Failure Analysis of a Femoral Cephalomedullary Nail

Abstract

1. Introduction

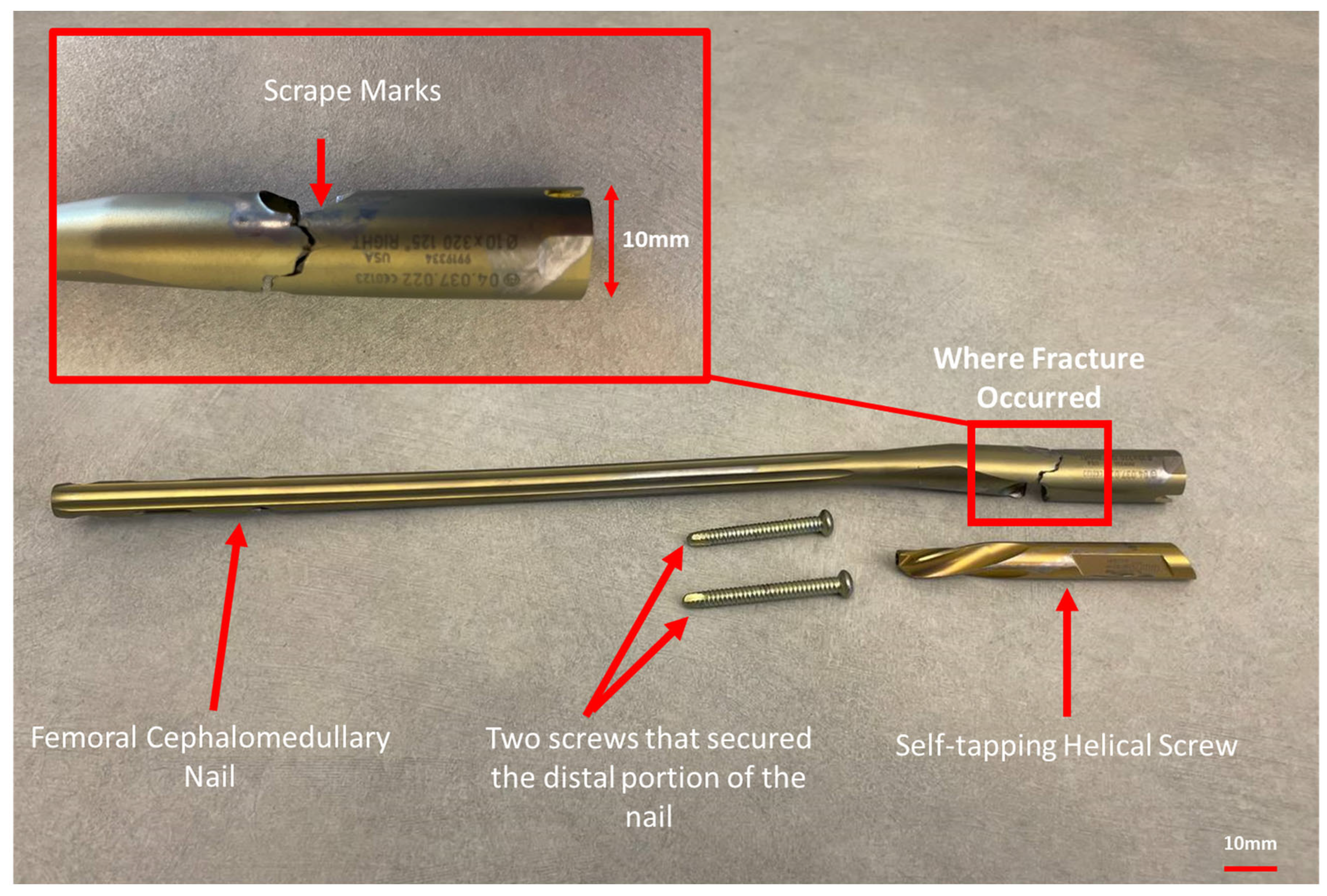

2. Case Study

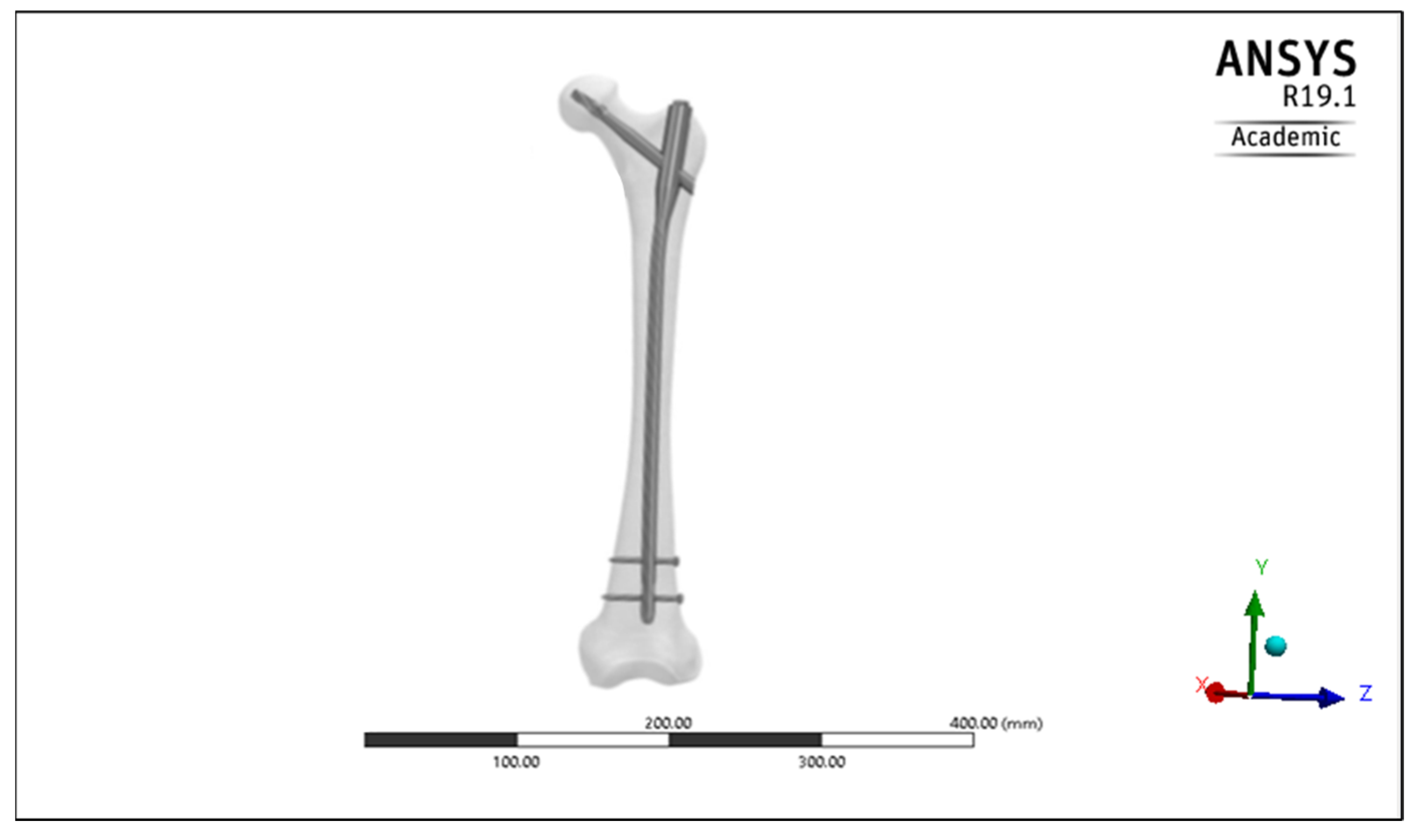

3. Physical Examination of the Failed Device

3.1. Visual Examination

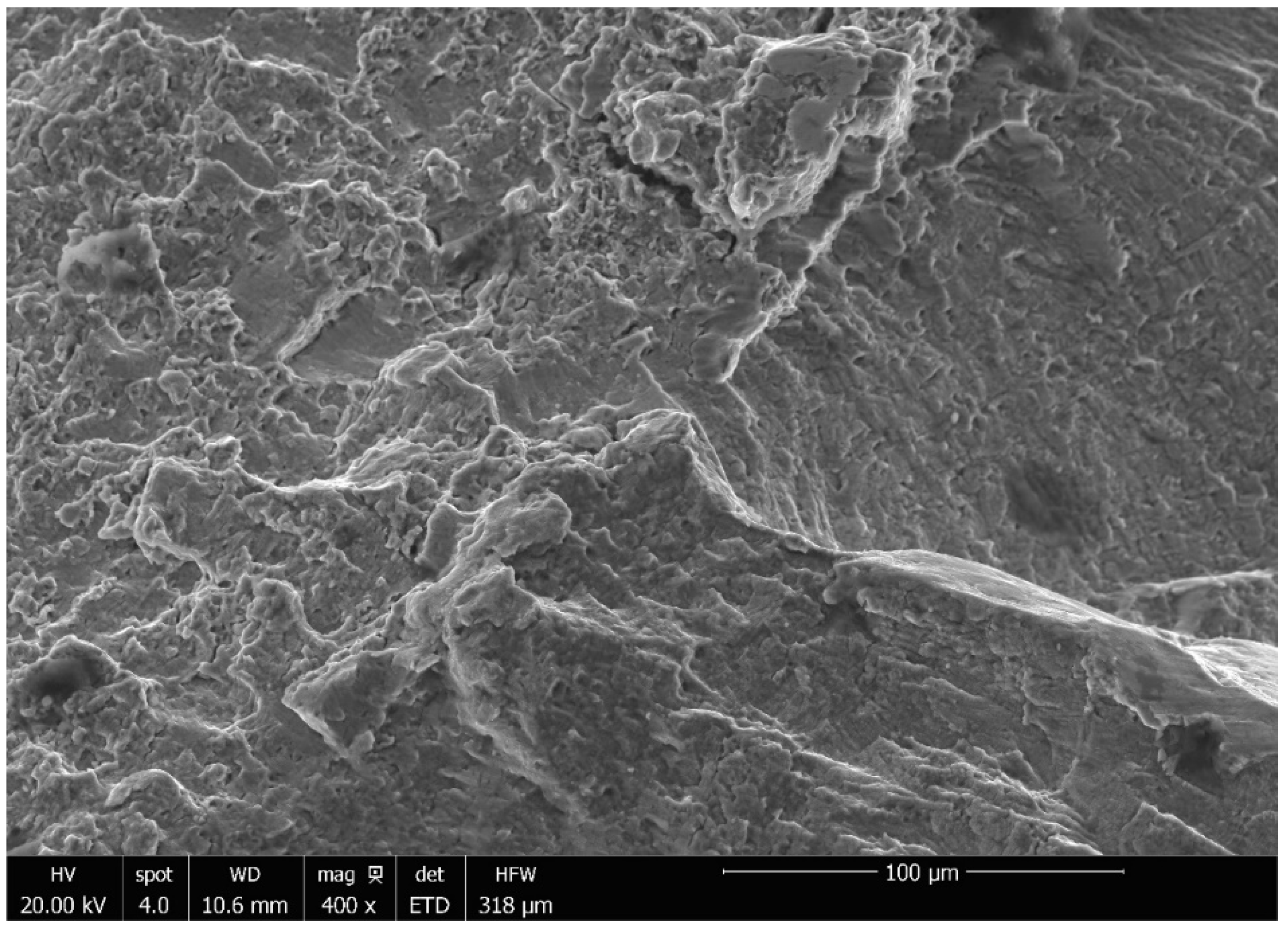

3.2. Fractographic Examination

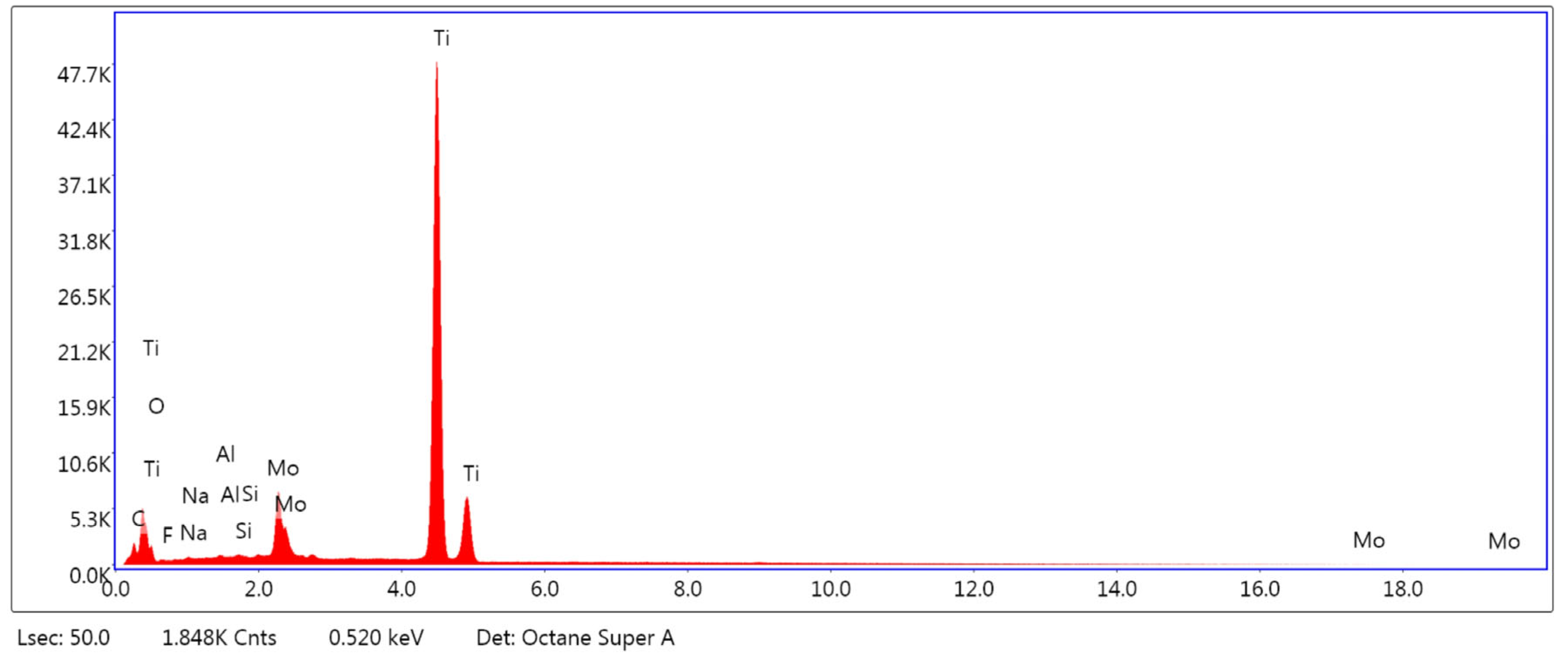

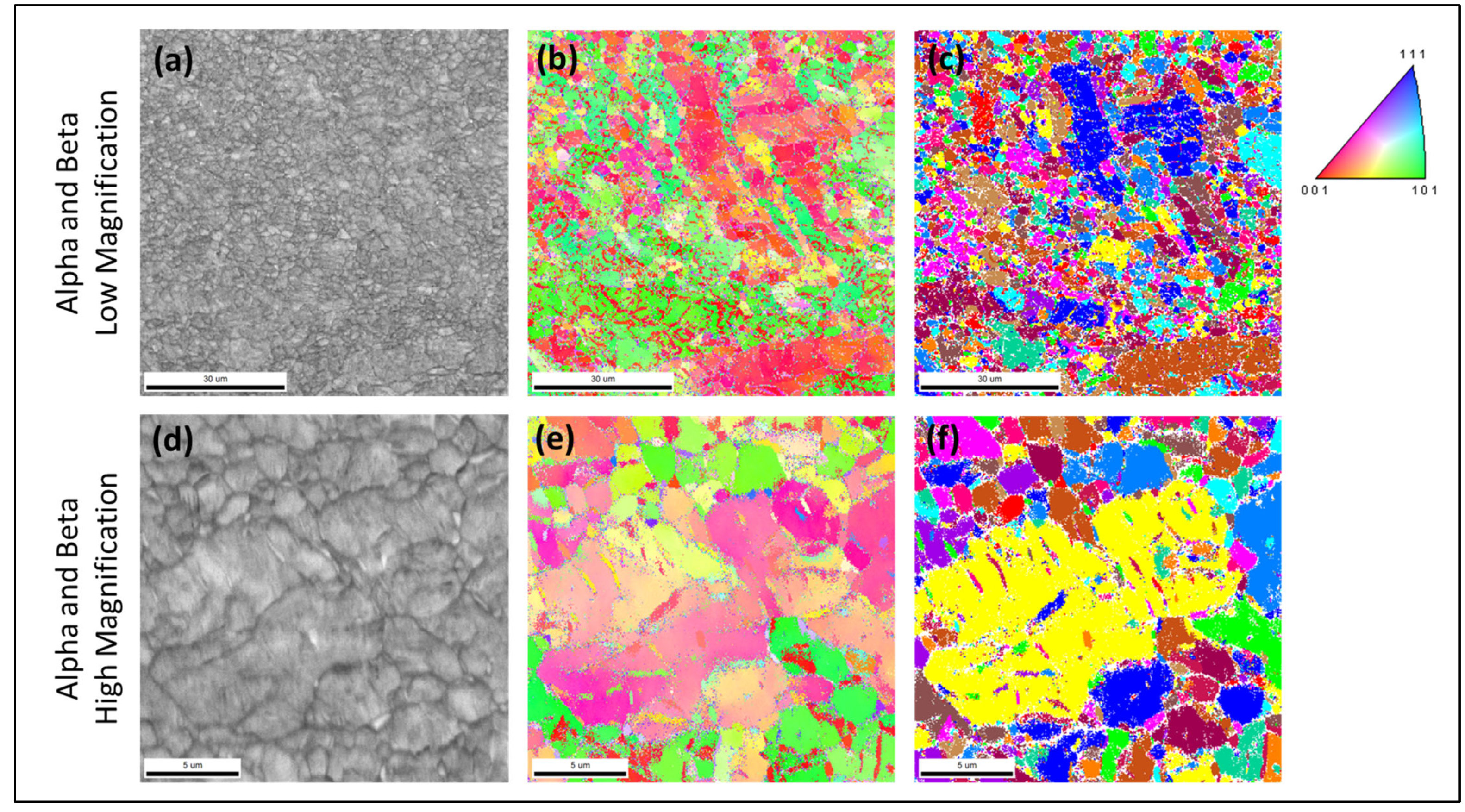

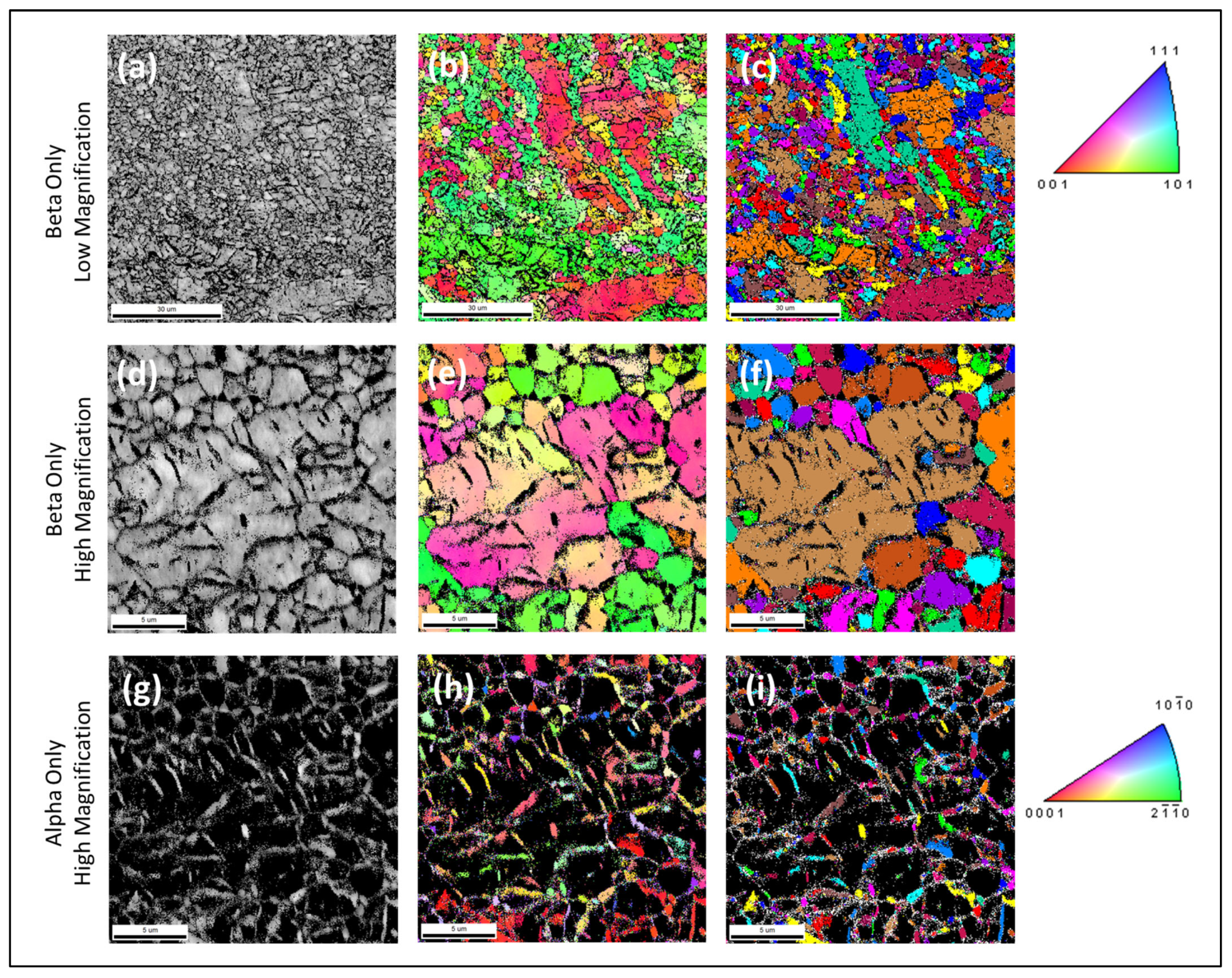

3.3. Material Conformity

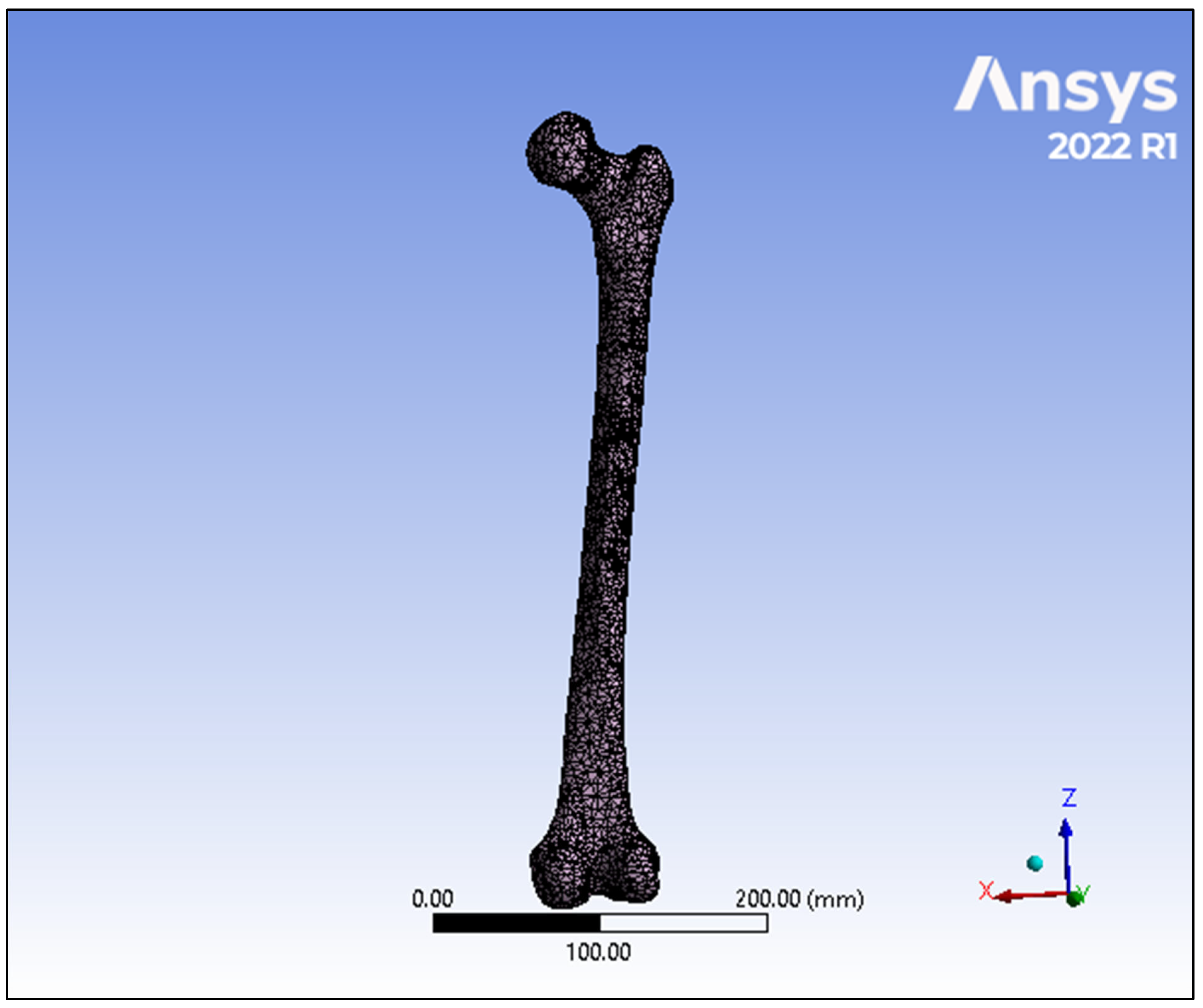

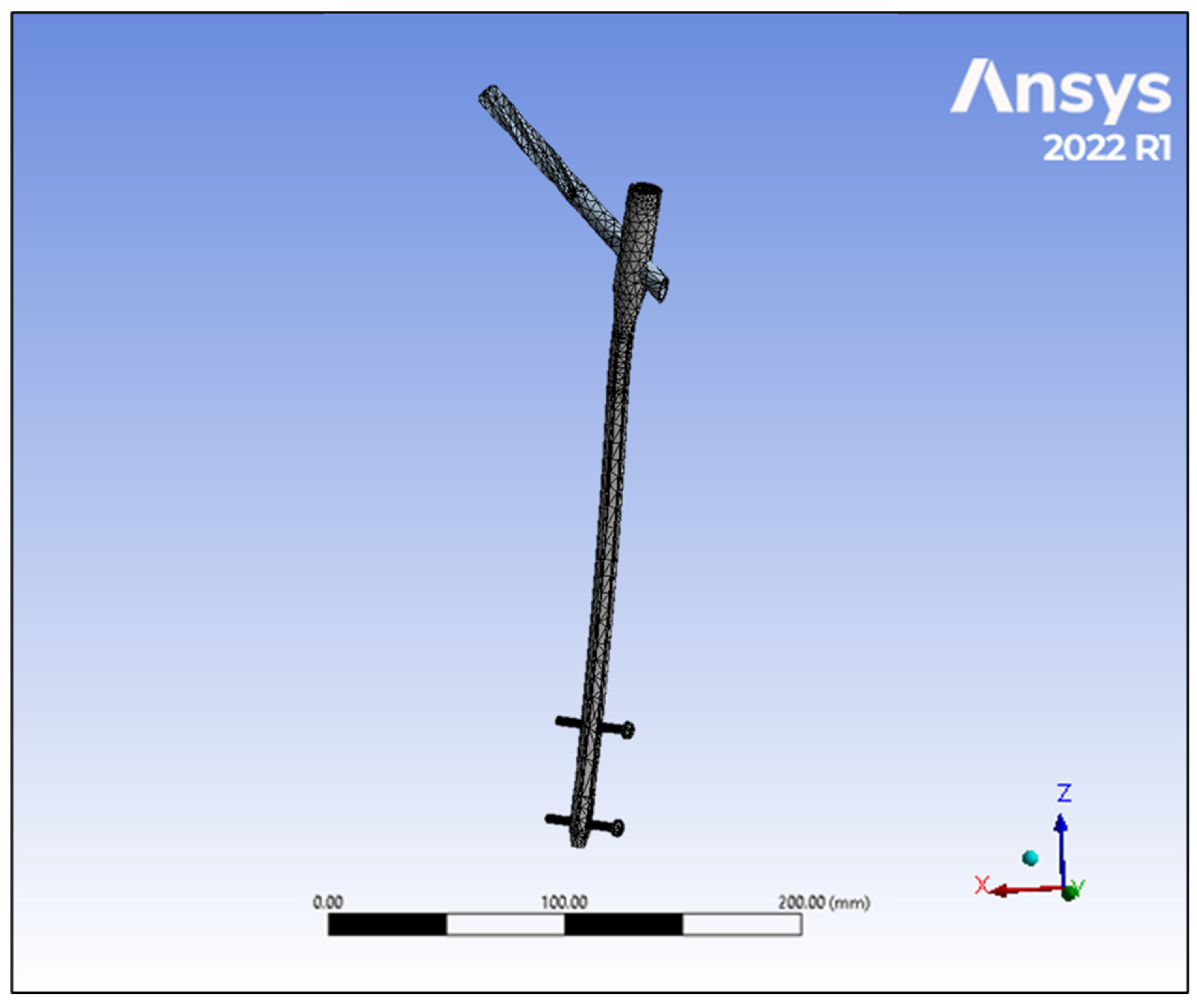

4. Computational Simulation Analysis of the Failed Device

5. Results

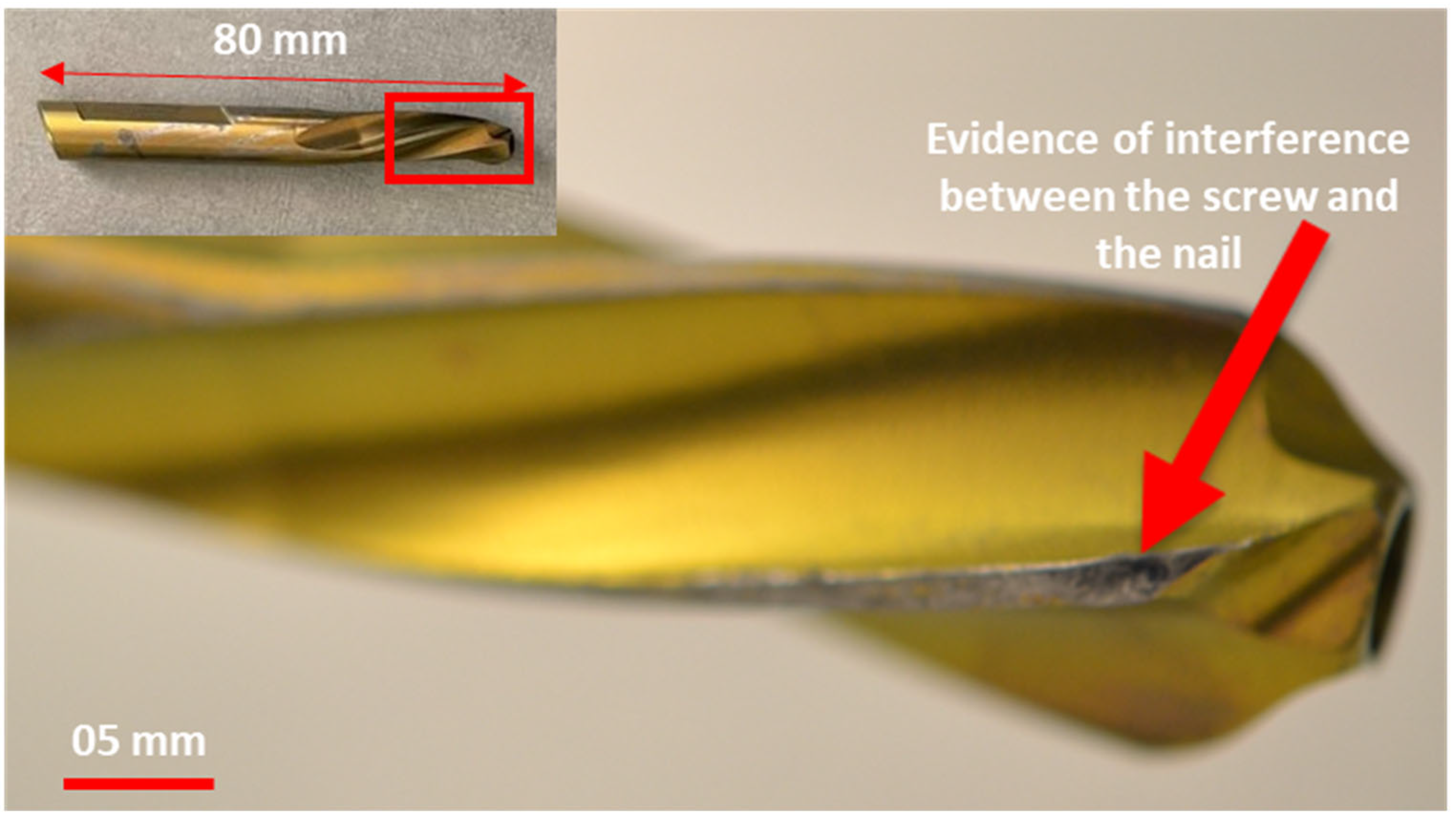

5.1. Visual Examination

5.2. Optical Microscopic Examination

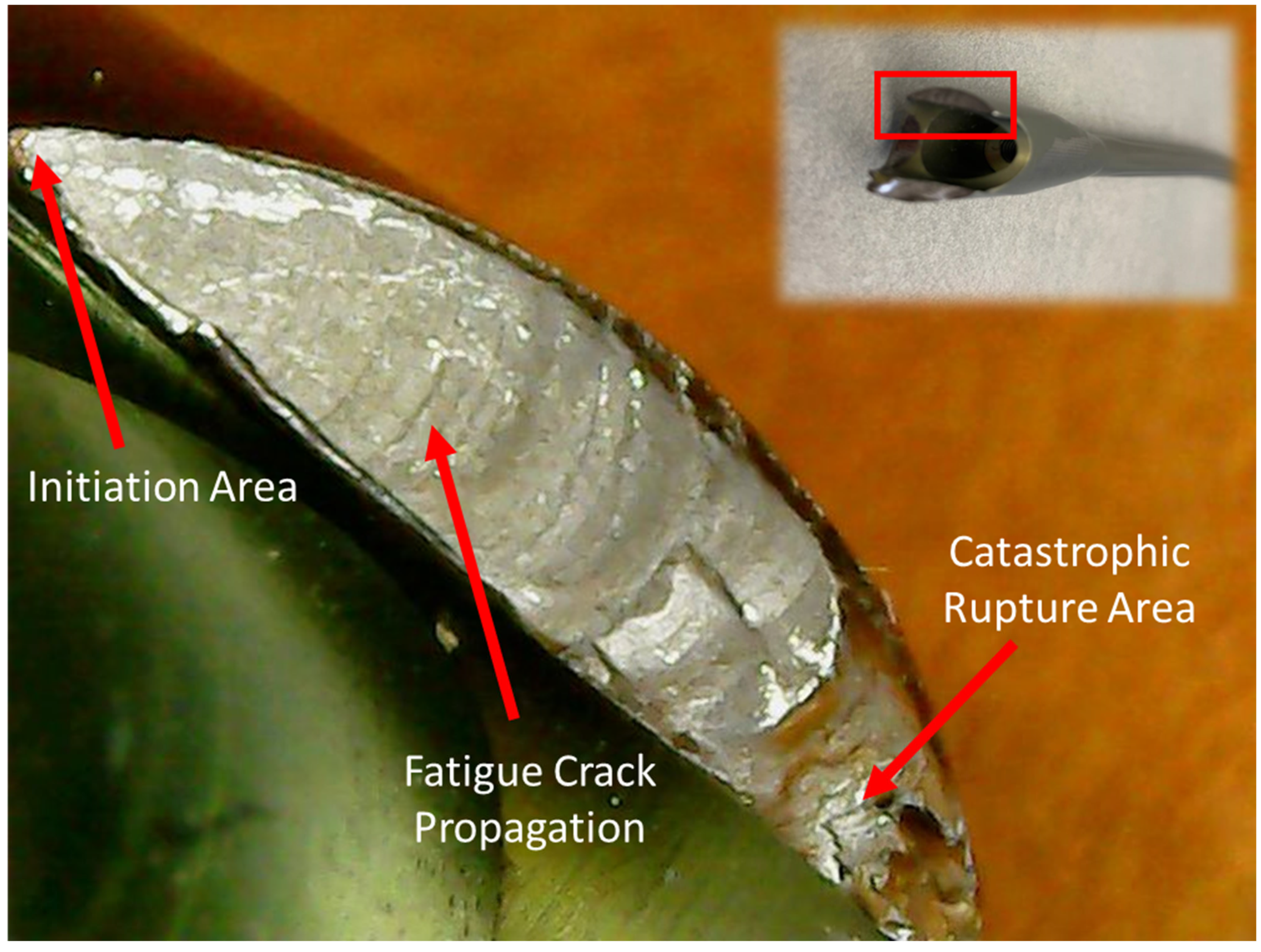

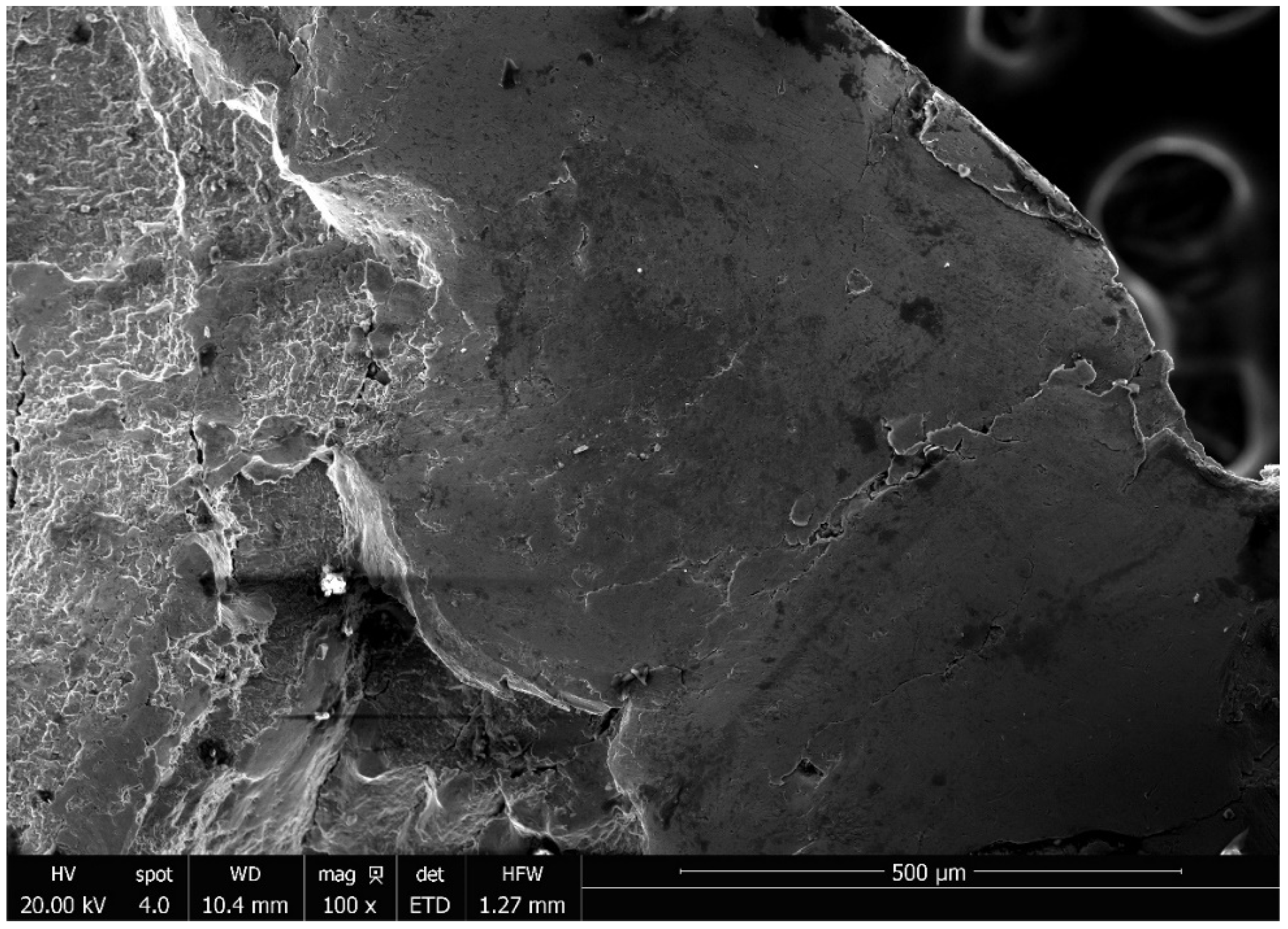

