Magnetic Properties of the Mn55Bi45/Nd2Fe14B Hybrid Magnetic Alloys

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

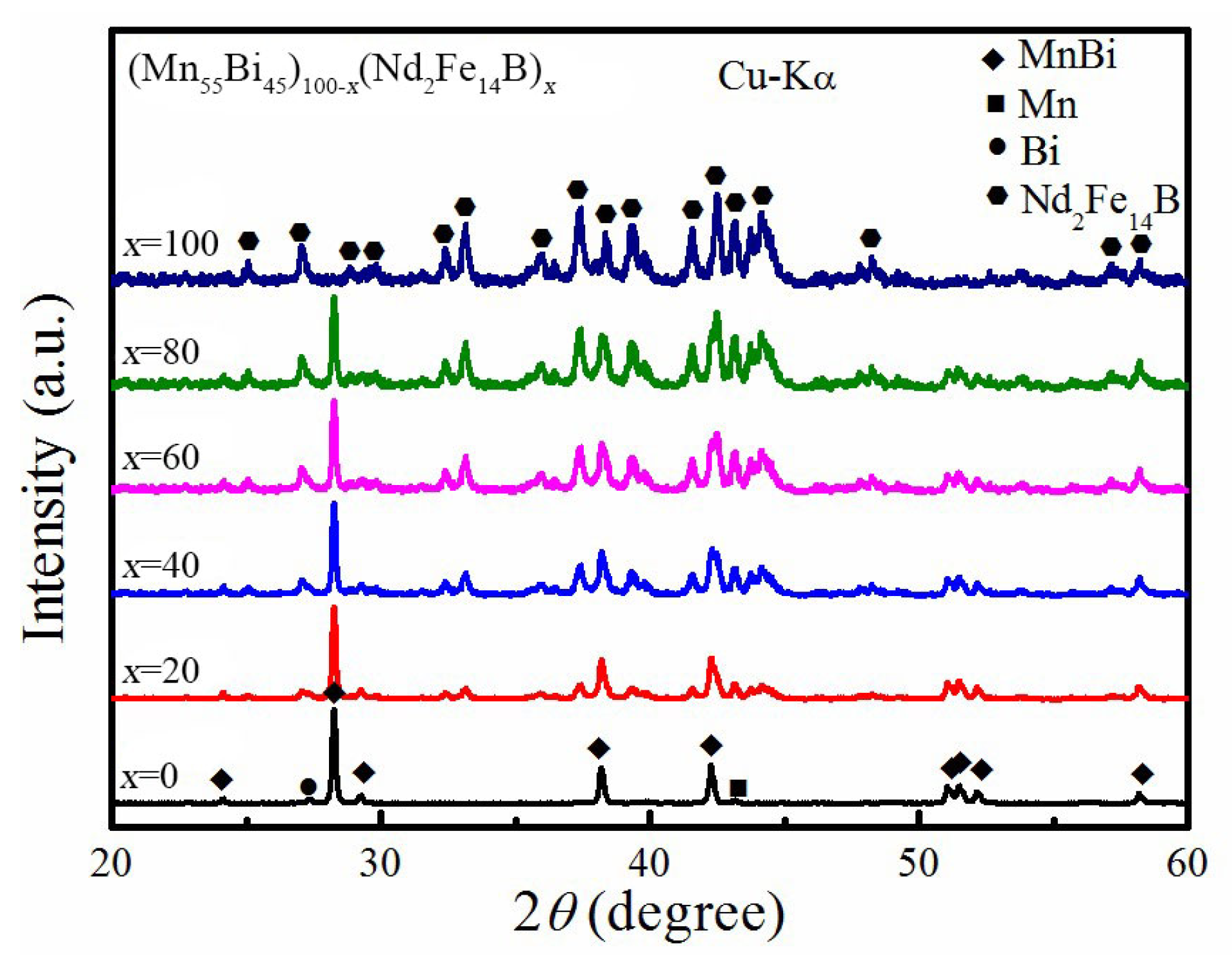

