Effects of Electroshock Treatment on Residual Stress and the Geometric Dimensions of Components Fabricated with Wire Arc Additive Manufacturing

Abstract

:1. Introduction

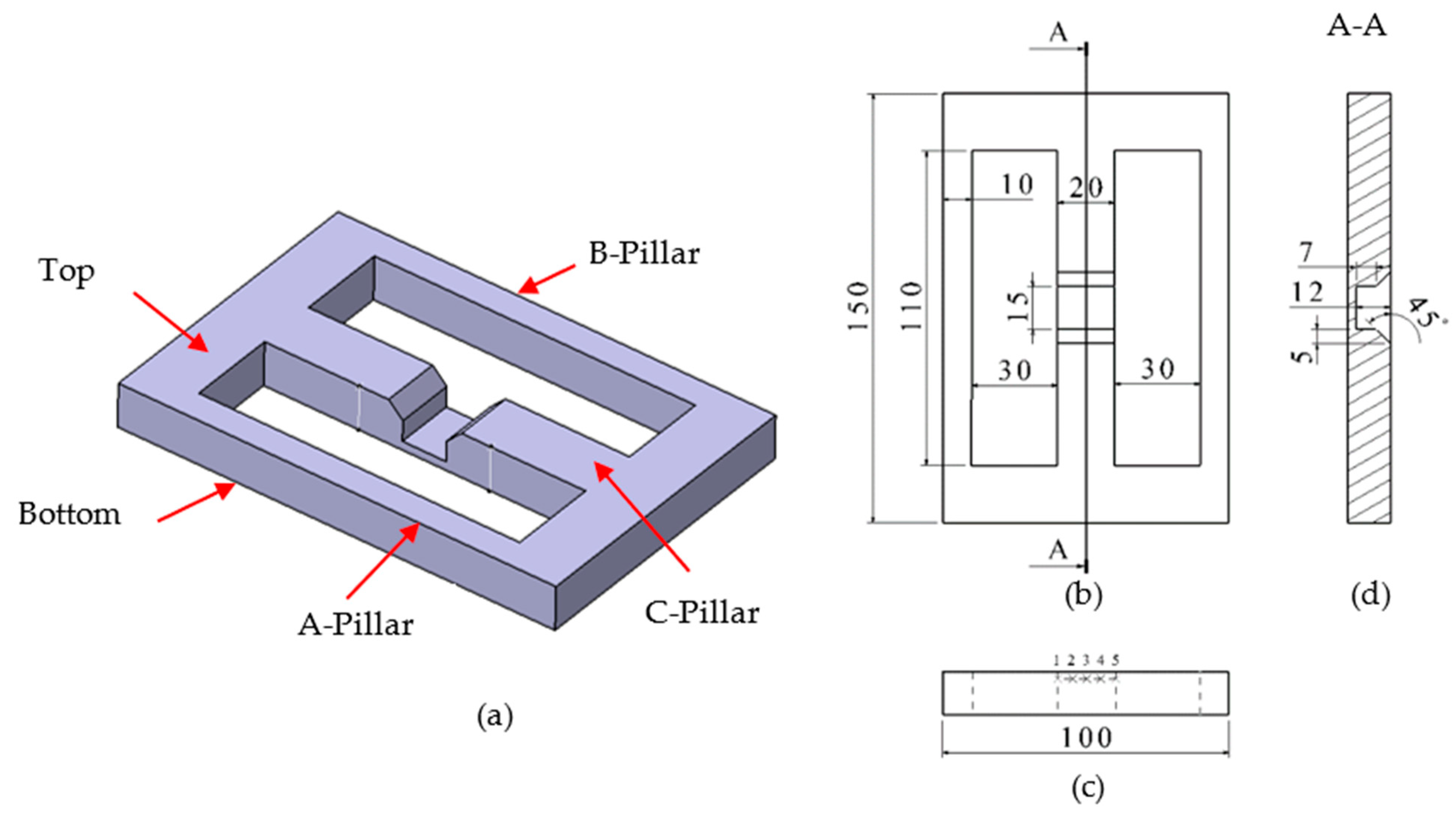

2. Experimental Details

2.1. Material and Wire