Study of Adaptation Processes in Tribofilms during Friction of Antifriction Aluminum Alloys for Journal Bearings

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Tribological Tests

2.3. Chemical and Microstructural Characterization

3. Results and Discussion

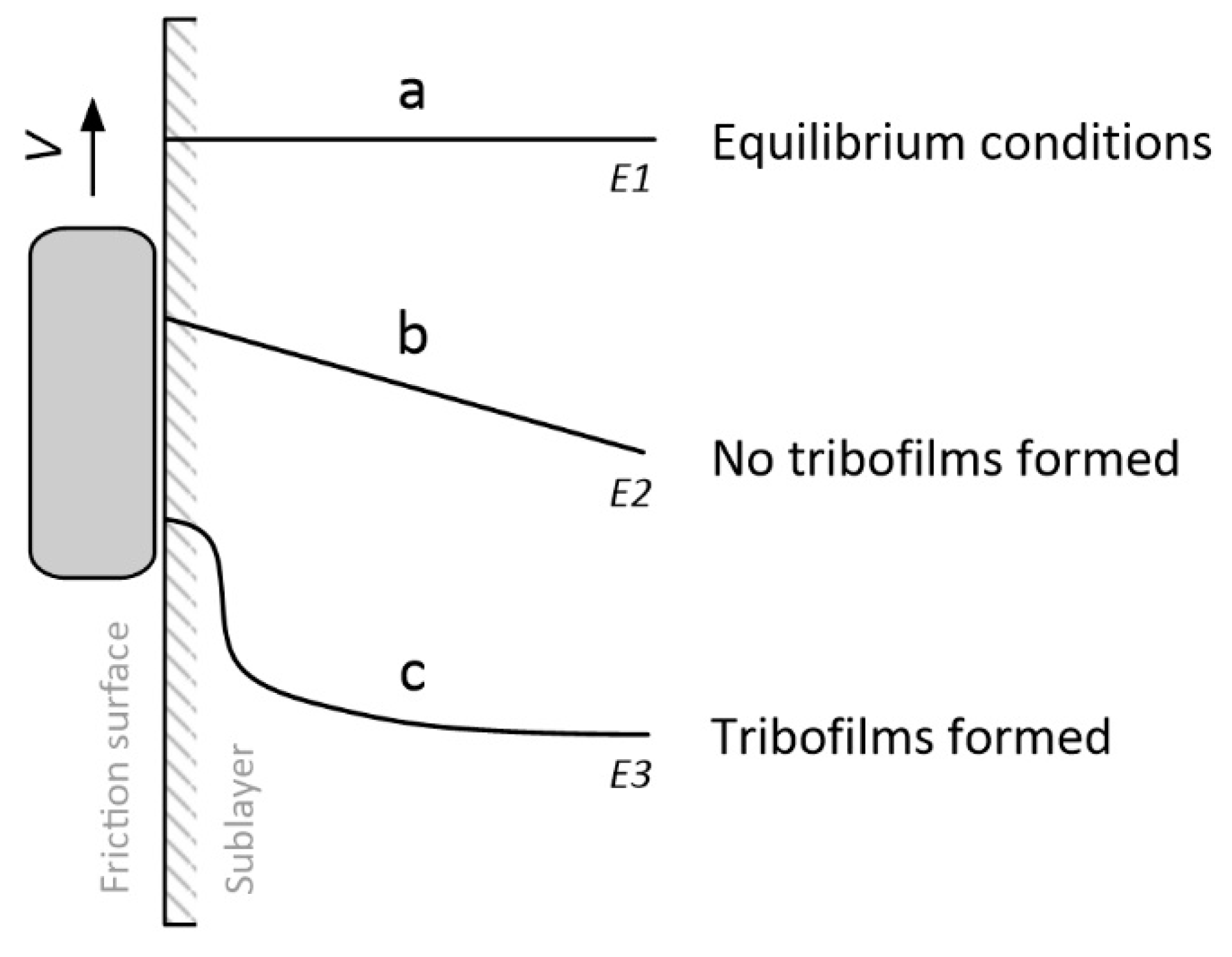

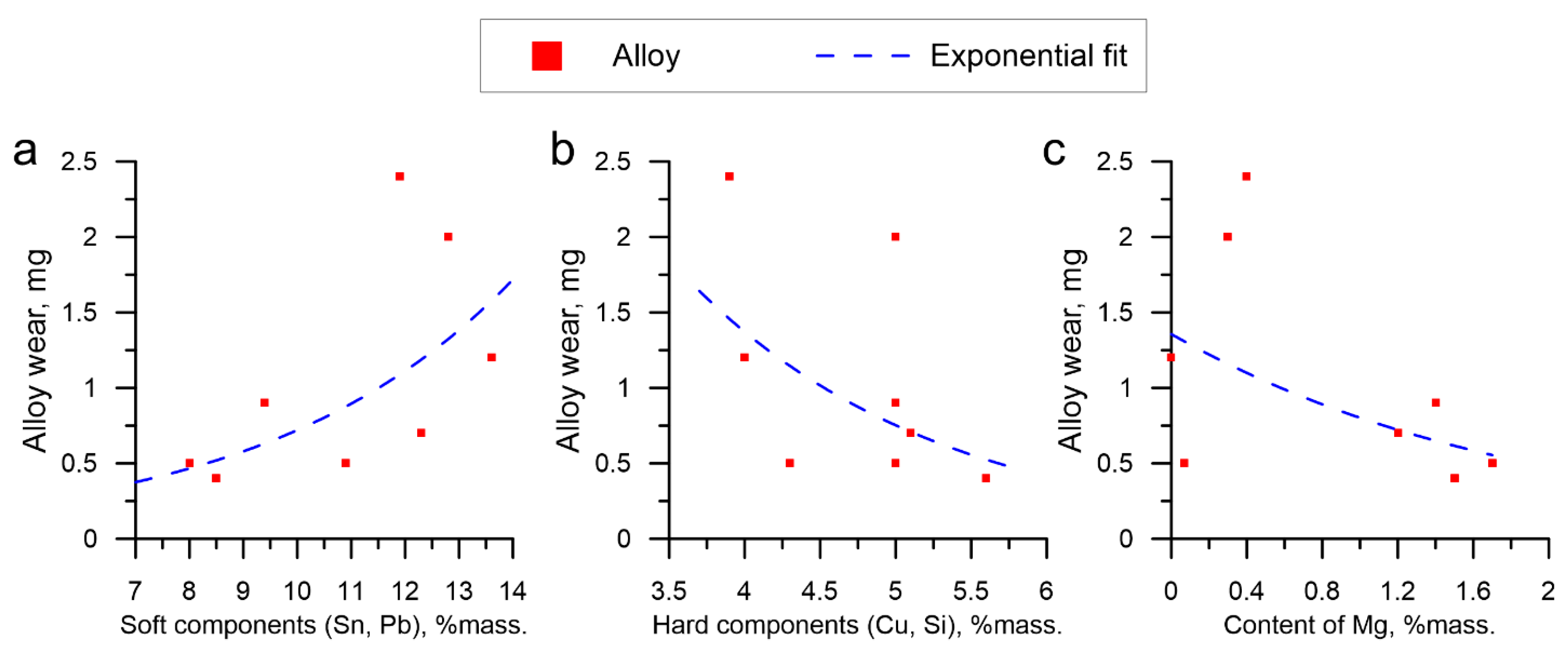

3.1. Tribological Behavior of the Alloys

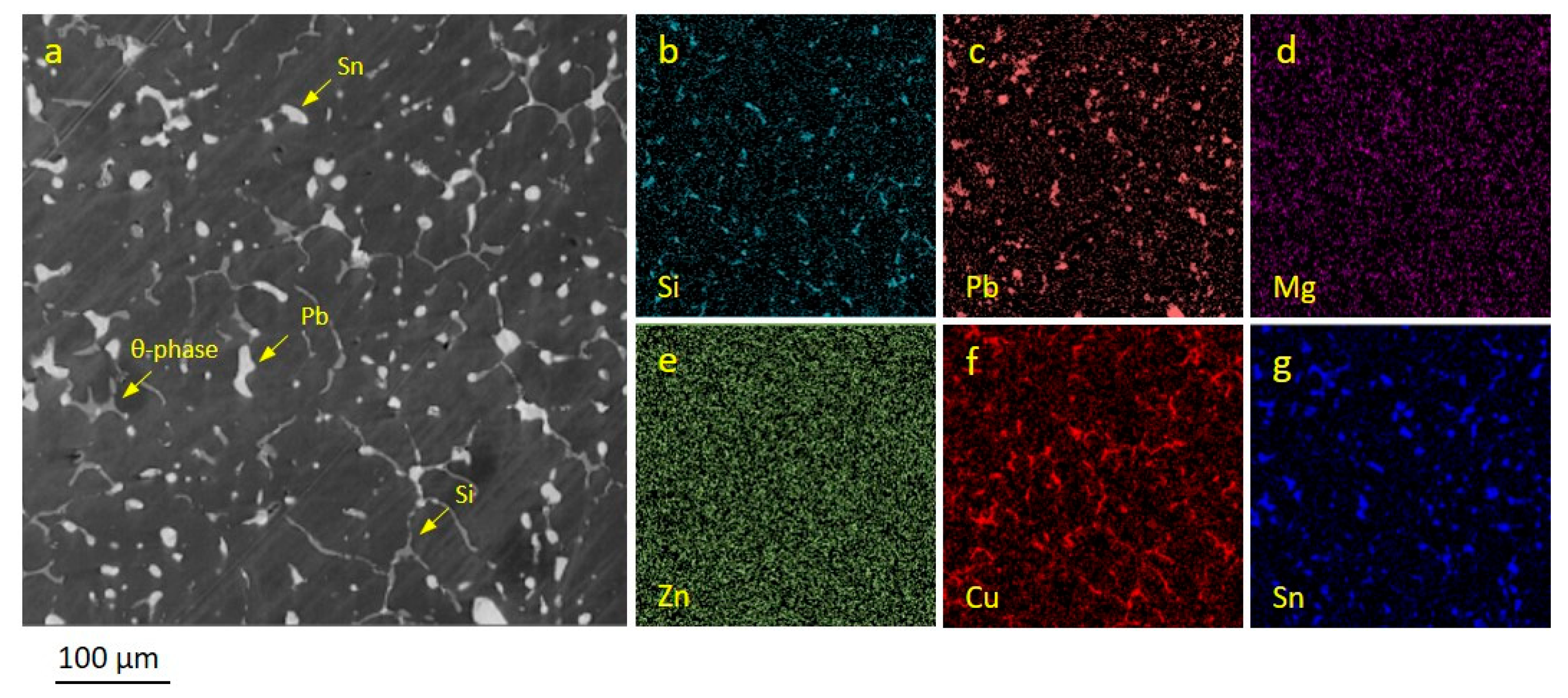

3.2. The State of Material before Friction

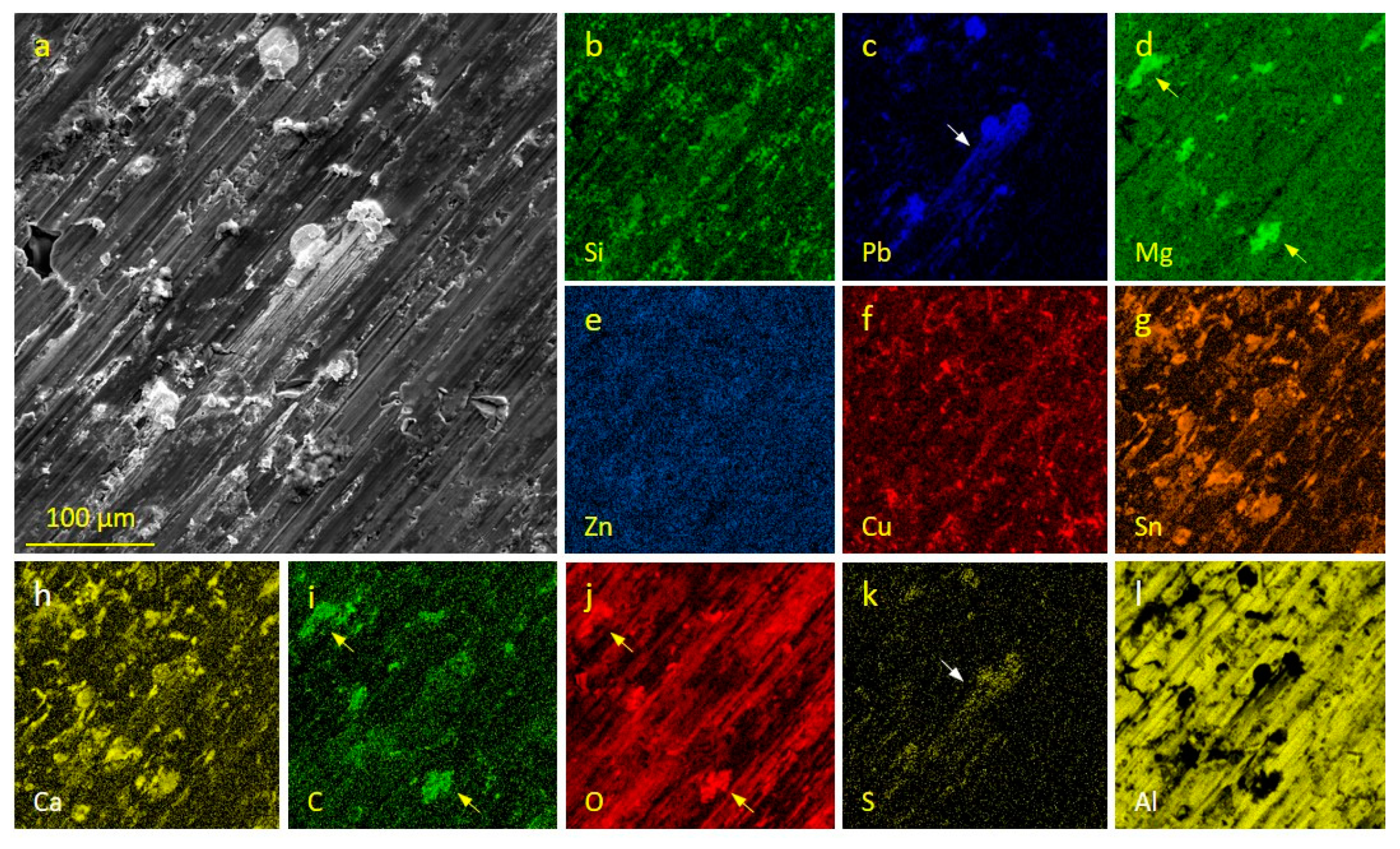

3.3. SEM Analysis

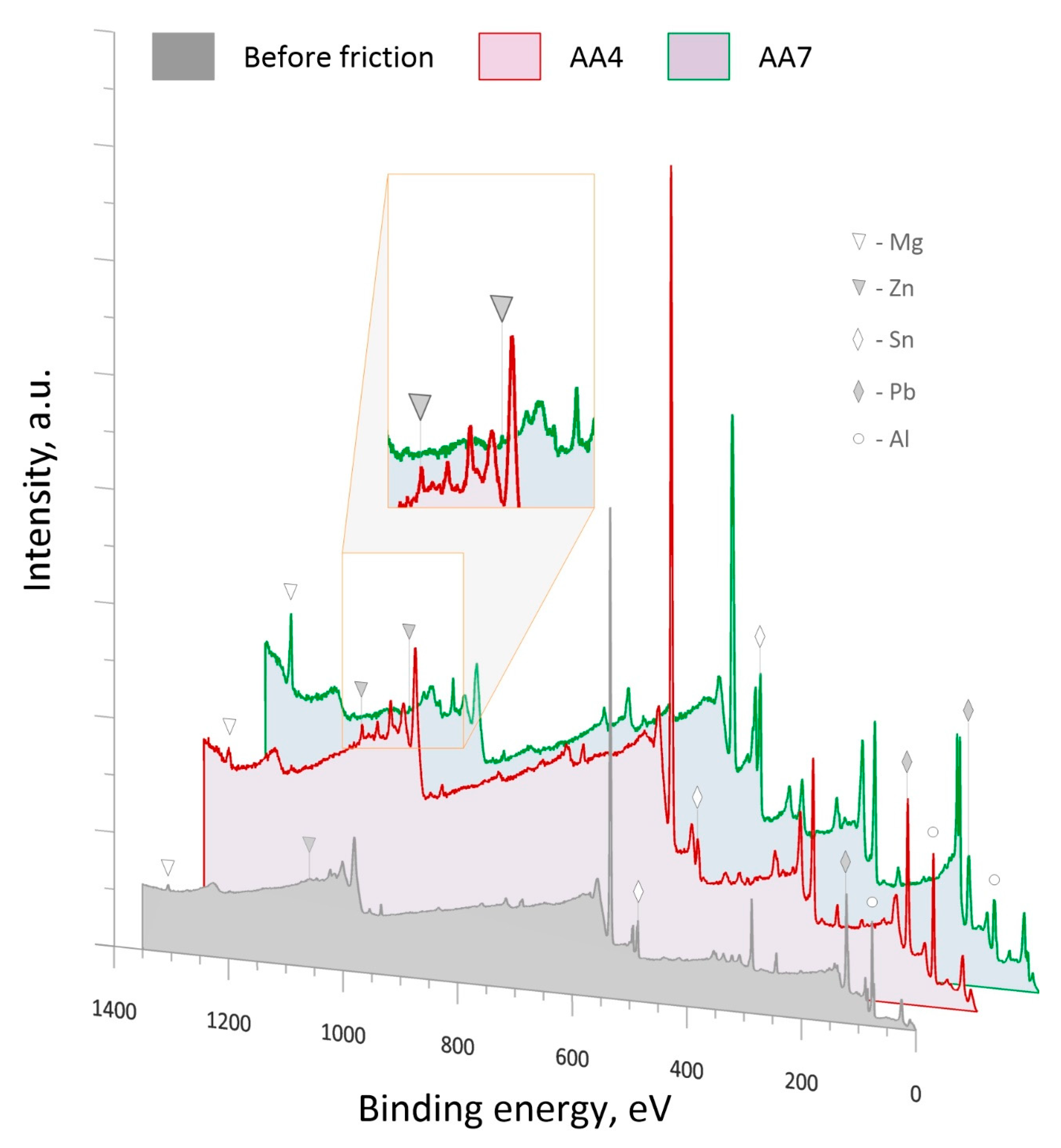

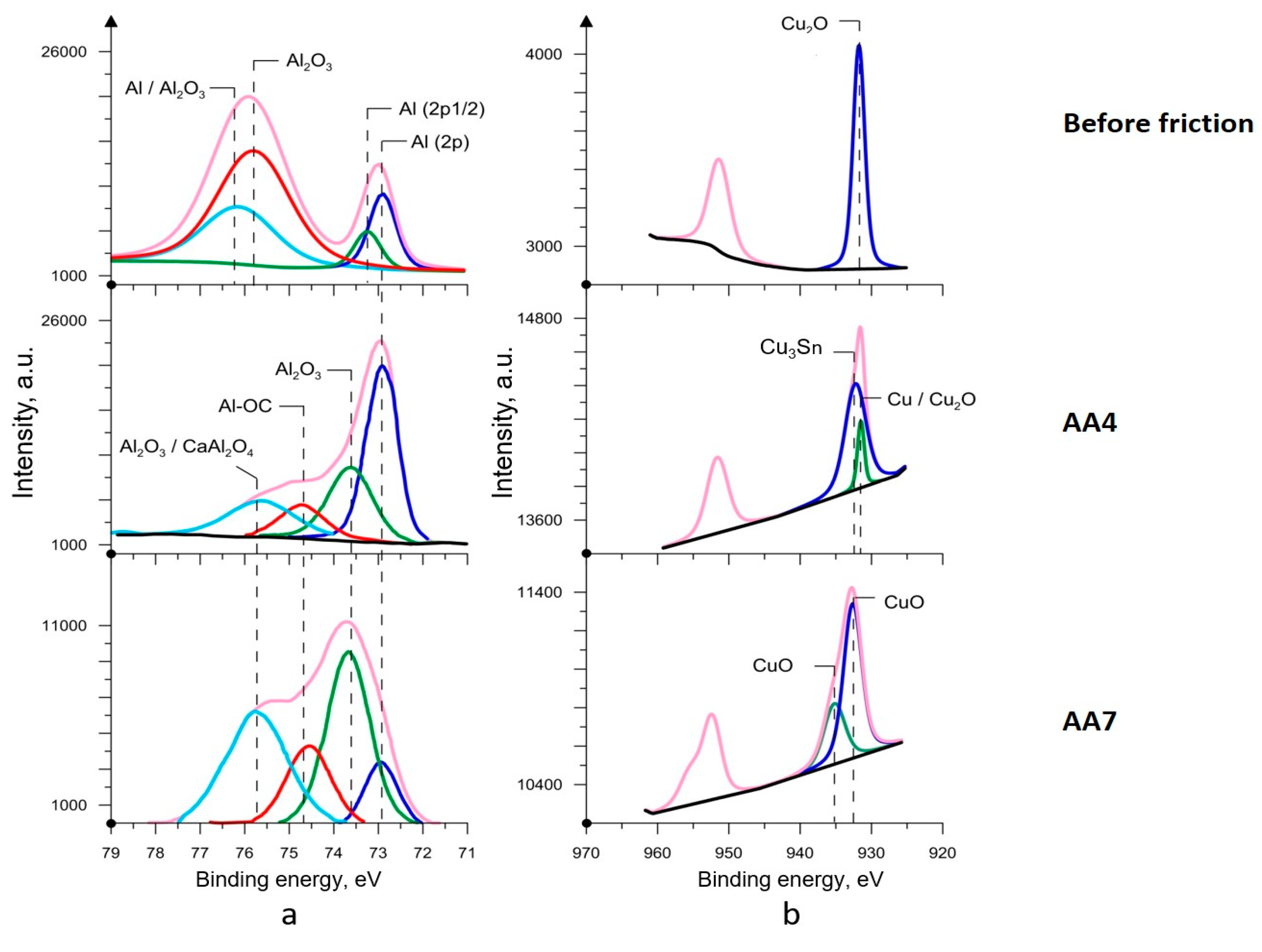

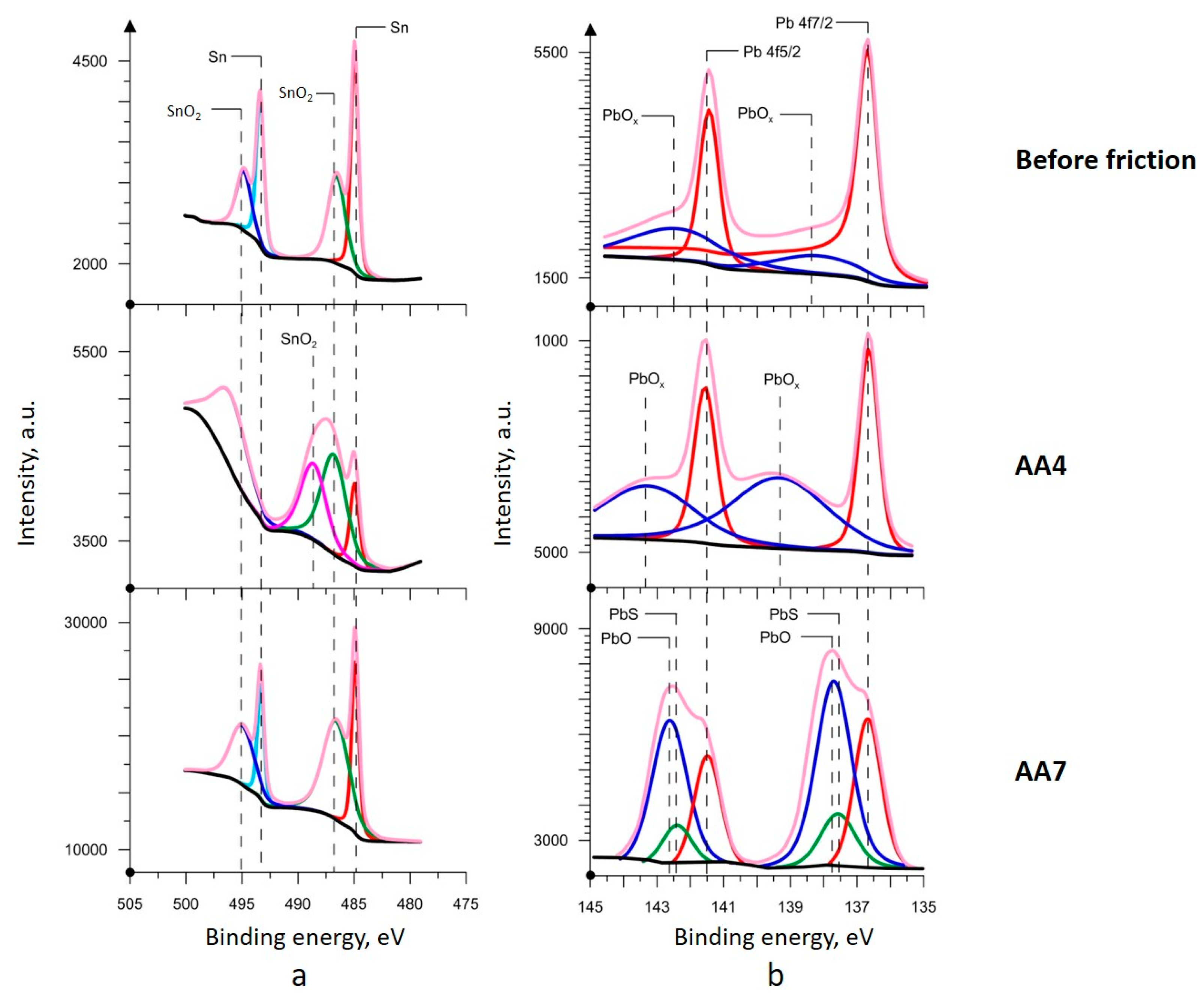

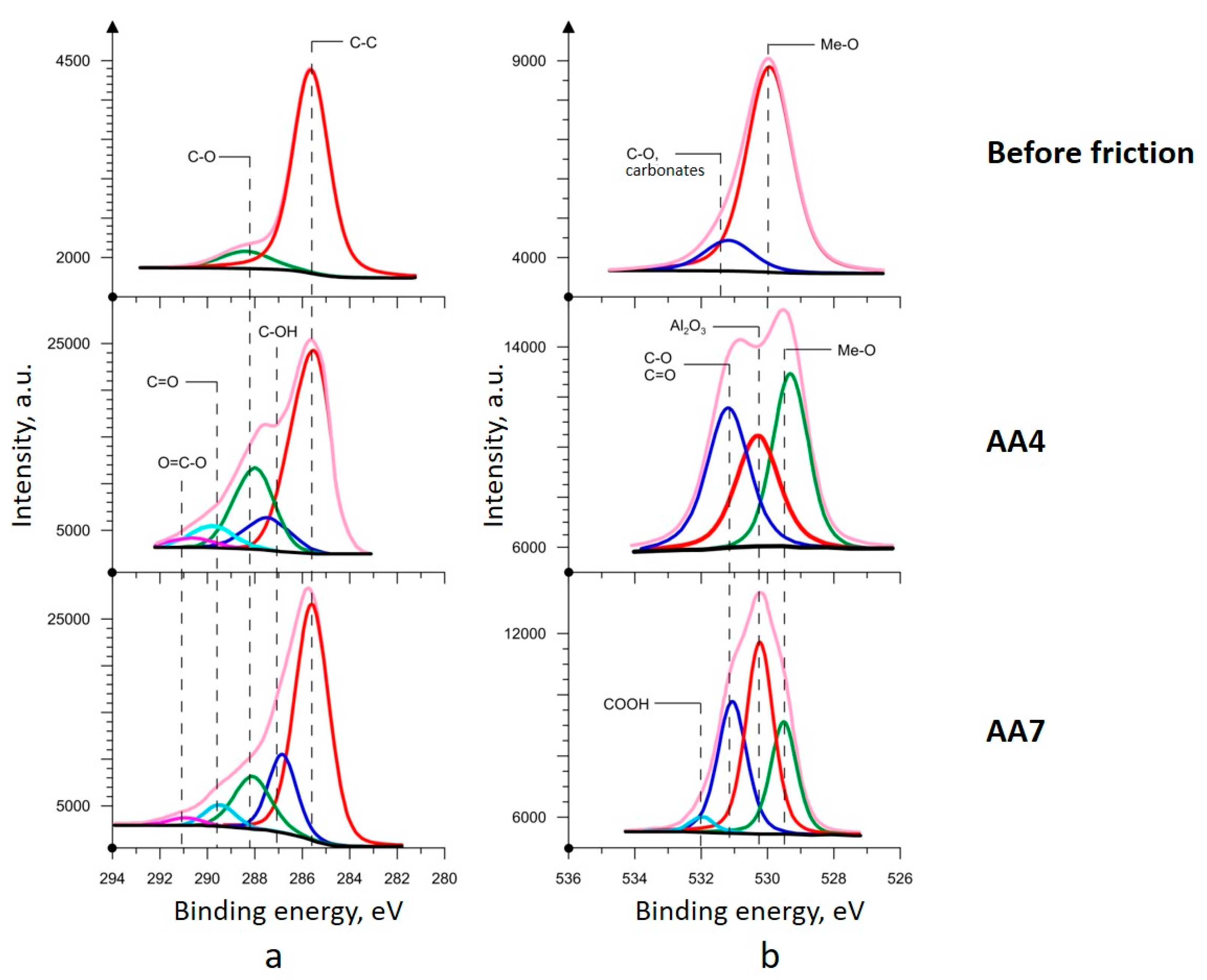

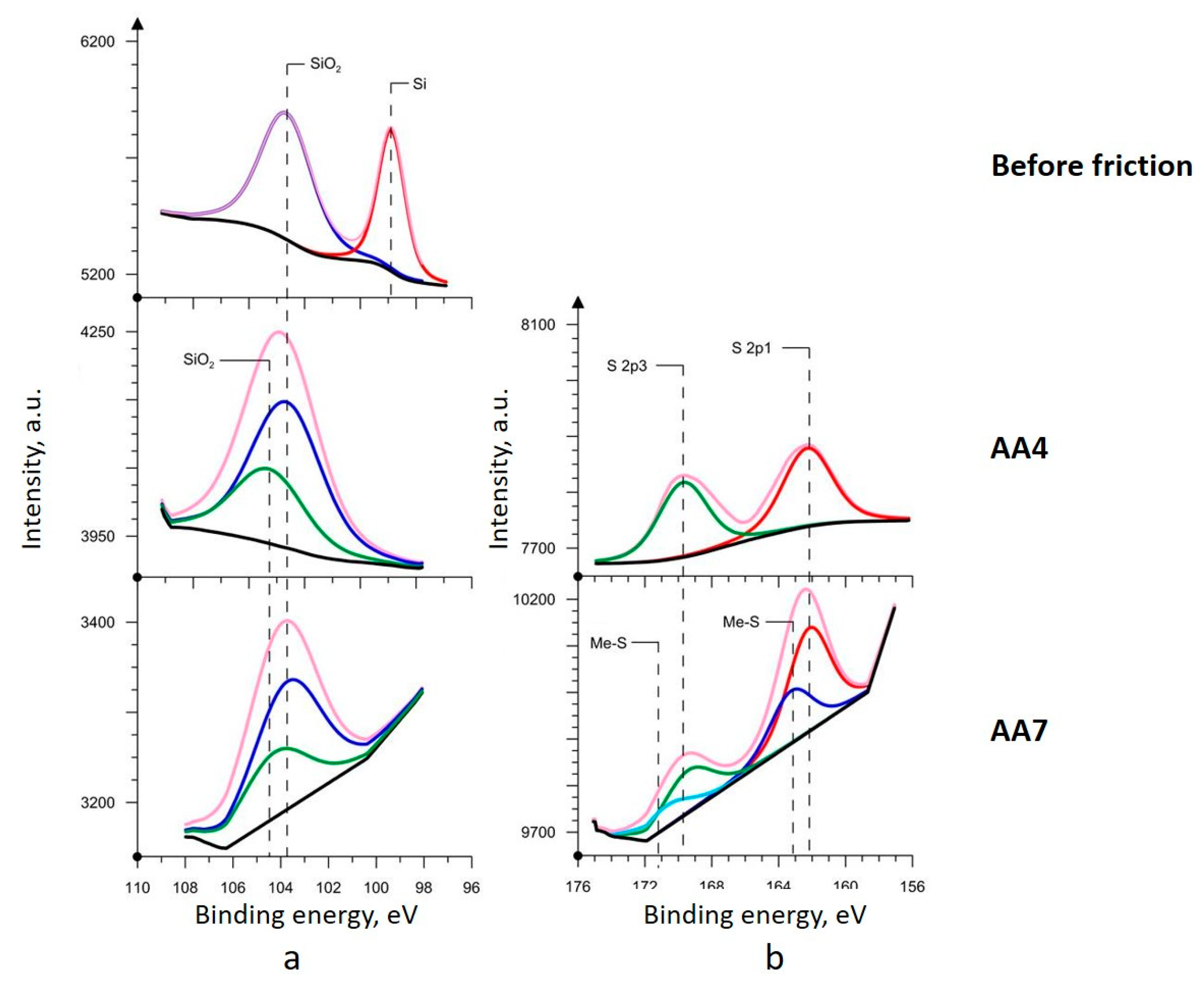

3.4. XPS Analysis

- Polymerized tribofilm, saturated with alloy elements and lubricant additives (I);

