Creep Aging Behavior of a Thermo-Mechanical Treated 7B04 Aluminum Alloy

Abstract

1. Introduction

2. Materials and Methods

2.1. Material and Thermo-Mechanical Treatments

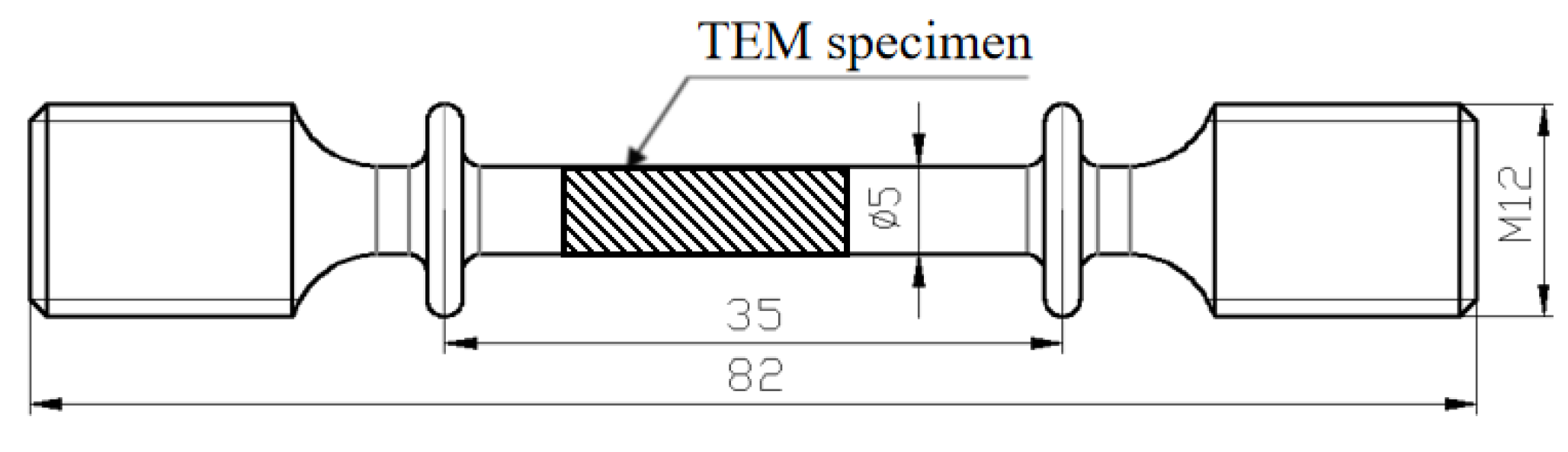

2.2. Creep Aging and Mechanical Properties Tests

2.3. Microstructure Characterization

3. Results and Discussion

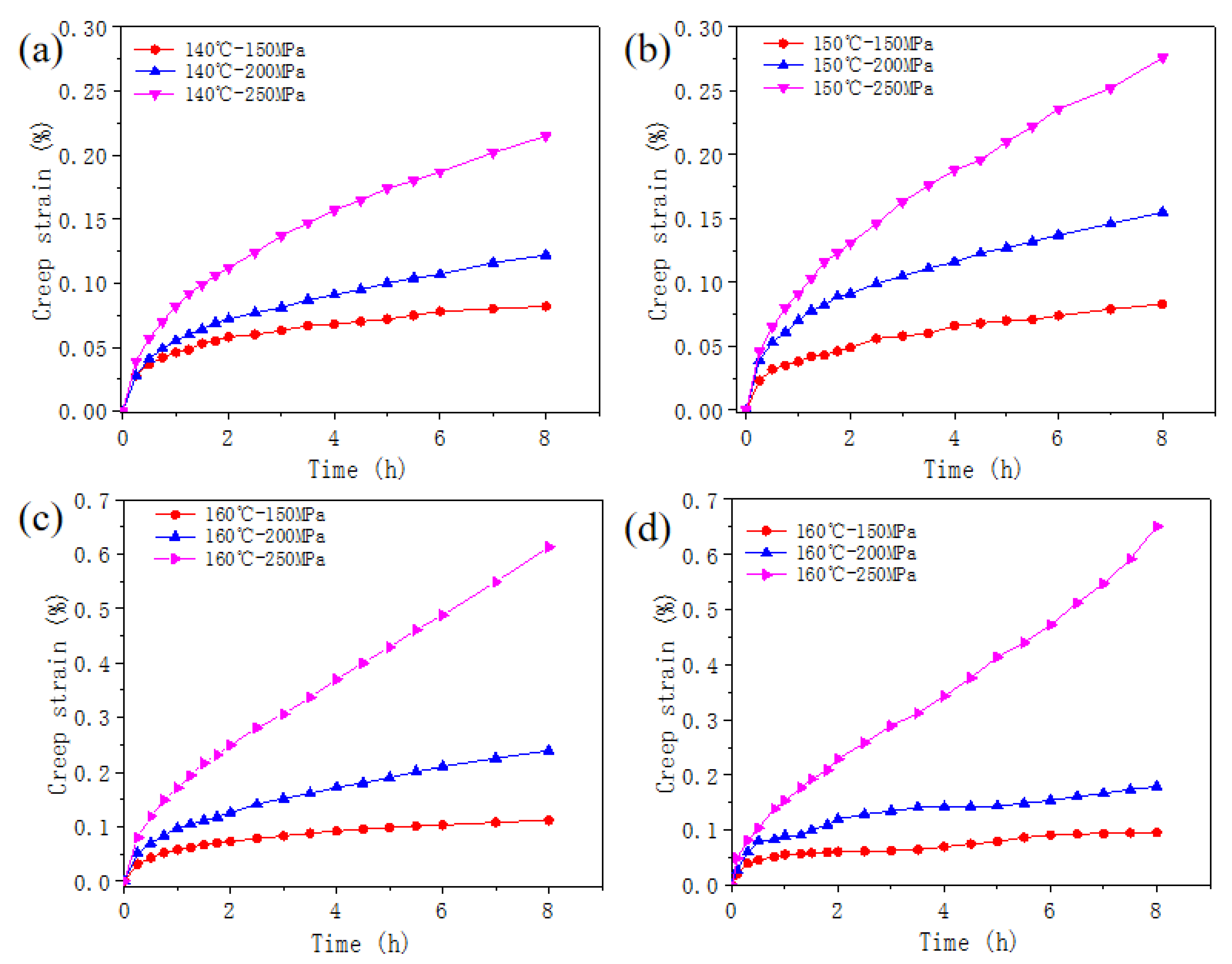

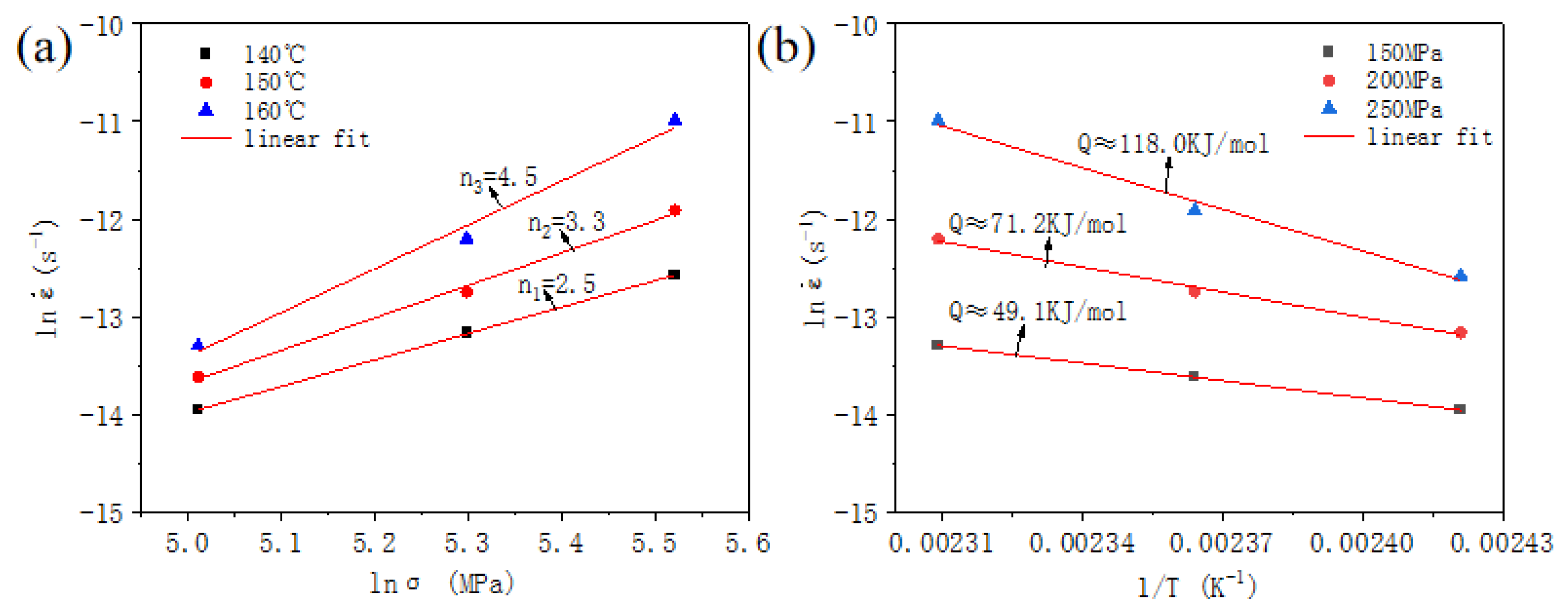

3.1. Creep Behavior of 7B04-P Aluminum Alloy

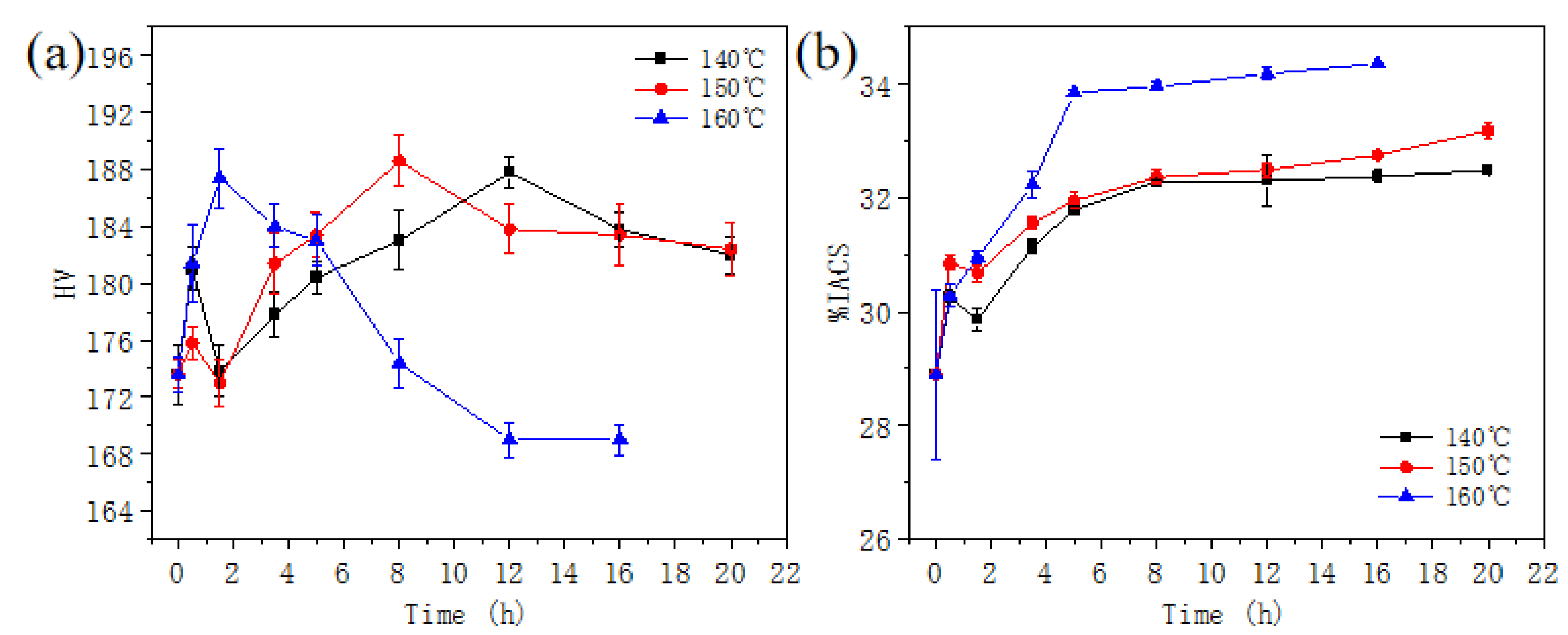

3.2. Mechanical Properties of Creep Aged 7B04-P Aluminum Alloy

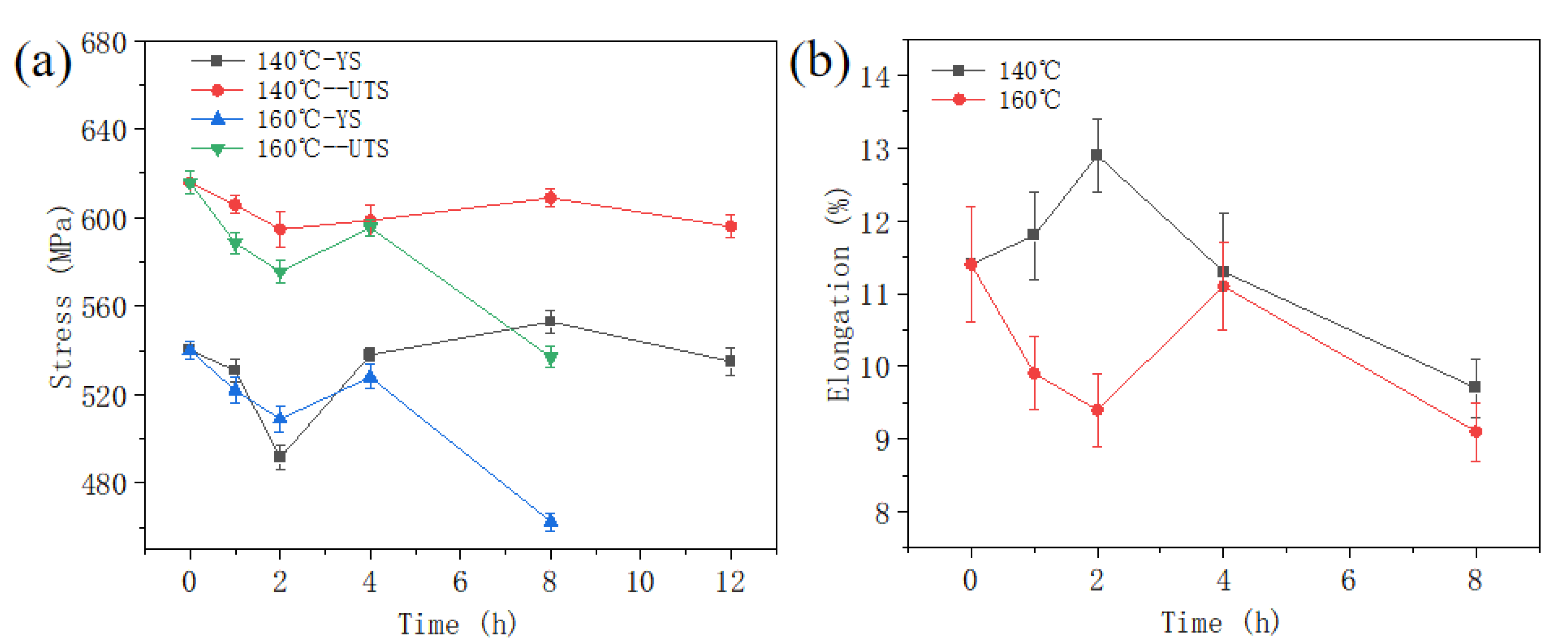

