Using an Internal State Variable Model Framework to Investigate the Influence of Microstructure and Mechanical Properties on Ballistic Performance of Steel Alloys

Abstract

1. Introduction

1.1. Ballistic Impact Modeling and Experiments

1.2. Internal State Variable-Based Constitutive Model for Ductile Materials

2. Materials and Methods

2.1. Part I: Ballistic Impact of Rolled Homogeneous Armor Steel Plates by Spherical Projectiles

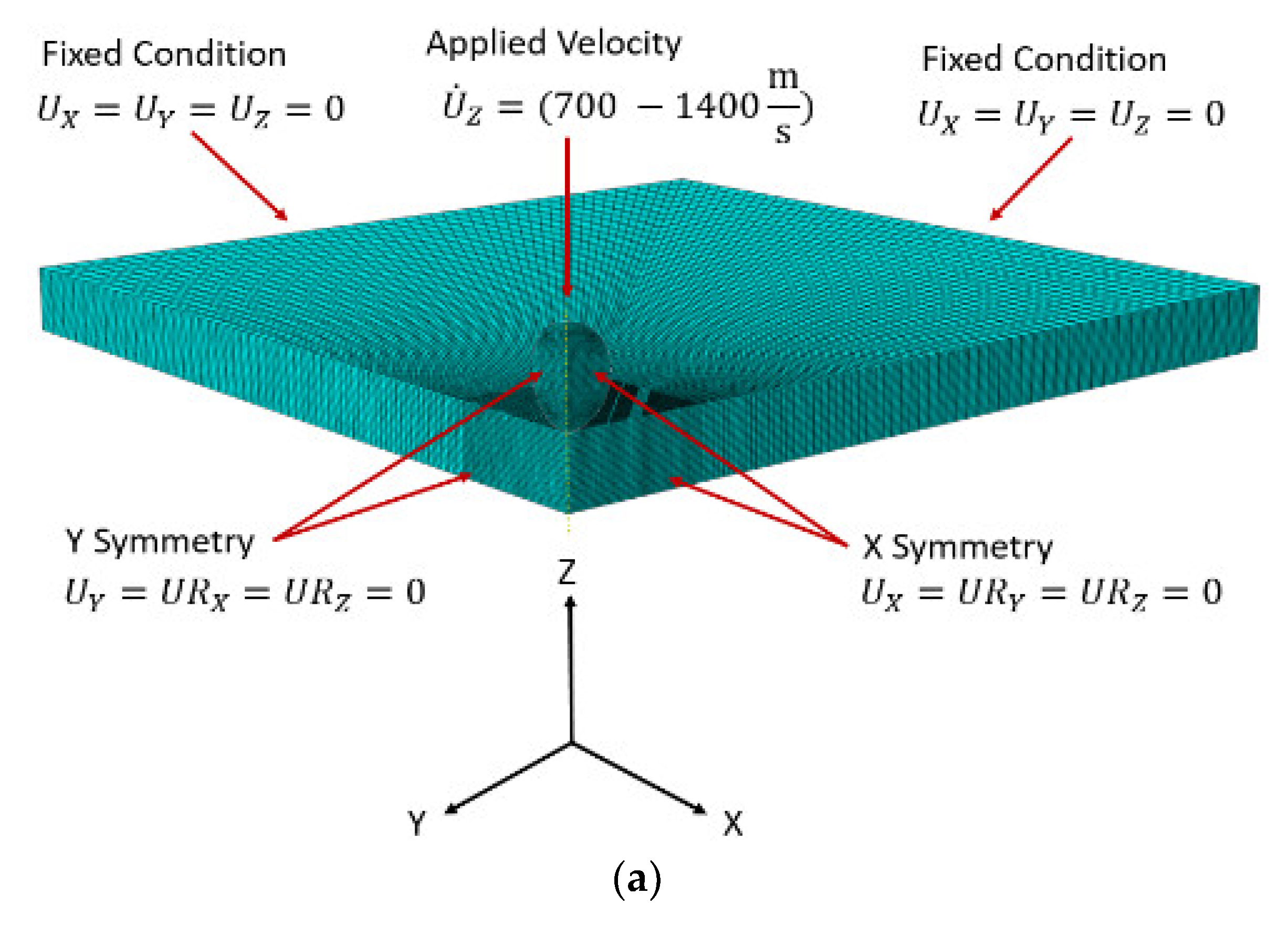

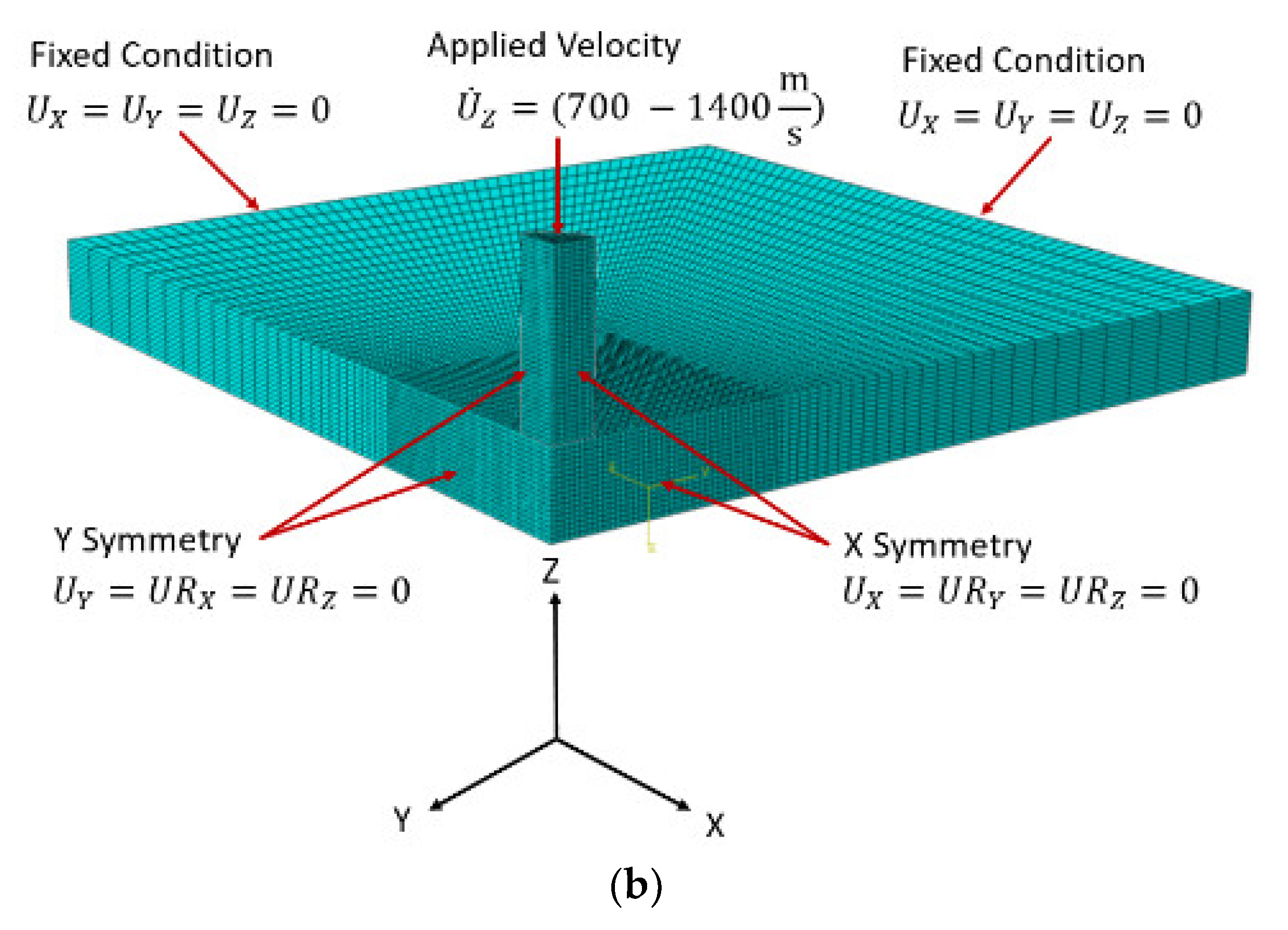

2.1.1. Finite Element Simulation Framework

2.1.2. Constitutive Model

2.2. Part II: Parameter Sensitivity Study

2.2.1. Second Phase Particle Number Density and Size

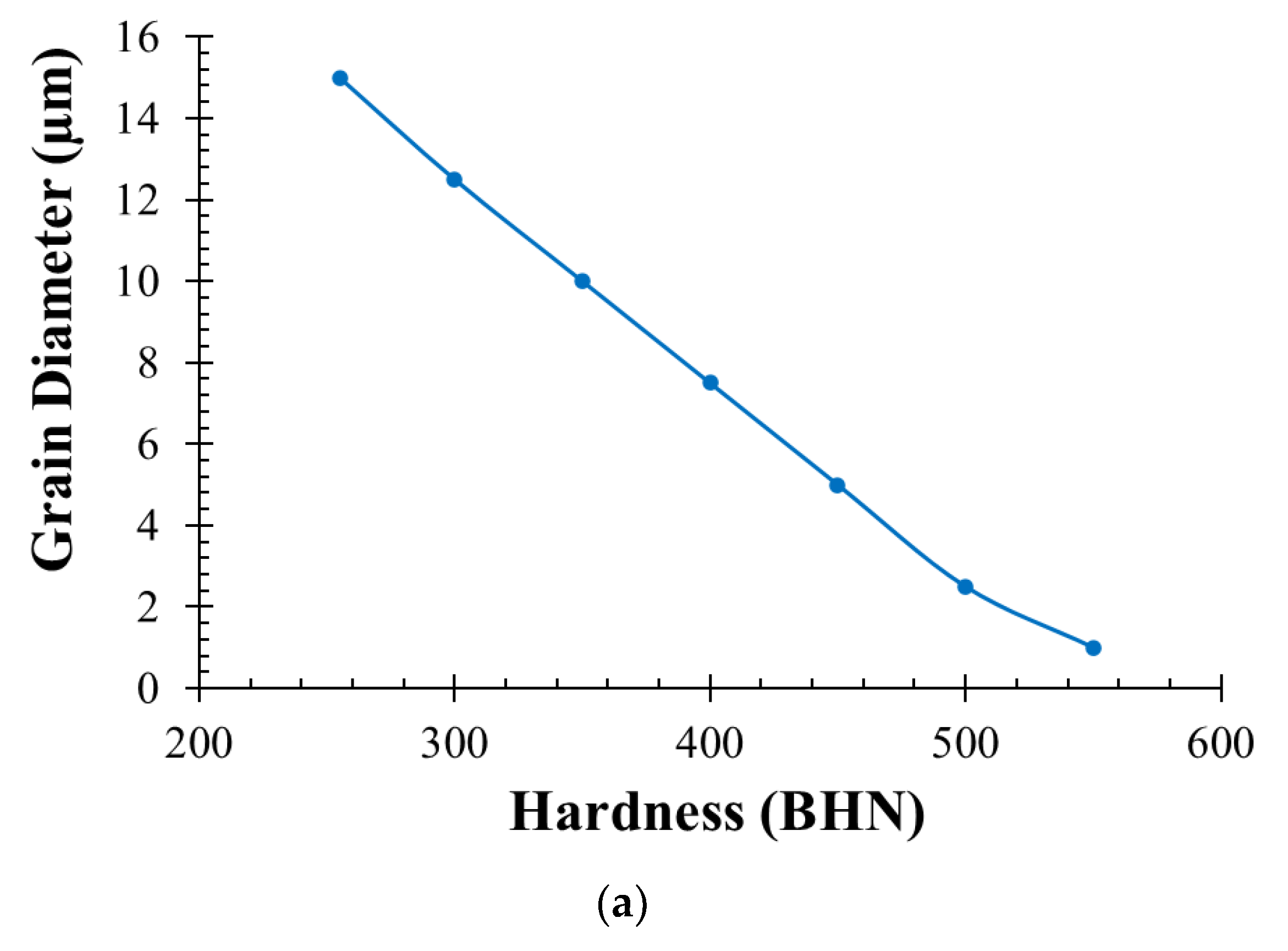

2.2.2. Grain Size

2.2.3. Initial Void Volume Fraction

2.2.4. Lattice Hydrogen Concentration

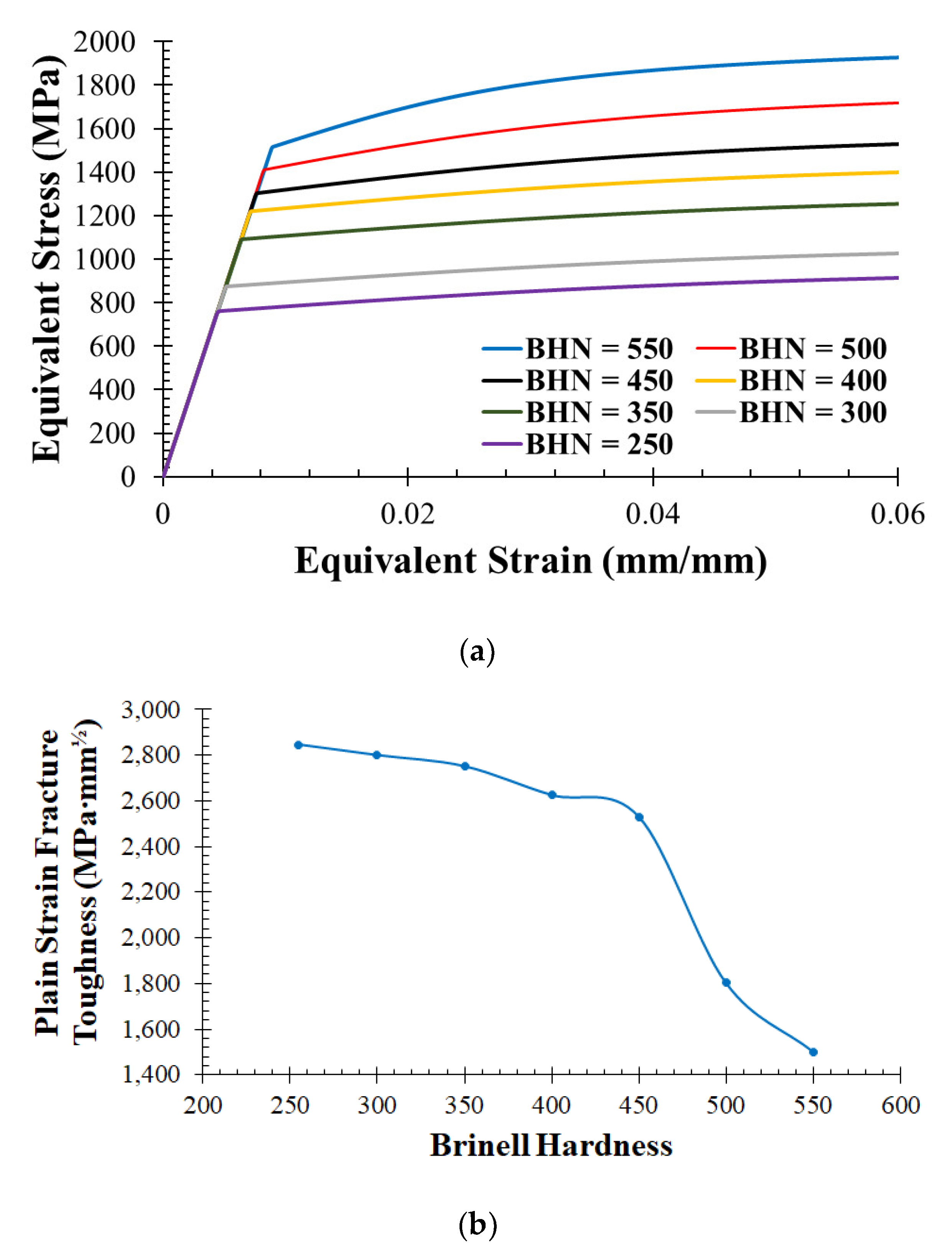

2.2.5. Material Hardness

2.2.6. Design of Experiments

2.3. Part III: Modeling the Microstructurally Driven Transition of Penetration Modes for Increasing Material Hardness

3. Results and Discussion

3.1. Part I: Validation of Internal State Variable Finite Element Framework

3.2. Part II: Parameter Sensitivity Study

