Fatigue Crack Growth Behavior and Failure Mechanism of Nickel-Based Alloy GH4169 under Biaxial Load Based on Fatigue Test of Cruciform Specimen

Abstract

1. Introduction

1.1. Background

1.2. Purpose

2. Experimental Procedures

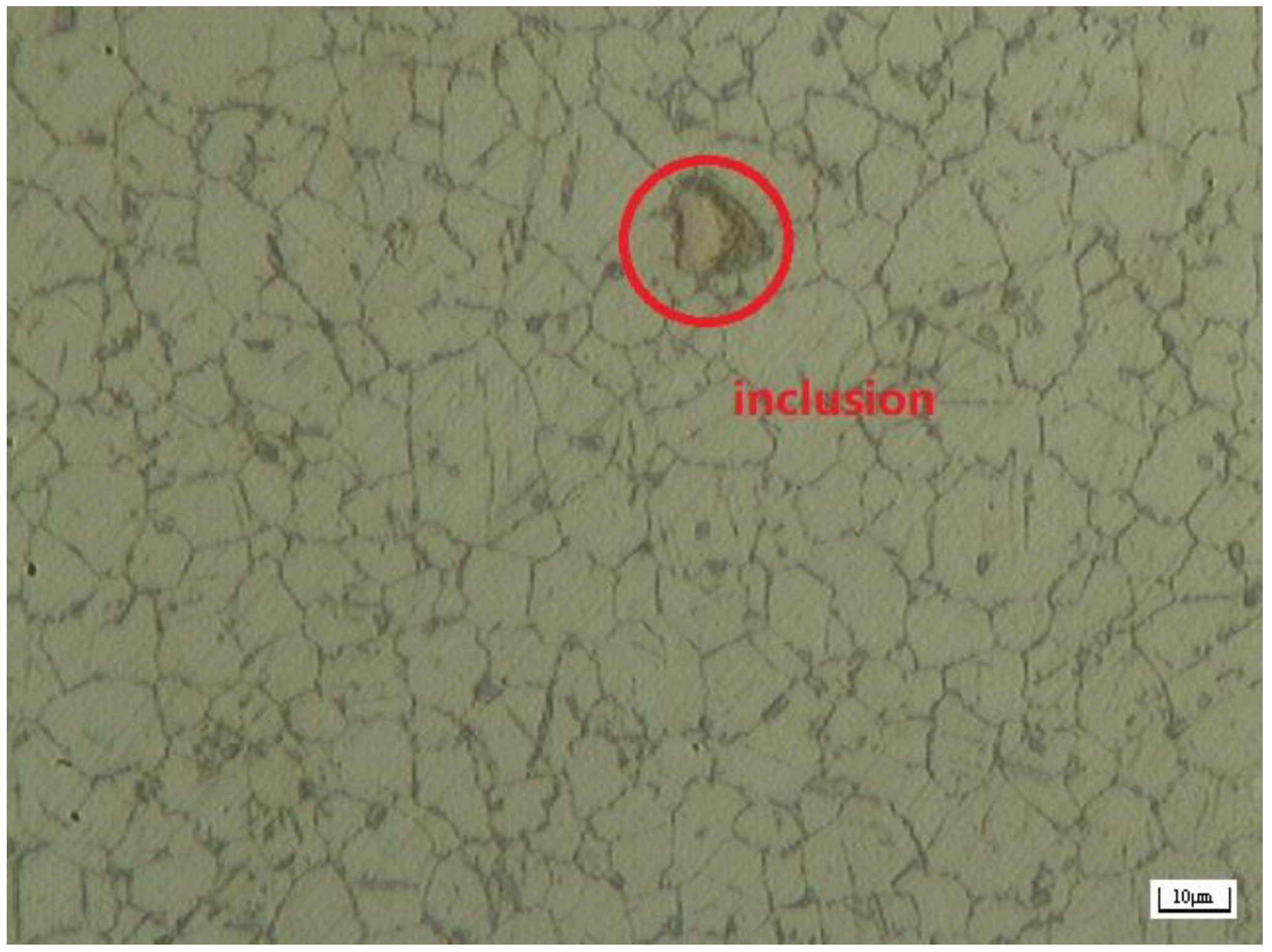

2.1. Materials and Mechanical Properties

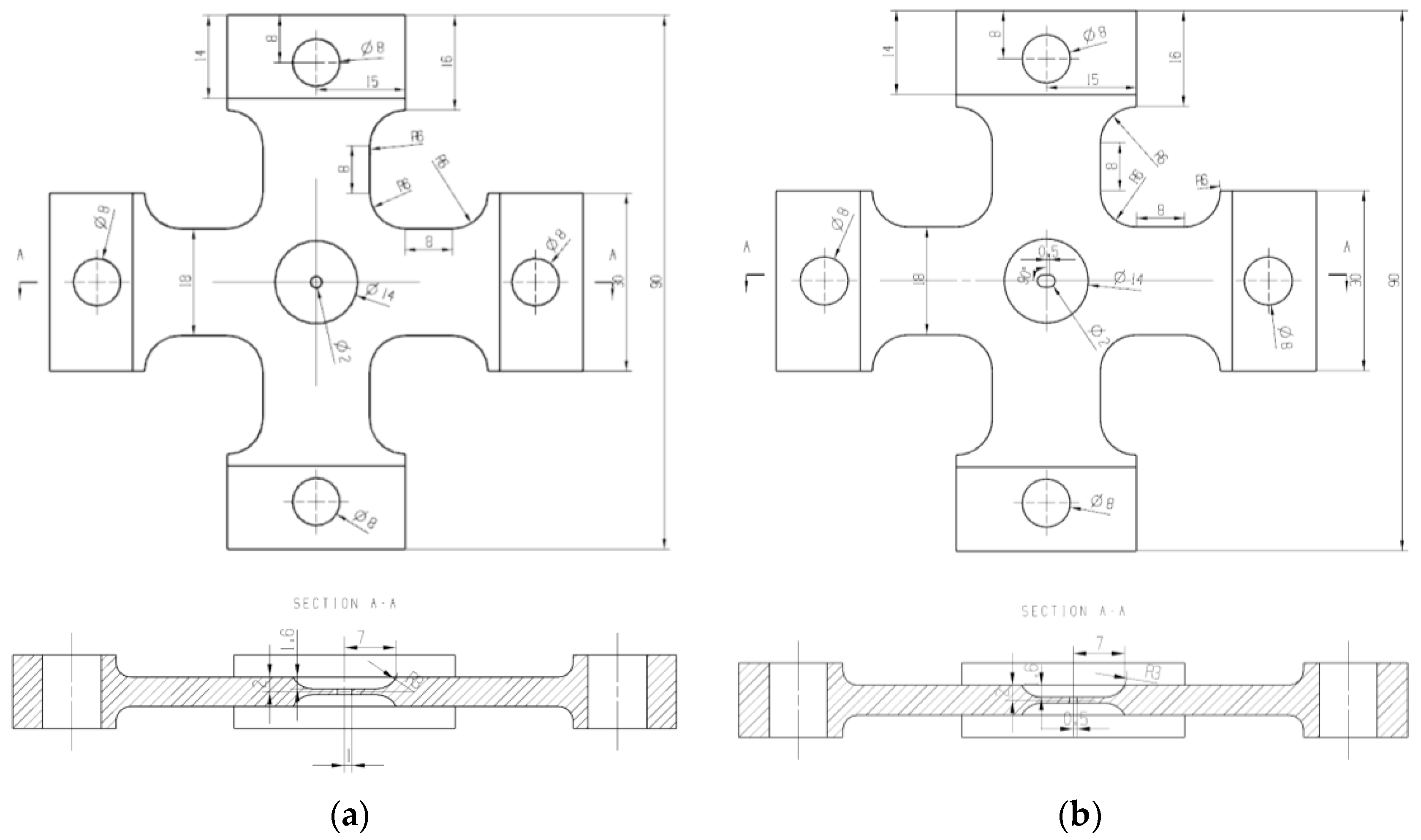

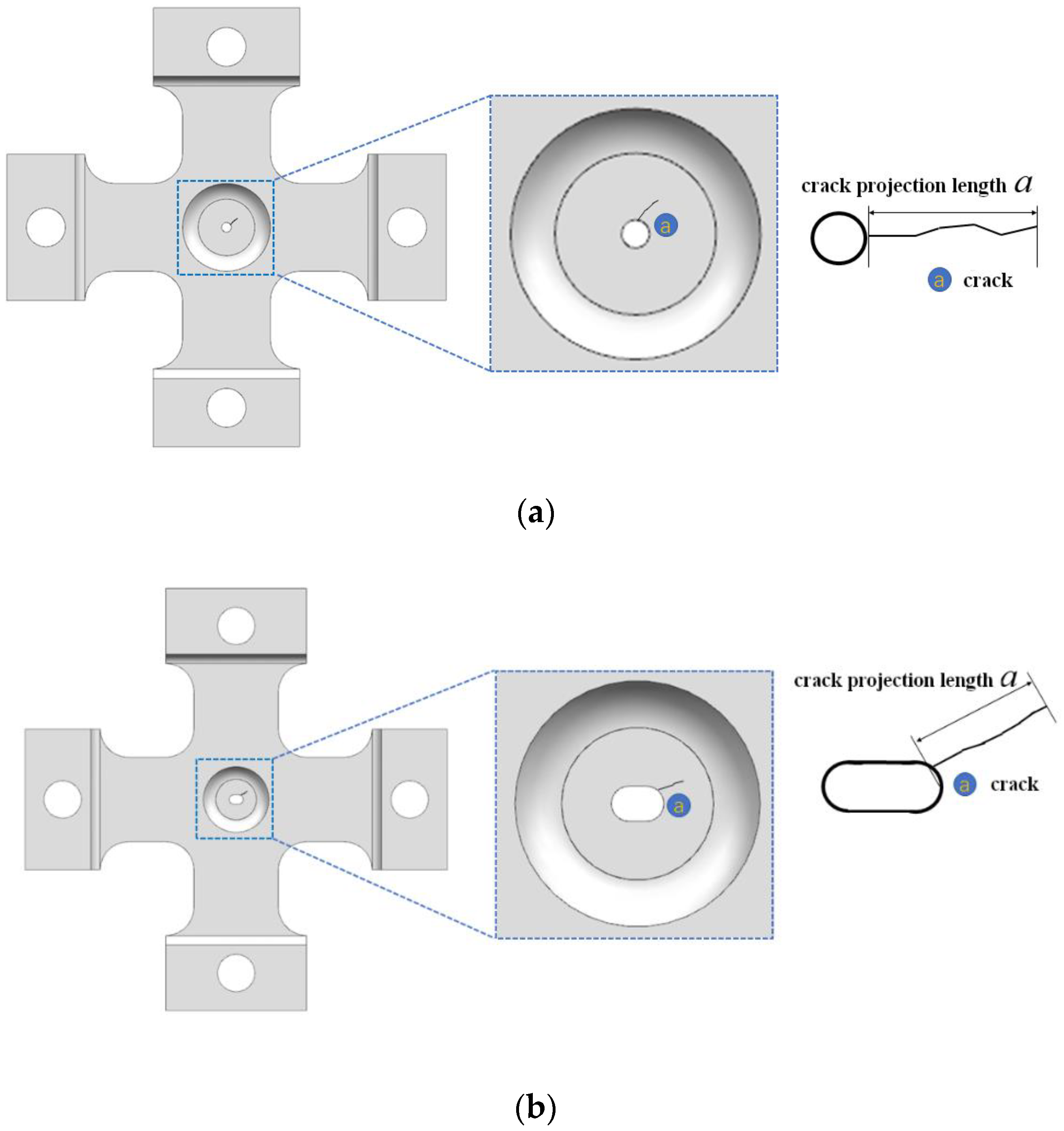

2.2. Preparation of Specimens

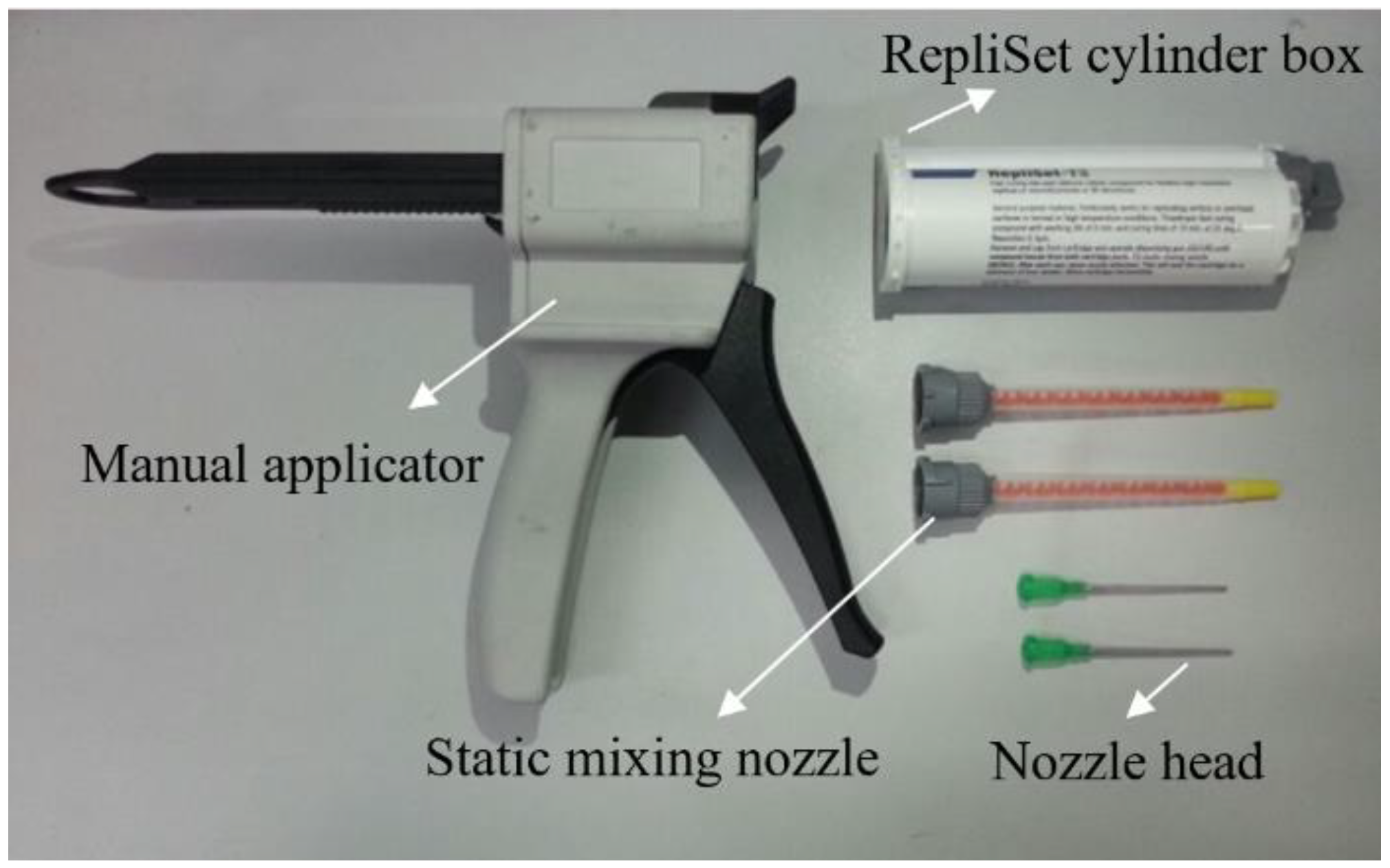