3.2.1. Artificial Aging Hardening

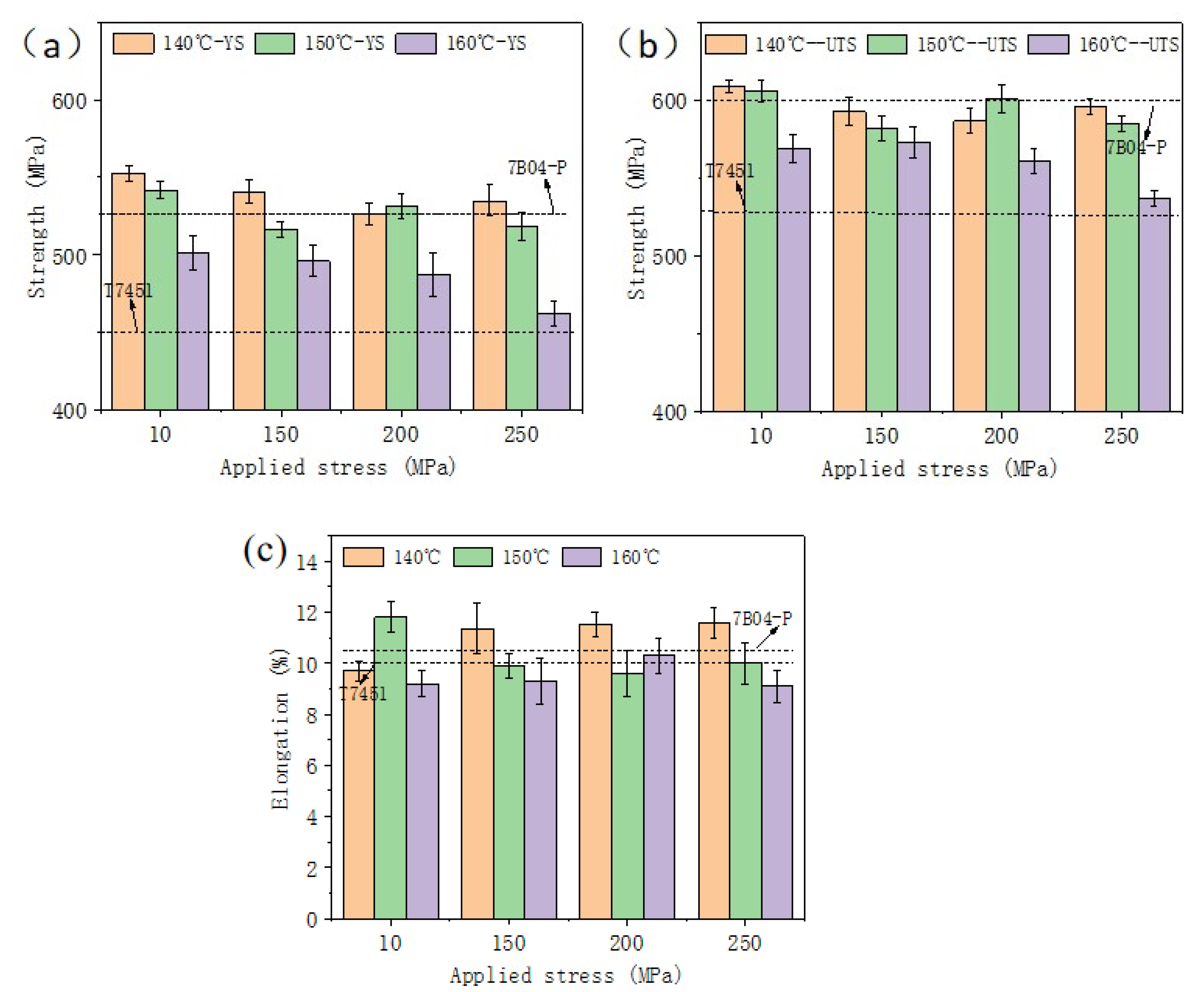

3.2.2. Mechanical Strength after Creep Aging

3.3. Microstructure Evolution of 7B04-P Aluminum Alloy during Creep Aging

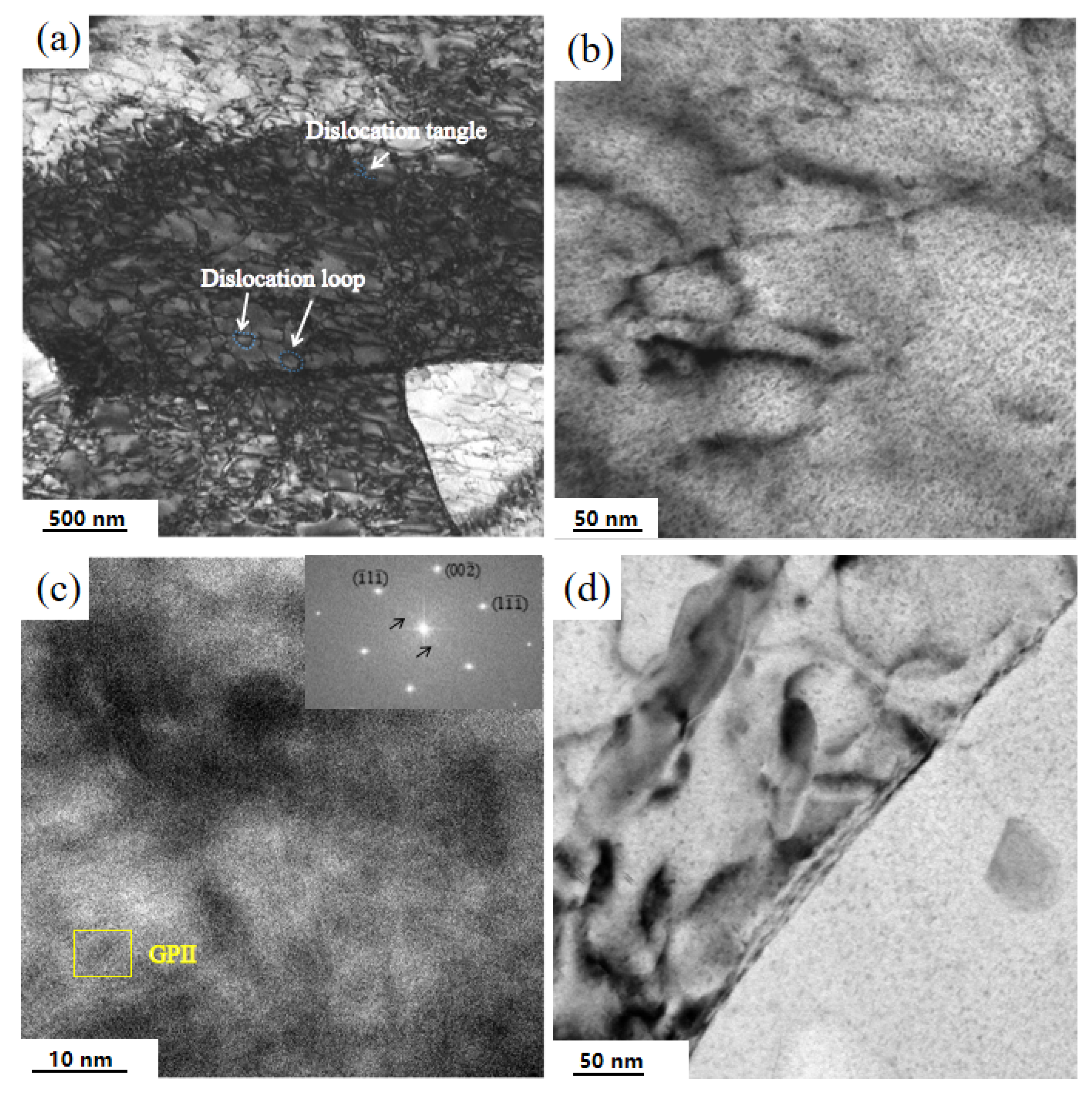

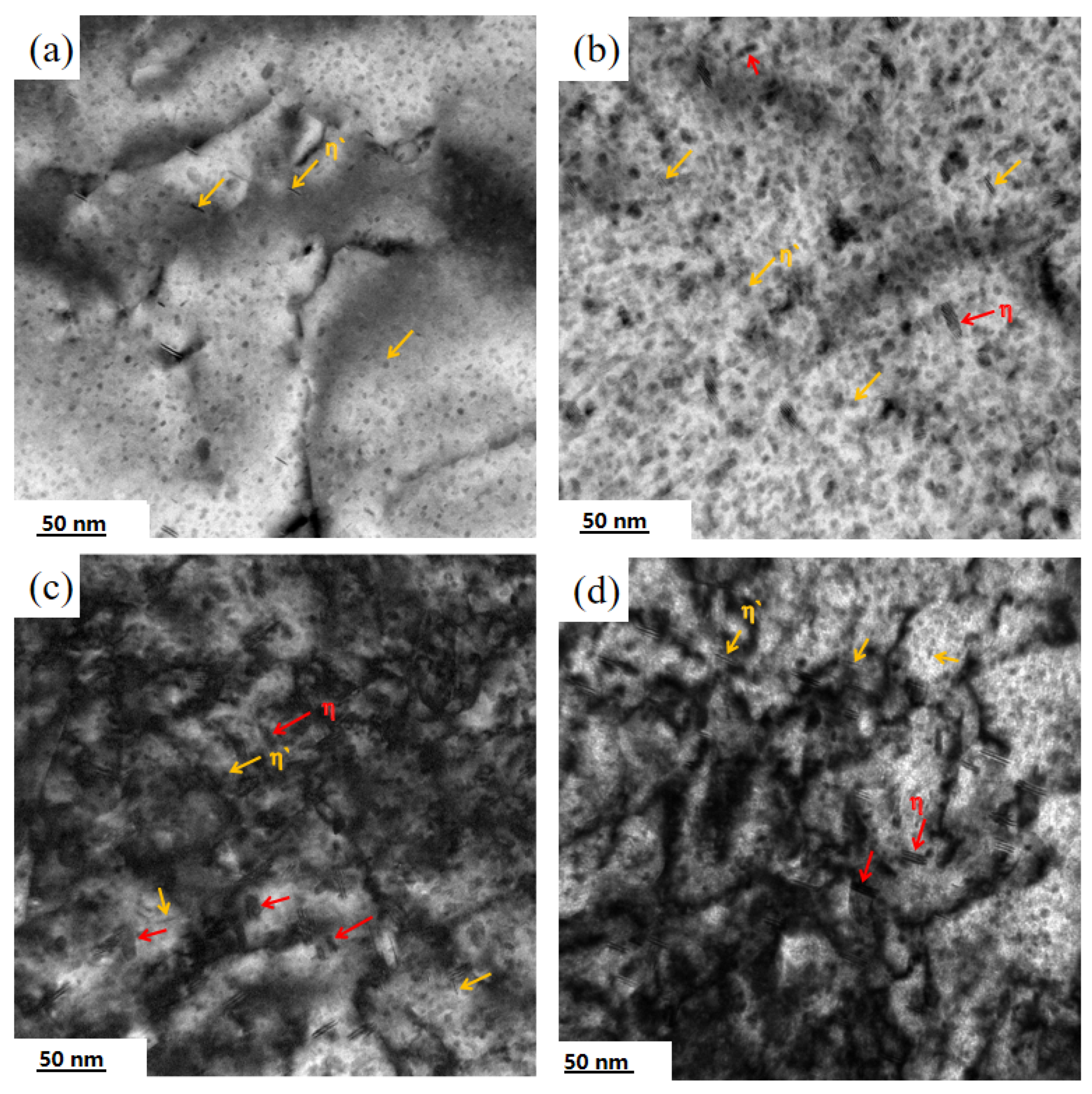

3.3.1. The Microstructure Morphology of 7B04-P Aluminum Alloy

3.3.2. Dislocation Morphology

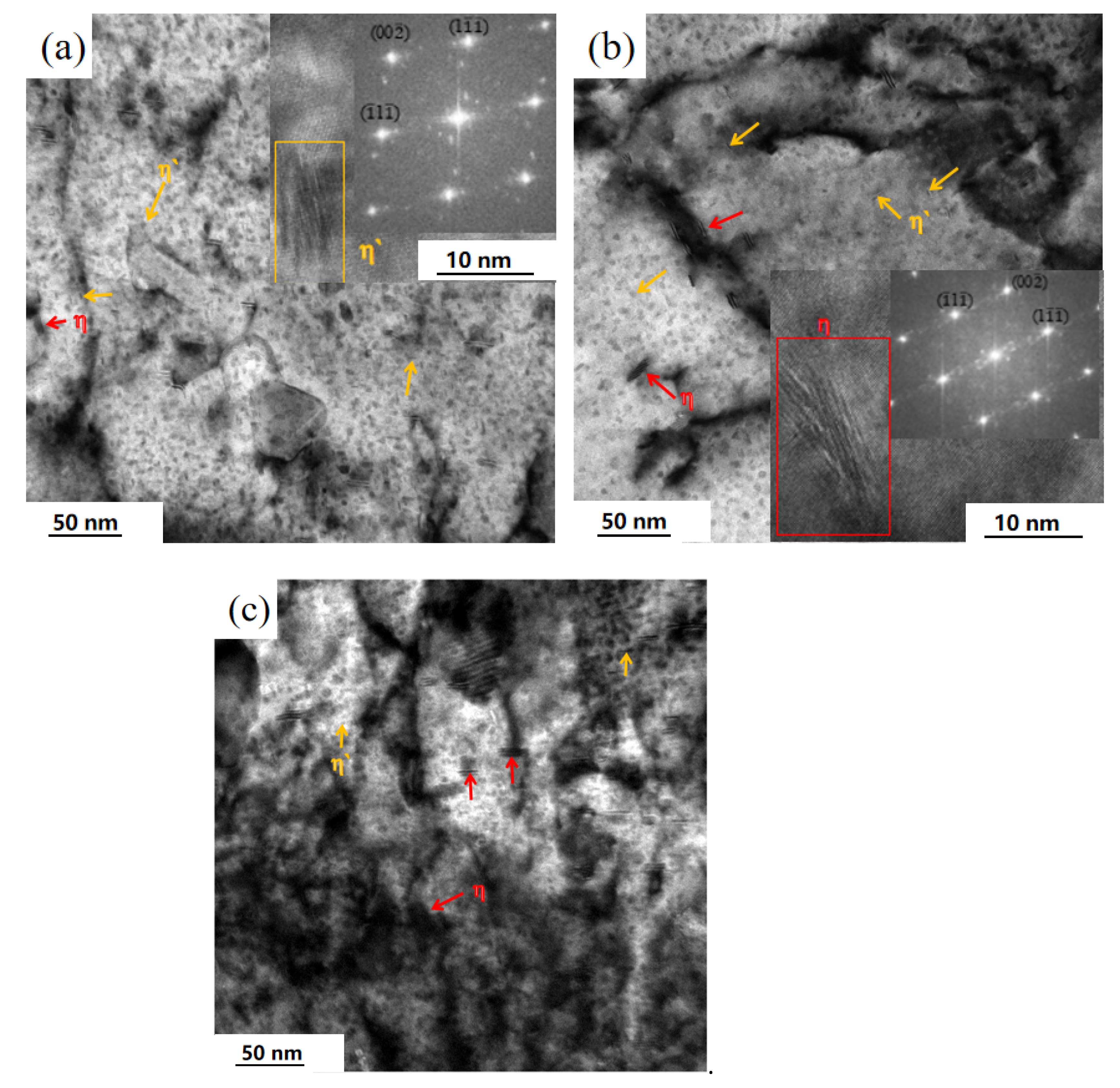

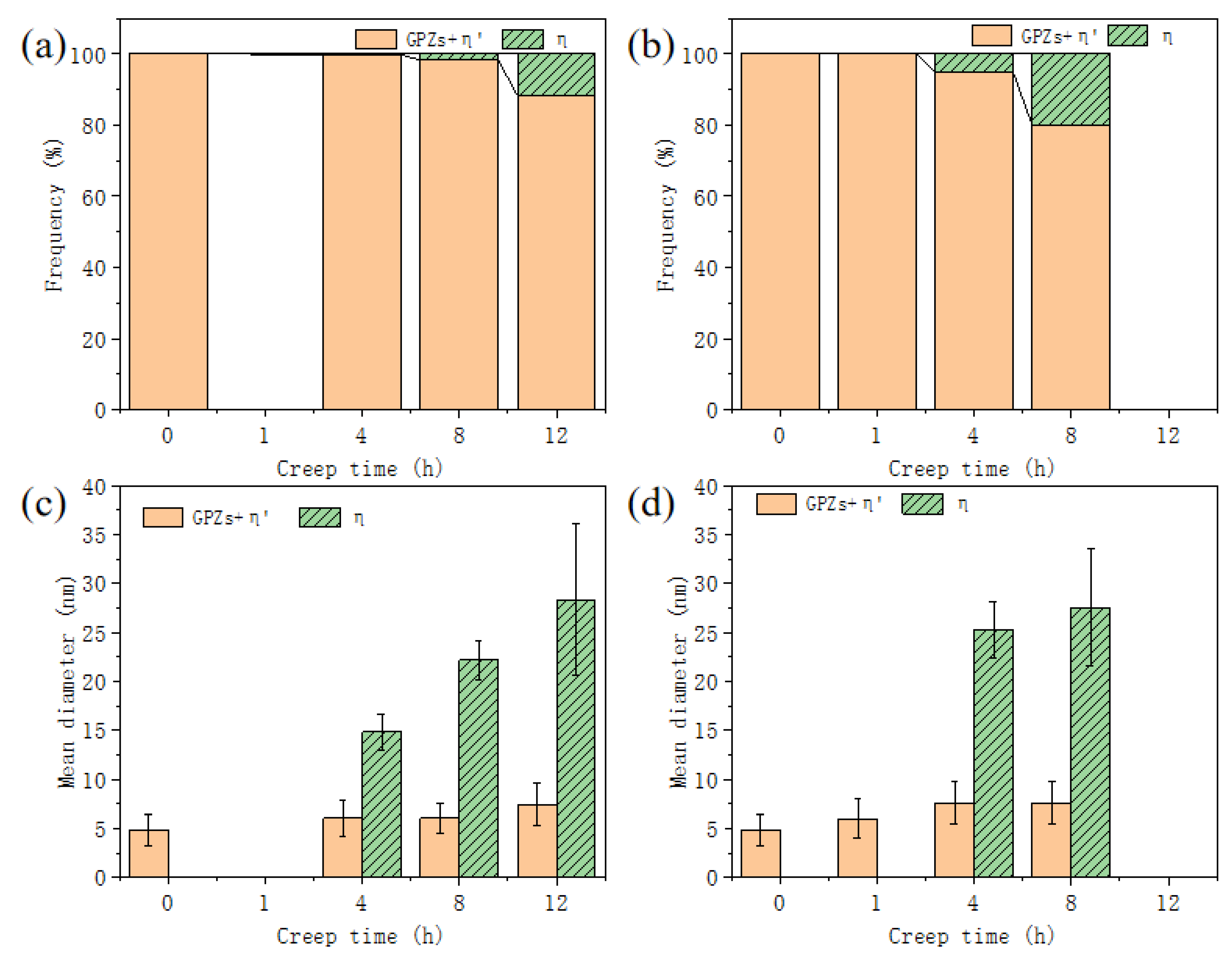

3.3.3. Distribution and Size of Phase Precipitates

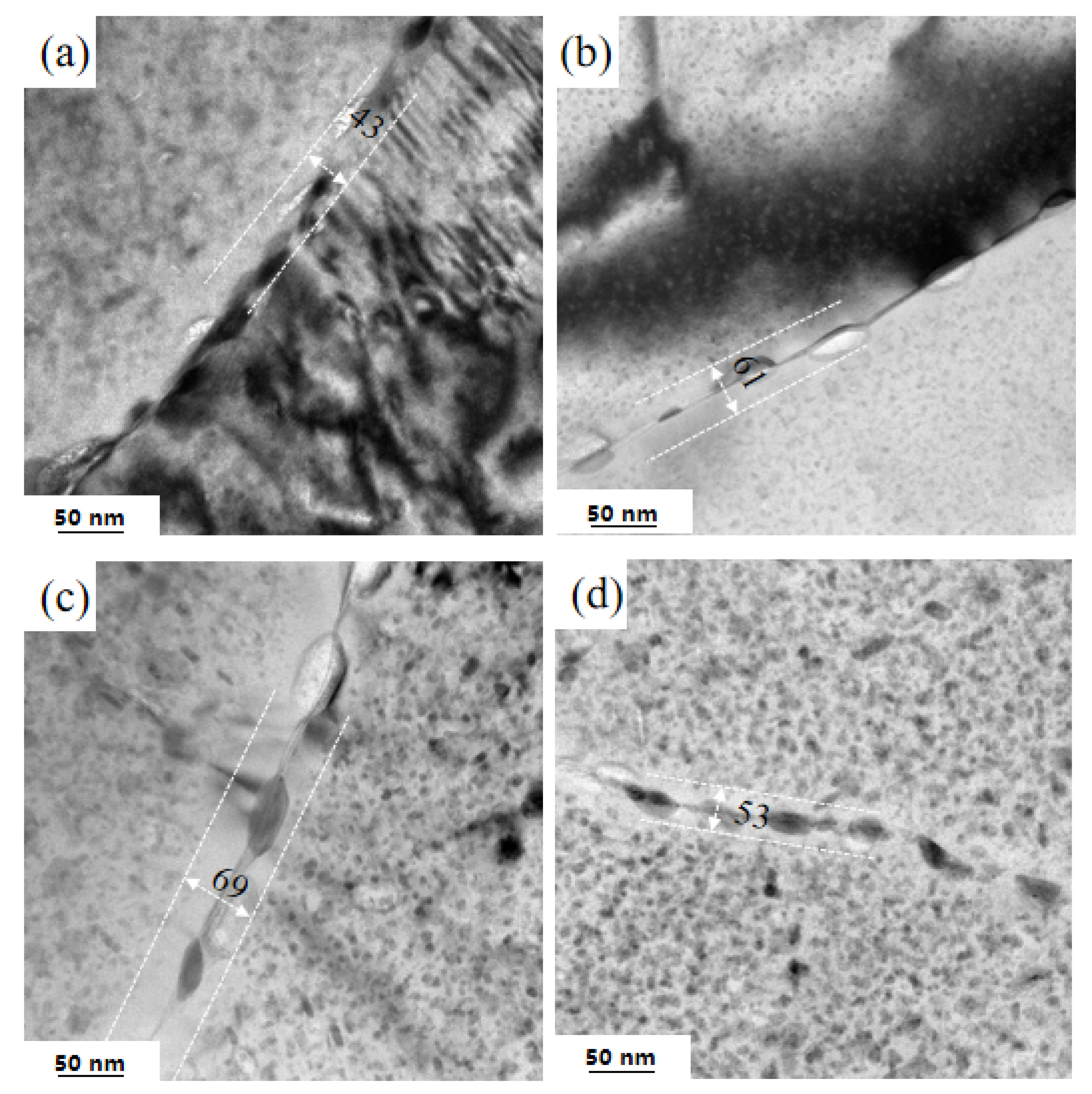

3.3.4. Grain Boundary Precipitates

