Relieving Residual Stress of 316L Stainless Steel by Acoustic/Thermal Composite Treatment

Abstract

1. Introduction

2. Test Materials and Methods

2.1. Experimental Materials

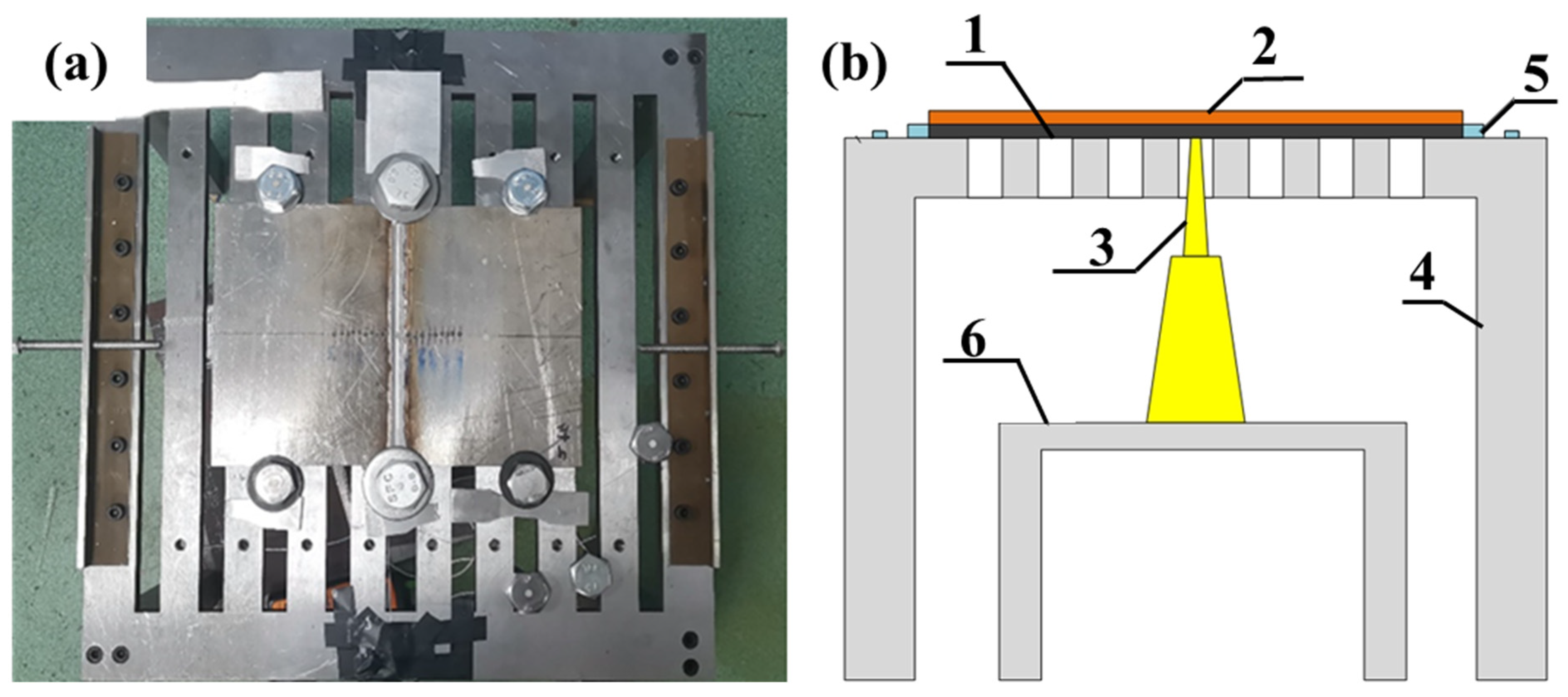

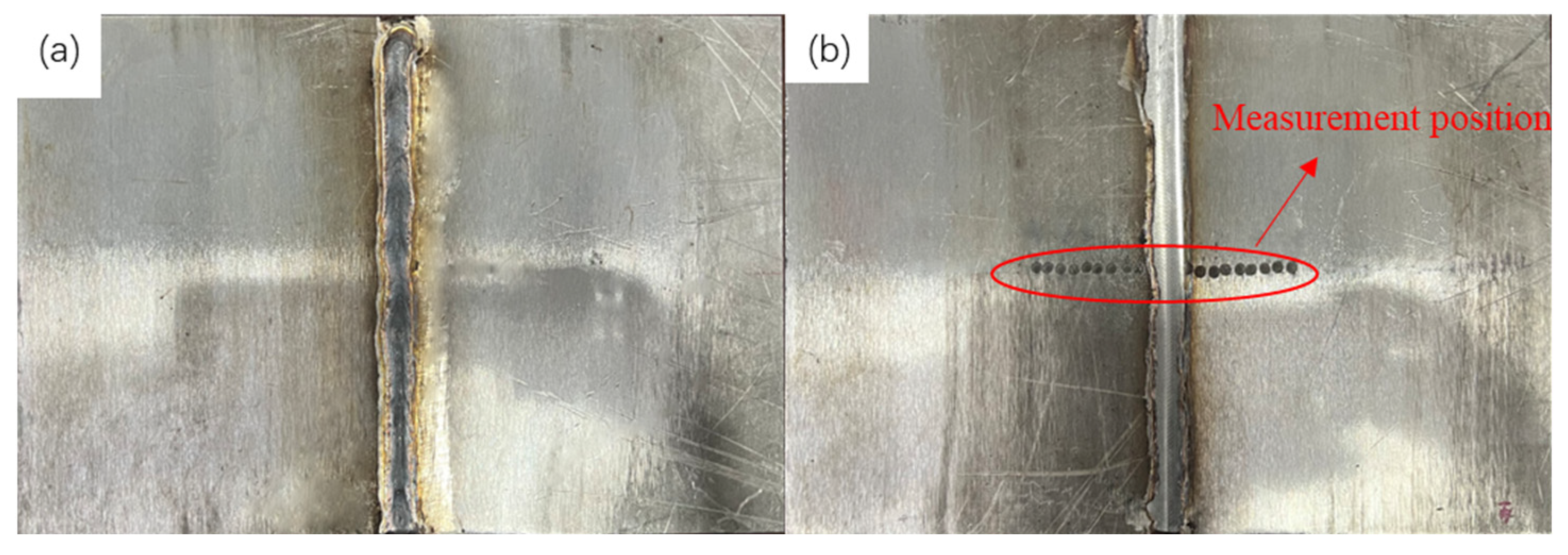

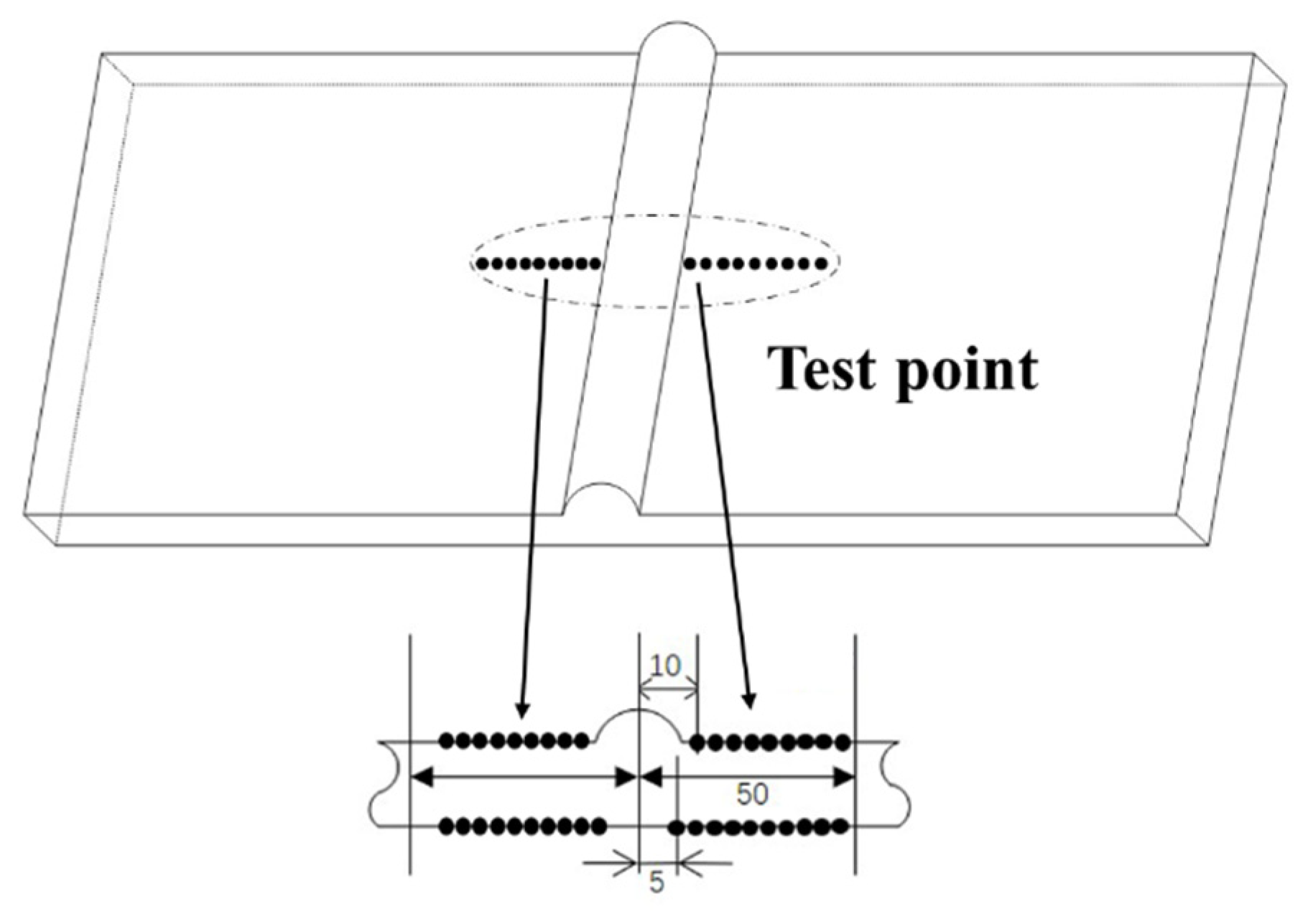

2.2. Test Method

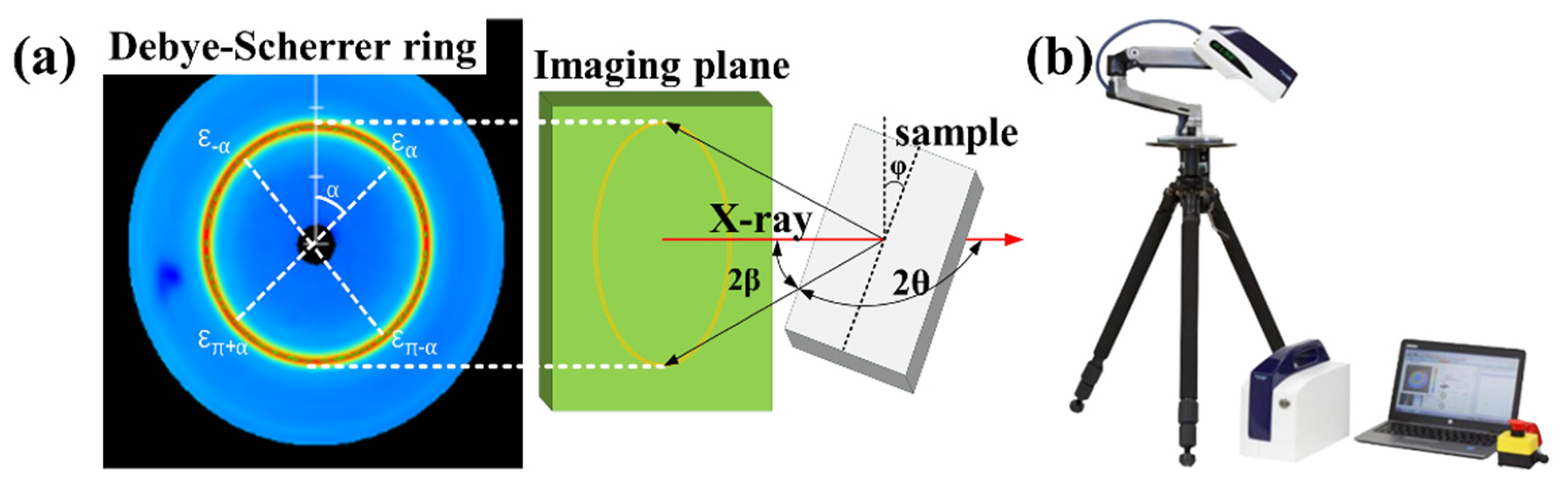

2.3. Residual Stress Test

3. Experimental Results

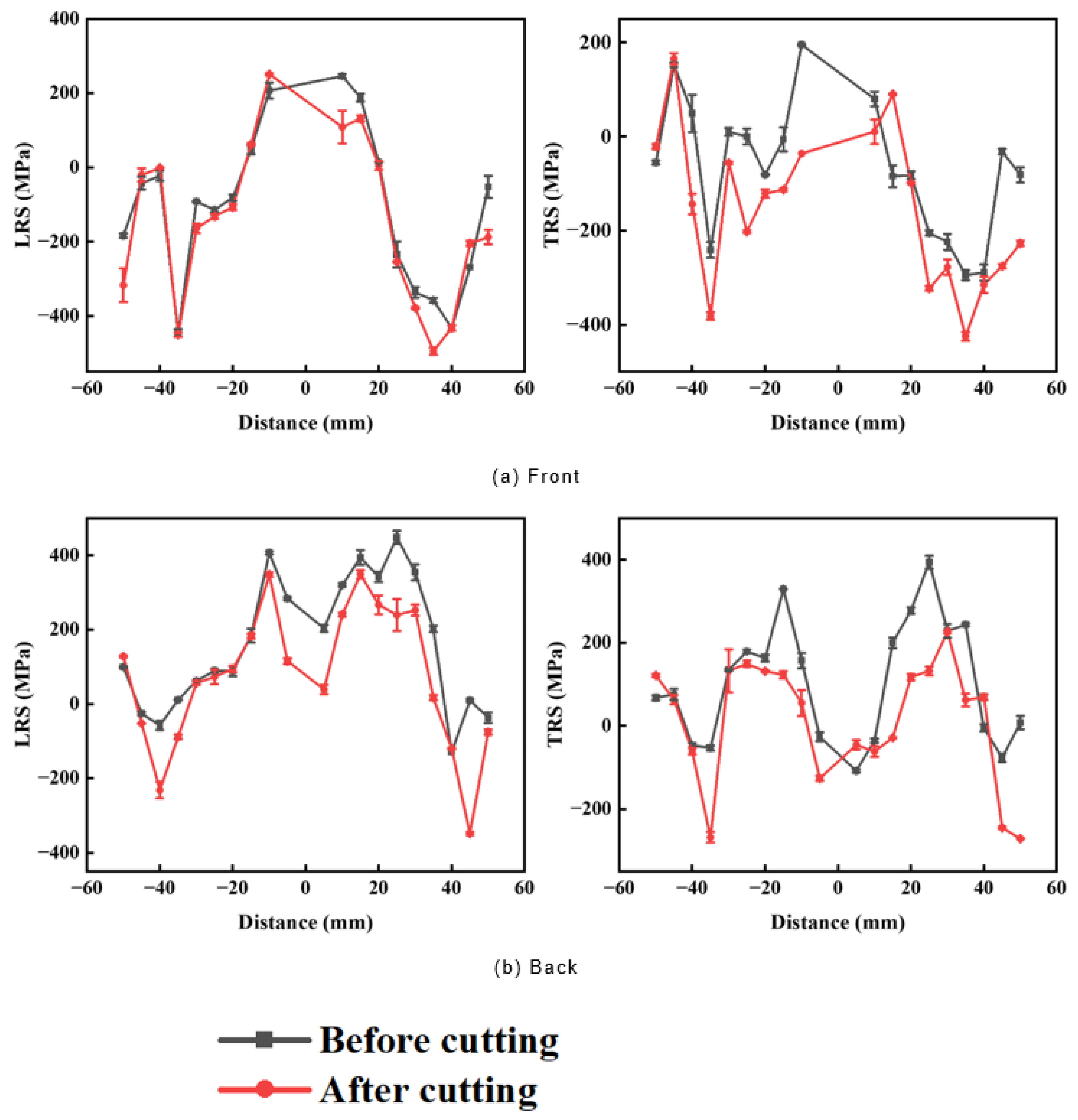

