Improved Tribological Performance of Nitride-Reinforced Biocompatible Titanium–Niobium–Zirconium–Tantalum (TNZT) Alloys for Advanced Orthopedic Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Material Synthesis and Characterization

2.2. Biocompatibility Tests of the Alloys

2.2.1. Materials

2.2.2. MG-63 Cell Culture

2.2.3. Cell Viability Test

2.2.4. MTT Assay

2.2.5. Cell Adhesion

3. Results

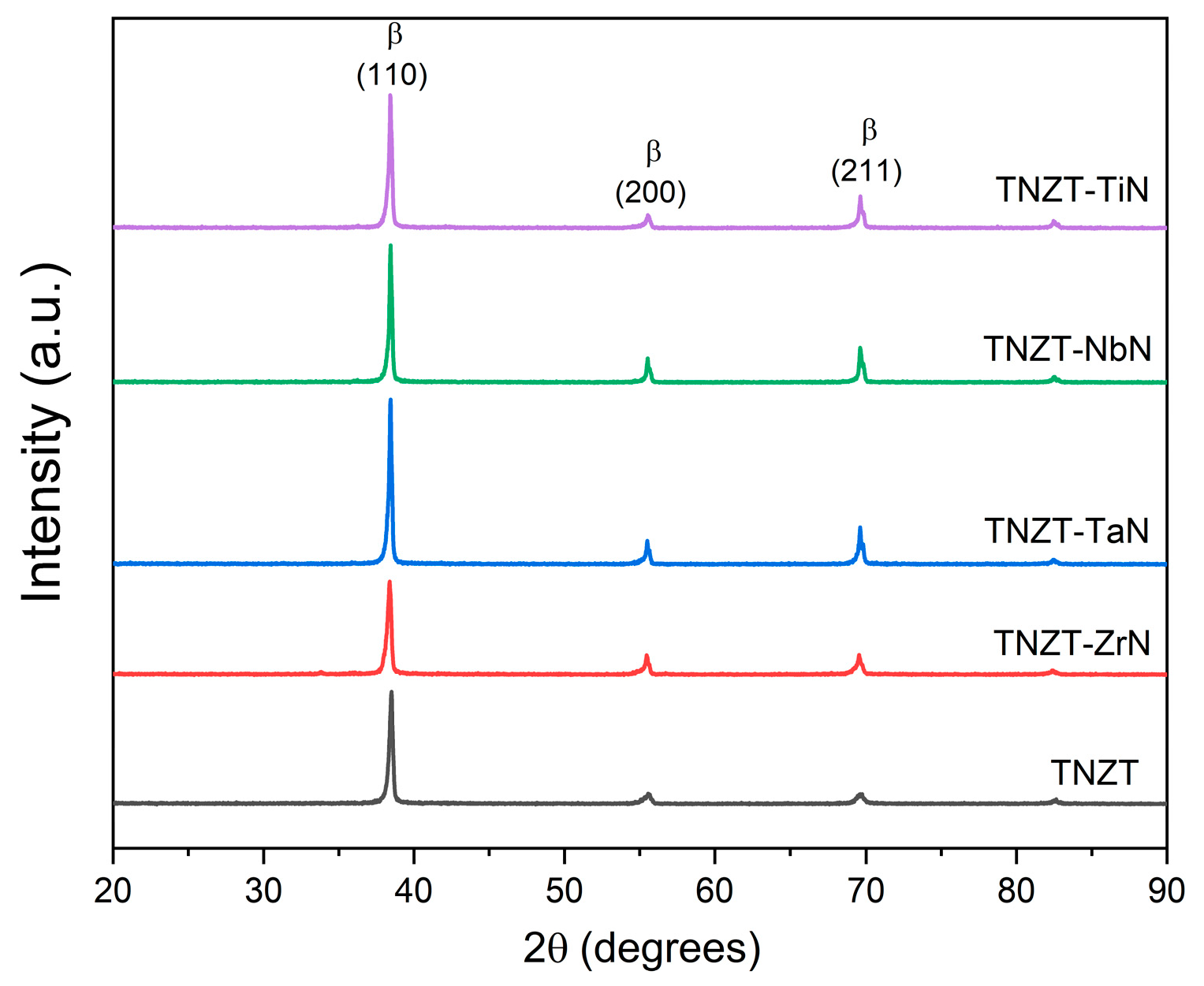

3.1. X-ray Diffraction

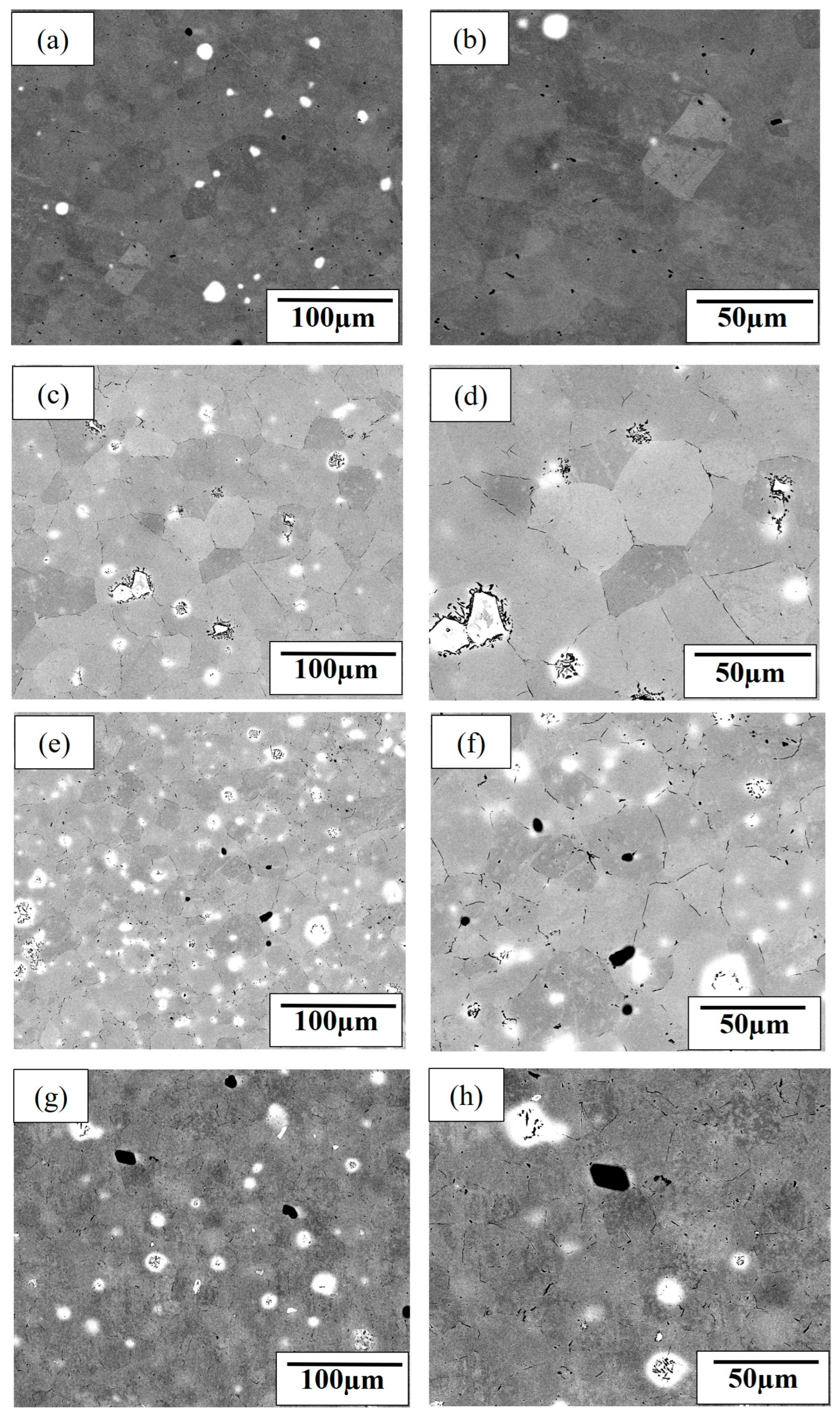

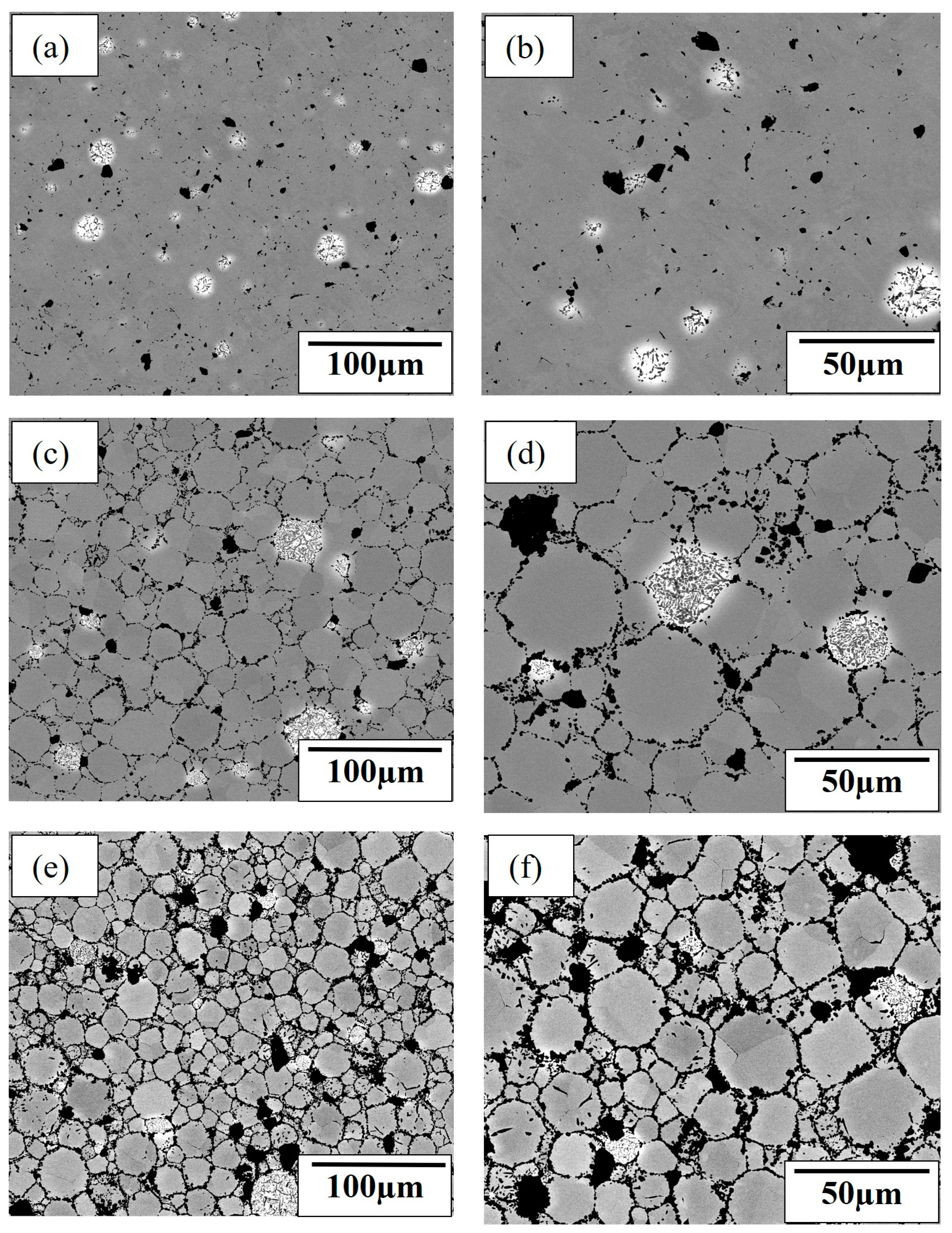

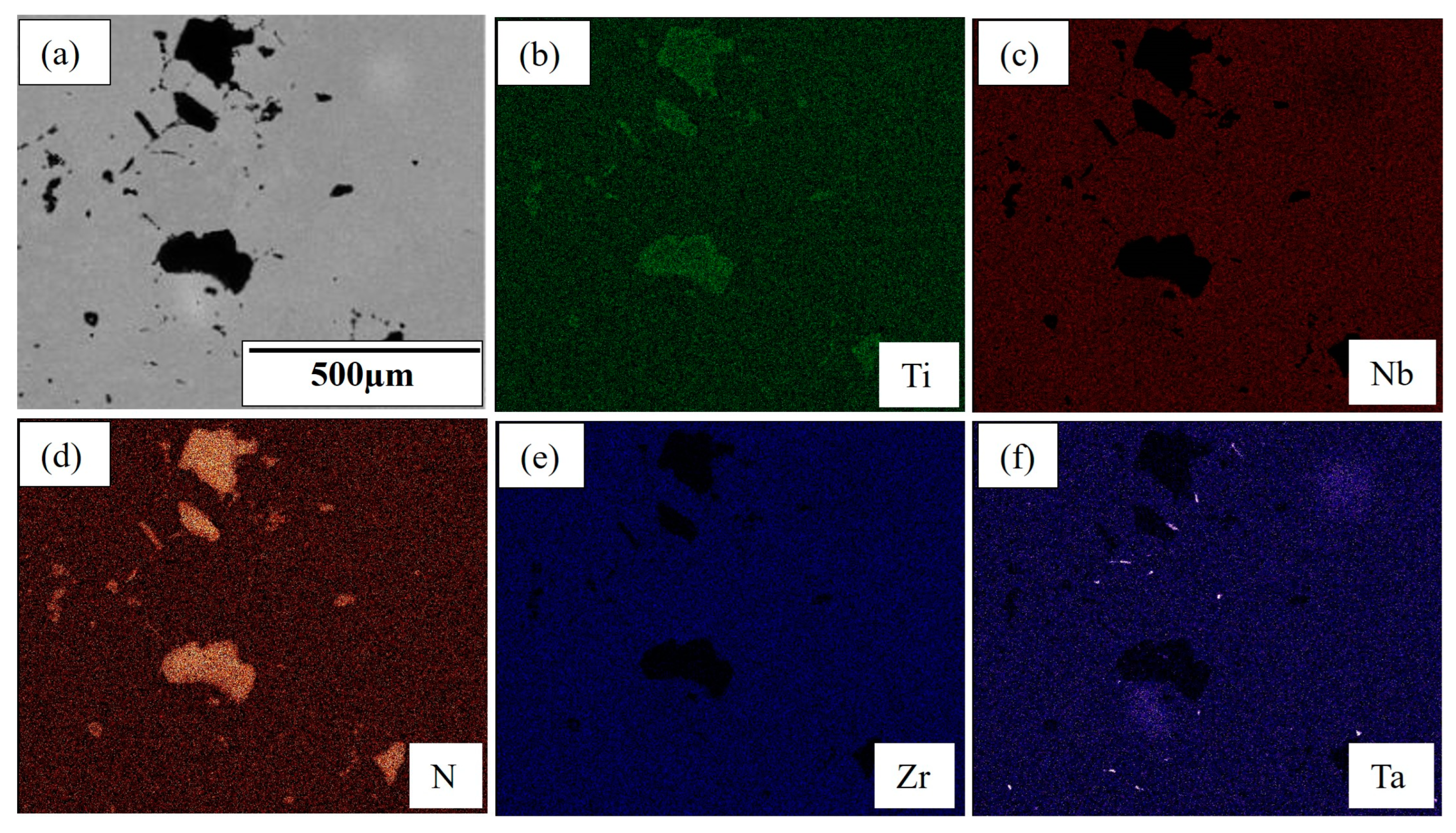

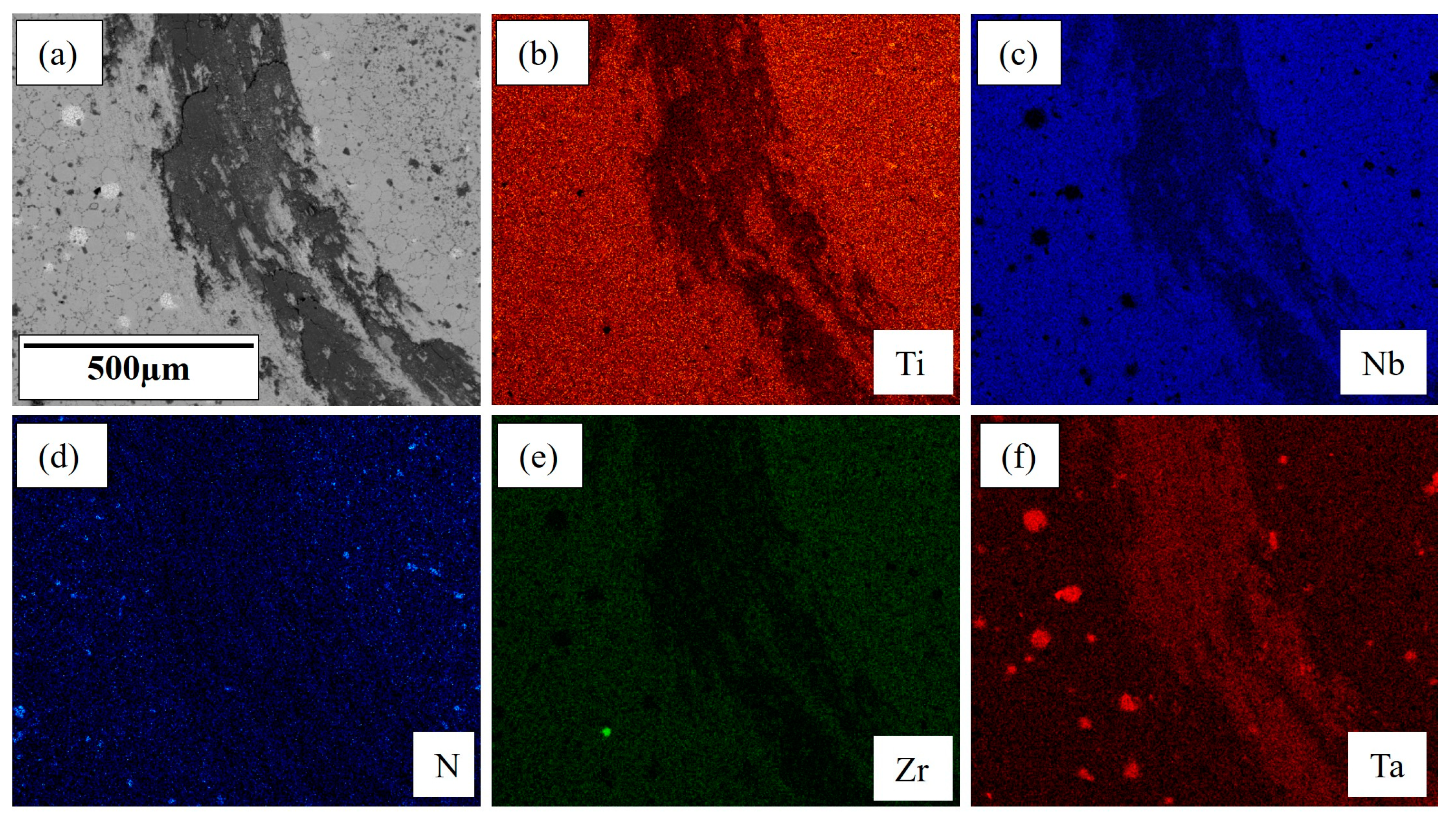

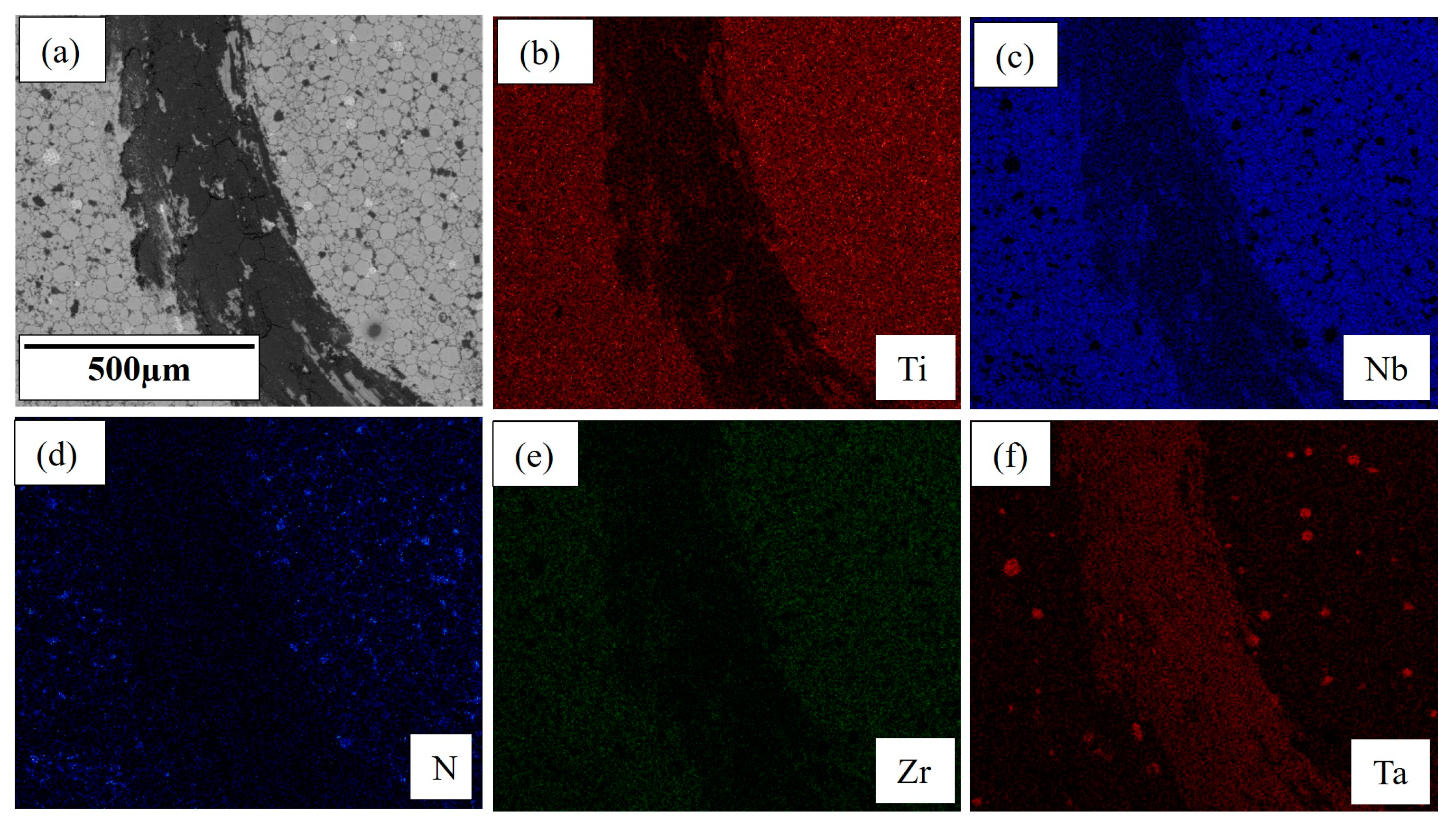

3.2. Scanning Electron Microscopy

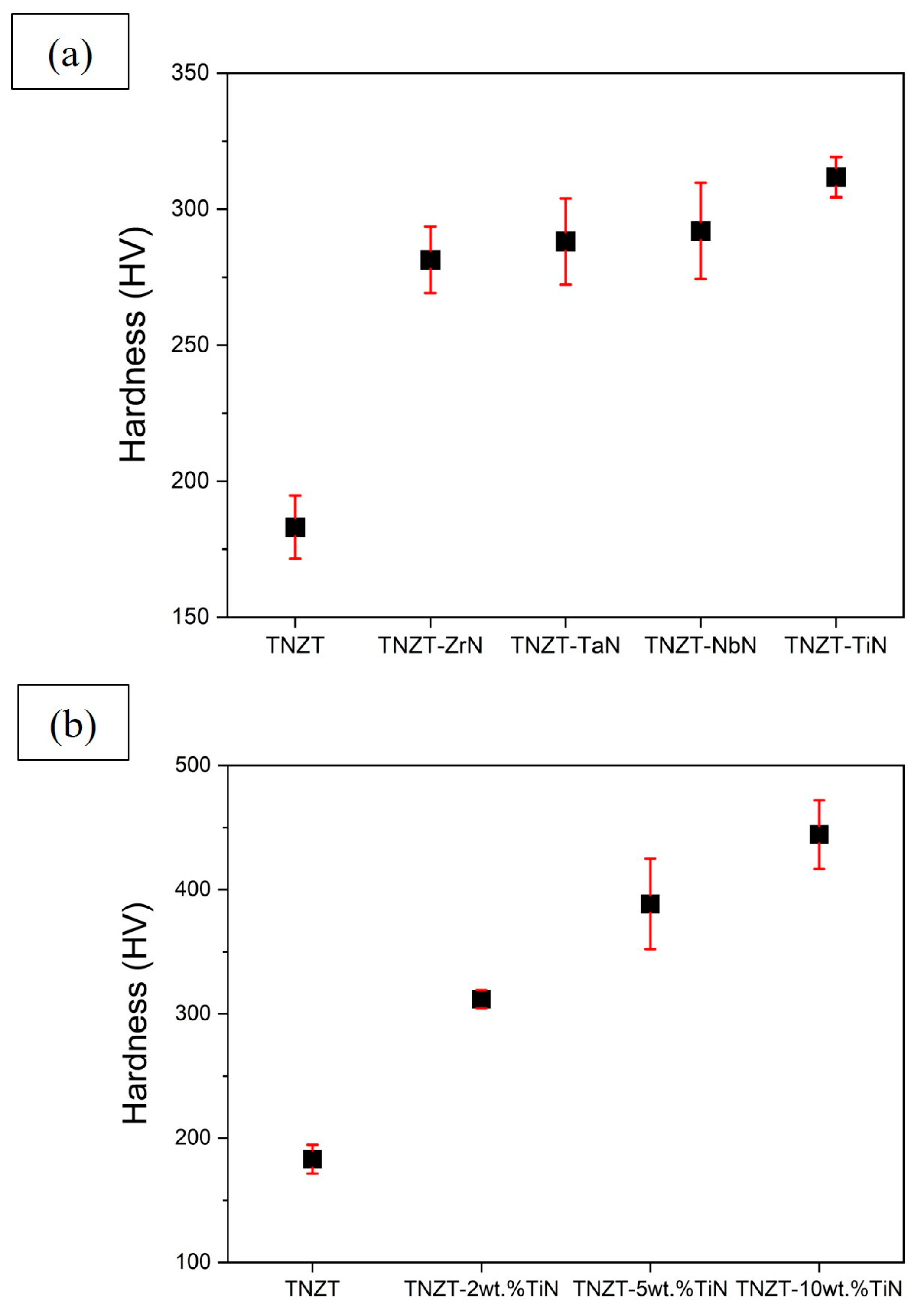

3.3. Microhardness

3.4. Wear Behavior

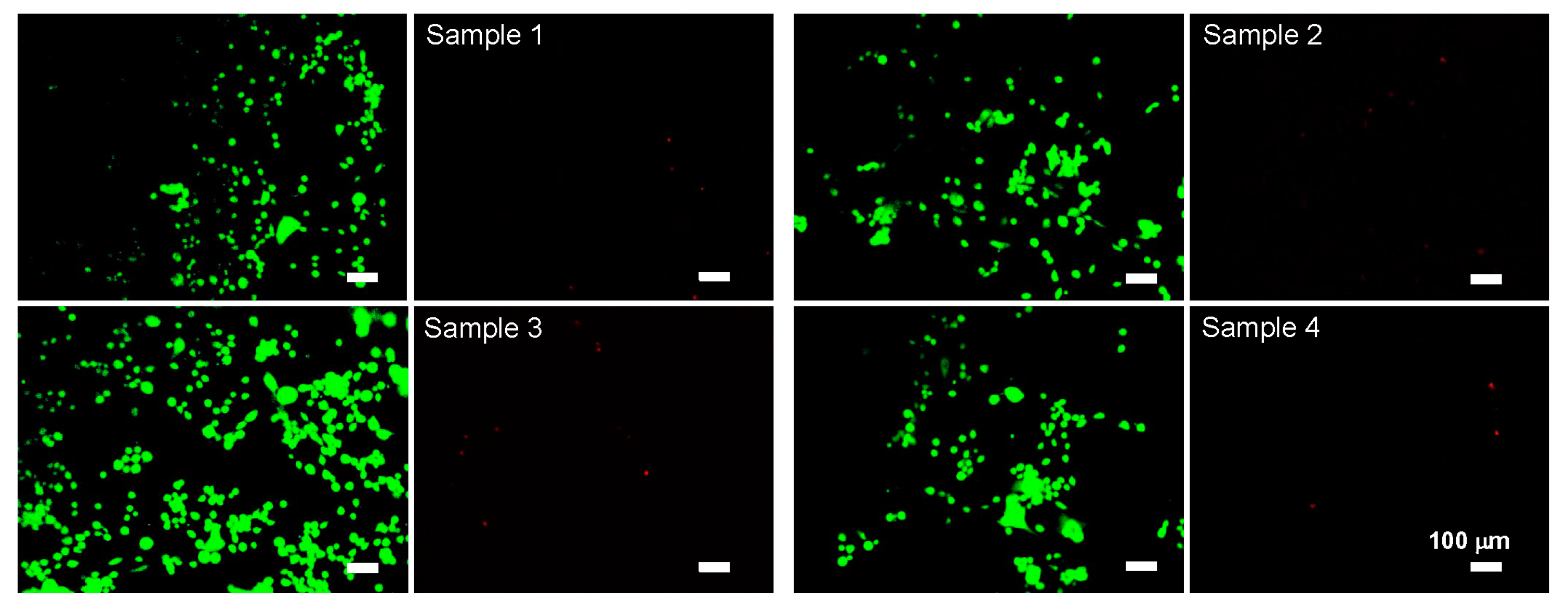

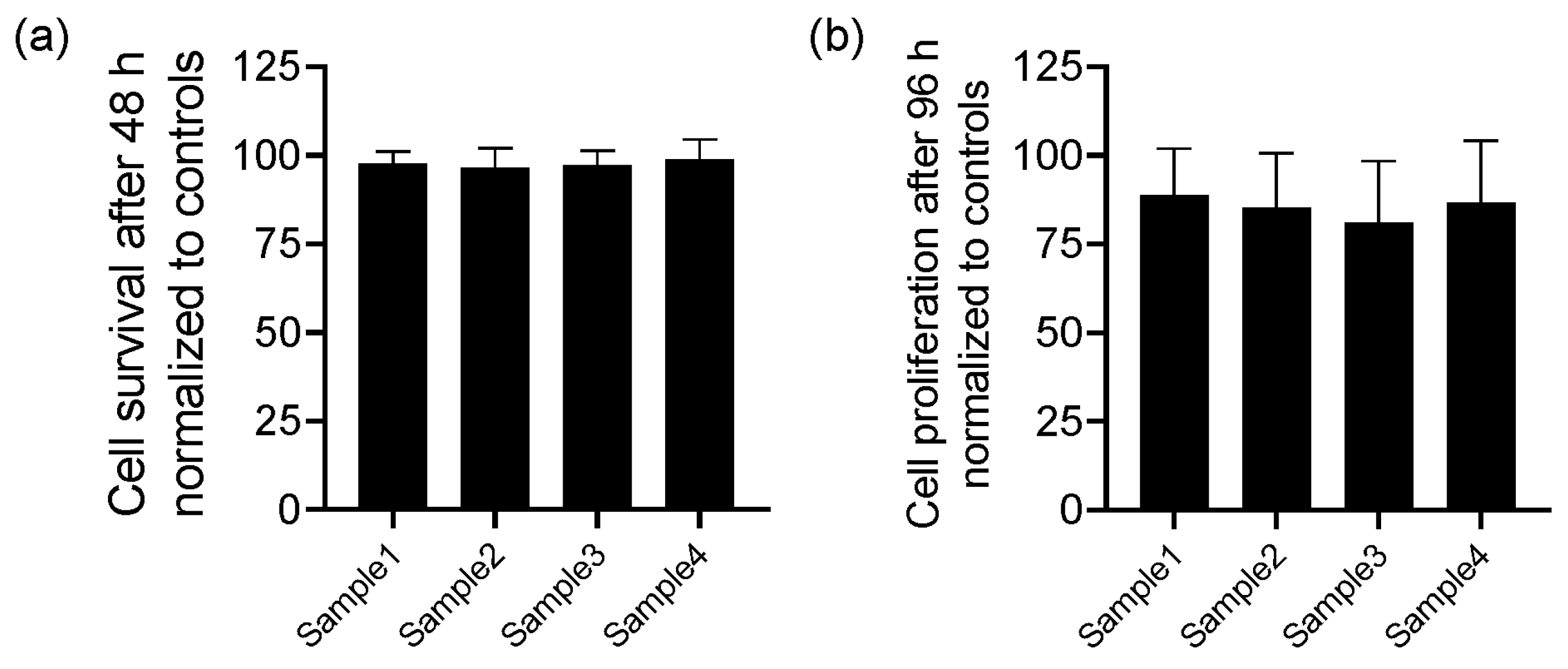

