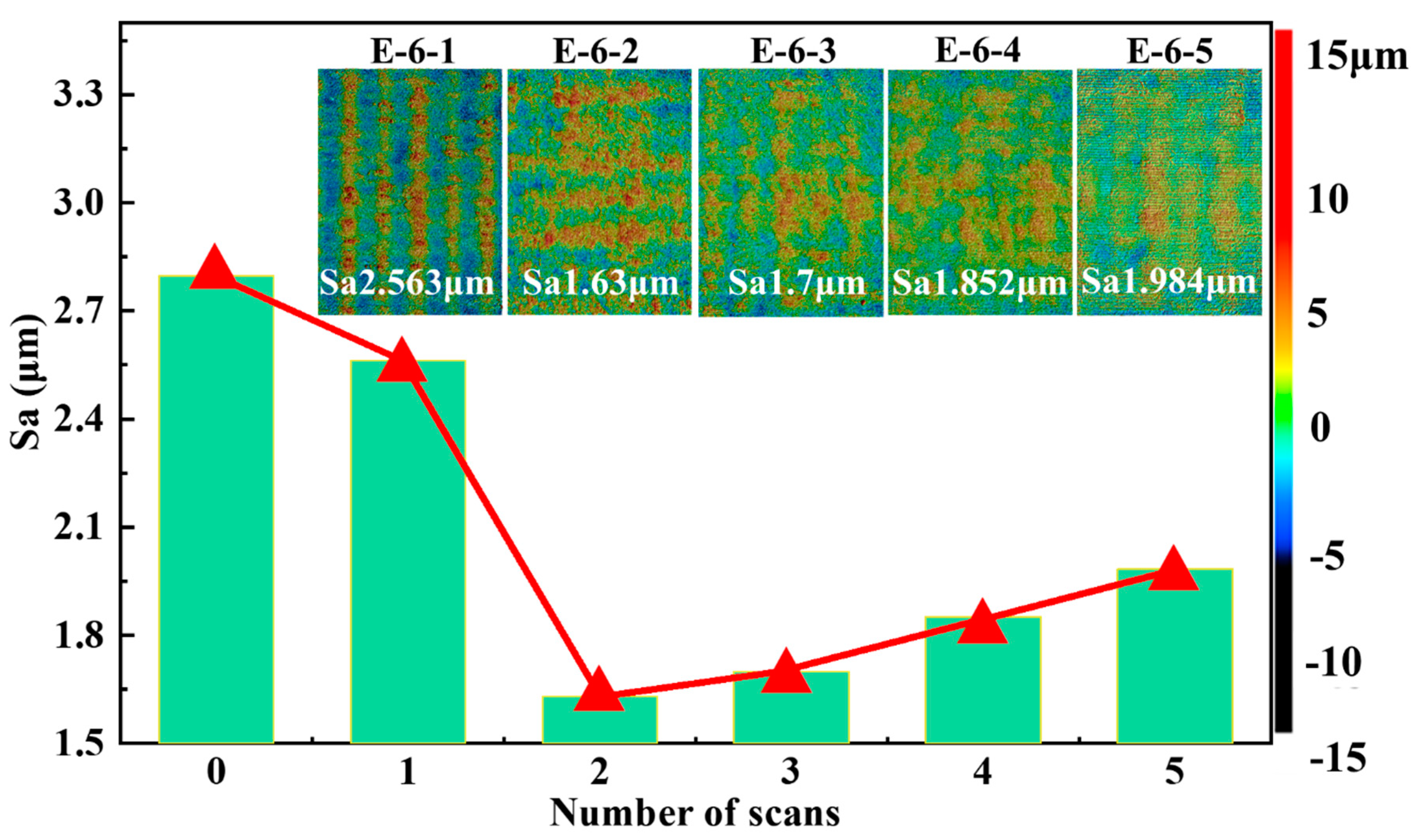

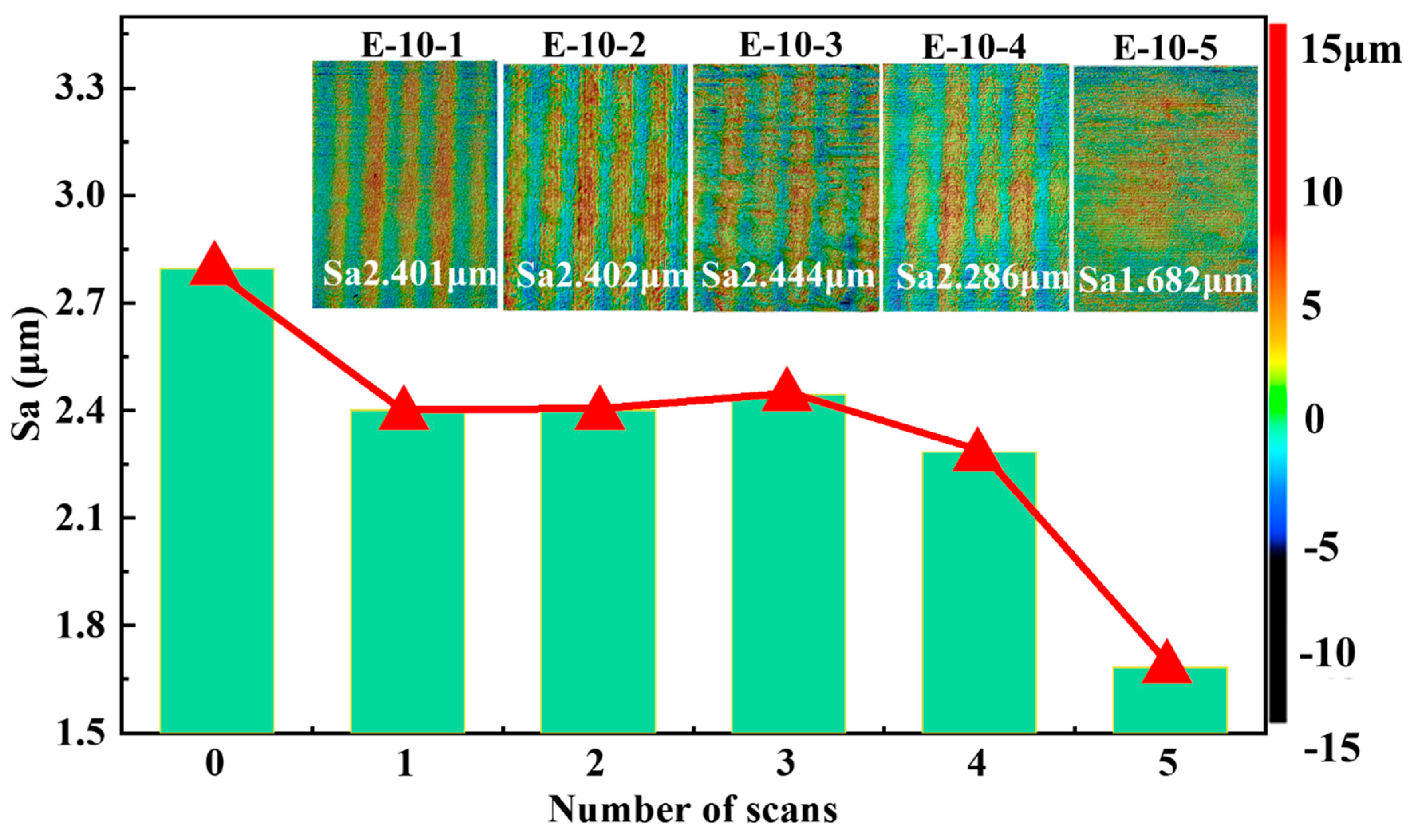

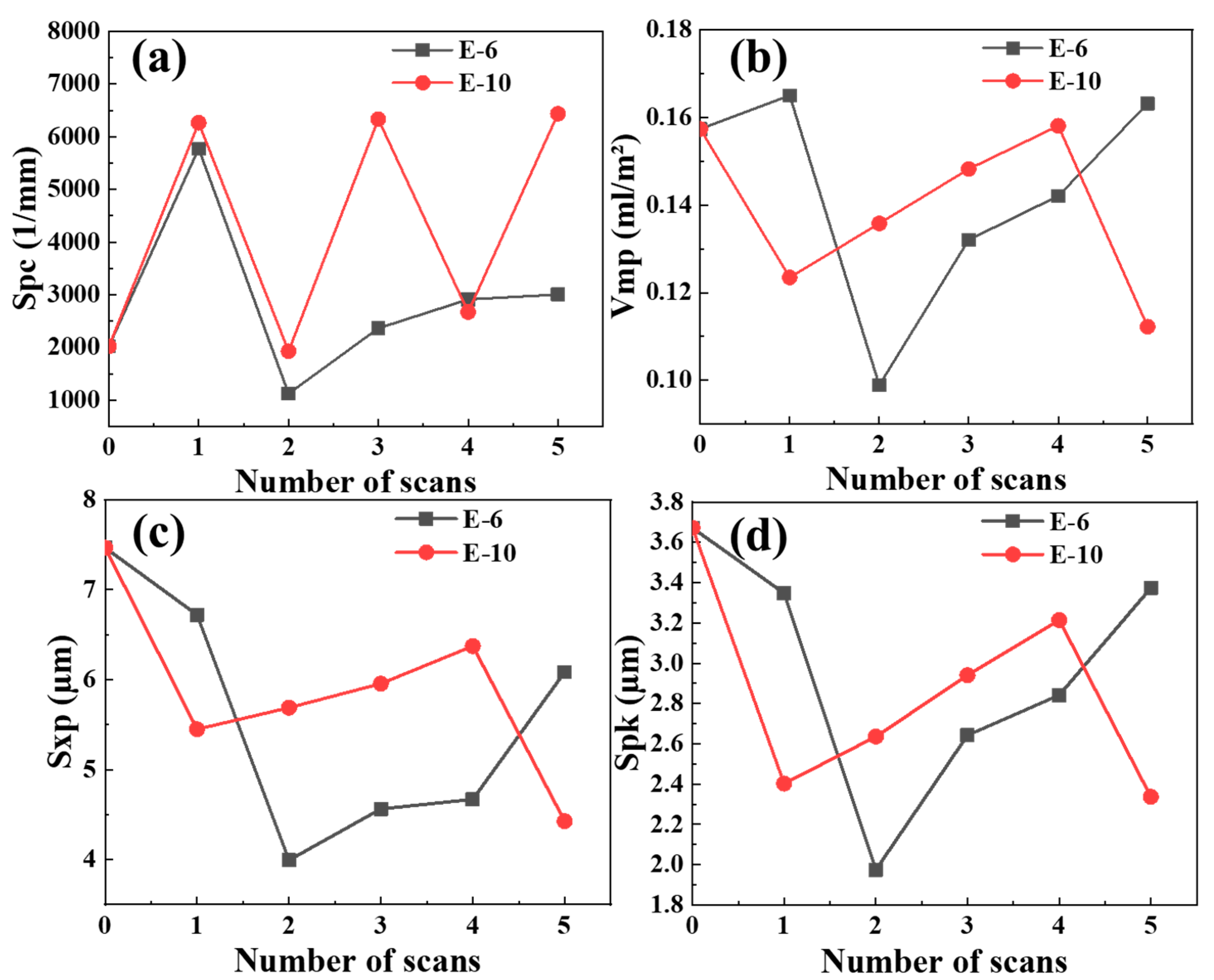

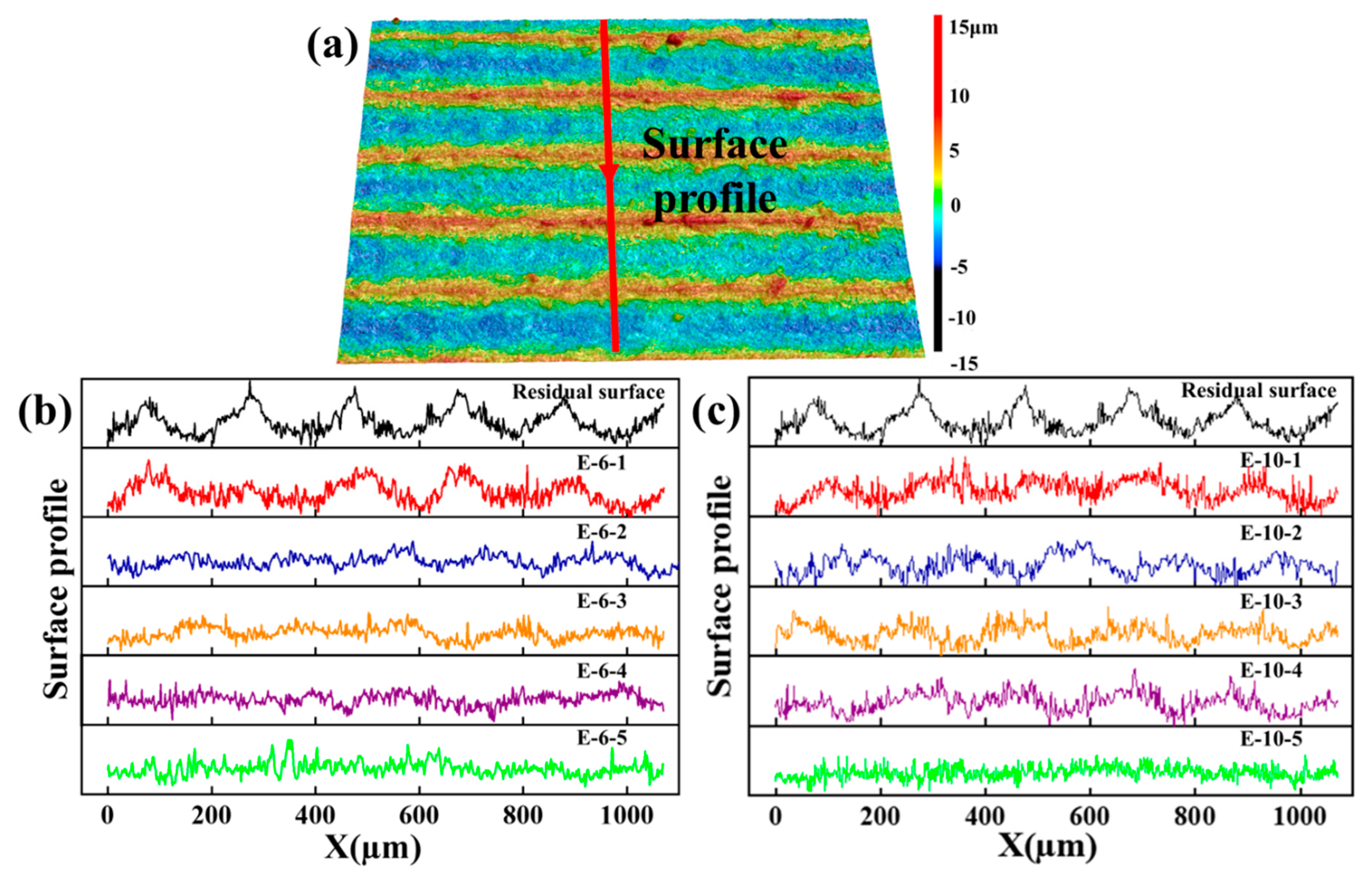

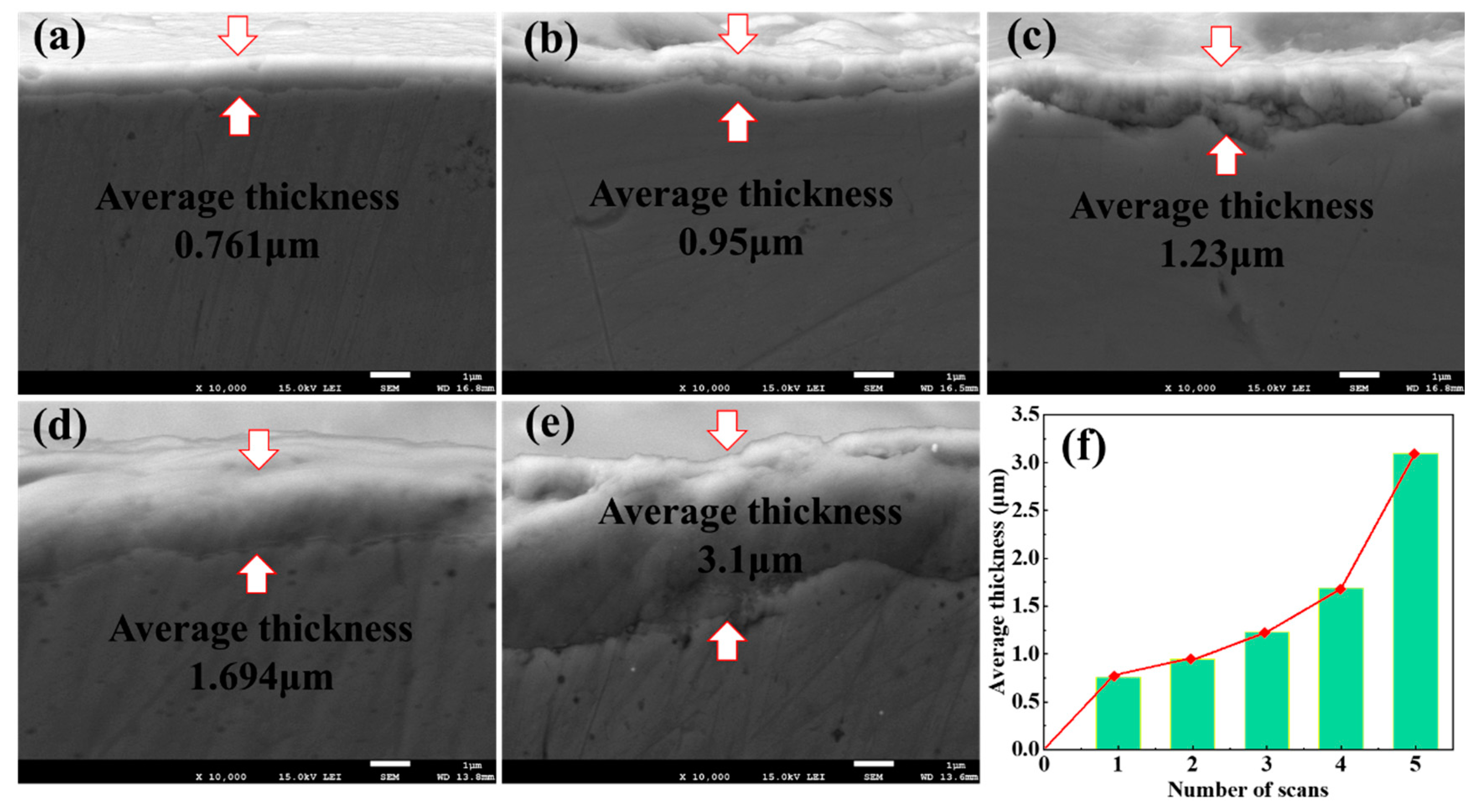

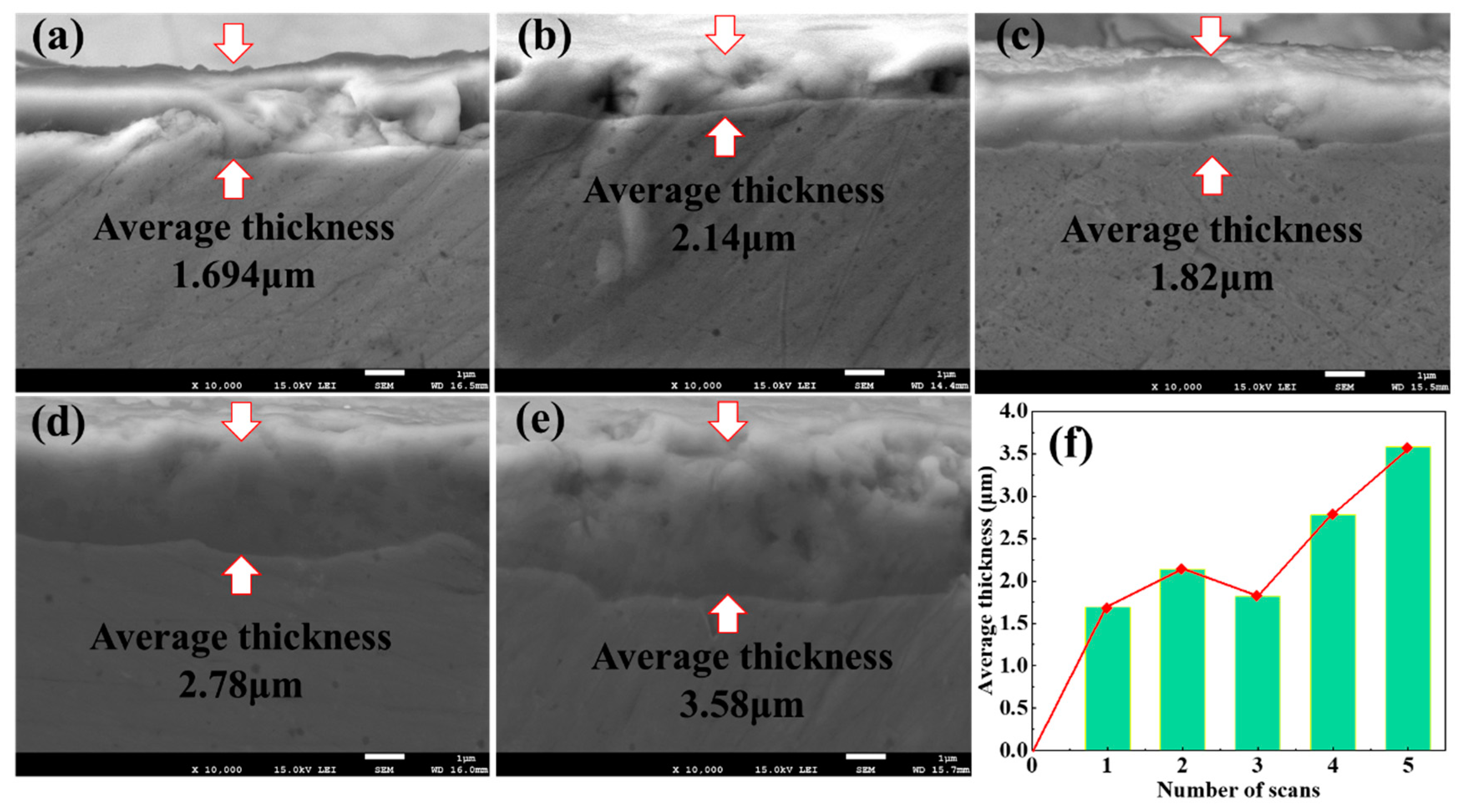

3.1.2. Analysis of the Effect of Multiple Scans

3.1.3. Application of Laser Polishing on Conical Hole

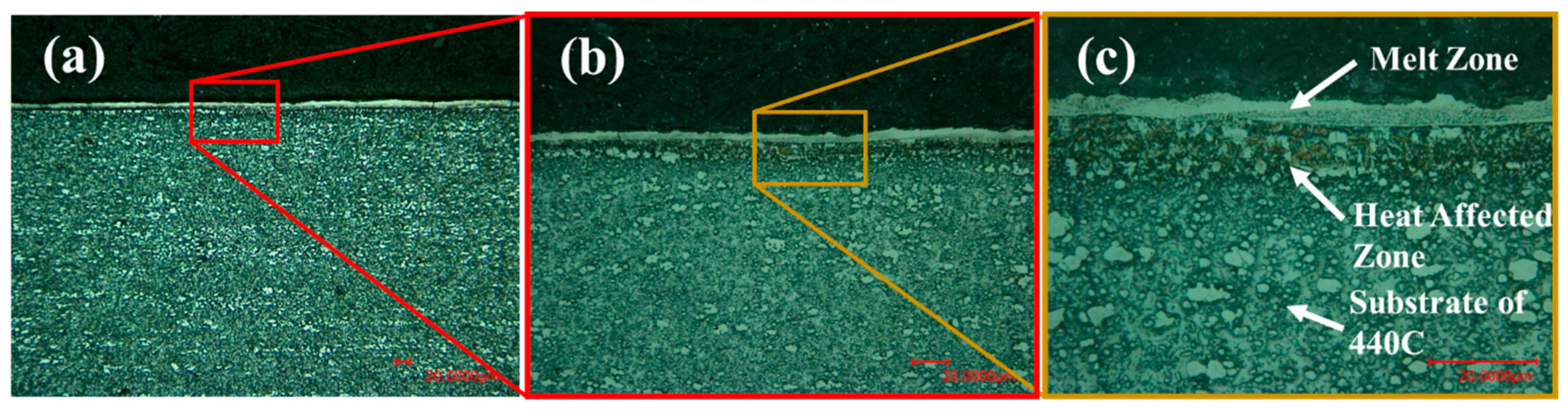

3.2. Analysis of Microstructure and Metallography

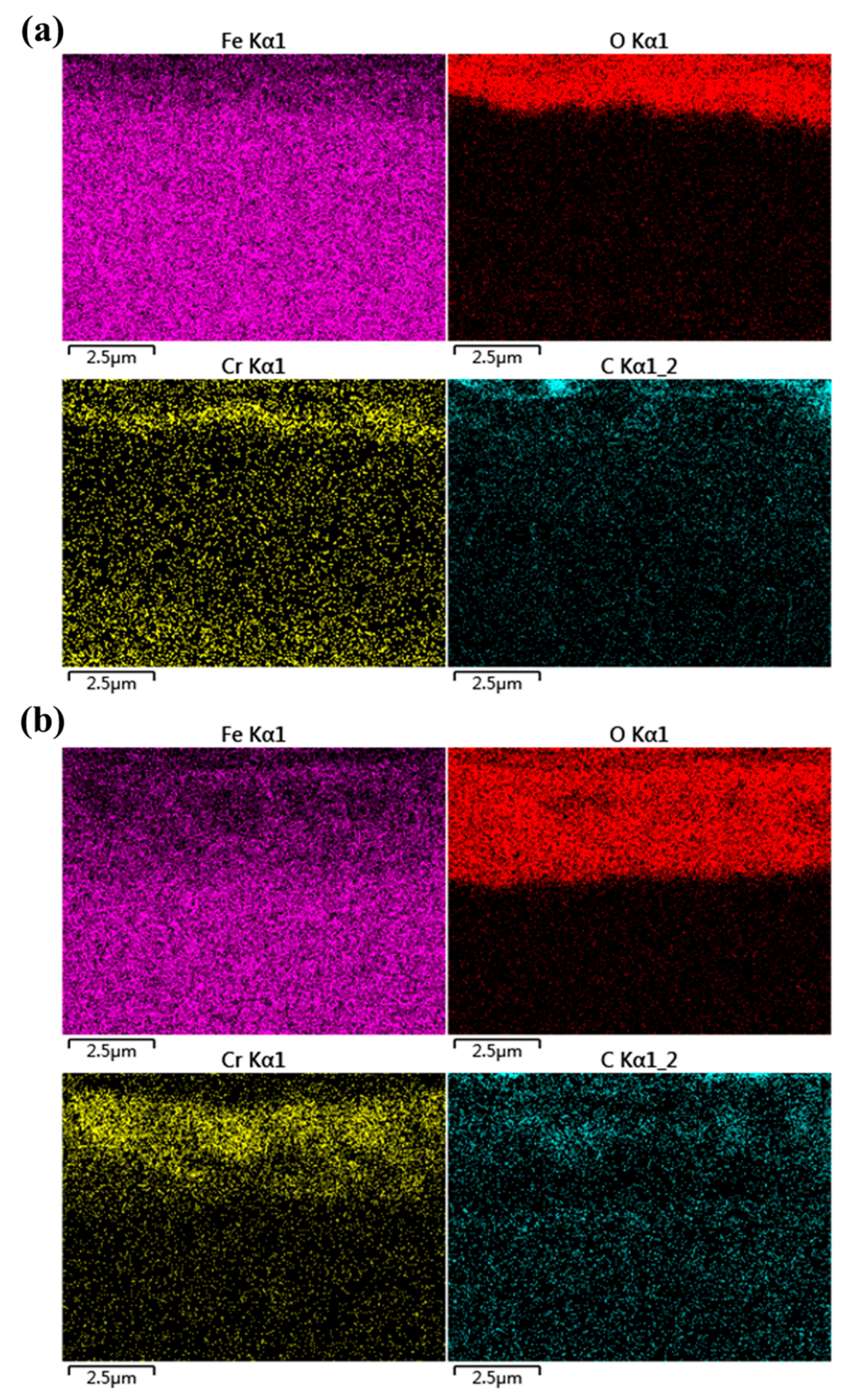