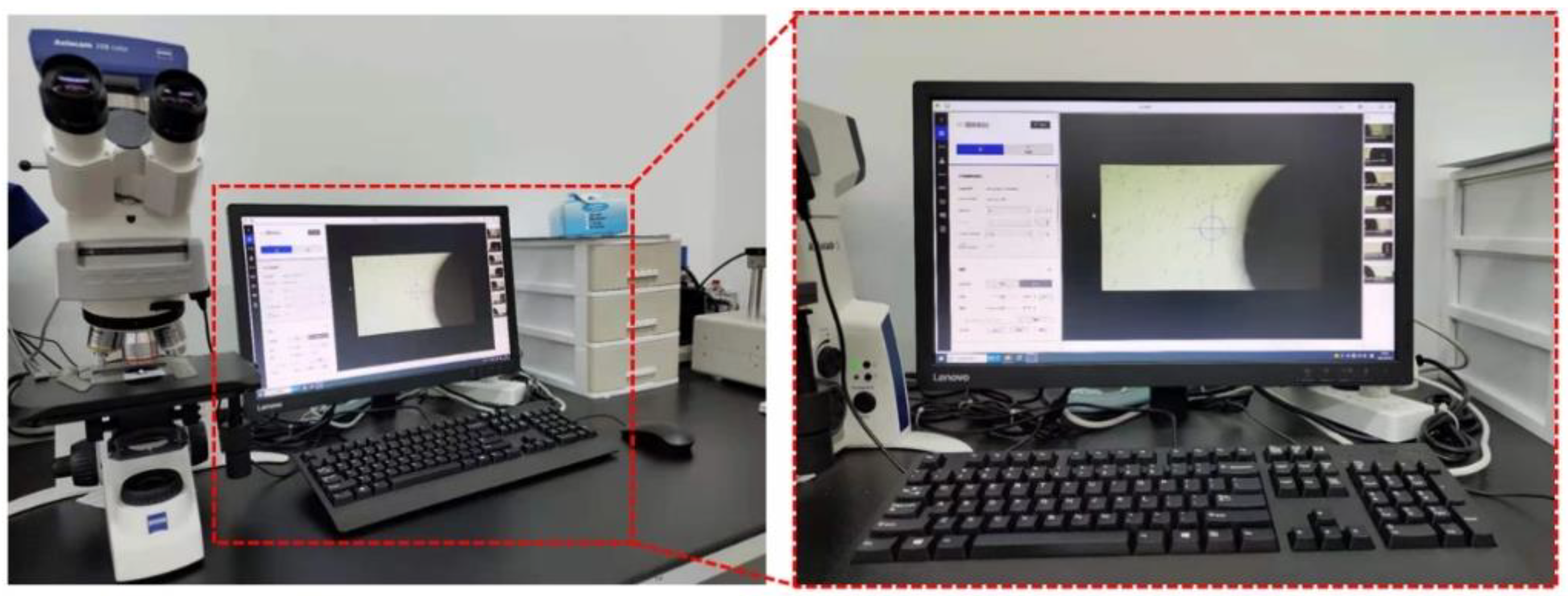

2.3. Fatigue Tests and Replication Method

3. Experimental Results and Discussion

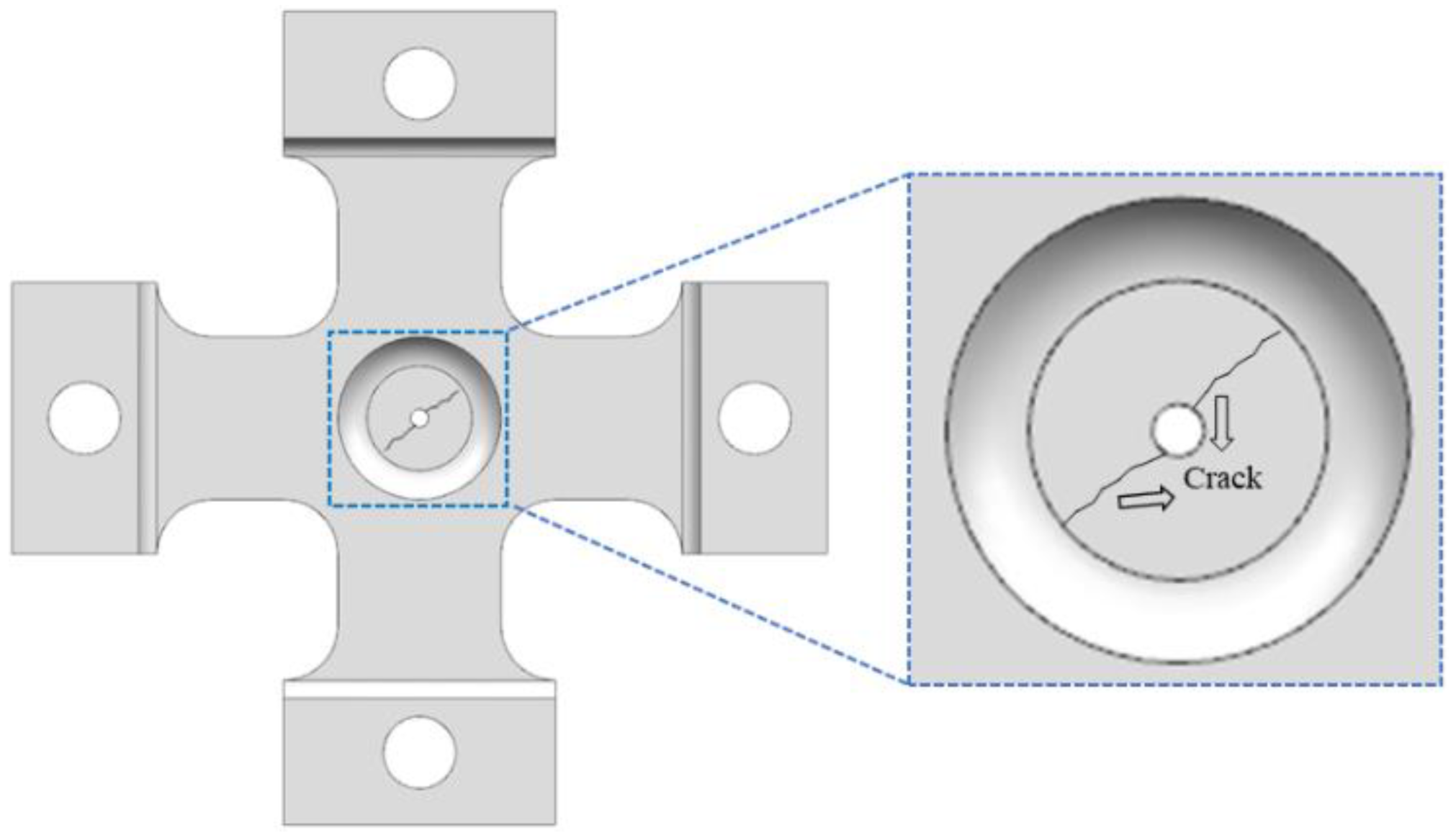

3.1. Result of Fatigue Tests

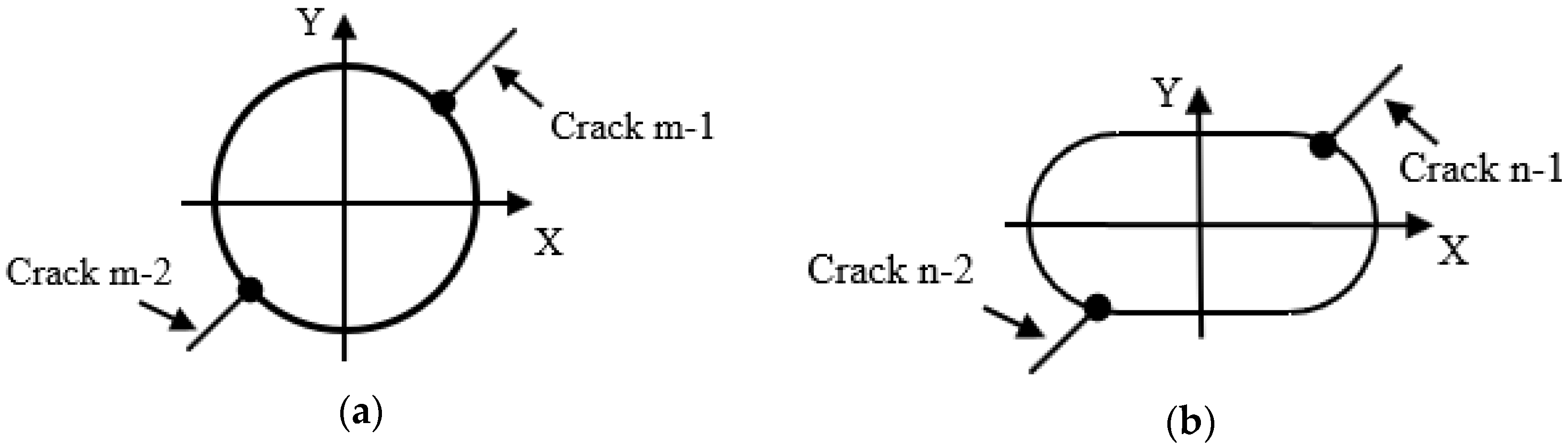

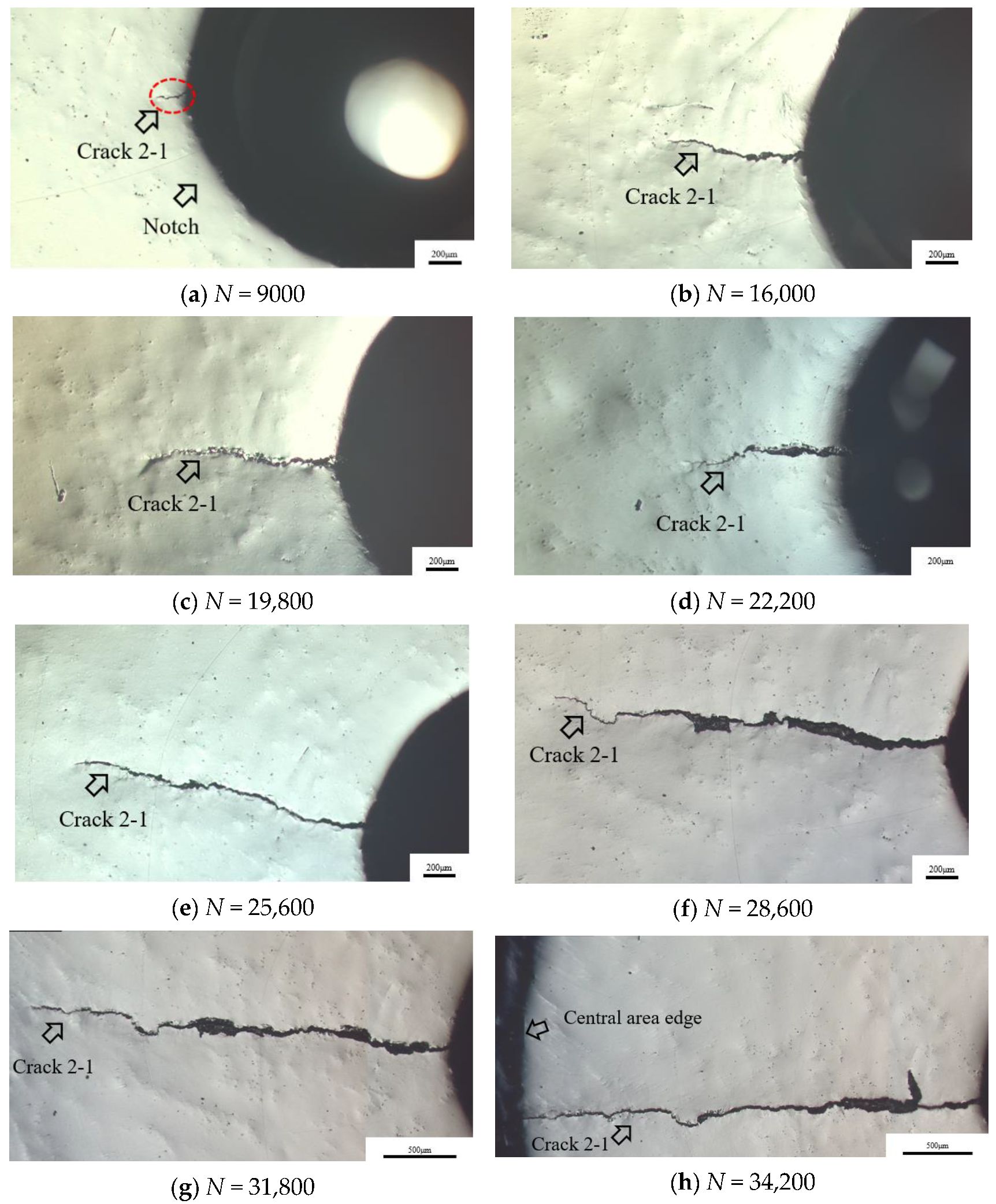

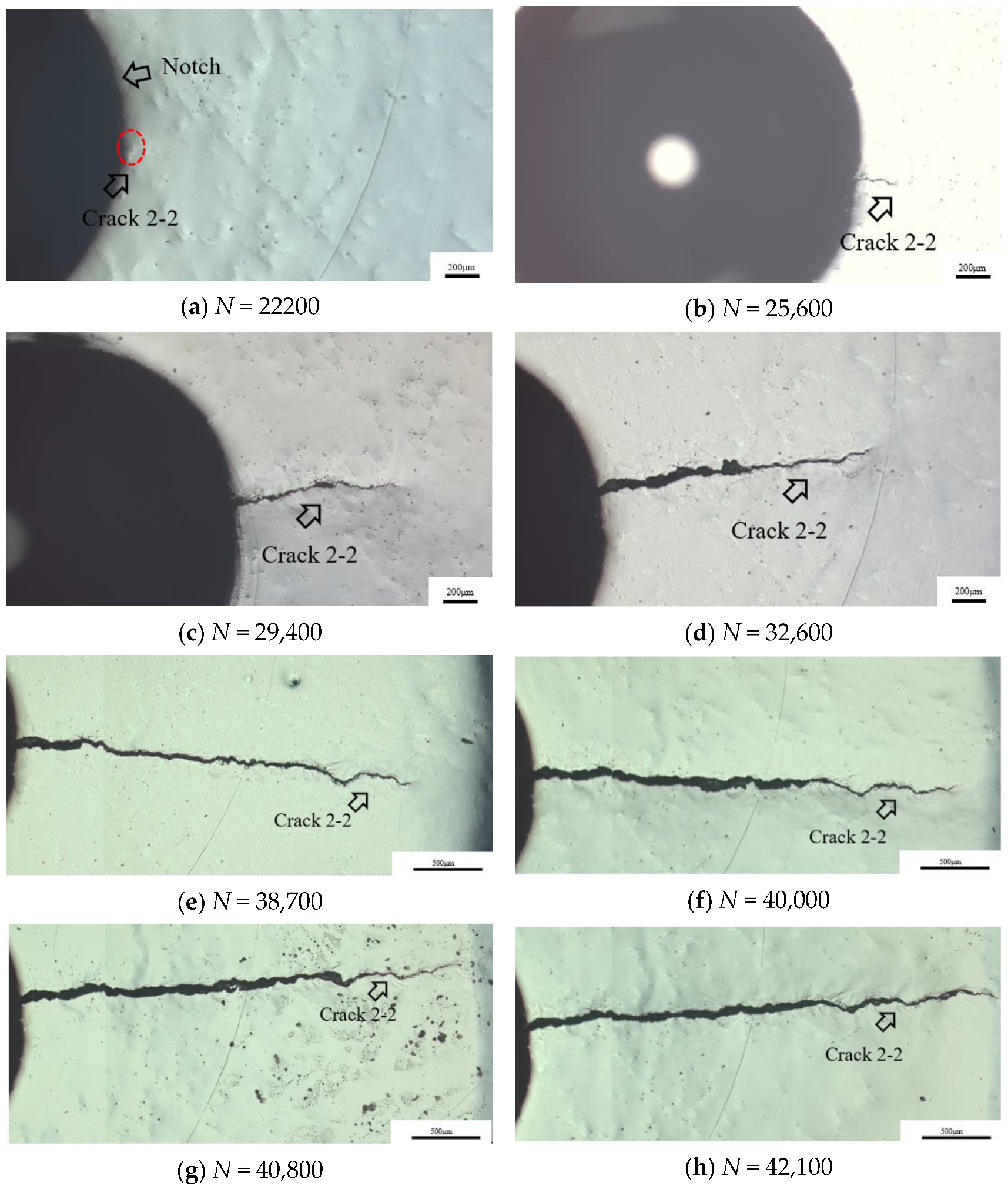

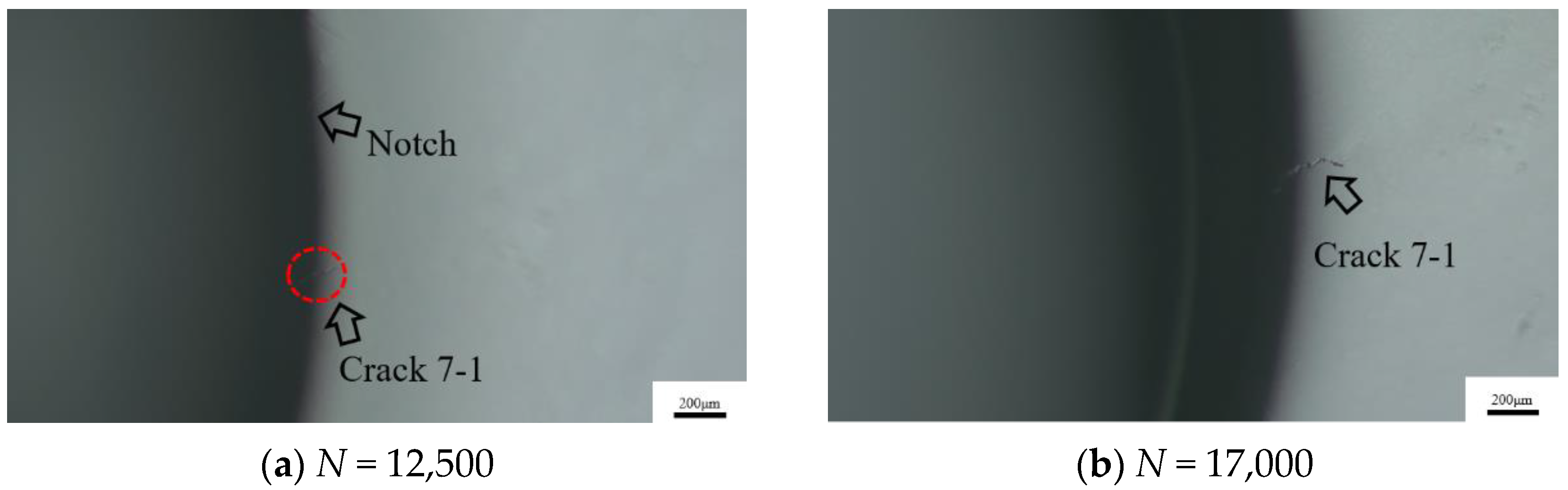

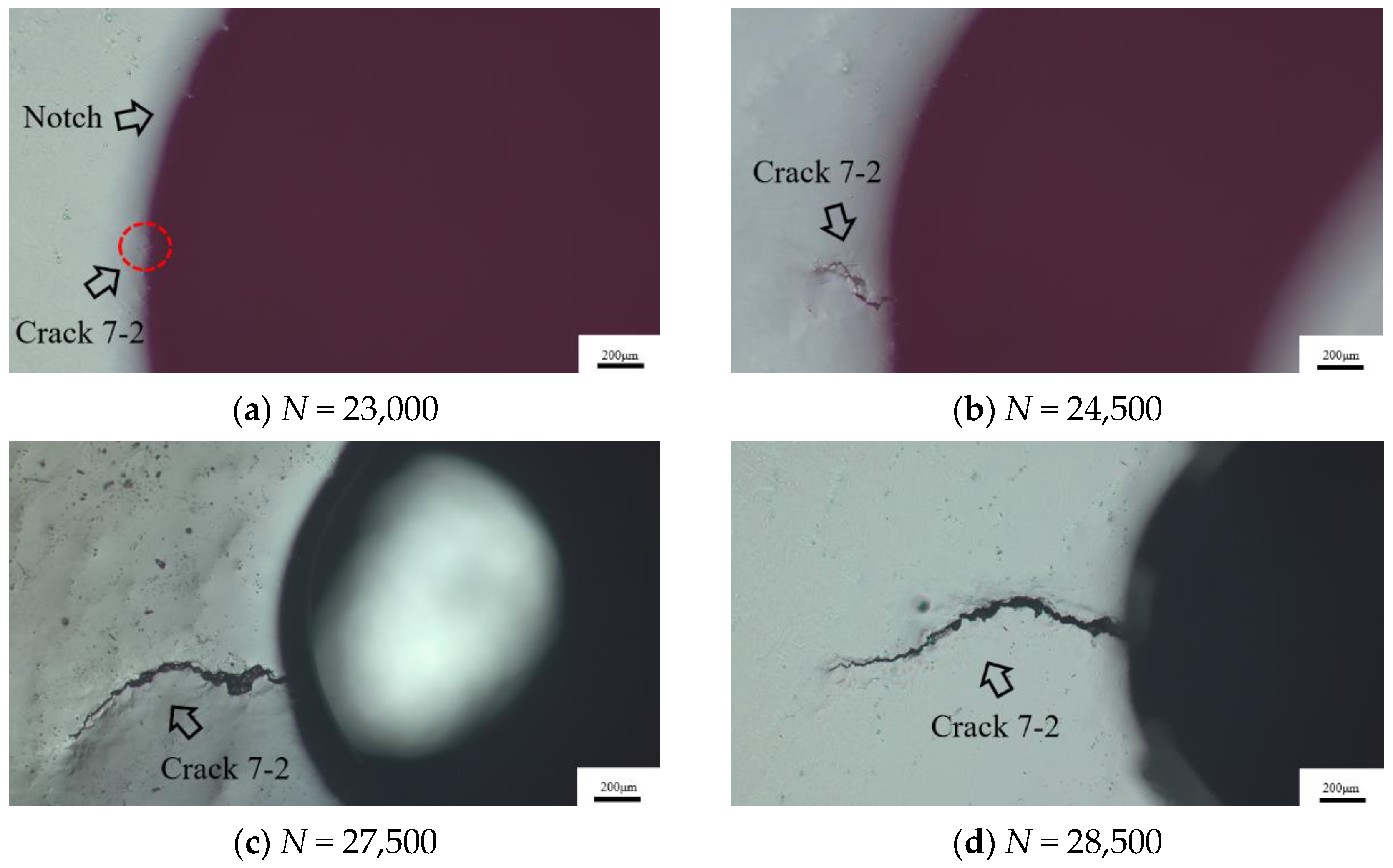

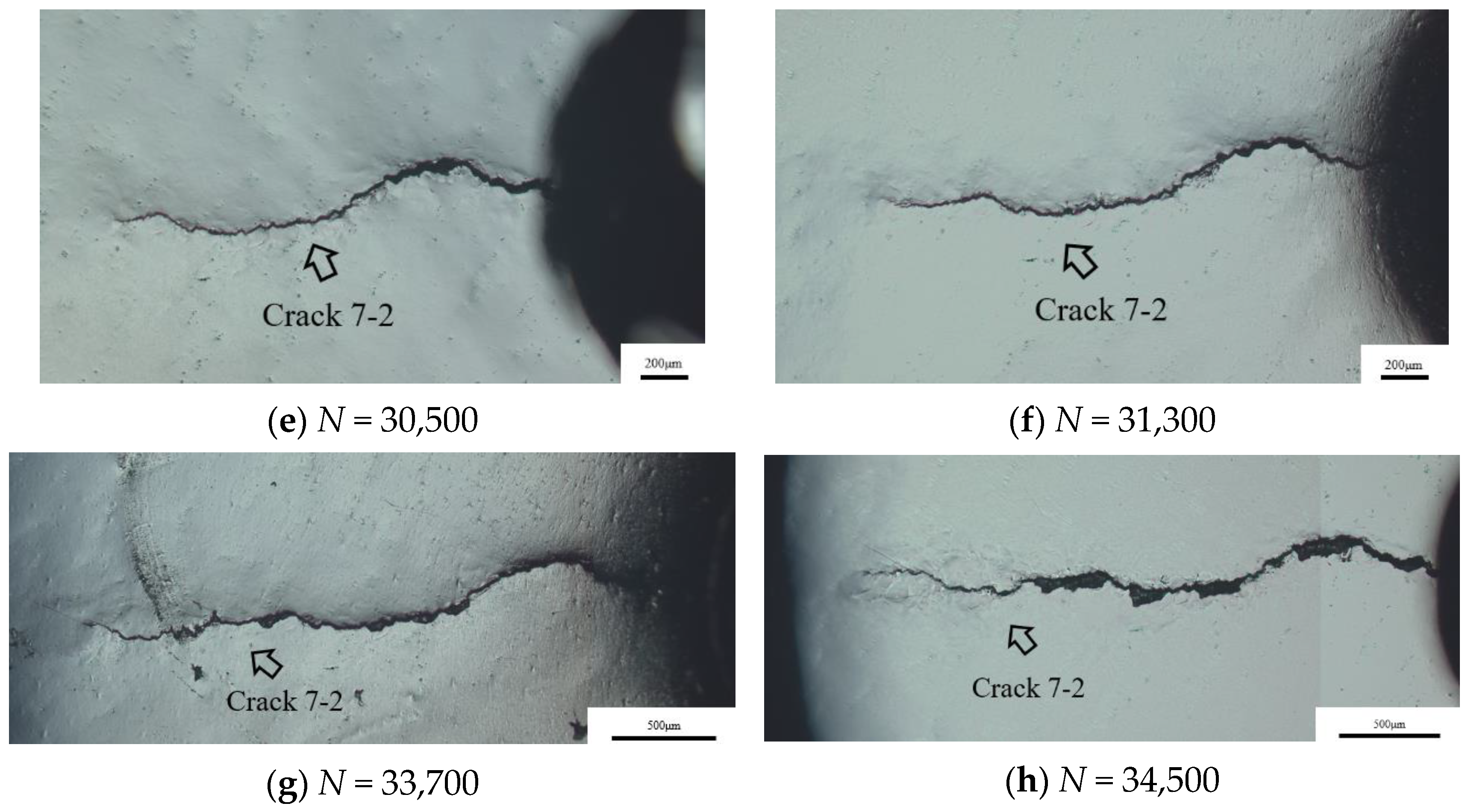

