Abstract

In this work, the behavior of a lean premixed stretched flame stabilized in a flat channel near a heated wall was studied. Dependences of the flame front position on the stretch rate parameter at temperatures of the heated wall of 1000 and 1200 K and the combustible mixture composition (ϕ = 0.7 and 0.6) were obtained experimentally. The reduced thermal diffusive model was used in numerical simulation for an explanation of obtained experimental results. Theoretical estimates are in qualitative agreement with the experiment. The performed qualitative analysis may be useful in estimation of the combustion product temperature and the residence time of the nanoparticles forming in combustion products before their impact with the hot wall.

1. Introduction

The recent development of new technologies, such as the synthesis of nanomaterials in a gas flame by combustion, including nanoparticles of metal oxides [1], graphene and fullerenes [2], created a strong need to understand flame characteristics under the conditions of preheated walls in the close vicinity of reaction fronts [3,4,5]. In these flame spray pyrolysis (FSP) technologies, the nanoparticles are formed in combustion products and deposited on the substrate after the gas combustion with precursors in the stagnant zone near the substrate, which often has an elevated temperature [2,6,7,8,9]. The hot wall can stabilize the combustion of low-calorie gas mixtures and helps to control the residence time of combustion products near the stagnation zone where nanoparticles are formed. This suggests the relevance of studying the features of the premixed gas combustion in divergent flow near a heated wall. In contrast to the well-studied stretched flames that stabilize in the space between two countercurrent burners [10], there is a lack of data on the stretched flame characteristics near the hot wall. Extinguishing of a stretched flame can occur both at high and low flow rates.

At a high flow rate, flame quenching is caused by a flow velocity gradient (stretching effects) [11,12]. At low flow velocities corresponding to small values of stretch rate, flame extinction is associated with radiation heat loss from the area of hot combustion products [13,14]. Experimental studies of the low stretched flames require the creation of microgravity conditions due to the significant effect of natural convection on the flame. This demands the use of expensive experimental facilities, such as “drop towers” or free-flight experiments. Microgravity experiments using premixed stretched flames stabilized near a hot wall and their theoretical analysis showed the existence of two different flame regimes [9]. It should be noted that early theoretical Reference [15] predicted the existence of stretched flames stabilized near the hot wall at low flow rates of the combustible mixture. In experiments in Reference [9], such regimes were not found, so proofing of their existence requires additional experiments.

In references [16,17], an experimental apparatus which makes it possible to eliminate influence of the natural convection and allows low stretched flames to be investigated under normal gravity conditions was proposed. The countercurrent flames in these works were stabilized inside a flat microchannel. In the current paper, we present the results of experiments on a low stretched flame near a heated wall. In order to weaken the effect of the natural convection, the flame was stabilized in a flat channel, inside which there was a heated wall.