3.3. Part III: Modeling the Microstructurally Driven Transition of Penetration Modes for Increasing Target Material Hardness

- Increasing lattice hydrogen concentration (from 10−5 to 10−3 APPM) exponentially increases void nucleation rates (Equation (9)) in materials subjected to greater than zero stress triaxiality through [85]. As the material expands under tension, hydrogen is freer to migrate through the lattice to preferential trapping sites near grain or inclusion boundaries. The hydrogen reduces the local fracture toughness contributing to increasing void nucleation rates. Macroscopically, this corresponds to more localized fracture and perforation modes in high-tensile pressure regions, less energy absorption through global plastic strain accumulation, and reduced perforation velocities.

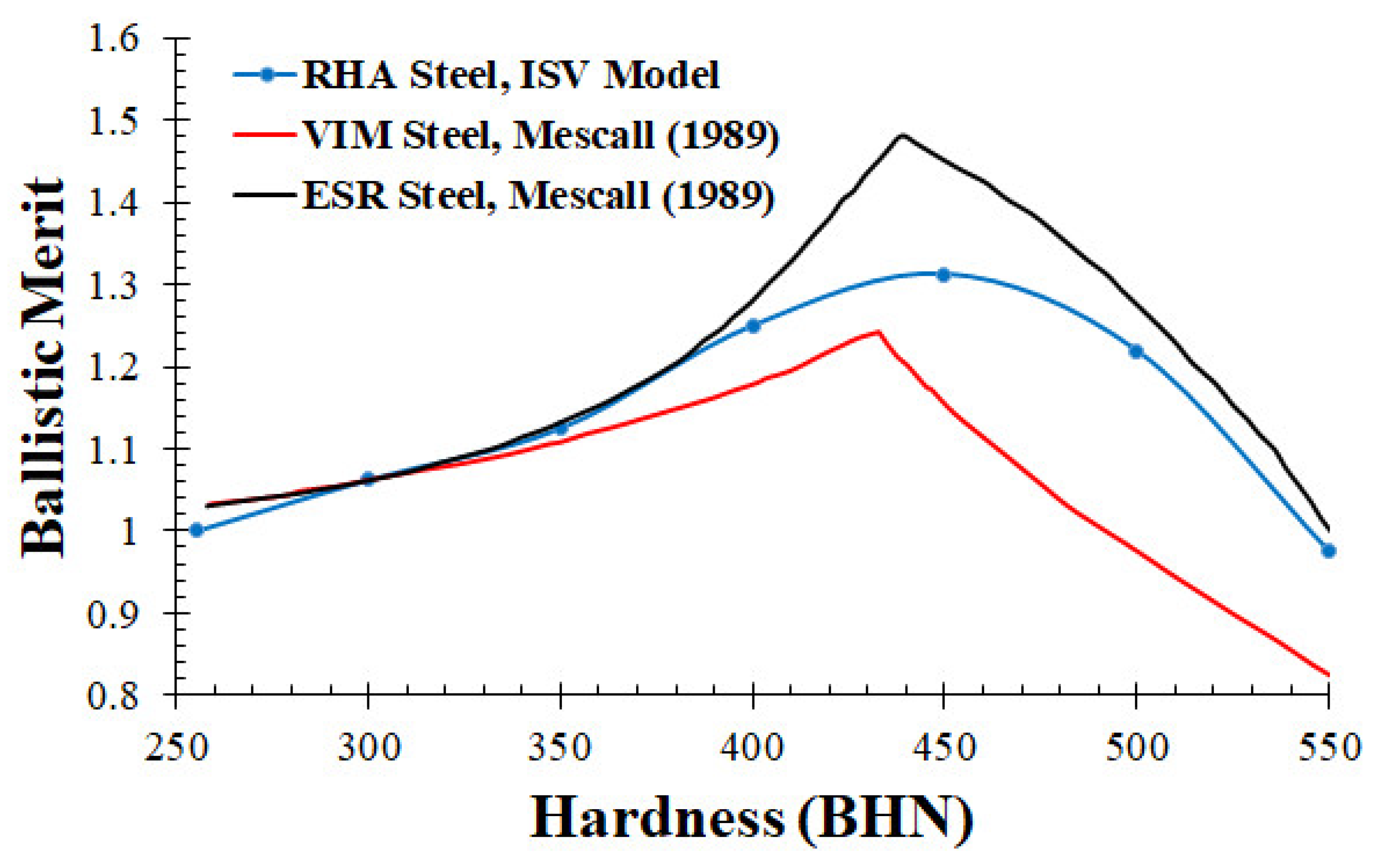

- Perforation velocity is strongly sensitive to target material hardness. Increasing hardness (and corresponding yield and rate hardening characteristics) from 250 BHN to 550 BHN increases the mechanical work for a given strain, thus reducing greater energy from the impact event, and subsequently increasing the velocity required to perforate the material.