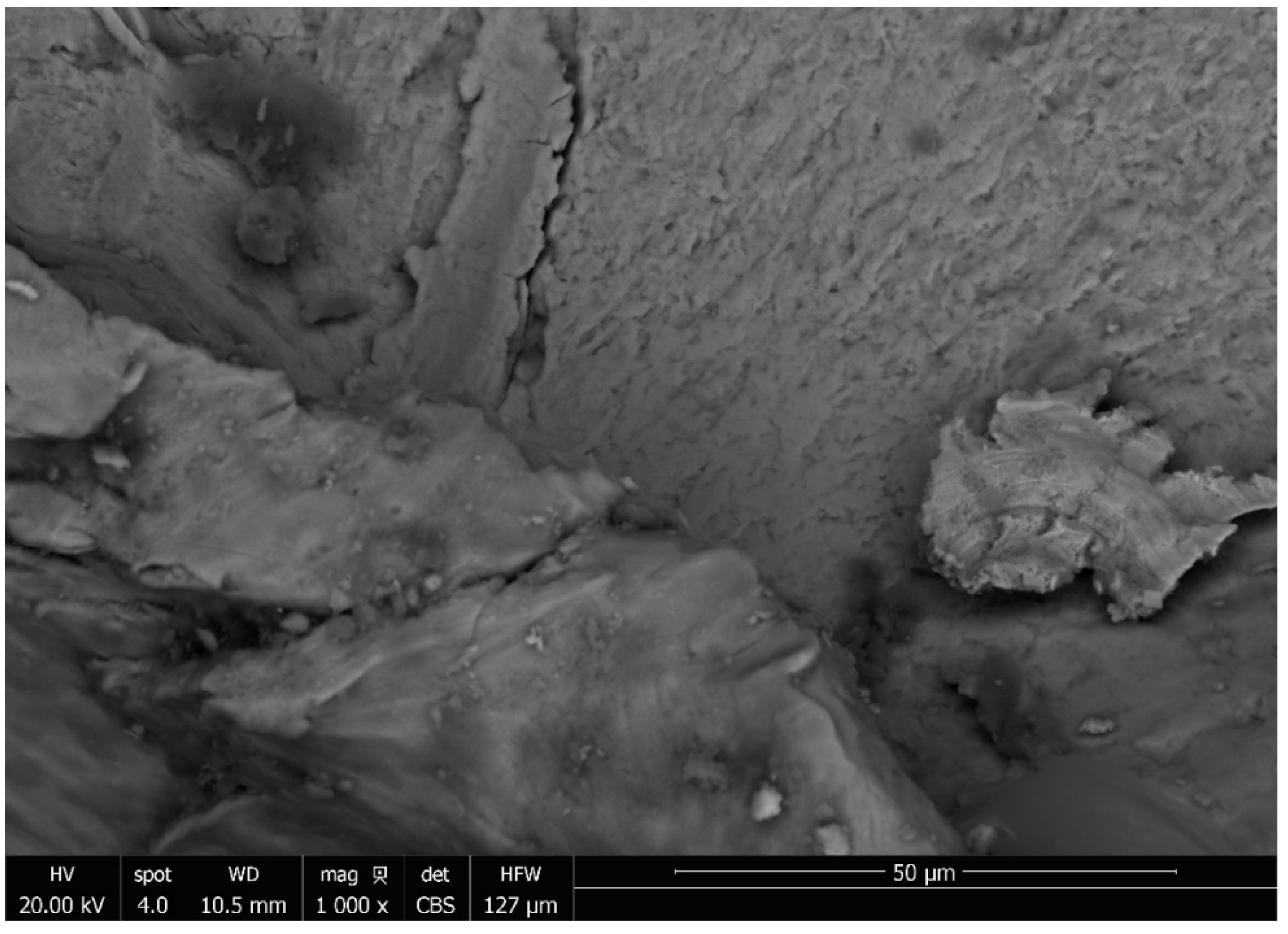

5.3. Fractographic Examination

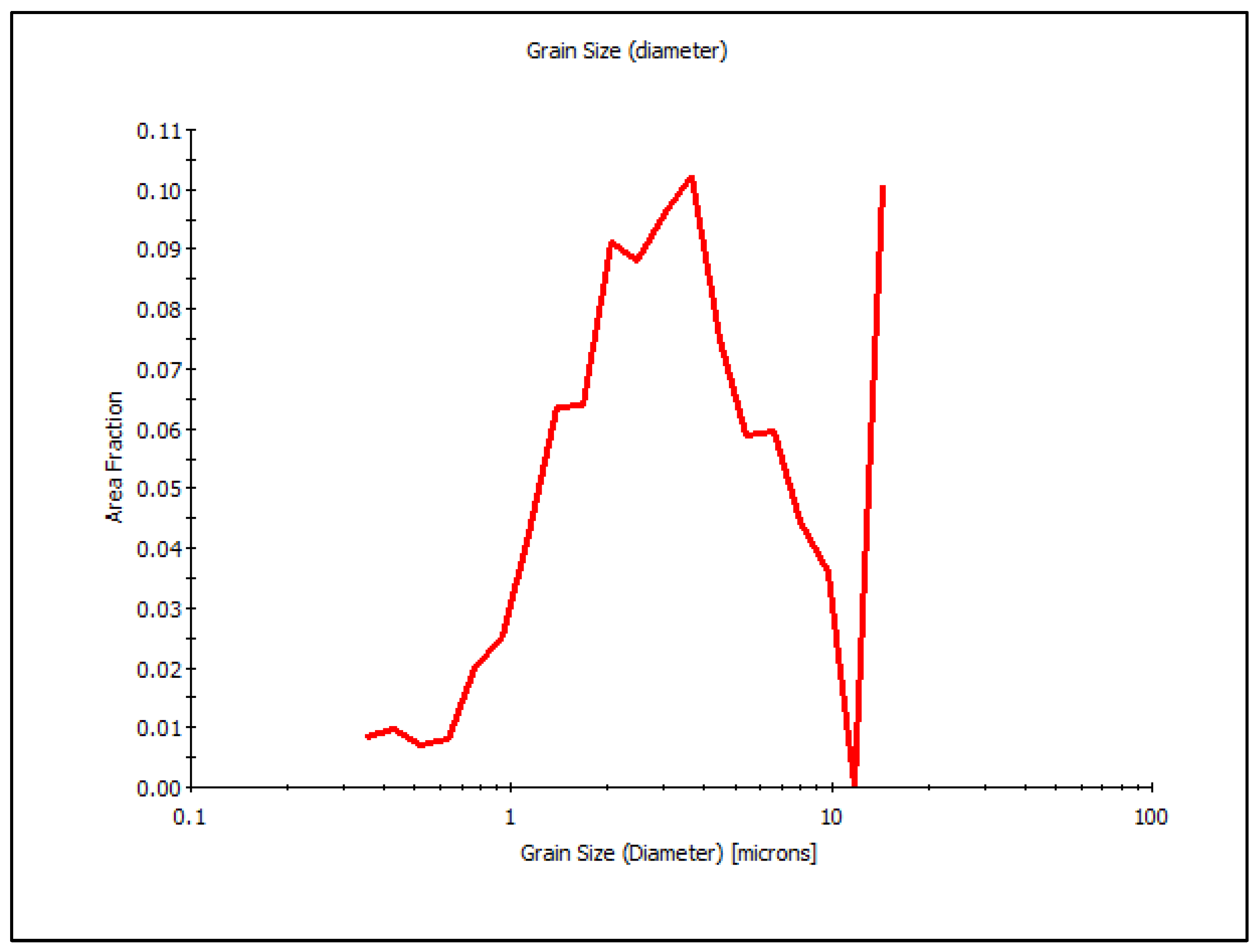

5.4. Material Conformity

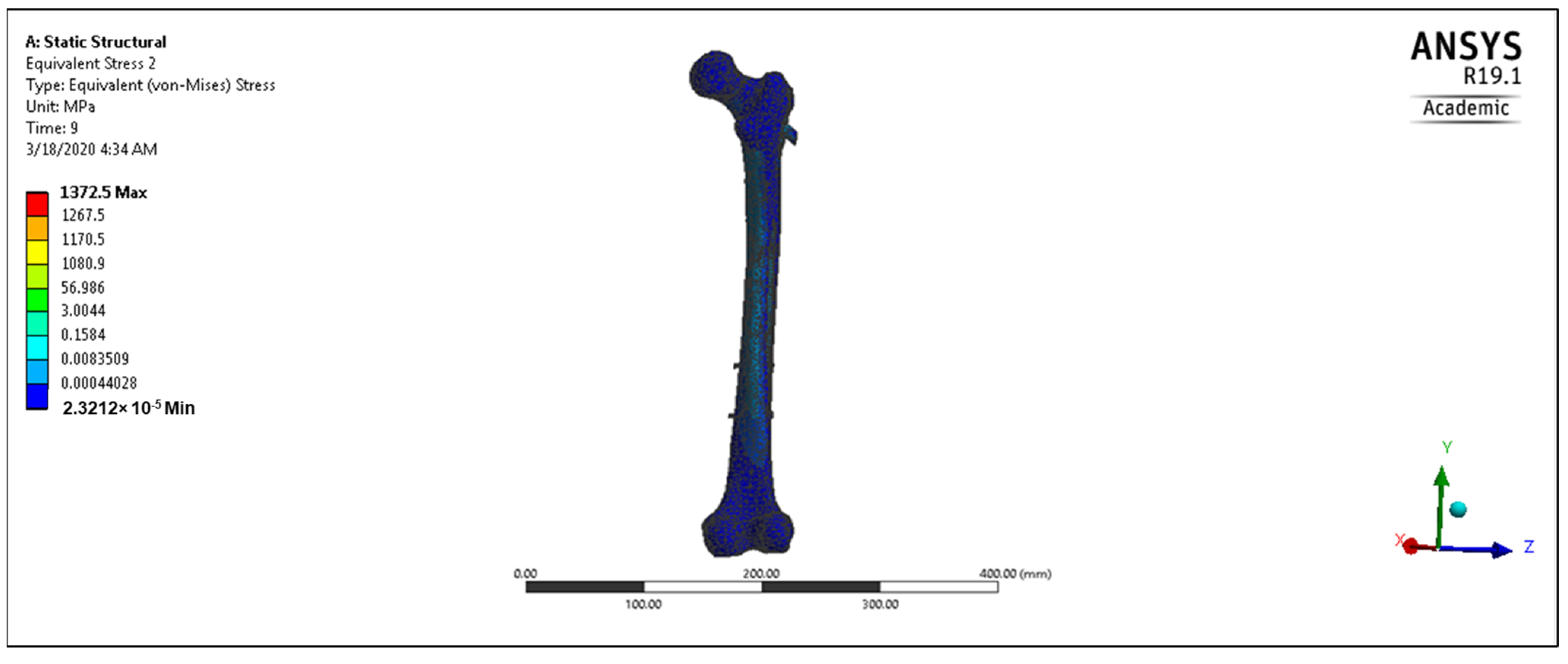

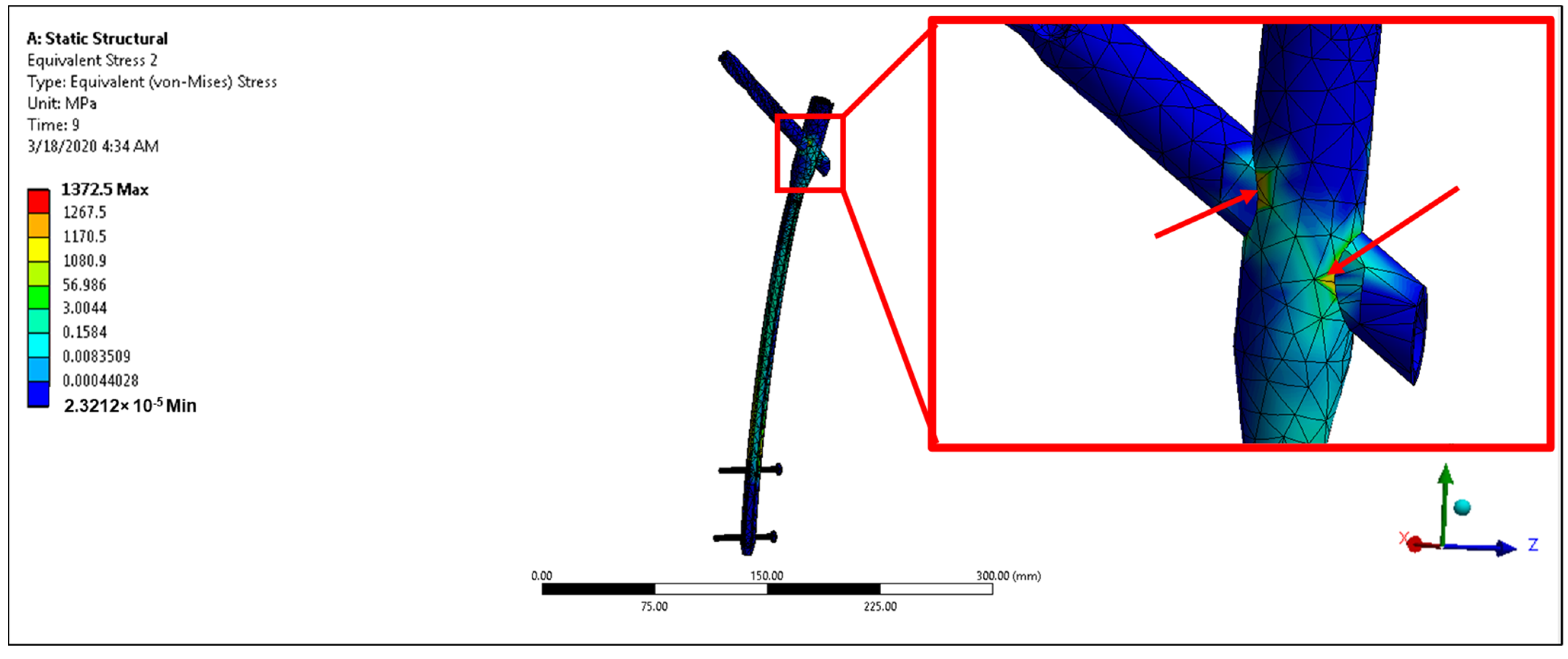

5.5. Computational Simulations of Failures

6. Discussion

7. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Centers for Disease Control and Prevention. Home and recreational safety. In Falls Among Older Adults: Hip Fractures among Older Adults; Centers for Disease Control and Prevention: Atlanta, FA, USA, 2018. [Google Scholar]

- Sing, C.-W.; Lin, T.-C.; Bartholomew, S.; Bell, J.S.; Bennett, C.; Beyene, K.; Bosco-Lévy, P.; Chan, A.H.Y.; Chandran, M.; Cheung, C.-L.; et al. Global epidemiology of hip fractures: A study protocol using a common analytical platform among multiple countries. BMJ Open 2021, 11, e047258. [Google Scholar] [CrossRef] [PubMed]