2. Experiment

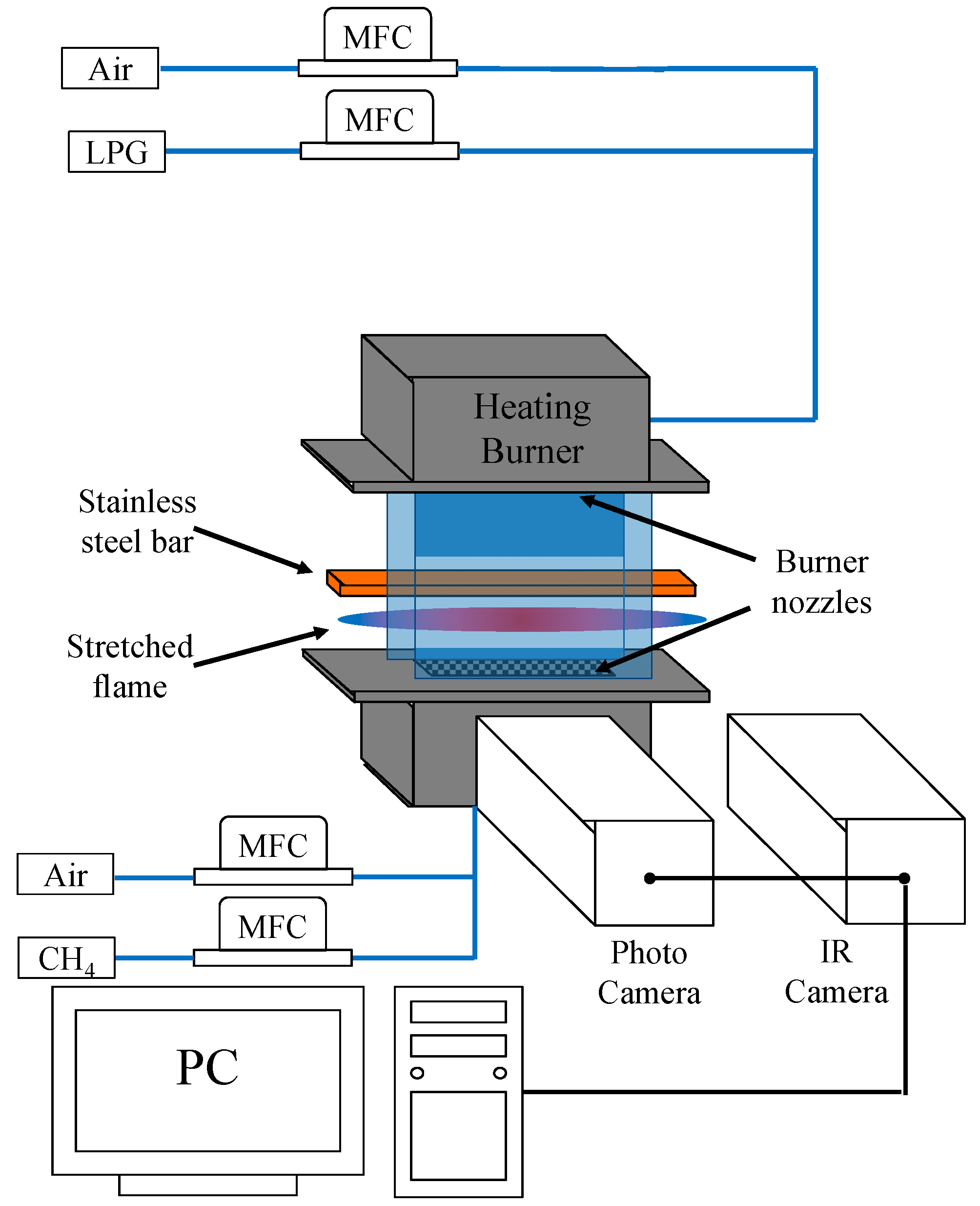

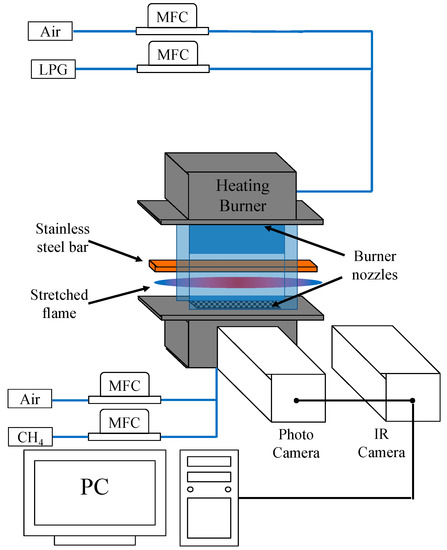

A scheme of the experimental setup is shown in Figure 1. The combustible mixture was supplied from slot-jet burner into the 7 mm gap, forming two parallel 1 mm thickness quartz plates. A stainless-steel bar (SS 316, HLMMM Co., Ltd., China) with a size of 100 × 7 × 3 mm was placed at a distance of 15 mm from the burner’s nozzle. A liquid petroleum gas (LPG, Gazpromneft, Moscow, Russia)/air slot-jet burner heated the rear side of the stainless-steel bar. The hot wall temperature control was implemented by operation of the LPG/air mixture flow rate and content. The stretched flame of lean methane/air premixture was studied in the experiment. The composition and flow rate of the air/fuel mixture in the investigated burner was controlled by gas mass flow controllers connected to a computer. In order to prevent the penetration of combustion products from the burner/heater into the study area, the contact points of the steel bar and the quartz plate were sealed and side screens were installed. A digital photo camera and an infrared (IR) camera (Optris GmbH, Berlin, Germany) were used to measure the flame front position and the temperature of the heated wall, respectively. The IR camera was pre-calibrated with a K-type thermocouple (Okazaki Manufacturing Company, Kobe, Japan). The inlet temperature of the combustible mixture was measured with a K-type thermocouple maintained at the burner’s nozzle.

Figure 1.

Scheme of experimental setup. LPG—liquid petroleum gas, MFC—mass flow controller, IR Camera—infrared camera.

