Research on the Pre-Control of Side Scrap Blockage Failure during Trimming with the Side Trimmer

Abstract

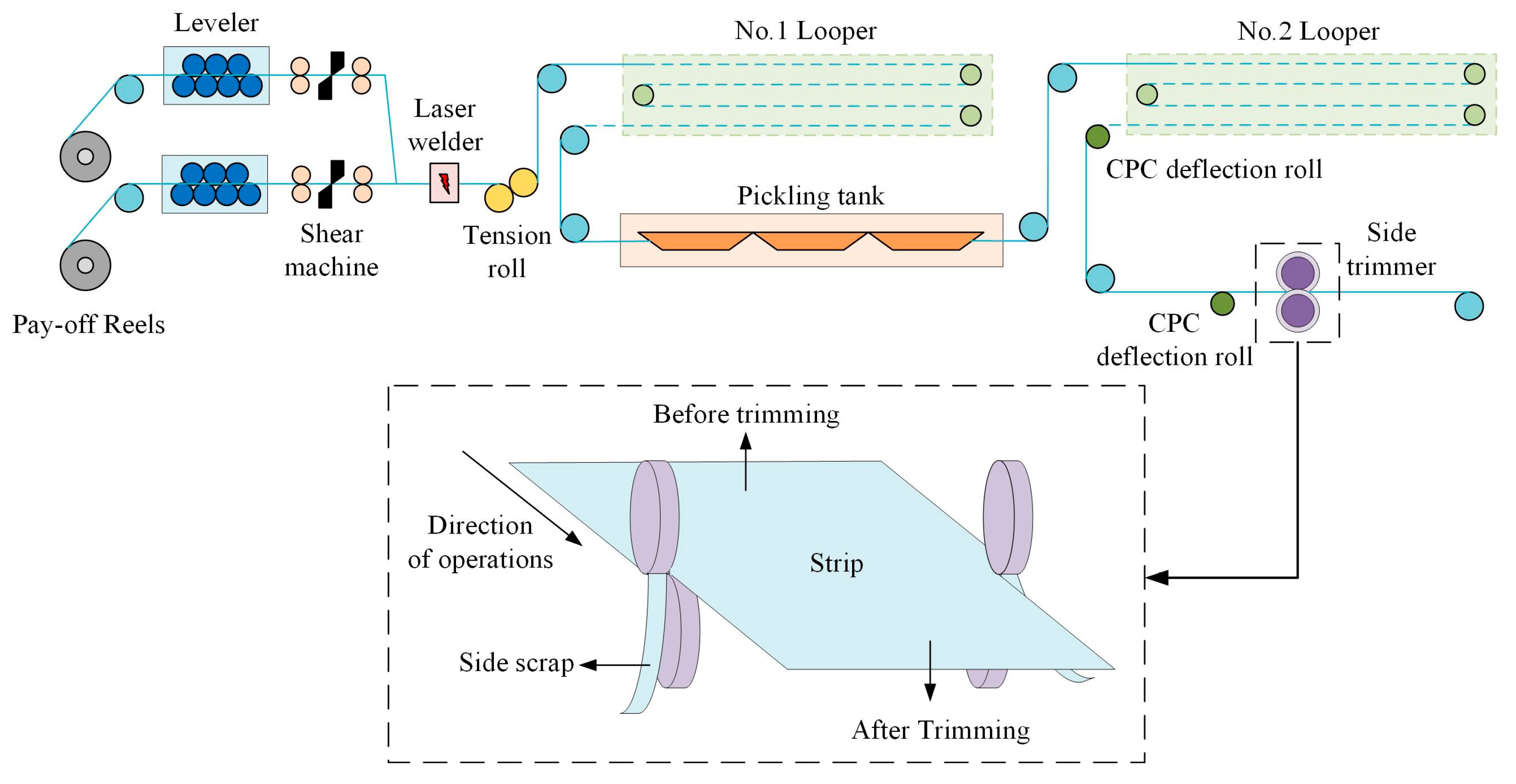

:1. Introduction

2. Analysis of the Causes of Side Scrap Blockage Risk during Trimming

3. Finite Element Model of Side Trimmer

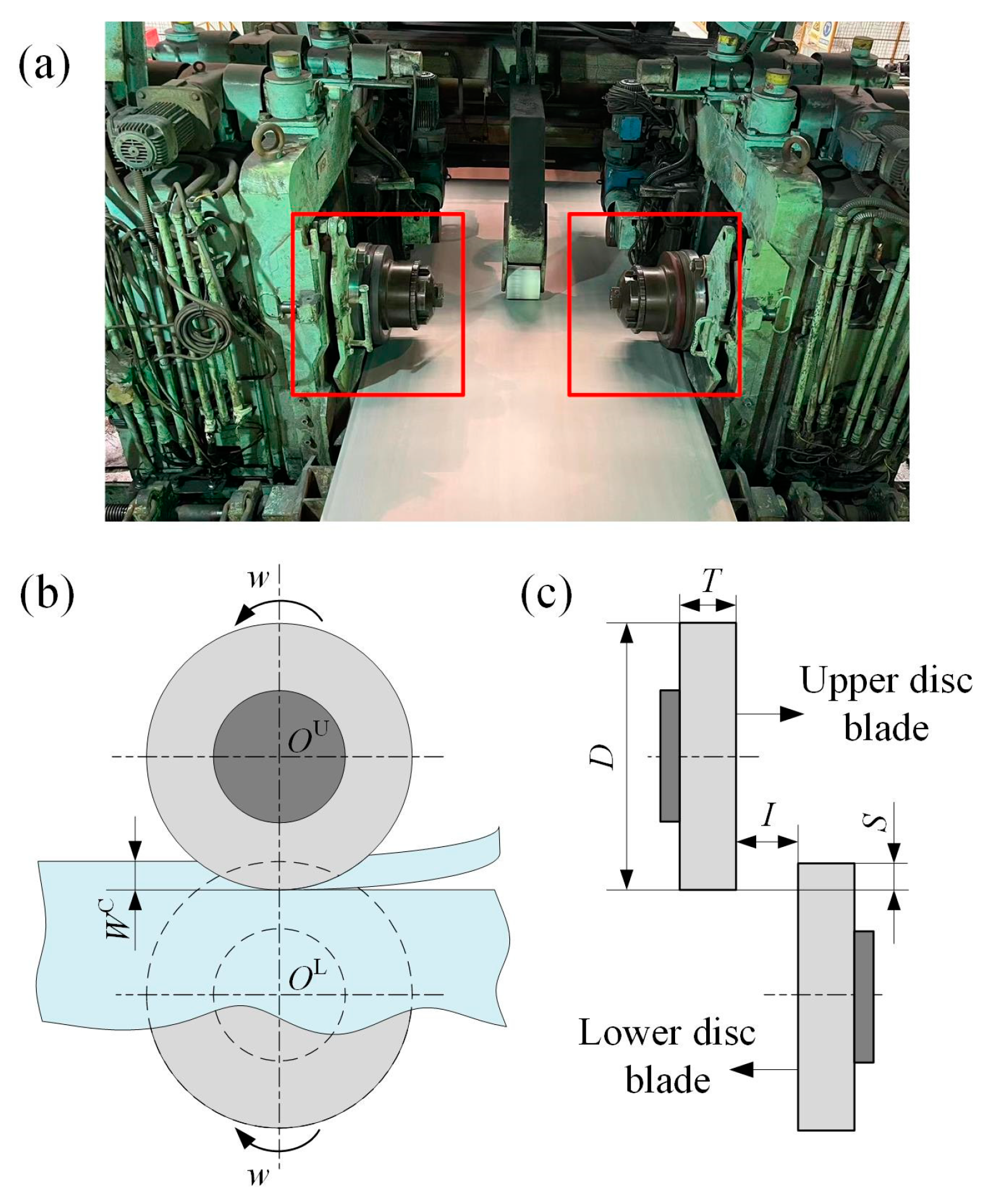

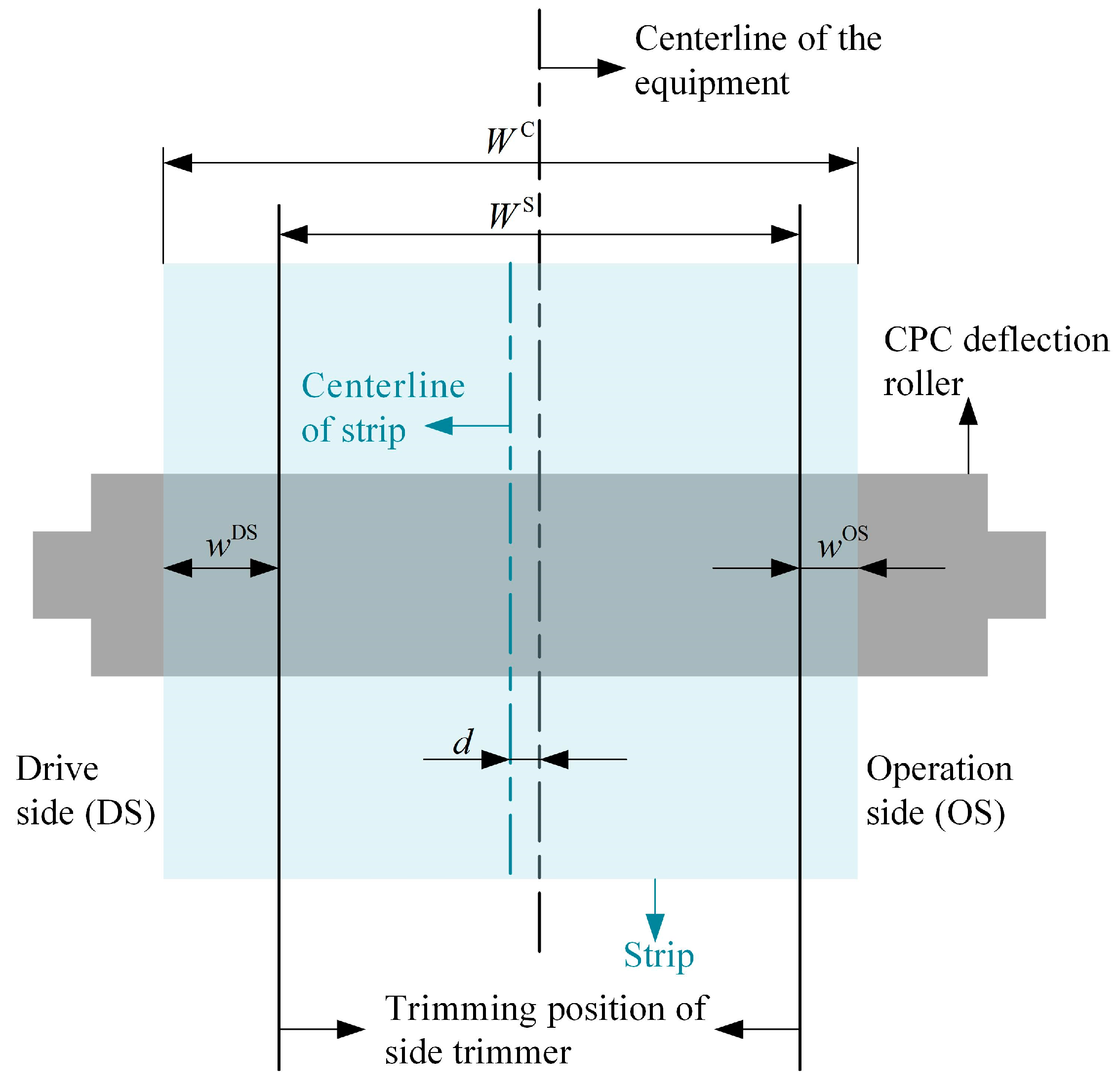

3.1. Structure of Side Trimmer

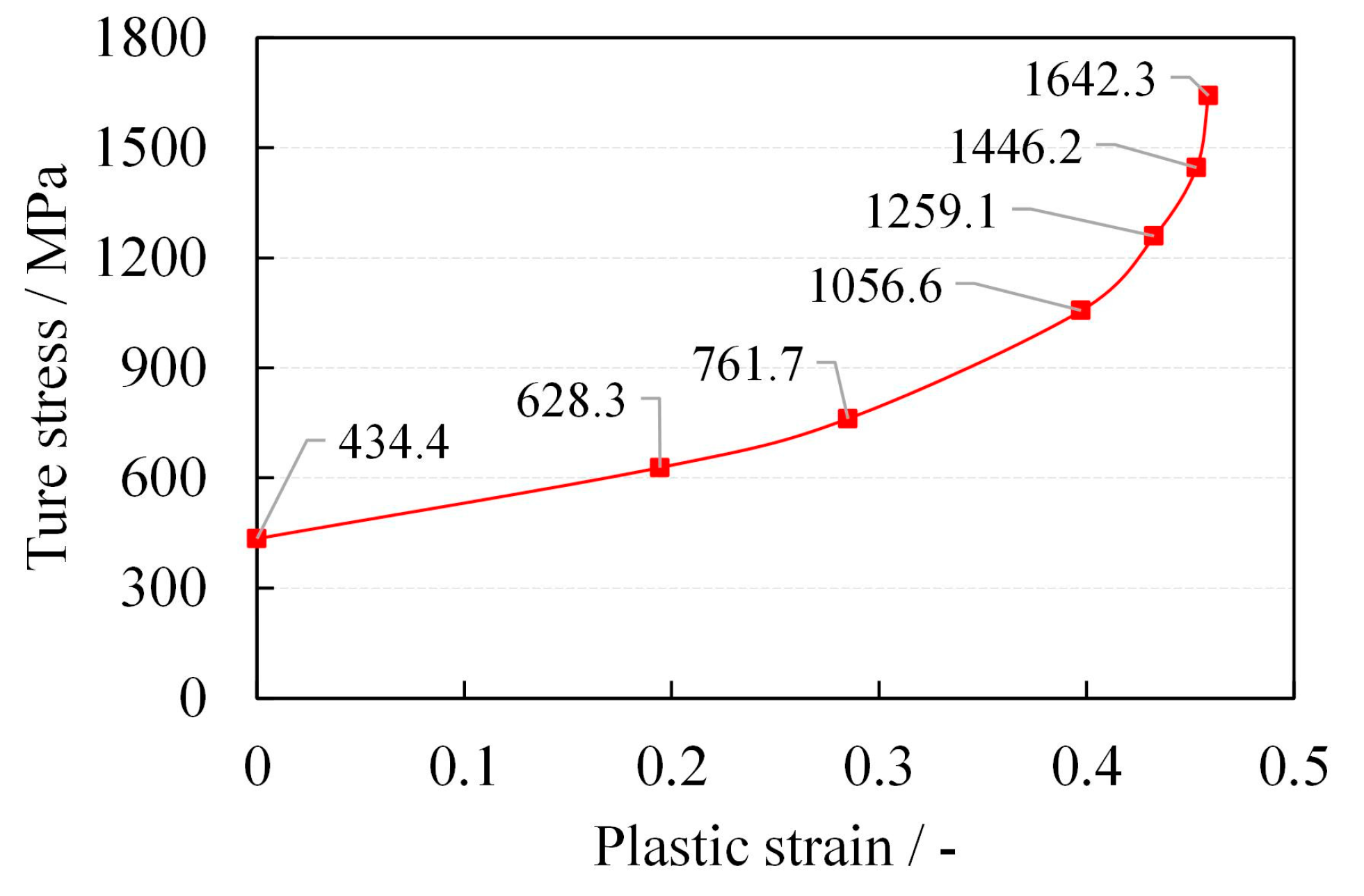

3.2. Finite Element Modeling of Side Trimmer

4. Effect of the Influencing Factors on the Trimming Process

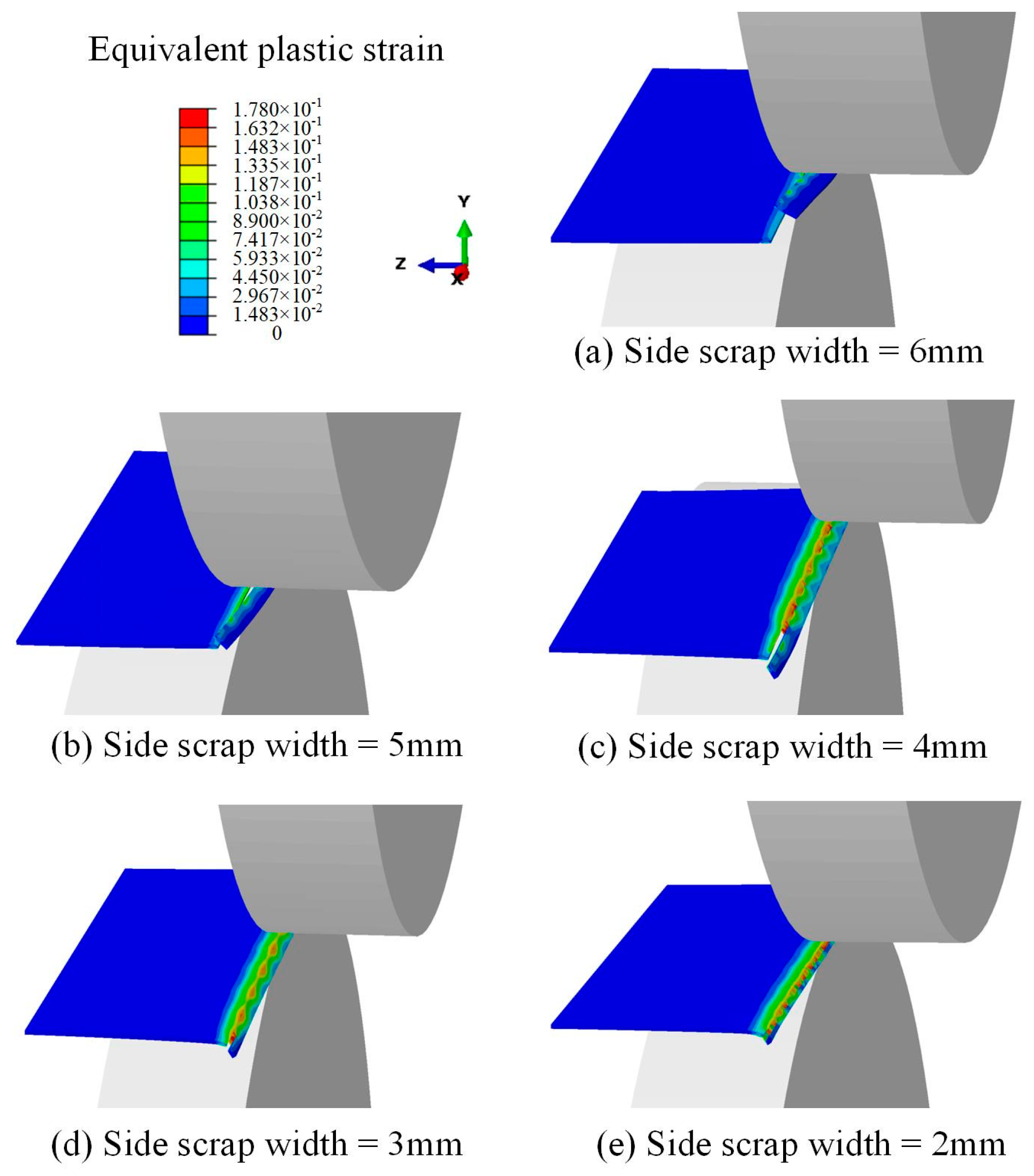

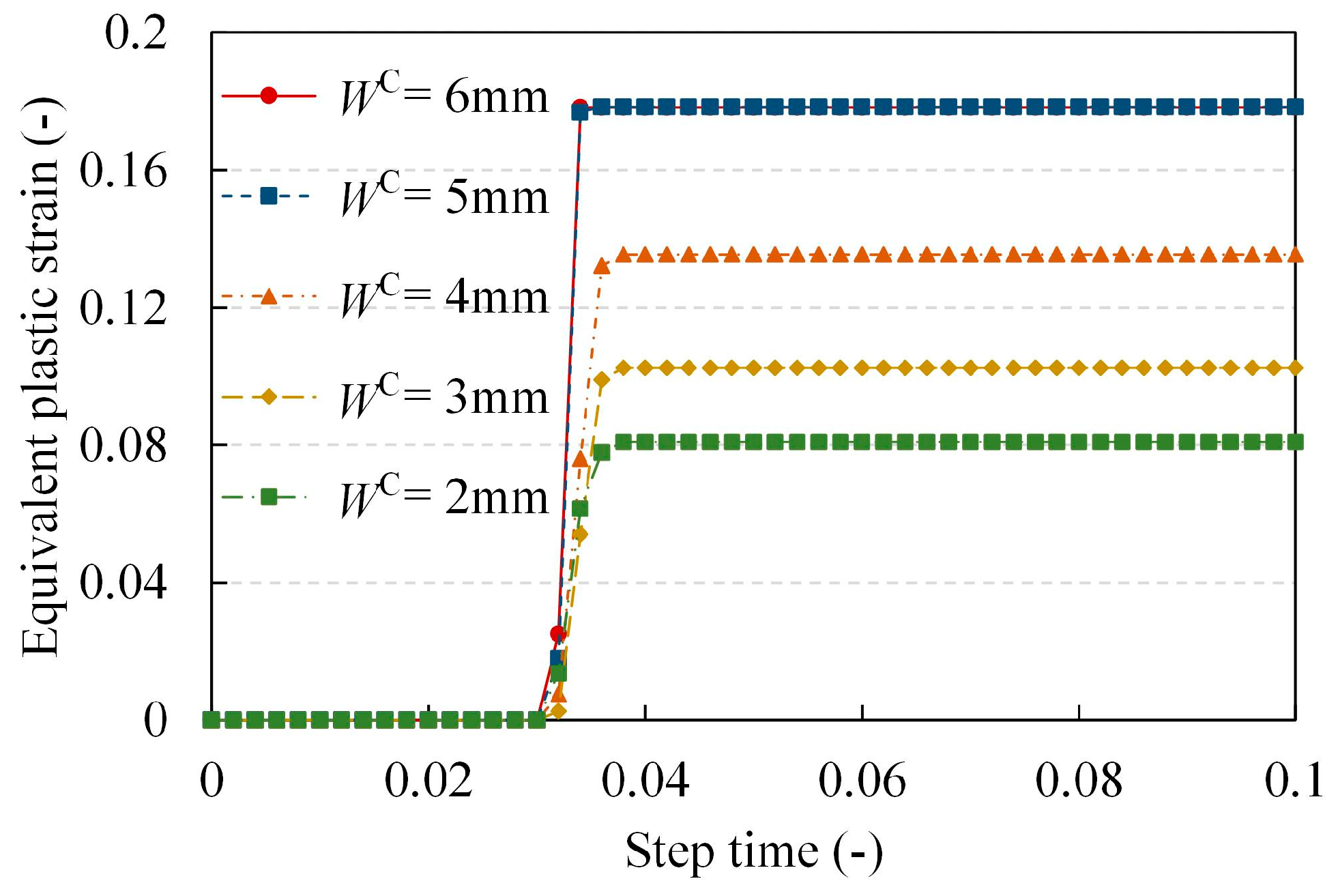

4.1. Effect of Side Scrap Width on the Trimming Process of Side Trimmer

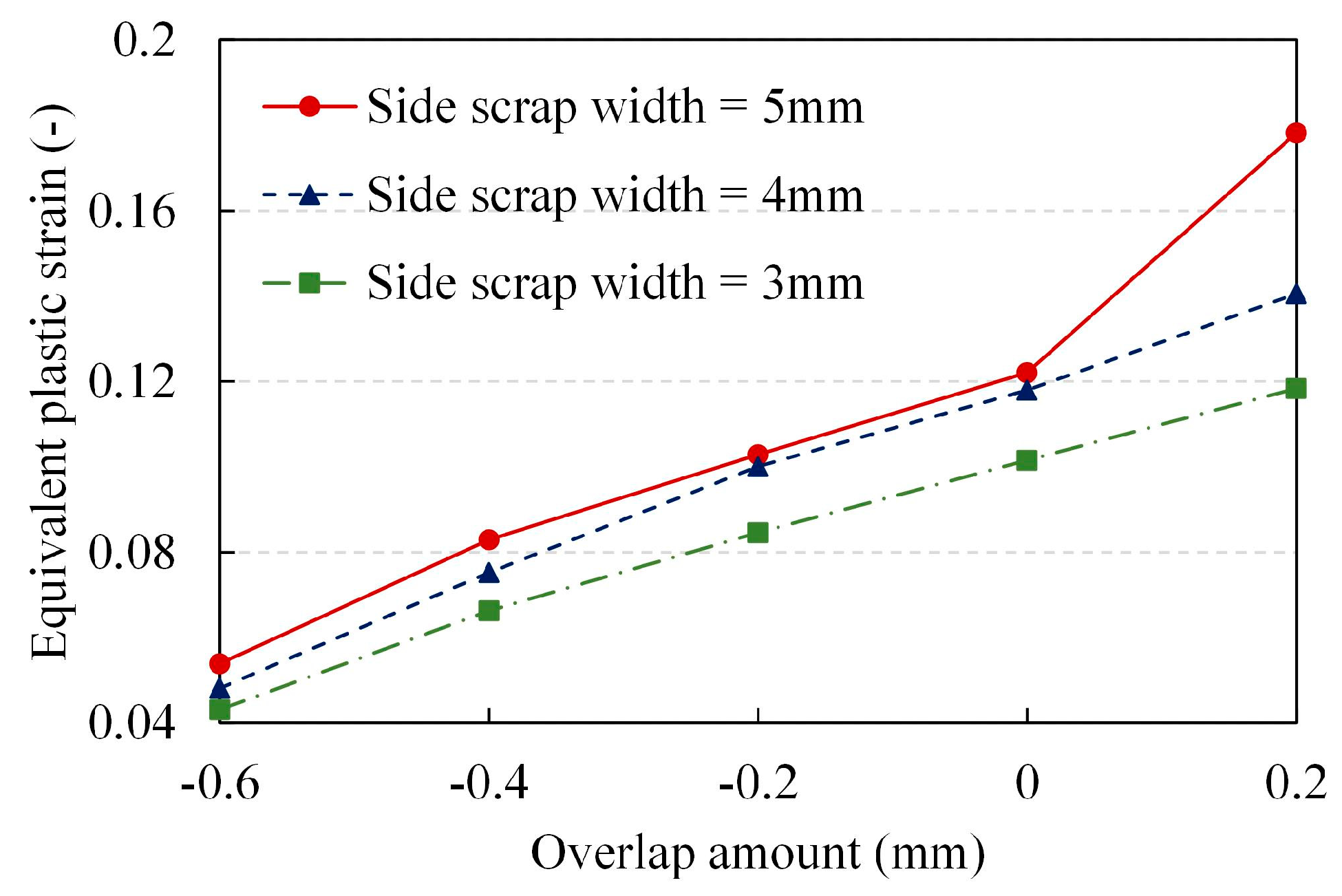

4.2. Effect of Structural Parameters of Side Trimmer on the Trimming Process