- A transition layer of aluminum oxide enriched with alloy elements (100–500 nm) (II);

- Plastically deformed matrix (>500 nm) (III).

- A polymerized tribofilm (<50 nm) (I);

- A polymerized and oxidized material (50–300 nm) (II);

- An aluminum oxide enriched with alloy components and lubricant additives (300–750 nm) (III);

- A plastically deformed matrix (>750 nm) (IV).

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Alloy | Line | State | |||||

|---|---|---|---|---|---|---|---|

| Before Friction | After Friction | ||||||

| Binding Energy, eV | Compound | Content, % Mass. | Binding Energy, eV | Compound | Content, % Mass. | ||

| AA7 | Al 2p | 72.9 | Al0 | 12.57 | 72.9 | Al0 | 4.21 |

| 75.7 | Al2O3 | 49.24 | 75.7 | Al2O3 | 3.54 | ||

| - | 74.6 | Al–OC | 1.87 | ||||

| C 1s | 285.7 | C–C | 7.88 | 285.7 | C–C | 26.41 | |

| 288.3 | C–O | 2.64 | 287.1 | C–OH | 3.22 | ||

| - | 288.3 | C–O | 8.74 | ||||

| - | 289.5 | C=O | 4.79 | ||||

| - | 291.1 | O=C–O | 3.53 | ||||

| Sn 3d | 484.8 | Sn0 | 1.33 | 484.8 | Sn0 | 5.34 | |

| 487.1 | SnO | 1.22 | 487.1 | SnO | 3.10 | ||

| Pb 4f | 136.6 | Pb0 | 0.89 | 136.6 | Pb0 | 4.61 | |

| 137.7 | PbOx | 1.10 | 137.7 | PbO | 6.45 | ||

| - | 137.5 | PbS | 1.62 | ||||

| Zn 2p | 1022.7 | Zn0 | 0.42 | 1022.7 | Zn0 | 0.79 | |

| 1022.1 | ZnO | 0.10 | 1022.1 | ZnO | 0.29 | ||

| Mg 1s | 1304.1 | MgO | 0.40 | 1304.1 | MgO | 2.15 | |

| - | 1303.1 | Mg0 | 1.00 | ||||

| - | 1305.0 | MgCO3 | 1.12 | ||||

| Cu 2p | 932.9 | Cu2O | 1.17 | 933.7 | CuO | 0.73 | |

| - | 936.1 | CuO | 0.32 | ||||

| Si 2p | 99.8 | Si0 | 0.84 | 103.6 | SiO2 | 0.59 | |

| 103.8 | SiO2 | 2.52 | - | ||||

