Friction and Wear of Electroless Ni-P-CS Composite Coating

Abstract

:1. Introduction

2. Materials and Methods

2.1. Coatings Preparation

2.2. Wear Test and Characterization

3. Results and Discussion

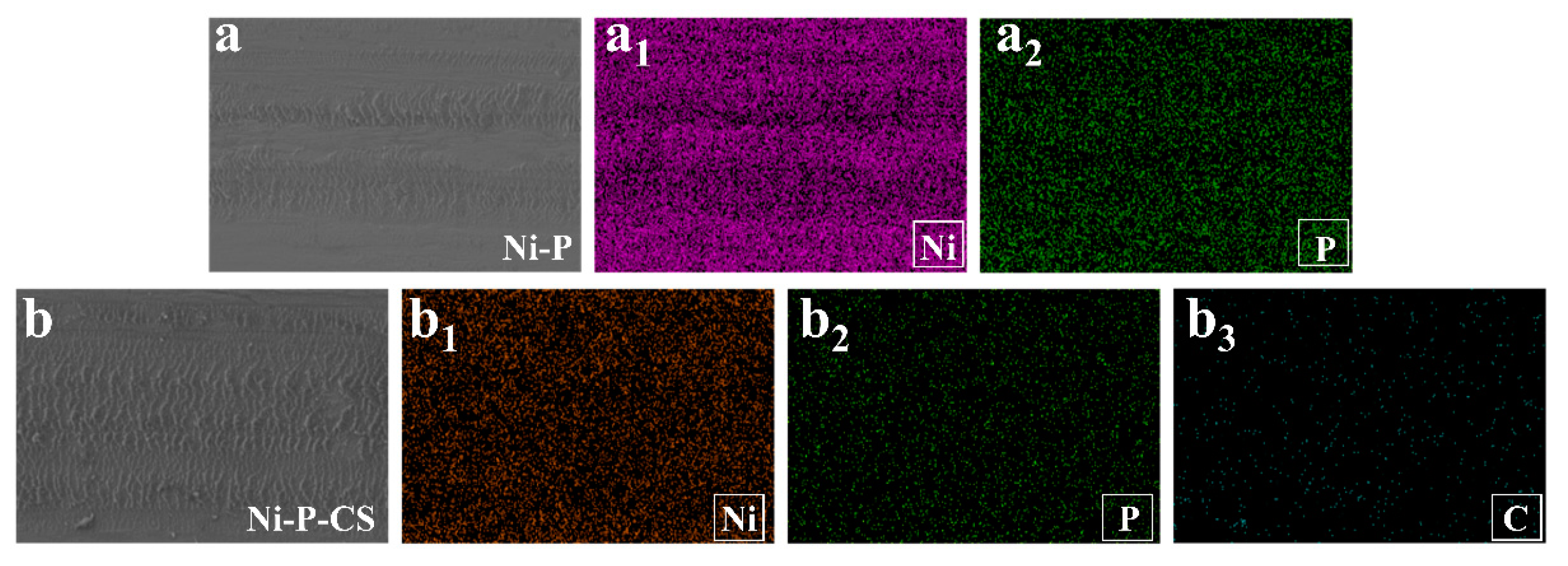

3.1. Characterization of Ni-P-CS Coatings

3.2. The Effect of Heat Treatment on the Ni-P-CS Coating

3.3. Friction Performance of Ni-P and Ni-P-CS Coatings

4. Conclusions

- Candle soot can combine well with chemical Ni-P plating.

- The Ni-P-CS composite coatings improved the wear behavior of the Ni-P coating.

- The composite coating of Ni-P-CS effectively reduces the friction coefficient and the amount of wear on the Ni-P coating.

- Thermal treatment improves the hardness of Ni-P-CS coatings but does not reduce the friction coefficient of the coatings.

- The introduction of candle soot particles in the electroless Ni-P coatings produces a significant rise in wear resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pancrecious, J.K.; Ulaeto, S.B.; Ramya, R.; Rajan, T.P.D.; Pai, B.C. Metallic composite coatings by electroless technique—A critical review. Int. Mater. Rev. 2018, 63, 488–512. [Google Scholar] [CrossRef]

- Agarwala, R.C.; Agarwala, V. Electroless alloy/composite coatings: A review. Sadhana 2003, 28, 475–493. [Google Scholar] [CrossRef]

- Li, D.Y.; Cui, X.F.; Wen, X.; Feng, L.T.; Hu, Y.T.; Jin, G.; Liu, E.B.; Zheng, W. Effect of CeO2 nanoparticles modified graphene oxide on electroless Ni-P coating for Mg-Li alloys. Appl. Surf. Sci. 2022, 593, 153381. [Google Scholar] [CrossRef]