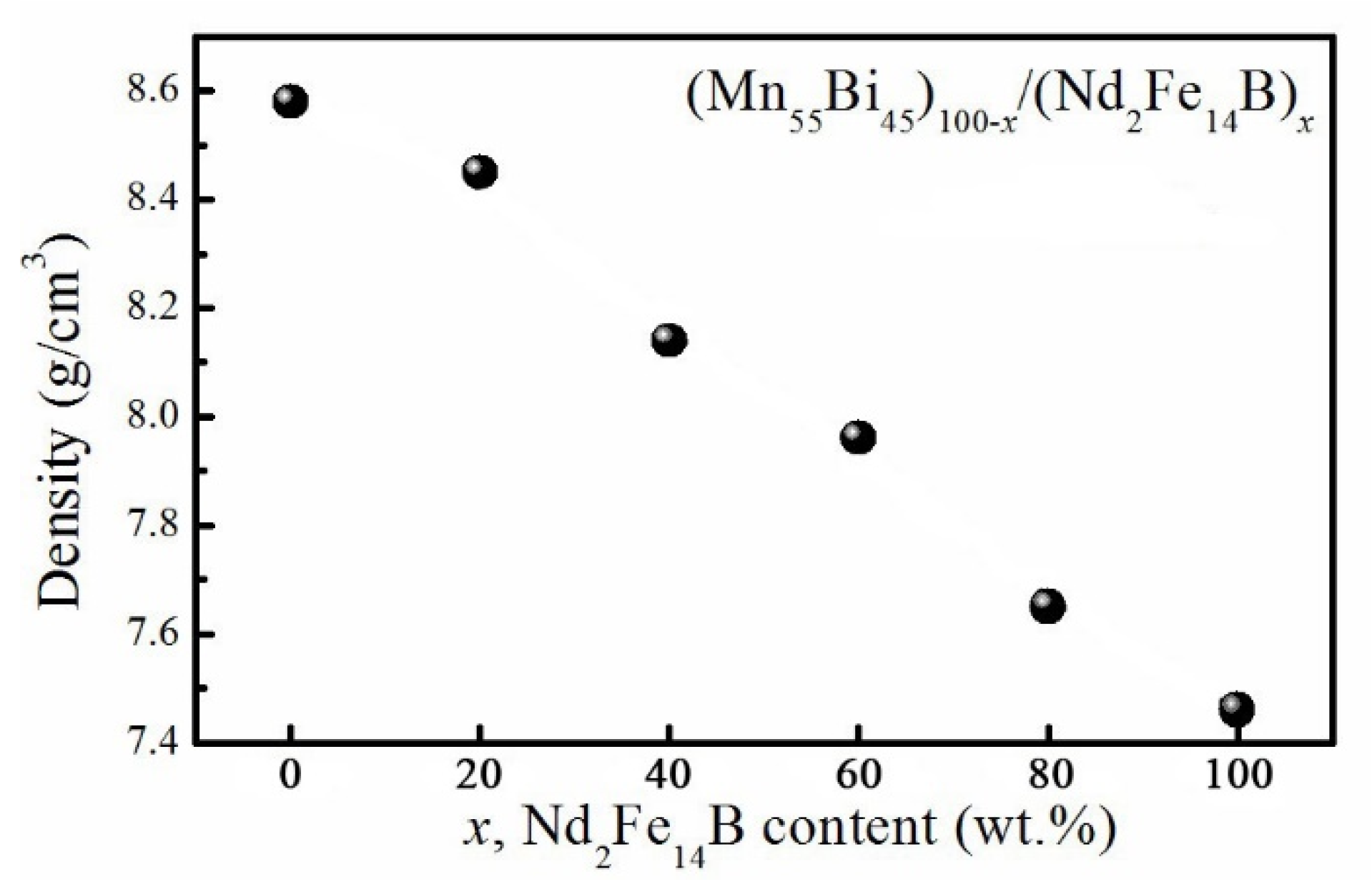

3.1. Microstructure of Mn55Bi45/Nd2Fe14B Hybrid Magnetic Alloys

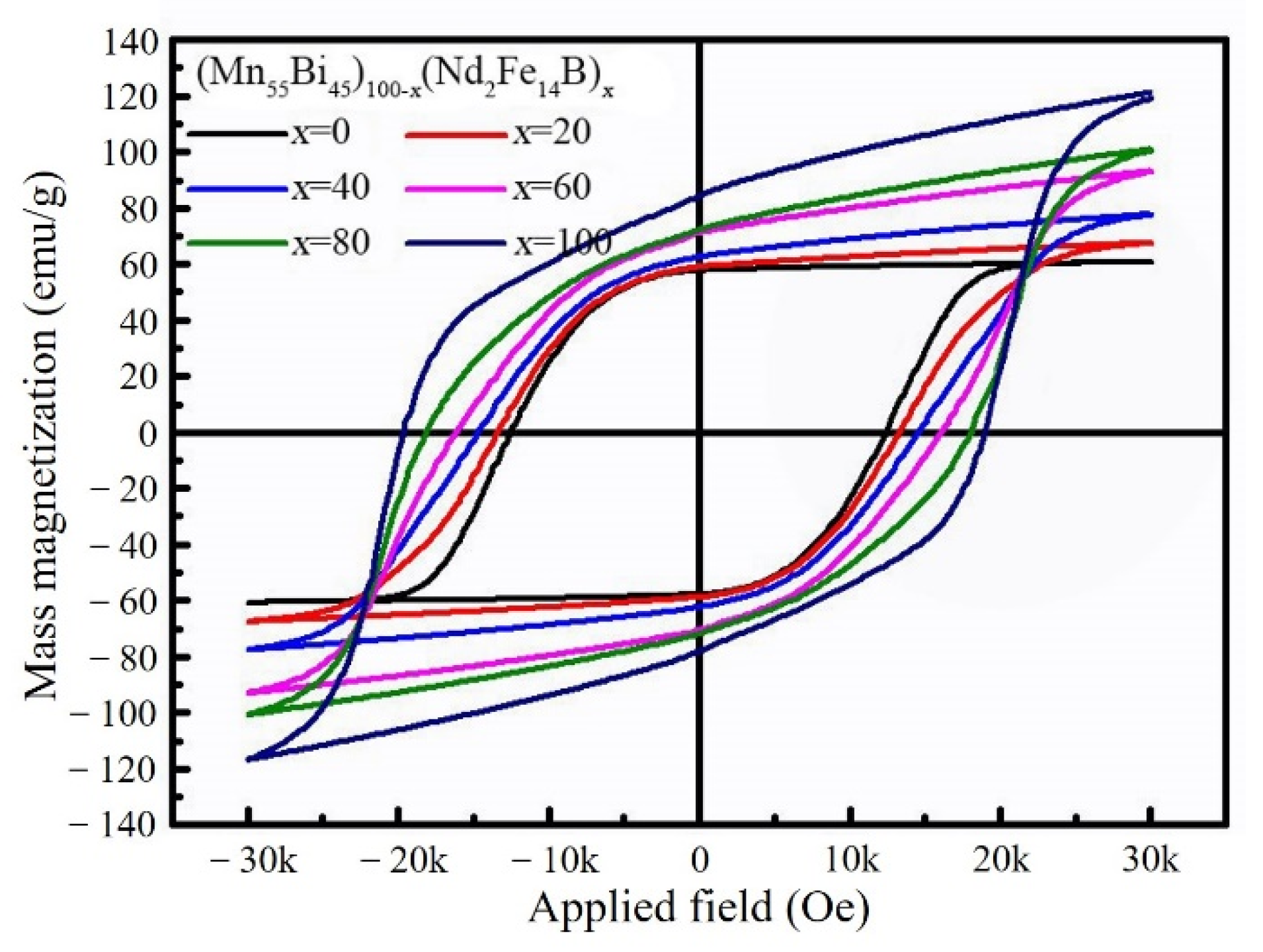