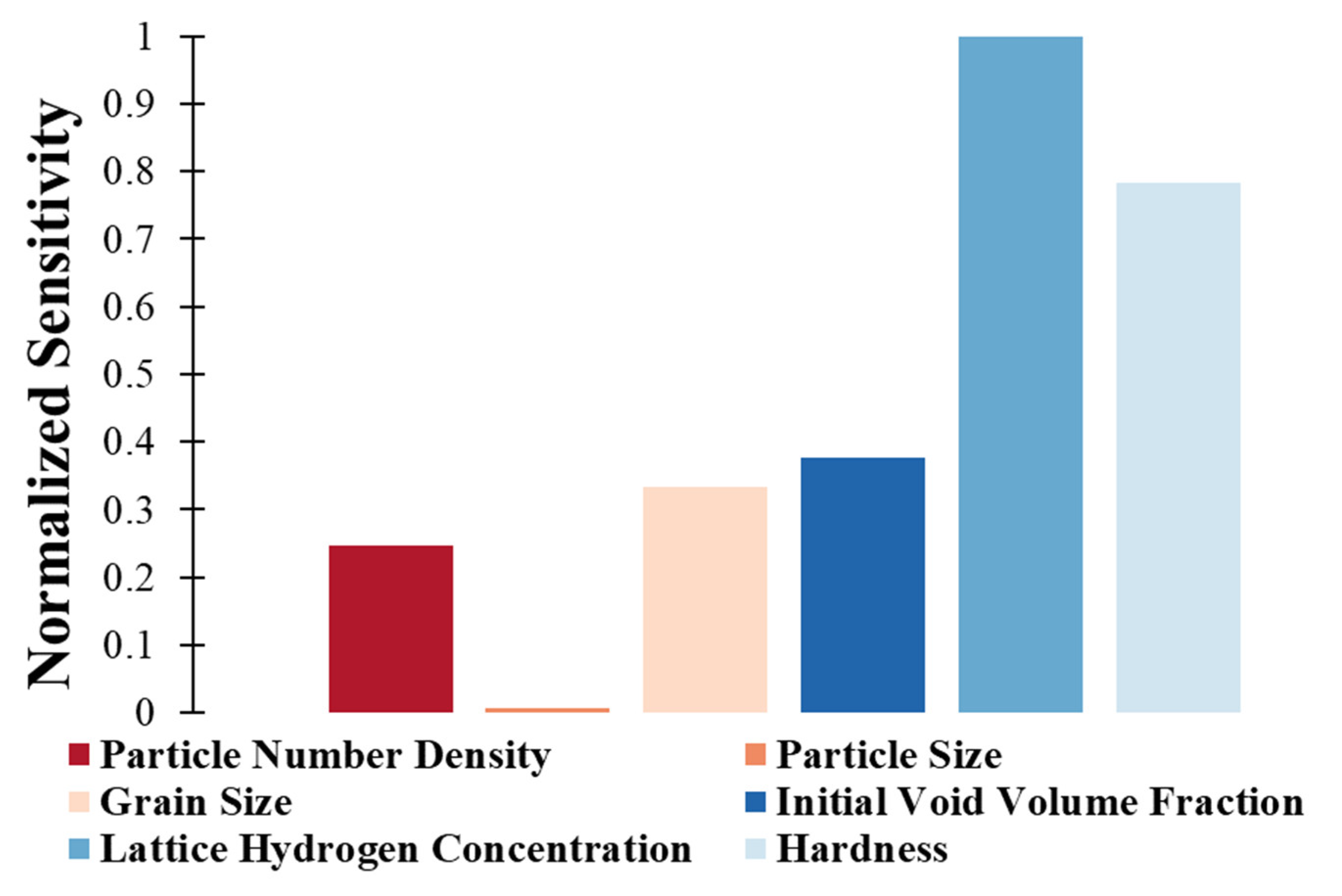

- Perforation velocity shows finite normalized sensitivity to initial void volume fraction (0.38), grain size (0.33), and particle number density (0.25) in descending order. These sensitivities are relatively smaller than the lattice hydrogen concentration (1.0) and hardness sensitivities (0.78) but are still significant. Increasing levels of initial porosity from 10−6 to 10−2 increases material compliance (Equation (3)) and reduces the void nearest-neighbor distance, thus accelerating the onset of void coalescence and unstable fracture (consider the coupled effects of Equations (6) and (13)). Reducing the grain size exponentially increases void coalescence rate (GS in Equation (13)) through reduction in defect nearest-neighbor distances, contributing to the earlier onset of coalescence with strain once voids have nucleated. Increasing the second-phase particle number density from 250 to 4000 voids/mm2 increases the number of initial points of localized stress concentration and void nucleation in the microstructure. Physically, increasing the particle number density reduces the neighbor distance once voids have begun to nucleate, contributing to earlier material instability.

- Perforation velocity shows negligible sensitivity to particle size. Mathematically, nucleation rate, is correlated to particle diameter, d, through a square root relationship ∝ d1/2, while the nucleation rate’s relationship to lattice hydrogen concentration and particle number density is exponential and linear, respectively. Physically, the fracture of larger particles would produce conditions conducive to void growth (Equation (12)), However, ballistic penetration is a high strain rate event that favors a large quantity of nucleation events leading to final rupture through coalescence rather than the growth of large voids.

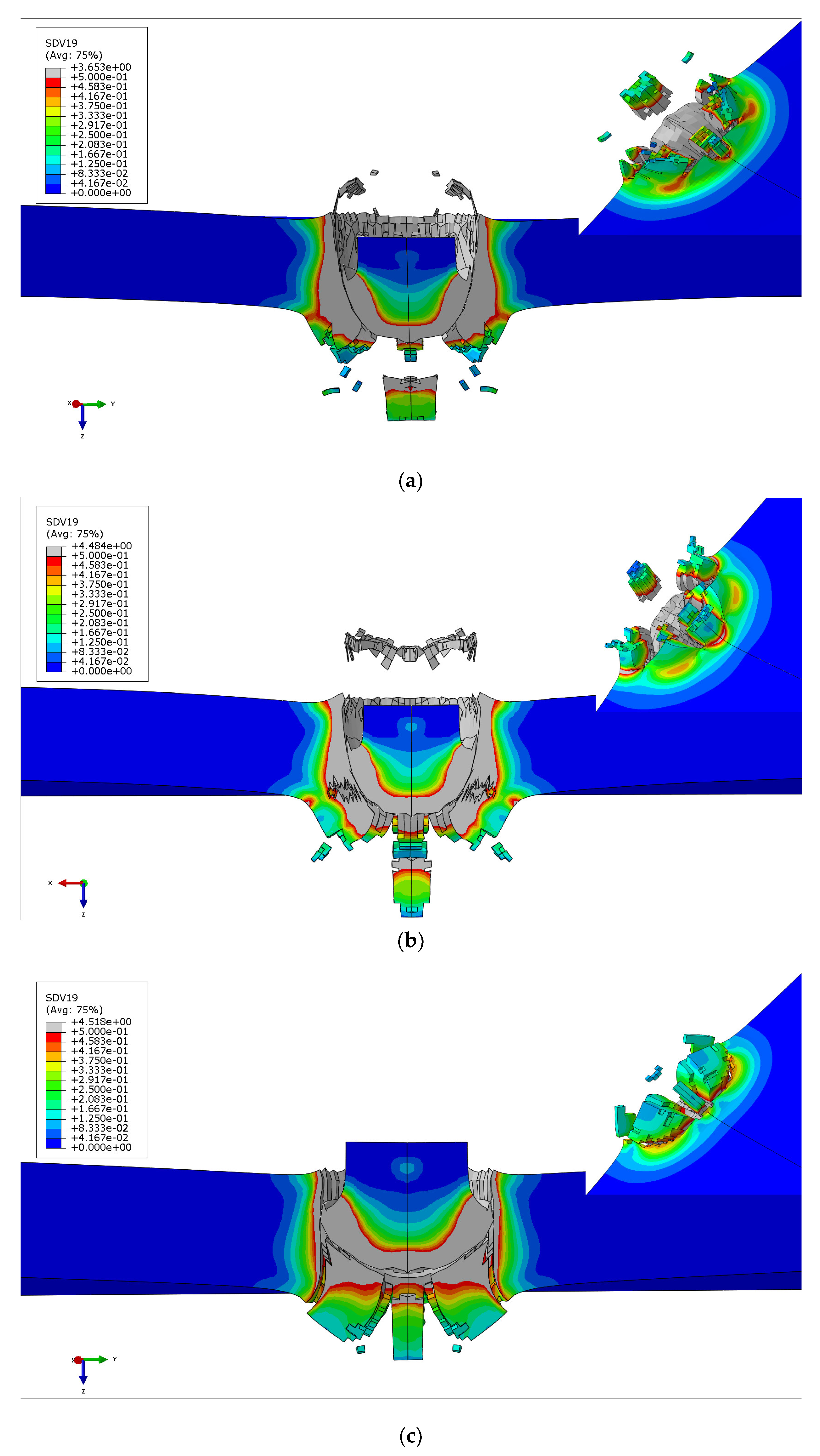

- Diminished ballistic performance trends in high hardness (>450 BHN) targets experimentally observed by [63] can be qualitatively predicted using an ISV based framework featuring decreasing grain size, particle size, particle volume fraction, and fracture toughness and increasing particle number density with increasing material hardness in accord with qualitative trends documented in the relevant literature. A single order of magnitude increase in particle number density (250 to 2000 particles/mm2) and corresponding reduction in grain size (5 to 2.5 μm) from 450 to 500 BHN hardness degrades the Ballistic Merit from 1.24 to 1.13, despite the increase in yield and flow strength of the material. The reduction in ballistic resistivity is caused by a transition from large ductility perforation modes to localized shear plugging (Figure 7).