Arc Additive Manufacturing Parameters

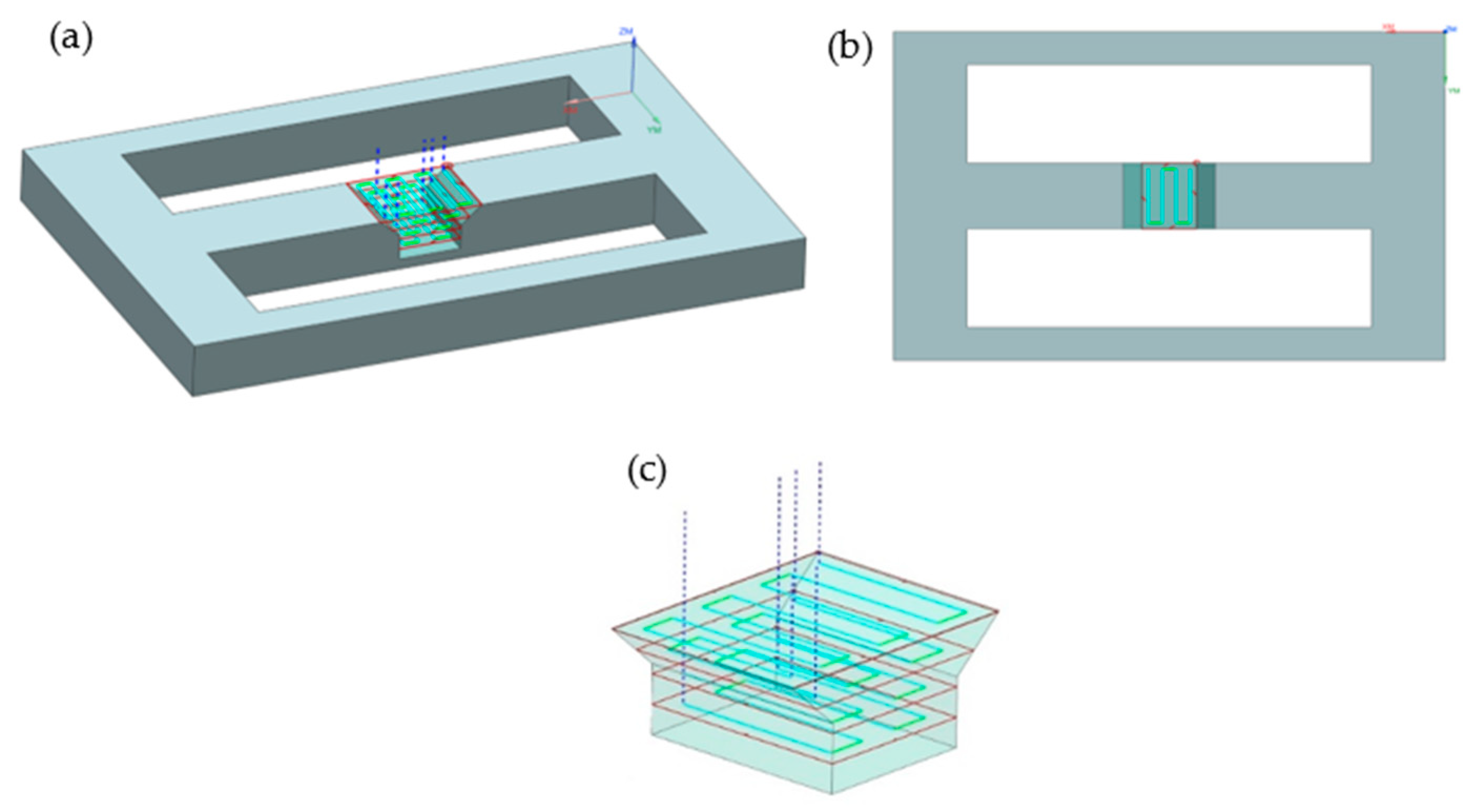

2.2. The Electroshock Treatment

2.3. Test Experiments