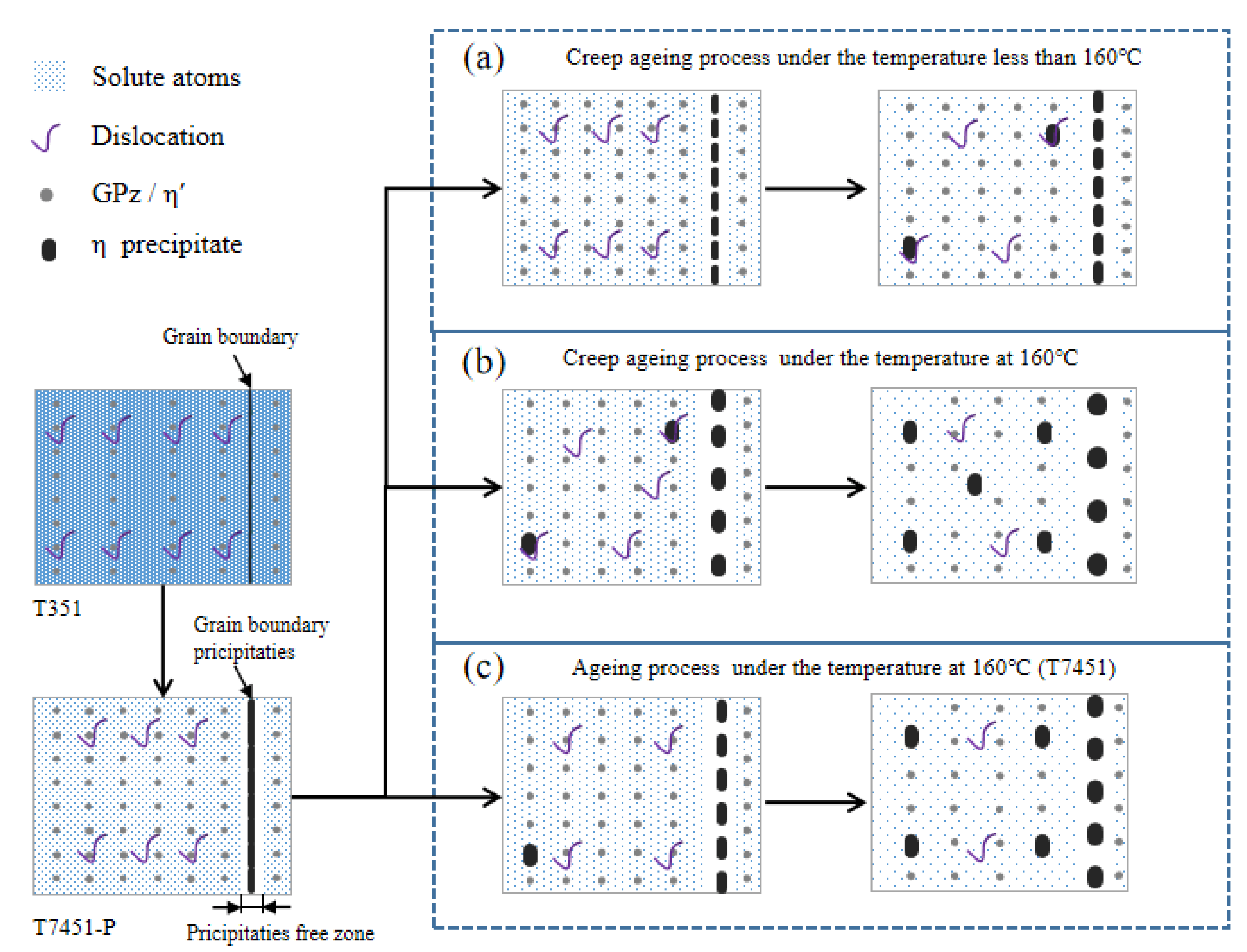

3.4. Relationship between Creep Behavior, Mechanical Properties and Microstructure

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, H.Y.; Liu, J.J.; Yu, W.C.; Hui, Z.H.A.O.; Li, D.W. Microstructure evolution of Al–Zn–Mg–Cu alloy during non-linear cooling process. Trans. Nonferrous Met. Soc. China 2016, 26, 1191–1200. [Google Scholar] [CrossRef]

- Lang, Y.; Zhou, G.; Hou, L.; Zhang, J.; Zhuang, L. Significantly enhanced the ductility of the fine-grained Al–Zn–Mg–Cu alloy by strain-induced precipitation. Mater. Des. 2015, 88, 625–631. [Google Scholar] [CrossRef]