- Traditional constitutive modeling approaches can struggle to successfully predict changes in perforation behavior for alloys of similar element composition and varying processing history [56,63,64]. This work demonstrates that a deformation history- and microstructure property-dependent ISV constitutive model can predict changes in ballistic perforation modes and nonmonotonic trends in ballistic limit for increasing target strength.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| RHA Steel (250 BHN) | Value |

|---|---|

| Density (tonne/mm3) | 7.83 × 10−9 |

| Elastic Modulus (MPa) | 205,000 |

| Poisson’s Ratio | 0.29 |

| Thermal Conductivity (W·m·K−1) | 42.5 |

| Specific Heat (J·kg−1·K−1) | 480 |

| Thermal Expansion (K−1) | 1.15 × 10−5 |

| Inelastic Heat Fraction | 0.3336 |

| Melt Temperature (K) | 1803.15 |

| ISV Model Coefficients | - |

| C01 (MPa) | 5 |

| C02 (K) | 0 |

| C03 (MPa) | 690 |

| C04 (K) | 22 |

| C05 (MPa−1) | 0.3 |

| C06 (K) | 0 |

| C07 (MPa−1) | 0.3 |

| C08 (K) | 150 |

| C09 (MPa) | 4416 |

| C10 (K) | 2 |

| C11 (s·MPa−1) | 0 |

| C12 (K) | 0 |

| C13 (MPa−1) | 0.07 |

| C14 (K) | 121.5 |

| C15 (MPa) | 700 |

| C16 (K) | 0 |

| C17 (s*MPa−1) | 0 |

| C18 (K) | 0 |

| C19 | 0.006 |

| C20 (K−1) | 1100 |

| C21 | 0 |

| Ca | −0.3 |

| Cb | 0 |

| Avoid | 0 |

| Bvoid | 0 |

| a | 32,000 |

| b | 10,800 |

| c | 36,000 |

| η0 (#/mm2) | 200 |

| KIC (MPa·mm½) | 2751 |

| d (mm) | 0.0035 |

| f | 0.00065 |

| NND (mm) | 0.16 |

| d0 (mm) | 0.002 |

| cd2 | 1.5 |

| GS0 (mm) | 0.01 |

| GS (mm) | 0.01 |

| ζ | 1 |

| Initial Porosity | 0.00065 |

| CTN (K) | 300 |

| CTC (K−1) | 0.002 |

| McClintock Growth, n | 0.3 |

| R0 (mm) | 0.001 |

| Cocks-Ashby Growth, m | 20 |

| RHA Steel | Hardness (BHN) | ||||||

|---|---|---|---|---|---|---|---|

| 250 | 300 | 350 | 400 | 450 | 500 | 550 | |

| Density (tonne/mm3) | 7.83 × 10−9 | 7.83 × 10−9 | 7.83 × 10−9 | 7.83 × 10−9 | 7.83 × 10−9 | 7.83 × 10−9 | 7.83 × 10−9 |

| Elastic Modulus (MPa) | 205,000 | 205,000 | 205,000 | 205,000 | 205,000 | 205,000 | 205,000 |

| Poisson’s Ratio | 0.29 | 0.29 | 0.29 | 0.29 | 0.29 | 0.29 | 0.29 |

| Conductivity (W·m·K−1) | 42.5 | 42.5 | 42.5 | 42.5 | 42.5 | 42.5 | 42.5 |

| Specific Heat (J·kg−1·K−1) | 480 | 480 | 480 | 480 | 480 | 480 | 480 |

| Thermal Expansion (K−1) | 1.15 × 10−5 | 1.15 × 10−5 | 1.15 × 10−5 | 1.15 × 10−5 | 1.15 × 10−5 | 1.15 × 10−5 | 1.15 × 10−5 |

| Inelastic Heat Fraction | 0.3336 | 0.3336 | 0.3336 | 0.3336 | 0.3336 | 0.3336 | 0.3336 |

| Melt Temperature (K) | 1803.15 | 1803.15 | 1803.15 | 1803.15 | 1803.15 | 1803.15 | 1803.15 |

| ISV Model Coefficients | - | - | - | - | - | - | - |

| C01 (MPa) | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| C02 (K) | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C03 (MPa) | 690 | 803 | 1003 | 1113 | 1203 | 1300 | 1400 |

| C04 (K) | 22 | 22 | 22 | 22 | 22 | 22 | 22 |

| C05 (MPa−1) | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| C06 (K) | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C07 (MPa−1) | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| C08 (K) | 150 | 150 | 150 | 150 | 150 | 150 | 150 |

| C09 (MPa) | 4416 | 4416 | 4416 | 4416 | 4416 | 5216 | 6016 |

| C10 (K) | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| C11 (s·MPa−1) | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C12 (K) | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C13 (MPa−1) | 0.07 | 0.07 | 0.07 | 0.07 | 0.07 | 0.07 | 0.07 |

| C14 (K) | 121.5 | 121.5 | 121.5 | 121.5 | 121.5 | 121.5 | 121.5 |

| C15 (MPa) | 700 | 700 | 700 | 700 | 700 | 1000 | 1300 |

| C16 (K) | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C17 (s·MPa−1) | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C18 (K) | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C19 | 0.006 | 0.006 | 0.006 | 0.006 | 0.006 | 0.006 | 0.006 |

| C20 (K−1) | 1100 | 1100 | 1100 | 1100 | 1100 | 1100 | 1100 |

| C21 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Ca | −0.3 | −0.3 | −0.3 | −0.3 | −0.3 | −0.3 | −0.3 |

| Cb | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Avoid | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Bvoid | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| a | 32,000 | 32,000 | 32,000 | 32,000 | 32,000 | 32,000 | 32,000 |

| b | 10,800 | 10,800 | 10,800 | 10,800 | 10,800 | 10,800 | 10,800 |

| c | 360 | 360 | 360 | 360 | 360 | 360 | 360 |

| η0 (#/mm2) | 200 | 200 | 200 | 200 | 250 | 2000 | 4000 |

| KIC (MPa·mm½) | 2846 | 2800 | 2751 | 2625 | 2530 | 1802 | 1500 |

| d (mm) | 0.007 | 0.00525 | 0.0035 | 0.002625 | 0.0015 | 0.000035 | 0.0000035 |

| f | 0.00245 | 0.001378 | 0.00065 | 0.000517 | 0.000375 | 1.23 × 10−8 | 6.13 × 10−7 |

| NND (mm) | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 |

| d0 (mm) | 0.002 | 0.002 | 0.002 | 0.002 | 0.002 | 0.002 | 0.002 |

| cd2 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| GS0 (mm) | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| GS (mm) | 0.015 | 0.0125 | 0.01 | 0.0075 | 0.005 | 0.0025 | 0.001 |

| ζ | 1.3 | 1.3 | 1.3 | 1.3 | 1.3 | 1.3 | 1.3 |

| Initial Porosity | 0.00065 | 0.00065 | 0.00065 | 0.00065 | 0.00065 | 0.00065 | 0.00065 |

| CTN (K) | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| CTC (K−1) | 0.002 | 0.002 | 0.002 | 0.002 | 0.002 | 0.002 | 0.002 |

| McClintock Growth, n | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| D0 (mm) | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 |

| Cocks-Ashby Growth, m | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

References

- Backman, M.E.; Goldsmith, W. The Mechanics of Penetration of Projectiles into Targets. Int. J. Eng. Sci. 1978, 16, 1–99. [Google Scholar] [CrossRef]

- Corbett, G.G.; Reid, S.R.; Johnson, W. Impact Loading of Plates and Shells by Free-Flying Projectiles: A Review. Int. J. Impact Eng. 1996, 18, 141–230. [Google Scholar] [CrossRef]

- Tsai, Y.M.; Kolsky, H. A Study of the Fractures Produced in Glass Blocks by Impact. J. Mech. Phys. Solids 1967, 15, 263–278. [Google Scholar] [CrossRef]

- Bowden, F.P.; Field, J.E. The Brittle Fracture of Solids by Liquid Impact, by Solid Impact, and by Shock. Proc. R. Soc. Lond. Ser. Math. Phys. Sci. 1964, 282, 331–352. [Google Scholar] [CrossRef]

- Camacho, G.T.; Ortiz, M. Computational Modelling of Impact Damage in Brittle Materials. Int. J. Solids Struct. 1996, 33, 2899–2938. [Google Scholar] [CrossRef]

- Holmen, J.K.; Thomesen, S.; Perez-Martin, M.J.; Hopperstad, O.S.; Børvik, T. Ballistic Impact of Structural Steels at Low Temperatures. J. Appl. Mech. 2022, 89, 101001. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, J.; Zhao, G.; Liu, Y. New Insights into the Damage Assessment and Energy Dissipation Weight Mechanisms of Ceramic/Fiber Laminated Composites under Ballistic Impact. Ceram. Int. 2023, 49, 21966–21977. [Google Scholar] [CrossRef]