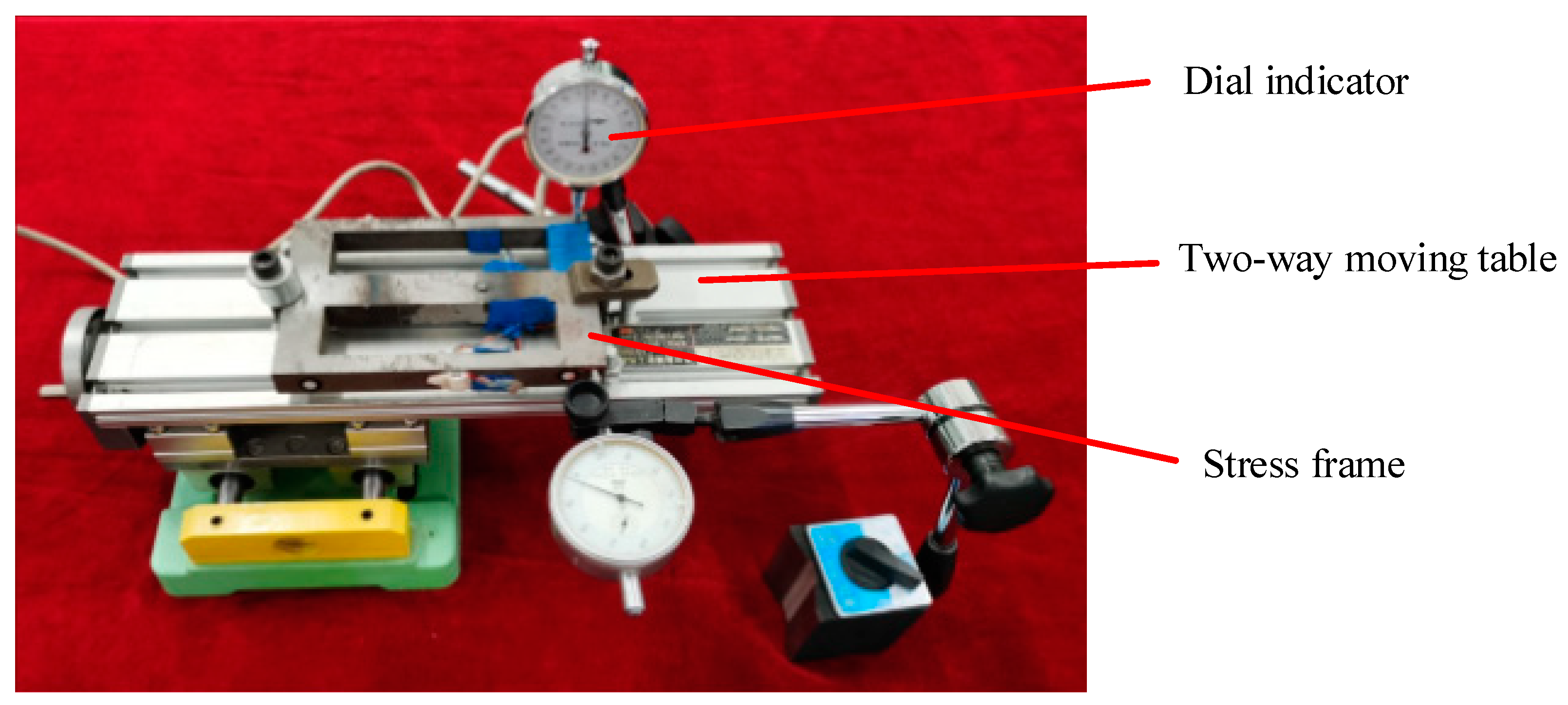

2.3.1. Measurement of Dimension

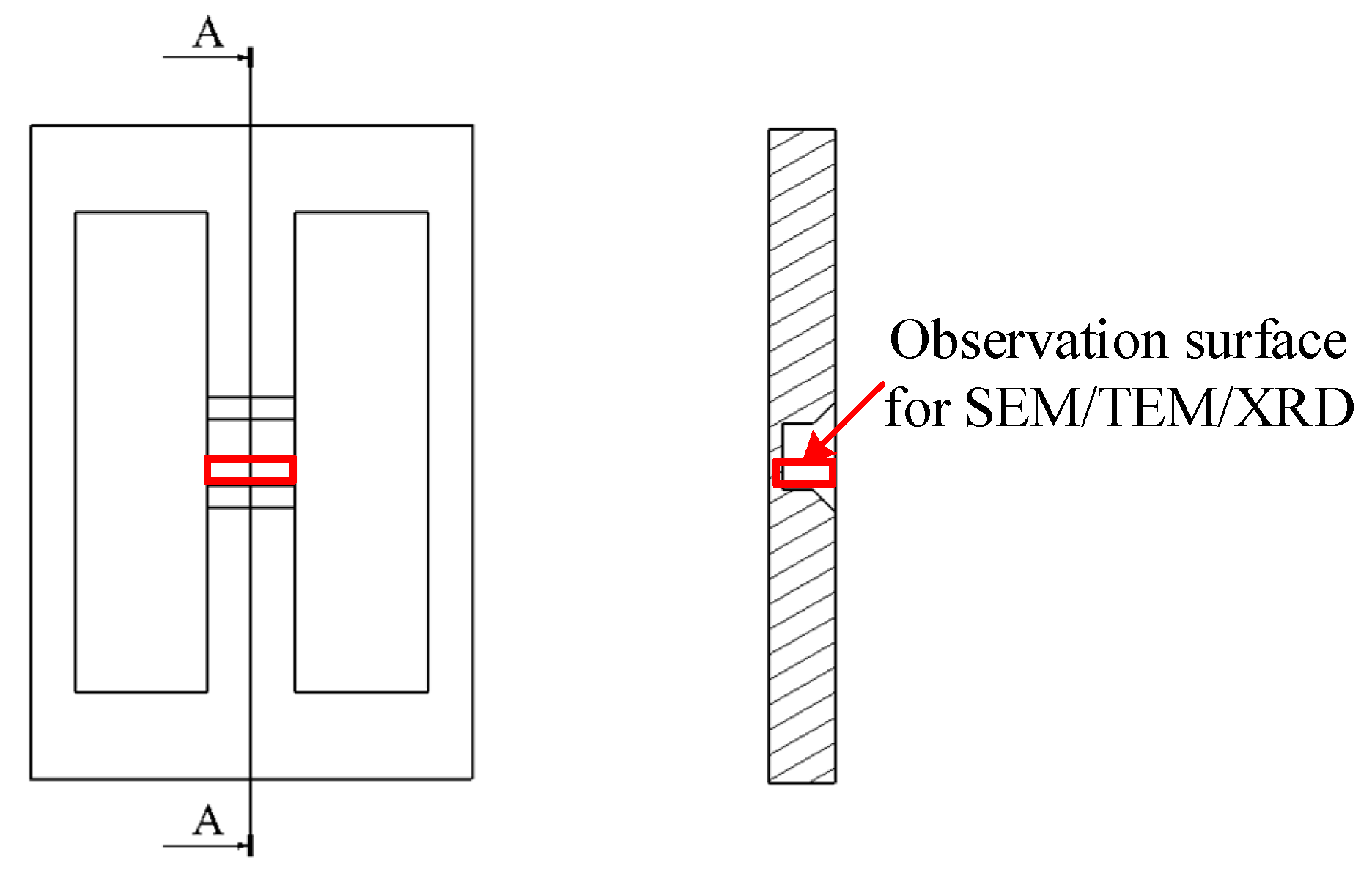

