Quantified Approach for Evaluation of Geometry Visibility of Optical-Based Process Monitoring System for Laser Powder Bed Fusion

Abstract

:1. Introduction

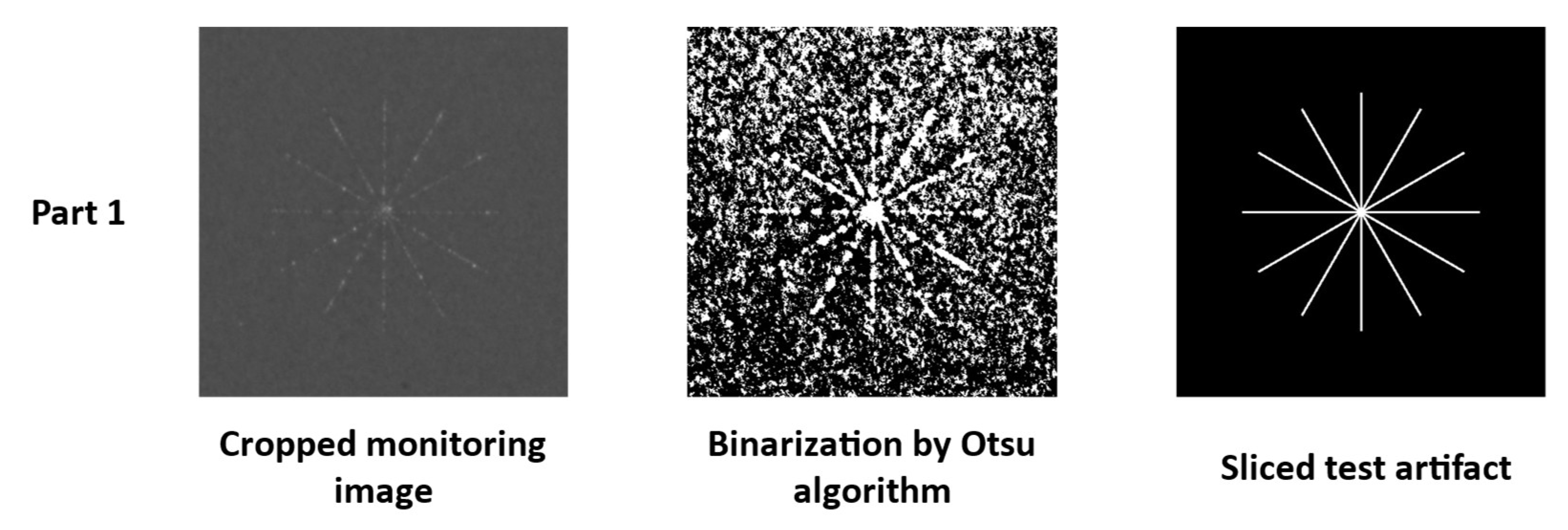

2. Materials and Methods

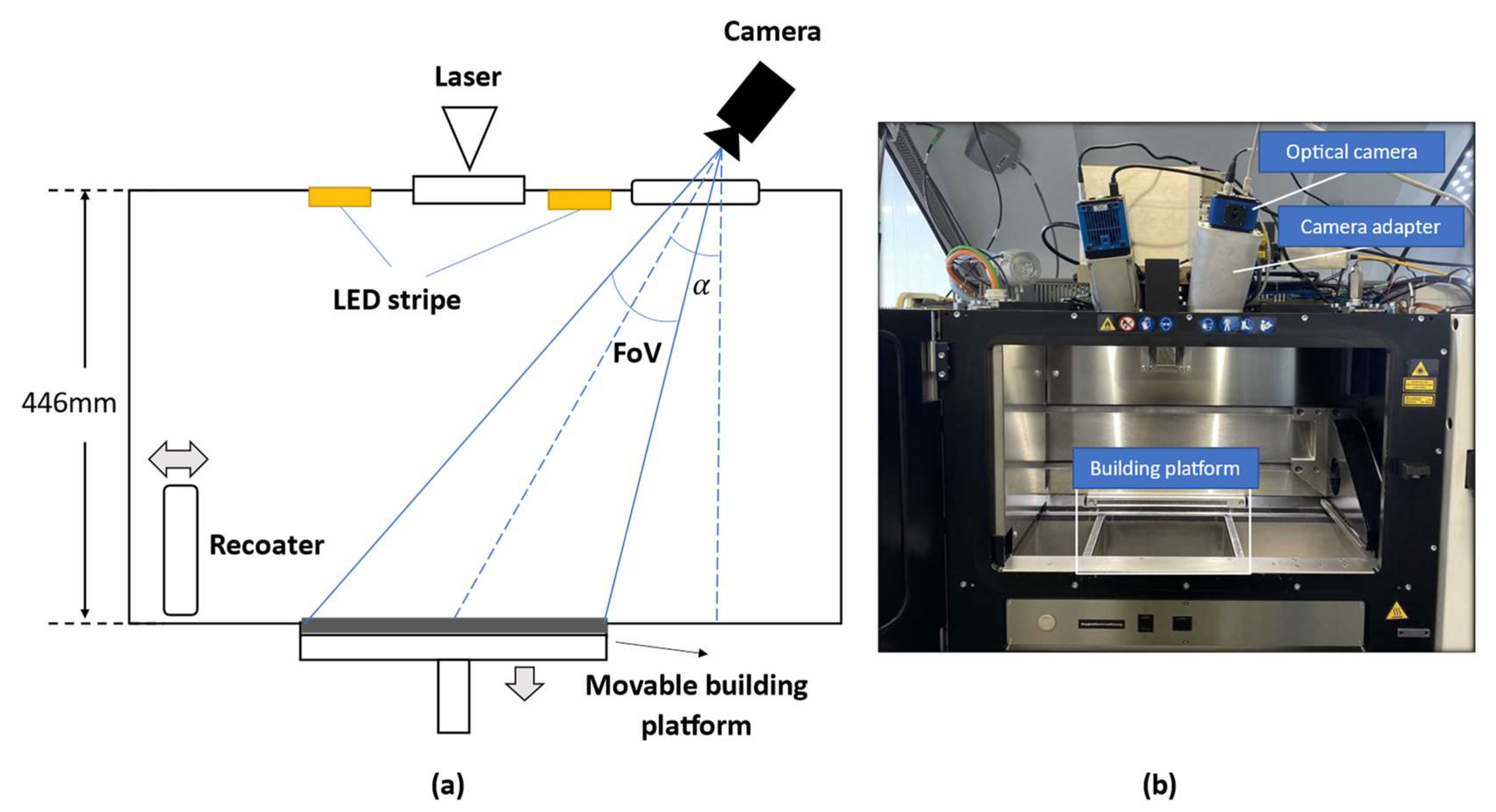

2.1. Optical Camera System Setup

2.2. Calibration

