1. Introduction

Dry machining is one of the ideal strategies to eliminate the environmental and human health impacts of the machining processes. This comes from eliminating all of the impacts associated with using cutting fluids [

1]. On the other hand, there are drawbacks related to dry machining, such as high friction forces and high cutting heat generation. Accordingly, researchers have paid great attention to optimizing the machining parameters to eliminate the drawbacks of dry machining. Many studies have provided new designs of cutting tools to overcome the disadvantages of dry machining, such as textured cutting tools [

2,

3]. Surface texture is defined as the generation of micro/nano-scale textures of different shapes on the rake or flank faces. These textures are utilized to achieve the following functions [

4,

5]: (a) reduce the friction in the chip-tool interface by decreasing the chip-tool contact length, resulting in less frictional force and cutting temperature; (b) reserve the lubricants during the machining process (i.e., acting as micro-pools), where the cutting fluids are trapped in the textures’ cavities to produce no direct contact between the chip and the tool; (c) trap the debris generated by different wear mechanisms such as abrasive and adhesive wear mechanisms to minimize the ploughing actions in tool-chip and tool-workpiece zones which leads to less tool wear and better surface roughness.

There are various techniques for generating different shapes of textures over the rake and flank surfaces of cutting tools. The textures can be linear grooves perpendicular, parallel, or cross-pattern orientation with respect to the chip direction [

6]. The textures can be in the shape of round and square dimples. In addition, the linear grooves can be perpendicular or parallel to the main cutting edge. The surface texturing techniques vary from thermal energy micro-machining techniques to mechanical micro-machining techniques [

4]. Examples of thermal energy micro-machining are laser surface texturing and electro-discharge micro-machining. Generally, the laser technique has the required capabilities to generate textures for different types of substrates. Laser techniques can be utilized to generate different shapes of textures, such as linear grooves, cylindrical dimples, and square pyramids [

7,

8]. In micro-Electro Discharge Machining (micro-EDM), material removal occurs due to the melting and vaporization at the point of discharge. This technique has been utilized to generate holes on the rake face of the carbide tool [

9]. For mechanical micro-machining techniques, micro-grinding is the most effective technique for generating linear grooves. Xie et al. [

10] used a grinding diamond wheel with a V-tip to generate linear microgrooves over the rake face of the carbide tool. Moreover, the hardness tester is used to apply textures as a result of the indentation on the cutting tool surface. This technique can generate different shapes of textures, such as the conical, round, and square pyramid, by utilizing different hardness testers, such as Rockwell and Vickers hardness testers [

11].

For the textured cutting tools, the contact length (i.e., frictional length) at the chip-tool interface is decreased according to the type and the dimensions of the textures. This results in reducing the frictional force, which is a function of the frictional length. Sharm et al. [

12] utilized carbide tools with elliptical grooves, parallel grooves to the cutting edge, and linear grooves to study the reduction in cutting forces. After that, these grooves were filled with a MoS2 solid lubricant. Dry Turning experiments were carried out using these tools for cutting 45# steel. The results revealed that the reduction in the cutting forces was between 15–25% when using the textured tools compared to the non-textured tool. In addition, Koshy et al. utilized micro-EDM techniques to generate areal and linear textures on the rake face of T-15 grade high-speed steel inserts to investigate the effectiveness of textured tools in reducing friction [

13]. In the same study, cutting and feed forces were measured when machining the annealed 1045 steel and 6061 aluminum workpieces. It was found that the reduction of the feed and cutting forces was 30% and 13%, respectively. Fatima et al. [

14] used the femtosecond laser technique to apply slot structure grooves over the rake and flank faces of an uncoated cemented carbide tool. Orthogonal cutting tests were carried out to machine a tube of AISI/SAE 4140 plain carbon steel. The observed average reductions in the cutting and feed forces were 10% and 23%, respectively. Thomas et al. [

11] reported that the reduction of the main cutting forces when using the textured tool for turning mild steel (EN3B) and aluminum (AA 6351) varied from 2% to 22% according to the shape of the textures and the operated cutting speed.

In the context of meeting environmental regulations, textured tools are promising candidates to replace machining with cutting fluids to reduce the cutting temperature. Liu et al. [

15] utilized a textured cemented carbide tool to turn green alumina ceramics. The obtained results showed that there was an obvious effect of the textured tool to reduce flank tool wear compared to the non-textured tool. The applied parallel micro-grooves helped to remove the hard particles at the tool-chip interface, which was beneficial in reducing the abrasive effect. Niketh et al. [

16] studied the effect of textured drill bits to reduce sliding friction in the drilling application of Ti-6Al-4V. The round dimple texture achieved a lower and more stable coefficient of friction according to the conducted pin and disc tests compared to the grooved and plain surfaces. For drilling with the conventional drill bit, the maximum reduction in thrust force was 10.68% when using a margin-textured drill. In terms of the surface quality of the machined holes, the holes machined with margin-textured drill bits showed lower burr formation. In a previous study [

11], improvements of 15.86% and 23.21% were observed in surface roughness when machining mild steel and aluminum, respectively. In addition, the dimple texture on the rake face showed better performance for stabilizing the BUE compared to the non-textured tool when machining plain carbon steel SAE 1045 with an uncoated cemented carbide tool [

17].

Despite the previously mentioned advantages of the textured cutting tool, it was found that there is an additional cutting of the bottom side of the chip when using the textured cutting tools [

18]. This micro-cutting by the micro-groove edges is defined as a “Derivative cutting phenomenon”. This micro-cutting phenomenon by the micro-grooves edges presents additional forces and cutting temperatures. Therefore, the derivative cutting phenomenon cuts down the benefits of using textured cutting tools. Duan et al. [

18] attempted to study the derivative cutting when dry turning medium carbon steel (AISI 1045) utilizing carbide tool with one micro-groove over the rake face. The obtained results showed higher forces and coefficients of friction associated when using the micro-grooved tool compared to the conventional tool, especially at the beginning of the cutting process. In addition, it was found that derivative cutting induces adhering of the chip’s material to the texture’s edge in the direction of the chip flow. In addition, the derivative cutting phenomenon leads to filling the cavity of the micro-grooves with the chip material. Thus, the cavity of the micro-grooves may be blocked at a certain time during the machining process, as noticed in [

7,

18]. This means that there will be a high affinity between the main chip and the blocked chip material inside the micro-groove’s cavities. Therefore, some particles of the chips (existing in the texture cavities) will stick on the bottom side of the newly generated chip and result in a high wear rate over the rake face. In another attempt [