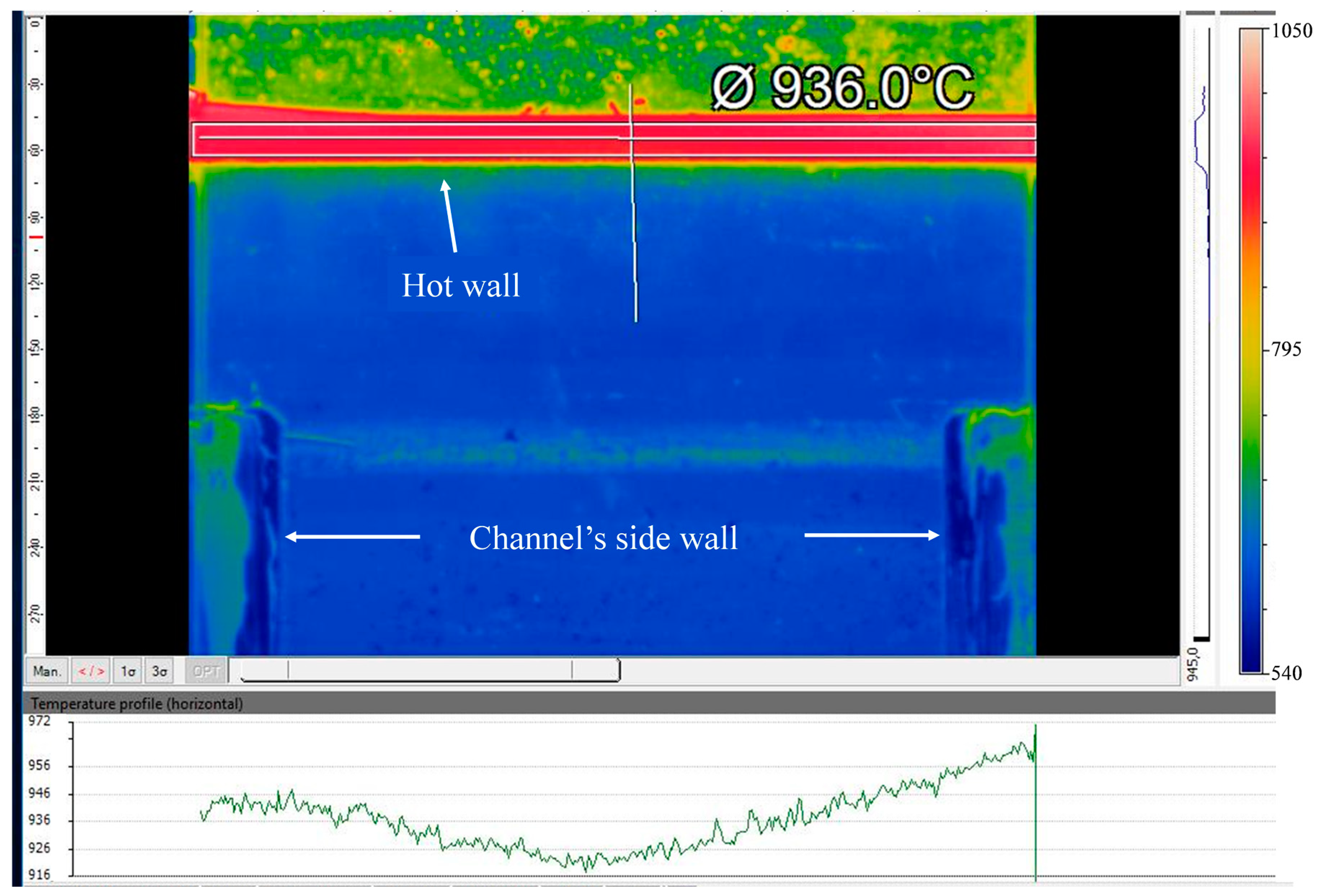

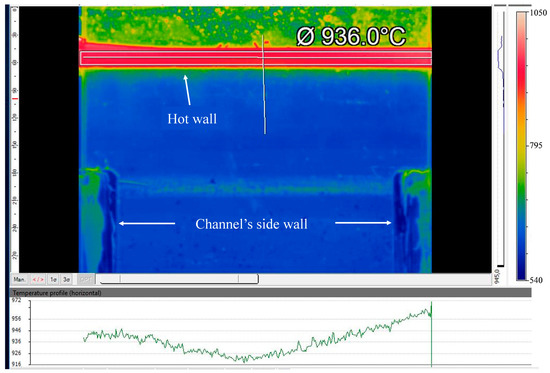

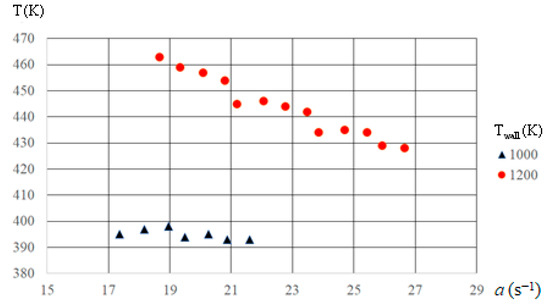

The flame characteristics of two methane/air mixtures with equivalence ratios ϕ = 0.6 and 0.7 were studied in the experiments. The stretch rate was defined as the ratio between the fresh mixture velocity at the burner nozzle to the distance from the burner’s nozzle to the heated wall. The distance was 15 mm. Measurements were conducted for two average temperatures of the hot wall equaling 1000 ± 20 and 1200 ± 25 K. Temperature distribution in the experimental area, obtained using an IR camera, is shown in Figure 2. As can be seen from Figure 2, the temperature profile along the surface of the heated wall was fairly uniform.

Figure 2.

Temperature profile of the heated wall (top view).