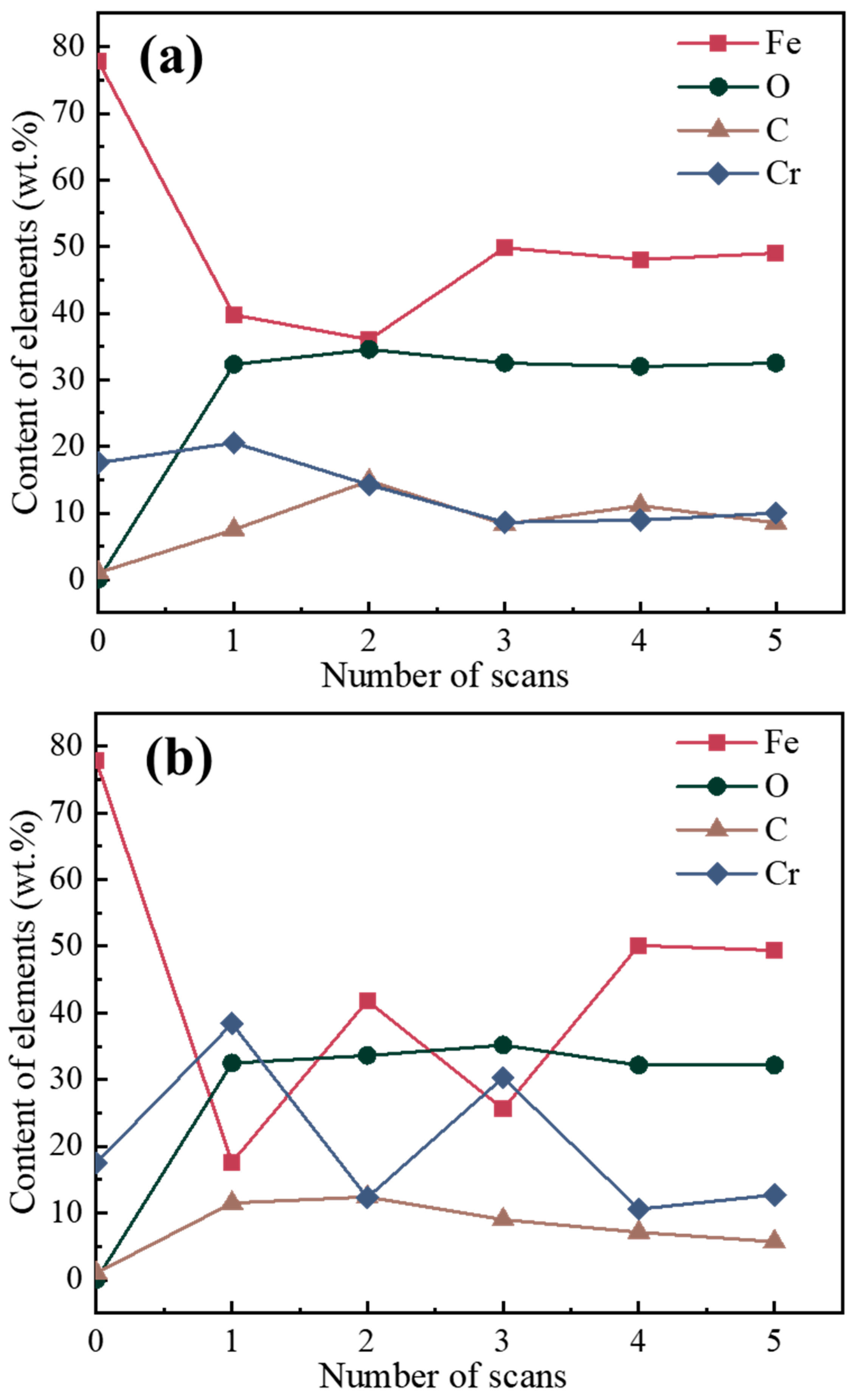

3.3. Analysis of Surface Components

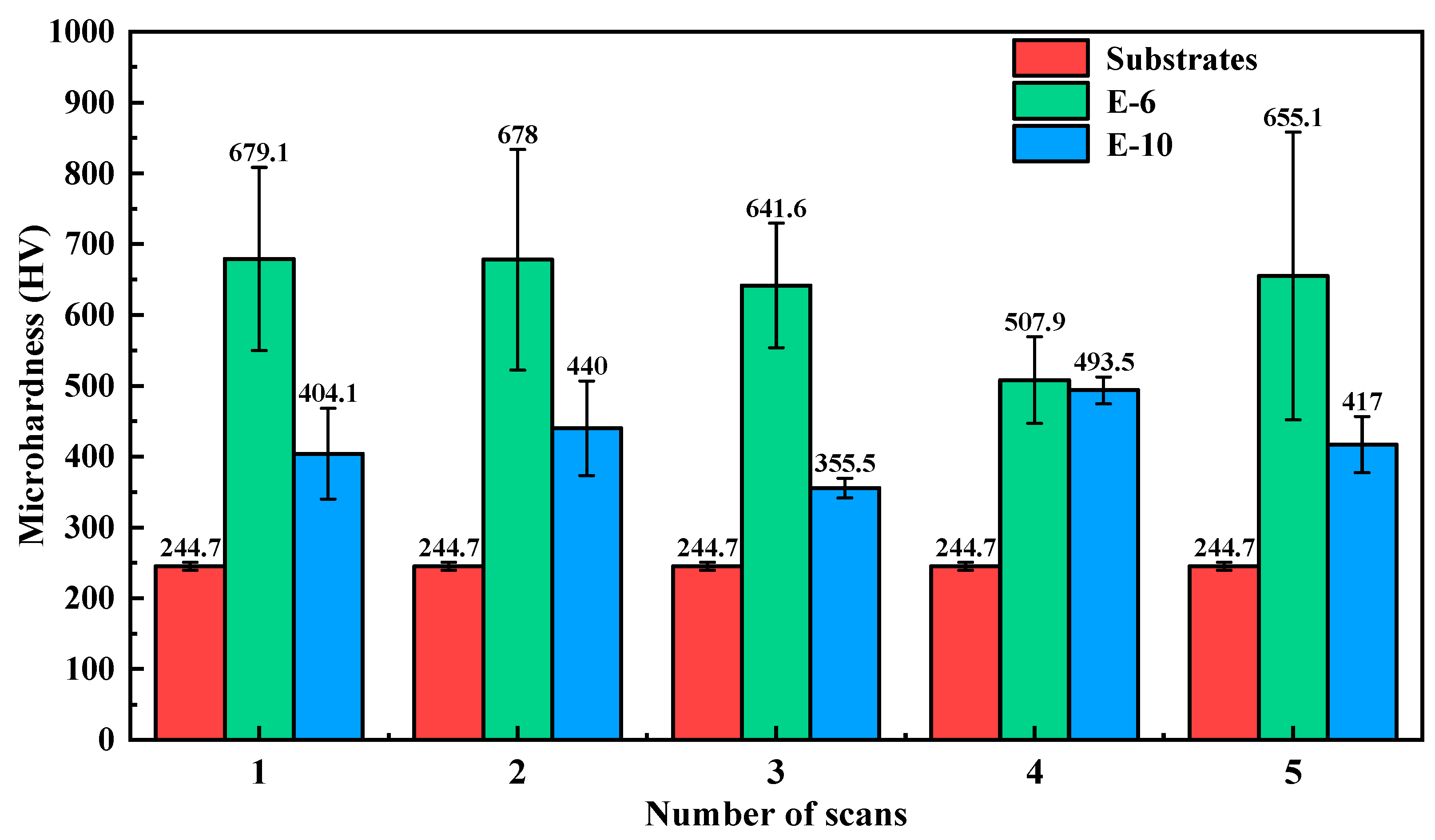

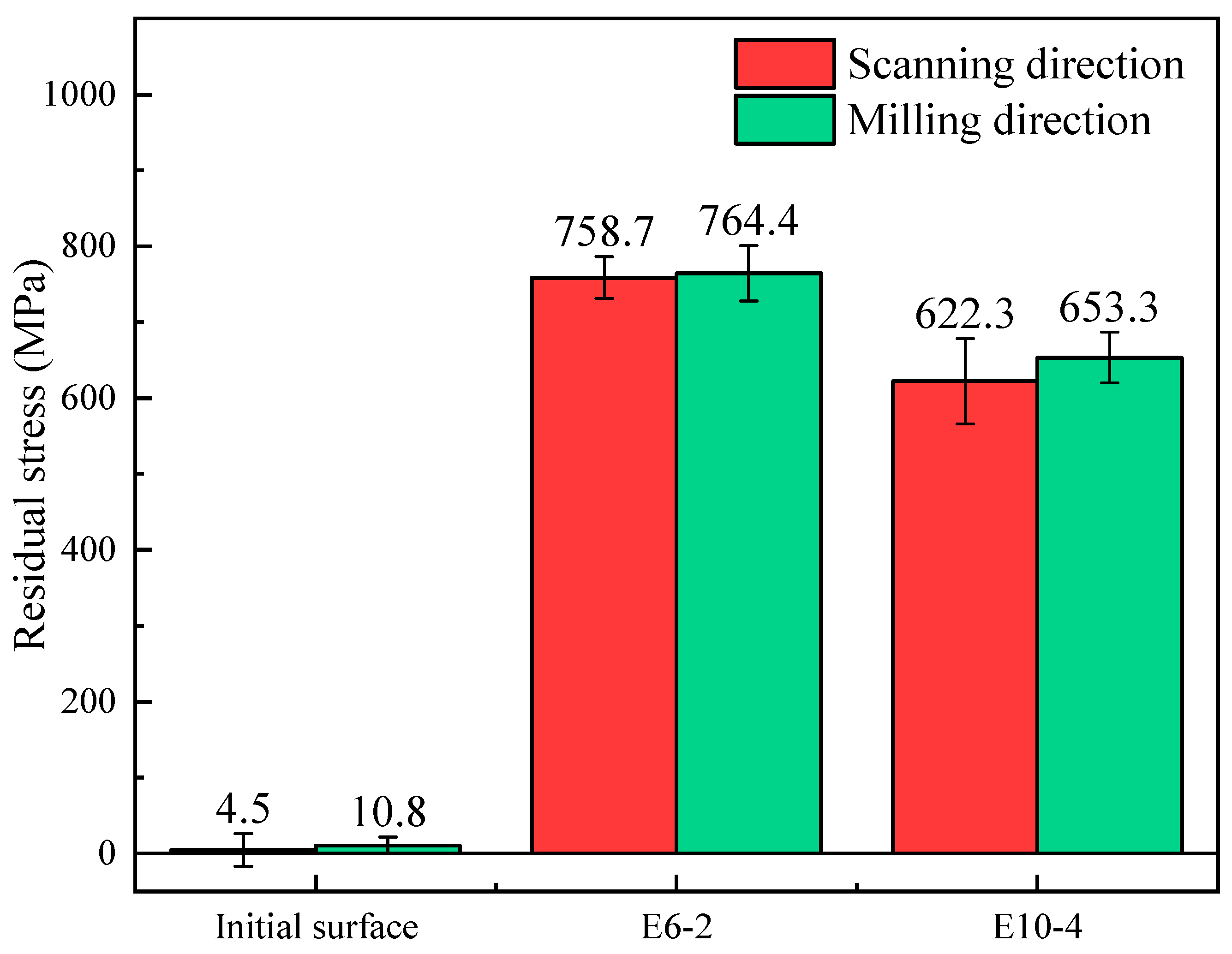

3.4. Analysis of Microhardness and Residual Stress

3.5. Summary

4. Conclusions

- A correlation was established between laser parameters and the surface polishing effect through a series of experiments. The findings indicate that the average energy density directly influences the polishing effect. Following multiple scanning iterations, the maximum roughness