| O 1s | 530.1 | Me–O | 12.33 | 529.5 | Me–O | 6.04 | |

| 531.5 | C–O | 2.95 | 530.3 | Al2O3 | 2.09 | ||

| - | 531.3 | C–O, C=O | 5.09 | ||||

| AA4 | Al 2p | 72.9 | Al0 | 11.31 | 72.9 | Al0 | 6.26 |

| 75.7 | Al2O3 | 45.75 | 75.7 | Al2O3 | 3.42 | ||

| 74.6 | Al–OC | 1.94 | |||||

| C 1s | 285.7 | C–C | 7.88 | 285.7 | C–C | 26.21 | |

| 288.3 | C–O | 2.64 | 287.1 | C–OH | 4.67 | ||

| - | 288.3 | C–O | 7.91 | ||||

| - | 289.5 | C=O | 3.77 | ||||

| - | 291.1 | O=C–O | 2.42 | ||||

| Sn 3d | 484.8 | Sn0 | 2.15 | 484.8 | Sn0 | 0.29 | |

| 487.1 | SnO2 | 1.86 | 487.1 | SnO2 | 0.43 | ||

| - | 488.0 | SnO2 | 0.38 | ||||

| Pb 4f | 136.6 | Pb0 | 1.05 | 136.6 | Pb0 | 6.07 | |

| 137.7 | PbOx | 1.66 | 139.4 | PbOx | 2.95 | ||

| Zn 2p | 1022.7 | Zn0 | 0.81 | 1022.7 | Zn0 | 1.41 | |