- Chen, K.; Zhan, L.; Xu, Y.; Ma, B.; Zeng, Q.; Luo, S. Optimizing strength and ductility in 7150 Al alloys via rapid electropulsing cyclic heat treatment. J. Alloys Compd. 2022, 903, 163985. [Google Scholar] [CrossRef]

- Wang, Q.; Zhan, L.-H.; Xu, Y.-Q.; Liu, C.-H.; Zhao, X.; Xu, L.-Z.; Yang, Y.-L.; Cai, Y.-X. Creep aging behavior of retrogression and re-aged 7150 aluminum alloy. Trans. Nonferrous Met. Soc. China 2020, 30, 2599–2612. [Google Scholar] [CrossRef]

- Xu, Y.; Zhan, L.; Huang, M.; Liu, C.; Wang, X. Anisotropy in creep-ageing behavior of textured Al-Cu-Mg alloy. Int. J. Lightweight Mater. Manuf. 2018, 1, 40–46. [Google Scholar] [CrossRef]

- Peng, N.; Zhan, L.; Song, Z.; Zhu, W.; Xu, Y.; Ma, B.; Zeng, Q.; Chen, K.; Lao, S.; Zheng, Q. Strengthening mechanism of 2219 Al-Cu alloy by room-temperature random vibration. J. Alloys Compd. 2023, 934, 167878. [Google Scholar] [CrossRef]

- Xu, L.; Zhan, L.; Xu, Y.; Liu, C.; Huang, M. Thermomechanical pretreatment of Al-Zn-Mg-Cu alloy to improve formability and performance during creep-age forming. J. Mater. Process. Technol. 2021, 293, 117089. [Google Scholar] [CrossRef]

- Peng, N.; Zhan, L.; Xu, Y.; Liu, C.; Ma, B.; Chen, K.; Ren, H. Anisotropy in creep-aging behavior of Al–Li alloy under different stress levels: Experimental and constitutive modeling. J. Mater. Res. Technol. 2022, 20, 3456–3470. [Google Scholar] [CrossRef]

- Zhan, L.; Yu, W.; Xu, Y.; Liu, C.; Ma, B.; Chen, K.; Su, B.; Luo, S.; Xia, K.; Yang, X. Creep aging behavior of Al-Cu-Mg-Si alloy with elastic and plastic loads. Mater. Charact. 2022, 191, 112132. [Google Scholar] [CrossRef]

- Azarniya, A.; Taheri, A.K.; Taheri, K.K. Recent advances in ageing of 7xxx series aluminum alloys: A physical metallurgy perspective. J. Alloys Compd. 2019, 781, 945–983. [Google Scholar] [CrossRef]