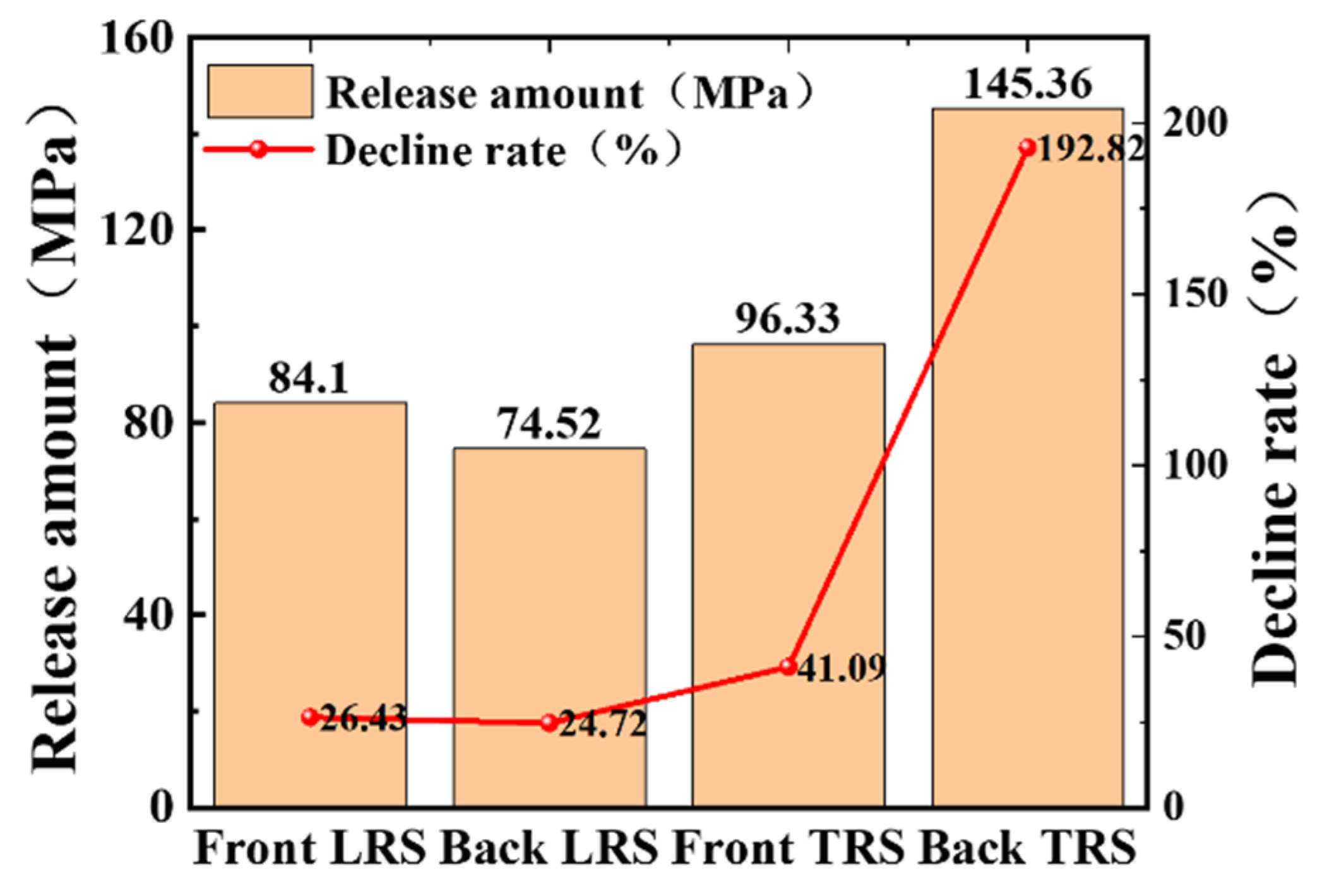

3.1. Residual Stress Distribution Change in Cutting Weld Reinforcement

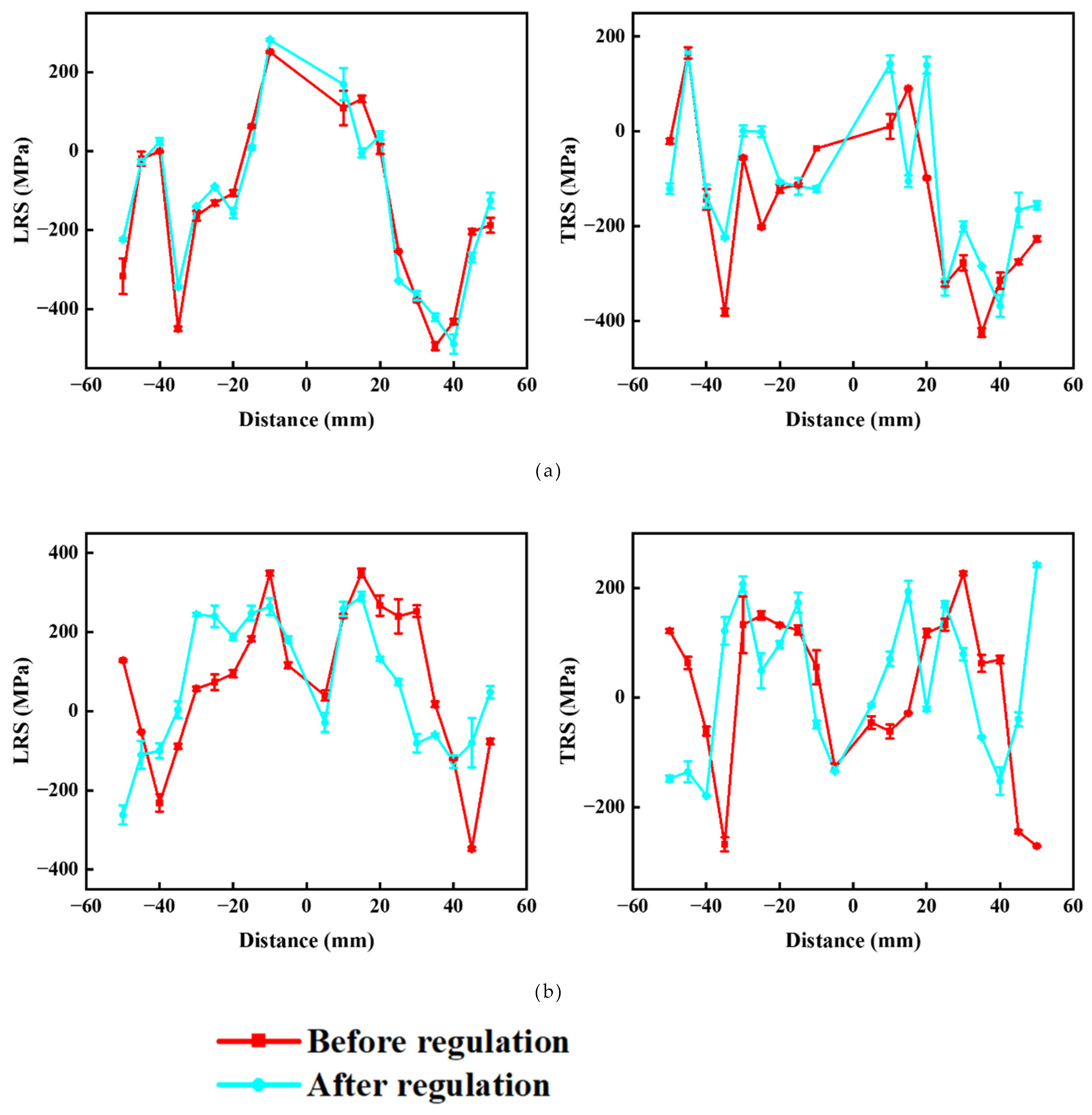

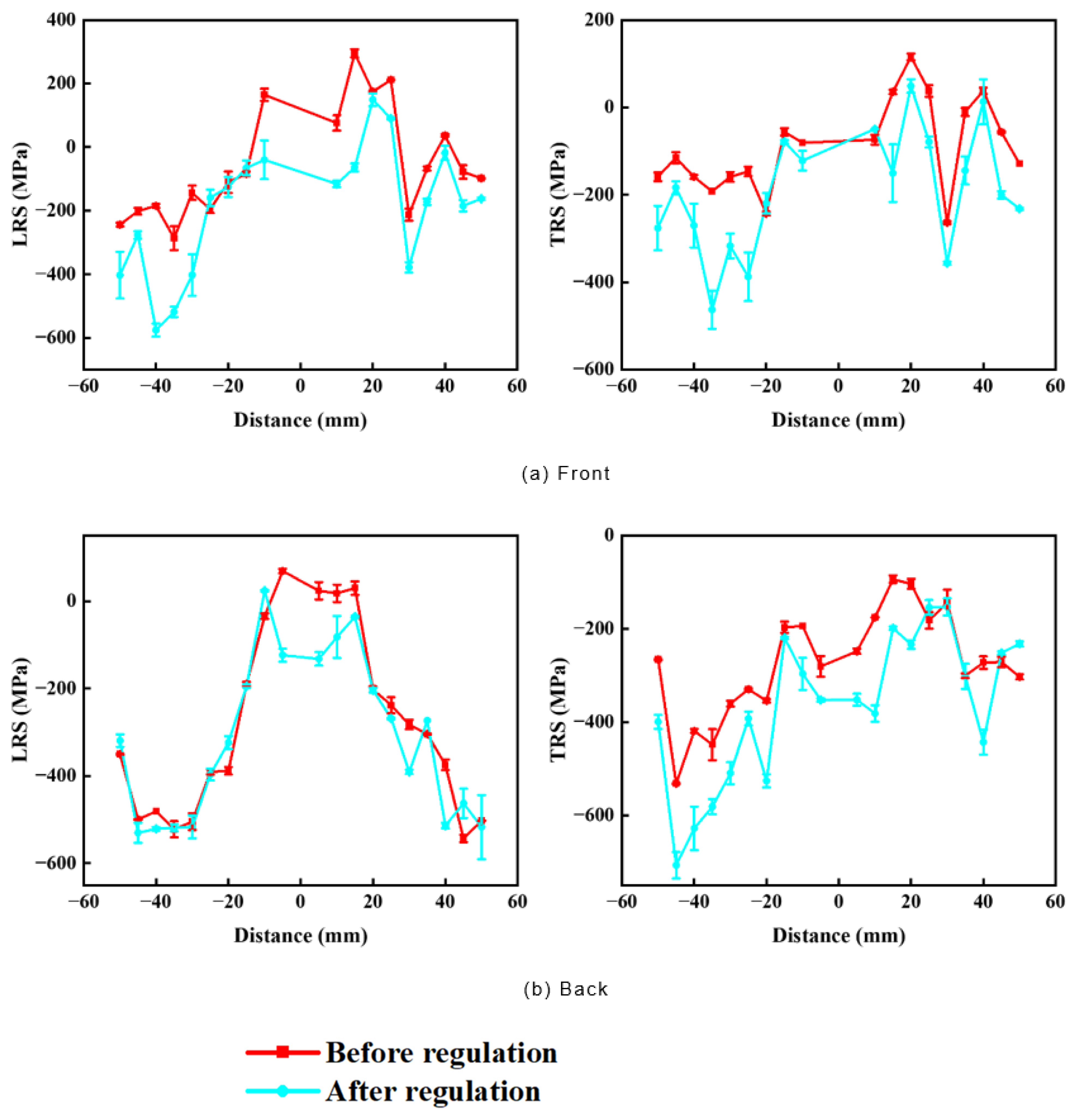

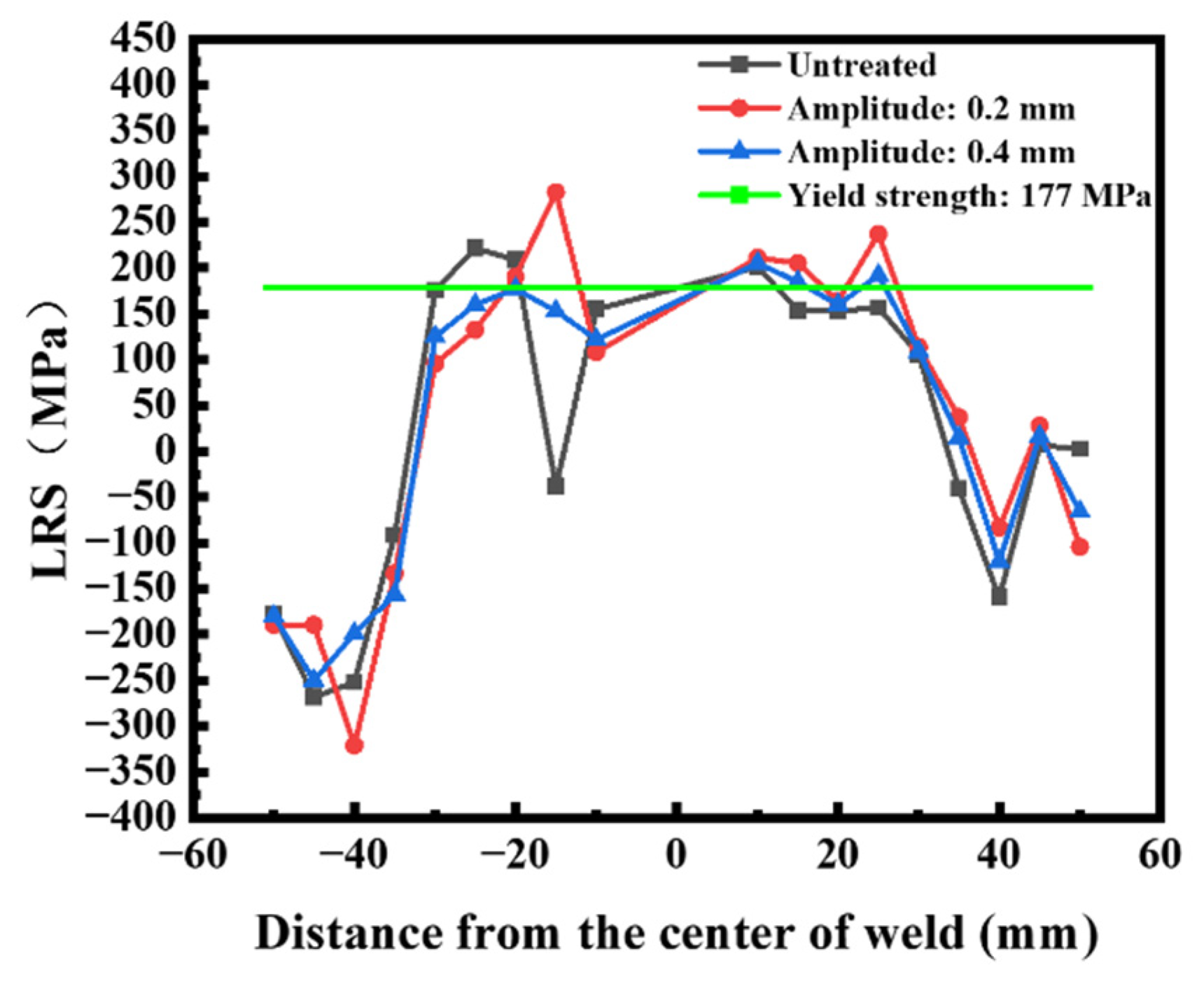

3.2. Residual Stress after Acoustic/Thermal Composite Treatment

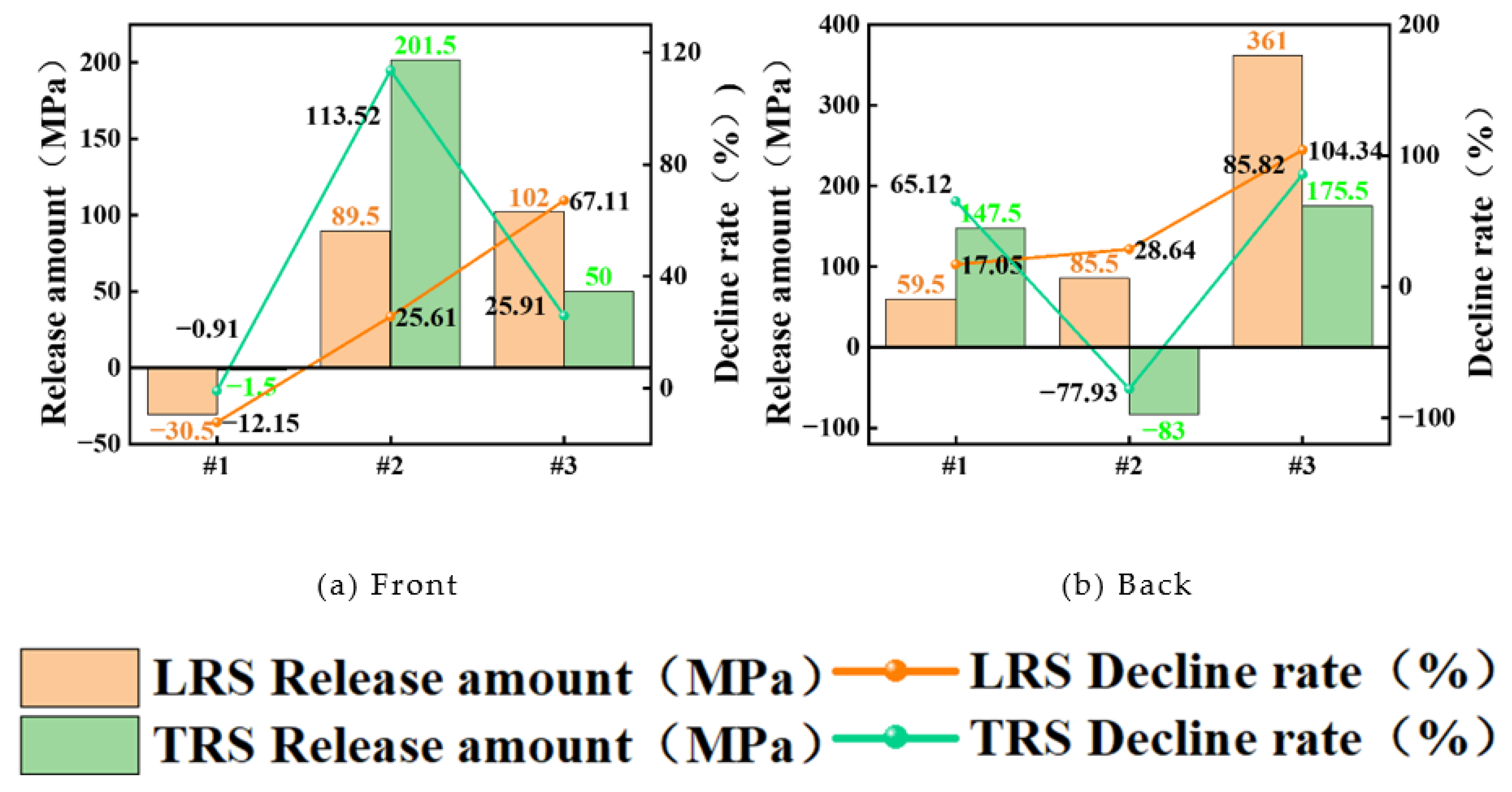

3.3. Comparison of Single and Compound Regulation Effects

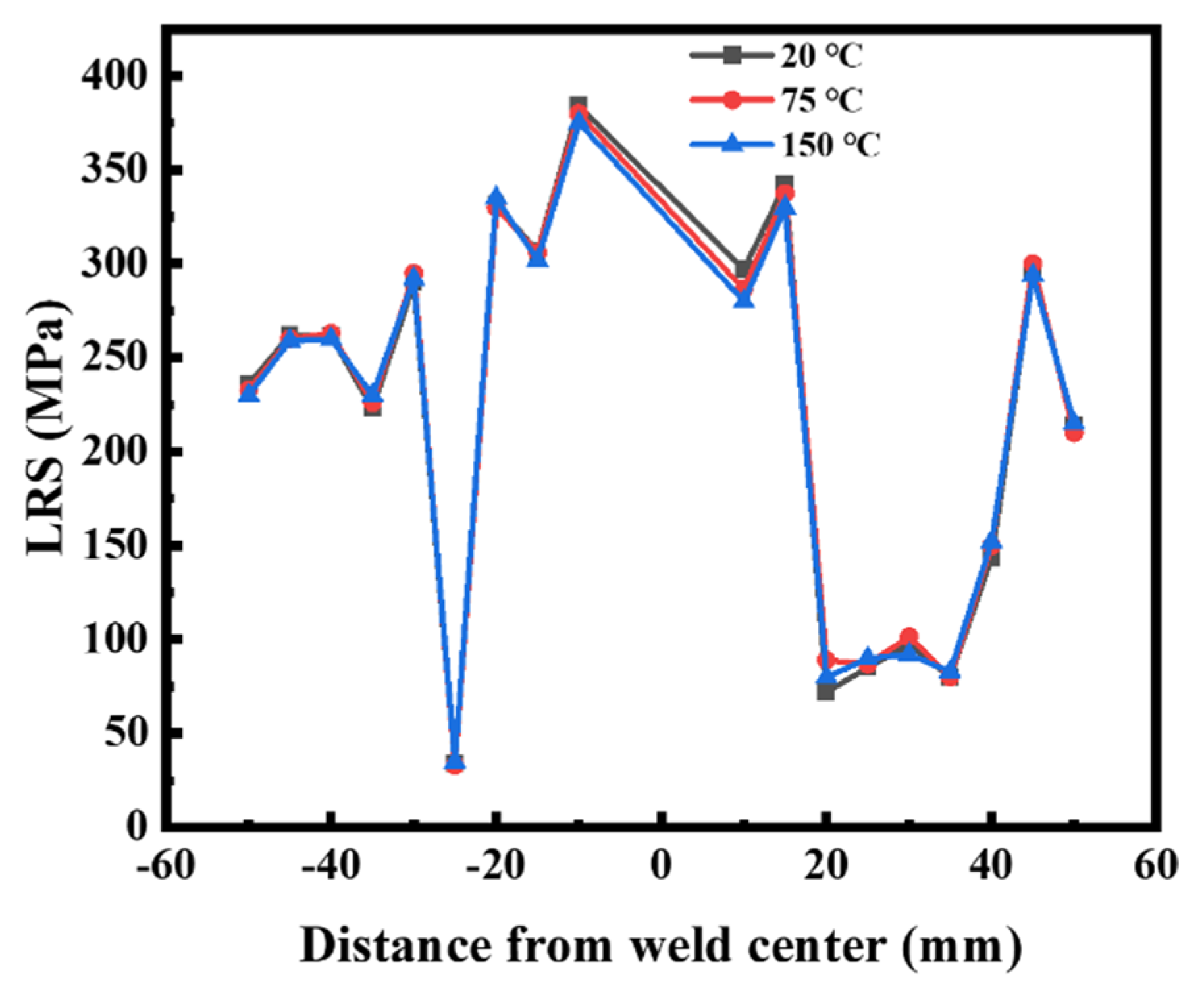