reduction rate achieved was 41.72%. Owing to variations in average energy density, the number of scans required to attain a specific roughness level differs. An analysis of the curvature, height, and volume of the surface peaks revealed the evolution trends of these two types of surfaces under different laser energy densities;

- Identical parameters and scanning strategy were employed to polish the ball-end milled conical hole. Post-polishing with optimized parameters and scanning strategy, the maximum roughness reduction rate achieved was 73.6%. The applicability of the scanning strategy was validated, and the surface morphology post-polishing was found to be largely consistent with predictions. The melt layer and heat-affected zone resulting from nanosecond laser polishing were observed to be extremely shallow, thereby affirming the suitability of nanosecond laser polishing for the inner surface of small conical components and significantly preserving the dimensional integrity;

- The oxygen content (O) in the melt zone (MZ) increased due to laser polishing under atmospheric conditions but did not rise with an increase in scanning iterations. Furthermore, owing to the differing melting points of various components, chromium (Cr) enrichment was observed on the polished surface, leading to an increase in chromium oxides and iron–chromium (Fe–Cr) intermetallic compounds on the surface, thereby significantly enhancing the surface microhardness. Simultaneously, due to rapid cooling and solidification, the residual tensile stress also saw a substantial increase post-laser polishing.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Balázs, B.Z.; Geier, N.; Takács, M.; Davim, J.P. A review on micro-milling: Recent advances and future trends. Int. J. Adv. Manuf. Technol. 2021, 112, 655–684. [Google Scholar] [CrossRef]

- Cai, Y.; Liu, Z.; Song, Q.; Shi, Z.; Wan, Y. Fluid mechanics of internal flow with friction and cutting strategies for micronozzles. Int. J. Mech. Sci. 2015, 100, 41–49. [Google Scholar] [CrossRef]