19] to study derivative cutting phenomena, cutting forces, tool wear, and chip formation were analyzed when dry-turning AISI H13 steel. The results revealed the negative effect of the derivative cutting phenomenon on the cutting forces. Higher forces of the textured tools were obtained compared to the conventional tools at all cutting speeds. For tool wear behavior, many plowing grooves near the cutting edge were found. In addition, crater wear and seizure zones were found due to the adhesion of the workpiece material to the rake face. Moreover, dragging damage was observed on the chip bottom side produced by textured tools. The derivative cutting phenomenon was investigated in [

20] when cutting Ti-6Al-4V using different machining strategies. These strategies were plain dry environment along with the non-textured tool, plain dry environment with laser textured cutting tools, textured tool with MQL-vegetable oil, and textured tool with MQL-alumina-DI water nano-fluid. The microscopic images of the used textured tool showed that filled and semi-filled textures were observed due to the derivative cutting phenomenon. This resulted in a higher contact area and generated heat, especially in a dry environment. Furthermore, derivative cutting has been directly observed in situ in [

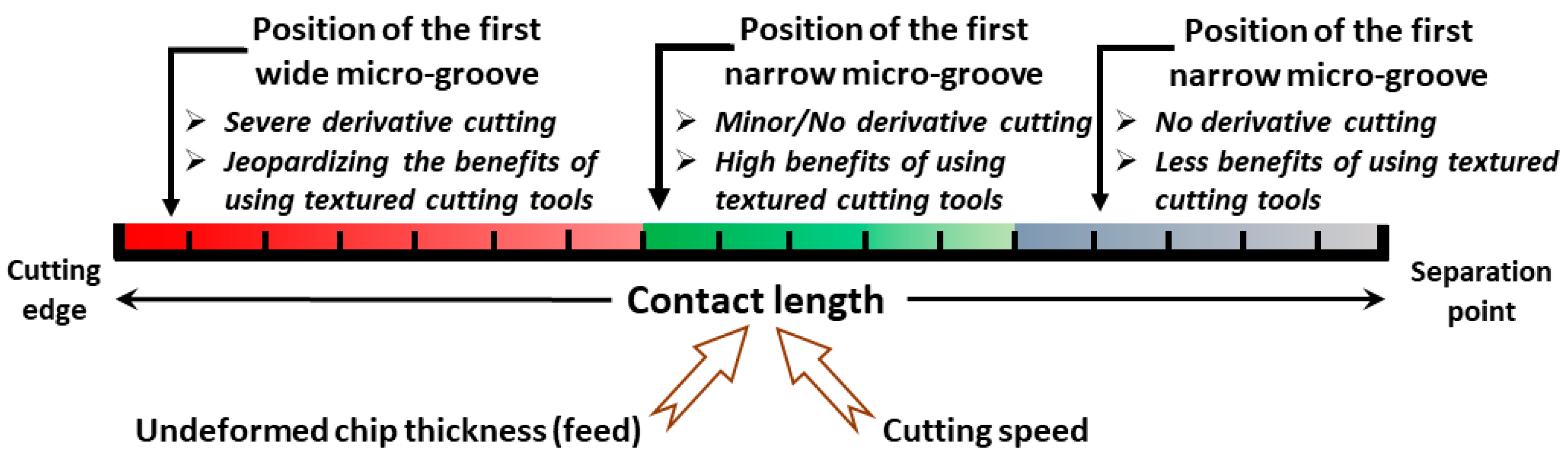

21] using particle image velocimetry. Shaping experiments were conducted with Al-1100. The results showed a high reduction in the frictional force at 30 µm and 50 µm undercut chip thickness. Slight reductions were obtained at 15 µm and 75 µm where the micro-groove was completely within the sliding and sticking contact regions, respectively. These results revealed that the frictional forces depend on the relative distance of the micro-groove from the cutting edge and its relationship with the undercut chip thickness.

The majority of previous studies focused on the benefits of using textured tools on cutting forces, temperature, chip formation, and tool wear. In addition, they showed the additional gains of integrating the textured tool with different cooling strategies. While a limited number of studies have explored the influence of texture parameter dimensions on the performance of textured cutting tools [