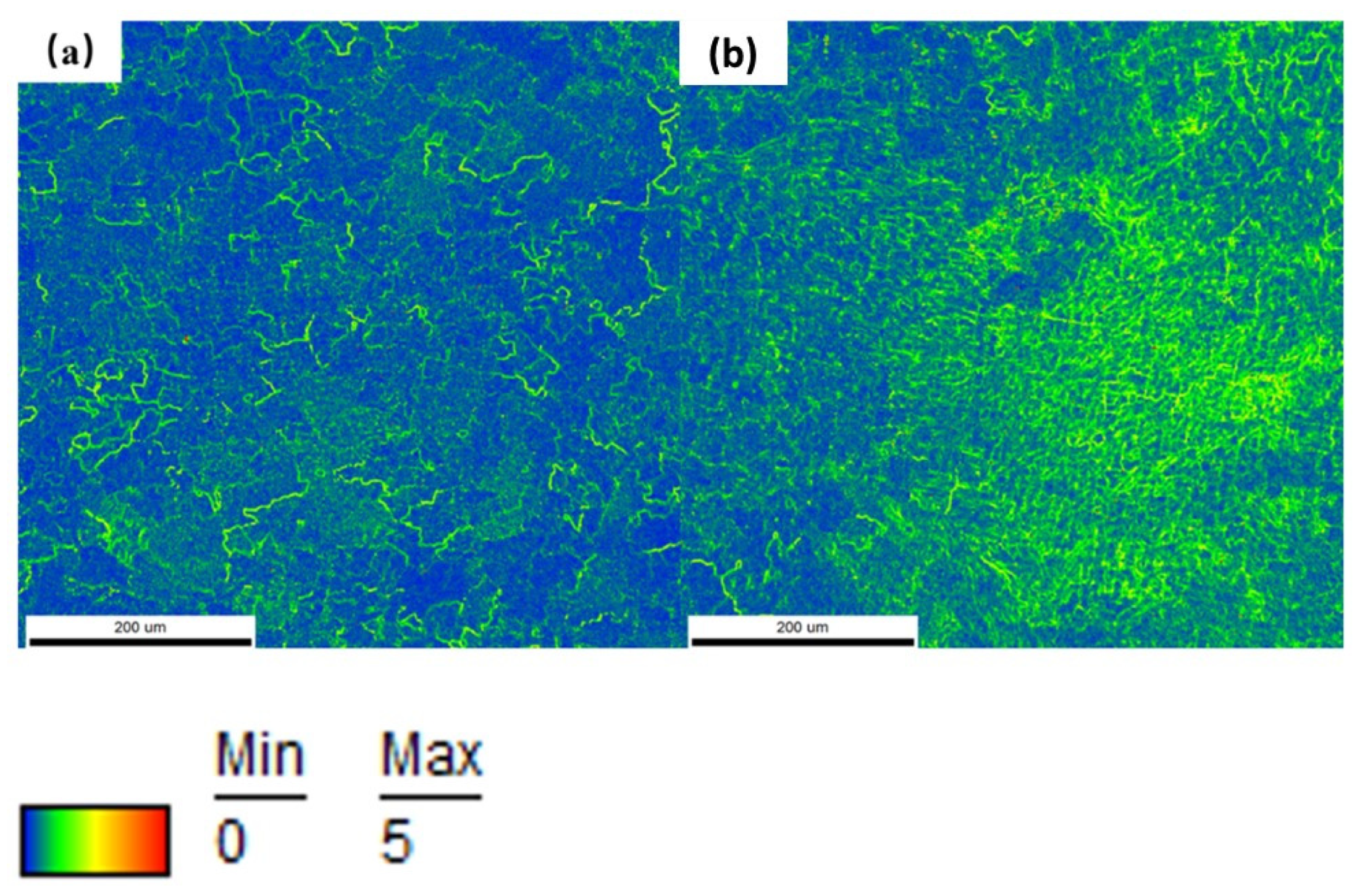

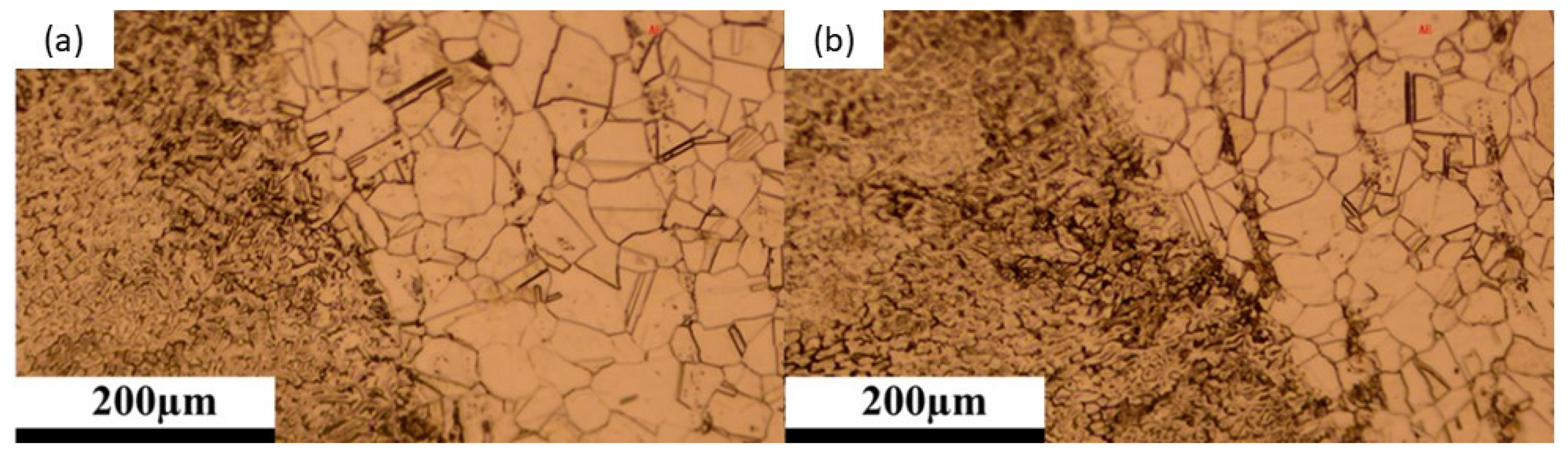

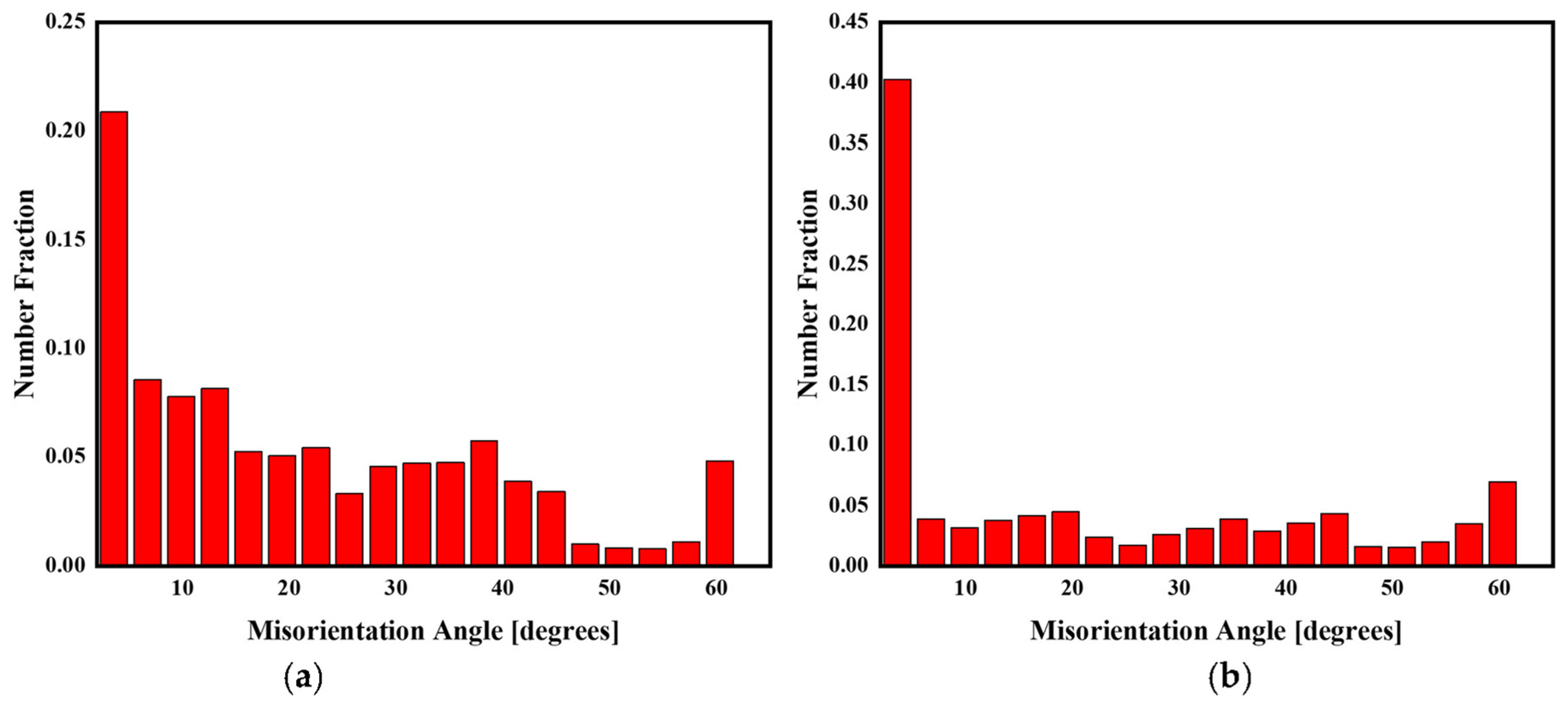

3.4. Analysis and Discussion of Regulation Mechanism

4. Conclusions

- (1)

- The influence that the weld reinforcement has on residual stress release was studied. This research found that residual stress near the weld is released after cutting the weld reinforcement, but residual stress at the weld is still the largest in relation to the overall residual stress distribution.

- (2)

- By changing the vibration time, heating temperature, and amplitude, the influence that acoustic/thermal composite treatment has on the residual stress of 316L stainless steel was studied. It was found that higher vibration times and temperatures resulted in better control effects. Excessive amplitude increases stress and may even result in material failure. The greater the amplitude in the range of 0.2~0.6 mm, the better the control effect.

- (3)

- From an energy conservation and efficiency perspective, a vibration time of 3–5 min, a heating temperature of 150–170 °C, and an amplitude of 0.4~0.6 mm can be selected as the control parameters as a means of achieving the best control effect on residual stress.

- (4)

- The control effect is best when the parameters of 0.6 mm amplitude, 170 °C heating, and 5 min are chosen. Residual stress near the weld is almost completely released, and the release amount reaches 359 MPa. In addition, residual stress on the positive and negative sides of the sample is released to a certain extent, and the residual stress relief effect is quite obvious.

- (5)

- In comparison to ultrasonic vibration and heat treatment alone, the acoustic/thermal composite treatment effect is obviously better than that of the single treatment.