- Evans, A.G.; Gulden, M.E.; Rosenblatt, M.; Tabor, D. Impact Damage in Brittle Materials in the Elastic-Plastic Response Régime. Proc. R. Soc. Lond. Math. Phys. Sci. 1978, 361, 343–365. [Google Scholar] [CrossRef]

- Johnson, J.N. Dynamic Fracture and Spallation in Ductile Solids. J. Appl. Phys. 1981, 52, 2812–2825. [Google Scholar] [CrossRef]

- Ranaweera, P.; Bambach, M.R.; Weerasinghe, D.; Mohotti, D. Ballistic Impact Response of Monolithic Steel and Tri-Metallic Steel–Titanium–Aluminium Armour to Nonrigid NATO FMJ M80 Projectiles. Thin-Walled Struct. 2023, 182, 110200. [Google Scholar] [CrossRef]

- Guo, G.; Alam, S.; Peel, L.D. Numerical Analysis of Ballistic Impact Performance of Two Ceramic-Based Armor Structures. Compos. Part C Open Access 2020, 3, 100061. [Google Scholar] [CrossRef]

- Meyers, M.A.; Aimone, C.T. Dynamic Fracture (Spalling) of Metals. Prog. Mater. Sci. 1983, 28, 1–96. [Google Scholar] [CrossRef]

- Curran, D.R.; Seaman, L.; Shockey, D.A. Dynamic Failure of Solids. Phys. Rep. 1987, 147, 253–388. [Google Scholar] [CrossRef]

- Grady, D.E. The Spall Strength of Condensed Matter. J. Mech. Phys. Solids 1988, 36, 353–384. [Google Scholar] [CrossRef]

- Dongare, A.M. Challenges to Model the Role of Heterogeneities on the Shock Response and Spall Failure of Metallic Materials at the Mesoscales. J. Mater. Sci. 2020, 55, 3157–3166. [Google Scholar] [CrossRef]

- Lloyd, J.T.; Jannotti, P.A.; Jones, T.L. An Overview of Penetration Behavior in Magnesium Alloys. Mech. Mater. 2021, 162, 104038. [Google Scholar] [CrossRef]

- Wen, K.; Chen, X.; Lu, Y. Research and Development on Hypervelocity Impact Protection Using Whipple Shield: An Overview. Def. Technol. 2021, 17, 1864–1886. [Google Scholar] [CrossRef]

- Recht, R.F.; Ipson, T.W. Ballistic Perforation Dynamics. J. Appl. Mech. 1963, 30, 384–390. [Google Scholar] [CrossRef]

- Awerbuch, J.; Bodner, S.R. Analysis of the Mechanics of Perforation of Projectiles in Metallic Plates. Int. J. Solids Struct. 1974, 10, 671–684. [Google Scholar] [CrossRef]

- Goldsmith, W.; Finnegan, S.A. Normal and Oblique Impact of Cylindro-Conical and Cylindrical Projectiles on Metallic Plates. Int. J. Impact Eng. 1986, 4, 83–105. [Google Scholar] [CrossRef]

- Børvik, T.; Langseth, M.; Hopperstad, O.S.; Malo, K.A. Ballistic Penetration of Steel Plates. Int. J. Impact Eng. 1999, 22, 855–886. [Google Scholar] [CrossRef]

- Dubey, R.; Jayaganthan, R.; Ruan, D.; Gupta, N.K.; Jones, N.; Velmurugan, R. Ballistic Perforation and Penetration of 6xxx-Series Aluminium Alloys: A Review. Int. J. Impact Eng. 2023, 172, 104426. [Google Scholar] [CrossRef]

- Bhat, A.; Naveen, J.; Jawaid, M.; Norrrahim, M.N.F.; Rashedi, A.; Khan, A. Advancement in Fiber Reinforced Polymer, Metal Alloys and Multi-Layered Armour Systems for Ballistic Applications–A Review. J. Mater. Res. Technol. 2021, 15, 1300–1317. [Google Scholar] [CrossRef]

- Schonberg, W.; Ryan, S. Predicting Metallic Armour Performance When Impacted by Fragment-Simulating Projectiles–Model Review and Assessment. Int. J. Impact Eng. 2021, 158, 104025. [Google Scholar] [CrossRef]

- Ranaweera, P.; Weerasinghe, D.; Fernando, P.; Raman, S.N.; Mohotti, D. Ballistic Performance of Multi-Metal Systems. Int. J. Prot. Struct. 2020, 11, 379–410. [Google Scholar] [CrossRef]

- Goldsmith, W.; Liu, T.W.; Chulay, S. Plate Impact and Perforation by Projectiles. Exp. Mech. 1965, 5, 385–404. [Google Scholar] [CrossRef]

- Levy, N.; Goldsmith, W. Normal Impact and Perforation of Thin Plates by Hemispherically-Tipped Projectiles—II. Experimental Results. Int. J. Impact Eng. 1984, 2, 299–324. [Google Scholar] [CrossRef]

- Hou, X.; Goldsmith, W. Projectile Perforation of Moving Plates: Experimental Investigation. Int. J. Impact Eng. 1996, 18, 859–875. [Google Scholar] [CrossRef]

- Elveli, B.S.; Berstad, T.; Børvik, T.; Aune, V. Performance of Thin Blast-Loaded Steel Plates after Ballistic Impact from Small-Arms Projectiles. Int. J. Impact Eng. 2023, 173, 104437. [Google Scholar] [CrossRef]

- Ebo-Quansah, I.; Hassanin, A.; Adachi, T.; Hassan, M. An Overview on Penetration Mechanism and Optimization Techniques of Steel Sandwich Structure under Ballistic Testing. Int. J. Mater. Technol. Innov. 2022, 2, 55–73. [Google Scholar] [CrossRef]

- Bekci, M.L.; Canpolat, B.H.; Usta, E.; Güler, M.S.; Cora, Ö.N. Ballistic Performances of Ramor 500 and Ramor 550 Armor Steels at Mono and Bilayered Plate Configurations. Eng. Sci. Technol. Int. J. 2021, 24, 990–995. [Google Scholar] [CrossRef]

- Mosa, M.H.; Hamza, M.N. Influence of Selection Materials and Construction Techniques on the Ballistic Performance of Armors: A Review. AIP Conf. Proc. 2021, 2404, 080025. [Google Scholar] [CrossRef]

- Grady, D.E. Local Inertial Effects in Dynamic Fragmentation. J. Appl. Phys. 1982, 53, 322–325. [Google Scholar] [CrossRef]

- Grady, D.E.; Kipp, M.E. Geometric Statistics and Dynamic Fragmentation. J. Appl. Phys. 1985, 58, 1210–1222. [Google Scholar] [CrossRef]

- Glenn, L.A.; Chudnovsky, A. Strain-energy Effects on Dynamic Fragmentation. J. Appl. Phys. 1986, 59, 1379–1380. [Google Scholar] [CrossRef]

- Cheng, C.; Du, Z.; Chen, X.; Xu, L.; Du, C.; Han, J.; Wang, X. Damage of Multi-Layer Spaced Metallic Target Plates Impacted by Radial Layered PELE. Def. Technol. 2020, 16, 201–207. [Google Scholar] [CrossRef]

- Andraskar, N.D.; Tiwari, G.; Goel, M.D. Impact Response of Ceramic Structures-A Review. Ceram. Int. 2022, 48, 27262–27279. [Google Scholar] [CrossRef]

- Zhao, C.; Wang, S.; Guo, C.; Liu, D.; Ma, F. Experimental Study on Fragmentation of Explosive Loaded Steel Projectile. Int. J. Impact Eng. 2020, 144, 103610. [Google Scholar] [CrossRef]

- Thomson, W.T. An Approximate Theory of Armor Penetration. J. Appl. Phys. 1955, 26, 80–82. [Google Scholar] [CrossRef]

- Masri, R. Practical Formulae for Predicting the Ballistic Limit Velocity of Armour Perforation by Ductile Hole Growth. Int. J. Impact Eng. 2022, 167, 104219. [Google Scholar] [CrossRef]

- Masri, R.; Ryan, S. Ballistic Limit Predictions of Non-Identical Layered Targets Perforated in Ductile Hole Formation. Int. J. Impact Eng. 2023, 171, 104391. [Google Scholar] [CrossRef]

- Buchely, M.; Marañon, A. Spherical Cavity Expansion Approach for the Study of Rigid-Penetrator’s Impact Problems. Appl. Mech. 2020, 1, 20–46. [Google Scholar] [CrossRef]

- Manganello, S.J.; Carter, G.C. Development of Heat-Treated Composite Steel Armor, technical report, United State Steel Corp, Monroeville PA, Applied Research Laboratory. 1967. Available online: https://apps.dtic.mil/sti/pdfs/AD0383336.pdf (accessed on 1 June 2023).

- Goldsmith, W.; Finnegan, S.A. High-Velocity Impact of Steel Spheres of Metallic Targets, Technical Report, Naval Weapons Center, China Lake, CA. 1971. Available online: https://apps.dtic.mil/sti/pdfs/AD0724289.pdf (accessed on 1 June 2023).