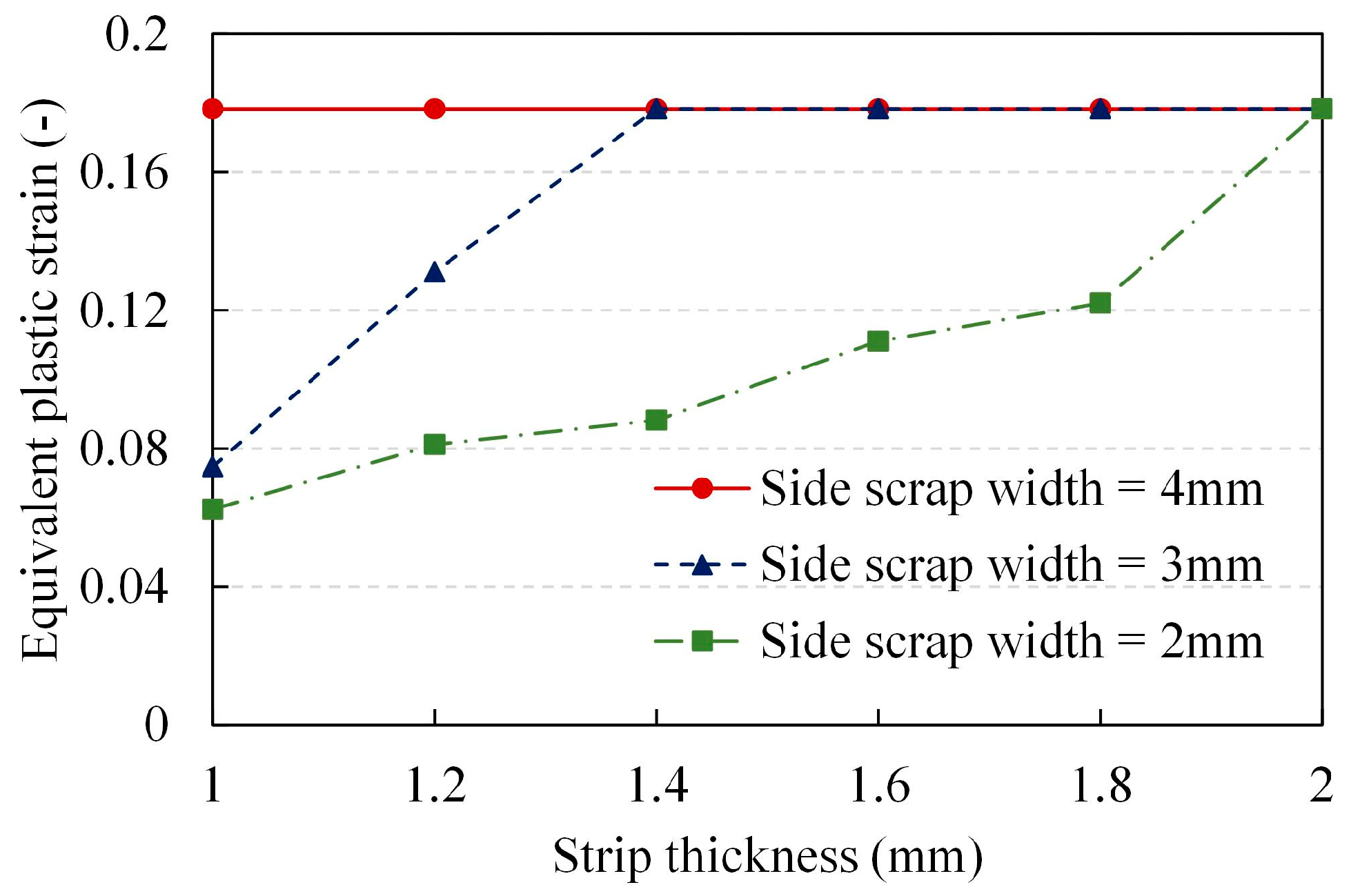

4.3. Effect of Strip Specification on the Trimming Process of Side Trimmer

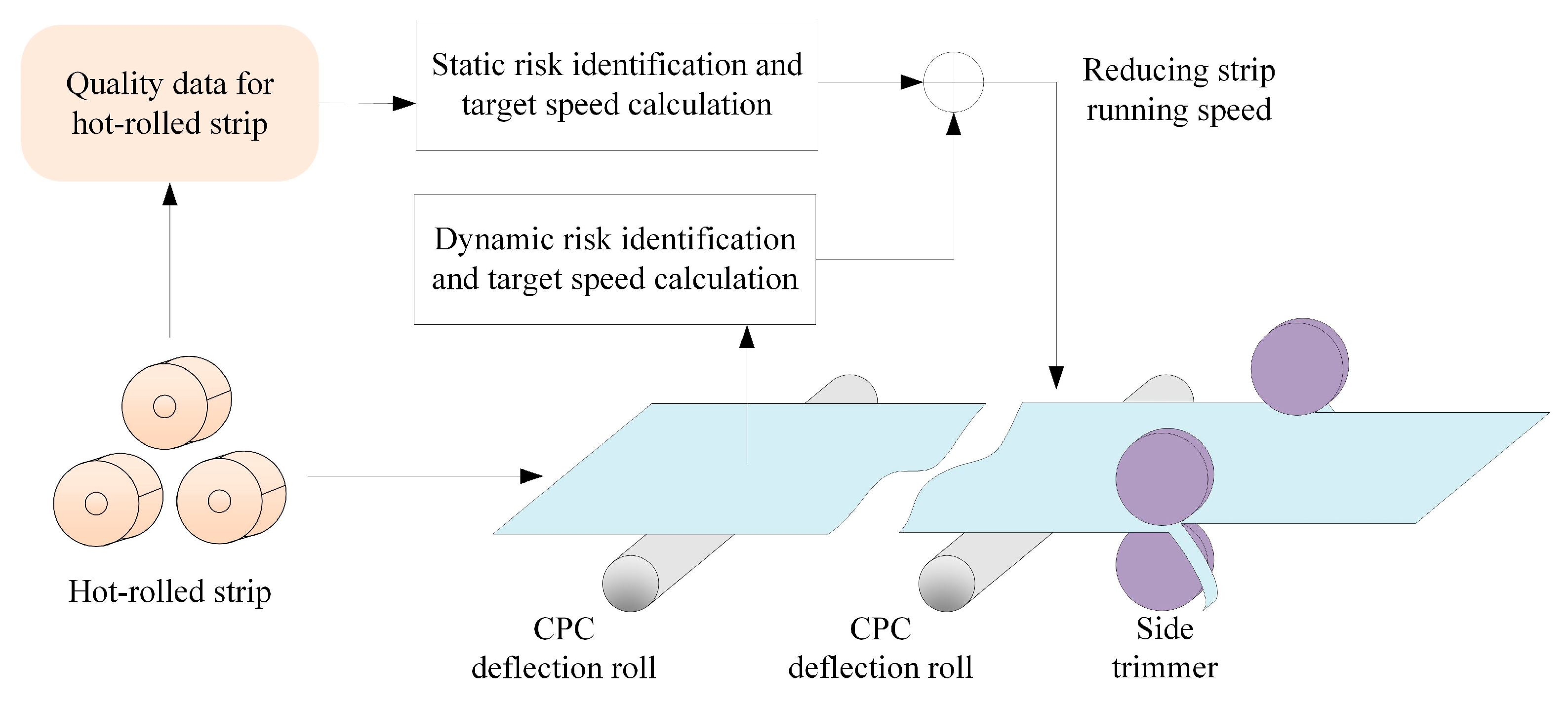

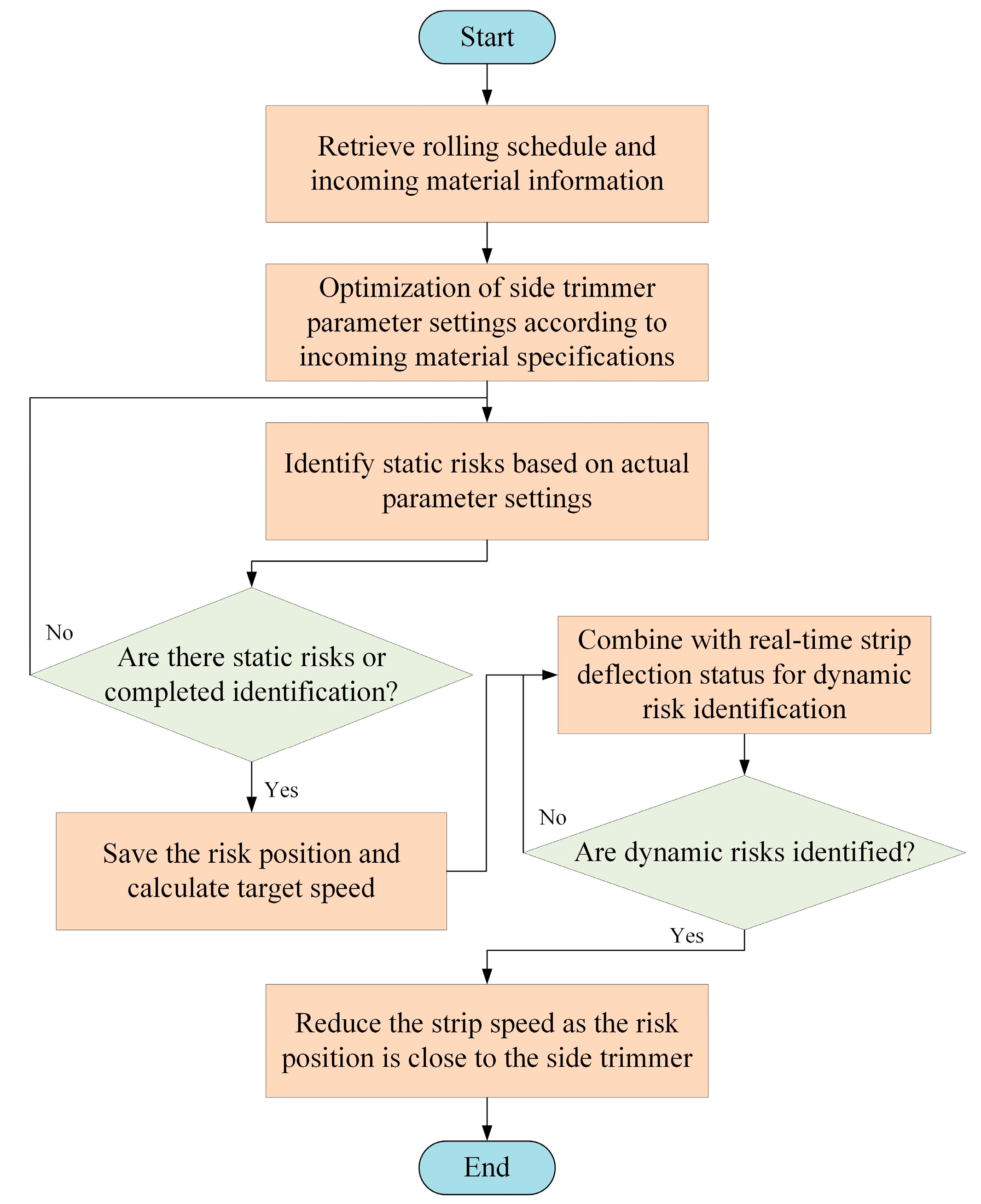

5. The Side Scrap Blockage Pre-Control Model of Side Trimmer

5.1. Identification of the Scrap Blockage Risk

5.2. Speed Reduction Strategy

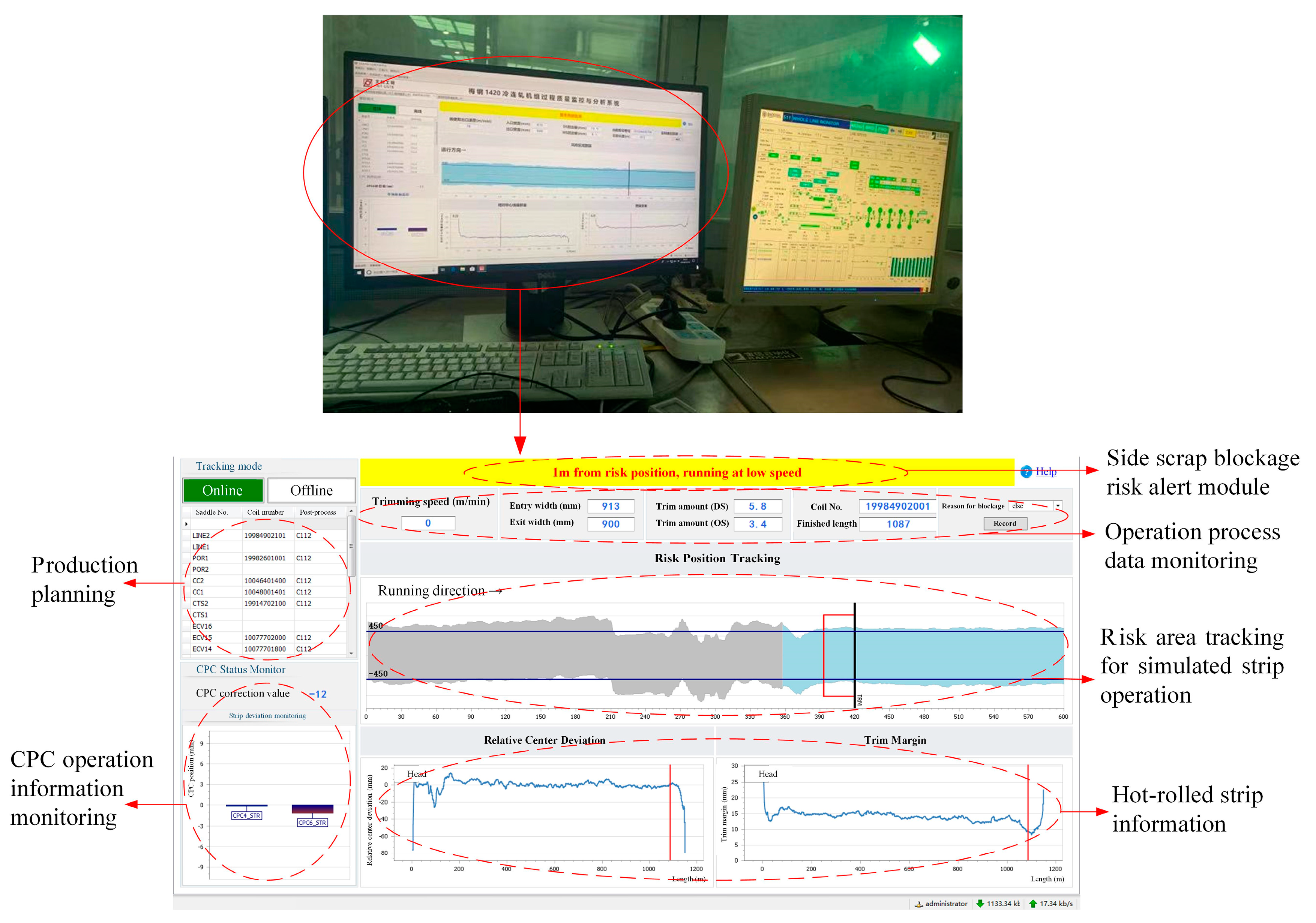

5.3. Industrial Applications

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, J.S.; Zhou, G.P. Development of control model for basic automation in pickling mills. J. Iron Steel Res. 2017, 29, 397–401. [Google Scholar]

- Liu, Y.; Wang, X.; Sun, J.; Liu, G.; Li, H.; Ji, Y. Strip Thickness and Profile–Flatness Prediction in Tandem Hot Rolling Process Using Mechanism Model-Guided Machine Learning. Steel Res. Int. 2023, 94, 2200447. [Google Scholar] [CrossRef]