18,

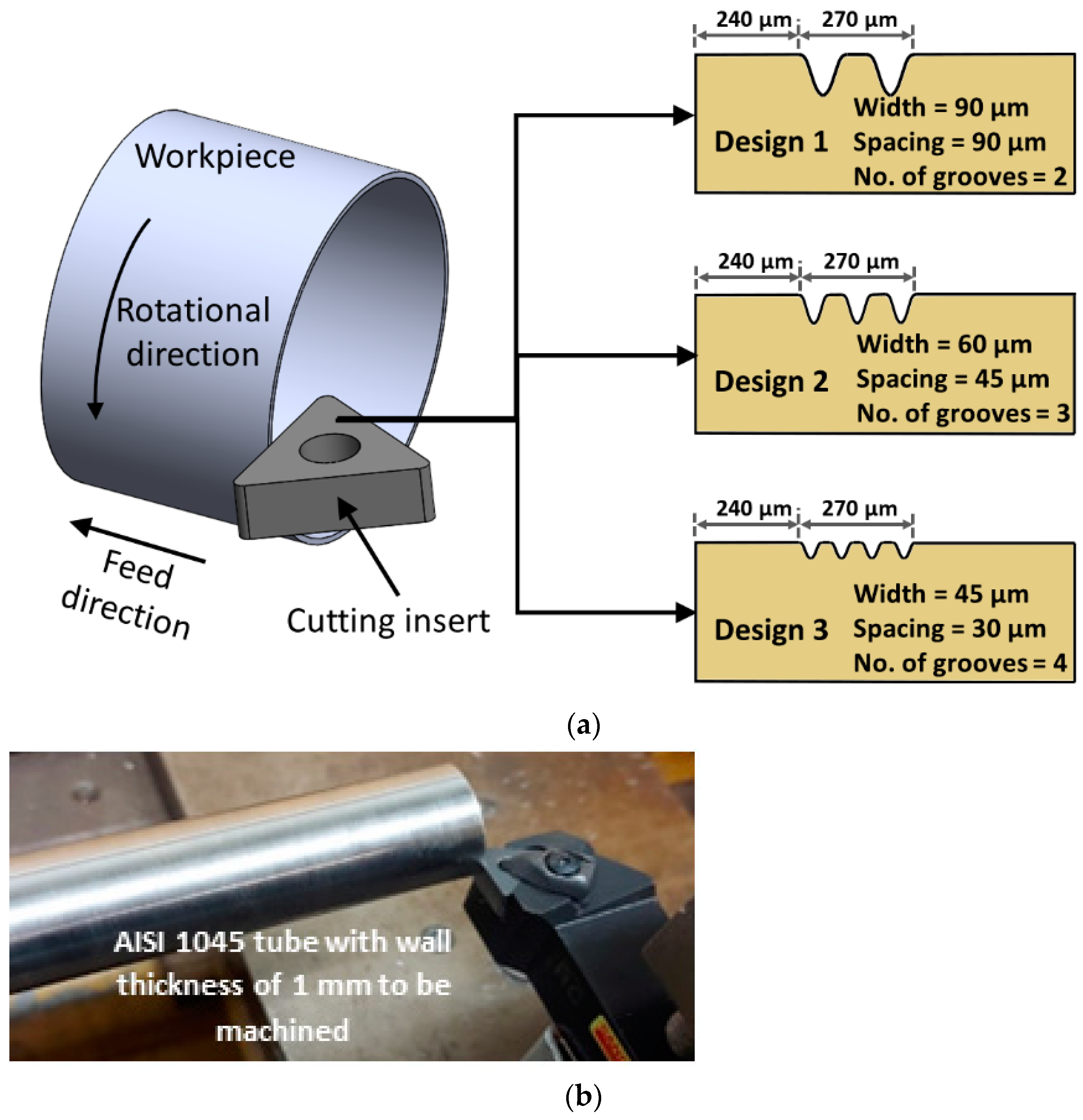

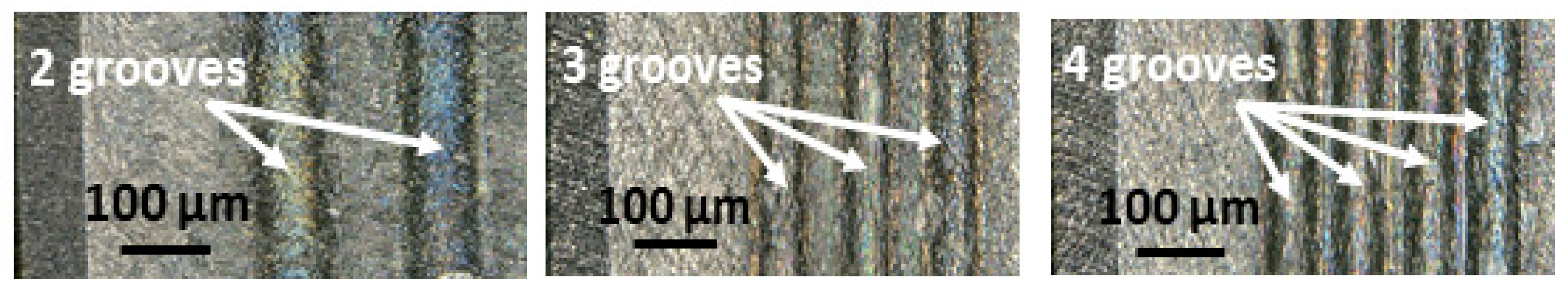

22], the fundamental physics of the process and the impact of different design parameters have not been thoroughly elucidated. Consequently, there is a clear need to comprehend the underlying phenomena and provide recommendations to ensure the reliable performance of such tools. Moreover, it is imperative to investigate the effects of different machining parameters, such as cutting velocity and feed, when employing various designs of textured cutting tools with different texture dimensions. This investigation should encompass not only the examination of forces but also the assessment of the effects of micro-textured tools on tool wear, surface roughness, and power consumption. By comprehensively studying these aspects, a more complete understanding of the potential benefits and limitations of micro-textured tools can be achieved. Thus, this paper aims to investigate the effects of significant texture design parameters when cutting AISI 1045 steel using different machining parameters. Each tool design was used under four different cutting conditions (a total of 16 experiments). According to the experimental findings provided in

Section 3, the authors have provided a mechanism of machining using textured cutting tools, including recommendations to minimize the derivative cutting. The recommendations and mechanisms proposed based on the experimental findings highlight the potential of micro-textured tools to serve as sustainable options in the machining industry, particularly when used in dry environments. Thus, this paper underscores the practical implications and significance of micro-textured cutting tools in achieving sustainable machining practices.

