Evaluation of Forged TiAl Alloy Usefulness Based on Their Impact Resistance

Abstract

:1. Introduction

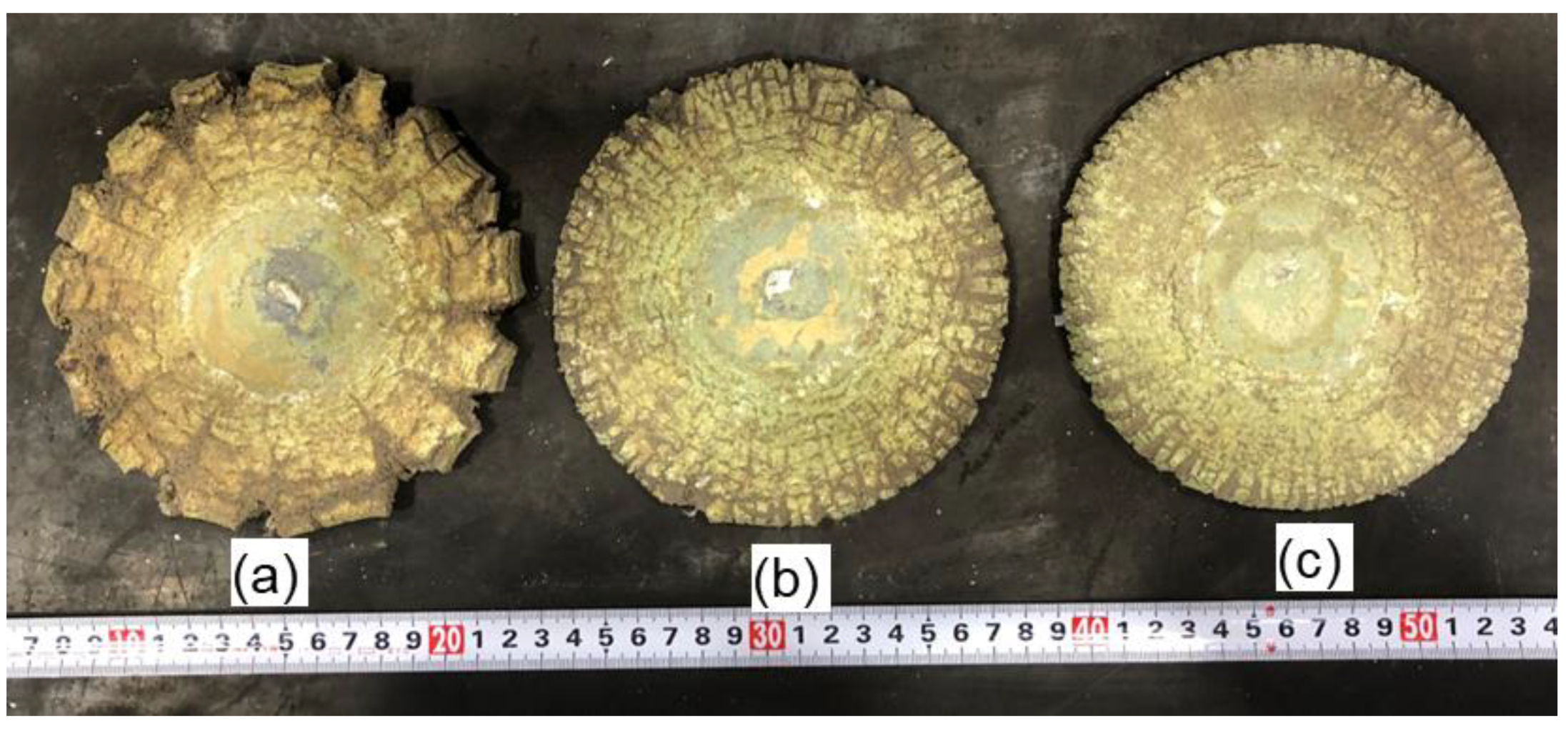

2. Materials and Methods

2.1. Materials

2.2. Evaluation Method for Impact Resistance

3. Results and Discussion

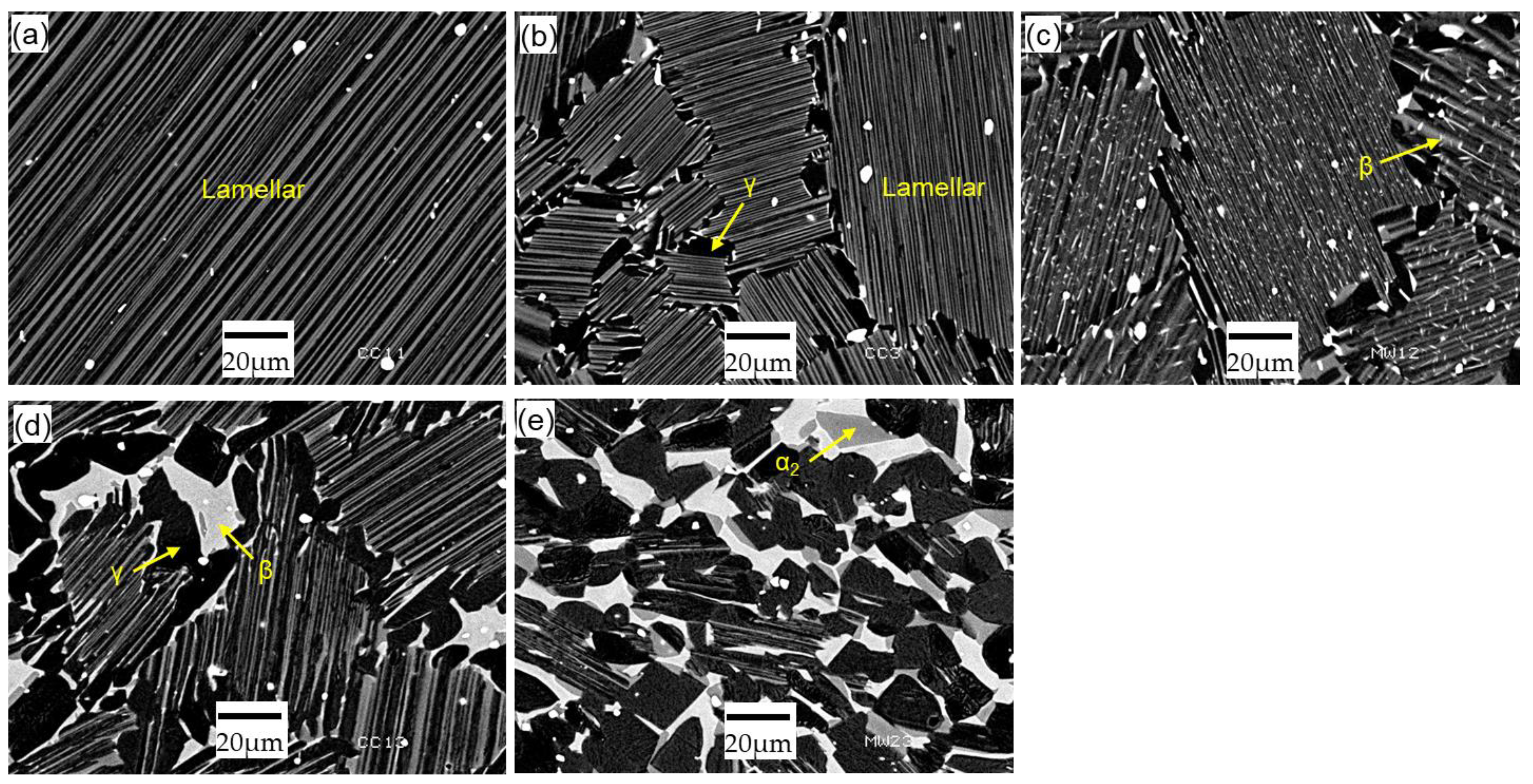

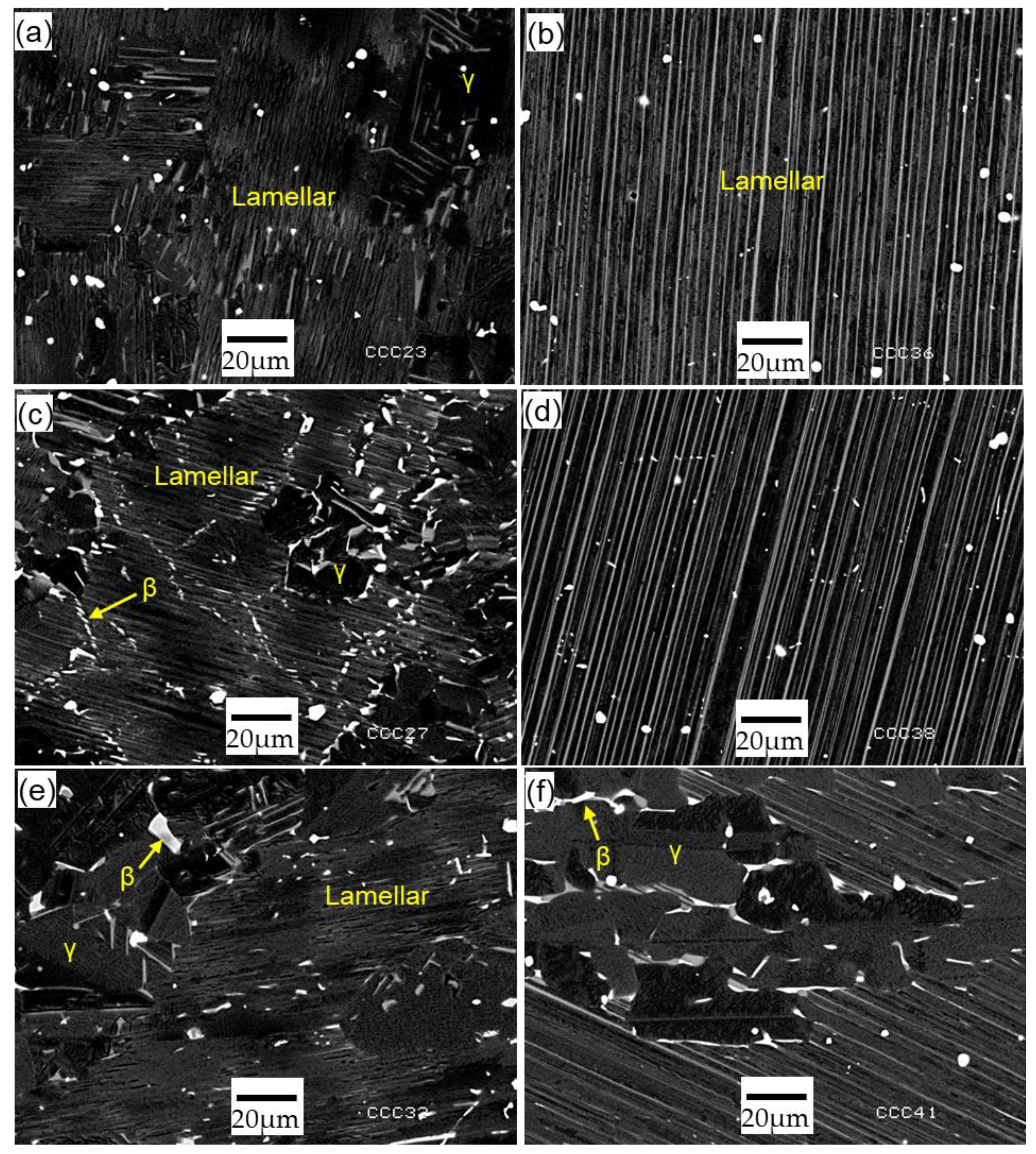

3.1. Microstructure of Forged TiAl Alloys

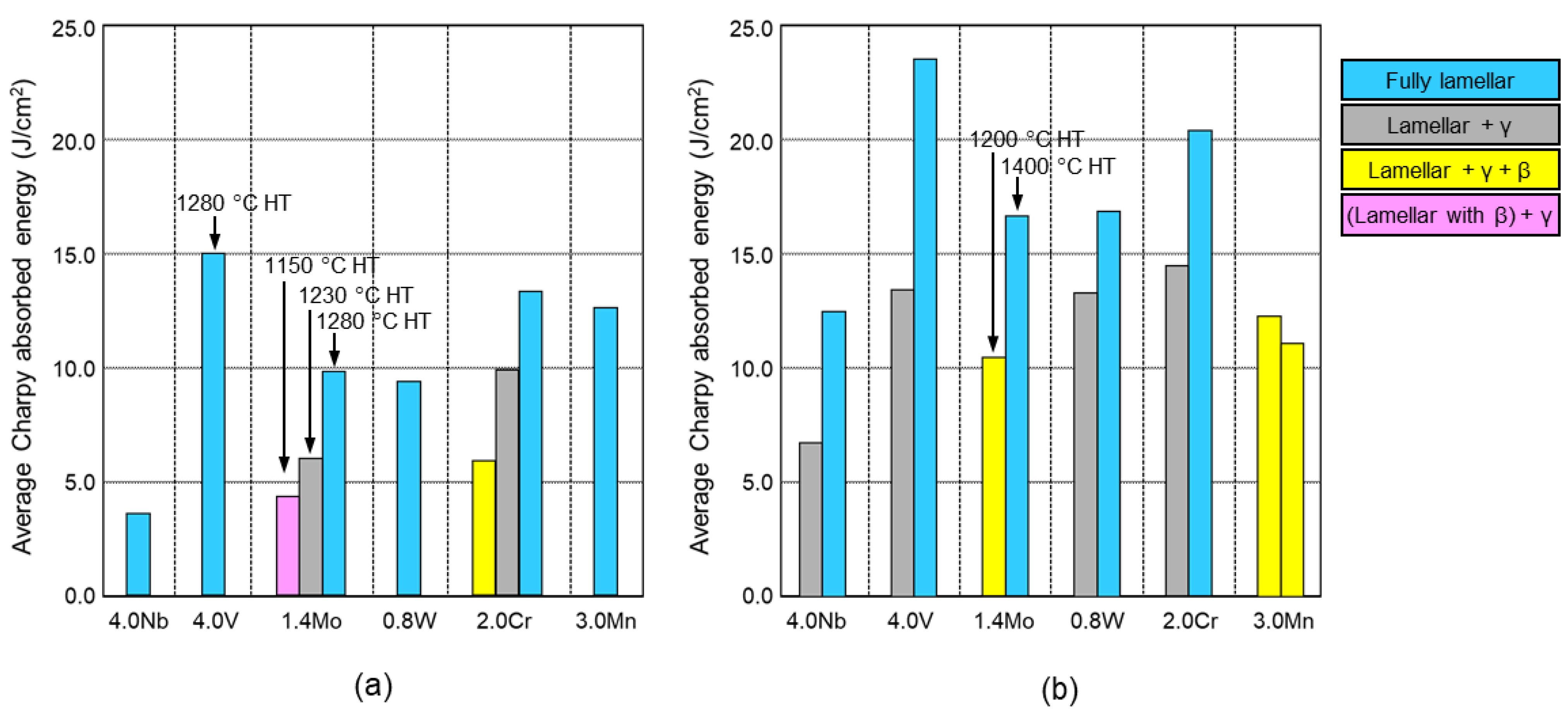

3.2. Impact Resistance of Forged TiAl Alloys

3.3. Impact Resistance of Cast TiAl Alloys

3.4. Comparison of Impact Resistance between Forged and Cast TiAl Alloys and Evaluation of the Usefulness of Forged TiAl Alloys