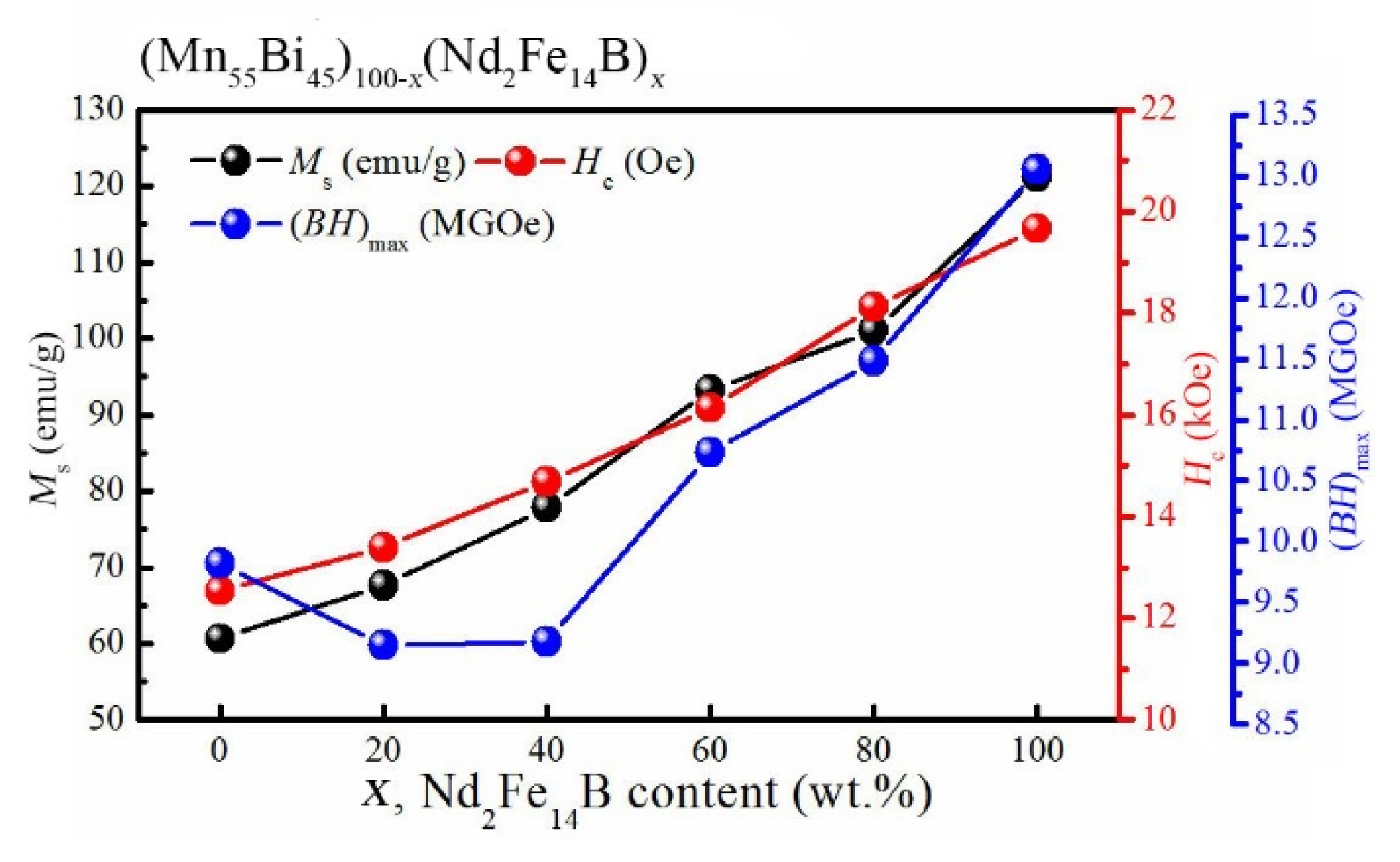

3.2. The Magnetic Properties of Mn55Bi45/Nd2Fe14B Hybrid Magnetic Alloys at Room Temperature

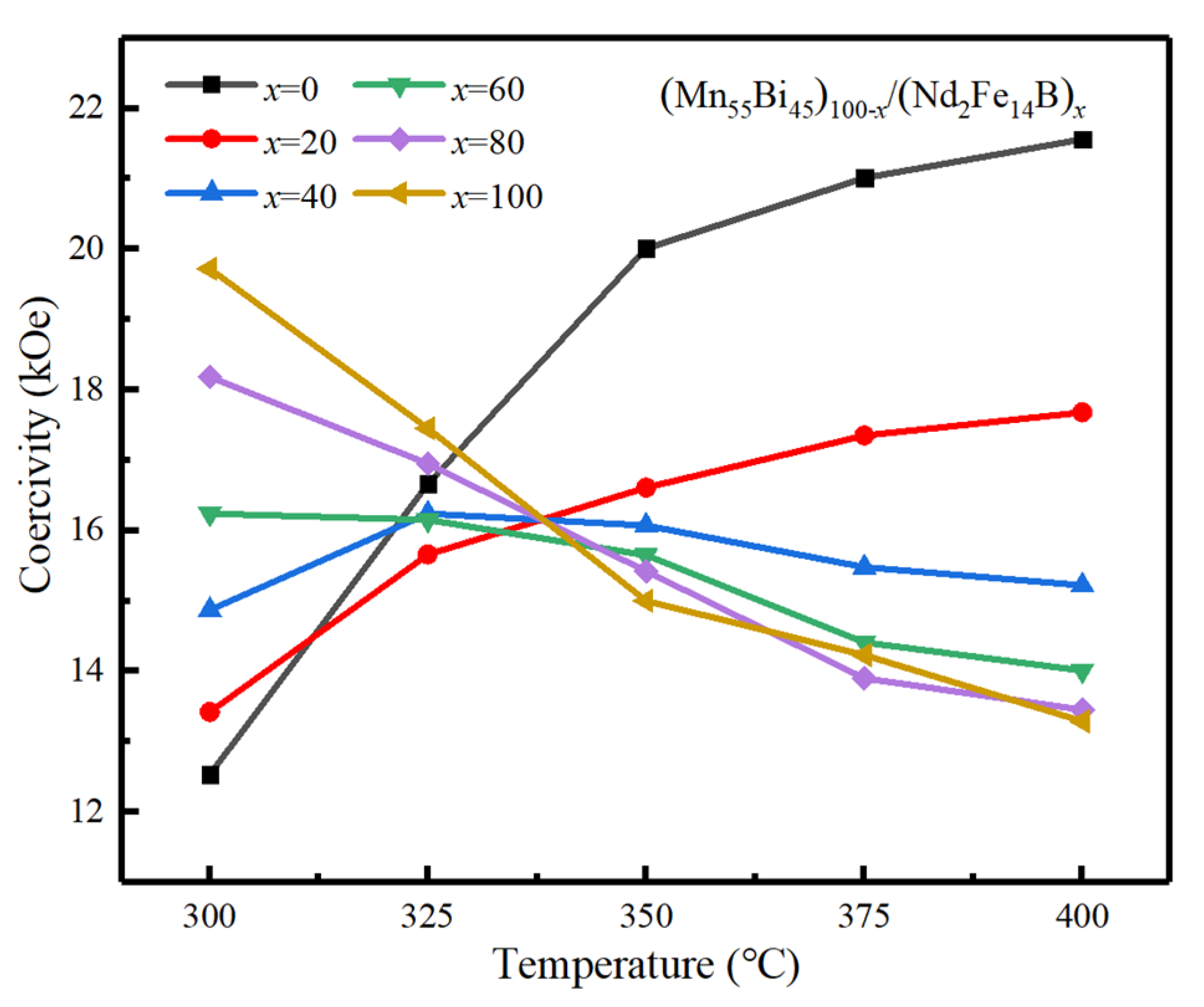