3.5. Cytotoxicity Studies

4. Conclusions

- All nitride-reinforced TNZT composites demonstrated superior tribological performance over pure TNZT alloys while retaining a single-phase BCC structure and excellent biocompatibility. This was attributed to the presence of very hard and strong nitrides in the β-Ti matrix.

- TNZT-2 wt.% TiN exhibited the optimum hardness (311.8 HV) and lowest CoF (0.659), showcasing the highest efficiency of TiN among other nitrides in improving the tribological performance of TNZT alloys.

- TNZT composites with 5 wt.% TiN and 10 wt.% TiN showed a higher hardness (388.5 HV and 444.3 HV, respectively) but also showed a higher CoF (0.674 and 0.715, respectively). This was attributed to the higher but nonuniform presence of TiN.

- This work will aid in producing superior β-Ti alloys for advanced orthopedic applications.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Scholz, M.S.; Blanchfield, J.P.; Bloom, L.D.; Coburn, B.H.; Elkington, M.; Fuller, J.D.; Bond, I.P. The use of composite materials in modern orthopedic medicine and prosthetic devices: A review. Compos. Sci. Technol. 2011, 71, 1791–1803. [Google Scholar] [CrossRef]

- Filip, N.; Radu, I.; Veliceasa, B.; Filip, C.; Pertea, M.; Clim, A.; Pinzariu, A.C.; Drochioi, L.C.; Hilitanu, R.L.; Serban, I.L. Biomaterials in Orthopedic Devices: Current Issues and Future Perspectives. Coatings 2022, 12, 1544. [Google Scholar] [CrossRef]

- Intravaia, J.T.; Graham, T.; Kim, H.S.; Nanda, H.S.; Kumbar, S.G.; Nukavarapu, S.P. Smart orthopedic biomaterials and implants. Curr. Opin. Biomed. Eng. 2023, 25, 100439. [Google Scholar] [CrossRef] [PubMed]

- Choi, S.R.; Kwon, J.W.; Suk, K.S.; Kim, H.S.; Moon, S.H.; Park, S.Y.; Lee, B.H. The Clinical Use of Osteobiologic and Metallic Biomaterials in Orthopedic Surgery: The Present and the Future. Materials 2023, 16, 3633. [Google Scholar] [CrossRef]

