Gradient Recrystallization Behavior of a Moderate Warm-Rolled Non-Oriented Fe-6.5wt%Si Alloy

Abstract

:1. Introduction

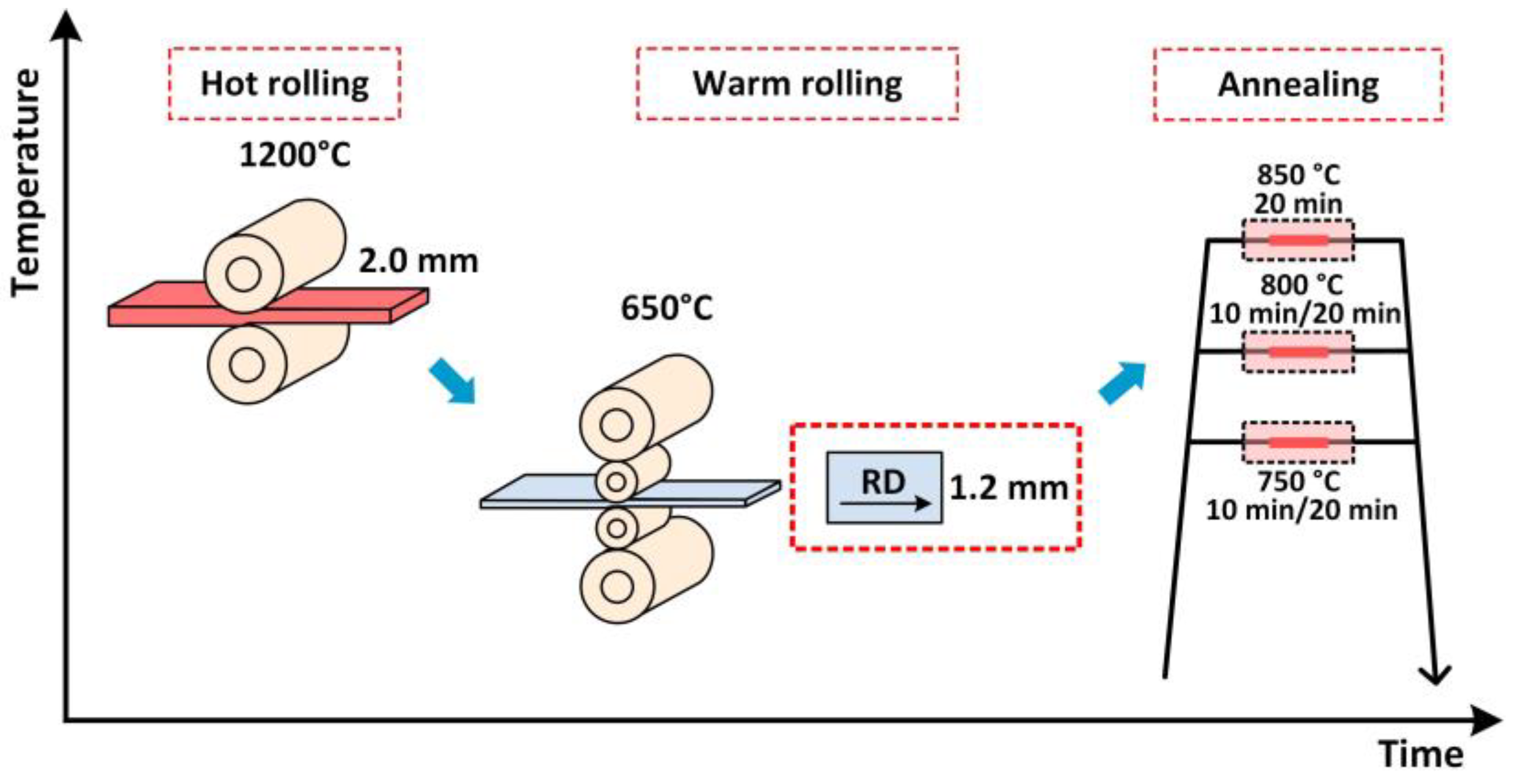

2. Materials and Experimental Procedure

3. Results and Discussion

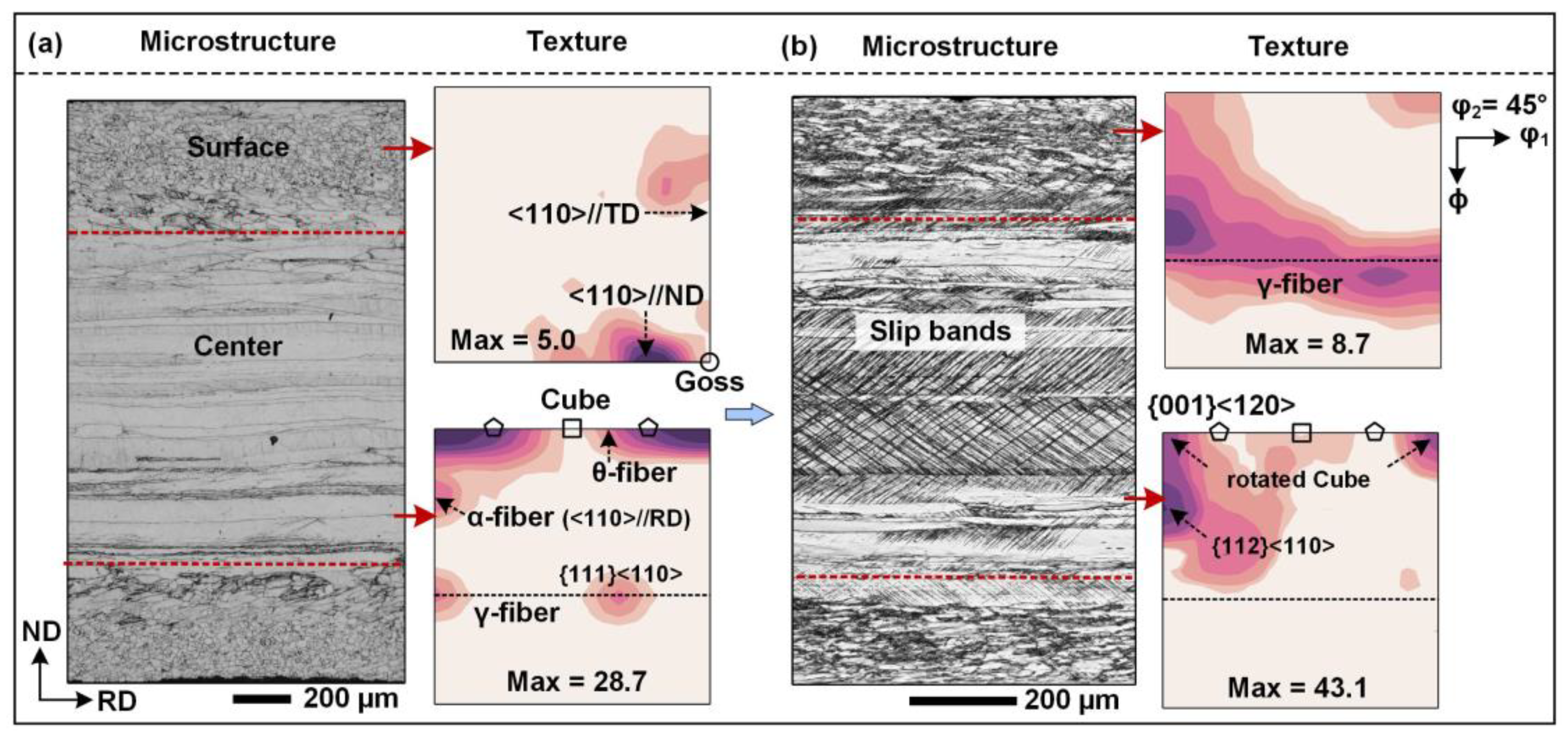