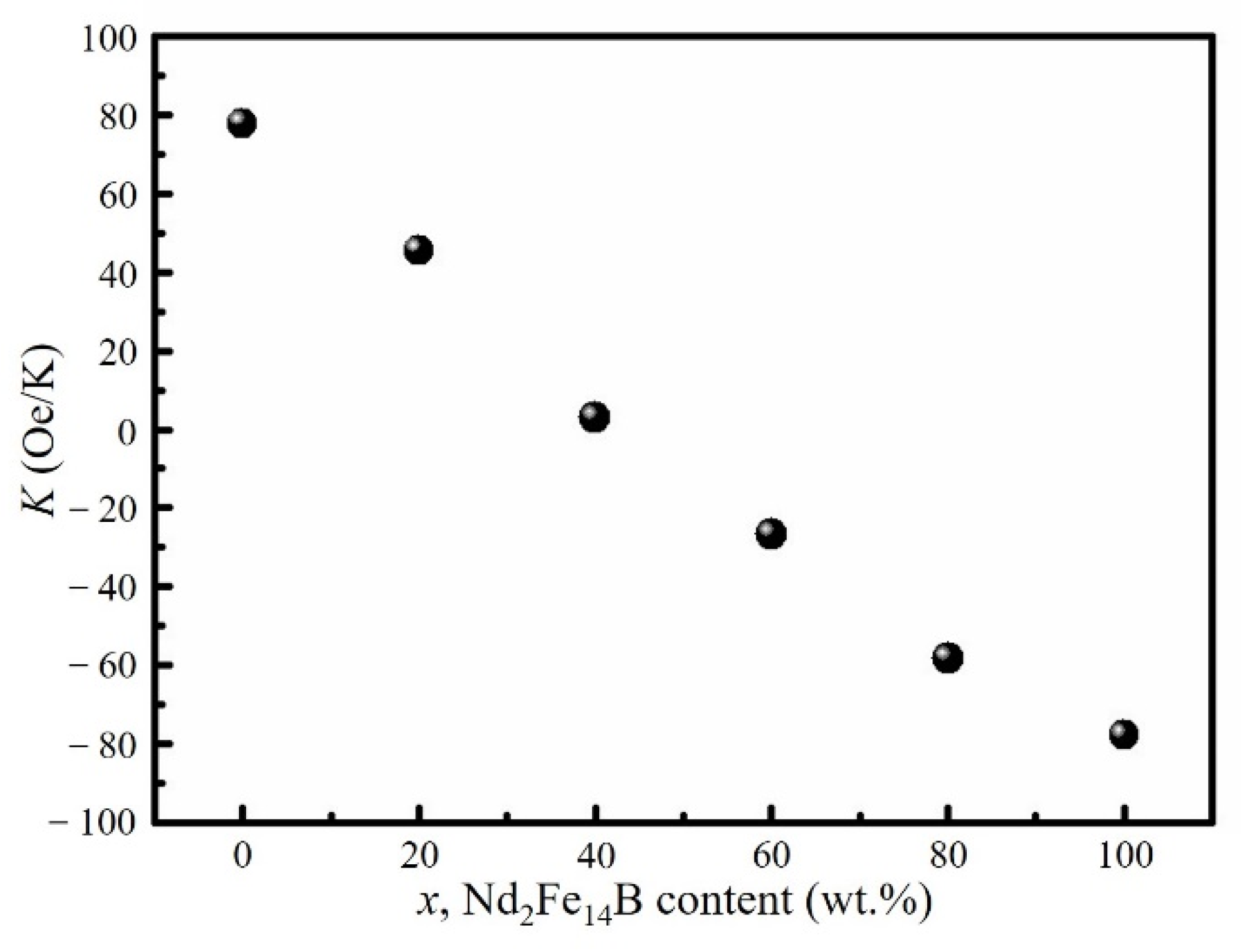

3.3. The Coercivity Temperature Dependence of Mn55Bi45/Nd2Fe14B Hybrid Magnetic Alloys

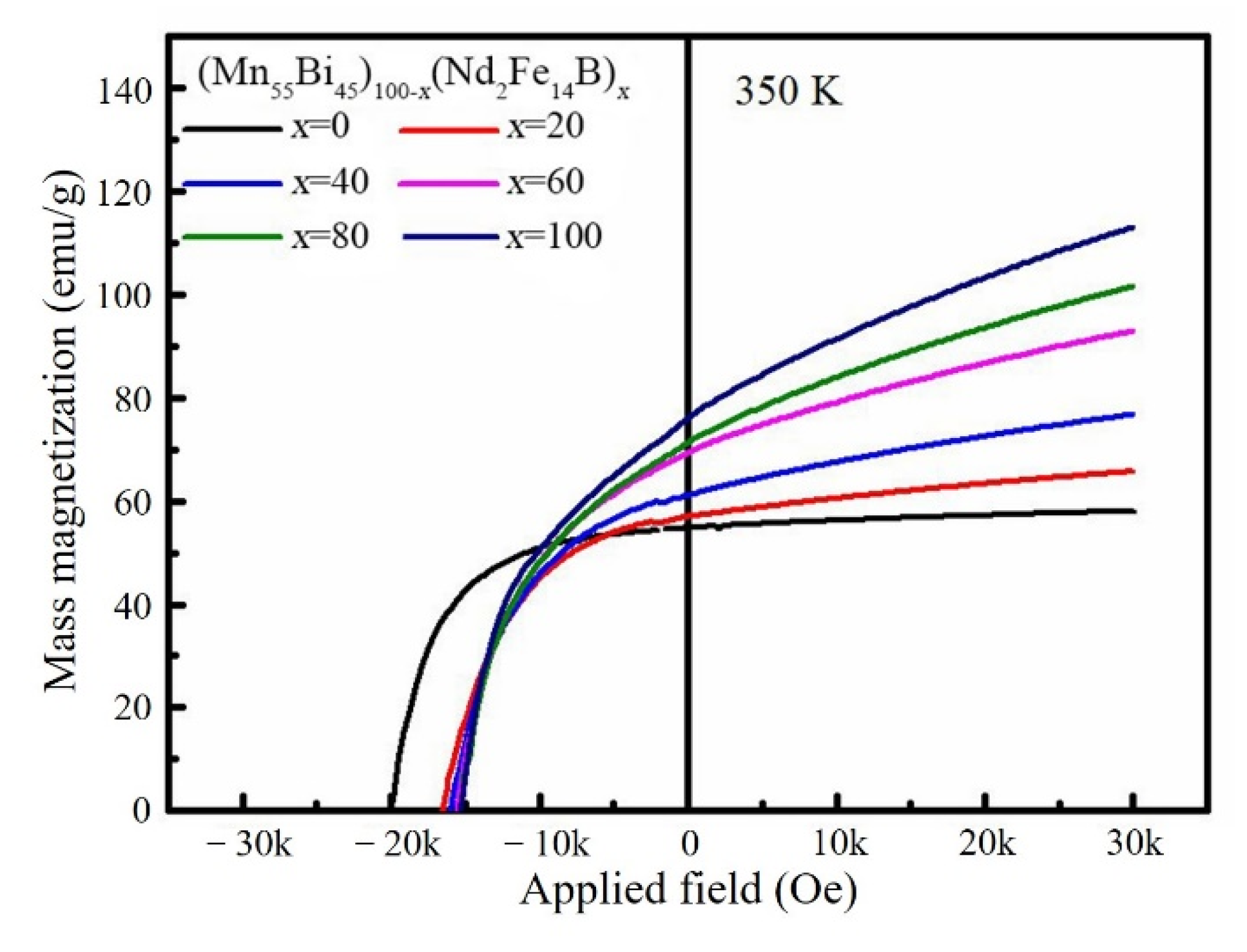