- Parker, M.J.; White, A.; Boyle, A. Fixation versus hemiarthroplasty for undisplaced intracapsular hip fractures. Injury 2008, 39, 791–795. [Google Scholar] [CrossRef] [PubMed]

- Adedapo, A.; Ikpeme, J. The results of internal fixation of three-and four-part proximal humeral fractures with the polarus nail. Injury 2001, 32, 115–121. [Google Scholar] [CrossRef] [PubMed]

- Gaines, R.W., Jr. The use of pedicle-screw internal fixation for the operative treatment of spinal disorders. J. Bone Jt. Surg. 2000, 82, 1458–1476. [Google Scholar] [CrossRef] [PubMed]

- Winquist, R.A.; Hansen, S.T., Jr. Comminuted fractures of the femoral shaft treated by intramedullary nailing. Orthop. Clin. N. Am. 1980, 11, 633–648. [Google Scholar] [CrossRef]

- White, G.M.; Healy, W.L.; Brumback, R.J.; Burgess, A.R.; Brooker, A.F. The treatment of fractures of the femoral shaft with the Brooker-Wills distal locking intramedullary nail. J. Bone Jt. Surg. 1986, 68, 865–876. [Google Scholar] [CrossRef]

- Frumberg, D.B.; Van Lanen-Wanek, D.J.; Jauregui, J.J.; Nadarajah, V.; Illical, E.M. Can flexible intramedullary nails provide proper fixation of long bone fractures in patients weighing over 100 pounds? J. Orthop. Trauma Rehabil. 2019, 26, 9–13. [Google Scholar] [CrossRef]

- Wheeless, C.R. Wheeless’ Textbook of Orthopaedics; Duke University Medical Center: Durham, NC, USA, 2001. [Google Scholar]

- Muminagic, S.N. History of Bone Fracture: Treatment and Immobilization. Mater. Socio Med. 2011, 23, 111. [Google Scholar] [CrossRef]

- Schatzker, J.; Tile, M.; Axelrod, T.S. The Rationale of Operative Fracture Care; Springer: Berlin/Heidelberg, Germany, 2005; Volume 24, pp. 385–407. [Google Scholar]

