Microstructure and Mechanical Performance of Tin-Based Babbitt Alloy Containing Iron Oxide and Silica Nanoparticles

Abstract

1. Introduction

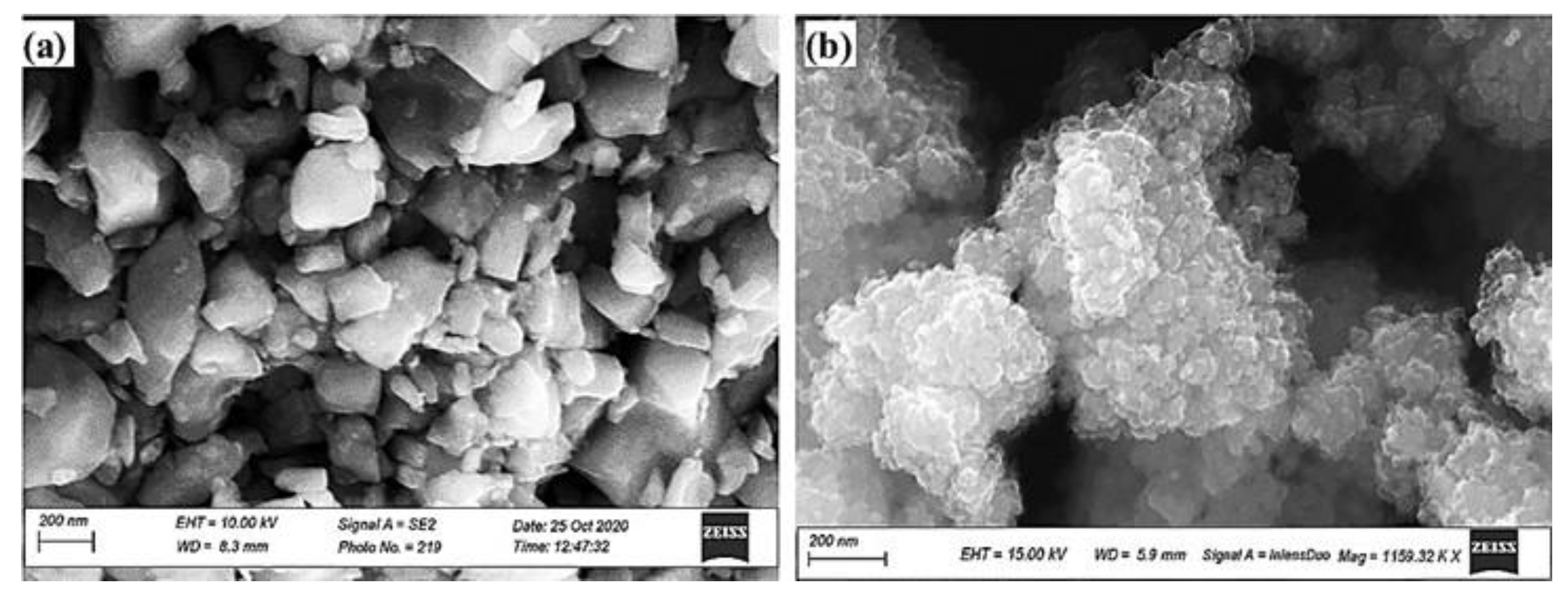