3.1. Microstructure and Texture after Hot Rolling and Warm Rolling

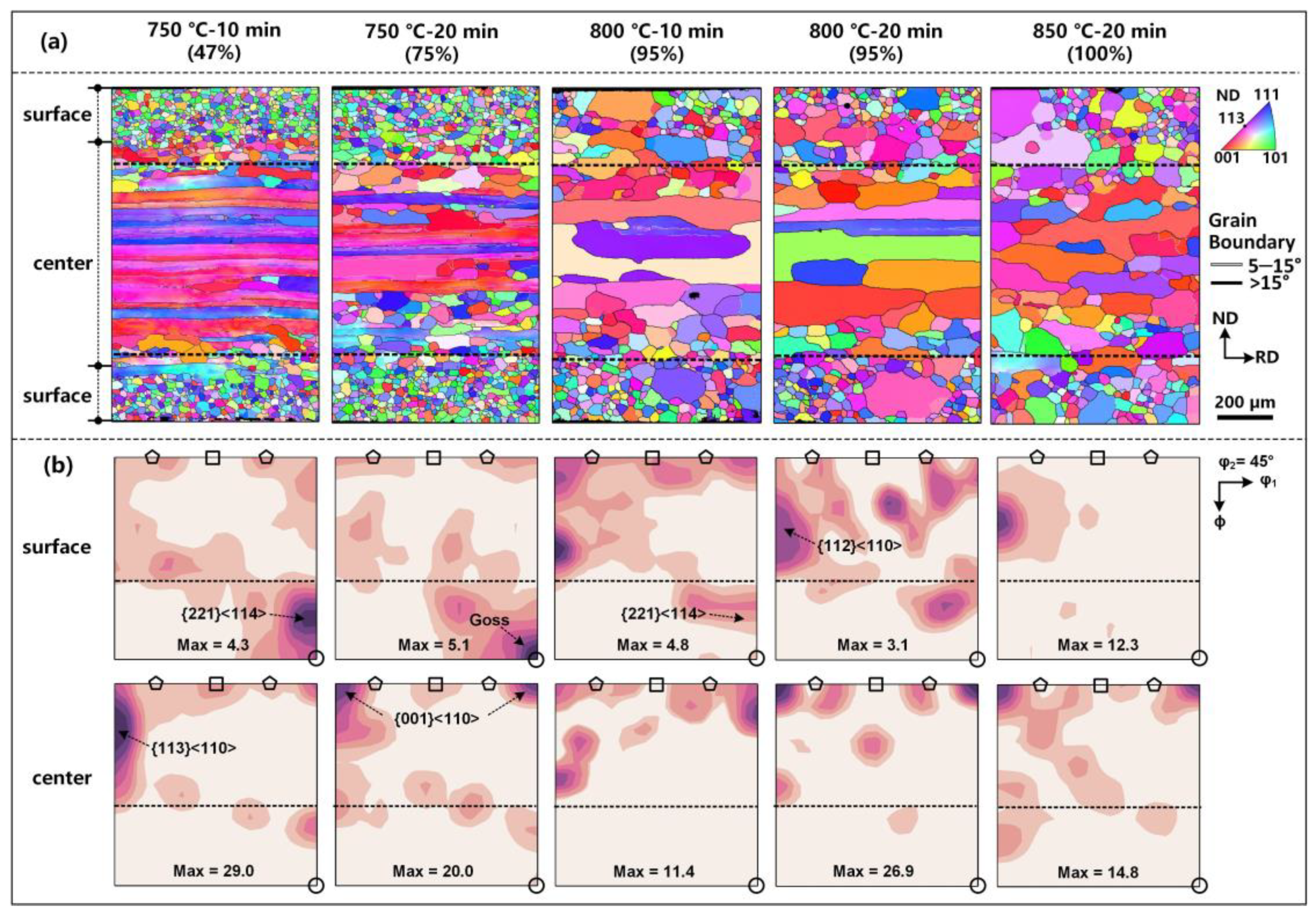

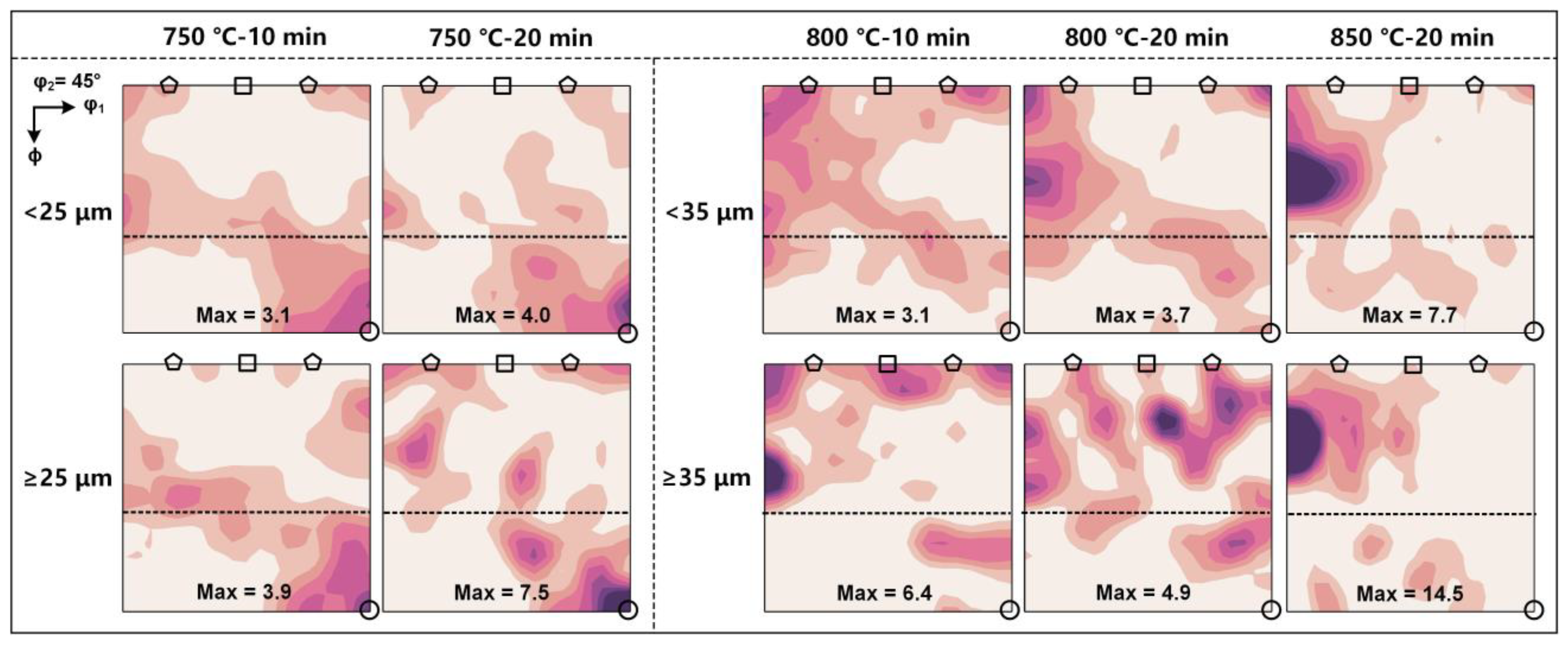

