Fracture Toughness of Ti6Al4V/Cp-Ti Multi-Material Produced via Selective Laser Melting

Abstract

:1. Introduction

2. Materials and Methods

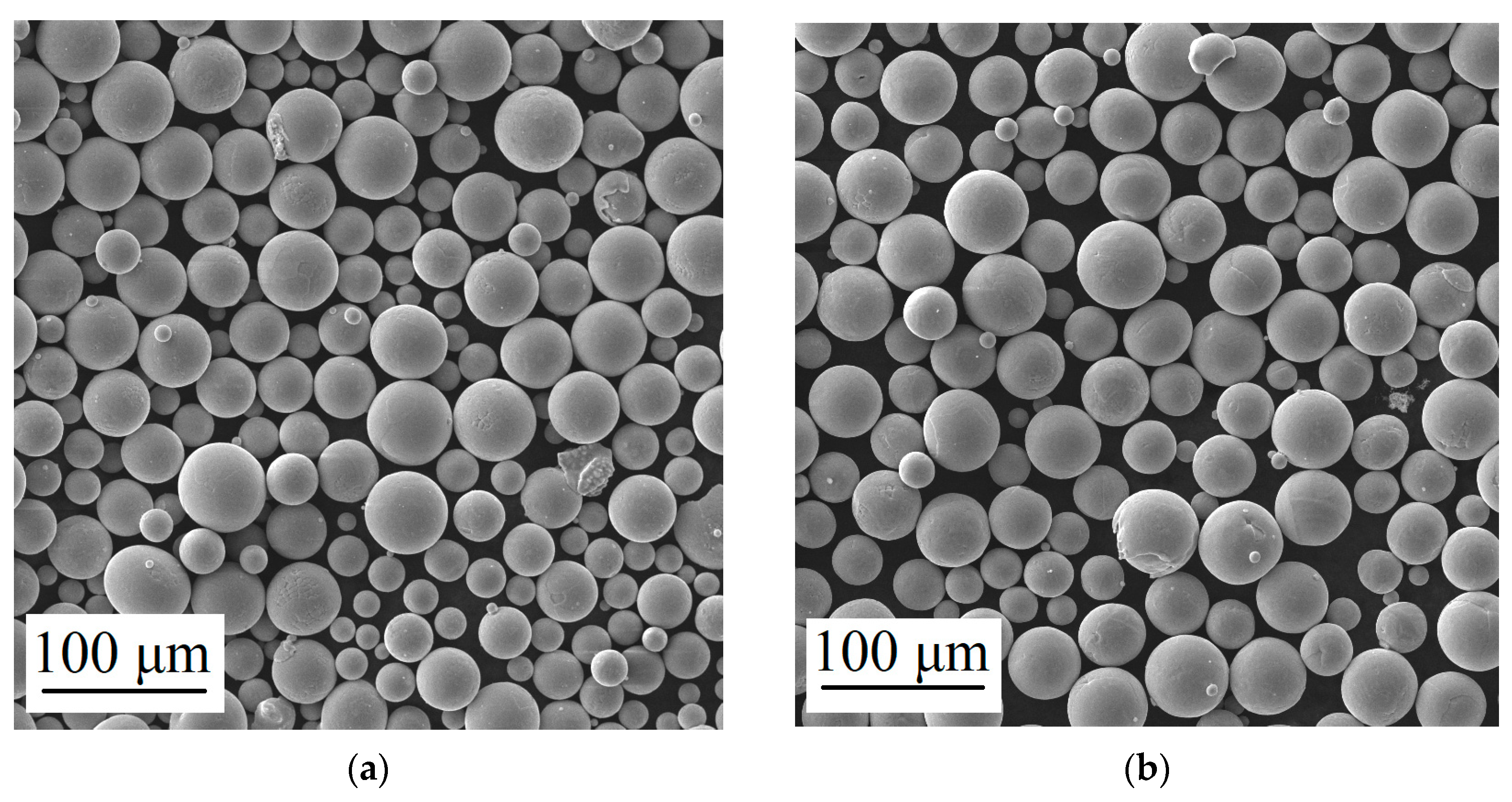

2.1. Starting Materials and the L-PBF Process Parameters

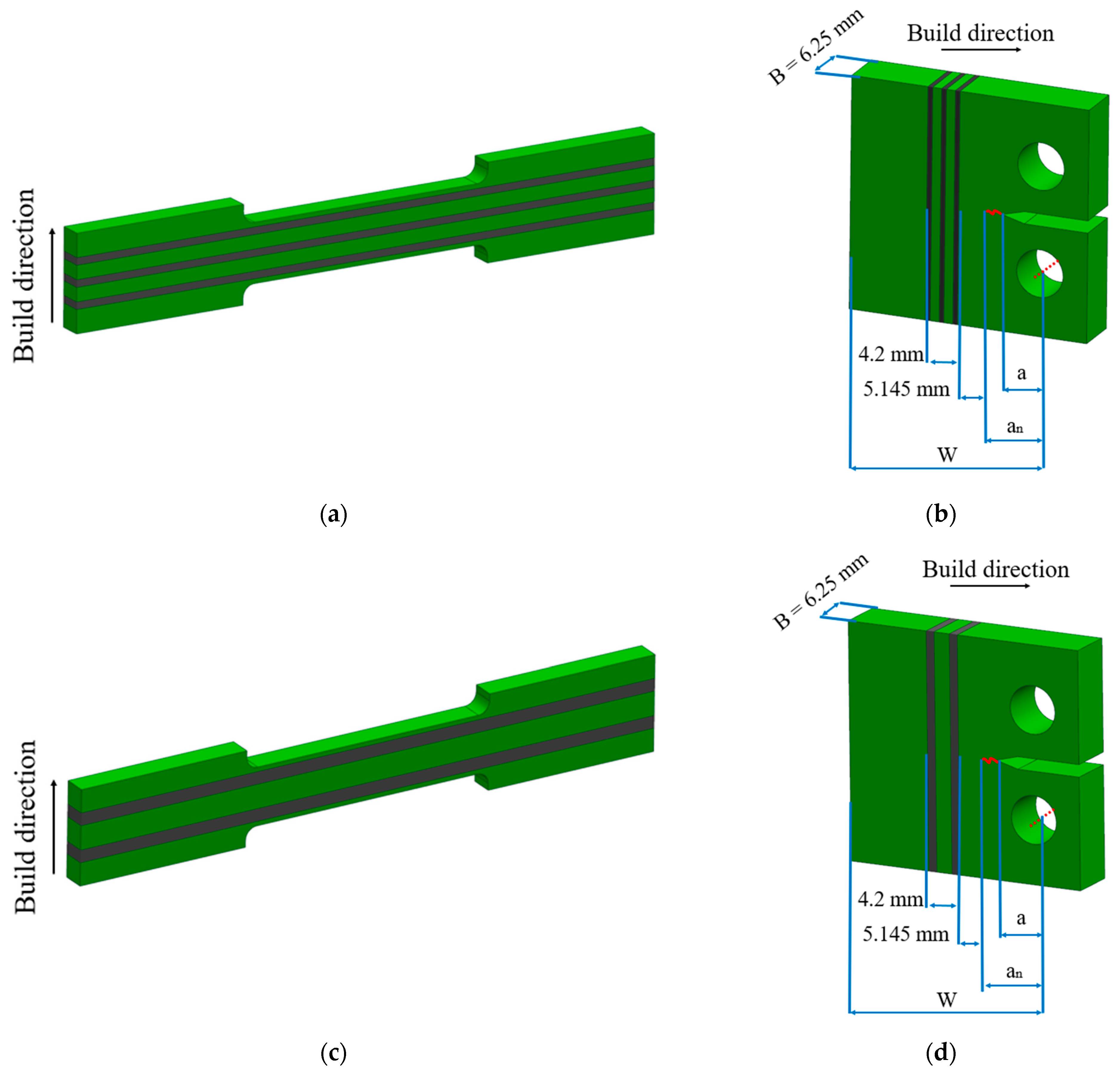

2.2. Multi-Material Ti6Al4V/Cp-Ti Samples for Tensile Test and Measurement of Fatigue Crack Growth Rate

2.3. Post-Treatment and Characterization

3. Results and Discussion

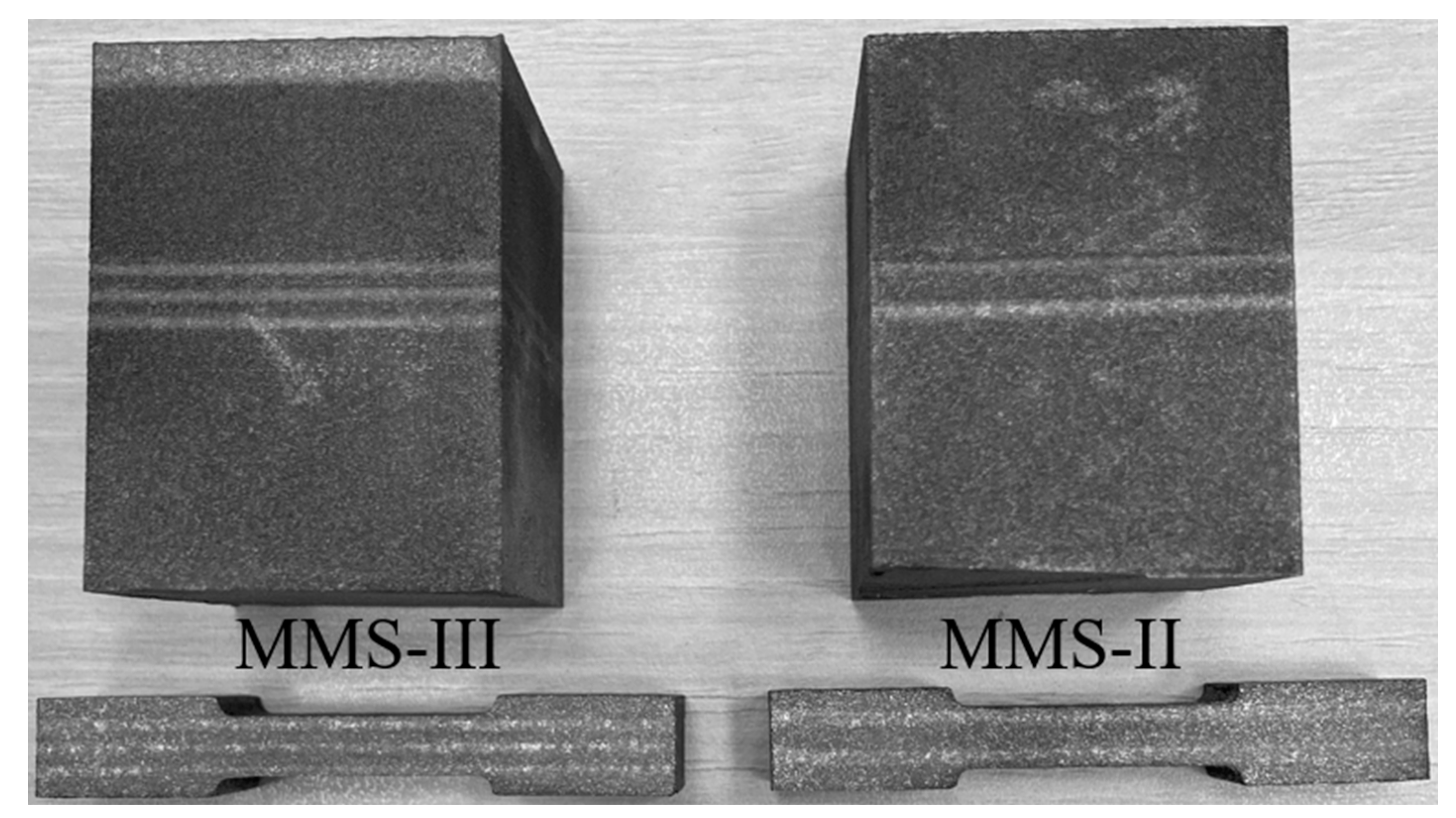

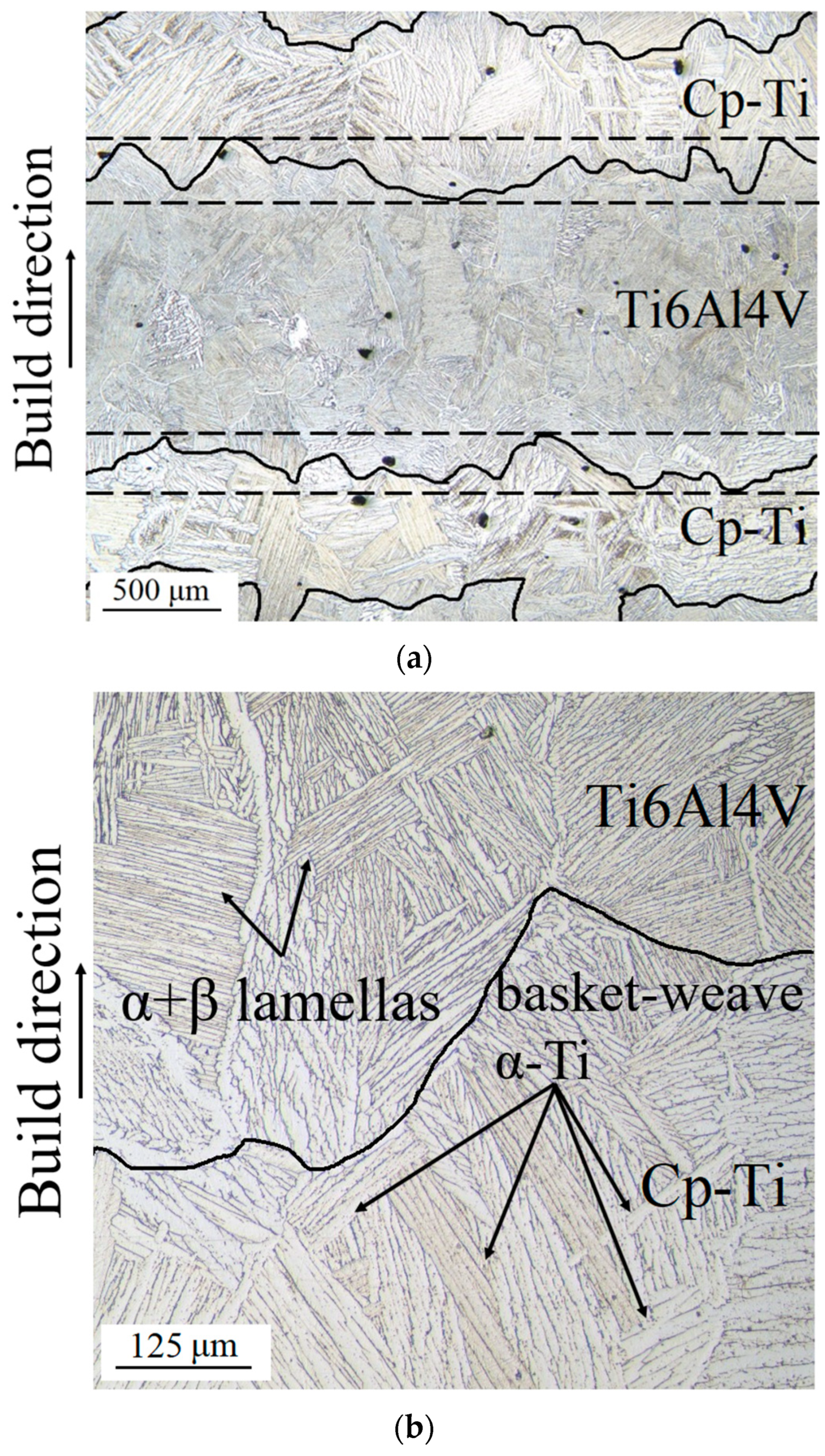

3.1. Porosity and Microstructure of the Multi-Material Ti6Al4V/Cp-Ti Samples

3.2. Chemical Composition and Hardness of the Multi-Material Ti6Al4V/Cp-Ti Samples