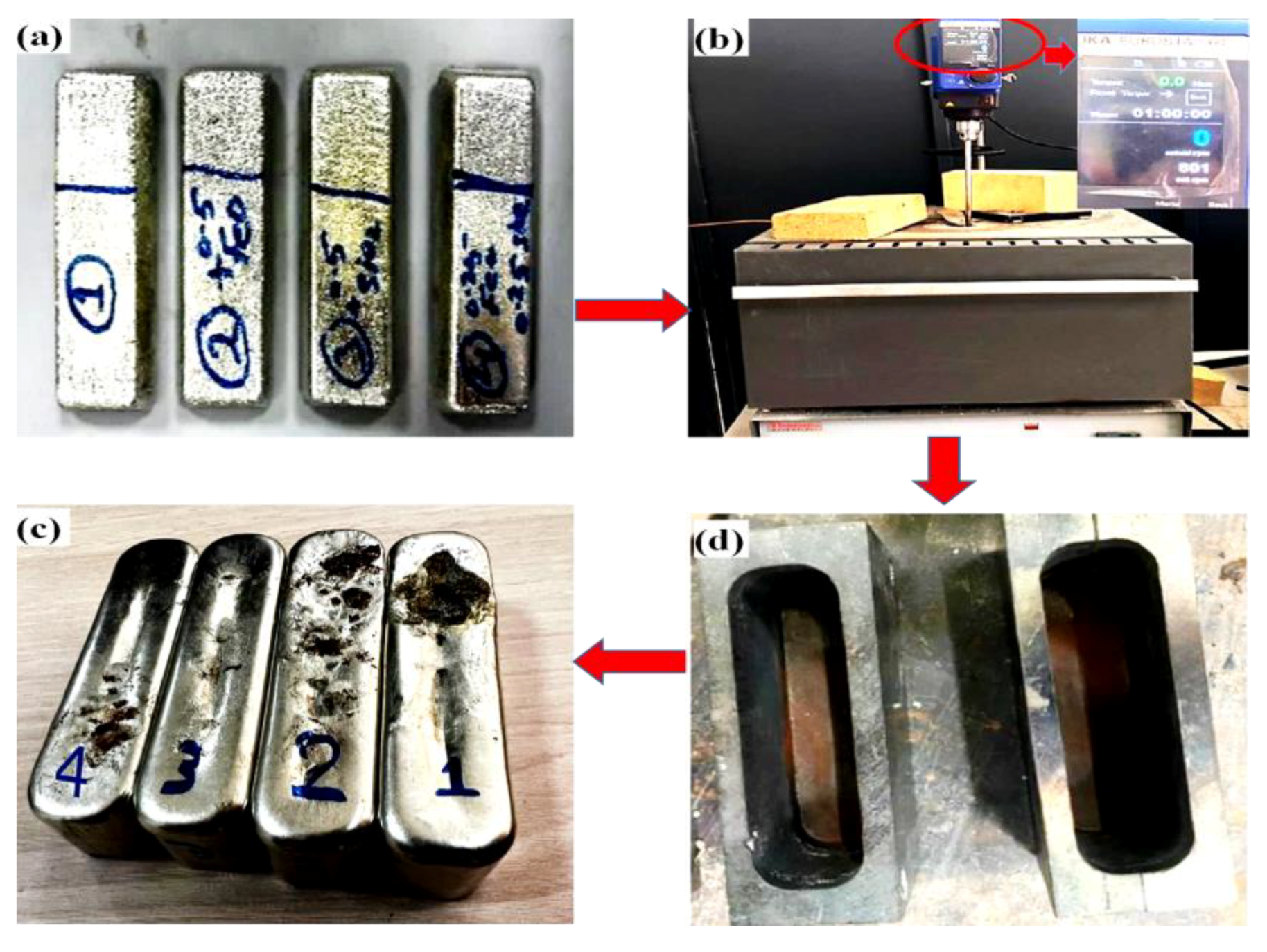

2. Materials and Methods

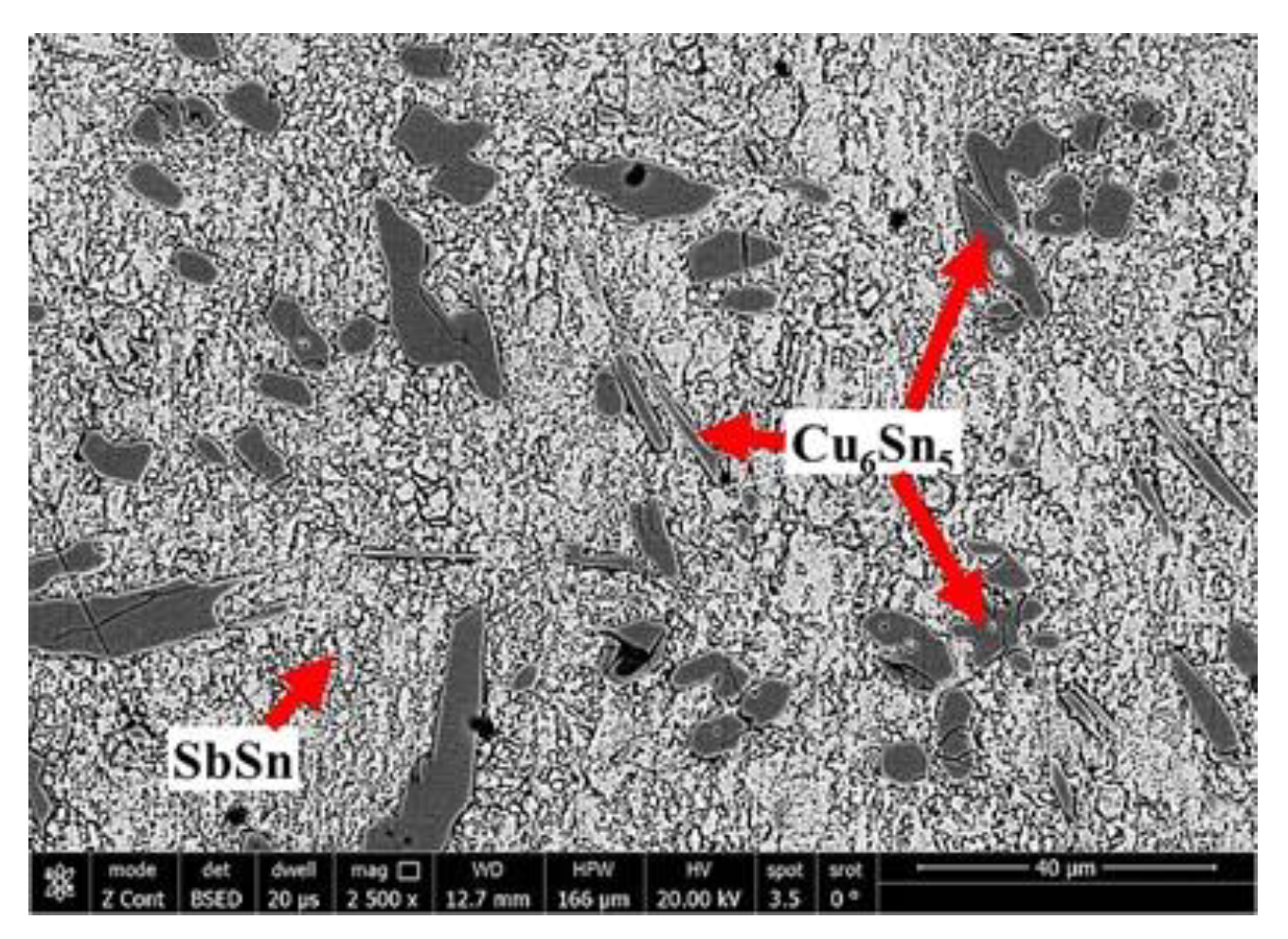

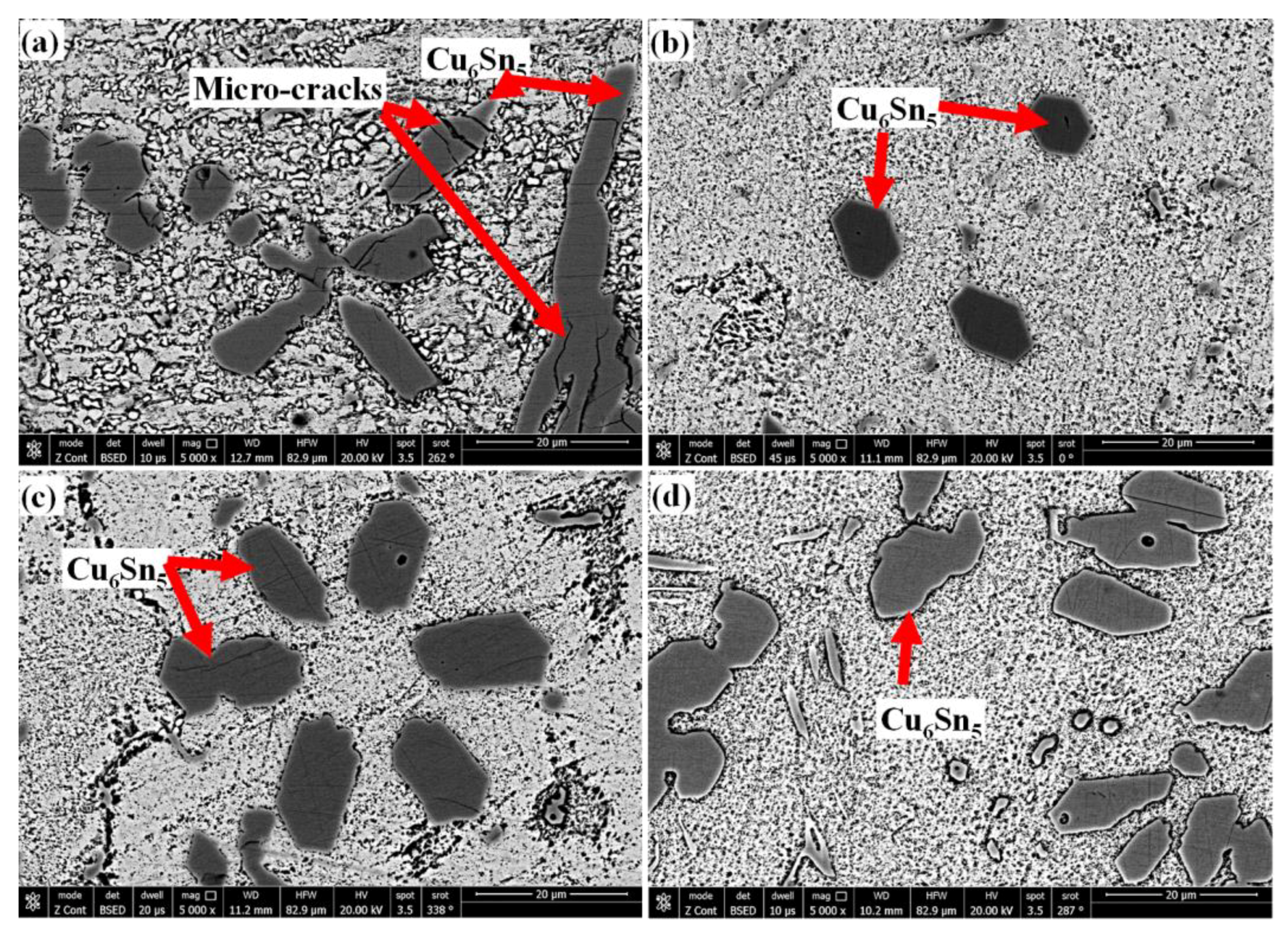

3. Results and Discussion