- Hernández, J.L.; Olmos, J.M.; Alonso, M.A.; González-Fernández, C.R.; Martínez, J.; Pajarón, M.; Llorca, J.; González-Macías, J. Trend in hip fracture epidemiology over a 14-year period in a Spanish population. Osteoporos. Int. 2006, 17, 464–470. [Google Scholar] [CrossRef] [PubMed]

- Seo, J.-S.; Min, H.-J.; Kim, D.M.; Oh, S.-M.; Kim, S.-M. Surgical Results of the Cephalomedullary Nail for the Femoral Intertrochanteric Fracture: Comparison between Non-experienced Surgeons and Experienced Surgeon. Hip Pelvis 2016, 28, 225–231. [Google Scholar] [CrossRef] [PubMed]

- ASTM F2066-18; Standard Specification for Wrought Titanium-15 Molybdenum Alloy for Surgical Implant Applications (UNS R58150). ASTM International: West Conshohocken, PA, USA, 2018. Available online: www.astm.org (accessed on 20 May 2019).

- ASTM F620-00; Standard Specification for Alpha Plus Beta Titanium Alloy Forgings for Surgical Implants. ASTM International: West Conshohocken, PA, USA, 2000. Available online: www.astm.org (accessed on 20 May 2019).

- Hamandi, F.; Goswami, T. Macrodamage Accumulation Model for a Human Femur. Appl. Bionics Biomech. 2017, 2017, 4539178. [Google Scholar] [CrossRef] [PubMed]

- Bergmann, G. HIP98, Loading of the Hip Joint; Compact Disc, Freie Universität Berlin: Berlin, Germany, 2001. [Google Scholar]

- Hamandi, F.; Whitney, A.; Stouffer, M.H.; Prayson, M.J.; Rittweger, J.; Goswami, T. Cyclic Damage Accumulation in the Femoral Constructs Made With Cephalomedullary Nails. Front. Bioeng. Biotechnol. 2021, 8, 593609. [Google Scholar] [CrossRef] [PubMed]