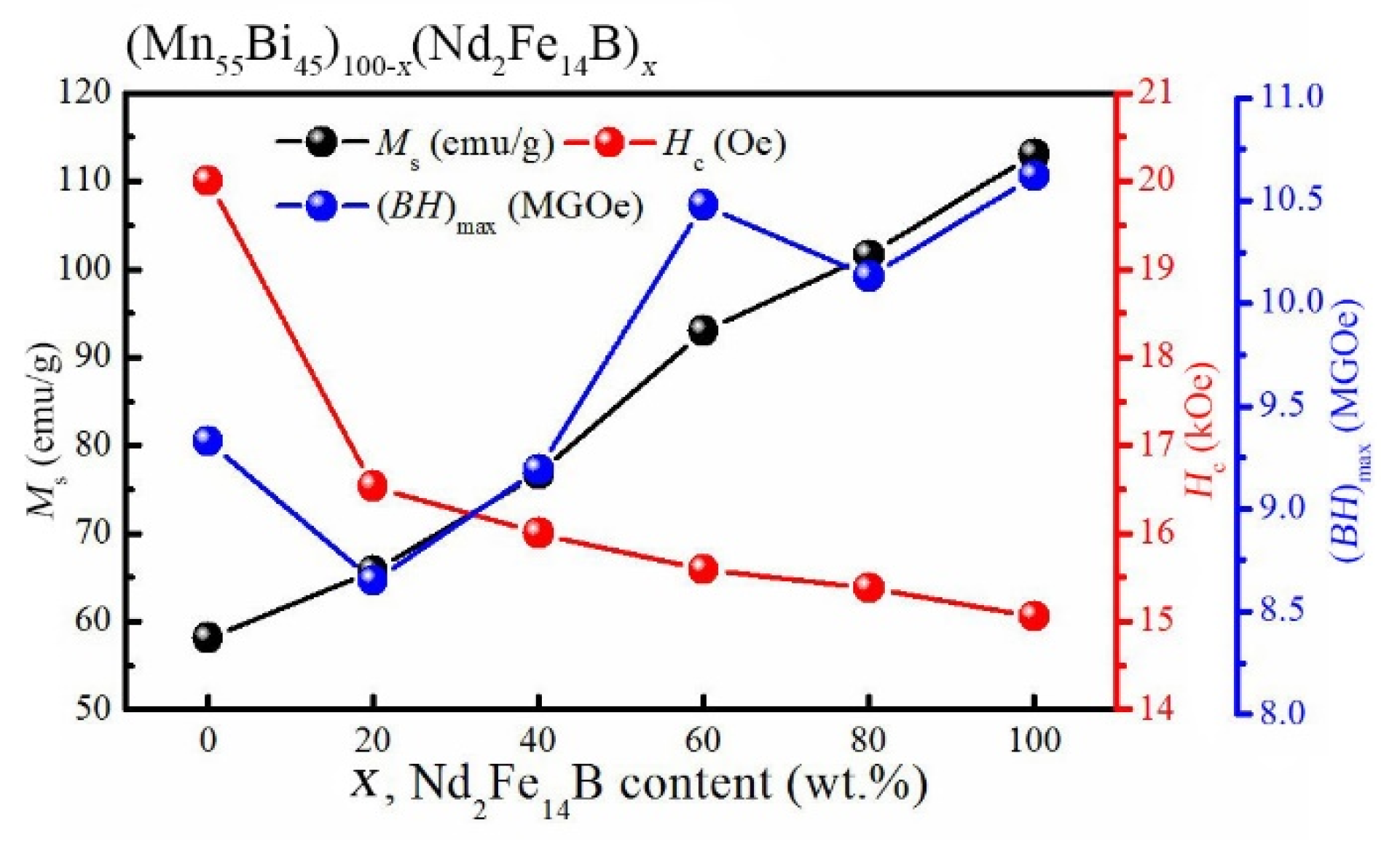

3.4. The High Temperature Magnetic Properties of Mn55Bi45/Nd2Fe14B Hybrid Magnetic Alloys

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Coey, J.M.D. Perspective and Prospects for Rare Earth Permanent Magnets. Engineering 2020, 6, 119–131. [Google Scholar] [CrossRef]