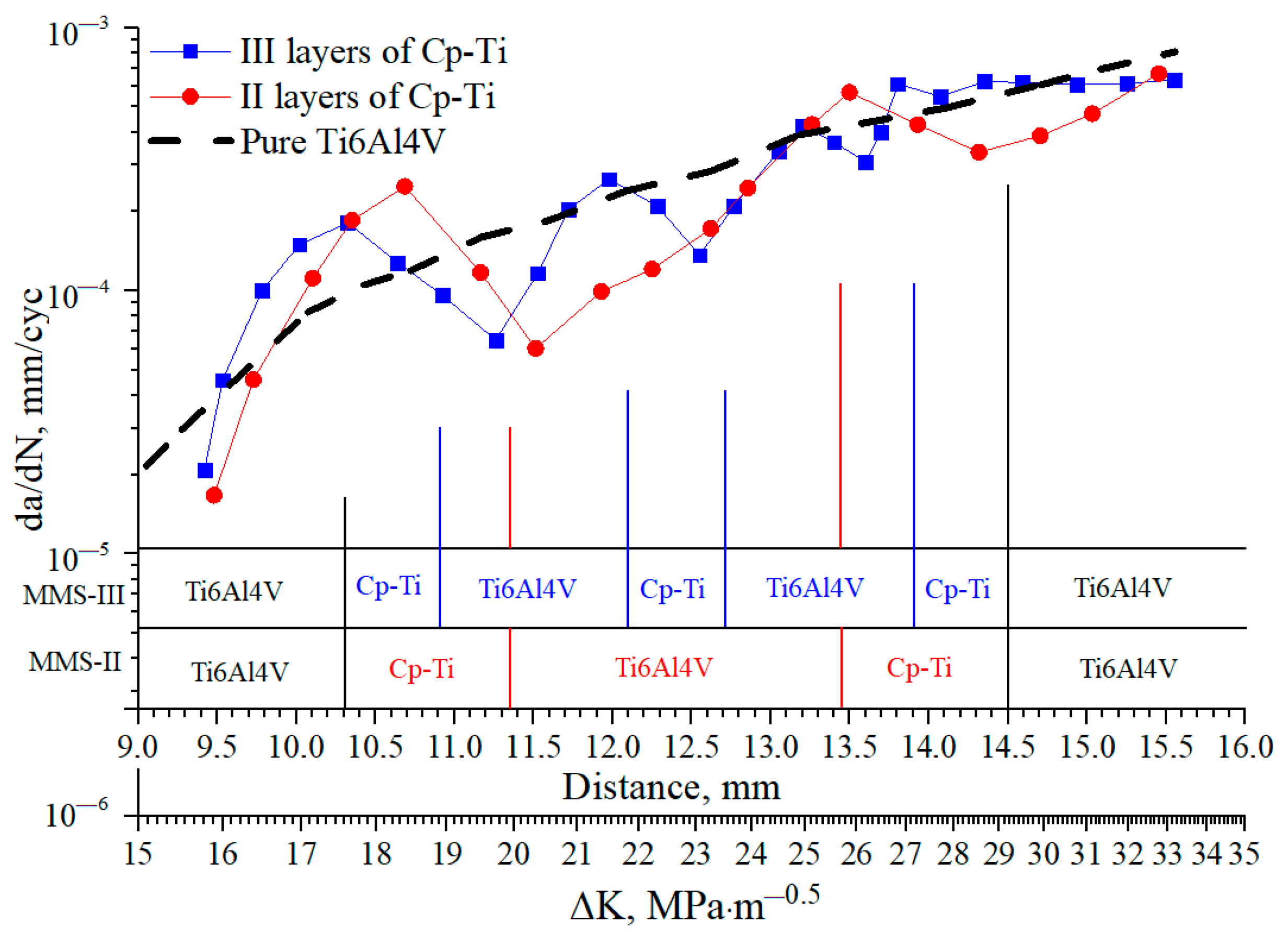

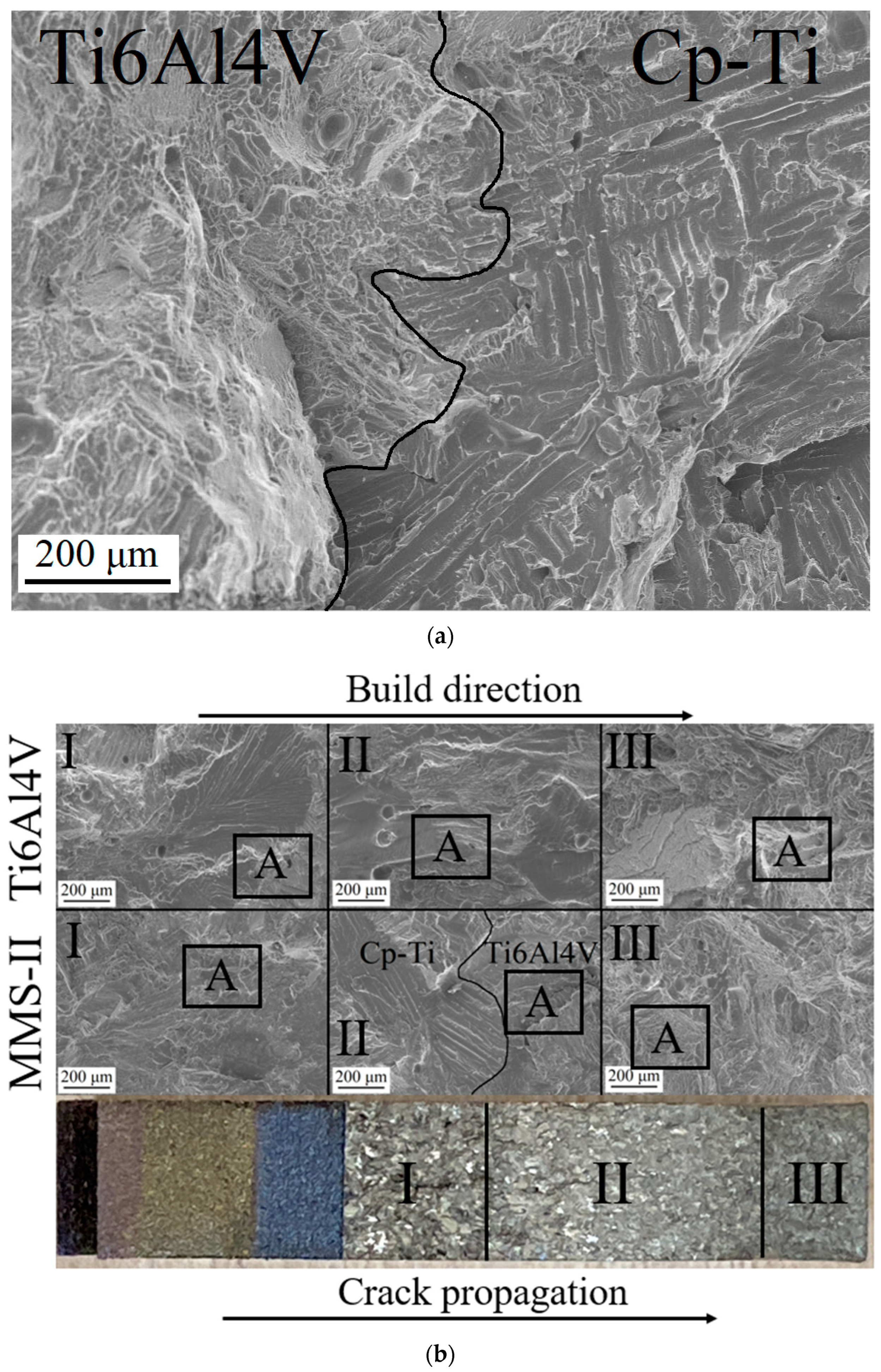

3.3. Room-Temperature Tensile Properties and Fatigue Crack Growth Rates of the Multi-Material Ti6Al4V/Cp-Ti Samples

4. Conclusions

- The size of the interfacial zone in the multi-material Ti6Al4V/Cp-Ti sample averaged between 250 and 300 μm. This was verified by examining the change in chemical composition (Al content) along the sample’s cross-section.

- The Ti6Al4V alloy zone had an average Vickers microhardness of about 300 HV, which decreased steadily to around 254 HV in the Cp-Ti zone. By comparing the results of the tensile tests with the literature data (of relatively pure Ti6Al4V alloy), it can be concluded that there is an insignificant decrease in tensile strength (by approximately 11% for MMS-III and by 8% for MMS-II) and a decrease in elongation (by 33% for MMS-III and by 25% for MMS-II).

- The obtained results confirm the principal possibility of a local increase in the fracture toughness due to the creation of a multi-material structure in products obtained via L-PBF. Additional research is necessary to examine the enhancement in fracture toughness locally in multi-materials obtained using L-PBF. The objective of this research was to analyze the extent of the influence of this local enhancement in properties.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bandyopadhyay, A.; Zhang, Y.; Onuike, B. Additive manufacturing of bimetallic structures. Virtual Phys. Prototyp. 2022, 17, 256–294. [Google Scholar] [CrossRef]

- Hasanov, S.; Alkunte, S.; Rajeshirke, M.; Gupta, A.; Huseynov, O.; Fidan, I.; Alifui-Segbaya, F.; Rennie, A. Review on Additive Manufacturing of Multi-Material Parts: Progress and Challenges. J. Manuf. Mater. Process. 2021, 6, 4. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Traxel, K.D.; Lang, M.; Juhasz, M.; Eliaz, N.; Bose, S. Alloy design via additive manufacturing: Advantages, challenges, applications and perspectives. Mater. Today 2022, 52, 207–224. [Google Scholar] [CrossRef]