3. Results and Discussion

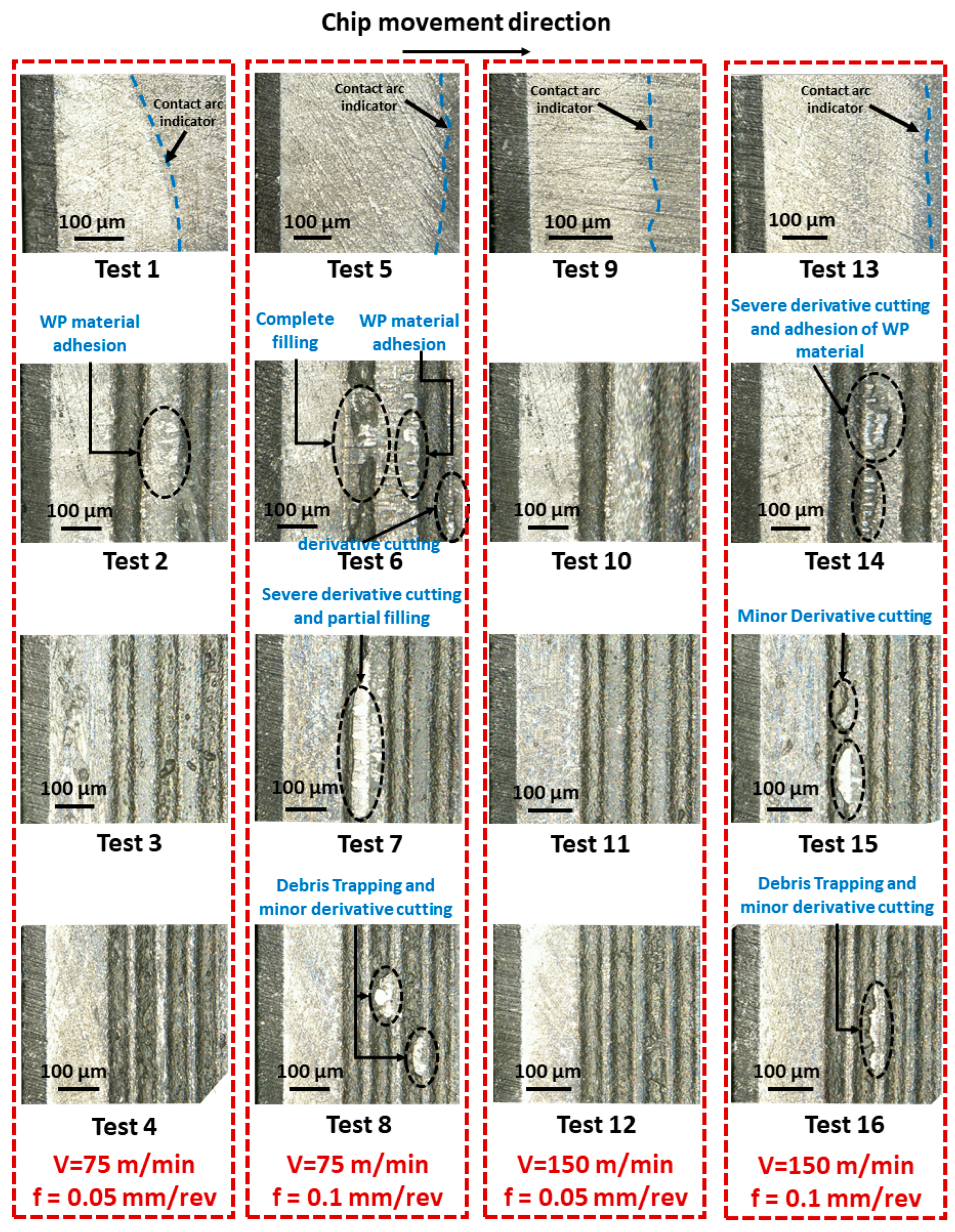

Figure 3 shows the 2D microscopical images of the 16 machining tests using different cutting tools, as presented in

Table 1. Different contact lengths can be seen in the microscopical images for the tests when non-textured cutting tools were used (tests 1, 5, 9, and 13). These contacts were about 318 μm, 519 μm, 264 μm, and 416 μm for test 1, test 5, test 9, and test 13, respectively. The normal and shear stresses at each test under the corresponding cutting conditions are responsible for varying the observed contact lengths. This confirms that the use of textured cutting tools with the same micro-groove position at different cutting conditions (i.e., different contact lengths) can address the effect of the micro-groove position. In other words, it is the same effect of using textured cutting tools with different micro-grooves positions in the same cutting condition (i.e., same contact length). The undeformed chip thickness (i.e., feed in the case of orthogonal cutting) played the dominant role in determining the contact length, where increasing the feed value was accompanied by increasing the contact length, as shown in the first four images in

Figure 3. This is well in line with the previously developed models for the contact length presented in [

27]. However, increasing the cutting velocity reduced the contact length of the chip over the rake face of the cutting tool. This agrees with the finding presented in [

28] that a higher cutting velocity results in a lower coefficient of friction and a shorter contact length.

Evidence of workpiece adhesion in the interstices between the two micro-grooves and the absence of derivative cutting can be seen in the micrograph for test 2 (when the first texture design was used). The first texture design showed a complete filling in the cavity of the first micro-groove with chip material, as shown in the microscopic image of test 6 (i.e., longest contact length at low cutting velocity and high feed). In addition, in test 6, there were marks of the derivative cutting at the edge of the second micro-groove, and there is a workpiece adhesion on the spacing between the two micro-grooves. For test 10 (i.e., design 1 at a high cutting velocity and low feed), there are no marks for derivative cutting. However, in test 14 (i.e., design 1 at high cutting velocity and high feed), both the derivative cutting marks and the material adhesion to the workpiece were visible. Regarding the second textured cutting tool design, there were no marks for derivative cutting in tests 3 and 11 when the low feed with low and high cutting velocity, respectively, was utilized. Severe derivative cutting and partial filling in the cavity of the first micro-groove was presented in test 7 (i.e., design 2 at low cutting velocity and high feed), as shown in

Figure 3. There were marks of minor derivative cutting that can be seen in test 15 (i.e., design 2 at high cutting velocity and high feed).

Tests 4 and 12 using textured cutting tool design 3 at the low feed with low and high cutting velocities, respectively, showed no marks for the derivative cutting, similar to design 2. In addition, when using design 3 at high feed, there were minor marks for derivative cutting and the trapping of the cutting debris, as shown in the microscopical images for tests 8 and 16 at low and high cutting velocities, respectively. The micro-groove with a narrow width (design 3) reduced the incidence of derivative cutting with the complete and partial filling actions observed with design 1 at high feed and with design 2 at high feed and low cutting velocity. These findings are consistent with the outcomes of simulation tests from a previous study [

23], illustrating that the utilization of textured cutting to eliminate derivative cutting diminishes the contact length between the rake face and the resultant chip.