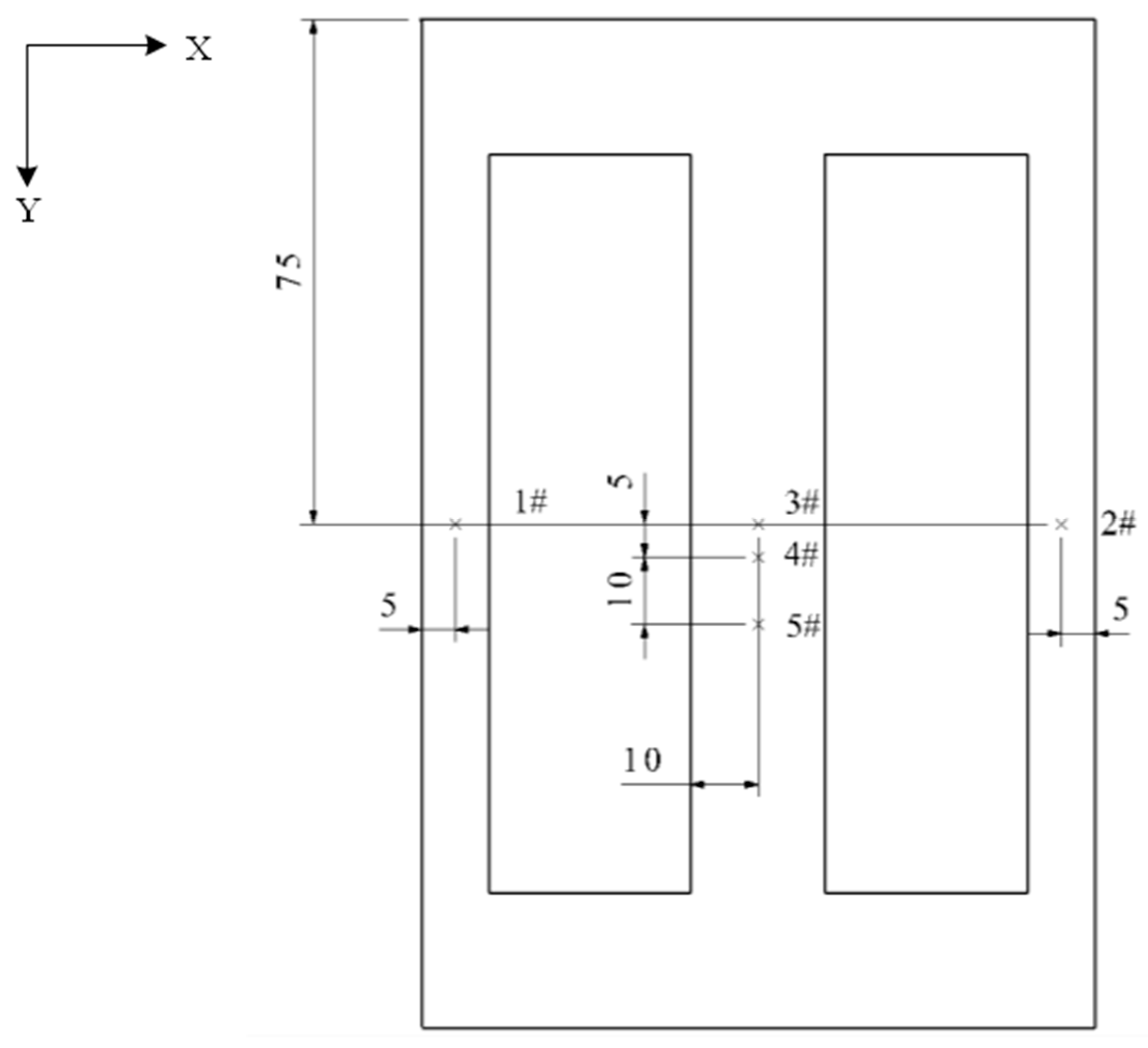

2.3.2. Characterization of Residual Stresses

2.3.3. Characterization of Microstructure