4. Conclusions

- The impact resistance of forged TiAl alloys improved with Cr, V, and Mn additions and deteriorated with Nb additions.

- The impact resistance of the microstructure including a β-phase, which is a common microstructure of forged alloys, was remarkably low.

- The FL structure has shown the best impact resistance in forged alloys. However, this can only be obtained by reducing the amount of additive elements at the expense of forgeability.

- Even with this FL structure, the impact resistance of the forged alloys was from one-half to two-thirds that of the cast alloys with the same additive content and microstructure. This is due to the difference in Al concentration in the two alloys.

- The low impact resistance of forged TiAl alloys is due to their different composition from other TiAl alloys (low Al concentration, addition of many β-stabilizing elements).

Funding

Data Availability Statement

Conflicts of Interest

References

- Dzogbewu, T.C.; Preez, W.B. Additive manufacturing of Ti-based intermetallic alloys: A review and conceptualization of a next-generation machine. Materials 2021, 14, 4317. [Google Scholar] [CrossRef]

- Emiralioglu, A.; Unal, R. Additive manufacturing of gamma titanium aluminide alloys: A review. J. Mater. Sci. 2022, 57, 4441–4466. [Google Scholar] [CrossRef]

- Liu, Y.; Pan, Y.; Liu, X.; Sun, J.; Hui, T.; Yang, Y.; Yu, A.; Qu, X.; Zhang, J. Fabrication of TiAl alloys turbocharger turbine wheel for engines by metal injection molding. Powder Technol. 2021, 384, 132–140. [Google Scholar] [CrossRef]

- Xu, H.; Li, X.; Xing, W.; Shu, L.; Ma, Y.; Liu, K. Processing map and hot working mechanism of as-cast Ti-42Al-5Mn alloy. Adv. Eng. Mater. 2018, 20, 1701059. [Google Scholar] [CrossRef]