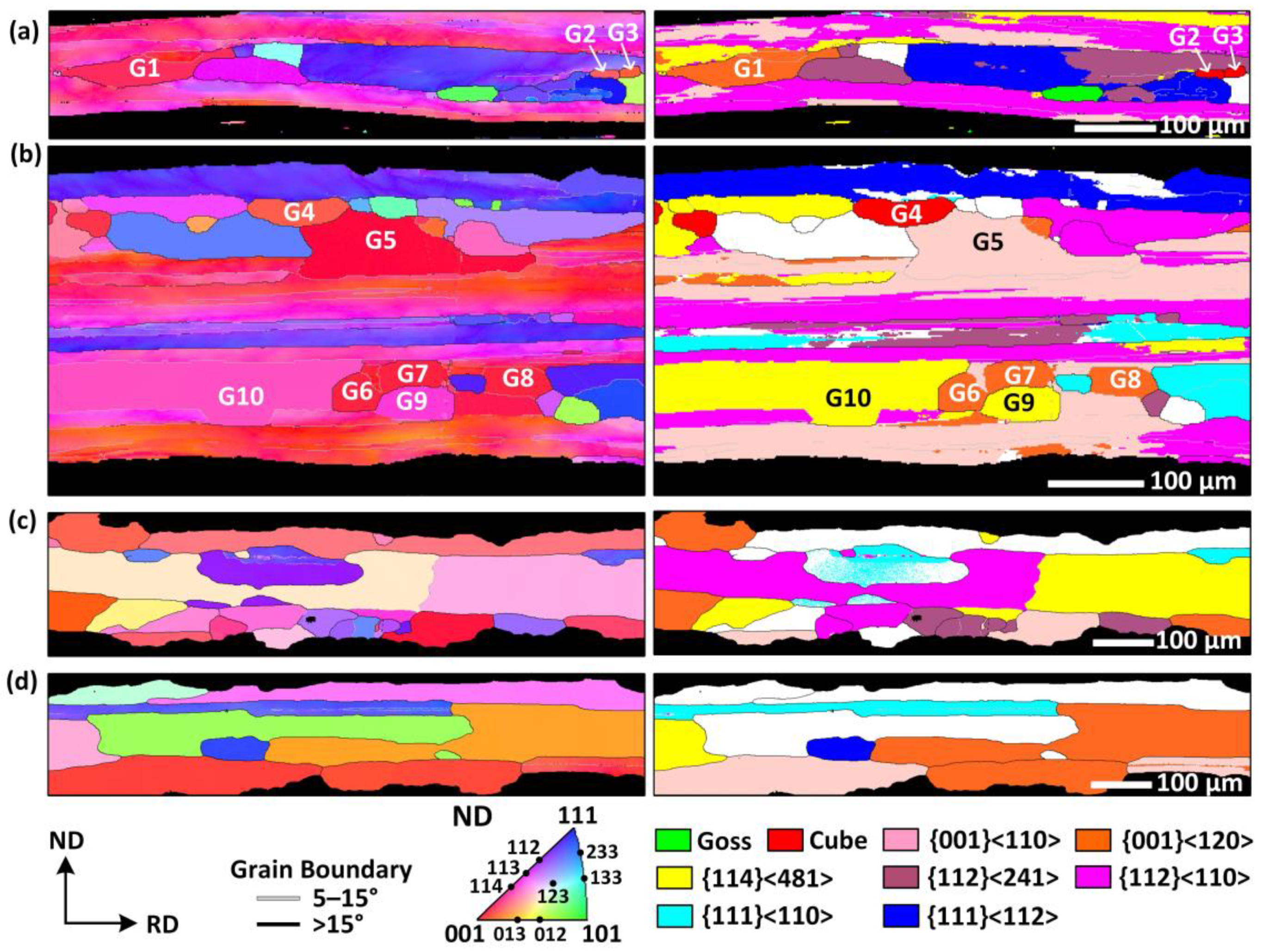

3.2. Microstructure and Texture after Annealing at Different Temperatures