3.1. Microstructural Evolution

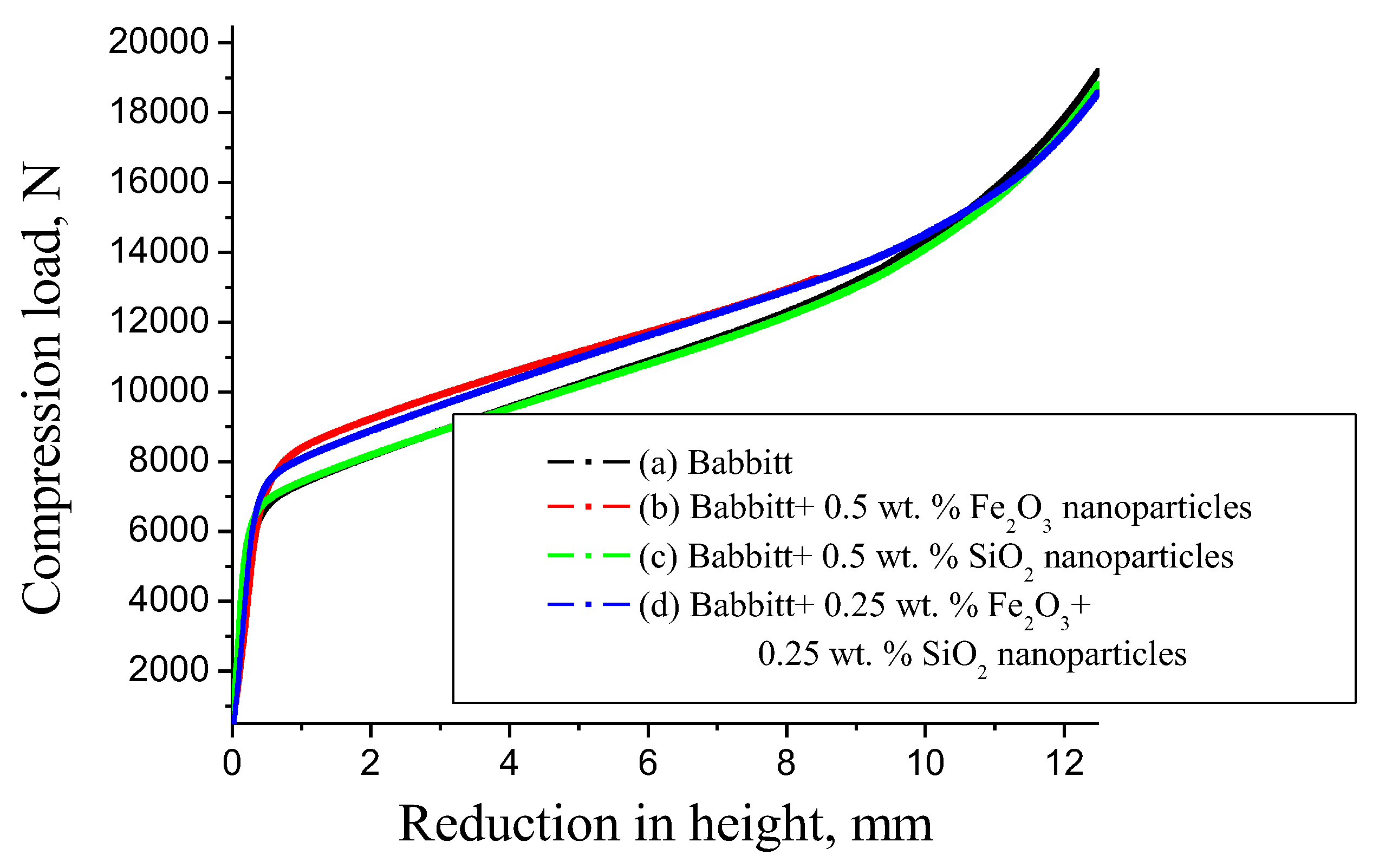

3.2. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kamal, M.; Mazen, S.; El-Bediwi, A.B.; El-Naggar, M. Structure, mechanical and electrical transport properties of low-melting half bearing metal alloys rapidly solidified from melt. Radiat. Eff. Defects Solids 2002, 157, 467–474. [Google Scholar] [CrossRef]