- Li, L.; Xie, H.; Li, X.; Zhang, T.; Pan, D.; Huo, M.; Chen, F.; Liu, T.; Shi, K.; Jiang, Z. Numerical Analysis of the Effect of Work Roll Bending on Strip Crown During Tandem Hot Rolling. Int. J. Appl. Mech. 2022, 14, 2250052. [Google Scholar] [CrossRef]

- Li, L.; Xie, H.; Liu, T.; Huo, M.; Liu, X.; Li, X.; Shi, K.; Li, J.; Liu, H.; Sun, L.; et al. Influence mechanism of rolling force on strip shape during tandem hot rolling using a novel 3D multi-stand coupled thermo-mechanical FE model. J. Manuf. Process. 2022, 81, 505–521. [Google Scholar] [CrossRef]

- Zhao, Z.; Song, R.; Wang, Y.; Hu, C. Lateral cracks damaging the stability of tensile sheet during tandem rolling conveying. Eng. Fail. Anal. 2022, 138, 106358. [Google Scholar] [CrossRef]

- Li, L.; Xie, H.; Zhang, T.; Huo, M.; Pan, D.; Wu, H.; Chen, F.; Liu, T.; Li, X.; Liu, X.; et al. Understanding the regulation ability of roll bending on strip shape in a CVC-6 tandem cold mill using a 3D multiple stand FE model. J. Manuf. Process. 2023, 101, 1013–1031. [Google Scholar] [CrossRef]

- Ji, J.P.; Sun, L.; Li, J.W. Precision Influence of Sickle-Like Curve of Hot Rolled Strip on Rotary Shear’s Cutting. Adv. Mater. Res. 2012, 421, 51–55. [Google Scholar] [CrossRef]

- Bai, Z.H.; Xing, B.X.; Qian, C.; Liu, Y.X.; Wang, R.; Chang, J.L. Comprehensive optimization technology of front and back tensions for disc shear in strip trimming process. J. Plast. Eng. 2017, 24, 82–87. [Google Scholar]

- Xu, K.; Xia, M.; Liu, J.; Wang, C.; Wang, Q.Y.; Ren, S.B. Simulation of stress on shear blade of disc shear based on Gissmo material failure criterion. J. Plast. Eng. 2021, 28, 110–116. [Google Scholar]