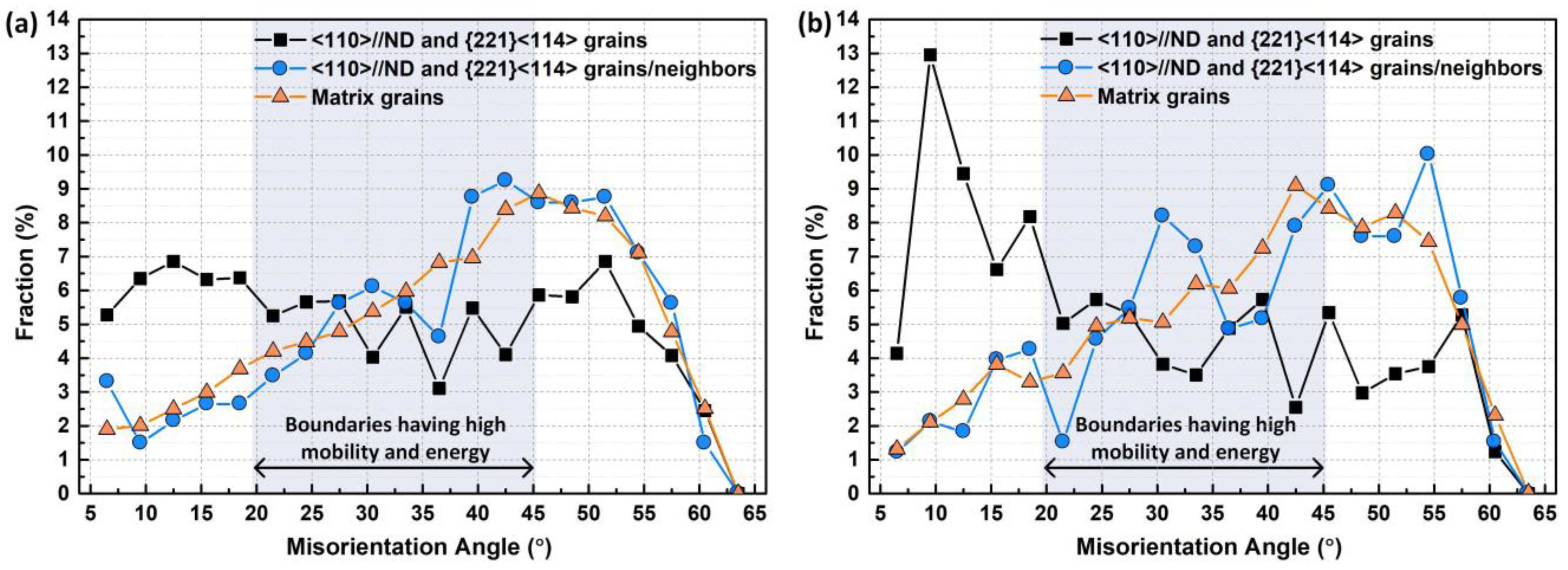

3.3. Gradient Recrystallization Behavior of the Moderate Warm-Rolled Sheets

4. Conclusions

- (1)