- Su, X.; Li, P.; Qu, H.; Feng, C.; Hou, R.; Song, W.; Tian, B.; Xu, H. A Study on the brittle-to-ductile transition temperature of forged β-Solidifying TiAlMn and TNM alloys. Crystals 2022, 12, 1498. [Google Scholar] [CrossRef]

- Graf, G.; Seyffertitz, M.; Erdely, P.S.; Clemens, H.; Stark, A.; Hatzenbichler, L.; Holec, D.; Burtscher, M.; Kiener, D.; Li, X.; et al. On the stability of Ti(Mn, Al)2 C14 Laves phase in an intermetallic Ti-42Al-5Mn alloy. Intermetallics 2023, 161, 107962. [Google Scholar] [CrossRef]

- Tetsui, T.; Hiroshi, H. The influence of oxygen concentration and phase composition on the manufacturability and high-temperature strength of Ti–42Al–5Mn (at%) forged alloy. J. Mater. Process. Technol. 2013, 213, 752–758. [Google Scholar] [CrossRef]

- Clemens, H.; Mayer, S. Design, processing, microstructure, properties, and applications of advanced intermetallic TiAl alloys. Adv. Eng. Mater. 2013, 15, 91–215. [Google Scholar] [CrossRef]

- Clemens, H.; Mayer, S. Intermetallic titanium aluminides in aerospace applications-processing, microstructure and properties. Mater. High Temp. 2016, 33, 560–570. [Google Scholar] [CrossRef]

- Janschek, P. Wrought TiAl blades. Mater. Today Proc. 2015, 2, S92–S97. [Google Scholar] [CrossRef]

- Wang, J.G.; Nieh, T.G. Creep of a beta phase-containing TiAl alloy. Intermetallics 2000, 8, 737–748. [Google Scholar] [CrossRef]

- Flightglobal.com. Available online: https://www.flightglobal.com/engines/faa-orders-pw1100g-low-pressure-turbine-bladereplacement/135575.article (accessed on 16 June 2023).

- Bartolotta, P.; Barrett, J.; Kelly, T.; Smashey, R. The use of cast Ti-48Al-2Cr-2Nb in jet engine. JOM J. Min. Met. Mat. Soc. 1997, 49, 48–50. [Google Scholar] [CrossRef]

- Bewlay, B.P.; Nag, S.; Suzuki, A.; Weimer, M.J. TiAl alloys in commercial aircraft engines. Mater. High Temp. 2016, 33, 549–559. [Google Scholar] [CrossRef]

- Yim, S.; Aoyagi, K.; Chiba, A. Effect of multi-stage heat treatment on mechanical properties and microstructure transformation of Ti–48Al–2Cr–2Nb alloy. Mater. Sci. Eng. A 2021, A816, 141321. [Google Scholar] [CrossRef]

- Xu, R.; Li, M.; Zhao, Y. A review of microstructure control and mechanical performance optimization of γ-TiAl alloys. J. Alloys Compd. 2023, 932, 167611. [Google Scholar] [CrossRef]

- Tetsui, T. Selection of additive elements focusing on impact resistance in practical TiAl cast alloys. Metals 2022, 12, 544. [Google Scholar] [CrossRef]

- Advanced Technical Products Supply Co. Inc. Available online: https://www.knowde.com/stores/advanced-technical-products-supply/products/atp-610 (accessed on 9 September 2023).

- Harding, T.S.; Jones, J.W. Effect of foreign object damage on the fatigue strength of an XDTM γ-TiAl alloy. Scr. Mater. 2000, 43, 631–636. [Google Scholar] [CrossRef]

- Huang, Z.W.; Lin, J.P.; Sun, H.L. Microstructural changes and mechanical behavior of a near lamellar γ-TiAl alloy during long-term exposure at 700 °C, s. Intermetallics 2017, 31, 59–68. [Google Scholar] [CrossRef]

- Pippan, R.; Hohenwarter, A. Crack propagation resistance of TiAl alloys. MRS Bull. 2000, 47, 824–831. [Google Scholar] [CrossRef]

- Niu, H.Z.; Chen, Y.Y.; Kong, F.T.; Lin, J.P. Microstructure evolution, hot deformation behavior and mechanical properties of Ti-43Al-6Nb-1B alloy. Intermetallics 2012, 31, 249–256. [Google Scholar] [CrossRef]