- Naebe, M.; Shirvanimoghaddam, K. Functionally graded materials: A review of fabrication and properties. Appl. Mater. Today 2016, 5, 223–245. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, F.; Huang, Z.; Jia, M.; Chen, G.; Ye, Y.; Lin, Y.; Liu, W.; Chen, B.; Shen, Q.; et al. Additive manufacturing of functionally graded materials: A review. Mater. Sci. Eng. A 2019, 764, 138209. [Google Scholar] [CrossRef]

- Nazir, A.; Gokcekaya, O.; Md Masum Billah, K.; Ertugrul, O.; Jiang, J.; Sun, J.; Hussain, S. Multi-material additive manufacturing: A systematic review of design, properties, applications, challenges, and 3D printing of materials and cellular metamaterials. Mater. Des. 2023, 226, 111661. [Google Scholar] [CrossRef]

- Attaran, M. The rise of 3-D printing: The advantages of additive manufacturing over traditional manufacturing. Bus. Horiz. 2017, 60, 677–688. [Google Scholar] [CrossRef]

- Rafiee, M.; Farahani, R.D.; Therriault, D. Multi-Material 3D and 4D Printing: A Survey. Adv. Sci. 2020, 7, 1902307. [Google Scholar] [CrossRef]

- Feenstra, D.R.; Banerjee, R.; Fraser, H.L.; Huang, A.; Molotnikov, A.; Birbilis, N. Critical review of the state of the art in multi-material fabrication via directed energy deposition. Curr. Opin. Solid State Mater. Sci. 2021, 25, 100924. [Google Scholar] [CrossRef]