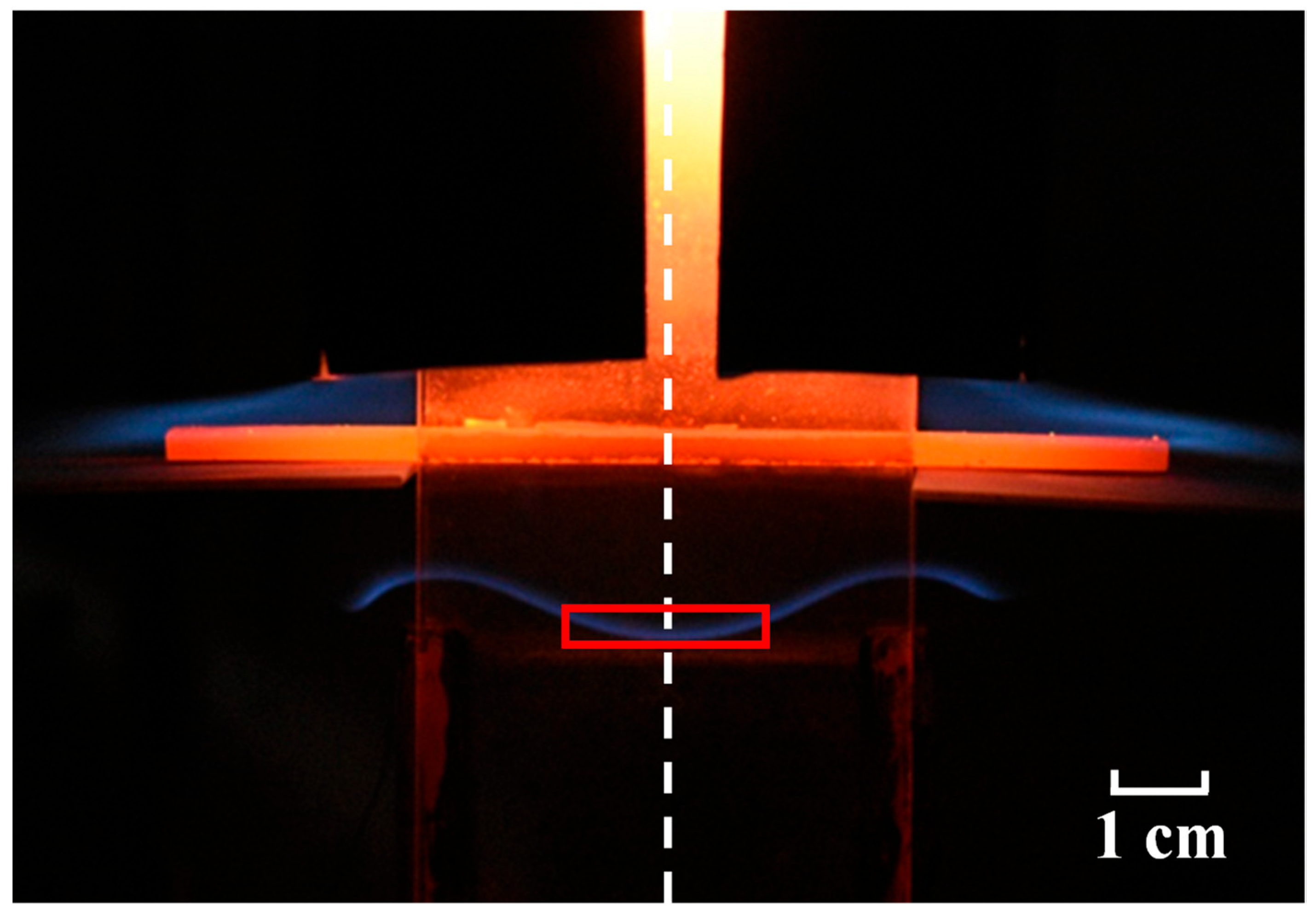

In the experiment, the position of the flame front was determined at different temperatures of the heated wall for different mixture compositions depending on the stretch rate. The flame position was determined by averaging the luminosity peaks along the flame front in the area restricted by the distance of ±1 cm from the gas flow central line. The flame front was slightly curved as shown in the momentary photo in Figure 3; therefore, to obtain one experimental point on the flame front location, we took five photos to average data and to determine the corresponding errors. The average time to establish a stationary combustion regime was about 10 min for each gas flow rate.

Figure 3.

Photo from the experiment. The white dotted line indicates the gas flow central line. The area in which the position of the flame front was averaged is enclosed in the red frame.

3. Mathematical Model

The simple model of a stretched flame near a hot wall [18] was used to estimate the flame front behavior depending on the problem parameters. Using the assumptions of constant gas density, constant transfer coefficients, potential flow and narrowness of the chemical reaction zone compared to the gas-preheating zone, the equations for temperature and fuel concentration can be written as:

here, is the chemical reaction rate in the “infinitely thin reaction zone” approximation. The Arrhenius type of chemical reaction rate is expressed in term of delta function , and N is nondimensional activation energy of chemical reaction; x is the nondimensional coordinate in units of flame thickness , where is the gas thermal diffusivity and is the laminar speed of the freely propagating flame. The temperature T is measured in units of adiabatic flame temperature Tb, is nondimensional initial temperature, is the nondimensional stretch parameter related to the inlet gas velocity V0 from burner and L is the distance between the burner and the hot wall. C is the nondimensional fuel concentration in units of the initial concentration of the premixture; Le is the Lewis number. H is the nondimensional parameter characterizing intensity of radiative heat loss and depending on the composition of the combustible mixture. The phenomenological formula proposed in Reference [19] allows this parameter to be estimated. Since experimental mixtures have close values of equivalence ratio, the same value of the parameter h = 10−4 is used in the calculations.

In this piecewise linear formulation, the solution of Equations (1) and (2) can be found analytically by the method proposed in Reference [18]. Application of the method to the system of Equations (1) and (2) results in algebraic equations relating flame front position xf and flame temperature Tf with the stretch rate a and other problem parameters.