- McCallum, R.W.; Lewis, L.; Skomski, R.; Kramer, M.J.; Anderson, I.E. Practical Aspects of Modern and Future Permanent Magnets. Annu. Rev. Mater. Res. 2014, 44, 451–477. [Google Scholar] [CrossRef]

- Coey, J.M. New permanent magnets; manganese compounds. J. Phys. Condens. Matter. 2014, 26, 064211. [Google Scholar] [CrossRef] [PubMed]

- Sarkar, A.; Mallick, A.B. Synthesizing the Hard Magnetic Low-Temperature Phase of MnBi Alloy: Challenges and Prospects. Jom 2020, 72, 2812–2825. [Google Scholar] [CrossRef]

- Cui, J.; Kramer, M.; Zhou, L.; Liu, F.; Gabay, A.; Hadjipanayis, G.; Balasubramanian, B.; Sellmyer, D. Current progress and future challenges in rare-earth-free permanent magnets. Acta Mater. 2018, 158, 118–137. [Google Scholar] [CrossRef]

- Cui, J.; Choi, J.-P.; Polikarpov, E.; Bowden, M.E.; Xie, W.; Li, G.; Nie, Z.; Zarkevich, N.; Kramer, M.J.; Johnson, D. Effect of composition and heat treatment on MnBi magnetic materials. Acta Mater. 2014, 79, 374–381. [Google Scholar] [CrossRef]

- Park, J.; Hong, Y.-K.; Lee, J.; Lee, W.; Kim, S.-G.; Choi, C.-J. Electronic Structure and Maximum Energy Product of MnBi. Metals 2014, 4, 455–464. [Google Scholar] [CrossRef]

- Patel, K.; Zhang, J.; Ren, S. Rare-earth-free high energy product manganese-based magnetic materials. Nanoscale 2018, 10, 11701–11718. [Google Scholar] [CrossRef]

- Yang, J.; Yang, W.; Shao, Z.; Liang, D.; Zhao, H.; Xia, Y.; Yang, Y. Mn-based permanent magnets. Chin. Phys. B 2018, 27, 117503. [Google Scholar] [CrossRef]

- Yang, Y.; Park, J.; Lim, J.T.; Kim, J.-W.; Li, O.L.; Choi, C.-J. Effect of phase purity on enhancing the magnetic properties of Mn-Bi alloy. J. Magn. Magn. Mater. 2021, 517, 167344. [Google Scholar] [CrossRef]

- Xiang, Z.; Wang, T.; Ma, S.; Qian, L.; Luo, Z.; Song, Y.; Yang, H.; Lu, W. Microstructural evolution and phase transformation kinetics of MnBi alloys. J. Alloys Compd. 2018, 741, 951–956. [Google Scholar] [CrossRef]

- Cui, J.; Choi, J.P.; Li, G.; Polikarpov, E.; Darsell, J.; Overman, N.; Olszta, M.; Schreiber, D.; Bowden, M.; Droubay, T. Thermal stability of MnBi magnetic materials. J. Phys. Condens. Mat. 2014, 26, 064212. [Google Scholar] [CrossRef]

- Gabay, A.M.; Hadjipanayis, G.C.; Cui, J. Preparation of highly pure α-MnBi phase via melt-spinning. AIP Adv. 2018, 8, 056702. [Google Scholar] [CrossRef]

- Xiang, Z.; Song, Y.; Pan, D.; Shen, Y.; Qian, L.; Luo, Z.; Liu, Y.; Yang, H.; Yan, H.; Lu, W. Coercivity enhancement and magnetization process in Mn55Bi45 alloys with refined particle size. J. Alloys Compd. 2018, 744, 432–437. [Google Scholar] [CrossRef]

- Xiang, Z.; Xu, C.; Wang, T.; Song, Y.; Yang, H.; Lu, W. Enhanced magnetization and energy product in isotropic nanocrystalline Mn55Al45 alloys with boron doping. Intermetallics 2018, 101, 13–17. [Google Scholar] [CrossRef]

- Gabay, A.M.; Hadjipanayis, G.C.; Cui, J. New anisotropic MnBi permanent magnets by field-annealing of compacted melt-spun alloys modified with Mg and Sb. J. Magn.Magn. Mater. 2020, 495, 165860. [Google Scholar] [CrossRef]

- Xiang, Z.; Song, Y.; Deng, B.; Cui, E.; Yu, L.; Lu, W. Enhanced formation and improved thermal stability of ferromagnetic τ phase in nanocrystalline Mn55Al45 alloys by Co addition. J. Alloys Compd. 2019, 783, 416–422. [Google Scholar] [CrossRef]

- Yang, J.B.; Yang, Y.B.; Chen, X.G.; Ma, X.B.; Han, J.Z.; Yang, Y.C.; Guo, S.; Yan, A.R.; Huang, Q.Z.; Wu, M.M.; et al. Anisotropic nanocrystalline MnBi with high coercivity at high temperature. Appl. Phys. Lett. 2011, 99, 082505. [Google Scholar] [CrossRef]

- Yang, Y.; Kim, J.-W.; Si, P.-Z.; Qian, H.-D.; Shin, Y.; Wang, X.; Park, J.; Li, O.L.; Wu, Q.; Ge, H.; et al. Effects of Ga-doping on the microstructure and magnetic properties of MnBi alloys. J. Alloys Compd. 2018, 769, 813–816. [Google Scholar] [CrossRef]