- Liang, W.; Zhou, C.; Zhang, H.; Bai, J.; Jiang, B.; Jiang, C.; Ming, W.; Zhang, H.; Long, H.; Huang, X.; et al. Recent advances in 3D printing of biodegradable metals for orthopaedic applications. J. Biol. Eng. 2023, 17, 56. [Google Scholar] [CrossRef] [PubMed]

- Affatato, S.; Ruggiero, A.; Merola, M. Advanced biomaterials in hip joint arthroplasty. A review on polymer and ceramics composites as alternative bearings. Compos. B Eng. 2015, 83, 276–283. [Google Scholar] [CrossRef]

- Niinomi, M.; Nakai, M.; Hieda, J. Development of new metallic alloys for biomedical applications. Acta Biomater. 2012, 8, 3888–3903. [Google Scholar] [CrossRef] [PubMed]

- Prakasam, M.; Locs, J.; Salma-Ancane, K.; Loca, D.; Largeteau, A.; Berzina-Cimdina, L. Biodegradable materials and metallic implants—A review. J. Funct. Biomater. 2017, 8, 44. [Google Scholar] [CrossRef]

- Kulkarni, M.; Mazare, A.; Gongadze, E.; Perutkova, Š.; Kralj-Iglič, V.; Milošev, I.; Schmuki, P.; Iglič, A.; Mozetič, M. Titanium nanostructures for biomedical applications. Nanotechnology 2015, 26, 062002. [Google Scholar] [CrossRef]

- Minagar, S.; Berndt, C.C.; Wang, J.; Ivanova, E.; Wen, C. A review of the application of anodization for the fabrication of nanotubes on metal implant surfaces. Acta Biomater. 2012, 8, 2875–2888. [Google Scholar] [CrossRef]

- Amaravathy, P.; Sowndarya, S.; Sathyanarayanan, S.; Rajendran, N. Novel sol gel coating of Nb2O5 on magnesium alloy for biomedical applications. Surf. Coat. Technol. 2014, 244, 131–141. [Google Scholar] [CrossRef]