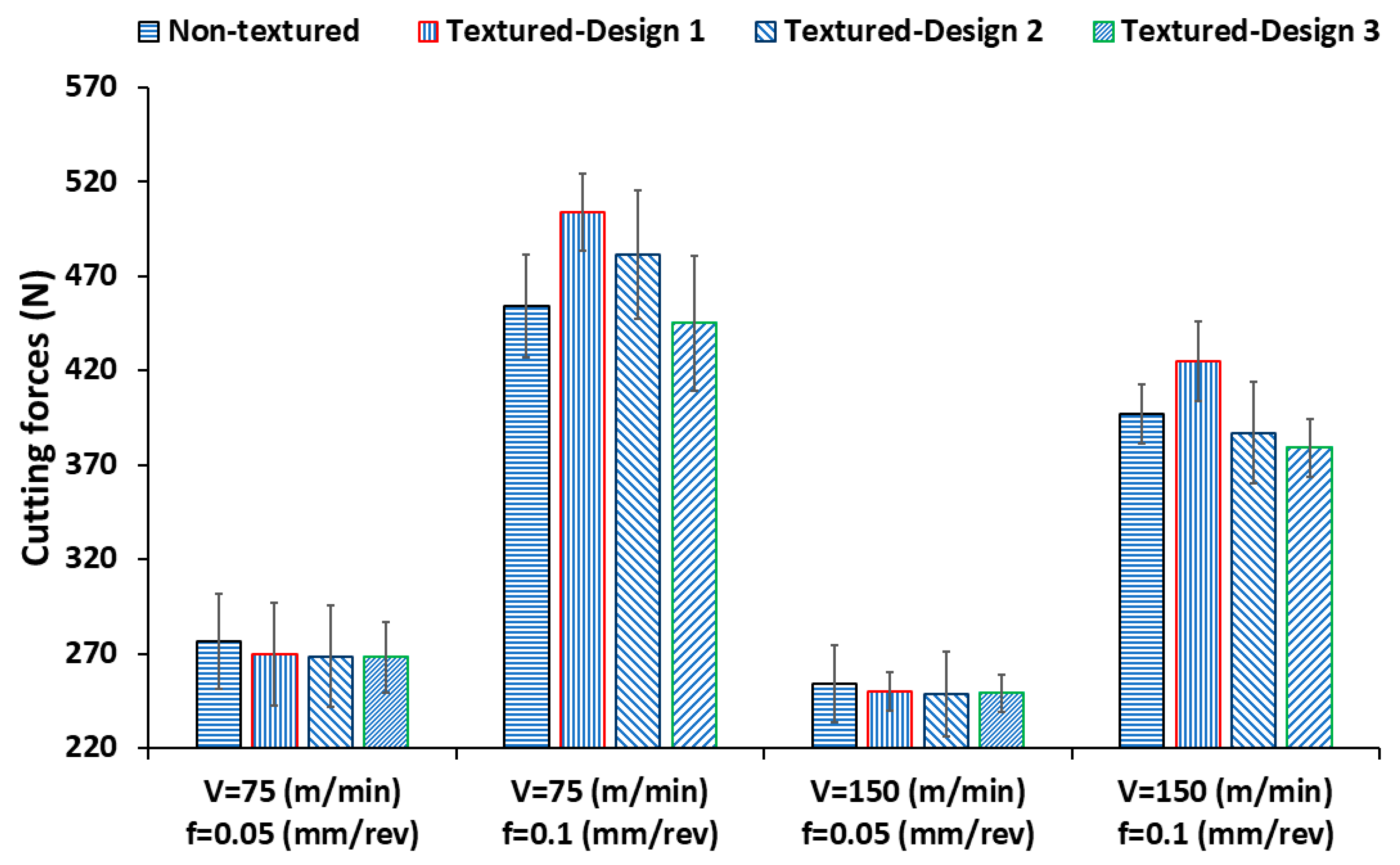

3.1. Cutting and Feed Forces

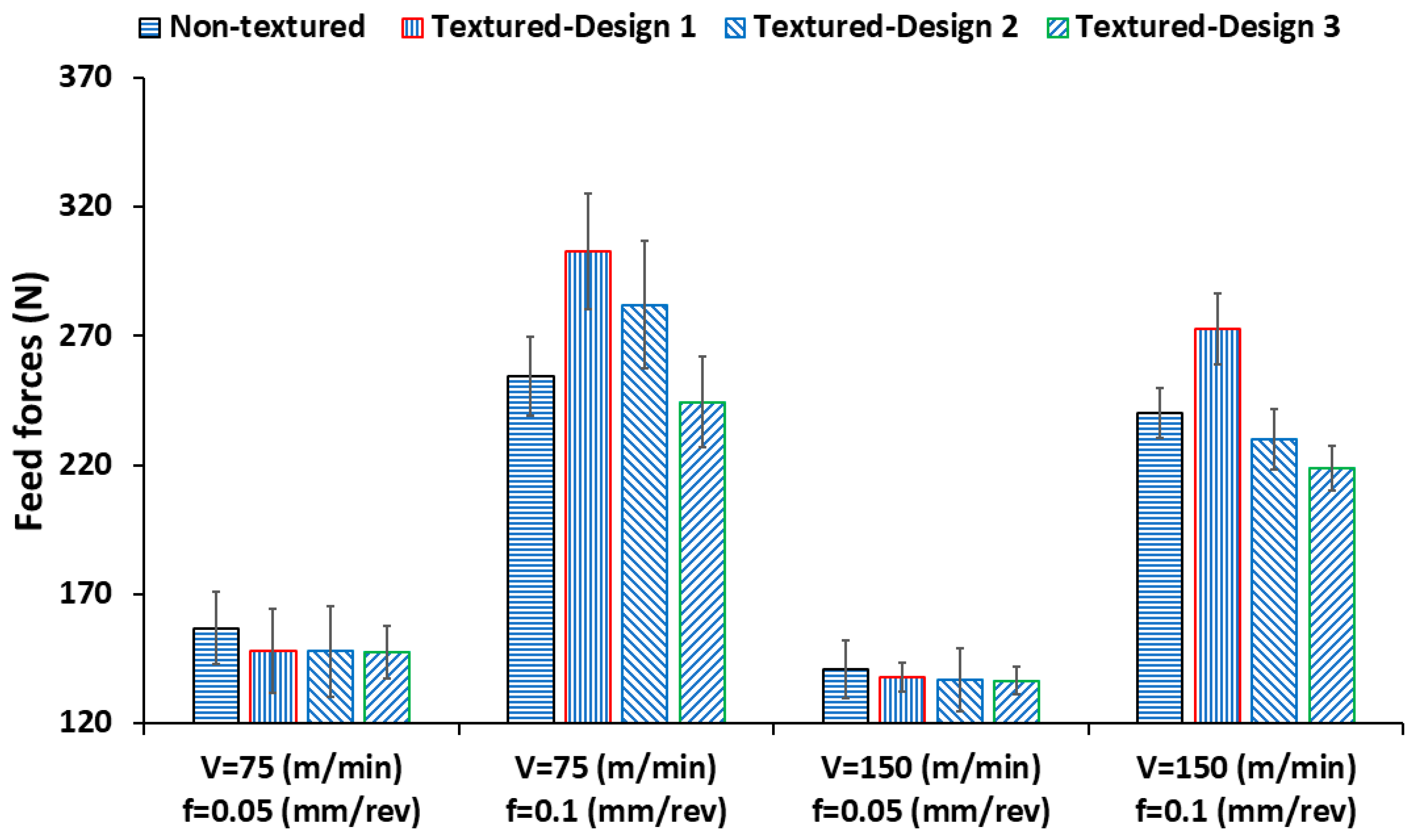

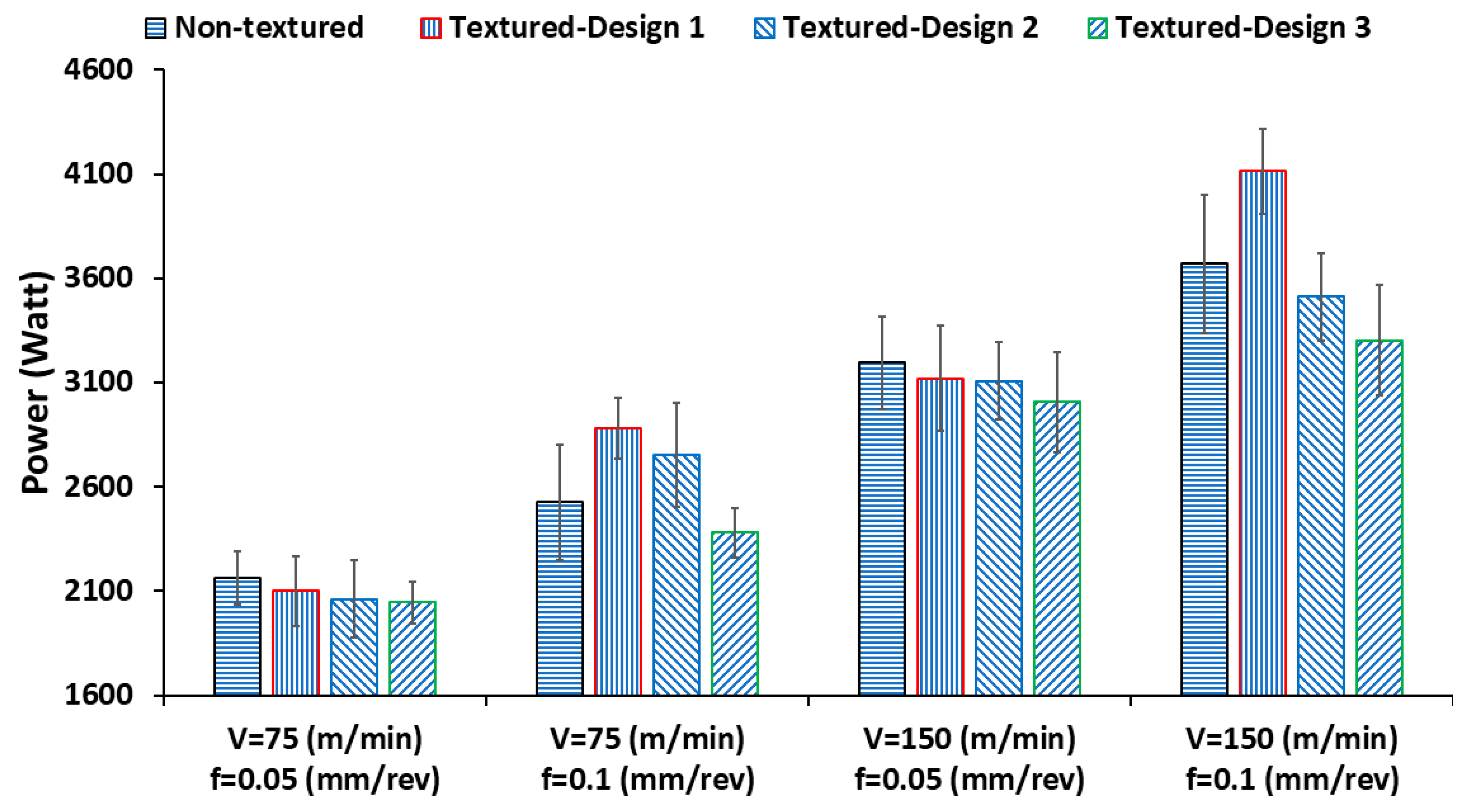

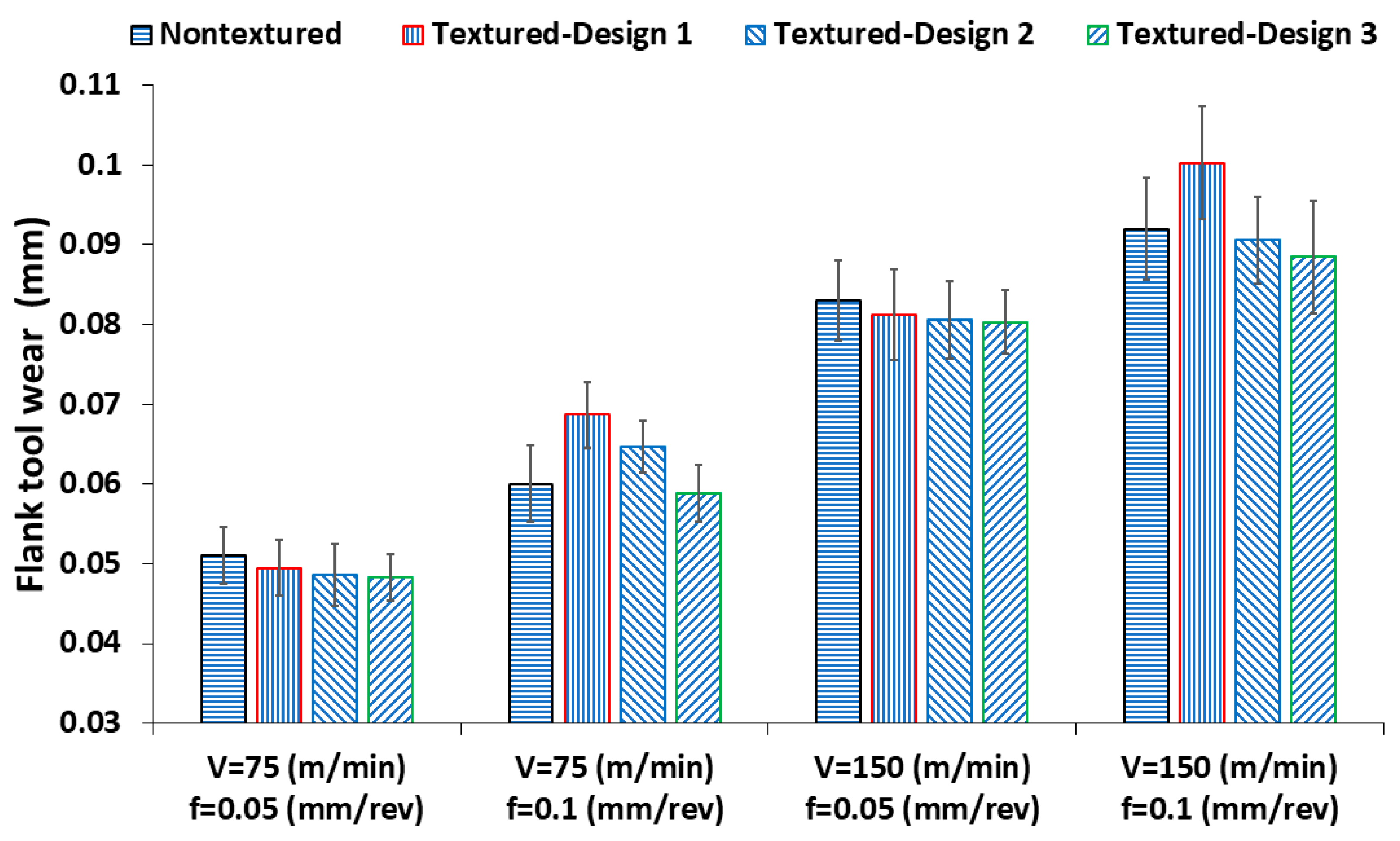

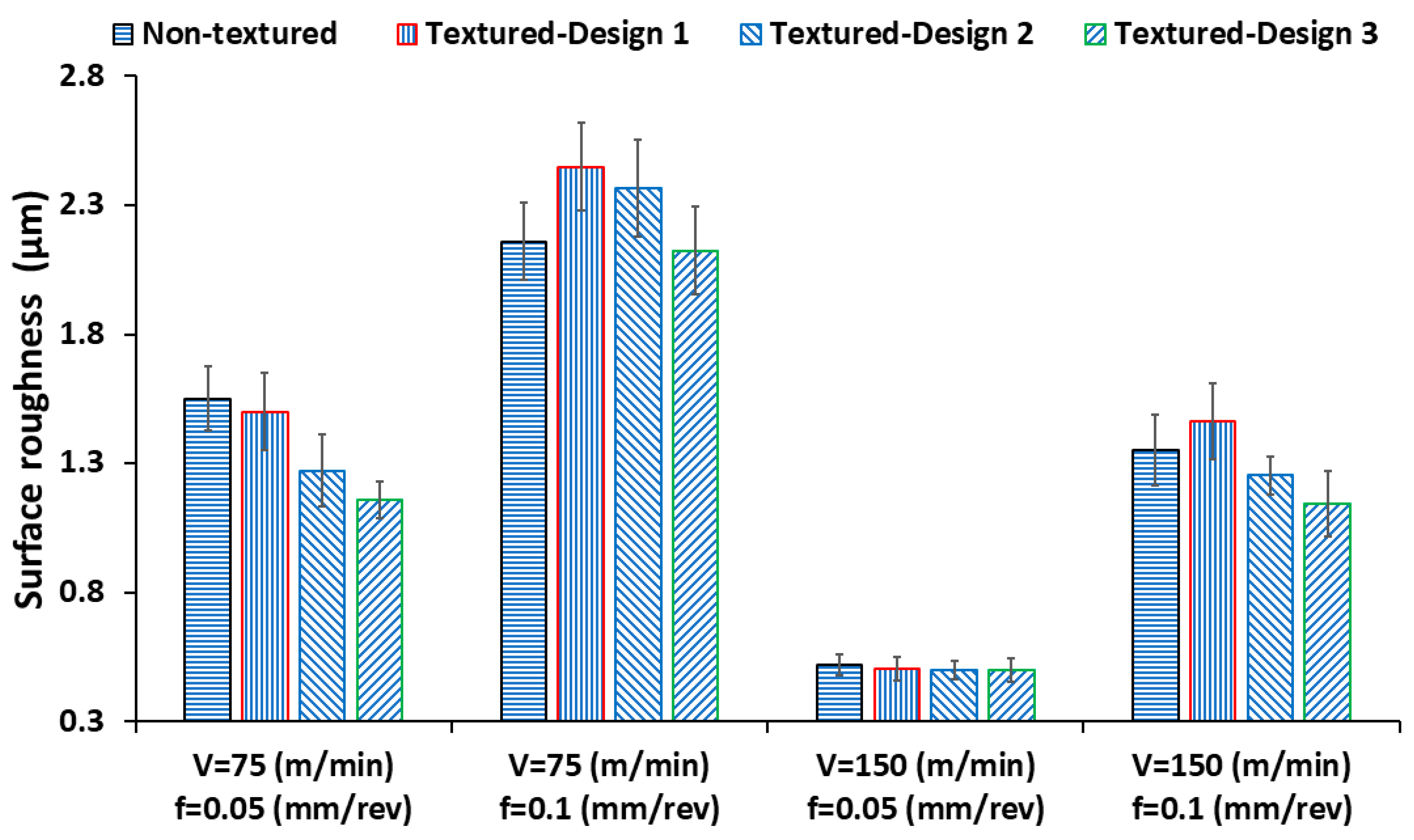

Figure 4 and

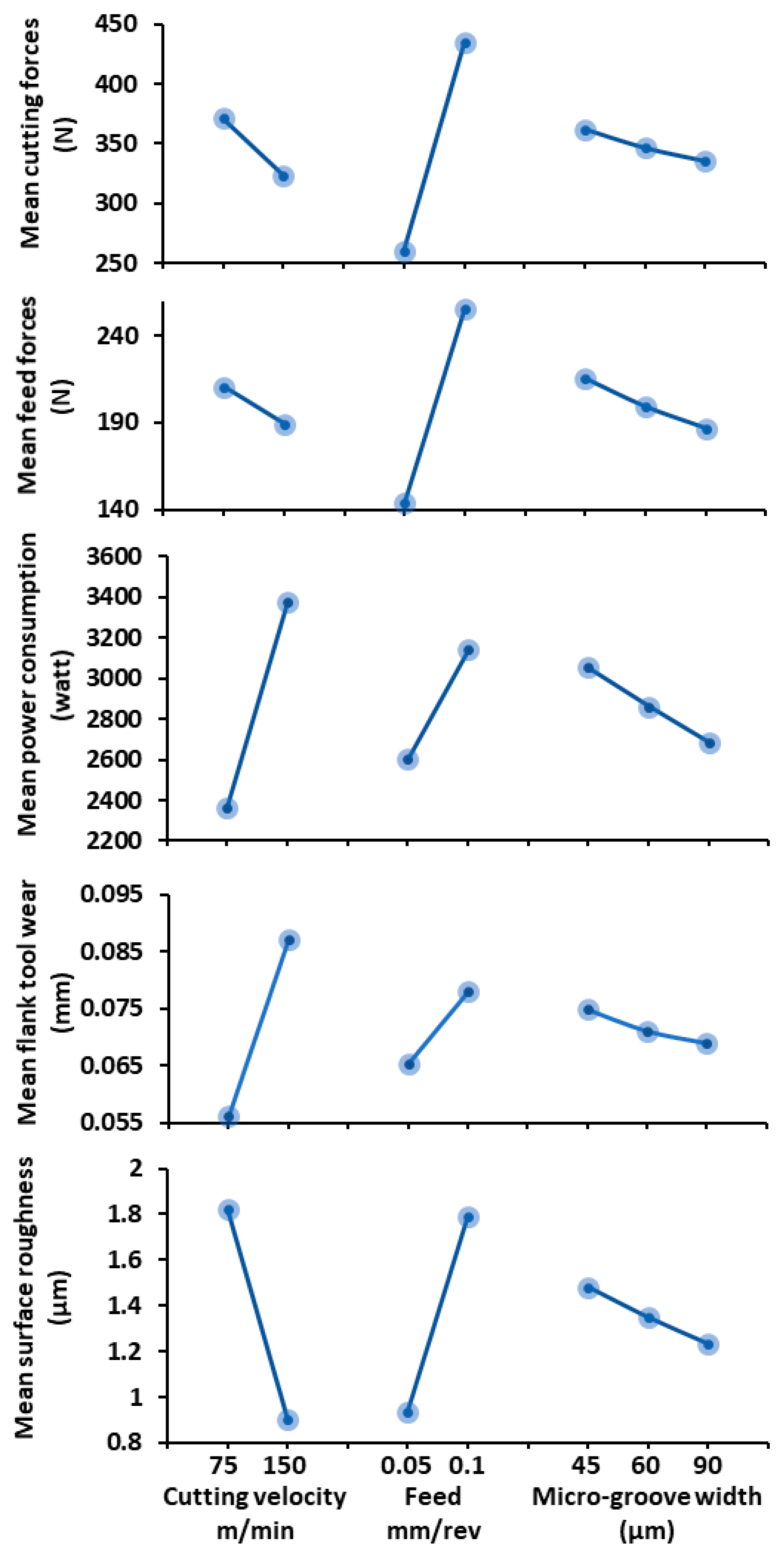

Figure 5 show the measured cutting and feed forces for the conducted experiments. It is known that the forces vary with changes in the cutting speed. This is because of strain hardening or thermal softening of the workpiece material during the machining process. These two reasons (i.e., strain hardening and thermal softening) alter at different cutting velocities. The measured forces indicate that thermal softening is dominated by an increase in cutting speed from 75 m/min to 150 m/min, which causes a decrease in the measured forces. Figure 9 shows a slight decrease in mean cutting and feed forces while increasing the cutting velocity. It is well understood that increasing the feed value will increase the forces. The outcomes shown in Figure 8 further supported the notion that the rise in feed value was correlated with a significant increase in the mean cutting and feed forces. This indicates that the effect of the feed was higher than the effect of other process parameters on the mean cutting and feed forces.

For the cutting conditions of 75 m/min cutting speed and 0.05 feed, all of the different textured cutting tools (i.e., design 1, design 2, and design 3) showed lower cutting forces and feed forces compared to the non-textured cutting tool (see

Figure 4 and