- Tasgin, Y. The Effects of Boron Minerals on the Microstructure and Abrasion Resistance of Babbitt Metal (Sn–Sb–Cu) Used as Coating Materials in Hydroelectric Power Plants. Int. Metalcast. 2022, 14, 257–265. [Google Scholar] [CrossRef]

- Kamal, M.; Bakr El-Bediwi, A.; El-Shobaki, M.R. Influence of alloying elements on structure and some physical properties of quenched Sn–Sb alloy. Radiat. Eff. Defects Solids 2006, 161, 549–557. [Google Scholar] [CrossRef]

- Thomson, J.; Zavadil, R.; Sahoo, M.; Dadouche, A.; Dmochowski, W.; Conlon, M. Development of a Lead-Free Bearing Material for Aerospace Applications. Int. Metalcast. 2010, 4, 19–30. [Google Scholar] [CrossRef]

- Zhang, Y.; Tudela, I.; Pal, M.; Kerr, I. High strength tin-based overlay for medium and high-speed diesel engine bearing tribological applications. Tribol. Int. 2016, 93, 687–695. [Google Scholar] [CrossRef]

- Aleshin, N.P.; Kobernik, N.V.; Mikheev, R.S.; Vaganov, V.E.; Reshetnyak, V.; Aborkin, A.V. Plasma–powder application of antifrictional babbitt coatings modified by carbon nanotubes. Russ. Eng. 2016, 36, 46–52. [Google Scholar] [CrossRef]

- Fathy, N.; Ramadan, M. Influence of volume ratio of liquid to solid and low pouring temperature on interface structure of cast Babbitt-steel bimetal composite. AIP Conf. Proc. 2018, 1966, 020028. [Google Scholar] [CrossRef]

- Belov, N.A.; Akopyan, T.K.; Gershman, I.S.; Stolyarova, O.O.; Yakovleva, A.O. Effect of Si and Cu additions on the phase composition, microstructure and properties of Al-Sn alloys. J. Alloys Compd. 2017, 695, 2730–2739. [Google Scholar] [CrossRef]

- Diouf, P.; Jones, A. Investigation of Bond Strength in Centrifugal Lining of Babbitt on Cast Iron. Metall. Mater. Trans. A 2010, 41, 603–609. [Google Scholar] [CrossRef]

- Ramadan, M.; Ayadi, B.; Rajhi, W.; Alghamdi, A.S. Influence of Tinning Material on Interfacial Microstructures and Mechanical Properties of Al12Sn4Si1Cu /Carbon Steel Bimetallic Castings for Bearing Applications. Key Eng. Mater. 2020, 835, 108–114. [Google Scholar] [CrossRef]

- Zeren, A.; Feyzullahoglu, E.; Zeren, M. A study on tribological behaviour of tin-based bearing material in dry sliding. Mater. Des. 2007, 28, 318–323. [Google Scholar] [CrossRef]

- Potekhin, B.A.; Il’yushin, V.V.; Khristolyubov, A.S. Effect of casting methods on the structure and properties of tin babbit. Met. Sci. Heat Treat 2009, 51, 378–382. [Google Scholar] [CrossRef]

- Gajmal, S.S.; Raut, D.N. An Investigation on Wear Behaviour of ASTM B23 tin-Based Babbitt Alloy Developed Through Microwave-Assisted Casting. Int. Metalcast. 2022, 16, 1995–2013. [Google Scholar] [CrossRef]

- Dong, Q.; Yin, Z.; Li, H.; Zhang, X.; Jiang, D.; Zhong, N. Effects of Ag micro-addition on structure and mechanical properties of Sn-11Sb-6Cu Babbitt. Mater. Sci. Eng. A 2018, 722, 225–230. [Google Scholar] [CrossRef]

- Tasgın, Y. Effect of MgO, Al2O3 and FeCr2O4 on microstructure and wear resistance of Babbitt metal (Sn–Sb–Cu). Mater. Res. Express 2019, 6, 046548. [Google Scholar] [CrossRef]

- Ramadan, M.; Alghamdi, A.S.; Subhani, T.; Abdel Halim, K.S. Fabrication and Characterization of Sn-Based Babbitt Alloy Nanocomposite Reinforced with Al2O3 Nanoparticles/Carbon Steel Bimetallic Material. Materials 2020, 13, 2759. [Google Scholar] [CrossRef] [PubMed]

- Buchanan, V.E.; Molian, P.A.; Sudarshan, T.S.; Akers, A. Frictional behaviour of non-equilibrium Cu-Pb alloys. Wear 1991, 146, 241–256. [Google Scholar] [CrossRef]

- Glaeser, W.A. Wear properties of heavy loaded Cu based bearing alloys. J. Met. 1983, 35, 50–55. [Google Scholar]