- The initial gradient structure of the hot band is inherited after warm rolling with a moderate thickness reduction of 40%, i.e., the surface regions are composed of fine deformed grains with strong α-fiber and γ-fiber textures, and the center region consist of coarse and elongated grains with strong α-fiber and θ-fiber textures.

- (2)

- During the annealing process of the moderate warm-rolled sheet, a gradient recrystallization phenomenon along the thickness occurs. The surface first densely nucleates and completely recrystallizes into fine equiaxed grains with strong <110>//ND and {221}<114> textures. The center region shows slower recrystallization. The absence of shear bands results in fewer nucleated grains, but larger grain sizes after growth.

- (3)

- During grain growth at the surface regions, the boundaries between the <110>//ND and {221}<114> grains have a small fraction of high-mobility and high-energy 20–45° boundaries than those between other oriented matrix grains, leading to insufficient grain growth advantage.

- (4)

- During recrystallization of the center region, warm rolling at a moderate thickness reduction induces θ-fiber inheritance from the initial hot band. The grains with θ-fiber and {114}<481> orientations nucleate in the strong α-fiber textured and deformed matrices, and form final strong θ-fiber and soft α*-fiber textures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gurbuz, I.; Martin, F.; Aydin, U.; Asaf, A.; Chamosa, M.; Rasilo, P.; Belahcen, A. Experimental characterization of the effect of uniaxial stress on magnetization and iron losses of electrical steel sheets cut by punching process. J. Magn. Magn. Mater. 2022, 549, 168983. [Google Scholar] [CrossRef]

- Tamimi, S.; He, Y.; Sanjari, M.; Pirgazi, H.; Kockelmann, W.; Robinson, F.; Mohammadi, M.; Kestens, L. Mechanical properties and crystallographic texture of non-oriented electrical steel processed by repetitive bending under tension. Mater. Sci. Eng. A 2022, 835, 142665. [Google Scholar] [CrossRef]

- Okubo, T.; Uesaka, M.; Zaizen, Y.; Oda, Y. Method of Manufacturing Non-Oriented Electrical Steel Sheet. U.S. Patent 2022010400A1, 13 January 2022. [Google Scholar]

- Feng, F.; Che, S.; Wang, F.; Zhao, Y.; Zhang, Y.; Wang, Y.; Cao, G.; Yuan, G.; Misra, R.; Wang, G. Microstructure evolution and strengthening mechanism in thin-gauge non-oriented silicon steel with high strength. J. Magn. Magn. Mater. 2022, 563, 169791. [Google Scholar] [CrossRef]

- He, Y.; Hilinski, E. Textures of non-oriented electrical steel sheets produced by skew cold rolling and annealing. Metals 2022, 12, 17. [Google Scholar] [CrossRef]

- Shen, X.; Meng, F.; Lau, K.; Wang, P.; Lee, C. Texture and microstructure characterizations of Fe-3.5wt%Si soft magnetic alloy fab-ricated via laser powder bed fusion. Mater. Charact. 2022, 189, 112012. [Google Scholar] [CrossRef]

- Ouyang, G.; Chen, X.; Liang, Y.; Macziewski, C.; Cui, J. Review of Fe-6.5 wt% Si high silicon steel-A promising soft magnetic mate-rial for sub-kHz application. J. Magn. Magn. Mater. 2019, 481, 234–250. [Google Scholar] [CrossRef]

- You, B.; Kim, J.; Lee, B.; Choi, G.; Yoo, D. Optimization of powder core inductors of buck-boost converters for hybrid electric vehicles. In Proceedings of the 2009 IEEE Vehicle Power and Propulsion Conference, Dearborn, MI, USA, 7–11 September 2009; pp. 730–735. [Google Scholar]

- Magnetics XFlux® Cores; Magnetics: Pittsburgh, PA, USA, 2016; pp. 1–4.