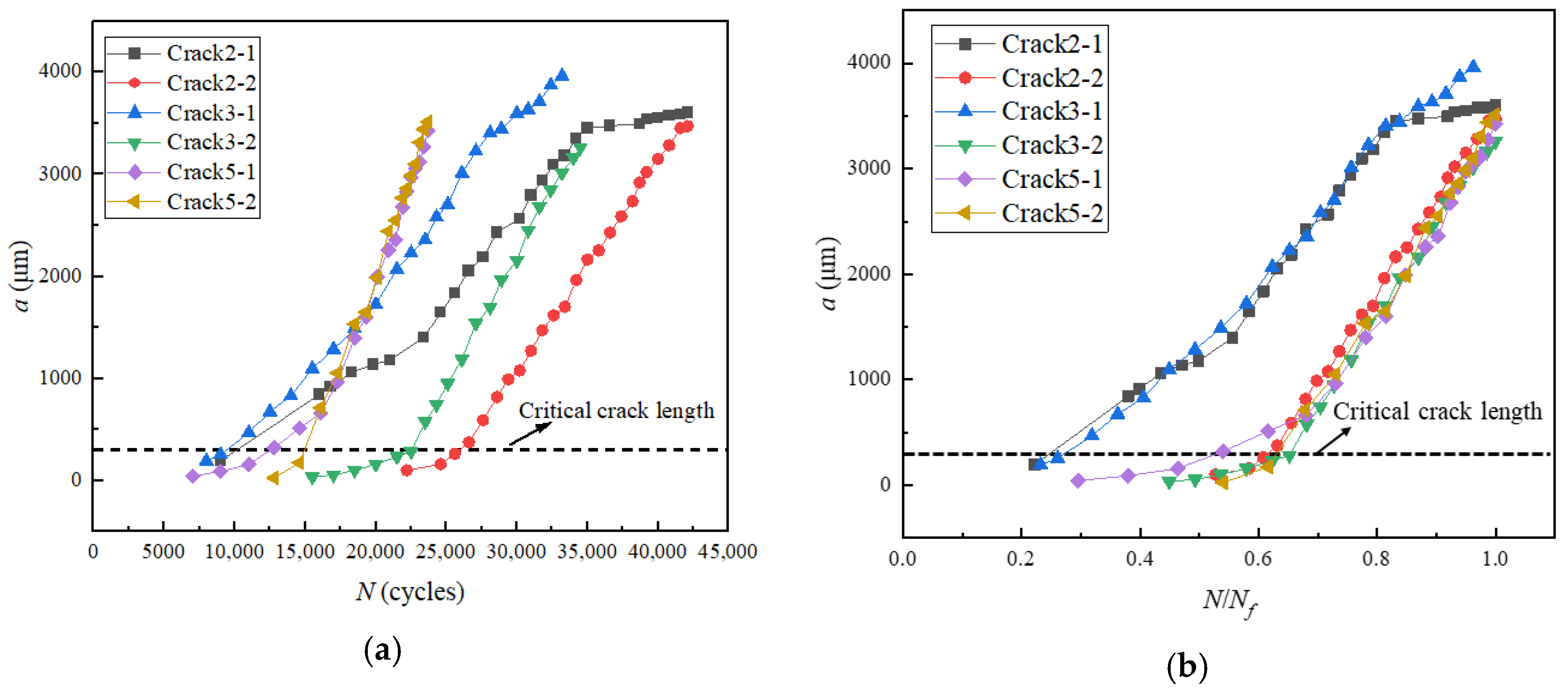

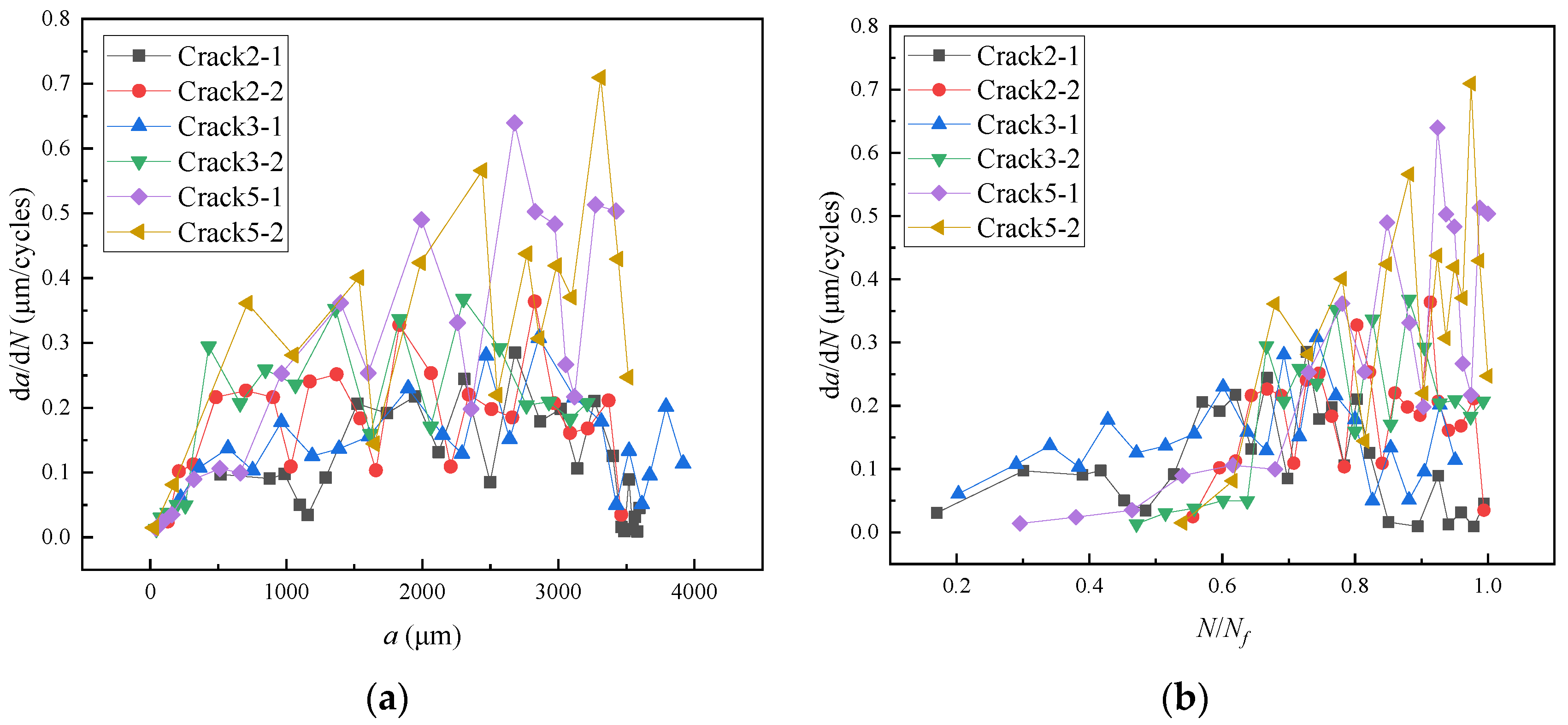

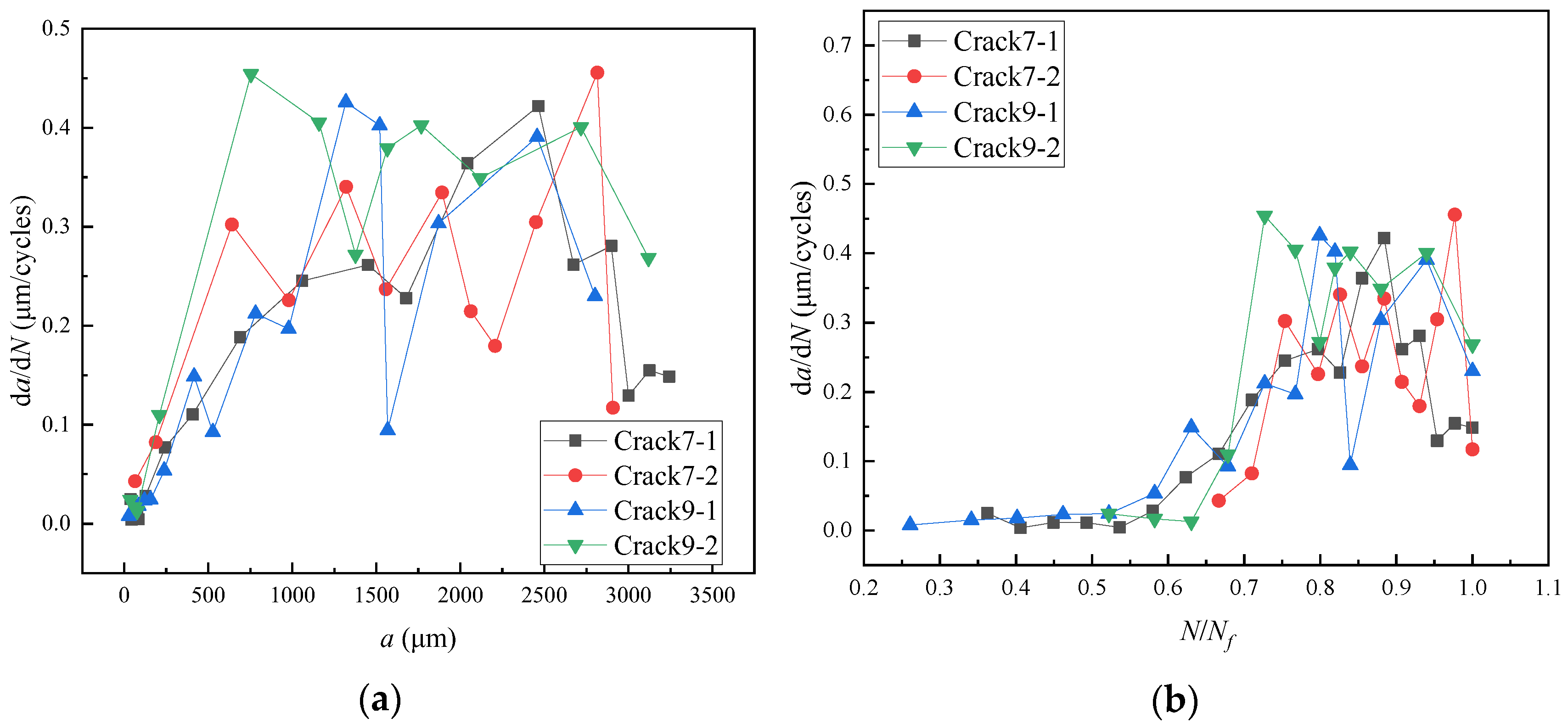

3.2. Biaxial Fatigue Crack Growth Behavior

3.3. Biaxial Fatigue Crack Deflection Behavior

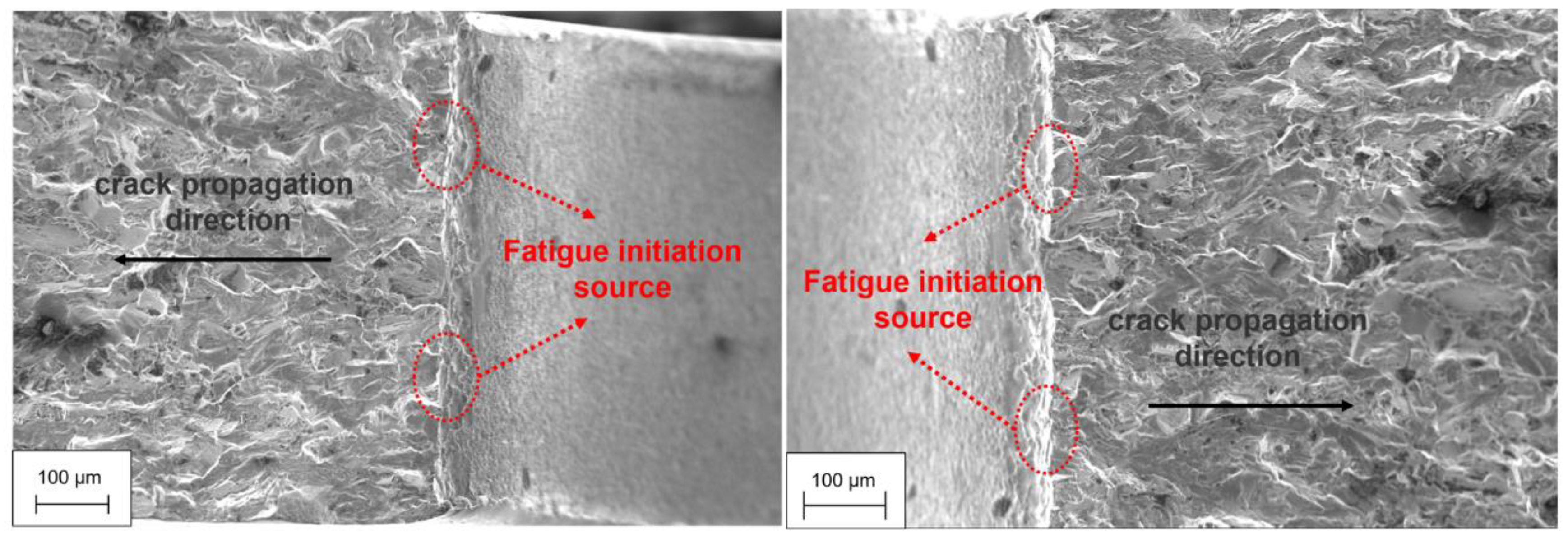

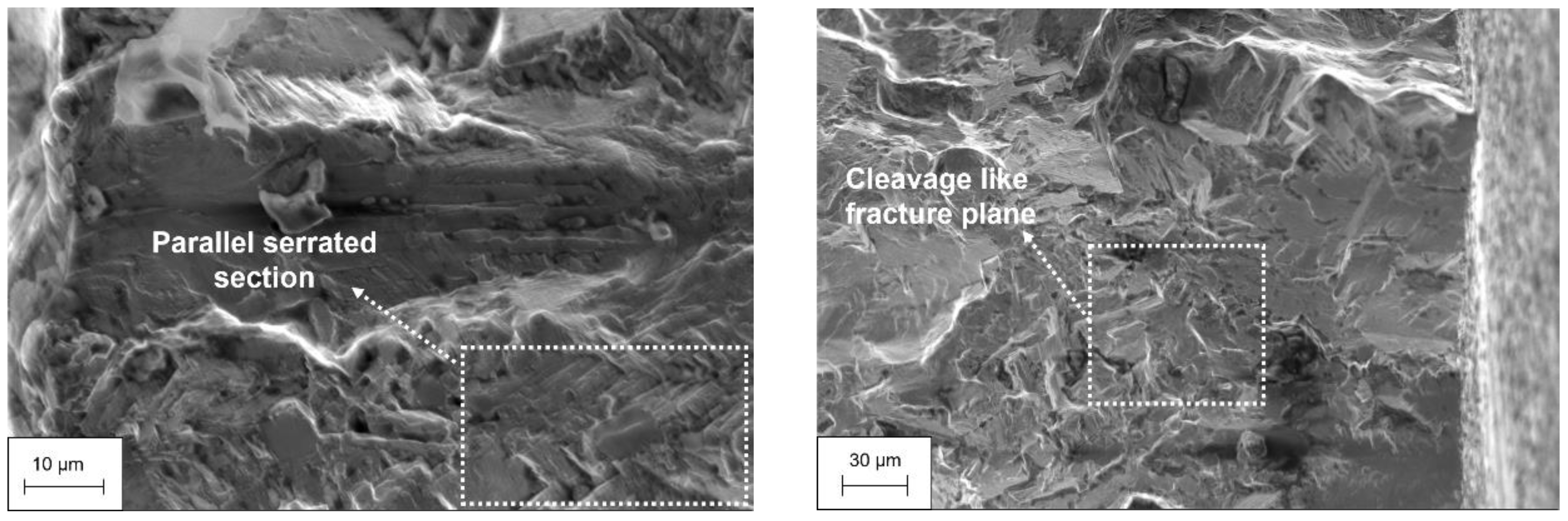

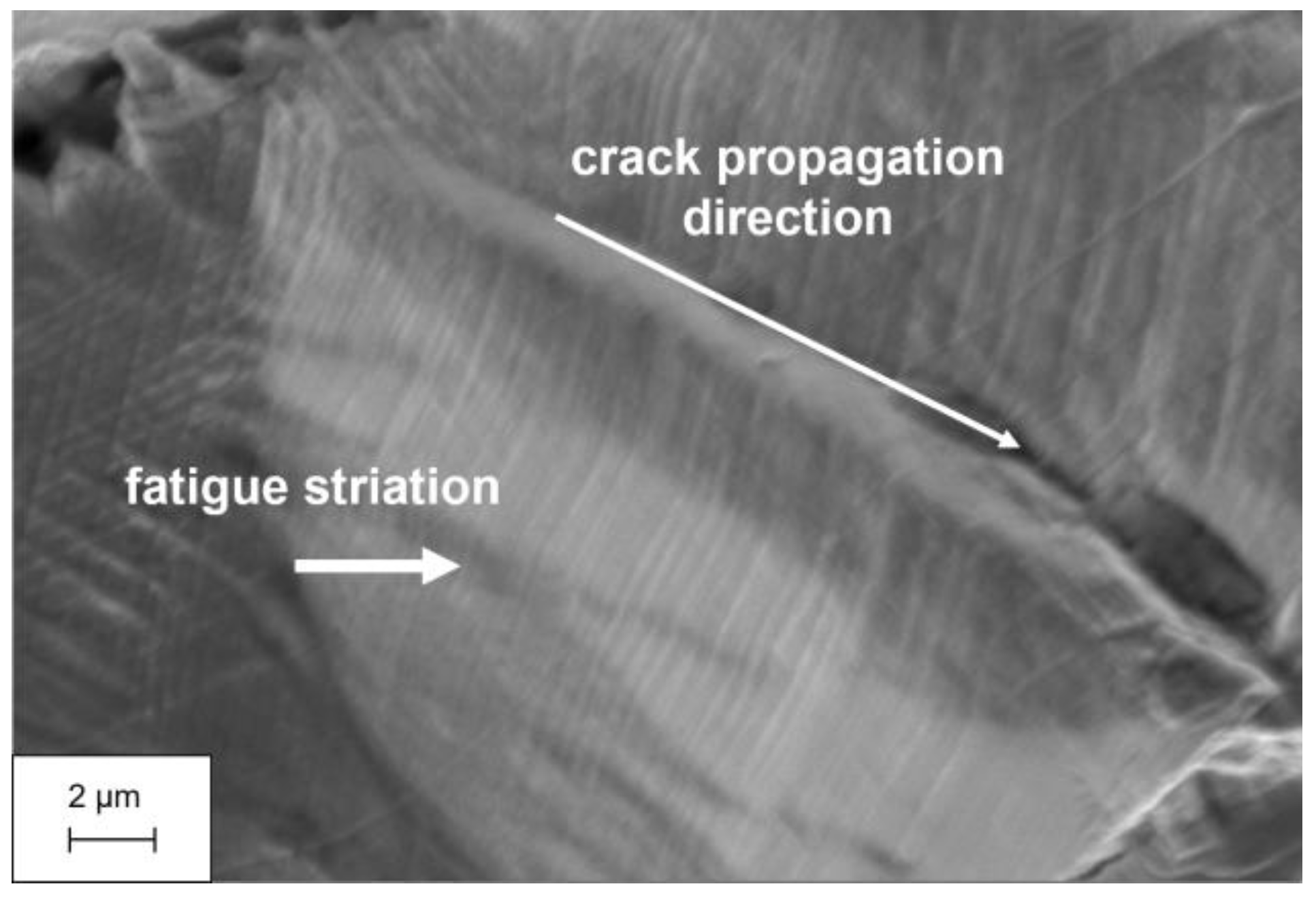

3.4. Fracture Morphology Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wolf, C.H.; Henkel, S.; Burgold, A.; Qiu, Y.X.; Kuna, M.; Biermann, H. Investigation