| 1022.1 | ZnO | 0.24 | 1022.1 | ZnO | 1.36 | ||

| Mg 1s | 1304.1 | MgO | 0.33 | 1304.1 | MgO | 0.43 | |

| - | 1303.1 | Mg0 | 0.11 | ||||

| Cu 2p | 932.9 | Cu2O | 1.34 | 932.6 | Cu/Cu2O | 1.17 | |

| - | 933.1 | CuO | 2.11 | ||||

| Si 2p | 99.8 | Si0 | 0.94 | 103.6 | SiO | 1.37 | |

| 103.8 | SiO2 | 2.11 | - | ||||

| O 1s | 103.8 | SiO2 | 2.46 | 529.5 | Me–O | 5.73 | |

| 530.1 | Me–O | 13.34 | 530.3 | Al2O3 | 10.40 | ||

| 531.5 | C–O | 2.16 | 531.3 | C–O, C=O | 7.04 | ||

References

- Holmberg, K.; Andersson, P.; Erdemir, A. Global energy consumption due to friction in passenger cars. Tribol. Int. 2012, 47, 221–234. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, V.; Singh, A.K. Influence of lubricants on the performance of journal bearings—A review. Tribol.-Mater. Surf. Interfaces 2020, 14, 67–78. [Google Scholar] [CrossRef]