- Jing, Q.P.; Jia, H.L.; Shuang, Y.H.; Yang, B.; Jin, L. Numerical simulation and experimental study of the shearing process on trimming disc shear. J. Plast. Eng. 2010, 17, 32–36. [Google Scholar]

- Chen, B.; Liu, S.H.; Yang, J. Simulation research for strip shearing section level distribution. Appl. Mech. Mater. 2012, 157, 231–235. [Google Scholar] [CrossRef]

- Ma, L.F.; Huang, Q.X.; Huang, Z.Q.; Chu, Z.B.; Han, H.Y. Energetic parameter test on disc shear of plate and establishment of the best blade clearance mathematical model. Chin. J. Eng. Des. 2012, 19, 434–439. [Google Scholar]

- Li, S.C. Research and Practice in Side Trimming Technology of IF Steel. Iron Steel 2014, 49, 85–89. [Google Scholar]

- Li, D.F.; Wu, S.L.; Liu, W.J. Numerical analysis of shear force of side trimmer based on ANSYS/LS-DYNA. J. Plast. Eng. 2016, 23, 56–61. [Google Scholar]

- Rasool, M.; Singha, M.K. A finite element study on the nonlinear behavior of rectangular shear panels. Thin-Walled Struct. 2016, 104, 248–258. [Google Scholar] [CrossRef]

- Zhu, Y.; Yan, Q.; Lu, J. Fault diagnosis method for disc slitting machine based on wavelet packet transform and support vector machine. Int. J. Comput. Integr. Manuf. 2020, 33, 1118–1128. [Google Scholar] [CrossRef]

- Jun, Z.; Qiusheng, Y.; Jiabin, L.; Zhang, X.W.; Ou, Y.B. Simulation research on wear mechanism of disc cutter in slitting process. J. Plast. Eng. 2019, 26, 259–266. [Google Scholar]

- Yan, Q. New technology analysis on metal strips no-burr precision slitting. China Mech. Eng. 2012, 23, 2102. [Google Scholar]

- Yan, Q.; Lai, Z.; Lu, J.; Li, Z.R.; Ou, Y.J.; Xie, Z.P. Influence of clearance on disc slitting surface morphology for galvanized steel sheet. J. Plast. Eng. 2014, 21, 69–73. [Google Scholar]

- Yan, Q.S.; Shi, X.J.; Lu, J.B. Studying Plastic Deformation in Burr-free Disc Slitting Process of Metal Sheet. Mech. Sci. Technol. Aerosp. Eng. 2016, 35, 98–103. [Google Scholar]

- Zeng, J.; Lu, J.B.; Yan, Q.S.; Li, S. Influence of blade profile of disc cutter on numerical simulation of the disc slitting process. In AIP Conference Proceedings; AIP Publishing: Bristol, UK, 2015; Volume 1653. [Google Scholar]

- Feng, W.Y.; Yan, Q.S.; Lu, J.B.; Li, H.Y. Influence of lateral clearance on the slitting surface morphology in the disc burrfree slitting. J. Plast. Eng. 2016, 23, 126–130. [Google Scholar]