of fatigue crack growth under in-phase loading as well as phase-shifted loading using cruciform specimens. Int. J. Fatigue 2019, 124, 595–617. [Google Scholar] [CrossRef]

- Meng, Y.X.; Gao, H.; Yan, Y.Z.; Gao, L.L. Effects of phase difference and stress ratio on biaxial tension–tension fatigue crack propagation behavior of rolled ZK60 magnesium alloy. Mater. Today Commun. 2020, 24, 101159. [Google Scholar] [CrossRef]

- Abecassis, M.; Köster, A.; Esin, V.A.; Chiaruttini, V.; Maurel, V. Crack Growth Behavior in Dissimilar Welded Ti Based Alloys under Biaxial Fatigue Loading. Int. J. Fatigue 2018, 118, 209–224. [Google Scholar] [CrossRef]

- Misak, H.E.; Perel, V.Y.; Sabelkin, V.; Mall, S. Biaxial tension–tension fatigue crack growth behavior of 2024-T3 under ambient air and salt water environments. Eng. Fract. Mech. 2014, 118, 83–97. [Google Scholar] [CrossRef]

- Limin, S.; Chao, Z. Experimental Research on Turning of Superalloy GH4169 under High Pressure Cooling Condition. Integr. Ferroelectr. 2020, 207, 75–85. [Google Scholar] [CrossRef]

- Xu, R.F.; Zhou, Y.X.; Li, X.; Yang, S.L.; Han, K.N.; Wang, S.J. The Effect of Milling Cooling Conditions on the Surface Integrity and Fatigue Behavior of the GH4169 Superalloy. Metals 2019, 9, 1179. [Google Scholar] [CrossRef]

- Wu, D.X.; Zhang, D.H.; Yao, C.F. Effect of Turning and Surface Polishing Treatments on Surface Integrity and Fatigue Performance of Nickel-Based Alloy GH4169. Metals 2018, 8, 549. [Google Scholar] [CrossRef]

- Zhu, L.; Wu, Z.R.; Hu, X.T.; Song, Y.D. Small Fatigue Crack Growth Behavior of Nickel-Based Alloy GH4169. J. Aeronaut. Power 2017, 32, 1984–1991. Available online: https://www.webofscience.com/wos/alldb/full-record/CSCD:6079438 (accessed on 23 August 2017).