- Ramadan, M.; Hafez, K.M. Interfacial microstructure and hardness of Sn-Based Babbitt/C93700 Cu-Pb-Sn bimetallic materials. Mater. Today Proc. 2021, 45, 5074–5080. [Google Scholar] [CrossRef]

- Babu, M.; Krishna, A.R.; Suman, K. Review of Journal Bearing Materials and Current Trends. Am. J. Mater. Sci. Technol. 2015, 4, 72–83. [Google Scholar] [CrossRef]

- Sturk, R.K.; Whitney, W.J. Fluid Film Bearing Materials. In Encyclopedia of Tribology; Wang, Q.J., Chung, Y.W., Eds.; Springer: Boston, MA, USA, 2013; pp. 1200–1216. [Google Scholar] [CrossRef]

- Ramadan, M.; Hafez, K.M.; Alghamdi, A.S.; Ayadi, B.; Halim, K.S.A. Novel Approach for Using Ductile Iron as Substrate in Bimetallic Materials for Higher Interfacial Bonding Bearings. Int. J. Met. 2021, 16, 987–1000. [Google Scholar] [CrossRef]

- Valeeva, A.K.; Valeev, I.S.; Fazlyakhmetov, R.F. Effect of structure of B83 babbit on its wear. J. Frict. Wear 2014, 35, 311–315. [Google Scholar] [CrossRef]

- Ji, X.; Chen, Y. Tribological Behavior of Babbitt Alloy Rubbing Against Si3N4 and Steel Under Dry Friction Condition. J. Mater. Eng. Perform. 2016, 25, 750–755. [Google Scholar] [CrossRef]

- Fathy, N. Interfacial Microstructure and Bonding Area of Sn based Alloy-GG25 Gray Iron Bimetallic Material Using Flux, Sn, and Sn-Zn Interlayer Compound Casting, Engineering. Technol. Appl. Sci. Res. 2022, 12, 8416–8420. [Google Scholar] [CrossRef]

- Mıćıć, M.; Đorđevıć, M.; Đajıć, G. Characteristics of white metal slide layer bearings produced by cast cladding and weld cladding. Metalurgija 2006, 12, 225–236. [Google Scholar]

- Ayadi, B.; Ramadan, M. Novel and simple technique for interfacial shear strength of liquid-solid compound casting specimen. Mater. Today Proc. 2021, 47, 2299–2304. [Google Scholar] [CrossRef]

- Ramadan, M.; Fathy, N.; Abdel Halim, K.S.; Alghamdi, A.S. New trends and advances in bimetal casting technologies. Int. J. Adv. Appl. Sci. 2019, 6, 75–80. [Google Scholar] [CrossRef]

- Altuner, S.; Kelesoglu, E. Productıon of Y2O3 coated Al2O3 reinforced aluminium matrix composites and the coating of interface effects over wettability properties. J. Eng. Nat. Sci. 2012, 30, 252–258. [Google Scholar]

- Barykin, N.P.; Sadykov, F.A.; Aslanyan, I.R. Wear and failure of Babbitt bushes in steam turbine sliding bearings. J. Mater. Eng. Perform. 2000, 9, 110–115. [Google Scholar] [CrossRef]

- Fathy, F. Interfacial Microstructure and Shear Strength Improvements of Babbitt–Steel Bimetal Composites Using Sn–Bi Interlayer via Liquid–Solid Casting. Sustainability 2023, 15, 804. [Google Scholar] [CrossRef]

- Townsend, T.; Sabio, E.; Browning, N.; Osterloh, F. The oxygen evolution reaction: Water oxidation photocatalysis—Photocatalytic water oxidation with suspended alpha-Fe2O3 particles—Effects of nanoscaling. In Inorganic Metal Oxide Nanocrystal Photocatalysts for Solar Fuel Generation from Water; Springer International Publishing: Berlin/Heidelberg, Germany, 2014; pp. 27–37. [Google Scholar]

- Shivakumara, S.; Penki, T.; Munichandraiah, N. Preparation and electrochemical performance of porous hematite (a-Fe2O3) nanostructures as supercapacitor electrode material. J. Solid State Electrochem. 2014, 18, 1057–1066. [Google Scholar] [CrossRef]

- Gu, Y.; Zhao, X.C.; Li, Y.; Liu, Y.; Wang, Y.; Li, Z. Effect of nano-Fe2O3 additions on wettability and interfacial intermetallic growth of low-Ag content Sn-Ag-Cu solders on Cusubstrates. J. Alloys Compd. 2015, 627, 39–47. [Google Scholar] [CrossRef]

- Moille, G.; Chang, L.; Xie, W.; Rao, A.; Lu, X.; Davanço, M.; Bowers, J.E.; Srinivasan, K. Dissipative ksdks-V m, (laser photonics rev. 14(8)/2020). Laser Photonics Rev. 2020, 14, 2070043. [Google Scholar] [CrossRef]