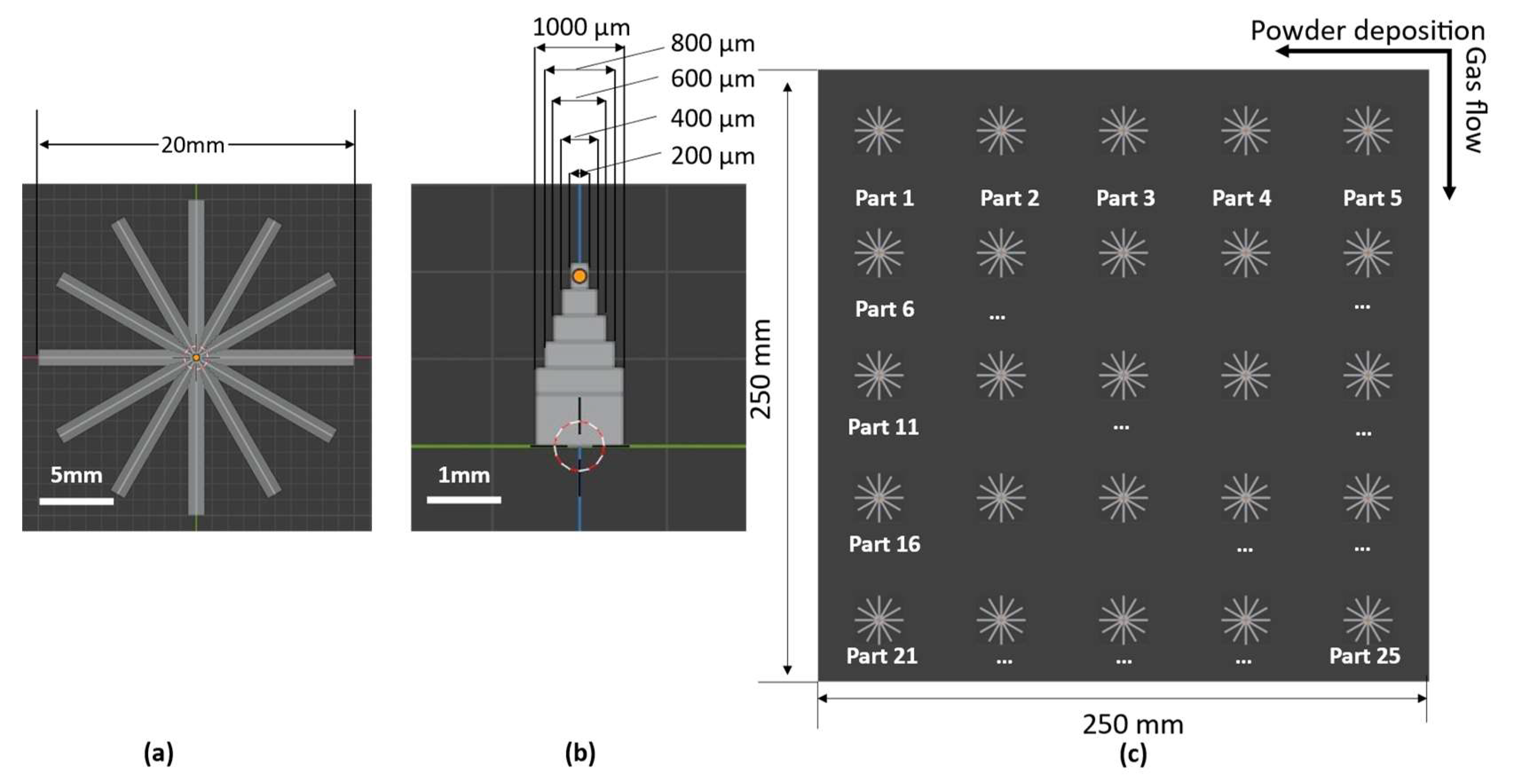

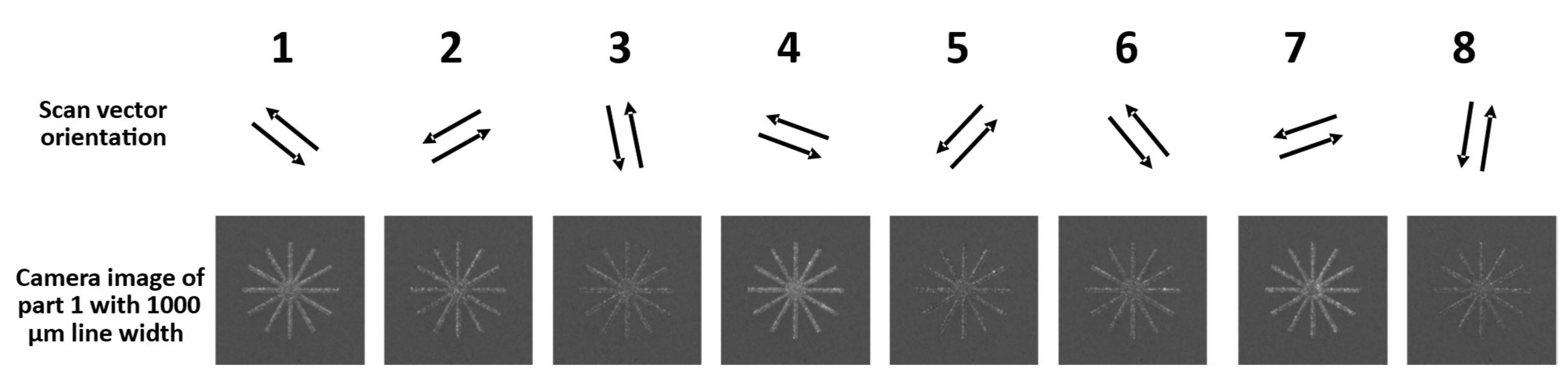

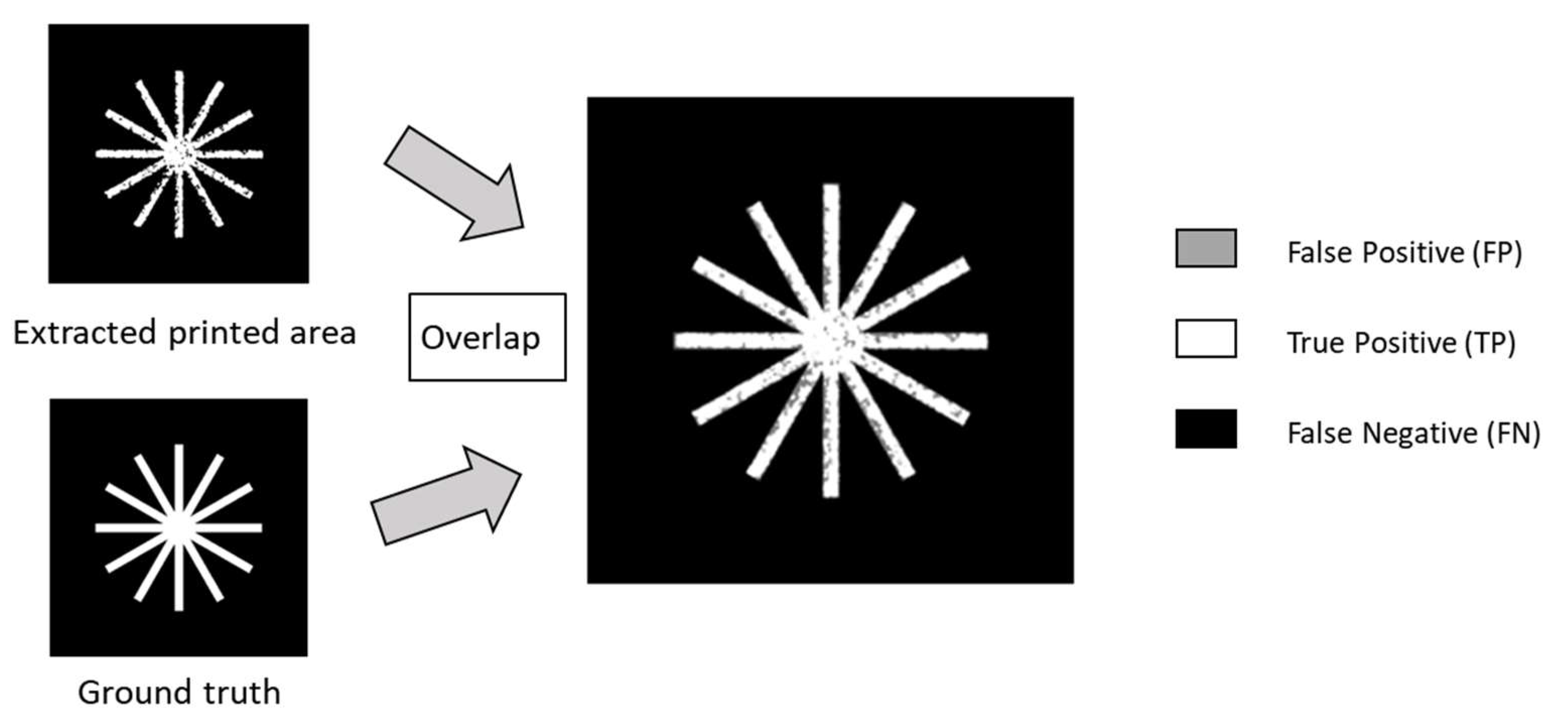

2.3. Experimental Design and Evaluation Method

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Raffeis, I.; Adjei-Kyeremeh, F.; Vroomen, U.; Suwanpinij, P.; Ewald, S.; Bührig-Polazcek, A. Investigation of the Lithium-Containing Aluminum Copper Alloy (AA2099) for the Laser Powder Bed Fusion Process [L-PBF]: Effects of Process Parameters on Cracks, Porosity, and Microhardness. JOM 2019, 71, 1543–1553. [Google Scholar] [CrossRef]

- Charalampous, P.; Kostavelis, I.; Tzovaras, D. Non-destructive quality control methods in additive manufacturing: A survey. Rapid Prototyp. J. 2020, 26, 777–790. [Google Scholar] [CrossRef]

- Smith, R.J.; Hirsch, M.; Patel, R.; Li, W.; Clare, A.T.; Sharples, S.D. Spatially resolved acoustic spectroscopy for selective laser melting. J. Mater. Process. Technol. 2016, 236, 93–102. [Google Scholar] [CrossRef]