- Zhu, L.; Hu, X.T.; Jiang, R.; Song, Y.D.; Qu, S.D. An investigation of small fatigue crack behavior in titanium alloy TC4 under different stress levels. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2019, 233, 5567–5578. [Google Scholar] [CrossRef]

- Chaves, V.; Beretta, G.; Balbín, J.A.; Navarro, A. Fatigue life and crack growth direction in 7075-T6 aluminium alloy specimens with a circular hole under biaxial loading. Int. J. Fatigue 2019, 125, 222–236. [Google Scholar] [CrossRef]

- Zhu, L.; Wu, Z.R.; Hu, X.T.; Song, Y.D. Investigation of small fatigue crack initiation and growth behaviour of nickel base superalloy GH4169. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 1150–1160. [Google Scholar] [CrossRef]

- Zhu, L.; Wu, Z.; Hu, X.T.; Song, Y.D. Comparative study of small crack growth behavior between specimens with and without machining-induced residual stress of alloy GH4169. J. Mech. Sci. Technol. 2018, 32, 5251–5261. [Google Scholar] [CrossRef]

- Deng, G.J.; Tu, S.T.; Zhang, X.C.; Wang, Q.Q.; Qin, C.H. Grain size effect on the small fatigue crack initiation and growth mechanisms of nickel-based superalloy GH4169. Eng. Fract. Mech. 2015, 134, 433–450. [Google Scholar] [CrossRef]

- Suresh, S. Crack deflection: Implications for the growth of long and short fatigue cracks. Metall. Trans. A 1983, 14, 2375–2385. [Google Scholar] [CrossRef]

- Wu, Z.R.; Liu, F.L.; Li, X.; Fang, L.; Song, Y.D. Multistage fatigue modeling of single-edge-notch tension specimens for Ni-based superalloy GH4169. Adv. Mech. Eng. 2017, 9, 168781401772994. [Google Scholar] [CrossRef]

- Neerukatti, R.K.; Datta, S.; Chattopadhyay, A.; Iyyer, N.; Phan, N. Fatigue crack propagation under in-phase and out-of-phase biaxial loading. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 387–399. [Google Scholar] [CrossRef]

- Elber, W. The Significance of Fatigue Crack Closure; ASTM International: West Conshohocken, PA, USA, 1971; p. 486. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, H.; Gao, K.Y.; Wen, S.P.; Zhang, P.P.; Nie, Z.R. Fatigue Fracture Behavior of Cold Rolled 5E06 and 5E83 Aluminum Alloy Plate. Chin. J. Rare Met. 2011, 35, 791–798. Available online: https://www.webofscience.com/wos/alldb/full-record/CSCD:4369885 (accessed on 1 June 2011).

- Bui, T.P.; Miyashita, Y.; Mutoh, Y.; Morikage, Y.; Tagawa, T.; Handa, T.; Otsuka, Y. Fatigue crack deflection and branching behavior of low carbon steel under mechanically large grain condition. Int. J. Fatigue 2021, 148, 106217. [Google Scholar] [CrossRef]

- Bui, T.P.; Miyashita, Y.; Morikage, Y.; Tagawa, T.; Handa, T.; Mutoh, Y.; Otsuka, Y. Contributions of Grain Size and Crystal Orientation to Fatigue Crack Deflection and Branching Behavior in Low Carbon Steel Plates. ISIJ Int. 2020, 61, 424–433. [Google Scholar] [CrossRef]

- Caton, M.J.; Jhon, R.; Porter, W.J.; Burba, M.E. Stress ratio effects on small fatigue crack growth in Ti-6Al-4V. Int. J. Fatigue 2011, 38, 36–45. [Google Scholar] [CrossRef]

| Element | Nb | Mo | Ti | Cr | Fe | Ni |

|---|---|---|---|---|---|---|

| Wt/% | 5.67 | 3.84 | 1.40 | 19.14 | 17.20 | 52.76 |

| Specimen | Notch Shape | Stress Radio | FA, max (kN) | Test Condition |

|---|---|---|---|---|

| 1 | circular notch | 0.1 | 30 | Non-SR |

| 2 | circular notch | 0.1 | 30 | SR |

| 3 | circular notch | 0.1 | 30 | SR |

| 4 | circular notch | 0.1 | 33 | Non-SR |

| 5 | circular notch | 0.1 | 33 | SR |

| 6 | waist round notch | 0.1 | 30 | Non-SR |

| 7 | waist round notch | 0.1 | 30 | SR |

| 8 | waist round notch | 0.1 | 33 | Non-SR |

| 9 | waist round notch | 0.1 | 33 | SR |

| Specimen | Nf (Cycles) | Nini (Cycles) | acrack-ini (μm) | Nini/Nf | Number of Cracks |

|---|---|---|---|---|---|

| 1 | 37,784 | / | / | / | 2 |

| 2 | 42,100 | 9000 | 193.9 | 21.38% | 2 |

| 3 | 34,500 | 7700 | 193 | 22.32% | 2 |

| 4 | 31,500 | / | / | / | 2 |

| 5 | 23,700 | 7000 | 42.4 | 29.53% | 2 |

| 6 | 34,000 | / | / | / | 2 |

| 7 | 34,500 | 12,500 | 37.4 | 36.23% | 2 |

| 8 | 21,500 | / | / | / | 2 |

| 9 | 24,900 | 8500 | 58.5 | 34.14% | 2 |

| Specimen Number | Nf (Cycles) | Ncrack-2-ini (Cycles) | Ncrack-2-ini/Nf | acrack-2-ini (μm) |

|---|---|---|---|---|

| 2 | 42,100 | 22,200 | 52.7% | 100.7 |

| 3 | 34,500 | 18,500 | 53.6% | 100.6 |

| 5 | 23,700 | 12,800 | 54.0% | 26.70 |

| 7 | 34,500 | 23,000 | 66.6% | 64.4 |

| 9 | 24,900 | 13,000 | 52.2% | 36.3 |

| Specimen Number | Crack Number | Angle |

|---|---|---|

| 1 | Crack 1-1 | 45.2° |

| Crack 1-2 | 44.3° | |

| 2 | Crack 2-1 | 45.3° |

| Crack 2-2 | 43.3° | |

| 3 | Crack 3-1 | 43.2° |

| Crack 3-2 | 45.5° | |

| 4 | Crack 4-1 | 44.1° |

| Crack 4-2 | 42.3° | |

| 5 | Crack 5-1 | 43.5° |

| Crack 5-2 | 44.3° | |

| 6 | Crack 6-1 | 40.7° |

| Crack 6-2 | 42.9° | |

| 7 | Crack 7-1 | 40.5° |

| Crack 7-2 | 41.4° | |

| 8 | Crack 8-1 | 44.4° |

| Crack 8-2 | 47.5° | |

| 9 | Crack 9-1 | 40.1° |

| Crack 9-2 | 42.6° |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Z.; Pan, Y.; Lei, H.; Wang, S.; Fang, L. Fatigue Crack Growth Behavior and Failure Mechanism of Nickel-Based Alloy GH4169 under Biaxial Load Based on Fatigue Test of Cruciform Specimen. Metals 2023, 13, 588. https://doi.org/10.3390/met13030588

Wu Z, Pan Y, Lei H, Wang S, Fang L. Fatigue Crack Growth Behavior and Failure Mechanism of Nickel-Based Alloy GH4169 under Biaxial Load Based on Fatigue Test of Cruciform Specimen. Metals. 2023; 13(3):588. https://doi.org/10.3390/met13030588

Chicago/Turabian StyleWu, Zhirong, Ying Pan, Hang Lei, Shuaiqiang Wang, and Lei Fang. 2023. "Fatigue Crack Growth Behavior and Failure Mechanism of Nickel-Based Alloy GH4169 under Biaxial Load Based on Fatigue Test of Cruciform Specimen" Metals 13, no. 3: 588. https://doi.org/10.3390/met13030588

APA StyleWu, Z., Pan, Y., Lei, H., Wang, S., & Fang, L. (2023). Fatigue Crack Growth Behavior and Failure Mechanism of Nickel-Based Alloy GH4169 under Biaxial Load Based on Fatigue Test of Cruciform Specimen. Metals, 13(3), 588. https://doi.org/10.3390/met13030588