- Mazur, M.; Kalisz, M.; Wojcieszak, D.; Grobelny, M.; Mazur, P.; Kaczmarek, D.; Domaradzki, J. Determination of structural, mechanical and corrosion properties of Nb2O5 and (NbyCu1−y) Ox thin films deposited on Ti6Al4V alloy substrates for dental implant applications. Mater. Sci. Eng. C 2015, 47, 211–221. [Google Scholar] [CrossRef]

- Li, Q.; Liu, T.; Li, J.; Cheng, C.; Niinomi, M.; Yamanaka, K.; Chiba, A.; Nakano, T. Microstructure, mechanical properties, and cytotoxicity of low Young’s modulus Ti–Nb–Fe–Sn alloys. J. Mater. Sci. 2022, 57, 5634–5644. [Google Scholar] [CrossRef]

- Bahl, S.; Suwas, S.; Chatterjee, K. Comprehensive review on alloy design, processing, and performance of β Titanium alloys as biomedical materials. Int. Mater. Rev. 2021, 66, 114–139. [Google Scholar] [CrossRef]

- Song, X.; Wang, L.; Niinomi, M.; Nakai, M.; Liu, Y. Fatigue characteristics of a biomedical β-type titanium alloy with titanium boride. Mater. Sci. Eng. A 2015, 640, 154–164. [Google Scholar] [CrossRef]