- Gao, Q.; Chen, W.; Lu, L.; Huo, D.; Cheng, K. Aerostatic bearings design and analysis with the application to precision engineering: State-of-the-art and future perspectives. Tribol. Int. 2019, 135, 1–17. [Google Scholar] [CrossRef]

- Zemtsova, E.G.; Arbenin, A.Y.; Sidorov, Y.V.; Morozov, N.F.; Korusenko, P.M.; Semenov, B.N.; Smirnov, V.M. The use of carbon-containing compounds to prepare functional and structural composite materials: A review. Appl. Sci. 2022, 12, 9945. [Google Scholar] [CrossRef]

- Mironov, A.; Gershman, I.; Gershman, E.; Podrabinnik, P.; Kuznetsova, E.; Peretyagin, P.; Peretyagin, N. Properties of Journal Bearing Materials That Determine Their Wear Resistance on the Example of Aluminum-Based Alloys. Materials 2021, 14, 535. [Google Scholar] [CrossRef] [PubMed]

- Sevostyanov, N.V.; Bolshakova, A.N.; Bolsunovskaya, T.A.; Burkovskaya, N.P. Tribotechnical Properties of Nickel Based Cermet Materials. J. Frict. Wear. 2021, 42, 335–339. [Google Scholar] [CrossRef]

- Dong, W.; Yang, X.; Song, F.; Wu, M.; Zhu, Y.; Wang, Z. Anti-friction and wear resistance analysis of cemented carbide coatings. Int. J. Adv. Manuf. Technol. 2022, 122, 2795–2821. [Google Scholar]

- Polmear, I.J.; St. John, D.H.; Nie, J.-F.; Qian, M. Light Alloys Metallurgy of the Light Metals, 5th ed.; Elsevier/Butterworth-Heinemann: Oxford, UK, 2017; 537p. [Google Scholar]

- Prasad, S.V.; Asthana, R. Aluminium Metal-Matrix Composites for Automotive Applications: Tribological Considerations. Tribol. Lett. 2004, 17, 445–453. [Google Scholar] [CrossRef]

- Huang, S.; Zhu, B.; Zhang, Y.; Liu, H.; Wu, S.; Xie, H. Microstructure Comparison for AlSn20Cu Antifriction Alloys Prepared by Semi-Continuous Casting, Semi-Solid Die Casting, and Spray Forming. Metals 2022, 12, 1552. [Google Scholar] [CrossRef]

- Kalogeropoulos, A.; Kalogeropoulou, A.; Theodorakakos, A.; Lelidakis, G. Experimental investigation of an Al-Cu alloy as an alternative cylinder liner material for internal combustion engines. Mater. Today Proc. 2020, 27, 2098–2104. [Google Scholar]

- Cui, S.; Sun, P.; Li, X.; Huang, H.; Gao, K. Oxidation and tribological behaviors of Cu-Al, Cu-Sn, and Cu-Zn solid solutions. Results Phys. 2019, 12, 2306–2315. [Google Scholar]

- Yang, M.; Ding, J.; Hu, Z.; Peng, Y.; Wang, R.; Jiang, W. Investigation on microstructure and tribological properties of ex situ nano-SiCp reinforced Al-Cu matrix composite prepared by the stirring-casting process. J. Alloys Compd. 2020, 848, 156454. [Google Scholar]

- Sohag, M.A.Z.; Gupta, P.; Kondal, N.; Kumar, D.; Singh, N.; Jamwal, A. Effect of ceramic reinforcement on the microstructural, mechanical and tribological behavior of Al-Cu alloy metal matrix composite. Mater. Today Proc. 2020, 21, 1407–1411. [Google Scholar] [CrossRef]

- Jain, S.; Naveen, L.; Kumar, V.; Samal, S. Effect of Ni and Si alloying elements on the phase evolution, mechanical properties, tribological behaviour of Al–Cu alloys. Mater. Chem. Phys. 2023, 297, 127421. [Google Scholar] [CrossRef]

- Carlton, H.; Huitink, D.; Liang, H. Tribochemistry as an Alternative Synthesis Pathway. Lubricants 2020, 8, 87. [Google Scholar] [CrossRef]

- Morina, A.; Neville, A. Tribofilms: Aspects of formation, stability and removal. J. Phys. D Appl. Phys. 2007, 40, 5476. [Google Scholar] [CrossRef]

- Gellman, A.J.; Spencer, N.D. Surface chemistry in tribology. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2002, 216, 443–461. [Google Scholar] [CrossRef]

- Bowden, F.P.; Tabor, D. The area of contact between stationary and moving surfaces. Proc. R. Soc. Lond. 1939, 169, 391–413. [Google Scholar] [CrossRef]

- Bershadskiy, N.Y. Structural Thermodynamics of Tribosystem; Znanie: Kiev, Russia, 1990. (In Russian) [Google Scholar]

- Gershman, J.S.; Bushe, N.A. Thin films and self-organization during friction under the current collection conditions. Surf. Coat 2004, 186, 405–411. [Google Scholar] [CrossRef]

- Gershman, I.S.; Mironov, A.E.; Gershman, E.I.; Fox-Rabinovich, G.S.; Veldhuis, S.C. Self-organization during friction of slide bearing antifriction materials. Entropy 2015, 17, 7967–7978. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.; Gershman, I.S.; Locks, E.; Paiva, J.M.; Endrino, J.L.; Dosbaeva, G.; Veldhuis, S. The Relationship between Cyclic Multi-Scale Self-Organized Processes and Wear-Induced Surface Phenomena under Severe Tribological Conditions Associated with Buildup Edge Formation. Coatings 2021, 11, 1002. [Google Scholar] [CrossRef]

- Naderi, M. On the Evidence of Thermodynamic Self-Organization during Fatigue: A Review. Entropy 2020, 22, 372. [Google Scholar] [CrossRef] [PubMed]

- Nakayama, K.; Martin, J.M. Tribochemical reactions at and in the vicinity of a sliding contact. Wear 2006, 26, 235–240. [Google Scholar] [CrossRef]

- Yin, C.H.; Liang, Y.L.; Liang, Y.; Li, W.; Yang, M. Formation of a self-lubricating layer by oxidation and solid-state amorphization of nano-lamellar micro-structures during dry sliding wear tests. Acta Mater. 2019, 166, 208–220. [Google Scholar] [CrossRef]

- Andrade, E.; Randall, R. The Rehbinder effect. Nature 1949, 164, 1127. [Google Scholar] [CrossRef]

- Yusuke, O.; Jingxiang, X.; Naoki, T.; Kenta, A.; Satoshi, S.; Yang, W.; Nobuki, O.; Takahiro, H.; Koshi, A.; Momoji, K. Self-Formed Double Tribolayers Play Collaborative Roles in Achieving Superlow Friction in an Aqueous Environment. J. Phys. Chem. C 2020, 124, 8295–8303. [Google Scholar] [CrossRef]

- Kuzharov, A.A.; Luk’yanov, B.S.; Kuzharov, A.S. Tribochemical transformations of glycerol. J. Frict. Wear 2016, 37, 337–345. [Google Scholar] [CrossRef]

- Wang, B.; Qiu, F.; Barber, G.C.; Zou, Q.; Wang, J.; Guo, S.; Yongfeng, Y.; Jiang, Q. Role of nano-sized materials as lubricant additives in friction and wear reduction: A review. Wear 2022, 490, 204206. [Google Scholar] [CrossRef]

- Luiz, J.F.; Spikes, H. Tribofilm formation, friction and wear-reducing properties of some phosphorus-containing antiwear additives. Tribol. Lett. 2020, 68, 75. [Google Scholar] [CrossRef]