- Li, J.; Zhang, T.; Wang, S.; Cheng, J.; Wang, W. Mechanism and Method of Testing Fracture Toughness and Impact Absorbed Energy of Ductile Metals by Spherical Indentation Tests. Chin. J. Mech. Eng. 2023, 36, 108. [Google Scholar] [CrossRef]

- Khademi, M.; Naeini, H.M.; Mirnia, M.J.; Kasaei, M.M.; da Silva, L.F. Fracture prediction of AA6061-T6 sheet in bending process using Gurson–Tvergaard–Needleman model. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2022, 14644207221134504. [Google Scholar] [CrossRef]

- Guo, M.; Tao, J.; Wu, C.; Luo, C.; Lin, Z. High-speed grinding fracture mechanism of Cf/SiC composite considering interfacial strength and anisotropy. Ceram. Int. 2023, 49, 2600–2612. [Google Scholar] [CrossRef]

- Zhao, Z.; Ji, H.; Zhong, Y.; Luo, C.; Lin, Z. Mechanical Properties and Fracture Behavior of a TC4 Titanium Alloy Sheet. Materials 2022, 15, 8589. [Google Scholar] [CrossRef]

- Faura, F.; Garcıa, A.; Estrems, M. Finite element analysis of optimum clearance in the blanking process. J. Mater. Process. Technol. 1998, 80, 121–125. [Google Scholar] [CrossRef]

- Zhang, D.W.; Yang, H. Numerical study of the friction effects on the metal flow under local loading way. Int. J. Adv. Manuf. Technol. 2013, 68, 1339–1350. [Google Scholar] [CrossRef]

- Liu, H.; Xu, X.; Zhang, J.; Liu, Z.; He, Y.; Zhao, W.; Liu, Z. The state of the art for numerical simulations of the effect of the microstructure and its evolution in the metal-cutting processes. Int. J. Mach. Tools Manuf. 2022, 177, 103890. [Google Scholar] [CrossRef]

- Chai, C.-g.; Feng, X.-l.; Wu, H.-j.; Guo, C.; Zhang, S.; Haung, F.L. Numerical Simulation of Dynamic Shear Properties of AerMet100 Steel. Trans. Beijing Inst. Technol. 2014, 34, 1223–1228. [Google Scholar]

- Moemeni, S.; Zarei-Hanzaki, A.; Abedi, H.R.; Torabinejad, V. The application of shear compression specimen to study shear deformation behavior of AZ31 Mg alloy at high temperatures and quasi-static regime. Exp. Mech. 2012, 52, 629–636. [Google Scholar] [CrossRef]

- Kwak, T.S.; Kim, Y.J.; Seo, M.K.; Bae, W. The effect of V-ring indenter on the sheared surface in the fine-blanking process of pawl. J. Mater. Process. Technol. 2003, 143, 656–661. [Google Scholar] [CrossRef]

- Zhu, L.; Estefen, S.F.; Lourenco, M.I. Fracture criteria applied to numerical simulation of blowout preventer ram shearing. Eng. Fail. Anal. 2020, 114, 104596. [Google Scholar] [CrossRef]

- Lorenz, S.J.; Sadeghi, F.; Sharma, A.; Wang, C.; Wang, B. An investigation into various failure criteria on rolling contact fatigue through an improved probabilistic model. Tribol. Int. 2023, 188, 108875. [Google Scholar] [CrossRef]

- Khadke, A.; Ghosh, S.; Li, M. Numerical simulations and design of shearing process for aluminum alloys. J. Manuf. Sci. Eng. 2005, 127, 612–621. [Google Scholar] [CrossRef]

- Hambli, R.; Reszka, M. Fracture criteria identification using an inverse technique method and blanking experiment. Int. J. Mech. Sci. 2002, 44, 1349–1361. [Google Scholar] [CrossRef]

- Bai, Y.; Wierzbicki, T. Application of extended Mohr–Coulomb criterion to ductile fracture. Int. J. Fract. 2010, 161, 1–20. [Google Scholar] [CrossRef]

- Lixi, L.; Qingli, Z.; Jian, Z.; Li, Z.Q. Effects of stress triaxiality and lode parameter on ductile fracture in aluminum alloy. Rare Met. Mater. Eng. 2019, 48, 433–439. [Google Scholar]

- Liu, B.; Zhou, Y. Damage failure mechanism of unidirectional fiber reinforced SiCf/SiC composites under uniaxial tension. Compos. Struct. 2023, 307, 116610. [Google Scholar] [CrossRef]

- Peshekhodov, I.; Dykiert, M.; Vucetic, M.; Behrens, B.-A. Evaluation of common tests for fracture characterisation of advanced high-strength sheet steels with the help of the FEA. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2016; Volume 159, p. 012014. [Google Scholar]

- Dong, D.; Liu, Y.; Yang, Y.; Li, J.; Ma, M.; Jiang, T. Microstructure and dynamic tensile behavior of DP600 dual phase steel joint by laser welding. Mater. Sci. Eng. A 2014, 594, 17–25. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Diameter of the blade (mm) | 350 |

| Thickness of the blade (mm) | 30 |

| Chamfering of the blade (mm) | 0.05 |

| Clearance amount (mm) | 0.2~1.4 |

| Overlap amount (mm) | −0.6~0.2 |

| Length of strip (mm) | 70 |

| Width of strip (mm) | 50 |

| Thickness of strip (mm) | 1~2 |

| Parameters | Value |

|---|---|

| Elastic modulus (MPa) | 2.154 × 105 |

| Poisson ratio (-) | 0.3 |

| Mass density (t/mm3) | 7.85 × 10−9 |

| Stress triaxiality weight factor (-) | 0.12 |

| Fracture strain (-) | 0.178 |

| Shear stress ratio (-) | 94 |

| Strain rate (s−1) | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Z.; Wang, X.; Yang, Q.; Xu, D.; Zhao, J. Research on the Pre-Control of Side Scrap Blockage Failure during Trimming with the Side Trimmer. Metals 2023, 13, 1725. https://doi.org/10.3390/met13101725

Wu Z, Wang X, Yang Q, Xu D, Zhao J. Research on the Pre-Control of Side Scrap Blockage Failure during Trimming with the Side Trimmer. Metals. 2023; 13(10):1725. https://doi.org/10.3390/met13101725

Chicago/Turabian StyleWu, Zedong, Xiaochen Wang, Quan Yang, Dong Xu, and Jianwei Zhao. 2023. "Research on the Pre-Control of Side Scrap Blockage Failure during Trimming with the Side Trimmer" Metals 13, no. 10: 1725. https://doi.org/10.3390/met13101725

APA StyleWu, Z., Wang, X., Yang, Q., Xu, D., & Zhao, J. (2023). Research on the Pre-Control of Side Scrap Blockage Failure during Trimming with the Side Trimmer. Metals, 13(10), 1725. https://doi.org/10.3390/met13101725