- (6)

- The acoustic/thermal composite control results in the microplastic deformation of the material and the movement of dislocations, which causes residual stress to be released to a certain extent.

- (7)

- The residual compressive stress mainly exists in the area far away from the weld. From the experimental results, it can be concluded that although the stress in this part has a certain release, it has little impact on the overall service life of the sample because the failure of the sample usually occurs at the weld. Therefore, the release of residual compressive stress is unfavourable. Although it is difficult to avoid, the overall advantages are greater than the disadvantages for the experimental results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, L.; Nakata, K.; Tsumura, T.; Fujii, H.; Ikeuchi, K.; Michishita, Y.; Fujiya, Y.; Morimoto, M. Microstructure and mechanical properties of 316L stainless steel filling friction stir-welded joints. J. Mater. Eng. Perform. 2014, 23, 3718–3726. [Google Scholar] [CrossRef]

- Sun, Q.; Guo, K.; Wang, X.; Liu, J.; Sun, J. Effect of scanning strategies on the microstructure and mechanical behavior of 316L stainless steel fabricated by selective laser melting. Mater. Sci. Eng. A 2020, 793, 139879. [Google Scholar]

- Zong, X.W.; Liu, W.J.; Yang, Y.M. Effect of Different Molding Process on Mechanical Properties of 316L Stainless Steel. J. Phys. Conf. Ser. 2020, 1676, 012097. [Google Scholar] [CrossRef]

- Robinson, J.S.; Hossain, M.S.; Truman, C.E. Residual stresses in the aluminium alloy 2014A subject to PAG quenching and vibratory stress relief. J. Strain Anal. Eng. Des. 2022, 57, 167–176. [Google Scholar] [CrossRef]

- Song, H.; Gao, H.; Wu, Q.; Zhang, Y. Residual stress relief mechanisms of 2219 Al–Cu alloy by thermal stress relief method. Rev. Adv. Mater. Sci. 2022, 61, 102–116. [Google Scholar] [CrossRef]

- Zhang, Q.; Yu, L.; Shang, X.; Zhao, S. Residual stress relief of welded aluminum alloy plate using ultrasonic vibration. Ultrasonics 2020, 107, 106164. [Google Scholar] [CrossRef] [PubMed]

- Song, J.; Xu, C.; Li, Z. Ultrasonic nondestructive testing and regulation technology of residual stress. Mater. Sci. Eng. 2018, 397, 012136. [Google Scholar] [CrossRef]

- Jiang, W.; Woo, W.; An, G.B.; Park, J.U. Neutron diffraction and finite element modeling to study the weld residual stress relaxation induced by cutting. Mater. Des. 2013, 51, 415–420. [Google Scholar] [CrossRef]

- Liang, H.; Kan, Y.; Chen, H.; Zhan, R.; Wang, D. Effect of cutting process on the residual stress and fatigue life of the welded joint treated by ultrasonic impact treatment. Int. J. Fatigue 2021, 143, 105–998. [Google Scholar] [CrossRef]

- Khonsari, V.; Zhang, J.; Dong, P. Residual Stresses in Welded Moment Frames and Implications for Structural Performance. J. Struct. Eng. 2001, 127, 306–315. [Google Scholar] [CrossRef]

- Miyazaki, T.; Maruyama, Y.; Fujimoto, Y.; Sasaki, T. Improvement of X-ray stress measurement from a Debye-Scherrer ring by oscillation of the X-ray incident angle. Powder Diffr. 2015, 30, 250–255. [Google Scholar] [CrossRef]

- Gelfi, M.; Bontempi, E.; Roberti, R.; Depero, L. X-ray diffraction Debye Ring Analysis for STress measurement (DRAST): A new method to evaluate residual stresses. Acta Mater. 2004, 52, 583–589. [Google Scholar] [CrossRef]

- Kondoh, T.; Tokimasa, T.S.; Hirose, Y. X-ray stress measurement for titanium aluminide intermetallic compound. Adv. X-Ray Anal. 2000, 43, 107–116. [Google Scholar]

- Sasaki, T.; Hirose, Y. Single incidence X-ray stress measurement for all plane stress components using imaging plate of two-dimensional x-ray detector. J. Soc. Mater. Sci. 1995, 44, 1138–1143. [Google Scholar] [CrossRef]

- Taira, S.; Tanaka, K.; Yamasaki, T. A method of X-ray microbeam measurement of local stress and its application to fatigue crack growth problems. Jpn. Soc. Mater. Sci. 1978, 27, 251–256. [Google Scholar] [CrossRef]

- Sasaki, T.; Hirose, Y.; Sasaki, K.; Yasukawa, S. Influence of image processing conditions of Debye Scherrer ring images in x-ray stress measurement using an imaging plate. JCPDS-Int. Cent. Diffr. Data 1997, 2, 12–54. [Google Scholar]

- Yamazaki, S.; Lu, Z.; Ito, Y.; Takeda, Y.; Shoji, T. The effect of prior deformation on stress corrosion cracking growth rates of Alloy 600 materials in a simulated pressurized water reactor primary water. Corros. Sci. 2008, 50, 835–846. [Google Scholar] [CrossRef]

| Method | Advantage | Shortcoming |

|---|---|---|

| Thermal stress method | Uniform stress release | It is time-energy consuming. It is only applicable to small and medium-sized structures and the cooling rate requires strict control. |

| Vibration stress relief | Portable, fast, low cost | The excitation frequency is low, meaning that the natural frequency of the sample must be considered, and the residual stress release is uneven. |

| High-frequency ultrasonic method | Portable, fast, low cost, uniform residual stress release, high-frequency, wider application | The residual stress release capacity is limited, meaning that it is not comparable to traditional methods. |

| Electromagnetic method | Portable and fast | The equipment construction is complex, equipment cost is high, there are strict working environment requirements, and the residual stress release capacity is limited, meaning that it cannot be compared to traditional methods. |

| C | Si | Mn | P | S | Ni | Cr | Mo | Fe |

|---|---|---|---|---|---|---|---|---|

| 0.019 | 0.66 | 1.19 | 0.033 | 0.001 | 12.11 | 17.41 | 2.05 | Bal. |

| Material | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|

| 316L | ≥177 | ≥480 | ≥40 |

| Electric Current (A) | Voltage (V) | Gas Flow (L.min−1) | Shielding Gas | Welding Speed (cm. min−1) |