- Littlefield, D.L.; Anderson, C.E.; Partom, Y.; Bless, S.J. The Penetration of Steel Targets Finite in Radial Extent. Int. J. Impact Eng. 1997, 19, 49–62. [Google Scholar] [CrossRef]

- Li, C.; Rasheed, S.; Malik, A.; Nazeer, F.; Long, J. Study on Ballistic Impact Behavior of Al Alloys against Two Different Shapes of Steel Core Projectiles. J. Mater. Res. Technol. 2022, 20, 2489–2500. [Google Scholar] [CrossRef]

- Mohammad, Z.; Gupta, P.K.; Baqi, A. Experimental and Numerical Investigations on the Behavior of Thin Metallic Plate Targets Subjected to Ballistic Impact. Int. J. Impact Eng. 2020, 146, 103717. [Google Scholar] [CrossRef]

- Radchenko, P.A.; Batuev, S.P.; Radchenko, A.V. The Influence of Steel Projectile Shape on Its Fracture at High Strain Rates. Russ. Phys. J. 2021, 64, 811–819. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, X.; Tan, K.; Zhang, C.; Liu, Z.; Liu, H.; Li, J. Simulation and Experimental Study of Fragment Penetration into Armored Steel Plate. J. Phys. Conf. Ser. 2023, 2478, 072009. [Google Scholar] [CrossRef]

- Anderson, C.E.; Morris, B.L.; Littlefield, D.L. A Penetration Mechanics Database, Technical Report, Southwest Research Institute, San Antonio, TX. 1992. Available online: https://apps.dtic.mil/sti/pdfs/ADA246351.pdf (accessed on 2 June 2023).

- Johnson, G.R.; Cook, W.H. Fracture Characteristics of Three Metals Subjected to Various Strains, Strain Rates, Temperatures and Pressures. Eng. Fract. Mech. 1985, 21, 31–48. [Google Scholar] [CrossRef]

- Bammann, D.J.; Chiesa, M.L.; Horstemeyer, M.F.; Weingarten, L.I. Failure in Ductile Materials Using Finite Element Methods. In Structural Crashworthiness and Failure; CRC Press: Boca Raton, FL, USA, 1993; ISBN 978-0-429-06826-3. [Google Scholar]

- Anderson, C.E., Jr.; Hohler, V.; Walker, J.D.; Stilp, A.J. The Influence of Projectile Hardness on Ballistic Performance. Int. J. Impact Eng. 1999, 22, 619–632. [Google Scholar] [CrossRef]

- Børvik, T.; Hopperstad, O.S.; Berstad, T.; Langseth, M. A Computational Model of Viscoplasticity and Ductile Damage for Impact and Penetration. Eur. J. Mech.-A Solids 2001, 20, 685–712. [Google Scholar] [CrossRef]

- Børvik, T.; Hopperstad, O.S.; Langseth, M.; Malo, K.A. Effect of Target Thickness in Blunt Projectile Penetration of Weldox 460 E Steel Plates. Int. J. Impact Eng. 2003, 28, 413–464. [Google Scholar] [CrossRef]

- Dey, S.; Børvik, T.; Hopperstad, O.S.; Leinum, J.R.; Langseth, M. The Effect of Target Strength on the Perforation of Steel Plates Using Three Different Projectile Nose Shapes. Int. J. Impact Eng. 2004, 30, 1005–1038. [Google Scholar] [CrossRef]

- Johnson, G.R.; Holmquist, T.J. Evaluation of Cylinder-impact Test Data for Constitutive Model Constants. J. Appl. Phys. 1988, 64, 3901–3910. [Google Scholar] [CrossRef]

- Dou, L.; He, L.; Yin, Y. Numerical Investigation on Protective Mechanism of Metal Cover Plate for Alumina Armor against Impact of Fragment by FE-Converting-SPH Method. Materials 2023, 16, 3405. [Google Scholar] [CrossRef]

- Shi, Y.; Hu, A.; Du, T.; Xiao, X.; Jia, B. Experimental and Numerical Study on the Protective Behavior of Weldox 900 E Steel Plates Impacted by Blunt-Nosed Projectiles. Metals 2022, 12, 141. [Google Scholar] [CrossRef]

- Deng, Y.; Zhang, Y.; Xiao, X.; Hu, A.; Wu, H.; Xiong, J. Experimental and Numerical Study on the Ballistic Impact Behavior of 6061-T651 Aluminum Alloy Thick Plates against Blunt-Nosed Projectiles. Int. J. Impact Eng. 2020, 144, 103659. [Google Scholar] [CrossRef]

- Jung, J.; Cho, Y.J.; Kim, S.-H.; Lee, Y.-S.; Kim, H.-J.; Lim, C.-Y.; Park, Y.H. Microstructural and Mechanical Responses of Various Aluminum Alloys to Ballistic Impacts by Armor Piercing Projectile. Mater. Charact. 2020, 159, 110033. [Google Scholar] [CrossRef]

- Vayig, Y.; Rosenberg, Z. On the Ballistic Performance of Weldox Steel Plates Impacted by Blunt Projectiles. Int. J. Impact Eng. 2023, 179, 104639. [Google Scholar] [CrossRef]

- Mescall, J.F.; Rogers, H. Role of Shear Instability in Ballistic Penetration, Technical Report, Army Lab Command, Watertown, MA, Material Technology Lab. 1989. Available online: https://apps.dtic.mil/sti/pdfs/ADA219186.pdf (accessed on 2 June 2023).

- Dikshit, S.N.; Kutumbarao, V.V.; Sundararajan, G. The Influence of Plate Hardness on the Ballistic Penetration of Thick Steel Plates. Int. J. Impact Eng. 1995, 16, 293–320. [Google Scholar] [CrossRef]

- Jo, M.C.; Kim, S.; Kim, D.W.; Park, H.K.; Hong, S.S.; Kim, H.K.; Kim, H.S.; Sohn, S.S.; Lee, S. Understanding of Adiabatic Shear Band Evolution during High-Strain-Rate Deformation in High-Strength Armor Steel. J. Alloys Compd. 2020, 845, 155540. [Google Scholar] [CrossRef]

- Li, X.-Y.; Zhang, Z.-H.; Cheng, X.-W.; Wang, Q.; Jia, X.-T.; Wang, D.; Wang, X.-F. The Evolution of Adiabatic Shear Band in High Co–Ni Steel during High Strain-Rate Compression. Mater. Sci. Eng. A 2022, 858, 144173. [Google Scholar] [CrossRef]

- Baik, S.-I.; Gupta, R.K.; Kumar, K.S.; Seidman, D.N. Temperature Increases and Thermoplastic Microstructural Evolution in Adiabatic Shear Bands in a High-Strength and High-Toughness 10 Wt.% Ni Steel. Acta Mater. 2021, 205, 116568. [Google Scholar] [CrossRef]

- Bammann, D.J. An Internal Variable Model of Viscoplasticity. Int. J. Eng. Sci. 1984, 22, 1041–1053. [Google Scholar] [CrossRef]

- Coleman, B.D.; Gurtin, M.E. Thermodynamics with Internal State Variables. J. Chem. Phys. 1967, 47, 597–613. [Google Scholar] [CrossRef]

- Bammann, D.J.; Aifantis, E.C. A Damage Model for Ductile Metals. Nucl. Eng. Des. 1989, 116, 355–362. [Google Scholar] [CrossRef]

- Horstemeyer, M.F.; Gokhale, A.M. A Void–Crack Nucleation Model for Ductile Metals. Int. J. Solids Struct. 1999, 36, 5029–5055. [Google Scholar] [CrossRef]

- Horstemeyer, M.F.; Ramaswamy, S.; Negrete, M. Using a Micromechanical Finite Element Parametric Study to Motivate a Phenomenological Macroscale Model for Void/Crack Nucleation in Aluminum with a Hard Second Phase. Mech. Mater. 2003, 35, 675–687. [Google Scholar] [CrossRef]

- Horstemeyer, M.F.; Lathrop, J.; Gokhale, A.M.; Dighe, M. Modeling Stress State Dependent Damage Evolution in a Cast Al–Si–Mg Aluminum Alloy. Theor. Appl. Fract. Mech. 2000, 33, 31–47. [Google Scholar] [CrossRef]

- McClintock, F.A. A Criterion for Ductile Fracture by the Growth of Holes. J. Appl. Mech. 1968, 35, 363–371. [Google Scholar] [CrossRef]

- Cocks, A.C.F.; Ashby, M.F. On Creep Fracture by Void Growth. Prog. Mater. Sci. 1982, 27, 189–244. [Google Scholar] [CrossRef]

- Jordon, J.B.; Horstemeyer, M.F.; Solanki, K.; Xue, Y. Damage and Stress State Influence on the Bauschinger Effect in Aluminum Alloys. Mech. Mater. 2007, 39, 920–931. [Google Scholar] [CrossRef]

- Tucker, M.T.; Horstemeyer, M.F.; Whittington, W.R.; Solanki, K.N.; Gullett, P.M. The Effect of Varying Strain Rates and Stress States on the Plasticity, Damage, and Fracture of Aluminum Alloys. Mech. Mater. 2010, 42, 895–907. [Google Scholar] [CrossRef]

- Horstemeyer, M.F.; Matalanis, M.M.; Sieber, A.M.; Botos, M.L. Micromechanical Finite Element Calculations of Temperature and Void Configuration Effects on Void Growth and Coalescence. Int. J. Plast. 2000, 16, 979–1015. [Google Scholar] [CrossRef]

- Horstemeyer, M.F.; Ramaswamy, S. On Factors Affecting Localization and Void Growth in Ductile Metals: A Parametric Study. Int. J. Damage Mech. 2000, 9, 5–28. [Google Scholar] [CrossRef]

- Guo, Y.B.; Wen, Q.; Horstemeyer, M.F. An Internal State Variable Plasticity-Based Approach to Determine Dynamic Loading History Effects on Material Property in Manufacturing Processes. Int. J. Mech. Sci. 2005, 47, 1423–1441. [Google Scholar] [CrossRef]

- Anurag, S.; Guo, Y.B.; Horstemeyer, M.F. The Effect of Materials Testing Modes on Finite Element Simulation of Hard Machining via the Use of Internal State Variable Plasticity Model Coupled with Experimental Study. Comput. Struct. 2009, 87, 303–317. [Google Scholar] [CrossRef]

- Whittington, W.R.; Oppedal, A.L.; Turnage, S.; Hammi, Y.; Rhee, H.; Allison, P.G.; Crane, C.K.; Horstemeyer, M.F. Capturing the Effect of Temperature, Strain Rate, and Stress State on the Plasticity and Fracture of Rolled Homogeneous Armor (RHA) Steel. Mater. Sci. Eng. A 2014, 594, 82–88. [Google Scholar] [CrossRef]