- Chirico, C.; Romero, A.V.; Gordo, E.; Tsipas, S.A. Improvement of wear resistance of low-cost powder metallurgy β-titanium alloys for biomedical applications. Surf. Coat. Technol. 2022, 434, 128207. [Google Scholar] [CrossRef]

- Biesiekierski, A.; Ping, D.; Li, Y.; Lin, J.; Munir, K.S.; Yamabe-Mitarai, Y.; Wen, C. Extraordinary high strength Ti-Zr-Ta alloys through nanoscaled, dual-cubic spinodal reinforcement. Acta Biomater. 2017, 53, 549–558. [Google Scholar] [CrossRef]

- Maity, T.; Balcı, Ö.; Gammer, C.; Ivanov, E.; Eckert, J.; Prashanth, K.G. High pressure torsion induced lowering of Young’s modulus in high strength TNZT alloy for bio-implant applications. J. Mech. Behav. Biomed. Mater. 2020, 108, 103839. [Google Scholar] [CrossRef]

- Liu, J.; Chang, L.; Liu, H.; Li, Y.; Yang, H.; Ruan, J. Microstructure, mechanical behavior and biocompatibility of powder metallurgy Nb-Ti-Ta alloys as biomedical material. Mater. Sci. Eng. C 2017, 71, 512–519. [Google Scholar] [CrossRef]

- Morais, L.S.; Serra, G.G.; Muller, C.A.; Andrade, L.R.; Palermo, E.F.; Elias, C.N.; Meyers, M. Titanium alloy mini-implants for orthodontic anchorage: Immediate loading and metal ion release. Acta Biomater. 2007, 3, 331–339. [Google Scholar] [CrossRef]

- Li, H.F.; Huang, J.Y.; Lin, G.C.; Wang, P.Y. Recent advances in tribological and wear properties of biomedical metallic materials. Rare Met. 2021, 40, 3091–3106. [Google Scholar] [CrossRef]

- Marin, E.; Lanzutti, A. Biomedical Applications of Titanium Alloys: A Comprehensive Review. Materials 2024, 17, 114. [Google Scholar] [CrossRef]

- Li, C.; Zhan, Y.; Jiang, W. β-Type Ti–Mo–Si ternary alloys designed for biomedical applications. Mater. Des. 2012, 34, 479–482. [Google Scholar] [CrossRef]

- Taddei, E.B.; Henriques, V.A.R.; Silva, C.R.M.; Cairo, C.A.A. Production of new titanium alloy for orthopedic implants. Mater. Sci. Eng. C 2004, 24, 683–687. [Google Scholar] [CrossRef]

- Hager Jr, C.H.; Sanders, J.; Sharma, S.; Voevodin, A. Gross slip fretting wear of CrCN, TiAlN, Ni, and CuNiIn coatings on Ti6Al4V interfaces. Wear 2007, 263, 430–443. [Google Scholar] [CrossRef]

- Gupta, M.K.; Etri, H.E.; Korkmaz, M.E.; Ross, N.S.; Krolczyk, G.M.; Gawlik, J.; Yasar, N.; Pimenov, D.Y. Tribological and surface morphological characteristics of titanium alloys: A review. Arch. Civ. Mech. Eng. 2022, 22, 72. [Google Scholar] [CrossRef]

- Samuel, S.; Nag, S.; Scharf, T.W.; Banerjee, R. Wear resistance of laser-deposited boride reinforced Ti-Nb–Zr–Ta alloy composites for orthopedic implants. Mater. Sci. Eng. C 2008, 28, 414–420. [Google Scholar] [CrossRef]

- Chan, C.W.; Lee, S.; Smith, G.; Sarri, G.; Ng, C.H.; Sharba, A.; Man, H.C. Enhancement of wear and corrosion resistance of beta titanium alloy by laser gas alloying with nitrogen. Appl. Surf. Sci. 2016, 367, 80–90. [Google Scholar] [CrossRef]

- Geetha, M.; Singh, A.K.; Asokamani, R.; Gogia, A.K. Ti based biomaterials, the ultimate choice for orthopaedic implants—A review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Raveh, A.; Hansen, P.L.; Avni, R.; Grill, A. Microstructure and composition of plasma-nitrided Ti-6Al-4V layers. Surf. Coat. Technol. 1989, 38, 339–351. [Google Scholar] [CrossRef]

- Matsuura, K.; Kudoh, M. Surface modification of titanium by a diffusional carbo-nitriding method. Acta Mater. 2002, 50, 2693–2700. [Google Scholar] [CrossRef]

- Sathish, S.; Geetha, M.; Pandey, N.D.; Richard, C.; Asokamani, R. Studies on the corrosion and wear behavior of the laser nitrided biomedical titanium and its alloys. Mater. Sci. Eng. C 2010, 30, 376–382. [Google Scholar] [CrossRef]

- Cui, Z.D.; Zhu, S.L.; Man, H.C.; Yang, X.J. Microstructure and wear performance of gradient Ti/TiN metal matrix composite coating synthesized using a gas nitriding technology. Surf. Coat. Technol. 2005, 190, 309–313. [Google Scholar] [CrossRef]

- Borkar, T.; Nag, S.; Ren, Y.; Tiley, J.; Banerjee, R. Reactive spark plasma sintering (SPS) of nitride reinforced titanium alloy composites. J. Alloys Compd. 2014, 617, 933–945. [Google Scholar] [CrossRef]

- Tjong, S.C.; Ma, Z.Y. Microstructural and mechanical characteristics of in situ metal matrix composites. Mater. Sci. Eng. R Rep. 2000, 29, 49–113. [Google Scholar] [CrossRef]

- Ma, Z.Y.; Ning, X.G.; Lu, Y.X.; Bi, J.; Wen, L.S.; Wu, S.J.; Jangg, G.; Daninger, H. In-situ Al4C3 dispersoid and SiC particle mixture-reinforced aluminium composite. Scr. Met. Mater. 1994, 31, 131–135. [Google Scholar] [CrossRef]

- Attar, H.; Ehtemam-Haghighi, S.; Kent, D.; Dargusch, M.S. Recent developments and opportunities in additive manufacturing of titanium-based matrix composites: A review. Int. J. Mach. Tools Manuf. 2018, 133, 85–102. [Google Scholar] [CrossRef]

- Mohseni, H.; Nandwana, P.; Tsoi, A.; Banerjee, R.; Scharf, T.W. In situ nitrided titanium alloys: Microstructural evolution during solidification and wear. Acta Mater. 2015, 83, 61–74. [Google Scholar] [CrossRef]