Here, , and are the hot wall temperature. The functions ψ and have the form:

4. Results and Discussion

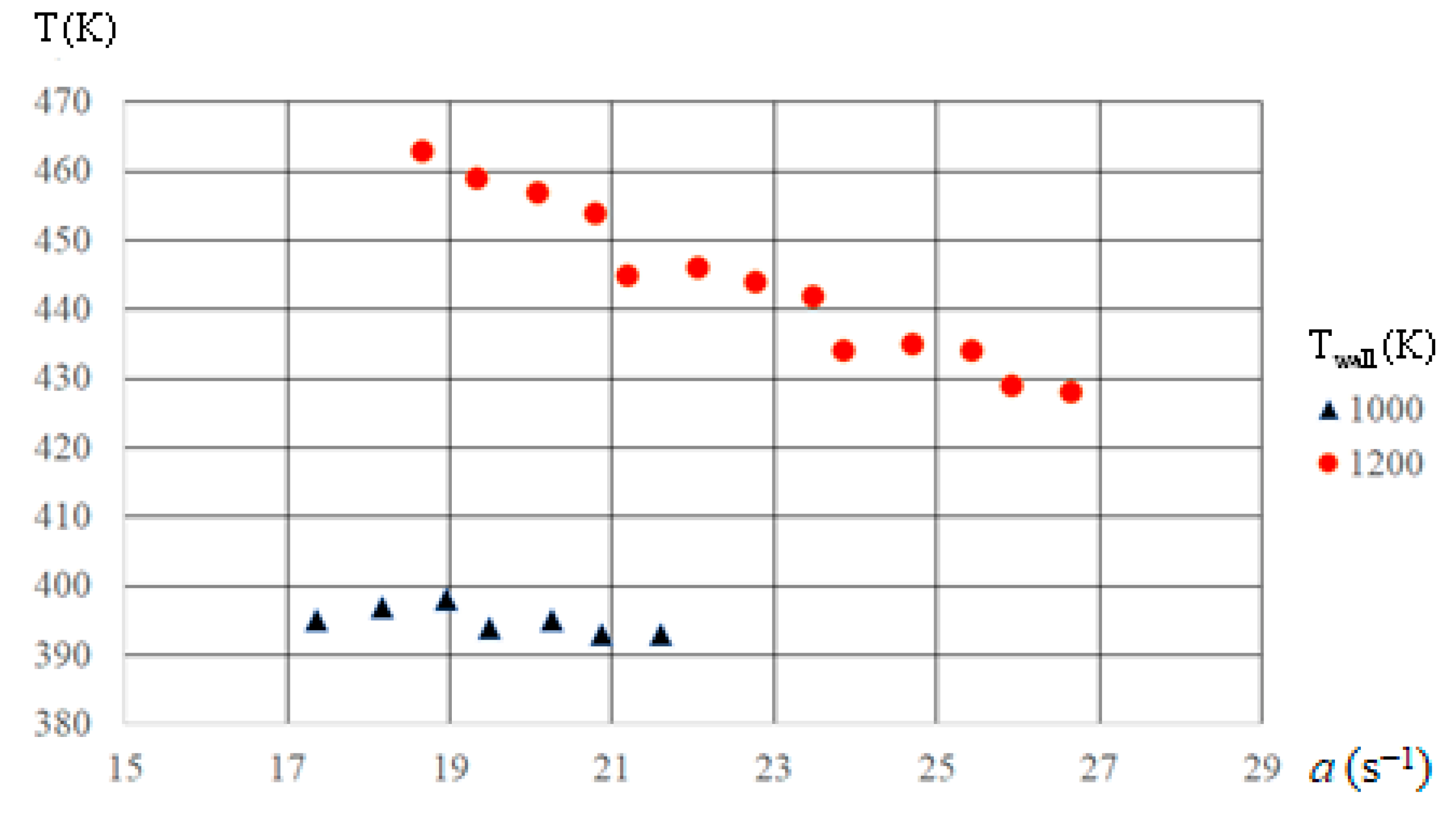

In the experiment, lean methane/air mixture was studied. Since the heated wall was installed inside the channel and the burner nozzle was within a sufficient distance, the fresh mixture was significantly heated due to the heat-conducting walls of the quartz channel. This led to an increase in the gas volume velocity of the fresh mixture relative to that set on the mass flow controllers. When processing the experimental data, we took into account the heating of the mixture that occurred and made an appropriate correction for the velocity of the fresh mixture and, consequently, for stretch rate. In all subsequent figures, the value of the stretching coefficient is corrected for the temperature of the fresh mixture. In addition, the increase in the temperature of the fresh mixture was taken into account in the numerical simulation. The dependency of the fresh mix temperature on the stretch ratio for equivalence ratio ϕ = 0.6 is shown in Figure 4.

Figure 4.

The dependency of the fresh mixture temperature on the stretch rate for equivalence ratio ϕ = 0.6.

As shown in Figure 4, in the case when the wall temperature was 1000 K, the temperature of the fresh mixture practically did not change and was equal to ~400 K. On the other hand, in case when the wall temperature was equal 1200 K, the temperature of the fresh mixture decreased linearly. As will be demonstrated later, this phenomenon occurred due to the fact that with an increase in the wall temperature, the flame was stabilized further from the burner nozzle, resulting in an expansion of the flammability limit. In addition, when the flame exists at higher stretch rates, and hence at higher fresh mixture velocities, the temperature of the fresh mixture decreased due to less intense heat transfer.