- Klauer, K.; Eifler, M.; Kirsch, B.; Seewig, J.; Aurich, J.C. Ball end micro milling of areal material measures: Influence of the tilt angle on the resulting surface topography. Prod. Eng. 2020, 14, 239–252. [Google Scholar] [CrossRef]

- Fayazfar, H.; Sharifi, J.; Keshavarz, M.K.; Ansari, M. An overview of surface roughness enhancement of additively manufactured metal parts: A path towards removing the post-print bottleneck for complex geometries. Int. J. Adv. Manuf. Technol. 2023, 125, 1061–1113. [Google Scholar] [CrossRef]

- Ermergen, T.; Taylan, F. Review on Surface Quality Improvement of Additively Manufactured Metals by Laser Polishing. Arab. J. Sci. Eng. 2021, 46, 7125–7141. [Google Scholar] [CrossRef]

- Mu, J.; Sun, T.; Leung, C.L.A.; Oliveira, J.; Wu, Y.; Wang, H.; Wang, H. Application of electrochemical polishing in surface treatment of additively manufactured structures: A review. Prog. Mater. Sci. 2023, 136, 101109. [Google Scholar] [CrossRef]

- Mohammadian, N.; Turenne, S.; Brailovski, V. Electropolishing of Laser Powder Bed-Fused IN625 Components in an Ionic Electrolyte. J. Manuf. Mater. Process. 2019, 3, 86. [Google Scholar] [CrossRef]

- Urlea, V.; Brailovski, V. Electropolishing and electropolishing-related allowances for powder bed selectively laser-melted Ti-6Al-4V alloy components. J. Mater. Process. Technol. 2017, 242, 1–11. [Google Scholar] [CrossRef]

- Atzeni, E.; Barletta, M.; Calignano, F.; Iuliano, L.; Rubino, G.; Tagliaferri, V. Abrasive Fluidized Bed (AFB) finishing of AlSi10Mg substrates manufactured by Direct Metal Laser Sintering (DMLS). Addit. Manuf. 2016, 10, 15–23. [Google Scholar] [CrossRef]

- Tan, K.L.; Yeo, S.H. Surface modification of additive manufactured components by ultrasonic cavitation abrasive finishing. Wear 2017, 378–379, 90–95. [Google Scholar] [CrossRef]

- Zhang, J.; Chaudhari, A.; Wang, H. Surface quality and material removal in magnetic abrasive finishing of selective laser melted 316L stainless steel. J. Manuf. Process. 2019, 45, 710–719. [Google Scholar] [CrossRef]

- Ali, M.; Almotari, A.; Algamal, A.; Qattawi, A. Recent Advancements in Post Processing of Additively Manufactured Metals Using Laser Polishing. J. Manuf. Mater. Process. 2023, 7, 115. [Google Scholar] [CrossRef]

- Gisario, A.; Barletta, M.; Veniali, F. Laser polishing: A review of a constantly growing technology in the surface finishing of components made by additive manufacturing. Int. J. Adv. Manuf. Technol. 2022, 120, 1433–1472. [Google Scholar] [CrossRef]

- Manco, E.; Cozzolino, E.; Astarita, A. Laser polishing of additively manufactured metal parts: A review. Surf. Eng. 2022, 38, 217–233. [Google Scholar] [CrossRef]

- Kumstel, J. Laser polishing of metallic freeform surfaces by using a dynamic laser beam preforming system. J. Laser Appl. 2021, 33, 022020. [Google Scholar] [CrossRef]

- Rosa, B.; Mognol, P.; Hascoët, J. Laser polishing of additive laser manufacturing surfaces. J. Laser Appl. 2015, 27, S29102. [Google Scholar] [CrossRef]

- Yung, K.C.; Xiao, T.Y.; Choy, H.S.; Wang, W.J.; Cai, Z.X. Laser polishing of additive manufactured CoCr alloy components with complex surface geometry. J. Mater. Process. Technol. 2018, 262, 53–64. [Google Scholar] [CrossRef]

- Mohajerani, S.; Miller, J.D.; Tutunea-Fatan, O.R.; Bordatchev, E.V. Thermo-Physical Modelling of Track Width During Laser Polishing of H13 Tool Steel. Procedia Manuf. 2017, 10, 708–719. [Google Scholar] [CrossRef]

- Zhao, L.; Klopf, J.M.; Reece, C.E.; Kelley, M.J. Laser polishing for topography management of accelerator cavity surfaces: Laserpolieren als Topographiemanagement zur schnellen Herstellung von Oberflächen mit Mulden. Mater. Werkst. 2015, 46, 675–685. [Google Scholar] [CrossRef]

- Zhihao, F.; Libin, L.; Longfei, C.; Yingchun, G. Laser Polishing of Additive Manufactured Superalloy. Procedia CIRP 2018, 71, 150–154. [Google Scholar] [CrossRef]

- Krishnan, A.; Fang, F. Review on mechanism and process of surface polishing using lasers. Front. Mech. Eng. 2019, 14, 299–319. [Google Scholar] [CrossRef]

- Jang, P.-R.; Kim, C.-G.; Kim, J.-H.; Jang, Y.-S.; Jo, C.-I. Dynamic Simulation analysis for laser micro-polishing process of metallic surface using UV nanosecond pulse laser. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 526. [Google Scholar] [CrossRef]

- Li, N.; Fan, P.; Zhu, Q.; Cui, B.; Silvain, J.-F.; Lu, Y.F. Femtosecond laser polishing of additively manufactured parts at grazing incidence. Appl. Surf. Sci. 2023, 612, 155833. [Google Scholar] [CrossRef]

- Xu, X.; Chen, X.; Zhou, Y.; Li, Y.; Liu, M. Laser Polishing and Annealing Injection Mold Using Dual-Beam Laser System. Coatings 2022, 12, 1822. [Google Scholar] [CrossRef]

- Shao, Y.; Sun, S.; Wang, P.; Zhang, F.; Wang, X.; Monka, P.P.; Liu, J.; Kim, D. Selective and noncontaminated surface polishing of medical Ti-6Al-4V titanium alloy by laser chemical processing. Opt. Eng. 2022, 61, 116107. [Google Scholar] [CrossRef]

- Li, P.; Wang, Y.; Li, L.; Gong, Y.; Zhou, J.; Lu, J. Ablation oxidation and surface quality during laser polishing of TA15 aviation titanium alloy. J. Mater. Res. Technol. 2023, 23, 6101–6114. [Google Scholar] [CrossRef]

- Bhaduri, D.; Ghara, T.; Penchev, P.; Paul, S.; Pruncu, C.I.; Dimov, S.; Morgan, D. Pulsed laser polishing of selective laser melted aluminium alloy parts. Appl. Surf. Sci. 2021, 558, 149887. [Google Scholar] [CrossRef]

- Yi, C.; Chen, X.; Chen, X.; Chen, T.; Zhang, W. Surface features of multi-beam coupling nanosecond laser processing of nickel-based superalloys. In Proceedings of the Seventeenth National Conference on Laser Technology and Optoelectronics, Shanghai, China, 17–20 October 2020; Chen, W., Qiu, J., Zhang, Z., Zhu, J., Wang, P., Eds.; SPIE: Washington, DC, USA, 2022; p. 15. [Google Scholar] [CrossRef]