Figure 5). This is because of the absence of the derivative cutting phenomena associated with using these tools in this cutting condition (see

Figure 3). The cutting forces were reduced by 2.5%, 2.9%, and 3% for designs 1, 2, and 3, respectively, but these reductions were modest. For the feed forces, the reductions were 5.5%, 5.7%, and 6% for textured design 1, textured design 2, and textured design 3, respectively. Because of the absence of derivative cutting and the use of the same total width of all micro-grooves throughout all designs, the cutting and feed force results were comparable (same reduction in the contact length). Since the feed force and frictional force had almost the same direction, the reduction in the feed forces was greater than the reduction in the cutting forces for all texture designs. Similarly, all textured cutting tools offered lower forces compared to the non-textured cutting tool at a feed of 0.05 mm/rev and cutting speed of 150 m/min (tests 9, 10, 11, and 12). For the cutting forces, the reductions were minimal: 1.6%, 2%, and 2% for textured designs 1, 2, and 3, respectively. The reductions in the feed forces were 2.4%, 3%, and 3.5% for textured design 1, textured design 2, and textured design 3, respectively. The smaller reduction associated with the textured tools at a higher speed and the same feed of 0.05 mm/rev was due to the shorter chip-tool contact length at a higher speed. According to the previously shown force results at low feed, the reduction in feed and cutting forces associated with using textured cutting tools was up to 6% and 