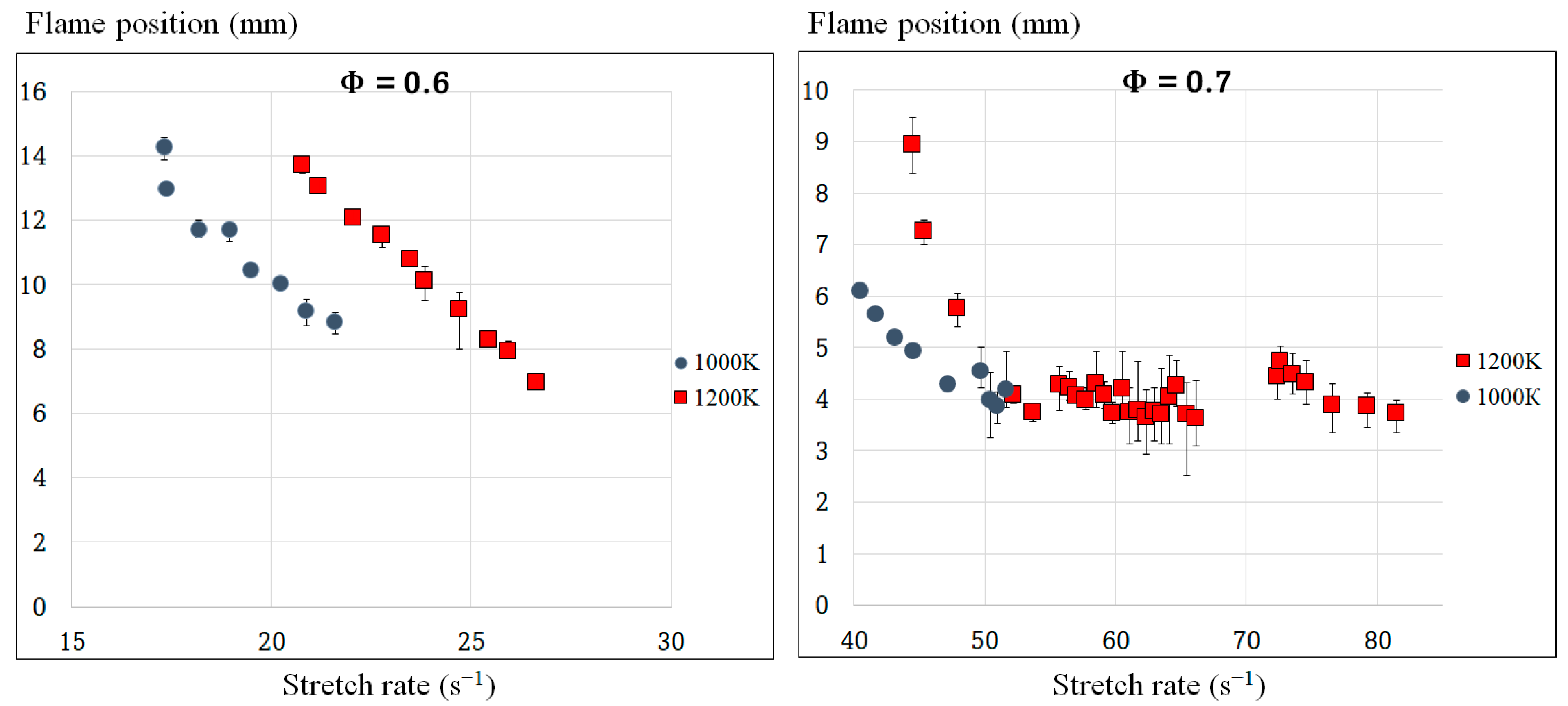

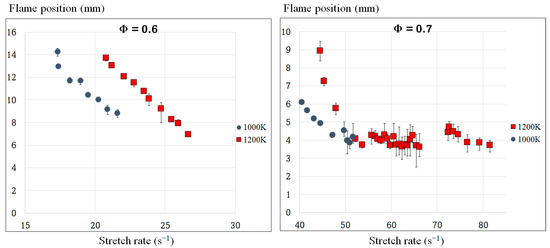

Dependency of the flame front position on stretch rate evaluated for equivalence ratios ϕ = 0.6 (left) and 0.7 (right) and wall temperatures 1000 (dark blue) and 1200 K (red) are shown in Figure 5. At small stretch rate values (exceeding the extreme left point), flame flashback to the burner occurred. Flame extinction at a large stretch rate (extreme right point) occurred at a finite distance from the wall that agrees with theoretical Reference [15]. At the same time, the combustion regimes near the wall, described in theoretical Reference [15], were not found. The same regimes were not observed in experiments in [9], performed under microgravity conditions.

Figure 5.

The dependency of flame front position on stretch rate evaluated for equivalence ratios ϕ = 0.6 (left) and 0.7 (right) and wall temperatures 1000 (dark blue) and 1200 K (red).