- Sadreddini, S.; Rahemi Ardakani, S.; Rassaee, H. Corrosion Behavior and Microhardness of Ni-P-SiO2-Al2O3 Nano-composite Coatings on Magnesium Alloy. Mater. Chem. Phys. 2017, 26, 2032–2039. [Google Scholar] [CrossRef]

- Hu, J.; Fang, L. Influences of different reinforcement particles on performances of electroless composites. Surf. Eng. 2016, 8, 362–368. [Google Scholar] [CrossRef]

- Rezagholizadeh, M.; Ghaderi, M.; Heidary, A.; Vaghefi, S.M.M. Electroless Ni-P/Ni-B-B4C duplex composite coatings for improving the corrosion and tribological behavior of Ck45 steel. Prot. Met. Phys. Chem. Surf. 2015, 51, 234–239. [Google Scholar] [CrossRef]

- Valentini, R.; Cavaliere, P.; Valerini, D. Nanoindentation and scratch behaviour of Ni–P electroless coatings. Tribol.-Mater. Surf. Interfaces 2019, 14, 22–32. [Google Scholar] [CrossRef]

- Fanjing, M.; Pang, M.; Ma, L. Application selection of dry film lubricant on carbon steel surface and antifriction mechanism. Ind. Lubr. Tribol. 2020, 74, 868–875. [Google Scholar] [CrossRef]

- Warren, B.E. X-Ray Diffraction; Addison-Weseley Publishing Company: Boston, MA, USA, 1969. [Google Scholar]

- Szasz, A.; Fabian, D.J.; Paal, Z.; Kojnok, J. Chemical mechanisms in electroless deposition: A study on the role of hydrogen in layer formation. J. Non.-Cryst. Solids. 1988, 103, 21–27. [Google Scholar] [CrossRef]

- Palaniappa, M.; Seshadri, S.K. Friction and wear behavior of electroless Ni–P and Ni–W–P alloy coatings. Wear 2008, 265, 735–740. [Google Scholar] [CrossRef]

- Gutsev, D.; Antonov, M.; Hussainova, I.; Grigoriev, A.Y.A. Effect of SiO2 and PTFE additives on dry sliding of NiP electroless coating. Tribol. Int. 2013, 65, 295–302. [Google Scholar] [CrossRef]

- Oguocha, I.N.A.; Taheri, R.; Yannacopoulos, S.; Uju, W.A.; Sammynaiken, R.; Wettig, S.; Hu, Y.F. Temperature effects on the chemical composition of nickel–phosphorus alloy thin films. Thin Solid Film. 2010, 518, 2045–2049. [Google Scholar] [CrossRef]

- Balaraju, J.N.; Rajam, K.S. Surface morphology and structure of electroless ternary NiWP deposits with various W and P contents. J. Alloys Compd. 2009, 486, 468–473. [Google Scholar] [CrossRef]

- Kong, L.; Bi, Q.; Zhu, S.; Yang, J.; Liu, W. Tribological properties of ZrO2 (Y2O3)–Mo–BaF2/CaF2 composites at high temperatures. Ttibol. Int. 2012, 45, 43–49. [Google Scholar] [CrossRef]

| Elements | Content (Wt. %) |

|---|---|

| C | 0.12~0.20 |

| Mn | 0.30~0.70 |

| Si | ≤0.30 |

| S | ≤0.045 |

| P | ≤0.045 |

| Ni-P (g) | Ni-P-CS (g) | |

|---|---|---|

| Before the test ( | 5.8370 | 2.6911 |

| After the test ( | 5.8345 | 2.6910 |

| 0.0025 | 0.0001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Wang, H.; Liu, G. Friction and Wear of Electroless Ni-P-CS Composite Coating. Metals 2023, 13, 315. https://doi.org/10.3390/met13020315

Zhang X, Wang H, Liu G. Friction and Wear of Electroless Ni-P-CS Composite Coating. Metals. 2023; 13(2):315. https://doi.org/10.3390/met13020315

Chicago/Turabian StyleZhang, Xiaoli, Heming Wang, and Guiqun Liu. 2023. "Friction and Wear of Electroless Ni-P-CS Composite Coating" Metals 13, no. 2: 315. https://doi.org/10.3390/met13020315

APA StyleZhang, X., Wang, H., & Liu, G. (2023). Friction and Wear of Electroless Ni-P-CS Composite Coating. Metals, 13(2), 315. https://doi.org/10.3390/met13020315