- Ahn, D.G. Directed Energy Deposition (DED) Process: State of the Art. Int. J. Precis. Eng. Manuf. Technol. 2021, 8, 703–742. [Google Scholar] [CrossRef]

- Wang, D.; Liu, L.; Deng, G.; Deng, C.; Bai, Y.; Yang, Y.; Wu, W.; Chen, J.; Liu, Y.; Wang, Y.; et al. Recent progress on additive manufacturing of multi-material structures with laser powder bed fusion. Virtual Phys. Prototyp. 2022, 17, 329–365. [Google Scholar] [CrossRef]

- Mussatto, A. Research progress in multi-material laser-powder bed fusion additive manufacturing: A review of the state-of-the-art techniques for depositing multiple powders with spatial selectivity in a single layer. Results Eng. 2022, 16, 100769. [Google Scholar] [CrossRef]

- Liu, F.; Li, T.; Jia, Z.; Wang, L. Combination of stiffness, strength, and toughness in 3D printed interlocking nacre-like composites. Extrem. Mech. Lett. 2020, 35, 100621. [Google Scholar] [CrossRef]

- Dzogbewu, T.C.; de Beer, D. Powder Bed Fusion of Multimaterials. J. Manuf. Mater. Process. 2023, 7, 15. [Google Scholar] [CrossRef]

- Nandhakumar, R.; Venkatesan, K. A process parameters review on selective laser melting-based additive manufacturing of single and multi-material: Microstructure, physical properties, tribological, and surface roughness. Mater. Today Commun. 2023, 35, 105538. [Google Scholar] [CrossRef]

- Wei, C.; Zhang, Z.; Cheng, D.; Sun, Z.; Zhu, M.; Li, L. An overview of laser-based multiple metallic material additive manufacturing: From macro- to micro-scales. Int. J. Extrem. Manuf. 2020, 3, 012003. [Google Scholar] [CrossRef]

- Borisov, E.; Polozov, I.; Starikov, K.; Popovich, A.; Sufiiarov, V. Structure and properties of Ti/Ti64 graded material manufactured by laser powder bed fusion. Materials 2021, 14, 6140. [Google Scholar] [CrossRef]

- Polozov, I.; Gracheva, A.; Popovich, A. Interface Characterization of Bimetallic Ti-6Al-4V/Ti2AlNb Structures Prepared by Selective Laser Melting. Materials 2022, 15, 8528. [Google Scholar] [CrossRef]

- Nguyen, H.D.; Pramanik, A.; Basak, A.K.; Dong, Y.; Prakash, C.; Debnath, S.; Shankar, S.; Jawahir, I.S.; Dixit, S.; Buddhi, D. A critical review on additive manufacturing of Ti-6Al-4V alloy: Microstructure and mechanical properties. J. Mater. Res. Technol. 2022, 18, 4641–4661. [Google Scholar] [CrossRef]

- Cain, V.; Thijs, L.; Van Humbeeck, J.; Van Hooreweder, B.; Knutsen, R. Crack propagation and fracture toughness of Ti6Al4V alloy produced by selective laser melting. Addit. Manuf. 2015, 5, 68–76. [Google Scholar] [CrossRef]

- Van Hooreweder, B.; Moens, D.; Boonen, R.; Kruth, J.P.; Sas, P. Analysis of Fracture Toughness and Crack Propagation of Ti6Al4V Produced by Selective Laser Melting. Adv. Eng. Mater. 2012, 14, 92–97. [Google Scholar] [CrossRef]

- Edwards, P.; Ramulu, M. Effect of build direction on the fracture toughness and fatigue crack growth in selective laser melted Ti-6Al-4 V. Fatigue Fract. Eng. Mater. Struct. 2015, 38, 1228–1236. [Google Scholar] [CrossRef]

- Kumar, P.; Ramamurty, U. Microstructural optimization through heat treatment for enhancing the fracture toughness and fatigue crack growth resistance of selective laser melted Ti6Al4V alloy. Acta Mater. 2019, 169, 45–59. [Google Scholar] [CrossRef]

- Zhang, H.; Dong, D.; Su, S.; Chen, A. Experimental study of effect of post processing on fracture toughness and fatigue crack growth performance of selective laser melting Ti-6Al-4V. Chin. J. Aeronaut. 2019, 32, 2383–2393. [Google Scholar] [CrossRef]

- Gushchina, M.O.; Kuzminova, Y.O.; Dubinin, O.N.; Evlashin, S.A.; Vildanov, A.M.; Klimova-Korsmik, O.G.; Turichin, G.A. Multilayer composite Ti-6Al-4 V/Cp-Ti alloy produced by laser direct energy deposition. Int. J. Adv. Manuf. Technol. 2022, 124, 907–918. [Google Scholar] [CrossRef]