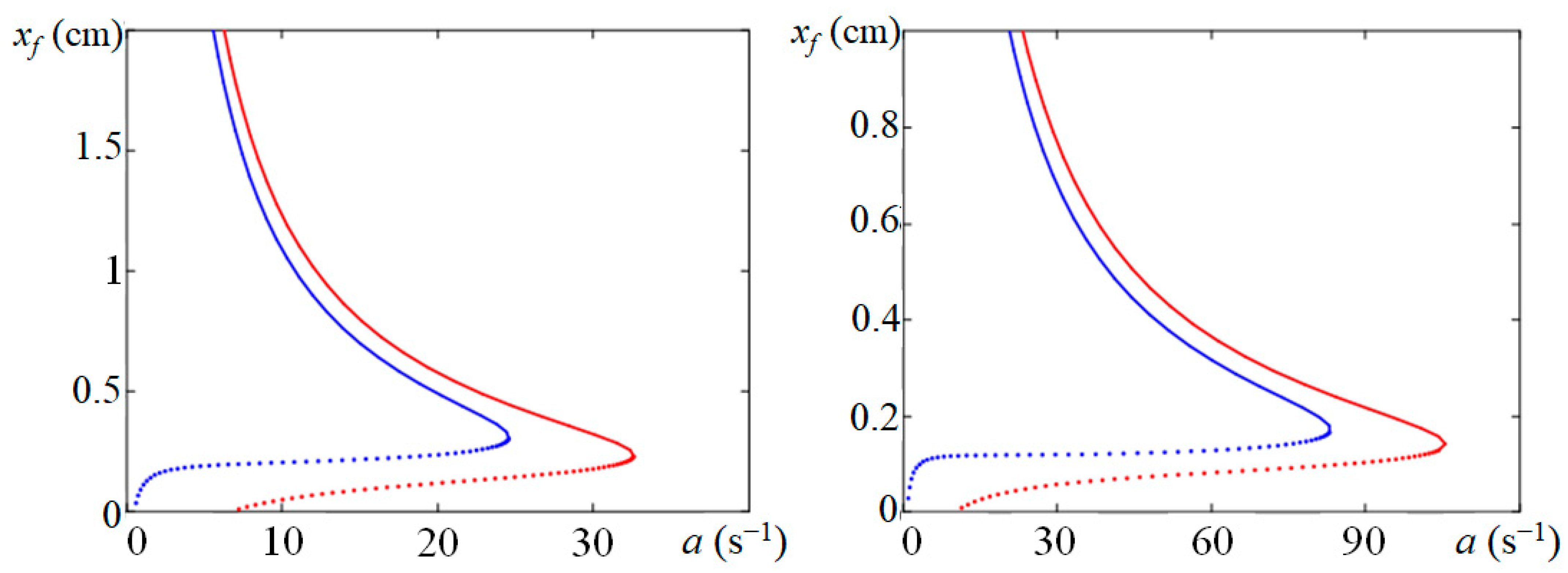

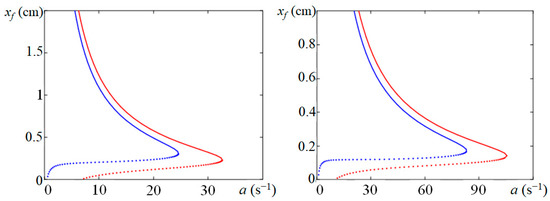

Experimental data showed that an increase in the wall temperature shifts points to the higher stretch rate side and increases the region of flame existence. Results of the flame front position xf depending on stretch rate a for equivalence ratios ϕ = 0.6 and 0.7 are shown in Figure 6. The following values of parameters were used in the calculations: N = 8.98, Le = 0.9, Dth = 0.7 cm2/s, Ub = 8.6 cm/s, Tb = 1670 K for ϕ = 0.6 and Ub = 16 cm/s, Tb = 1840 K for ϕ = 0.7. Since the burner was heated by the radiation from the hot wall, the measured temperatures of the fresh mixture were T0 = 400 and T0 = 450 K when the wall temperatures were Tw = 1000 and Tw = 1200 K, respectively. All curves in Figure 6 have an upper stable branch and unstable branches lying below turning points corresponding to the flame quenching. The conclusion on the stability of these branches follows from the linear stability analysis of the stationary solutions conducted in Reference [20]. The linear stability analysis explains why the flame was extinguished in the experiment at a certain distance from the hot wall. The increase in the wall temperature shifts the domain of existence of the stable flames towards larger values of the stretch rate. In addition, it allows the flame to be stabilized closer to the stagnation zone. The same tendency is observed with the increase in the fuel concentration in the combustion mixture. Theoretical results described above are in accordance with obtained experimental data shown in Figure 5.

Figure 6.

Flame coordinate xf depending on the stretch rate a evaluated for flame with equivalence ratios ϕ = 0.6 (left) and 0.7 (right). Solid lines correspond to the stable flame, and point lines mark unstable branches. The red curve represents the case of Tw = 1200 K, and the blue curve represents Tw = 1000 K.

5. Conclusions

Experimental data of the stretched flame location near the hot wall were obtained for different mass flow rates of lean methane/air mixtures and for two values of hot wall temperatures 1000 and 1200 K. The possibility of the simple model predicting the general tendency in estimation of the flame location with variation of the stretch rate, the lean mixture composition and the hot wall temperature was demonstrated. This qualitative analysis may be useful in estimation of the combustion product temperature and the residence time of the nanoparticles forming in combustion products before their impact with the hot wall.

Author Contributions

Conceptualization, S.M. (Sergey Mokrin) and S.M. (Sergey Minaev); methodology, S.M. (Sergey Mokrin) and V.G.; validation, S.M. (Sergey Minaev); writing—original draft preparation, S.M. (Sergey Mokrin) and S.M. (Sergey Minaev); writing—review and editing, V.G.; visualization, S.M. (Sergey Mokrin) and S.M. (Sergey Minaev); supervision, S.M. (Sergey Minaev); project administration, S.M. (Sergey Minaev); funding acquisition, S.M. (Sergey Minaev). All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Ministry of Science and Higher Education of the Russian Federation (project #075-15-2020-806).

Data Availability Statement

All the data presented and/or analyzed in this study are available upon request to the corresponding author.