- Shevchik, S.A.; Kenel, C.; Leinenbach, C.; Wasmer, K. Acoustic emission for in situ quality monitoring in additive manufacturing using spectral convolutional neural networks. Addit. Manuf. 2018, 21, 598–604. [Google Scholar] [CrossRef]

- Colosimo, B.M.; Garghetti, F.; Pagani, L.; Grasso, M. A novel method for in-process inspection of lattice structures via in-situ layerwise imaging. Manuf. Lett. 2022, 32, 67–72. [Google Scholar] [CrossRef]

- Fischer, F.G.; Birk, N.; Rooney, L.; Jauer, L.; Schleifenbaum, J.H. Optical process monitoring in Laser Powder Bed Fusion using a recoater-based line camera. Addit. Manuf. 2021, 47, 102218. [Google Scholar] [CrossRef]

- Craeghs, T.; Clijsters, S.; Yasa, E.; Kruth, J.-P. Online Quality Control of Selective Laser Melting; University of Texas at Austin: Austin, TX, USA, 2011. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Krakhmalev, P.; Yadroitsava, I. Selective laser melting of Ti6Al4V alloy for biomedical applications: Temperature monitoring and microstructural evolution. J. Alloy. Compd. 2014, 583, 404–409. [Google Scholar] [CrossRef]

- Zenzinger, G.; Bamberg, J.; Ladewig, A.; Hess, T.; Henkel, B.; Satzger, W. Process Monitoring of additive Manufacturing by Using Optical Tomography; AIP Publishing LLC: Melville, NY, USA, 2015; pp. 164–170. [Google Scholar] [CrossRef] [Green Version]

- Du Plessis, A.; Yadroitsev, I.; Yadroitsava, I.; Le Roux, S.G. X-Ray Microcomputed Tomography in Additive Manufacturing: A Review of the Current Technology and Applications. 3D Print. Addit. Manuf. 2018, 5, 227–247. [Google Scholar] [CrossRef]

- Du Plessis, A.; Yadroitsava, I.; Yadroitsev, I. Effects of defects on mechanical properties in metal additive manufacturing: A review focusing on X-ray tomography insights. Mater. Des. 2020, 187, 108385. [Google Scholar] [CrossRef]

- Smurov, I.; Doubenskaia, M. Temperature Monitoring by Optical Methods in Laser Processing. In Laser-Assisted Fabrication of Materials; Majumdar, J.D., Manna, I., Eds.; Springer Series in Materials Science; Springer: Berlin/Heidelberg, Germany, 2013; pp. 375–422. [Google Scholar] [CrossRef]

- Grasso, M.; Remani, A.; Dickins, A.; Colosimo, B.M.; Leach, R.K. In-situ measurement and monitoring methods for metal powder bed fusion: An updated review. Meas. Sci. Technol. 2021, 32, 112001. [Google Scholar] [CrossRef]

- Pagani, L.; Grasso, M.; Scott, P.J.; Colosimo, B.M. Automated layerwise detection of geometrical distortions in laser powder bed fusion. Addit. Manuf. 2020, 36, 101435. [Google Scholar] [CrossRef]

- Wang, P.; Yang, Y.; Moghaddam, N.S. Process modeling in laser powder bed fusion towards defect detection and quality control via machine learning: The state-of-the-art and research challenges. J. Manuf. Process. 2022, 73, 961–984. [Google Scholar] [CrossRef]

- Foster, B.K.; Reutzel, E.W.; Nassar, A.R.; Hall, B.T.; Brown, S.W.; Dickman, C.J. Optical, Layerwise Monitoring of Powder Bed Fusion; University of Texas at Austin: Austin, TX, USA, 2015. [Google Scholar]

- Aminzadeh, M.; Kurfess, T.R. Online quality inspection using Bayesian classification in powder-bed additive manufacturing from high-resolution visual camera images. J. Intell. Manuf. 2019, 30, 2505–2523. [Google Scholar] [CrossRef]

- Seibert, J.A.; Boone, J.M.; Lindfors, K.K. Flat-field correction technique for digital detectors. In Medical Imaging 1998: Physics of Medical Imaging; Dobbins, J.T., III, Boone, J.M., Eds.; SPIE: Bellingham, WA, USA, 1998; p. 348. [Google Scholar] [CrossRef]