- Bammann, D.J.; Chiesa, M.L.; Johnson, G.C. Modeling Large Deformation and Failure in Manufacturing Processes. Theor. Appl. Mech. 1996, 9, 359–376. [Google Scholar]

- Gokhale, A.M.; Dighe, M.D.; Horstemeyer, M. Effect of Temperature on Silicon Particle Damage in A356 Alloy. Metall. Mater. Trans. A 1998, 29, 905–907. [Google Scholar] [CrossRef]

- Chandler, M.Q.; Bammann, D.J.; Horstemeyer, M.F. A Continuum Model for Hydrogen-Assisted Void Nucleation in Ductile Materials. Model. Simul. Mater. Sci. Eng. 2013, 21, 055028. [Google Scholar] [CrossRef]

- McLean, D. Grain Boundaries in Metals; Oxford University Press: Oxford, UK, 1957. [Google Scholar]

- Oriani, R.A.; Josephic, P.H. Hydrogen-Enhanced Load Relaxation in a Deformed Medium-Carbon Steel. Acta Metall. 1979, 27, 997–1005. [Google Scholar] [CrossRef]

- Peterson, L.A.; Horstemeyer, M.F.; Lacy, T.E.; Moser, R.D. Experimental Characterization and Constitutive Modeling of an Aluminum 7085-T711 Alloy under Large Deformations at Varying Strain Rates, Stress States, and Temperatures. Mech. Mater. 2020, 151, 103602. [Google Scholar] [CrossRef]

- Allison, P.G. Structure-Property Relations for Monotonic and Fatigue Loading Conditions for a Powder Metal Steel; Mississippi State University: Starkville, MS, USA, 2009. [Google Scholar]

- Puttick, K.E. Ductile Fracture in Metals. Philos. Mag. J. Theor. Exp. Appl. Phys. 1959, 4, 964–969. [Google Scholar] [CrossRef]

- Gangulee, A.; Gurland, J. On the Fracture of Silicon Particles in Aluminum-Silicon Alloys. AIME Met. Soc. Trans. 1967, 239, 269–272. [Google Scholar]

- Lindley, T.C.; Oates, G.; Richards, C.E. A Critical of Carbide Cracking Mechanisms in Ferride/Carbide Aggregates. Acta Metall. 1970, 18, 1127–1136. [Google Scholar] [CrossRef]

- Brown, L.M.; Embury, J.D. Initiation and Growth of Voids at Second-Phase Particles. In Proceedings of the Conference on Microstructure and Design of Alloys, Cambridge, UK, 20–25 August 1973; Institute of Metals and Iron and Steel Institute: London, UK, 1973; Volume 1, pp. 164–169. [Google Scholar]

- Hancock, J.W.; Mackenzie, A.C. On the Mechanisms of Ductile Failure in High-Strength Steels Subjected to Multi-Axial Stress-States. J. Mech. Phys. Solids 1976, 24, 147–160. [Google Scholar] [CrossRef]

- Conrad, H. Work-Hardening Model for the Effect of Grain Size on the Flow Stress of Metals; Syracuse University Press: Syracuse, NY, USA, 1970. [Google Scholar]

- Thompson, A.W. Effect of Grain Size on Work Hardening in Nickel. Acta Metall. 1977, 25, 83–86. [Google Scholar] [CrossRef]

- Narutani, T.; Takamura, J. Grain-Size Strengthening in Terms of Dislocation Density Measured by Resistivity. Acta Metall. Mater. 1991, 39, 2037–2049. [Google Scholar] [CrossRef]

- Bertolo, V.; Jiang, Q.; Scholl, S.; Petrov, R.H.; Hangen, U.; Walters, C.; Sietsma, J.; Popovich, V. A Comprehensive Quantitative Characterisation of the Multiphase Microstructure of a Thick-Section High Strength Steel. J. Mater. Sci. 2022, 57, 7101–7126. [Google Scholar] [CrossRef]

- Gurson, A.L. Continuum Theory of Ductile Rupture by Void Nucleation and Growth: Part I—Yield Criteria and Flow Rules for Porous Ductile Media. J. Eng. Mater. Technol. 1977, 99, 2–15. [Google Scholar] [CrossRef]

- Gurland, J. Observations on the Fracture of Cementite Particles in a Spheroidized 1.05% c Steel Deformed at Room Temperature. Acta Metall. 1972, 20, 735–741. [Google Scholar] [CrossRef]

- Cox, T.B.; Low, J.R. An Investigation of the Plastic Fracture of AISI 4340 and 18 Nickel-200 Grade Maraging Steels. Metall. Trans. 1974, 5, 1457–1470. [Google Scholar] [CrossRef]

- Fisher, J.R.; Gurland, J. Void Nucleation in Spheroidized Carbon Steels Part 1: Experimental. Met. Sci. 1981, 15, 185–192. [Google Scholar] [CrossRef]

- Maloney, J.L.; Garrison, W.M. Comparison of Void Nucleation and Growth at MnS and Ti2CS Inclusions in HY180 Steel. Scr. Metall. 1989, 23, 2097–2100. [Google Scholar] [CrossRef]

- Hall, E.O. The Deformation and Ageing of Mild Steel: III Discussion of Results. Proc. Phys. Soc. Sect. B 1951, 64, 747. [Google Scholar] [CrossRef]

- Petch, N.J. The Cleavage Strength of Polycrystals. J. Iron Steel Inst 1953, 174, 25–28. [Google Scholar]

- Meakin, J.D.; Petch, N.J. Strain-Hardening of Polycrystals: The α-Brasses. Philos. Mag. J. Theor. Exp. Appl. Phys. 1974, 29, 1149–1156. [Google Scholar] [CrossRef]

- Conrad, H.; Feuerstein, S.; Rice, L. Effects of Grain Size on the Dislocation Density and Flow Stress of Niobium. Mater. Sci. Eng. 1967, 2, 157–168. [Google Scholar] [CrossRef]

- Yasnikov, I.S.; Kaneko, Y.; Uchida, M.; Vinogradov, A. The Grain Size Effect on Strain Hardening and Necking Instability Revisited from the Dislocation Density Evolution Approach. Mater. Sci. Eng. A 2022, 831, 142330. [Google Scholar] [CrossRef]

- Thompson, A.W.; Baskes, M.I.; Flanagan, W.F. The Dependence of Polycrystal Work Hardening on Grain Size. Acta Metall. 1973, 21, 1017–1028. [Google Scholar] [CrossRef]

- Cottrell, A.H. Theoretical Aspects of Fracture. In Fracture; Chapman and Hall: London, UK, 1959; pp. 20–53. [Google Scholar]

- Bourcier, R.J.; Koss, D.A. Ductile Fracture under Multiaxial Stress States between Pairs of Holes. Adv. Fract. Res. 1979, 1, 187–194. [Google Scholar]

- Cho, H.E.; Hammi, Y.; Francis, D.K.; Stone, T.; Mao, Y.; Sullivan, K.; Wilbanks, J.; Zelinka, R.; Horstemeyer, M.F. Microstructure-Sensitive, History-Dependent Internal State Variable Plasticity-Damage Model for a Sequential Tubing Process. In Integrated Computational Materials Engineering (ICME) for Metals; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2018; pp. 199–234. ISBN 978-1-119-01837-7. [Google Scholar]

- Li, Z.; Wen, Z.; Su, F.; Zhang, R.; Li, Z. Austenite Grain Growth Behavior of a GCr15 Bearing Steel Cast Billet in the Homogenization Heat Treatment Process. J. Mater. Res. 2016, 31, 2105–2113. [Google Scholar] [CrossRef]

- Yamamoto, H. Conditions for Shear Localization in the Ductile Fracture of Void-Containing Materials. Int. J. Fract. 1978, 14, 347–365. [Google Scholar] [CrossRef]

- Tvergaard, V. On Localization in Ductile Materials Containing Spherical Voids. Int. J. Fract. 1982, 18, 237–252. [Google Scholar] [CrossRef]

- Department of the Army, Ordnance Corps, Investigation of Solidification of High Strength Steel Castings under Simulated Production Conditions Technical Report, Watertown Arsenal Rodman Laboratory. 1959. Available online: https://apps.dtic.mil/sti/citations/AD0711515 (accessed on 2 June 2023).

- Dong, M.J.; Prioul, C.; François, D. Damage Effect on the Fracture Toughness of Nodular Cast Iron: Part I. Damage Characterization and Plastic Flow Stress Modeling. Metall. Mater. Trans. A 1997, 28, 2245–2254. [Google Scholar] [CrossRef]

- Hardin, R.A.; Beckermann, C. Effect of Porosity on the Stiffness of Cast Steel. Metall. Mater. Trans. A 2007, 38, 2992–3006. [Google Scholar] [CrossRef]

- Barnett, W.J.; Troiano, A.R. Crack Propagation in the Hydrogen-Induced Brittle Fracture of Steel. JOM 1957, 9, 486–494. [Google Scholar] [CrossRef]

- Westlake, D.G. Generalized Model for Hydrogen Embrittlement. ASM Amer. Soc. Met. Trans. 1969, 62, 1000. [Google Scholar]

- Beachem, C.D. A New Model for Hydrogen-Assisted Cracking (Hydrogen “Embrittlement”). Metall. Mater. Trans. B 1972, 3, 441–455. [Google Scholar] [CrossRef]

- Ferreira, P.J.; Robertson, I.M.; Birnbaum, H.K. Hydrogen Effects on the Character of Dislocations in High-Purity Aluminum. Acta Mater. 1999, 47, 2991–2998. [Google Scholar] [CrossRef]

- Li, X.; Ma, X.; Zhang, J.; Akiyama, E.; Wang, Y.; Song, X. Review of Hydrogen Embrittlement in Metals: Hydrogen Diffusion, Hydrogen Characterization, Hydrogen Embrittlement Mechanism and Prevention. Acta Metall. Sin. Engl. Lett. 2020, 33, 759–773. [Google Scholar] [CrossRef]