- Yang, W.; Ji, S.; Zhang, Q.; Wang, M. Investigation of mechanical and corrosion properties of an Al–Zn–Mg–Cu alloy under various ageing conditions and interface analysis of η′ precipitate. Mater. Des. 2015, 85, 752–761. [Google Scholar] [CrossRef]

- Giummarra, C.; Thomas, B.; Rioja, R. New Aluminum Lithium Alloys for Aerospace Applications. In Proceedings of the Light Metals Technology Conference, Saint-Sauveur, QC, Canada, 24–26 September 2007. [Google Scholar]

- Liu, J.Z.; Chen, J.H.; Yuan, D.W.; Wu, C.L.; Zhu, J.; Cheng, Z.Y. Fine precipitation scenarios of AlZnMg(Cu) alloys revealed by advanced atomic-resolution electron microscopy study Part II: Fine precipitation scenarios in AlZnMg(Cu) alloys. Mater. Charact. 2015, 99, 142–149. [Google Scholar] [CrossRef]

- Guo, W.; Yang, M.; Zheng, Y.; Zhang, X.; Li, H.; Wen, X.; Zhang, J. Influence of elastic tensile stress on aging process in an Al–Zn–Mg–Cu alloy. Mater. Lett. 2013, 106, 14–17. [Google Scholar] [CrossRef]

- Lotz, S.; Scharifi, E.; Weidig, U.; Steinhoff, K. Ursula Weidi Effect of Combined Forming and Aging Processes on the Mechanical Properties of the Precipitation-Hardenable High-Strength Aluminum Alloys AA6082 and AA7075. Metals 2022, 12, 1250. [Google Scholar] [CrossRef]

- Zhan, L.; Lin, J.; Dean, T.A.; Huang, M. Experimental studies and constitutive modelling of the hardening of aluminium alloy 7055 under creep age forming conditions. Int. J. Mech. Sci. 2011, 53, 595–605. [Google Scholar] [CrossRef]

- Zhou, C.; Zhan, L.-H.; Li, H.; Zhao, X.; Huang, M.-H. Influence of temperature on creep behavior, mechanical properties and microstructural evolution of an Al-Cu-Li alloy during creep age forming. J. Cent. South Univ. 2021, 28, 2285–2294. [Google Scholar] [CrossRef]

- Liu, Y.; Jiang, D.; Li, W. The effect of multistage ageing on microstructure and mechanical properties of 7050 alloy. J. Alloys Compd. 2016, 671, 408–418. [Google Scholar] [CrossRef]

- Marlaud, T.; Deschamps, A.; Bley, F.; Lefebvre, W.; Baroux, B. Evolution of precipitate microstructures during the retrogression and re-ageing heat treatment of an Al–Zn–Mg–Cu alloy. Acta Mater. 2010, 58, 4814–4826. [Google Scholar] [CrossRef]

- Lin, Y.; Zhang, J.-L.; Chen, M.-S. Evolution of precipitates during two-stage stress-aging of an Al-Zn-Mg-Cu alloy. J. Alloys Compd. 2016, 684, 177–187. [Google Scholar] [CrossRef]

- Luo, J.; Luo, H.; Li, S.; Wang, R.; Ma, Y. Effect of pre-ageing treatment on second nucleating of GPII zones and precipitation kinetics in an ultrafine grained 7075 aluminum alloy. Mater. Des. 2020, 187, 108402. [Google Scholar] [CrossRef]

- Heider, B.; Scharifi, E.; Engler, T.; Oechsner, M.; Steinhoff, K. Influence of heated forming tools on corrosion behavior of high strength aluminum alloys. Mater. Sci. Eng. Technol. 2021, 52, 145–151. [Google Scholar] [CrossRef]

- Chen, K.; Zhan, L.; Xu, Y.; Liu, Y. Effect of pulsed current density on creep-aging behavior and microstructure of AA7150 aluminum alloy. J. Mater. Res. Technol. 2020, 9, 15433–15441. [Google Scholar] [CrossRef]

- Hosford, W.F.; Agrawal, S. Effect of stress during aging on the precipitation of θ′ in Al-4 Wt pct Cu. Metall. Trans. A 1975, 6, 487. [Google Scholar] [CrossRef]

- Zhu, A.W.; Starke, E. Stress aging of Al– xCu alloys: Experiments. Acta Mater. 2001, 49, 2285–2295. [Google Scholar] [CrossRef]

- Scharifi, E.; Savaci, U.; Kavaklioglu, Z.B.; Weidig, U.; Turan, S.; Steinhoff, K. Effect of thermo-mechanical processing on quench-induced precipitates morphology and mechanical properties in high strength AA7075 aluminum alloy. Mater. Charact. 2021, 174, 111026. [Google Scholar] [CrossRef]

- Guo, W.; Guo, J.; Wang, J.; Yang, M.; Li, H.; Wen, X.; Zhang, J. Evolution of precipitate microstructure during stress aging of an Al–Zn–Mg–Cu alloy. Mater. Sci. Eng. A 2015, 634, 167–175. [Google Scholar] [CrossRef]

- Bian, T.; Li, H.; Yang, J.; Lei, C.; Wu, C.; Zhang, L.; Chen, G. Through-thickness heterogeneity and in-plane anisotropy in creep aging of 7050 Al alloy. Mater. Des. 2020, 196, 109190. [Google Scholar] [CrossRef]

- Li, C.; Wan, M.; Wu, X.-D.; Huang, L. Constitutive equations in creep of 7B04 aluminum alloys. Mater. Sci. Eng. A 2010, 527, 3623–3629. [Google Scholar] [CrossRef]

- Yang, Y.; Zhan, L.; Liu, C.; Wang, X.; Wang, Q.; Tang, Z.; Li, G.; Huang, M.; Hu, Z. Stress-relaxation ageing behavior and microstructural evolution under varying initial stresses in an Al–Cu alloy: Experiments and modeling. Int. J. Plast. 2020, 127, 102646. [Google Scholar] [CrossRef]

- Starke, E.A.; Sanders, T.H.J.T.S. Aluminum-Lithium Alloys II: Proceedings of the Second International Aluminum-Lithium Conference; The Metallurgical Society of AIME: Monterey, CA, USA, 1984. [Google Scholar]

- Ma, Z.; Liu, C.; Xu, L.; Huang, M.; Yang, Y.; Xu, Y.; Ma, B.; Zhan, L. Pre-strain-dependent creep ageing behavior of an Al Cu alloy. Mater. Charact. 2022, 192, 112225. [Google Scholar] [CrossRef]

- Es-Souni, M.J.M.C. Creep behaviour and creep microstructures of a high-temperature titanium alloy Ti–5.8Al–4.0Sn–3.5Zr–0.7Nb–0.35Si–0.06C (Timetal 834): Part I. Prim. Steady-State Creep. 2001, 46, 365–379. [Google Scholar] [CrossRef]

- Chen, X.; Zhan, L.; Ma, Z.; Xu, Y.; Zheng, Q.; Cai, Y. Study on tensile/compressive asymmetry in creep ageing behavior of Al–Cu alloy under different stress levels. J. Alloys Compd. 2020, 843, 156157. [Google Scholar] [CrossRef]

- Jiang, F.; Takaki, S.; Masumura, T.; Uemori, R.; Zhang, H.; Tsuchiyama, T. Nonadditive strengthening functions for cold-worked cubic metals: Experiments and constitutive modeling. Int. J. Plast. 2020, 129, 102700. [Google Scholar] [CrossRef]

- Ren, X.; Jiang, X.; Yuan, T.; Zhao, X.; Chen, S. Microstructure and properties research of Al-Zn-Mg-Cu alloy with high strength and high elongation fabricated by wire arc additive manufacturing. J. Mater. Process. Technol. 2022, 307, 117665. [Google Scholar] [CrossRef]