Acknowledgments

We are grateful to Mariia Mokrina for editing a draft of this manuscript as well as some useful suggestions.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ren, Y.; Ran, K.; Kruse, S.; Mayer, J.; Pitsch, H. Flame Synthesis of Carbon Metal-Oxide Nanocomposites in a Counterflow Burner. Proc. Combust. Inst. 2021, 38, 1269–1277. [Google Scholar] [CrossRef]

- Mansurov, Z.A. Producing Nanomaterials in Combustion. Combust. Explos. Shock. Waves 2012, 48, 561–569. [Google Scholar] [CrossRef]

- Kruse, S.; Wick, A.; Medwell, P.; Attili, A.; Beeckmann, J.; Pitsch, H. Experimental and Numerical Study of Soot Formation in Counterflow Diffusion Flames of Gasoline Surrogate Components. Combust. Flame 2019, 210, 159–171. [Google Scholar] [CrossRef]

- Sun, J.; Ren, Y.; Tang, Y.; Li, S. Influences of Heat Flux on Extinction Characteristics of Steady/Unsteady Premixed Stagnation Flames. Proc. Combust. Inst. 2021, 38, 2305–2314. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Z.; Wu, X.; Sun, L.; Zhang, Z.; Zhang, H.; Li, S. In Situ Laser Diagnostics of Nanoparticle Transport across Stagnation Plane in a Counterflow Flame. J. Aerosol Sci. 2017, 105, 145–150. [Google Scholar] [CrossRef]

- Howard, J.B. Fullerenes Formation in Flames. Symp. (Int.) Combust. 1992, 24, 933–946. [Google Scholar] [CrossRef]

- Li, Z.; Zhu, H.; Xie, D.; Wang, K.; Cao, A.; Wei, J.; Li, X.; Fan, L.; Wu, D. Flame Synthesis of Few-Layered Graphene/Graphite Films. Chem. Commun. 2011, 47, 3520–3522. [Google Scholar] [CrossRef] [PubMed]

- Memon, N.K.; Tse, S.D.; Al-Sharab, J.F.; Yamaguchi, H.; Goncalves, A.M.B.; Kear, B.H.; Jaluria, Y.; Andrei, E.Y.; Chhowal, M. Flame Synthesis of Graphene Films in Open Environments. Carbon 2011, 49, 5064–5070. [Google Scholar] [CrossRef]

- Nakamura, H.; Fan, A.; Minamizono, H.; Maruta, K.; Kobayashi, H.; Niioka, T. Bifurcations of Stretched Premixed Flame Stabilized by a Hot Wall. Proc. Combust. Inst. 2009, 32, 1367–1374. [Google Scholar] [CrossRef]

- Law, C.K. Combustion Physics; Cambridge University Press: Cambridge, UK, 2006; ISBN 9780521870528. [Google Scholar] [CrossRef]

- Tsuji, H.; Yamaoka, I. Structure and Extinction of Near-Limit Flames in a Stagnation Flow. Symp. (Int.) Combust. 1982, 19, 1533–1540. [Google Scholar] [CrossRef]

- Maruta, K.; Yoshida, M.; Ju, Y.; Niioka, T. Experimental Study on Methane-Air Premixed Flame Extinction at Small Stretch Rates in Microgravity. Symp. (Int.) Combust. 1996, 26, 1283–1289. [Google Scholar] [CrossRef]

- Ju, Y.; Guo, H.; Maruta, K.; Liu, F. On the Extinction Limit and Flammability Limit of Non-Adiabatic Stretched Methane–Air Premixed Flames. J. Fluid Mech. 1997, 342, 315–334. [Google Scholar] [CrossRef]

- Guo, H.; Ju, Y.; Maruta, K.; Niioka, T.; Liu, F. Radiation Extinction Limit of Counterflow Premixed Lean Methane-Air Flames. Combust. Flame 1997, 109, 639–646. [Google Scholar] [CrossRef]

- Ju, Y.; Minaev, S. Dynamics and Flammability Limit of Stretched Premixed Flames Stabilized by a Hot Wall. Proc. Combust. Inst. 2002, 29, 949–956. [Google Scholar] [CrossRef]

- Lee, M.J.; Cho, M.S.; Kim, N.I. Characteristics of Opposed Flow Partially Premixed Flames in Mesoscale Channels at Low Strain Rates. Proc. Combust. Inst. 2015, 35, 3439–3446. [Google Scholar] [CrossRef]

- Mokrin, S.N.; Odintsov, E.S.; Uriupin, G.V.; Tezuka, T.; Minaev, S.S.; Maruta, K. Flammability Limit of Moderate- and Low-Stretched Premixed Flames Stabilized in Planar Channel. Combust. Flame 2017, 185, 261–264. [Google Scholar] [CrossRef]

- Minaev, S.; Fursenko, R.; Ju, Y.; Law, C.K. Stability Analysis of Near-Limit Stretched Premixed Flames. J. Fluid Mech. 2003, 488, 225–244. [Google Scholar] [CrossRef]

- Buckmaster, J. The Effects of Radiation on Stretched Flames. Combust. Theory Model. 1997, 1, 1–11. [Google Scholar] [CrossRef]

- Minaev, S.; Fursenko, R.; Ju, Y. Stability of Stretched Premixed Flames near the Extinction Limit. Thermophys. Aeromech. 2002, 2, 261–274. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).