- Jagannathan, L.; Jawahar, C.V. Perspective correction methods for camera based document analysis. In Proc. First Int. Workshop on Camera-based Document Analysis and Recognition; International Institute of Information Technology: Hyderabad, India, 2005. [Google Scholar]

- Jyotsna; Chauhan, S.; Sharma, E.; Doegar, A. Binarization techniques for degraded document images—A review. In Proceedings of the 2016 5th International Conference on Reliability, Infocom Technologies and Optimization (Trends and Future Directions) (ICRITO), Noida, India, 7–9 September 2016. [Google Scholar] [CrossRef]

- Otsu, N. A Threshold Selection Method from Gray-Level Histograms. IEEE Trans. Syst. Man, Cybern. 1979, 9, 62–66. [Google Scholar] [CrossRef]

- Dawson-Haggerty, M. Trimesh [Computer software], 2019. Available online: https://trimsh.org/ (accessed on 10 October 2022).

| Research | LPBF System | Resolution of Camera | Illumination Setup | Approach |

|---|---|---|---|---|

| [16] | EOS M280 | 7360 × 4912 pixels | Multiple flash modules | N/A |

| [17] | Machine of Edison Welding Institute | 4096 × 2160 pixels | Microscope ring LED | Sauvola thresholding |

| [14] | EOS M290 | 1280 × 1024 pixels | Low-angle side illumination source | Active contour segmentation |

| Item | Value |

|---|---|

| Type of sensor | Monochrome Charge-coupled Device (CCD) |

| Sensor size | 36 mm × 24 mm |

| Pixel size | 5.5 µm × 5.5 µm |

| Bit depth | 8 bits |

| Resolution | 6576 × 4384 (29 Megapixels) |

| Exposure time | 1.5 s |

| Laser Beam Diameter ds [µm] | Scan Velocity vs [mm/s] | Layer Height Ds [µm] | Laser Power PL [W] | Hatching Distance ∆ys [µm] | Volume Energy Ev [J/mm3] |

|---|---|---|---|---|---|

| 75 | 800 | 30 | 120 | 80 | 62.5 |

| F1 Score | Column 1 | Column 2 | Column 3 | Column 4 | Column 5 |

|---|---|---|---|---|---|

| Row 1 | 0.5717 | 0.5938 | 0.7034 | 0.7173 | 0.6943 |

| Row 2 | 0.6016 | 0.7122 | 0.7471 | 0.7703 | 0.7466 |

| Row 3 | 0.6453 | 0.7178 | 0.7645 | 0.7481 | 0.7528 |

| Row 4 | 0.6757 | 0.7181 | 0.7393 | 0.7624 | 0.7715 |

| Row 5 | 0.6709 | 0.7256 | 0.7573 | 0.7650 | 0.7794 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Adjei-Kyeremeh, F.; Wang, H.; Kolter, M.; Raffeis, I.; Schleifenbaum, J.H.; Bührig-Polaczek, A. Quantified Approach for Evaluation of Geometry Visibility of Optical-Based Process Monitoring System for Laser Powder Bed Fusion. Metals 2023, 13, 13. https://doi.org/10.3390/met13010013

Zhang S, Adjei-Kyeremeh F, Wang H, Kolter M, Raffeis I, Schleifenbaum JH, Bührig-Polaczek A. Quantified Approach for Evaluation of Geometry Visibility of Optical-Based Process Monitoring System for Laser Powder Bed Fusion. Metals. 2023; 13(1):13. https://doi.org/10.3390/met13010013

Chicago/Turabian StyleZhang, Song, Frank Adjei-Kyeremeh, Hui Wang, Moritz Kolter, Iris Raffeis, Johannes Henrich Schleifenbaum, and Andreas Bührig-Polaczek. 2023. "Quantified Approach for Evaluation of Geometry Visibility of Optical-Based Process Monitoring System for Laser Powder Bed Fusion" Metals 13, no. 1: 13. https://doi.org/10.3390/met13010013

APA StyleZhang, S., Adjei-Kyeremeh, F., Wang, H., Kolter, M., Raffeis, I., Schleifenbaum, J. H., & Bührig-Polaczek, A. (2023). Quantified Approach for Evaluation of Geometry Visibility of Optical-Based Process Monitoring System for Laser Powder Bed Fusion. Metals, 13(1), 13. https://doi.org/10.3390/met13010013