- Gao, C.; Wu, W.; Shi, J.; Xiao, Z.; Akbarzadeh, A. Simultaneous enhancement of strength, ductility, and hardness of TiN/AlSi10Mg nanocomposites via selective laser melting. Addit. Manuf. 2020, 34, 101378. [Google Scholar] [CrossRef]

- Wu, Z.; Sandlöbes, S.; Wang, Y.; Gibson, J.S.-L.; Korte-Kerzel, S. Creep behaviour of eutectic Zn-Al-Cu-Mg alloys. Mater. Sci. Eng. A 2018, 724, 80–94. [Google Scholar] [CrossRef]

- Lin, Y.; Jiang, Y.-Q.; Chen, X.-M.; Wen, D.-X.; Zhou, H.-M. Effect of creep-aging on precipitates of 7075 aluminum alloy. Mater. Sci. Eng. A 2013, 588, 347–356. [Google Scholar] [CrossRef]

- Lin, Y.C.; Zhang, J.L.; Liu, G.; Liang, Y.J. Effects of pre-treatments on aging precipitates and corrosion resistance of a creep-aged Al–Zn–Mg–Cu alloy. Mater. Des. 2015, 83, 866–875. [Google Scholar] [CrossRef]

- Zhou, C.; Zhan, L.; Li, H.; Liu, C.; Xu, Y.; Ma, B.; Yang, Y.; Huang, M. Dislocation reconfiguration during creep deformation of an Al-Cu-Li alloy via electropulsing. J. Mater. Sci. Technol. 2022, 130, 27–34. [Google Scholar] [CrossRef]

- Xiao, B.; Yadav, S.D.; Zhao, L.; Tang, Z.; Han, Y.; Yang, X.; Kai, J.-J.; Yang, T.; Xu, L. Deep insights on the creep behavior and mechanism of a novel G115 steel: Micromechanical modeling and experimental validation. Int. J. Plast. 2021, 147, 103124. [Google Scholar] [CrossRef]

- Xiao, X.; Li, S.; Yu, L. A general steady-state creep model incorporating dislocation static recovery for pure metallic materials. Int. J. Plast. 2022, 157. [Google Scholar] [CrossRef]

- Chen, J.F.; Jiang, J.T.; Zhen, L.; Shao, W.Z. Stress relaxation behavior of an Al–Zn–Mg–Cu alloy in simulated age-forming process. J. Mater. Process. Technol. 2014, 214, 775–783. [Google Scholar] [CrossRef]

- Anderson, P.M.; Hirth, J.P.; Lothe, J. The Theory of Dislocations. Cambridge University Press: Cambridge, UK, 2017. [Google Scholar]

- Cottrell, A.H. Theory of dislocations. Prog. Met. Phys. 1953, 4, 205–208. [Google Scholar] [CrossRef]

- Wang, X.; Rong, Q.; Shi, Z.; Li, Y.; Cao, J.; Chen, B.; Lin, J. Investigation of stress effect on creep, precipitation and dislocation evolution of Al–Li alloy during creep age forming. Mater. Sci. Eng. A 2022, 836, 142723. [Google Scholar] [CrossRef]

- Hu, J.L.; Zhao, Z.H.; Bo, H.; Jiao, Z.T.; Jin, M. Quantitative Study of Dislocation Density Evolution of 77AA8585 Aluminum Alloy During the Aging Treatment Process. Proc. Rare Met. Mater. Eng. 2022, 51, 1183–1187. [Google Scholar]

- Zhao, J.; Deng, Y.; Zhang, J.; Tang, J. Effect of forging speed on the formability, microstructure and mechanical properties of isothermal precision forged of Al–Zn–Mg–Cu alloy. Mater. Sci. Eng. A 2019, 767, 138366. [Google Scholar] [CrossRef]

- Zhao, Y.; Liao, X.; Jin, Z.; Valiev, R.; Zhu, Y. Microstructures and mechanical properties of ultrafine grained 7075 Al alloy processed by ECAP and their evolutions during annealing. Acta Mater. 2004, 52, 4589–4599. [Google Scholar] [CrossRef]

- Chen, X.; Ma, X.; Zhao, G.; Wang, Y.; Xu, X. Effects of re-solution and re-aging treatment on mechanical property, corrosion resistance and electrochemical behavior of 2196 Al-Cu-Li alloy. Mater. Des. 2021, 204, 109662. [Google Scholar] [CrossRef]

- Cai, B.; Adams, B.; Nelson, T. Relation between precipitate-free zone width and grain boundary type in 7075-T7 Al alloy. Acta Mater. 2007, 55, 1543–1553. [Google Scholar] [CrossRef]

- Zou, Y.; Wu, X.; Tang, S.; Wang, Y.; Zhao, K.; Cao, L. The effect of pre-ageing/stretching on the ageing-hardening behavior of Al–Zn–Mg–Cu alloys correlated with Zn/Mg ratio. Mater. Sci. Eng. A 2022, 830, 142331. [Google Scholar] [CrossRef]

- Hansen, V.; Gjønnes, J.; Skjervold, S.R. Effect of predeformation and preaging at room temperature in Al–Zn–Mg–(Cu,Zr) alloys. Mater. Sci. Eng. A 2001, 303, 226–233. [Google Scholar]

| Applied Stress/MPa | Steady Creep Strain Rate/s−1 | Total Creep Strain/% | Steady Creep Strain Rate/s−1 | Total Creep Strain/% | Steady Creep Strain Rate/s−1 | Total Creep Strain/% | Steady Creep Strain Rate/s−1 | Total Creep Strain/% |

|---|---|---|---|---|---|---|---|---|

| 140 °C | 150 °C | 160 °C | 160 °C (T7451) | |||||

| 150 | 8.67 × 10−7 | 0.082 | 1.66 × 10−6 | 0.083 | 1.68 × 10−6 | 0.112 | 1.57 × 10−6 | 0.096 |

| 200 | 1.92 × 10−6 | 0.122 | 2.92 × 10−6 | 0.155 | 5.03 × 10−6 | 0.239 | 3.16 × 10−6 | 0.179 |

| 250 | 3.44 × 10−6 | 0.215 | 6.73 × 10−6 | 0.276 | 1.69 × 10−5 | 0.613 | 1.87 × 10−5 | 0.651 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lao, S.; Zhan, L.; Qian, W.; Xu, Y.; Ma, B.; Liu, C.; Huang, M.; Yang, Y.; Chen, K.; Peng, N.; et al. Creep Aging Behavior of a Thermo-Mechanical Treated 7B04 Aluminum Alloy. Metals 2023, 13, 182. https://doi.org/10.3390/met13020182

Lao S, Zhan L, Qian W, Xu Y, Ma B, Liu C, Huang M, Yang Y, Chen K, Peng N, et al. Creep Aging Behavior of a Thermo-Mechanical Treated 7B04 Aluminum Alloy. Metals. 2023; 13(2):182. https://doi.org/10.3390/met13020182

Chicago/Turabian StyleLao, Shanfeng, Lihua Zhan, Wei Qian, Yongqian Xu, Bolin Ma, Chuhui Liu, Minghui Huang, Youliang Yang, Kuigen Chen, Nanhui Peng, and et al. 2023. "Creep Aging Behavior of a Thermo-Mechanical Treated 7B04 Aluminum Alloy" Metals 13, no. 2: 182. https://doi.org/10.3390/met13020182

APA StyleLao, S., Zhan, L., Qian, W., Xu, Y., Ma, B., Liu, C., Huang, M., Yang, Y., Chen, K., Peng, N., Gao, T., & Xi, H. (2023). Creep Aging Behavior of a Thermo-Mechanical Treated 7B04 Aluminum Alloy. Metals, 13(2), 182. https://doi.org/10.3390/met13020182