- Sakamoto, Y.; Mantani, T. Effect of Quenching and Tempering on Diffusion of Hydrogen in Carbon Steel. Trans. Jpn. Inst. Met. 1976, 17, 743–748. [Google Scholar] [CrossRef]

- Chandler, M.Q.; Horstemeyer, M.F.; Baskes, M.I.; Wagner, G.J.; Gullett, P.M.; Jelinek, B. Hydrogen Effects on Nanovoid Nucleation at Nickel Grain Boundaries. Acta Mater. 2008, 56, 619–631. [Google Scholar] [CrossRef]

- Daw, M.S.; Baskes, M.I. Embedded-Atom Method: Derivation and Application to Impurities, Surfaces, and Other Defects in Metals. Phys. Rev. B 1984, 29, 6443–6453. [Google Scholar] [CrossRef]

- Angelo, J.E.; Moody, N.R.; Baskes, M.I. Trapping of Hydrogen to Lattice Defects in Nickel. Model. Simul. Mater. Sci. Eng. 1995, 3, 289. [Google Scholar] [CrossRef]

- Baskes, M.I.; Sha, X.; Angelo, J.E.; Moody, N.R. Trapping of Hydrogen to Lattice Defects in Nickel. Model. Simul. Mater. Sci. Eng. 1997, 5, 651. [Google Scholar] [CrossRef]

- Lee, Y.; Gangloff, R.P. Measurement and Modeling of Hydrogen Environment–Assisted Cracking of Ultra-High-Strength Steel. Metall. Mater. Trans. A 2007, 38, 2174–2190. [Google Scholar] [CrossRef]

- Speich, G.R.; Hu, H.; Miller, R.L. Effect of Preferred Orientation and Related Metallurgical Parameters on Mechanical Properties and Ballistic Performance of High-Hardness Steel Armor; United States Steel Corp Monroeville PA Research Laboratory: Monroeville, PA, USA, 1974. [Google Scholar]

- Hu, H.; Speich, G.R.; Miller, R.L. Effect of Crystallographic Texture, Retained Austenite, and Austenite Grain Size on the Mechanical and Ballistic Properties of Steel Armor Plates; United States Steel Corp Monroeville PA Research Laboratory: Monroeville, PA, USA, 1976. [Google Scholar]

- Bhat, M.S. Microstructure and Mechanical Properties of Aisi 4340 Steel Modified with Aluminum and Silicon. Ph.D. Thesis, University of California, Berkeley, CA, USA, 1977. [Google Scholar]

- Horn, R.M.; Ritchie, R.O. Mechanisms of Tempered Martensite Embrittlement in Low Alloy Steels. Metall. Trans. A 1978, 9, 1039–1053. [Google Scholar] [CrossRef]

- Taguchi, G. System of Experimental Design; Engineering Methods to Optimize Quality and Minimize Cost, 1st ed.; Experimental Design; UNIPUB/Kraus International Publications: White Planes, NY, USA, 1987; ISBN 978-0-527-91621-3. [Google Scholar]

- US Army. Military Specification Armor Plate, Steel, Wrought, Homogeneous; MIL-A-12560J (MR); U.S. Army Research Laboratory: Adelphi, MD, USA, 2009. [Google Scholar]

- Baker, A.; Lauta, F.; Wei, R. Relationships Between Microstructure and Toughness in Quenched and Tempered Ultrahigh-Strength Steels. In Structure and Properties of Ultrahigh-Strength Steels; ASTM International: Singapore, 1965. [Google Scholar]

- Parker, E.R.; Zackay, V.F. Microstructural Features Affecting Fracture Toughness of High Strength Steels. Eng. Fract. Mech. 1975, 7, 371–375. [Google Scholar] [CrossRef]

- Cowie, J.G.; Azrin, M.; Olson, G.B. Microvoid Formation during Shear Deformation of Ultrahigh Strength Steels. Metall. Trans. A 1989, 20, 143–153. [Google Scholar] [CrossRef]

- Ayer, R.; Machmeier, P.M. Transmission Electron Microscopy Examination of Hardening and Toughening Phenomena in Aermet 100. Metall. Mater. Trans. A 1993, 24, 1943–1955. [Google Scholar] [CrossRef]

- Doherty, R.D.; Hughes, D.A.; Humphreys, F.J.; Jonas, J.J.; Jensen, D.J.; Kassner, M.E.; King, W.E.; McNelley, T.R.; McQueen, H.J.; Rollett, A.D. Current Issues in Recrystallization: A Review. Mater. Sci. Eng. A 1997, 238, 219–274. [Google Scholar] [CrossRef]

- Takaki, S.; Kawasaki, K.; Kimura, Y. Mechanical Properties of Ultra Fine Grained Steels. J. Mater. Process. Technol. 2001, 117, 359–363. [Google Scholar] [CrossRef]

| Case | Object | Shape | Thickness (mm) | Width (mm) | Diameter (mm) | # Elements |

|---|---|---|---|---|---|---|

| 1 | Projectile | Sphere | - | - | 12.70 | 11,424 |

| Target | Square | 9.53 | 127.0 | - | 206,400 | |

| 2 | Projectile | Sphere | - | - | 12.70 | 10,136 |

| Target | Square | 12.70 | 170.0 | - | 238,680 | |

| 3 | Projectile | Cylinder | - | 12.70 | 6.35 | 3840 |

| Target | Square | 6.35 | 63.50 | - | 97,344 |

| Study | Material | Number Density (#/mm2) | Diameter (μm) | Vol. Fraction |

|---|---|---|---|---|

| [101] | 4340 Steel | 800–4000 | 4.5–9.7 | 0.060 |

| [102] | 0.17-0.44 C Steel | 430 | 14.0 | 0.066 |

| [103] | HY 180 Steel | 2600–6000 | 0.20–0.32 | 0.00019–0.00021 |

| [82] | RHA Steel | 170 | 7.0 | 0.00065 |

| Brinell Hardness (BHN) | ||||||

|---|---|---|---|---|---|---|

| Description | 250 | 350 | 450 | 500 | 550 | |

| Yield (MPa) | - | 700 | 1075 | 1250 | 1400 | 1500 |

| UTS (MPa) | - | 870 | 1150 | 1392 | 1600 | 1740 |

| C03 (MPa) | Model constant affecting yield | 690 | 1003 | 1203 | 1300 | 1403 |

| C09 (MPa) | Kinematic hardening modulus | 4416 | 4416 | 4416 | 5216 | 6016 |

| C15 (MPa) | Isotropic hardening modulus | 700 | 700 | 700 | 1000 | 1300 |

| Parameter Levels | |||||

|---|---|---|---|---|---|

| Parameter | +1 | +0.5 | 0 | −0.5 | −1 |

| Particle No. Density (#/mm2) | 250 | 500 | 1000 | 2000 | 4000 |

| Particle Diameter (μm) | 0.1 | 0.5 | 1.0 | 5.0 | 10.0 |

| Grain Diameter (μm) | 1.0 | 5.0 | 10.0 | 50.0 | 100.0 |

| Initial Porosity | 10−6 | 10−5 | 10−4 | 10−3 | 10−2 |

| Lattice Hydrogen (APPM) | 10−5 | 10−4 | 2.5 × 10−4 | 5 × 10−4 | 10−3 |

| Brinell Hardness | 250 | 350 | 450 | 500 | 550 |

| Test | Particle No. Density (μm) | Particle Diameter (μm) | Grain Diameter (μm) | Initial Porosity | Lattice Hydrogen (APPM) | Brinell Hardness (BHN) | Residual Velocity (m/s) |

|---|---|---|---|---|---|---|---|

| 7 | 500 | 0.5 | 10 | 10−3 | 10−3 | 250 | 589.60 |

| 8 | 500 | 1.0 | 50 | 10−2 | 10−5 | 350 | 518.94 |

| 13 | 1000 | 1.0 | 100 | 10−5 | 5 × 10−4 | 250 | 559.44 |

| 19 | 2000 | 5.0 | 5 | 10−2 | 2.5 × 10−4 | 250 | 521.16 |

| 25 | 4000 | 10.0 | 50 | 10−4 | 10−4 | 250 | 560.12 |

| 9 | 500 | 5.0 | 100 | 10−6 | 10−4 | 450 | 0 |

| 10 | 500 | 10.0 | 1 | 10−5 | 2.5 × 10−4 | 500 | 0 |

| 15 | 1000 | 10.0 | 5 | 10−3 | 10−5 | 450 | 0 |

| 18 | 2000 | 1.0 | 1 | 10−3 | 10−4 | 550 | 0 |

| 24 | 4000 | 5.0 | 10 | 10−6 | 10−5 | 550 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peterson, L.; Horstemeyer, M.; Lacy, T.; Moser, R. Using an Internal State Variable Model Framework to Investigate the Influence of Microstructure and Mechanical Properties on Ballistic Performance of Steel Alloys. Metals 2023, 13, 1285. https://doi.org/10.3390/met13071285

Peterson L, Horstemeyer M, Lacy T, Moser R. Using an Internal State Variable Model Framework to Investigate the Influence of Microstructure and Mechanical Properties on Ballistic Performance of Steel Alloys. Metals. 2023; 13(7):1285. https://doi.org/10.3390/met13071285

Chicago/Turabian StylePeterson, Luke, Mark Horstemeyer, Thomas Lacy, and Robert Moser. 2023. "Using an Internal State Variable Model Framework to Investigate the Influence of Microstructure and Mechanical Properties on Ballistic Performance of Steel Alloys" Metals 13, no. 7: 1285. https://doi.org/10.3390/met13071285

APA StylePeterson, L., Horstemeyer, M., Lacy, T., & Moser, R. (2023). Using an Internal State Variable Model Framework to Investigate the Influence of Microstructure and Mechanical Properties on Ballistic Performance of Steel Alloys. Metals, 13(7), 1285. https://doi.org/10.3390/met13071285