- Benjamin, J.S.; Volin, T.E. The mechanism of mechanical alloying. Metall. Trans. 1974, 5, 1929–1934. [Google Scholar] [CrossRef]

- Gilman, P.S.; Benjamin, J.S. Mechanical alloying. Annu. Rev. Mater. Sci. 1983, 13, 279–300. [Google Scholar] [CrossRef]

- Zhou, D.; Qiu, F.; Wang, H.; Jiang, Q. Manufacture of nano-sized particle-reinforced metal matrix composites: A review. Acta Metall. Sin-Engl. 2014, 27, 798–805. [Google Scholar] [CrossRef]

- Mamedov, V. Spark plasma sintering as advanced PM sintering method. Powder Metall. 2002, 45, 322–328. [Google Scholar] [CrossRef]

- Walunj, G.; Desai, J.; Bohara, S.; Contieri, R.; Kothapalli, C.; Ivanov, E.; Borkar, T. Light Weight-Low Modulus Biocompatible Titanium Alloys Processed via Spark Plasma Sintering. J. Alloys Metall. Syst. 2023, 3, 100018. [Google Scholar] [CrossRef]

- Batalha, R.L.; Batalha, R.L.; Pinotti, V.E.; Pinotti, V.E.; Alnoaimy, O.O.S.; Alnoaimy, O.O.S.; Batalha, W.C.; Batalha, W.C.; Gustmann, T.; Gustmann, T.; et al. Microstructure and properties of TiB2-reinforced Ti–35Nb–7Zr–5Ta processed by laser-powder bed fusion. J. Mater. Res. 2022, 37, 259–271. [Google Scholar] [CrossRef]

- Facchini, D. Biomedical nanocrystalline metals and alloys: Structure, properties and applications. In Nanomedicine; Woodhead Publishing: Sawston, UK, 2012; pp. 36–67. [Google Scholar] [CrossRef]

- Li, Y.; Garabedian, N.; Schneider, J.; Greiner, C. Waviness affects friction and abrasive wear. Tribol. Lett. 2023, 71, 64. [Google Scholar] [CrossRef]

- Long, M.; Rack, H.J. Friction and surface behavior of selected titanium alloys during reciprocating-sliding motion. Wear 2001, 249, 157–167. [Google Scholar] [CrossRef]

- Li, Y.; Schreiber, P.; Schneider, J.; Greiner, C. Tribological mechanisms of slurry abrasive wear. Friction 2023, 11, 1079–1093. [Google Scholar] [CrossRef]

- Carreño, G.; Pereira, A.; Ávila-Salas, F.; Marican, A.; Andrade, F.; Roca-Melendres, M.M.; Valdes, O.; Vijayakumar, S.; Schwartz, S., Jr.; Abasolo, I.; et al. Development of “on-demand” thermo-responsive hydrogels for anti-cancer drugs sustained release: Rational design, in silico prediction and in vitro validation in colon cancer models. Mater. Sci. Eng. C 2021, 131, 112483. [Google Scholar] [CrossRef]

- Niinomi, M. Design and development of metallic biomaterials with biological and mechanical biocompatibility. J. Biomed. Mater. Res. A 2019, 107, 944–954. [Google Scholar] [CrossRef]

- Luo, J.P.; Sun, J.F.; Huang, Y.J.; Zhang, J.H.; Zhang, Y.D.; Zhao, D.P.; Yan, M. Low-modulus biomedical Ti–30Nb–5Ta–3Zr additively manufactured by Selective Laser Melting and its biocompatibility. Mater. Sci. Eng. C 2019, 97, 275–284. [Google Scholar] [CrossRef]

- Luo, J.P.; Huang, Y.J.; Xu, J.Y.; Sun, J.F.; Dargusch, M.S.; Hou, C.H.; Ren, L.; Wang, R.Z.; Ebel, T.; Yan, M. Additively manufactured biomedical Ti-Nb-Ta-Zr lattices with tunable Young’s modulus: Mechanical property, biocompatibility, and proteomics analysis. Mater. Sci. Eng. C 2020, 114, 110903. [Google Scholar] [CrossRef] [PubMed]

- Rossi, M.C.; Ventura, B.N.; Milián, L.; Escuder, A.V.; Amigó Borrás, V. Study of Electrochemical and Biological Characteristics of As-Cast Ti-Nb-Zr-Ta System Based on Its Microstructure. Metals 2022, 12, 476. [Google Scholar] [CrossRef]

- Luo, X.; Yang, C.; Li, R.Y.; Wang, H.; Lu, H.Z.; Song, T.; Ma, H.W.; Li, D.D.; Gebert, A.; Li, Y.Y. Effect of silicon content on the microstructure evolution, mechanical properties, and biocompatibility of β-type TiNbZrTa alloys fabricated by laser powder bed fusion. Biomater. Adv. 2022, 133, 112625. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Digole, S.; Desai, J.; Christopher, C.; Bohara, S.; Witharamage, C.S.; Kothapalli, C.; Gupta, R.K.; Borkar, T. Improved Tribological Performance of Nitride-Reinforced Biocompatible Titanium–Niobium–Zirconium–Tantalum (TNZT) Alloys for Advanced Orthopedic Applications. Metals 2024, 14, 122. https://doi.org/10.3390/met14010122

Digole S, Desai J, Christopher C, Bohara S, Witharamage CS, Kothapalli C, Gupta RK, Borkar T. Improved Tribological Performance of Nitride-Reinforced Biocompatible Titanium–Niobium–Zirconium–Tantalum (TNZT) Alloys for Advanced Orthopedic Applications. Metals. 2024; 14(1):122. https://doi.org/10.3390/met14010122

Chicago/Turabian StyleDigole, Satyavan, Jay Desai, Calvin Christopher, Smriti Bohara, Chathuranga Sandamal Witharamage, Chandra Kothapalli, Rajeev Kumar Gupta, and Tushar Borkar. 2024. "Improved Tribological Performance of Nitride-Reinforced Biocompatible Titanium–Niobium–Zirconium–Tantalum (TNZT) Alloys for Advanced Orthopedic Applications" Metals 14, no. 1: 122. https://doi.org/10.3390/met14010122

APA StyleDigole, S., Desai, J., Christopher, C., Bohara, S., Witharamage, C. S., Kothapalli, C., Gupta, R. K., & Borkar, T. (2024). Improved Tribological Performance of Nitride-Reinforced Biocompatible Titanium–Niobium–Zirconium–Tantalum (TNZT) Alloys for Advanced Orthopedic Applications. Metals, 14(1), 122. https://doi.org/10.3390/met14010122