- Hamandi, F.; Laughlin, R.; Goswami, T. Failure analysis of PHILOS plate construct used for pantalar arthrodesis Paper II—Screws and FEM simulations. Metals 2018, 8, 279. [Google Scholar] [CrossRef]

- Perren, S.M. Evolution of the internal fixation of long bone fractures. The scientific basis of biological internal fixation: Choosing a new balance between stability and biology. J. Bone Jt. Surg. 2002, 84, 1093–1110. [Google Scholar] [CrossRef]

- Goswami, T.; Gundapaneni, D.; Slocum, M.; Paul, P.; Christof, S. Failure investigation of a tibiotalocalcaneal arthrodesis system. Eng. Fail. Anal. 2016, 59, 588–604. [Google Scholar] [CrossRef]

| Element | Composition, wt.% |

|---|---|

| Nitrogen, max | 0.05 |

| Carbon, max | 0.10 |

| Hydrogen, max | 0.015 |

| Iron, max | 0.10 |

| Oxygen, max | 0.20 |

| Molybdenum | 14.00–16.00 |

| Titanium | Balance |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hamandi, F.; Whatley, S.; Simon, G.; Venkatarayappa, I.; Goswami, T. Failure Analysis of a Femoral Cephalomedullary Nail. Metals 2023, 13, 506. https://doi.org/10.3390/met13030506

Hamandi F, Whatley S, Simon G, Venkatarayappa I, Goswami T. Failure Analysis of a Femoral Cephalomedullary Nail. Metals. 2023; 13(3):506. https://doi.org/10.3390/met13030506

Chicago/Turabian StyleHamandi, Farah, Stephen Whatley, Gerard Simon, Indresh Venkatarayappa, and Tarun Goswami. 2023. "Failure Analysis of a Femoral Cephalomedullary Nail" Metals 13, no. 3: 506. https://doi.org/10.3390/met13030506

APA StyleHamandi, F., Whatley, S., Simon, G., Venkatarayappa, I., & Goswami, T. (2023). Failure Analysis of a Femoral Cephalomedullary Nail. Metals, 13(3), 506. https://doi.org/10.3390/met13030506