- Kong, L.; Zhang, L.; Bao, Y.; Liu, D.; Liu, S. Effect of Surface Roughness and Particle Size on Lubrication Mechanisms of SiO2 Nanoparticles. Adv. Mater. Sci. Eng. 2022, 2022, 7051650. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, X.; Xie, X.; Gu, Y.; Liu, Y. Effects of nano-SiO2 particles addition on the microstructure, wettability, joint shear force and the interfacial IMC growth of Sn3.0Ag0.5Cu solder. J. Mater. Sci. Mater. Electron. 2015, 26, 9387–9395. [Google Scholar] [CrossRef]

- Iqbal, A.A.; Ismail, N.B. Mechanical Properties and Corrosion Behavior of Silica Nanoparticle Reinforced Magnesium Nanocomposite for Bio-Implant Application. Materials 2022, 15, 8164. [Google Scholar] [CrossRef]

- Wu, H.; Bi, Q.; Zhu, S.; Yang, J.; Liu, W. Friction and wear properties of Babbitt alloy 16-16-2 under sea water environment. Tribol. Int. 2011, 44, 161–1167. [Google Scholar] [CrossRef]

- Wu, H.R.; Bi, Q.L.; Yang, J.; Liu, W.M. Tribological performance of tin-based white metal ZChSnSb 8-8 under simulated sea water environment. Mocaxue Xuebao/Tribology 2011, 31, 271–277. [Google Scholar]

- Zhao, X.; Wen, Y.; Li, Y.; Liu, Y.; Wang, Y. Effect of g-Fe2O3 nanoparticles size on the properties of Sn-1.0Age0.5Cu nano-composite solders and joints. J. Alloys Compd. 2016, 662, 272–282. [Google Scholar] [CrossRef]

- Babu, M.V.S.; Krishna, A.R.; Suman, K.N.S. Improvement of Tensile Behaviour of Tin Babbitt by Reinforcing with Nano Ilmenite and its Optimisation by using Response Surface Methodology. Int. J. Manuf. Mater. Mech. Eng. 2017, 7, 37–51. [Google Scholar]

- Zhao, X.; Hai, X. Microstructure and tribological behaviour of the nickel-coated-graphite-reinforced Babbitt metal composite fabricated via selective laser melting. Int. J. Min. Metall. Mater. 2022, 29, 320. [Google Scholar] [CrossRef]

- Kolev, M.; Drenchev, L.; Petkov, V. Wear analysis of an advanced Al-Al2O3 composite infiltrated with a tin-based alloy. Metals 2021, 11, 1692. [Google Scholar] [CrossRef]

- Madej, M.; Madej, B.L.; Wisnios, J.H.; Weglowska, A. Effect of FSP on Tribological Properties of Grade B89 Tin Babbitt. Materials 2021, 14, 2627. [Google Scholar] [CrossRef]

- Saboori, A.; Dadkhah, M.; Fino, P.; Pavese, M. An Overview of Metal Matrix Nanocomposites Reinforced with Graphene Nanoplatelets; Mechanical, Electrical and Thermophysical Properties. Metals 2018, 8, 423. [Google Scholar] [CrossRef]

- Malaki, M.; Xu, W.; Kasar, A.K.; Menezes, P.L.; Dieringa Varma, H.; Gupta, M. Advanced Metal Matrix Nanocomposites. Metals 2019, 9, 330. [Google Scholar] [CrossRef]