- Bae, C.; Lee, G.; Kang, M.K.; Lee, H.; Moon, K.W.; Kim, J. Synthesis and Magnetic Properties of Sb added MnBi Magnets for Applications at Sub-zero Temperatures. J. Alloys Compd. 2021, 899, 163365. [Google Scholar] [CrossRef]

- Xu, X.; Hong, Y.-K.; Park, J.; Lee, W.; Lane, A.M.; Cui, J. Magnetic self-assembly for the synthesis of magnetically exchange coupled MnBi/Fe–Co composites. J. Solid. State. Chem. 2015, 231, 108–113. [Google Scholar] [CrossRef]

- Yang, Y.B.; Wei, J.Z.; Peng, X.L.; Xia, Y.H.; Chen, X.G.; Wu, R.; Du, H.L.; Han, J.Z.; Wang, C.S.; Yang, Y.C.; et al. Magnetic properties of the anisotropic MnBi/Sm2Fe17Nx hybrid magnet. J. Appl. Phys. 2014, 115, 17A721. [Google Scholar] [CrossRef]

- Akiya, T.; Kato, H.; Sagawa, M.; Koyama, K. Enhancement of coercivity in Al and Cu added Nd-Fe-B sintered magnets by high feld annealing. IOP Conf. Ser. Mater. Sci. Eng. 2009, 1, 012034. [Google Scholar] [CrossRef]

- Yang, J.B.; Yelon, W.B.; James, W.J.; Cai, Q.; Roy, S.; Ali, N. Structure and magnetic properties of the MnBi low temperature phase. J. Appl. Phys. 2002, 91, 7866–7868. [Google Scholar] [CrossRef]

- Yang, J.B.; Kamaraju, K.; Yelon, W.B.; James, W.J.; Cai, Q.; Bollero, A. Magnetic properties of the MnBi intermetallic compound. Appl. Phys. Lett. 2001, 79, 1846–1848. [Google Scholar] [CrossRef]

- Song, Y.; Xiang, Z.; Wang, T.; Niu, J.; Xia, K.; Lu, W.; Zhang, H.; Cao, Y.; Yoshimura, S.; Saito, H. High temperature exchange bias effect in melt-spun Mn55Bi45alloys. Appl. Phys. Lett. 2016, 109, 112402. [Google Scholar] [CrossRef]

| (Mn55Bi45)100−x/(Nd2Fe14B)x | Density (g/cm3) |

|---|---|

| x = 0 | 8.61 ± 0.02 |

| x = 20 | 8.45 ± 0.03 |

| x = 40 | 8.14 ± 0.02 |

| x = 60 | 7.96 ± 0.03 |

| x = 80 | 7.66 ± 0.04 |

| x = 100 | 7.45 ± 0.02 |

| (Mn55Bi45)100−x/(Nd2Fe14B)x | Ms (emu/g) | Hc (kOe) | (BH)max(MGOe) | Mr/Ms |

|---|---|---|---|---|

| x = 0 | 61.2 (4) | 12.5 (3) | 9.8 (2) | 0.98 |

| x = 20 | 67.6 (2) | 13.4 (2) | 9.1 (6) | 0.89 |

| x = 40 | 78.2 (1) | 14.8 (7) | 9.2 (1) | 0.80 |

| x = 60 | 93.8 (6) | 16.2 (4) | 10.7 (6) | 0.76 |

| x = 80 | 101.4 (5) | 18.1 (8) | 11.5 (1) | 0.71 |

| x = 100 | 120.9 (2) | 19.7 (2) | 13.0 (9) | 0.69 |

| (Mn55Bi45)100−x/(Nd2Fe14B)x | Ms(emu/g) | Hc(kOe) | (BH)max(MGOe) |

|---|---|---|---|

| x = 0 | 58.3 (8) | 20.1 (2) | 9.3 (5) |

| x = 20 | 66.2 (3) | 16.6 (1) | 8.5 (8) |

| x = 40 | 76.1 (6) | 16.0 (9) | 9.1 (8) |

| x = 60 | 92.9 (4) | 15.6 (4) | 10.4 (9) |

| x = 80 | 101.7 (2) | 15.4 (3) | 10.1 (3) |

| x = 100 | 113.6 (3) | 15.1 (1) | 10.6 (2) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, S.; Yang, Y.; Chen, L.; Xiang, Z.; Lu, W. Magnetic Properties of the Mn55Bi45/Nd2Fe14B Hybrid Magnetic Alloys. Metals 2022, 12, 1543. https://doi.org/10.3390/met12091543

Lu S, Yang Y, Chen L, Xiang Z, Lu W. Magnetic Properties of the Mn55Bi45/Nd2Fe14B Hybrid Magnetic Alloys. Metals. 2022; 12(9):1543. https://doi.org/10.3390/met12091543

Chicago/Turabian StyleLu, Shunda, Yang Yang, Linfeng Chen, Zhen Xiang, and Wei Lu. 2022. "Magnetic Properties of the Mn55Bi45/Nd2Fe14B Hybrid Magnetic Alloys" Metals 12, no. 9: 1543. https://doi.org/10.3390/met12091543

APA StyleLu, S., Yang, Y., Chen, L., Xiang, Z., & Lu, W. (2022). Magnetic Properties of the Mn55Bi45/Nd2Fe14B Hybrid Magnetic Alloys. Metals, 12(9), 1543. https://doi.org/10.3390/met12091543