|---|---|---|---|---|

| 260 | 23.5 | 20 | Ar | 10 |

| No. | Time (min) | Temperature (°C) | Amplitude (mm) |

|---|---|---|---|

| #1 | 1 | 75 | 0.2 |

| #2 | 1 | 100 | 0.2 |

| #3 | 1 | 125 | 0.2 |

| #4 | 3 | 150 | 0.4 |

| #5 | 3 | 150 | 0.6 |

| #6 | 3 | 170 | 0.6 |

| #7 | 5 | 170 | 0.6 |

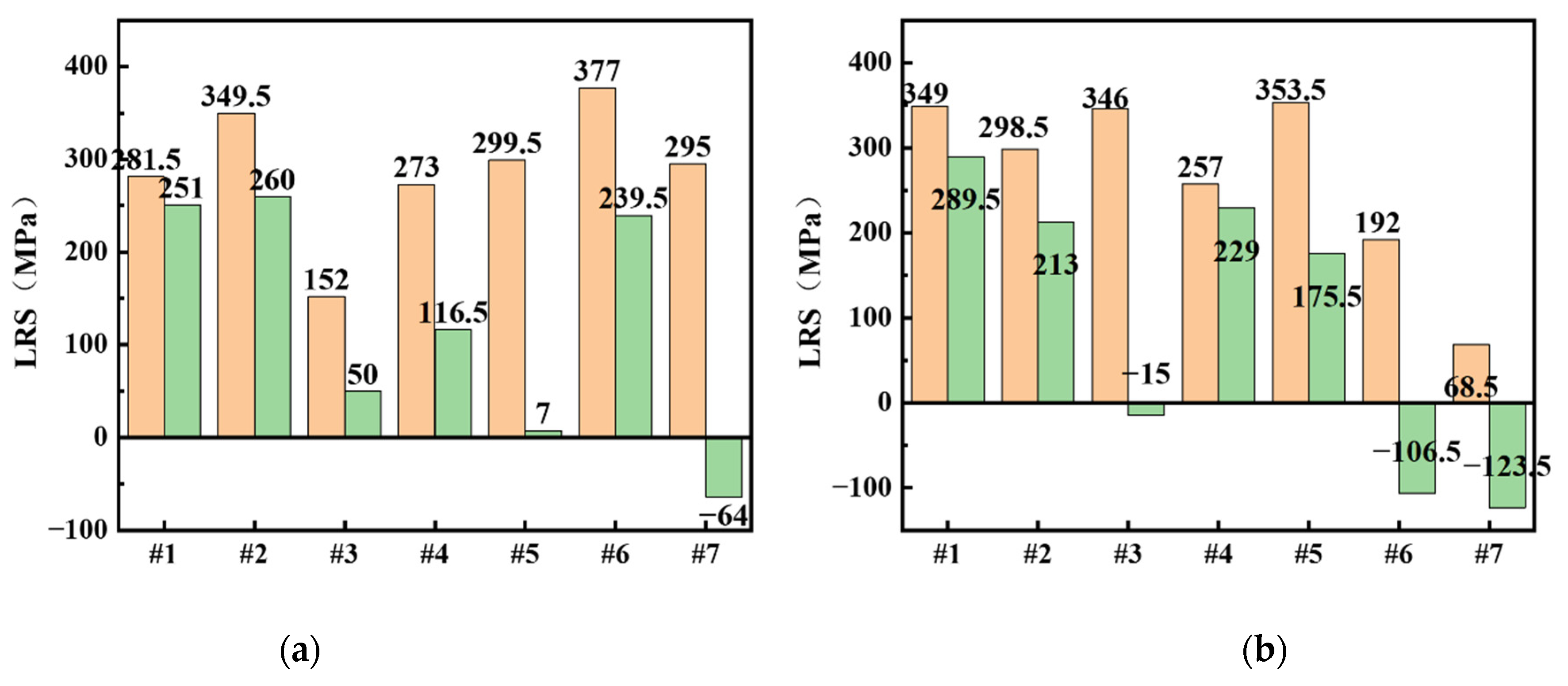

| No. | #1-LRS | #2-LRS | #3-LRS | #1-TRS | #2-5TRS | #3-TRS |

|---|---|---|---|---|---|---|

| After regulation (MPa) | 281.5 | 260.0 | 50.0 | 167.0 | −24.0 | 143.0 |

| Before regulation (MPa) | 251.0 | 349.5 | 152.0 | 165.5 | 177.5 | 193.0 |

| Decline rate (%) | −12.15 | 25.61 | 67.11 | −0.91 | 113.52 | 25.91 |

| Release amount (MPa) | −30.5 | 89.5 | 102.0 | −1.5 | 201.5 | 50.0 |

| No. | #1-LRS | #2-LRS | #3-LRS | #1-TRS | #2-TRS | #3-TRS |

|---|---|---|---|---|---|---|

| After regulation (MPa) | 289.5 | 213.0 | −15.0 | 79.0 | 189.5 | 29.0 |

| Before regulation (MPa) | 349.0 | 298.5 | 346.0 | 226.5 | 106.5 | 204.5 |

| Decline rate (%) | 17.05 | 28.64 | 104.34 | 65.12 | −77.93 | 85.82 |

| Release amount (MPa) | 59.5 | 85.5 | 361.0 | 147.5 | −83.0 | 175.5 |

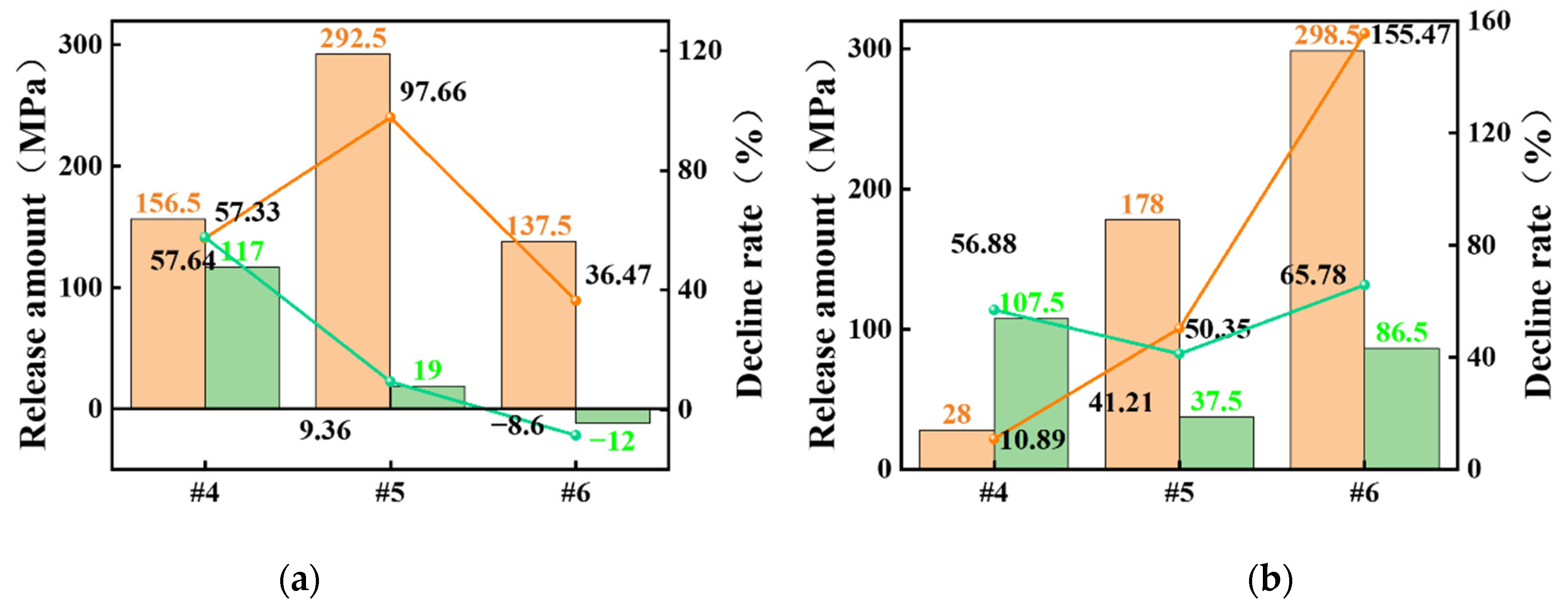

| No. | #4-LRS | #5-LRS | #6-LRS | #4-TRS | #5-TRS | #6-TRS |

|---|---|---|---|---|---|---|

| After regulation (MPa) | 116.5 | 7.0 | 239.5 | 86.0 | 184.0 | 151.5 |

| Before regulation (MPa) | 273.0 | 299.5 | 377.0 | 203.0 | 203.0 | 139.5 |

| Decline rate (%) | 57.33 | 97.66 | 36.47 | 57.64 | 9.36 | −8.60 |

| Release amount (MPa) | 156.5 | 292.5 | 137.5 | 117.0 | 19.0 | −12.0 |

| No. | #4-LRS | #5-LRS | #6-LRS | #4-TRS | #5-TRS | #6-TRS |

|---|---|---|---|---|---|---|

| After regulation (MPa) | 229.0 | 175.5 | −106.5 | 81.5 | 53.5 | 45.0 |

| Before regulation (MPa) | 257.0 | 353.5 | 192.0 | 189.0 | 91.0 | 131.5 |

| Decline rate (%) | 10.89 | 50.35 | 155.47 | 56.88 | 41.21 | 65.78 |

| Release amount (MPa) | 28.0 | 178.0 | 298.5 | 107.5 | 37.5 | 86.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiang, P.; Zhang, C.; Jin, J.; Zhu, Z.; Gou, G. Relieving Residual Stress of 316L Stainless Steel by Acoustic/Thermal Composite Treatment. Metals 2023, 13, 18. https://doi.org/10.3390/met13010018

Xiang P, Zhang C, Jin J, Zhu Z, Gou G. Relieving Residual Stress of 316L Stainless Steel by Acoustic/Thermal Composite Treatment. Metals. 2023; 13(1):18. https://doi.org/10.3390/met13010018

Chicago/Turabian StyleXiang, Pengyu, Chenhao Zhang, Junjun Jin, Zhongyin Zhu, and Guoqing Gou. 2023. "Relieving Residual Stress of 316L Stainless Steel by Acoustic/Thermal Composite Treatment" Metals 13, no. 1: 18. https://doi.org/10.3390/met13010018

APA StyleXiang, P., Zhang, C., Jin, J., Zhu, Z., & Gou, G. (2023). Relieving Residual Stress of 316L Stainless Steel by Acoustic/Thermal Composite Treatment. Metals, 13(1), 18. https://doi.org/10.3390/met13010018