- Waqas, M.; Zahid, R.; Bhutta, M.U.; Khan, Z.A.; Saeed, A. A review of friction performance of lubricants with nano additives. Materials 2021, 14, 6310. [Google Scholar] [CrossRef]

- Dawczyk, J.; Morgan, N.; Russo, J.; Spikes, H. Film thickness and friction of ZDDP tribofilms. Tribol. Lett. 2019, 67, 34. [Google Scholar] [CrossRef]

- Gershman, I.; Bushe, N. Elements of thermodynamics and self-organization during friction. In Self-Organization during Friction: Advanced Surface Engineered Materials and Systems Designed, 1st ed.; Fox-Rabinovich, G., Totten, G.E., Eds.; CRC Press, Taylor and Francis Group: Boca Raton, FL, USA, 2006; pp. 13–58. [Google Scholar]

- Klamecki, B.E. A thermodynamic model of friction. Wear 1980, 63, 113–120. [Google Scholar] [CrossRef]

- Klimontovich, Y.L. Introduction to the Physics of Open Systems; Yanus: Moscow, Russia, 2002; 284p. [Google Scholar]

- Genovese, A.; D’Angelo, G.A.; Sakhnevych, A.; Farroni, F. Review on Friction and Wear Test Rigs: An Overview on the State of the Art in Tyre Tread Friction Evaluation. Lubricants 2020, 8, 91. [Google Scholar] [CrossRef]

- Maruyama, B.; Ohuchi, F.S. H2O catalysis of aluminum carbide formation in the aluminum-silicon carbide system. J. Mater. Res. 1991, 6, 1131–1134. [Google Scholar] [CrossRef]

- Popoola, O.O.; Kriven, W.M. Interfacial structure and chemistry in a ceramic/polymer composite material. J. Mater. Res. 1992, 7, 1545–1552. [Google Scholar] [CrossRef]

- Dubé, C.E.; Workie, B.; Kounaves, S.P.; Robbat, A.; Aksub, M.L.; Davies, G. Electrodeposition of metal alloy and mixed oxide films Using a single-precursor tetranuclear copper-nickel complex. J. Electrochem. Soc. 1995, 142, 3357. [Google Scholar] [CrossRef]

- Wang, D.; Miller, A.C.; Notis, M.R. XPS study of the oxidation behavior of the Cu3Sn intermetallic compound at low temperatures. Surf. Interface Anal. 1996, 24, 127–132. [Google Scholar] [CrossRef]

- Kaldas, M.L.; Cooper, P.A.; Sodhi, R. Oxidation of wood components during chromated copper arsenate (CCA-C) fixation. J. Wood Chem. Technol. 1998, 18, 53–67. [Google Scholar] [CrossRef]

- Célerier, S.; Morisset, S.; Batonneau-Gener, I.; Belin, T.; Younes, K.; Batiot-Dupeyrat, C. Glycerol dehydration to hydroxyacetone in gas phase over copper supported on magnesium oxide (hydroxide) fluoride catalysts. Appl. Catal. A Gen. 2018, 557, 135–144. [Google Scholar] [CrossRef]

- Gaarenstroom, S.W.; Winograd, N.J.T.J. Initial and final state effects in the ESCA spectra of cadmium and silver oxides. J. Chem. Phys. 1977, 67, 3500–3506. [Google Scholar] [CrossRef]

- Zhang, H.; Li, X.; Yao, P.; Wen, L.; Zhu, Y.; He, X.; Yang, G. Microstructure evolution and mechanical properties of Cu-Sn intermetallic joints subjected to high-temperature aging. Mater. Charact. 2022, 186, 111791. [Google Scholar] [CrossRef]

- Junior, P.R.C.A.; Pukasiewicz, A.G.M. Evaluation of microstructure, mechanical and tribological properties of a Babbitt alloy deposited by arc and flame spray processes. Tribol. Int. 2019, 131, 148–157. [Google Scholar] [CrossRef]

- Thomas III, J.H.; Sharma, S.P. An XPS/AES study of films on electroplated Co–Sn alloy. JVSTA J. Vac. Sci. Technol. 1978, 15, 1706–1711. [Google Scholar] [CrossRef]

- Badrinarayanan, S.; Mandale, A.B.; Gunjikar, V.G.; Sinha, A.P.B. Mechanism of high-temperature oxidation of tin selenide. J. Mater. Sci. 1986, 21, 3333–3338. [Google Scholar] [CrossRef]

- Bertrand, P.A.; Fleischauer, P.D. X-ray photoelectron spectroscopy study of the surface adsorption of lead naphthenate. JVSTA J. Vac. Sci. Technol. 1980, 17, 1309–1314. [Google Scholar] [CrossRef]

- Taylor, J.A.; Perry, D.L. An X-ray photoelectron and electron energy loss study of the oxidation of lead. JVSTA J. Vac. Sci. Technol. 1984, 2, 771–774. [Google Scholar] [CrossRef]

- Pederson, L.R. Two-dimensional chemical-state plot for lead using XPS. J. Electron Spectrosc. Relat. Phenom. 1982, 28, 203–209. [Google Scholar] [CrossRef]

- Kovalev, A.I.; Wainstein, D.L.; Rashkovskiy, A.Y.; Osherov, A.; Golan, Y. Size shift of XPS lines observed from PbS nanocrystals. Surf. Interface Anal. 2010, 42, 850–854. [Google Scholar] [CrossRef]

- Ali, H.A.; Iliadis, A.A.; Mulligan, R.F.; Cresce, A.V.W.; Kofinas, P.; Lee, U. Properties of self-assembled ZnO nanostructures. Solid State Electron. 2002, 46, 1639–1642. [Google Scholar] [CrossRef]

- Zanoni, R.; Aurora, A.; Cattaruzza, F.; Decker, F.; Fastiggi, P.; Menichetti, V.; Tagliatesta, P.; Capodilupo, A.L.; Lembo, A. Metalloporphyrins as molecular precursors of electroactive hybrids: A characterization of their actual electronic states on Si (100) and (111) by AFM and XPS. Mater. Sci. Eng. C 2007, 27, 1351–1354. [Google Scholar] [CrossRef]

- Cui, W.; Li, P.; Wang, Z.; Zheng, S.; Zhang, Y. Adsorption study of selenium ions from aqueous solutions using MgO nanosheets synthesized by ultrasonic method. J. Hazard. Mater. 2018, 341, 268–276. [Google Scholar] [CrossRef]

- Hosking, N.C.; Ström, M.A.; Shipway, P.H.; Rudd, C.D. Corrosion resistance of zinc–magnesium coated steel. Corros. Sci. 2007, 49, 3669–3695. [Google Scholar] [CrossRef]

- De Wit, F.M.; Mol, J.M.C.; Terryn, H.; De Wit, J.H.W. The influence of chemical pre-treatment and magnesium surface enrichment on bonding of succinic acid molecules to aluminium alloy. J. Adhes. Sci. Technol. 2008, 22, 1089–1104. [Google Scholar] [CrossRef]

- Bournel, F.; Laffon, C.; Parent, P.; Tourillon, G. Adsorption of some substituted ethylene molecules on Pt (111) at 95 K Part 1: NEXAFS, XPS and UPS studies. Surf. Sci. 1996, 350, 60–78. [Google Scholar] [CrossRef]

- Cardinaud, C.; Rhounna, A.; Turban, G.; Grolleau, B. Contamination of Silicon Surfaces Exposed to CHF 3 Plasmas: An XPS Study of the Film and the Film-Surface Interface. J. Electrochem. Soc. 1988, 135, 1472. [Google Scholar] [CrossRef]

- Cherkashinin, G.; Nikolowski, K.; Ehrenberg, H.; Jacke, S.; Dimesso, L.; Jaegermann, W. The stability of the SEI layer, surface composition and the oxidation state of transition metals at the electrolyte–cathode interface impacted by the electrochemical cycling: X-ray photoelectron spectroscopy investigation. Phys. Chem. 2012, 14, 12321–12331. [Google Scholar] [CrossRef] [PubMed]