- Chen, Y.-D.; Tsai, W.-J.; Liu, S.-H.; Horng, J.-B. Picosecond laser pulse polishing of ASP23 steel. Opt. Laser Technol. 2018, 107, 180–185. [Google Scholar] [CrossRef]

- Yi, C.; Chen, X.; Zhou, Y.; Chen, T.; Zhang, W. Effects of scanning speed and scanning times on surface quality of line spot laser polishing of nickel-based superalloys. J. Mater. Res. Technol. 2023, 26, 2179–2190. [Google Scholar] [CrossRef]

- Yao, J.; Huang, J.; Wang, G.; Min, D.; Wang, L. Pulsed Laser Polishing Mechanism on High Roughness Surface Cut by Wire Electrical Discharge Machining. Chin. J. Lasers-Zhongguo Jiguang 2021, 48, 1402003. [Google Scholar] [CrossRef]

- Jaritngam, P.; Saetang, V.; Qi, H.; Dumkum, C. Surface polishing of additively manufactured Ti6Al4V titanium alloy by using a nanosecond pulse laser. Int. J. Adv. Manuf. Technol. 2023, 127, 3463–3480. [Google Scholar] [CrossRef]

- Wei, L.; Du, C.; Zhao, H. Effects of Laser Power on Quenched Microstructure and Properties of 440C Steel. Hot Work. Technol. 2023, 52, 146–158. [Google Scholar] [CrossRef]

- Bang, G.B.; Hwang, Y.J.; Kim, W.R.; Song, Y.H.; Kim, G.H.; Hyun, S.-K.; Cha, S.C.; Park, H.J.; Lee, T.W.; Kim, H.G. Microstructural and mechanical properties of AISI 440C stainless steel fabricated using selective laser melting. Mater. Sci. Eng. A 2022, 860, 144259. [Google Scholar] [CrossRef]

- Lim, D.-W.; Kim, J.-H.; Kim, B.-C.; Park, J.Y.; Ha, S.J. Evaluation of Surface Characteristics with Pre-treatment Polishing Process in Pulsed Laser Polishing AISI 4140 Mold Steel. Int. J. Precis. Eng. Manuf. 2021, 22, 1911–1921. [Google Scholar] [CrossRef]

- Zhou, H.; Zhou, H.; Zhao, Z.; Li, K.; Yin, J. Numerical Simulation and Verification of Laser-Polishing Free Surface of S136D Die Steel. Metals 2021, 11, 400. [Google Scholar] [CrossRef]

- Zhou, J.; Liao, C.; Shen, H.; Ding, X. Surface and property characterization of laser polished Ti6Al4V. Surf. Coat. Technol. 2019, 380, 125016. [Google Scholar] [CrossRef]

- Temmler, A.; Dai, W.; Schmickler, T.; Küpper, M.E.; Häfner, C.L. Experimental investigation on surface structuring by laser remelting (WaveShape) on Inconel 718 using varying laser beam diameters and scan speeds. Appl. Surf. Sci. 2021, 541, 147814. [Google Scholar] [CrossRef]

- Chen, L.; Richter, B.; Zhang, X.; Bertsch, K.B.; Thoma, D.J.; Pfefferkorn, F.E. Effect of laser polishing on the microstructure and mechanical properties of stainless steel 316L fabricated by laser powder bed fusion. Mater. Sci. Eng. A 2021, 802, 140579. [Google Scholar] [CrossRef]

- Liu, W.; Al-Hammadi, G.; Saleheen, K.M.; Abdelrahman, A.; Liu, H.; Zhang, Z. Impact of Pulsed Laser Parameters and Scanning Pattern on the Properties of Thin-Walled Parts Manufactured Using Laser Metal Deposition. Nanomanuf. Metrol. 2022, 5, 381–393. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | P | S | Cr | Fe |

|---|---|---|---|---|---|---|---|

| Content (%) | 0.95–1.2 | ≤1.0 | ≤1.0 | ≤0.035 | ≤0.03 | 16.0–18.0 | Balance |

| Laser Parameters | Max. Power | Wavelength | Pulse Width | Max. Repetition Rate | Laser Beam Diameter |

|---|---|---|---|---|---|

| Value | 20 W | 1064 nm | 100 ns | 200 kHz | 30 µm |

| Parameters | Spindle Speed | Feed Rate per Tooth | Feed Rate | Axial Cutting Depth | Horizontal Step |

|---|---|---|---|---|---|

| Value | 20,000 r/min | 1 µm/z | 40 mm/min | 0.05 mm | 0.2 mm |

| Specimen Code | P (W) | f (kHz) | V (mm/s) | FOD (mm) | ED (J/cm2) |

|---|---|---|---|---|---|

| E-1 | 6 | 125 | 8 | 0 | 5000 |

| E-2 | 6 | 150 | 14 | 0.332 | 2284 |

| E-3 | 6 | 175 | 20 | 0.664 | 1000 |

| E-4 | 6 | 200 | 26 | 1.15 | 384 |

| E-5 | 9 | 125 | 14 | 0.664 | 2142 |

| E-6 | 9 | 150 | 8 | 1.15 | 1875 |

| E-7 | 9 | 175 | 26 | 0 | 2307.6 |

| E-8 | 9 | 200 | 20 | 0.332 | 2400 |

| E-9 | 12 | 125 | 20 | 1.15 | 1000 |

| E-10 | 12 | 150 | 26 | 0.664 | 1538 |

| E-11 | 12 | 175 | 8 | 0.332 | 8000 |

| E-12 | 12 | 200 | 14 | 0 | 5714 |

| E-13 | 15 | 125 | 26 | 0.332 | 3076 |

| E-14 | 15 | 150 | 20 | 0 | 5000 |

| E-15 | 15 | 175 | 14 | 0.664 | 3572 |

| E-16 | 15 | 200 | 8 | 1.15 | 3125 |

| P | f | V | FOD | |

|---|---|---|---|---|

| Probability value | 0.047 | 0.877 | 0.976 | 0.534 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Cai, Y.; Zhang, H.; Li, J.; Song, Q.; Wang, B.; Liu, Z. Investigation of Surface Integrity of Conical Hole in Laser Polishing 440C Stainless Steel. Metals 2024, 14, 58. https://doi.org/10.3390/met14010058

Zhang C, Cai Y, Zhang H, Li J, Song Q, Wang B, Liu Z. Investigation of Surface Integrity of Conical Hole in Laser Polishing 440C Stainless Steel. Metals. 2024; 14(1):58. https://doi.org/10.3390/met14010058

Chicago/Turabian StyleZhang, Chuanqi, Yukui Cai, Haotian Zhang, Jiahang Li, Qinghua Song, Bing Wang, and Zhanqiang Liu. 2024. "Investigation of Surface Integrity of Conical Hole in Laser Polishing 440C Stainless Steel" Metals 14, no. 1: 58. https://doi.org/10.3390/met14010058

APA StyleZhang, C., Cai, Y., Zhang, H., Li, J., Song, Q., Wang, B., & Liu, Z. (2024). Investigation of Surface Integrity of Conical Hole in Laser Polishing 440C Stainless Steel. Metals, 14(1), 58. https://doi.org/10.3390/met14010058