3%, respectively. This is because of the far position of the first micro-groove (at 240 µm from the cutting edge) along with the shorter contact length in the case of a small feed value compared to the higher feed value. In addition, it can be stated that the effect of the micro-groove width is less significant if the micro-groove is located far from the cutting edge (i.e., near the separation point).

The derivative cutting observed when using design 1 was the cause of the higher cutting and feed forces compared to the non-textured cutting tool at a feed of 0.1 mm/rev and cutting velocity of 75 m/min (i.e., test 6). Cutting and feed forces increased by about 11% and 19%, respectively, when using design 1. Similarly, design 2 in the same cutting condition (i.e., test 7) showed higher cutting and feed forces compared to the non-textured cutting tool by 6% and 10.6%, respectively. This was because of the presence of derivative cutting (see test 7 in

Figure 3). This phenomenon arises due to the proximity of the initial micro-groove (located at 240 µm from the cutting edge), coupled with the increased contact length observed in situations involving higher feed values, as opposed to lower feed values. The existence of derivative cutting augments the extent of contact between the rake face and the resultant chip. Consequently, this results in escalated cutting and feed forces.

However, the textured tool of design 3 provided lower cutting and feed forces compared to the non-textured tool by 2% and 4%, respectively. This confirms that the absence of severe derivative cutting (see test 8 in