- Stipp, S.L.S. Where the bulk terminates: Experimental evidence for restructuring, chemibonded OH− and H+, adsorbed water and hydrocarbons on calcite surfaces. Mol. Simul. 2002, 28, 497–516. [Google Scholar] [CrossRef]

- Laajalehto, K.; Kartio, I.; Nowak, P. XPS study of clean metal sulfide surfaces. Appl. Surf. Sci. 1994, 81, 11–15. [Google Scholar] [CrossRef]

- Gane, N.; Skinner, J. The generation of dislocations in metals under a sliding contact and the dissipation of frictional energy. Wear 1973, 25, 381–384. [Google Scholar] [CrossRef]

- Furey, M.J.; Kajdas, C.; Ward, T.C.; Hellgeth, J.W. Thermal and catalytic effects on tribopolymerization as a new boundary lubrication mechanism. Wear 1990, 136, 85–97. [Google Scholar] [CrossRef]

- Furey, M.J. The formation of polymeric films directly on rubbing surfaces to reduce wear. Wear 1973, 26, 369–392. [Google Scholar] [CrossRef]

- Hu, Y.; Liu, H.; Fujii, H.; Ushioda, K.; Araki, H.; Sugita, K.; Liu, K. Vacancy-induced θ′ precipitation during ultrasonic-affected friction stir welding of Al–Cu alloy. J. Mater. Sci. 2020, 55, 14626–14641. [Google Scholar] [CrossRef]

- Garbar, I.I. Some patterns of metal structure formation during friction. J. Frict. Wear. 1981, 2, 1076–1084. (In Russian) [Google Scholar]

- Rybin, A.A. Large Plastic Deformations and Destruction of Metals; Metallurgia: Moscow, Russia, 1986; 224p. (In Russian) [Google Scholar]

- Lychagin, D.V.; Filippov, A.V.; Kolubaev, E.A.; Novitskaia, O.S.; Chumlyakov, Y.I.; Kolubaev, A.V. Dry sliding of Hadfield steel single crystal oriented to deformation by slip and twinning: Deformation, wear, and acoustic emission characterization. Tribol. Int. 2018, 119, 1–18. [Google Scholar] [CrossRef]

- Wang, X.; Mao, D.; Wei, X.; Li, J.; Meng, H.; Wang, W. Sliding friction induced atom diffusion in the deformation layer of 0.45% C steel rubbed against Tin alloy. Tribol. Int. 2013, 64, 128–134. [Google Scholar] [CrossRef]

| Alloy | Composition, % Mass. | Impurities, % Mass. | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Sn | Pb | Cu | Zn | Mg | Si | Al | Ti | Fe | |

| AA1 | 11.0 | 2.6 | 3.9 | 2.6 | 0.0 | 0.1 | bal. | 0.04 | 0.2 |

| AA2 | 9.8 | 2.5 | 4.5 | 2.4 | 1.2 | 0.6 | bal. | 0.03 | 0.3 |

| AA3 | 9.6 | 3.2 | 4.9 | 4.4 | 0.3 | 0.1 | bal. | 0.02 | 0.3 |

| AA4 | 8.7 | 3.2 | 3.4 | 2.9 | 0.4 | 0.5 | bal. | 0.03 | 0.1 |

| AA5 | 7.6 | 3.3 | 4.0 | 0.5 | 0.07 | 1.0 | bal. | 0.05 | 0.1 |

| AA6 | 6.4 | 3.0 | 4.1 | 1.9 | 1.4 | 0.9 | bal. | 0.03 | 0.2 |

| AA7 | 5.8 | 2.7 | 4.1 | 2.3 | 1.5 | 1.5 | bal. | 0.04 | 0.1 |

| AA8 | 5.4 | 2.6 | 3.5 | 2.3 | 1.7 | 0.8 | bal. | 0.04 | 0.1 |

| Bronze | 5.1 | 18.5 | bal. | 4.9 | - | 0.1 | 0.1 | - | <0.4 |

| 38HN3MA Steel | Composition, % Mass. | |||||||||

| C | Si | Mn | Ni | S | P | Cr | Mo | Cu | Fe | |

| 0.36 | 0.25 | 0.35 | 2.90 | <0.025 | <0.025 | 1.0 | 0.3 | 0.24 | bal. | |

| CH2 | S | Ca | Al | Mg | Zn | Si | P | Mo | Fe | Cl |

|---|---|---|---|---|---|---|---|---|---|---|

| 98.3% | 1.16% | 0.23% | 910 ppm | 648 ppm | 590 ppm | 514 ppm | 499 ppm | 126 ppm | 65 ppm | 50 ppm |

| Alloy | Tribological Parameters | ||

|---|---|---|---|

| Steel Wear, mg | Linear Wear of the Alloy, mm | CoF | |

| AA1 | 0.6 ± 0.1 | 0.0025 ± 0.0004 | 0.020 ± 0.003 |

| AA2 | 0.7 ± 0.1 | 0.0015 ± 0.0003 | 0.015 ± 0.002 |

| AA3 | 2.1 ± 0.3 | 0.0042 ± 0.0007 | 0.019 ± 0.003 |

| AA4 | 0.8 ± 0.1 | 0.0051 ± 0.0006 | 0.022 ± 0.002 |

| AA5 | 0.8 ± 0.1 | 0.0011 ± 0.0002 | 0.026 ± 0.004 |

| AA6 | 1.0 ± 0.2 | 0.0019 ± 0.0004 | 0.014 ± 0.002 |

| AA7 | 0.6 ± 0.1 | 0.0008 ± 0.0002 | 0.018 ± 0.003 |

| AA8 | 0.7 ± 0.1 | 0.0011 ± 0.0002 | 0.017 ± 0.003 |

| Bronze | 4.0 ± 0.3 | 0.0017 ± 0.0003 | 0.016 ± 0.004 |

| Object | Elements Composition, % Mass. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | Sn | Pb | Cu | Si | Zn | Mg | C | O | Fe | S | Ca | |

| Surface before friction | 77.7 | 3.7 | 2.1 | 2.9 | 1.8 | 2.2 | 0.3 | 5.1 | 3.9 | - | - | - |

| Surface after friction | 39.5 | 3.9 | 4.7 | 2.0 | 0.4 | 1.5 | 0.6 | 31.3 | 15.5 | 0.2 | 0.3 | 0.1 |

| Change, % | 50.8 | 105.4 | 223.8 | 69.0 | 22.2 | 68.2 | 200 | 611.8 | 397.4 | - | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Podrabinnik, P.; Gershman, I.; Mironov, A.; Kuznetsova, E.; Okunkova, A.A.; Grigoriev, S.N. Study of Adaptation Processes in Tribofilms during Friction of Antifriction Aluminum Alloys for Journal Bearings. Metals 2023, 13, 1936. https://doi.org/10.3390/met13121936

Podrabinnik P, Gershman I, Mironov A, Kuznetsova E, Okunkova AA, Grigoriev SN. Study of Adaptation Processes in Tribofilms during Friction of Antifriction Aluminum Alloys for Journal Bearings. Metals. 2023; 13(12):1936. https://doi.org/10.3390/met13121936

Chicago/Turabian StylePodrabinnik, Pavel, Iosif Gershman, Alexander Mironov, Ekaterina Kuznetsova, Anna A. Okunkova, and Sergey N. Grigoriev. 2023. "Study of Adaptation Processes in Tribofilms during Friction of Antifriction Aluminum Alloys for Journal Bearings" Metals 13, no. 12: 1936. https://doi.org/10.3390/met13121936

APA StylePodrabinnik, P., Gershman, I., Mironov, A., Kuznetsova, E., Okunkova, A. A., & Grigoriev, S. N. (2023). Study of Adaptation Processes in Tribofilms during Friction of Antifriction Aluminum Alloys for Journal Bearings. Metals, 13(12), 1936. https://doi.org/10.3390/met13121936