- Alloy Powder Ring Cores; Hengdian Group Dmegc Magnetics Co., Ltd.: Dongyang, China, 2018; pp. 1–24.

- He, Z.; Zhao, Y.; Luo, H. Electrical Steel; Metallurgical Industry Press: Beijing, China, 2012. [Google Scholar]

- Cava, R.; Botta, W.; Kiminami, C.; Olzon-Dionysio, M.; Souza, S.; Jorge, A.; Bolfarini, C. Ordered phases and texture in spray-formed Fe-5wt%Si. J. Alloys Compd. 2011, 509, S260–S264. [Google Scholar] [CrossRef]

- Rementeria, R.; Poplawsky, J.; Aranda, M.; Guo, W.; Jimenez, J.; Garcia-Mateo, C.; Caballero, F. Carbon concentration measurements by atom probe tomography in the ferritic phase of high-silicon steels. Acta Mater. 2017, 125, 359–368. [Google Scholar] [CrossRef]

- Takamiya, T.; Hanazawa, K.; Suzuki, T. Recent development of grain-oriented electrical steel in JFE Steel. JFE Tech. Rep. 2016, 21, 1–6. [Google Scholar]

- Cramer, C.; Nandwana, P.; Yan, J.; Evans, S.; Paranthaman, M. Binder jet additive manufacturing method to fabricate near net shape crack-free highly dense Fe-6.5 wt.% Si soft magnets. Heliyon 2019, 5, e02804. [Google Scholar] [CrossRef]

- Zhang, Y.; Lu, X.; Yuan, G.; Wang, Y.; Fang, F.; Zhang, X.; Wang, G. Texture and microstructure evolution during different rolling methods in strip-cast grain-oriented 6.5% Si steel. J. Magn. Magn. Mater. 2020, 499, 166256. [Google Scholar] [CrossRef]

- Xu, H.; Xu, Y.; He, Y.; Cheng, S.; Jiao, H.; Yue, S.; Li, J. Two-stage warm cross rolling and its effect on the microstructure, texture and magnetic properties of an Fe-6.5 wt% Si non-oriented electrical steel. J. Mater. Sci. 2020, 55, 12525–12543. [Google Scholar] [CrossRef]

- Xu, H.; Xu, Y.; Jiao, H.; Cheng, S.; Misra, R.; Li, J. Influence of grain size and texture prior to warm rolling on microstructure, tex-ture and magnetic properties of Fe-6.5 wt% Si steel. J. Magn. Magn. Mater. 2018, 453, 236–245. [Google Scholar] [CrossRef]

- Lee, K.; Huh, M.; Lee, H.; Park, J.; Kim, J.; Shin, E.; Engler, O. Effect of hot band grain size on development of textures and mag-netic properties in 2.0% Si non-oriented electrical steel sheet. J. Magn. Magn. Mater. 2015, 396, 53–64. [Google Scholar] [CrossRef]

- Paolinelli, S.; Cunha, M.; Cota, A. Effect of hot band grain size on the texture evolution of 2% Si non-oriented steel during final annealing. IEEE Trans. Magn. 2015, 51, 1–4. [Google Scholar] [CrossRef]

- Yao, Y.; Sha, Y.; Liu, J.; Zhang, F.; Zuo, L. Texture and microstructure for magnetic properties of two-stage cold-rolled Fe-6.5 wt pct Si thin sheets. Metall. Mater. Trans. A 2016, 47, 5771–5776. [Google Scholar] [CrossRef]

- Liang, R.; Yang, P.; Mao, W. Cube texture evolution and magnetic properties of 6.5 wt% Si electrical steel fabricated by surface energy and three-stage rolling method. J. Magn. Magn. Mater. 2018, 457, 38–45. [Google Scholar] [CrossRef]

- Xu, H. Study on Microstructure Evolution and Preferred Orientation in Warm-Rolled Fe-6.5wt%Si Steel. Ph.D. Thesis, Northeastern University, Shenyang, China, 2021. [Google Scholar]