- Wei, B.; Tang, B.; Chu, Y.; Du, L.; Chen, X.; Zhu, L.; Li, J. The microstructure evolution and tensile properties of Ti–43Al–4Nb–1Mo-0.2B alloy during hot rolling. Mater. Sci. Eng. A 2022, A861, 144347. [Google Scholar] [CrossRef]

| Additive Element | Additive Amount (at. %) | Heat Treatment Condition | Microstructure | Charpy Impact Test Results on Specimens Heated to 500 °C Prior to Testing | |

|---|---|---|---|---|---|

| Average Absorbed Energy (J/cm2) | SD | ||||

| Nb | 4.0 | 1280 °C/5 h/FC | FL | 3.6 | 0.6 |

| V | 4.0 | 1280 °C/5 h/FC | FL | 14.9 | 3.9 |

| Mo | 1.4 | 1150 °C/20 h/FC | (L/β) + γ | 4.3 | 0.5 |

| 1230 °C/10 h/FC | L + γ | 6.0 | 0.9 | ||

| 1280 °C/5 h/FC | FL | 9.8 | 1.5 | ||

| 2.2 | 1150 °C/20 h/FC | γ + β + L + α2 | 3.4 | 0.4 | |

| 1230 °C/10 h/FC | γ + β + L + α2 | 3.6 | 0.6 | ||

| 2.6 | 1280 °C/5 h/FC | (L/β) + γ | 3.9 | 0.5 | |

| 1330 °C/2 h/FC | L + γ+ β | 4.2 | 1.1 | ||

| W | 0.8 | 1280 °C/5 h/FC | FL | 9.3 | 1.3 |

| Cr | 2.0 | 1150 °C/20 h/FC | L + γ + β | 5.9 | 0.7 |

| 1230 °C/10 h/FC | L + γ | 9.8 | 2.0 | ||

| 1280 °C/5 h/FC | FL | 13.2 | 1.9 | ||

| 1330 °C/2 h/FC | FL | 12.1 | 2.0 | ||

| 2.5 | 1230 °C/10 h/FC | L + γ + β | 7.8 | 0.9 | |

| 1330 °C/2 h/FC | L + γ + β | 8.2 | 0.9 | ||

| 3.0 | 1150 °C/20 h/FC | γ + β + L + α2 | 4.9 | 0.6 | |

| Mn | 3.0 | 1280 °C/5 h/FC | FL | 12.6 | 1.8 |

| Additive Element | Additive Amount (at. %) | Heat Treatment Condition | Microstructure | Charpy Impact Test Results on Specimens Heated to 500 °C Prior to Testing | |

|---|---|---|---|---|---|

| Average Absorbed Energy (J/cm2) | SD | ||||

| Nb | 4.0 | 1200 °C/4 h/FC | L + γ | 6.7 | 1.2 |

| 1400 °C/1 h/FC | FL | 12.4 | 2.6 | ||

| V | 4.0 | 1200 °C/4 h/FC | L + γ | 13.4 | 4.2 |

| 1400 °C/1 h/FC | FL | 23.4 | 2.1 | ||

| Mo | 1.4 | 1200 °C/4 h/FC | L + γ +β | 10.4 | 2.8 |

| 1400 °C/1 h/FC | FL | 16.6 | 4.3 | ||

| W | 0.8 | 1200 °C/4 h/FC | L + γ | 13.2 | 4.0 |

| 1400 °C/1 h/FC | FL | 16.8 | 4.1 | ||

| Cr | 2.0 | 1200 °C/4 h/FC | L + γ | 14.4 | 1.6 |

| 1400 °C/1 h/FC | FL | 20.3 | 2.8 | ||

| Mn | 3.0 | 1200 °C/4 h/FC | L + γ +β | 12.2 | 2.0 |

| 1400 °C/1 h/FC | L + γ +β | 11.0 | 2.4 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tetsui, T. Evaluation of Forged TiAl Alloy Usefulness Based on Their Impact Resistance. Metals 2023, 13, 1991. https://doi.org/10.3390/met13121991

Tetsui T. Evaluation of Forged TiAl Alloy Usefulness Based on Their Impact Resistance. Metals. 2023; 13(12):1991. https://doi.org/10.3390/met13121991

Chicago/Turabian StyleTetsui, Toshimitsu. 2023. "Evaluation of Forged TiAl Alloy Usefulness Based on Their Impact Resistance" Metals 13, no. 12: 1991. https://doi.org/10.3390/met13121991

APA StyleTetsui, T. (2023). Evaluation of Forged TiAl Alloy Usefulness Based on Their Impact Resistance. Metals, 13(12), 1991. https://doi.org/10.3390/met13121991