- Shanyavskiy, A.; Soldatenkov, A. Crack path of in-service fatigued fan titanium disk of D-18T gas-turbine engine of the aircraft An-124. Procedia Struct. Integr. 2022, 39, 327–332. [Google Scholar] [CrossRef]

- Frkan, M.; Konecna, R.; Nicoletto, G.; Kunz, L. Microstructure and fatigue performance of L-PBF-fabricated Ti6Al4V alloy after different stress-relief heat treatments. Transp. Res. Procedia 2019, 40, 24–29. [Google Scholar] [CrossRef]

- Sufiiarov, V.; Sokolova, V.; Borisov, E.; Orlov, A.; Popovich, A. Investigation of accuracy, microstructure and properties of additive manufactured lattice structures. Mater. Today Proc. 2020, 30, 572–577. [Google Scholar] [CrossRef]

- Yadav, P.; Saxena, K.K. Effect of heat-treatment on microstructure and mechanical properties of Ti alloys: An overview. Mater. Today Proc. 2020, 26, 2546–2557. [Google Scholar] [CrossRef]

- Vrancken, B.; Thijs, L.; Kruth, J.P.; Van Humbeeck, J. Heat treatment of Ti6Al4V produced by Selective Laser Melting: Microstructure and mechanical properties. J. Alloys Compd. 2012, 541, 177–185. [Google Scholar] [CrossRef]

- Leuders, S.; Thöne, M.; Riemer, A.; Niendorf, T.; Tröster, T.; Richard, H.A.; Maier, H.J. On the mechanical behaviour of titanium alloy TiAl6V4 manufactured by selective laser melting: Fatigue resistance and crack growth performance. Int. J. Fatigue 2013, 48, 300–307. [Google Scholar] [CrossRef]

- Wang, D.; Wang, H.; Chen, X.; Liu, Y.; Lu, D.; Liu, X.; Han, C. Densification, Tailored Microstructure, and Mechanical Properties of Selective Laser Melted Ti–6Al–4V Alloy via Annealing Heat Treatment. Micromachines 2022, 13, 331. [Google Scholar] [CrossRef] [PubMed]

- Wu, M.W.; Lai, P.H. The positive effect of hot isostatic pressing on improving the anisotropies of bending and impact properties in selective laser melted Ti-6Al-4V alloy. Mater. Sci. Eng. A 2016, 658, 429–438. [Google Scholar] [CrossRef]

- Schur, R.; Ghods, S.; Schultz, E.; Wisdom, C.; Pahuja, R.; Montelione, A.; Arola, D.; Ramulu, M. A Fractographic Analysis of Additively Manufactured Ti6Al4V by Electron Beam Melting: Effects of Powder Reuse. J. Fail. Anal. Prev. 2020, 20, 794–803. [Google Scholar] [CrossRef]

| Types of the Multi-Material Ti6Al4V/Cp-Ti Samples | UTS, Mpa | Elongation, % |

|---|---|---|

| MMS-III | 794 ± 12 | 8.2 ± 0.5 |

| MMS-II | 816 ± 11 | 9.2 ± 0.2 |

| B. Vrancken et al. [30] for Ti6Al4V | 840 ± 27 | 14.1 ± 2.5 |

| S. Leuders et al. [31] for Ti6Al4V | 945 | 11.6 |

| D. Wang et al. [32] for Ti6Al4V | 877 ± 16 | 11 ± 1 |

| Everage for Ti6Al4V from references | 887 | 12.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Repnin, A.; Borisov, E.; Emelianov, A.; Popovich, A. Fracture Toughness of Ti6Al4V/Cp-Ti Multi-Material Produced via Selective Laser Melting. Metals 2023, 13, 1738. https://doi.org/10.3390/met13101738

Repnin A, Borisov E, Emelianov A, Popovich A. Fracture Toughness of Ti6Al4V/Cp-Ti Multi-Material Produced via Selective Laser Melting. Metals. 2023; 13(10):1738. https://doi.org/10.3390/met13101738

Chicago/Turabian StyleRepnin, Arseniy, Evgenii Borisov, Anton Emelianov, and Anatoliy Popovich. 2023. "Fracture Toughness of Ti6Al4V/Cp-Ti Multi-Material Produced via Selective Laser Melting" Metals 13, no. 10: 1738. https://doi.org/10.3390/met13101738

APA StyleRepnin, A., Borisov, E., Emelianov, A., & Popovich, A. (2023). Fracture Toughness of Ti6Al4V/Cp-Ti Multi-Material Produced via Selective Laser Melting. Metals, 13(10), 1738. https://doi.org/10.3390/met13101738