- Humphreys, F.; Hatherly, M. Recrystallization and Related Annealing Phenomena; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Lu, X.; Fang, F.; Zhang, Y.; Wang, Y.; Yuan, G.; Xu, Y.; Misra, R.; Zhang, W.; Wang, G. Microstructure and magnetic properties of strip-cast grain-oriented 4.5%Si steel under isochronal and isothermal secondary annealing. J. Mater. Sci. 2018, 53, 2928–2941. [Google Scholar] [CrossRef]

- Song, H.; Wang, Y.; Esling, C.; Wang, G.; Liu, H. The role of grain colony on secondary recrystallization in grain-oriented electri-cal steel: New insights from an original tracking experiment. Acta Mater. 2020, 206, 116611. [Google Scholar] [CrossRef]

- Sandsttrom, R. Subgrain growth occurring by boundary migration. Acta Metall. 1977, 25, 905–911. [Google Scholar] [CrossRef]

- Read, W.; Shockley, W. Dislocation models of crystal grain boundaries. Phys. Rev. 1950, 78, 275–289. [Google Scholar] [CrossRef]

- Xu, H.; Xu, Y.; He, Y.; Jiao, H.; Yue, S.; Li, J. A quasi in-situ EBSD study of the nucleation and growth of Goss grains during prima-ry and secondary recrystallization of a strip-cast Fe-6.5 wt% Si alloy. J. Alloys Compd. 2021, 861, 158550. [Google Scholar] [CrossRef]

- Jiao, H.; Xu, Y.; Zhao, L.; Misra, R.; Tang, Y.; Liu, D.; Hu, Y.; Zhao, M.; Shen, M. Texture evolution in twin-roll strip cast non-oriented electrical steel with strong Cube and Goss texture. Acta Mater. 2020, 199, 311–325. [Google Scholar] [CrossRef]

- Takajo, S.; Merriman, C.; Vogel, S.; Field, D. In-situ EBSD study on the cube texture evolution in 3 wt% Si steel complemented by ex-situ EBSD experiment-From nucleation to grain growth. Acta Mater. 2019, 166, 100–112. [Google Scholar] [CrossRef]

- Mehdi, M.; He, Y.; Hilinski, E.; Kestens, L.; Edrisy, A. The evolution of cube ({001}<100>) texture in non-oriented electrical steel. Acta Mater. 2020, 185, 540–554. [Google Scholar]

- Park, J.; Szpunar, J. Evolution of recrystallization texture in nonoriented electrical steels. Acta Mater. 2003, 51, 3037.e3051. [Google Scholar] [CrossRef]

- Zhang, N.; Yang, P.; Mao, W. {001}<120>-{113}<361> recrystallization textures induced by initial {001} grains and related microstructure evolution in heavily rolled electrical steel. Mater. Charact. 2016, 119, 225–232. [Google Scholar]

- Verbeken, K.; Kestens, L.; Nave, M. Re-evaluation of the Ibe-Lücke growth selection experiment in a Fe-Si single crystal. Acta Mater. 2005, 53, 2675–2682. [Google Scholar] [CrossRef]

- Gobernado, P.; Petrov, R.H.; Kestens, L.A. Recrystallized {311}<136> orientation in ferrite steels. Scr. Mater. 2012, 66, 623–626. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, H.; Xu, C.; Jiang, L.; Zhang, Y.; Shu, X.; Lin, X. Gradient Recrystallization Behavior of a Moderate Warm-Rolled Non-Oriented Fe-6.5wt%Si Alloy. Metals 2023, 13, 370. https://doi.org/10.3390/met13020370

Xu H, Xu C, Jiang L, Zhang Y, Shu X, Lin X. Gradient Recrystallization Behavior of a Moderate Warm-Rolled Non-Oriented Fe-6.5wt%Si Alloy. Metals. 2023; 13(2):370. https://doi.org/10.3390/met13020370

Chicago/Turabian StyleXu, Haijie, Cheng Xu, Lulan Jiang, Yuanxiang Zhang, Xuedao Shu, and Xiaogang Lin. 2023. "Gradient Recrystallization Behavior of a Moderate Warm-Rolled Non-Oriented Fe-6.5wt%Si Alloy" Metals 13, no. 2: 370. https://doi.org/10.3390/met13020370

APA StyleXu, H., Xu, C., Jiang, L., Zhang, Y., Shu, X., & Lin, X. (2023). Gradient Recrystallization Behavior of a Moderate Warm-Rolled Non-Oriented Fe-6.5wt%Si Alloy. Metals, 13(2), 370. https://doi.org/10.3390/met13020370