Figure 3) can show up the benefits of using textured cutting tools in reducing forces. In addition, it can be noticed that using a narrow micro-groove can eliminate derivative cutting.

For the performance of design 1 at a feed of 0.1 mm/rev and a cutting velocity of 150 m/min, the cutting and feed forces were still higher compared to the non-textured tool by 7% and 13.5%, respectively. These increases in the forces of test 14 (i.e., high cutting velocity and high feed) were lower than the increases in the forces of test 6 (i.e., low cutting velocity and high feed). This was due to the shorter chip-tool contact length associated with a higher cutting velocity. Unlike the performance of design 2 in test 7 (i.e., low cutting velocity and high feed), design 2 showed lower cutting and feed forces in test 15 (i.e., high cutting velocity and high feed) compared to the non-textured tool by 2.5% and 4.3%, respectively. In addition, design 3 provided lower cutting and feed forces in test 16 by 4.5% and 9%, respectively. It can be stated that the effect of the micro-groove width is more significant when the micro-groove is generated close to the main cutting edge (i.e., in the case of high feed). This was seen especially in the different performances of design 2 in test 7 and test 15. The advantages of the textured cutting tool become especially apparent when the micro-groove is applied neither very close to nor very far from the cutting edge. In addition, Figure 9 displays how the mean cutting and feed forces can be reduced by employing a narrower micro-groove.