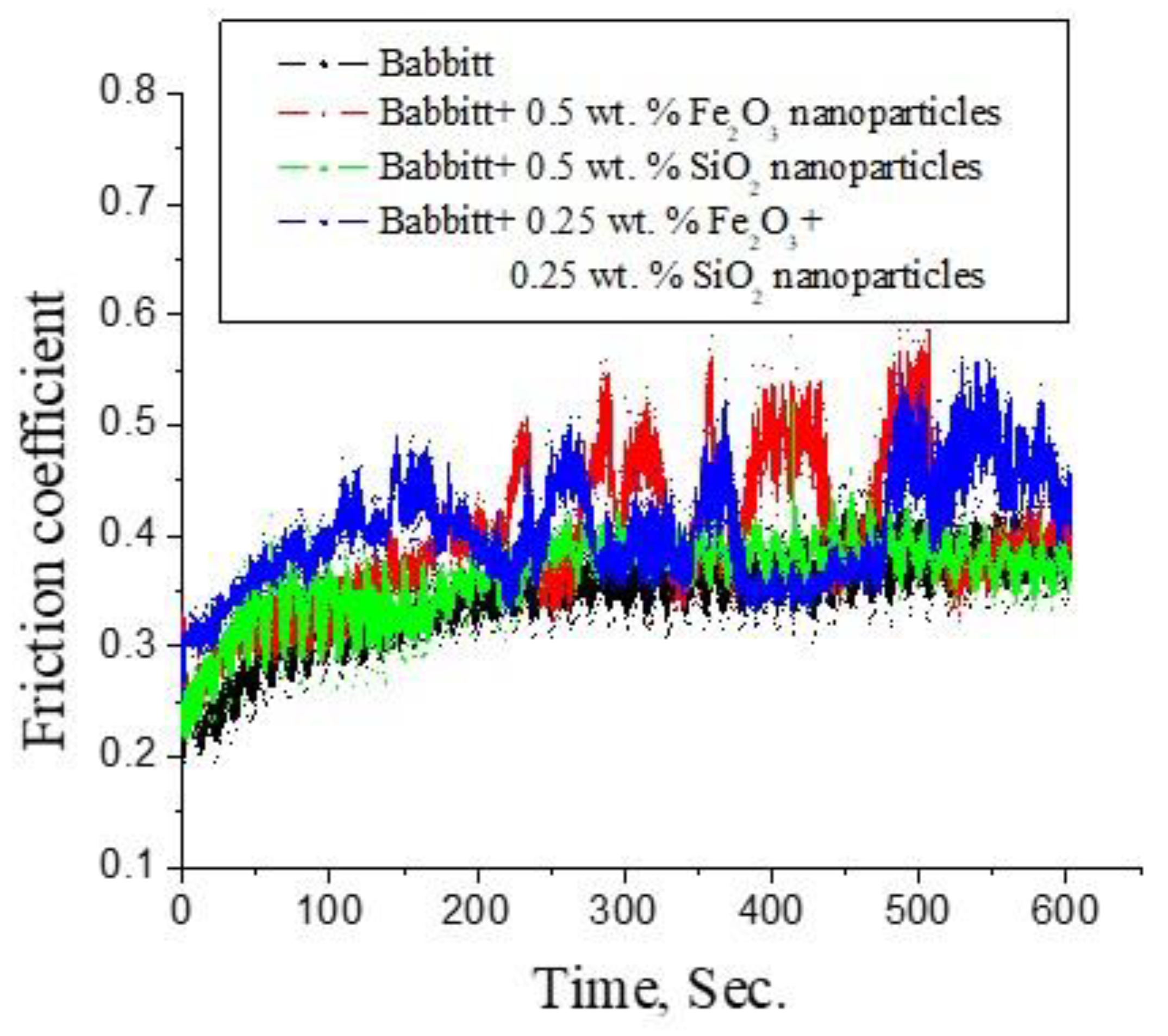

| No. | Additions | Weight Loss (g) | Friction Coefficient |

|---|---|---|---|

| S1 | Babbitt alloy | 0.00819 ± 000024 | 0.352 |

| S2 | Babbitt + 0.50% Fe2O3 nanoparticles | 0.00830 ± 000015 | 0.396 |

| S3 | Babbitt + 0.50% SiO2 nanoparticles | 0.00810 ± 000005 | 0.364 |

| S4 | Babbitt + 0.25% Fe2O3 + 0.25% SiO2 nanoparticles | 0.00800 ± 000008 | 0.399 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramadan, M.; Subhani, T.; Hafez, K.M.; Fathy, N.; Ayadi, B.; Abdel Halim, K.S.; Alghamdi, A.S.; Ibrahim, K.M. Microstructure and Mechanical Performance of Tin-Based Babbitt Alloy Containing Iron Oxide and Silica Nanoparticles. Metals 2023, 13, 324. https://doi.org/10.3390/met13020324

Ramadan M, Subhani T, Hafez KM, Fathy N, Ayadi B, Abdel Halim KS, Alghamdi AS, Ibrahim KM. Microstructure and Mechanical Performance of Tin-Based Babbitt Alloy Containing Iron Oxide and Silica Nanoparticles. Metals. 2023; 13(2):324. https://doi.org/10.3390/met13020324

Chicago/Turabian StyleRamadan, Mohamed, Tayyab Subhani, Khalid M. Hafez, Naglaa Fathy, Badreddine Ayadi, K. S. Abdel Halim, Abdulaziz S. Alghamdi, and Khaled M. Ibrahim. 2023. "Microstructure and Mechanical Performance of Tin-Based Babbitt Alloy Containing Iron Oxide and Silica Nanoparticles" Metals 13, no. 2: 324. https://doi.org/10.3390/met13020324

APA StyleRamadan, M., Subhani, T., Hafez, K. M., Fathy, N., Ayadi, B., Abdel Halim, K. S., Alghamdi, A. S., & Ibrahim, K. M. (2023). Microstructure and Mechanical Performance of Tin-Based Babbitt Alloy Containing Iron Oxide and Silica Nanoparticles. Metals, 13(2), 324. https://doi.org/10.3390/met13020324