3. Results and Discussion

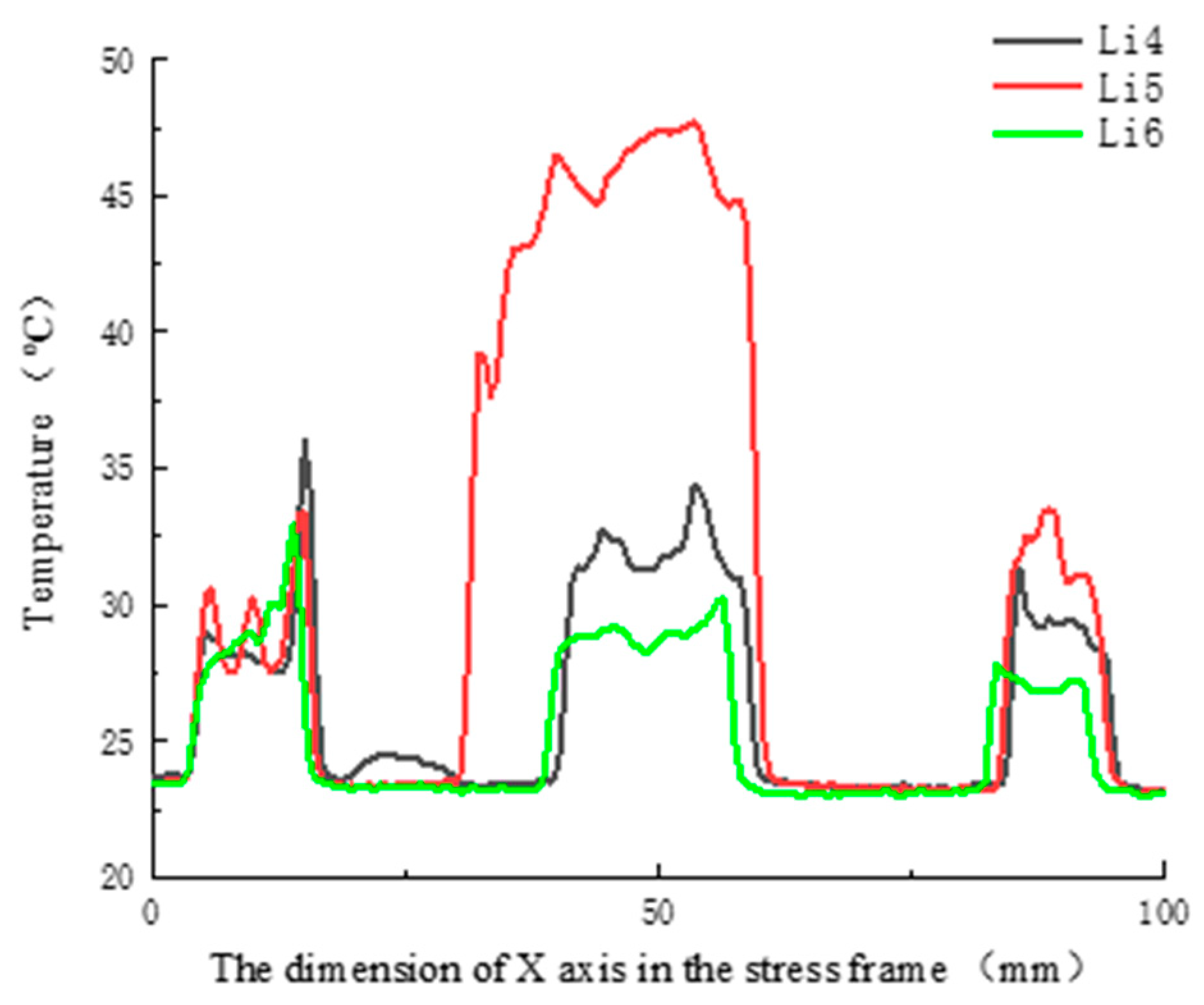

3.1. Effects of the Electroshock Temperature on the Geometric Dimensions

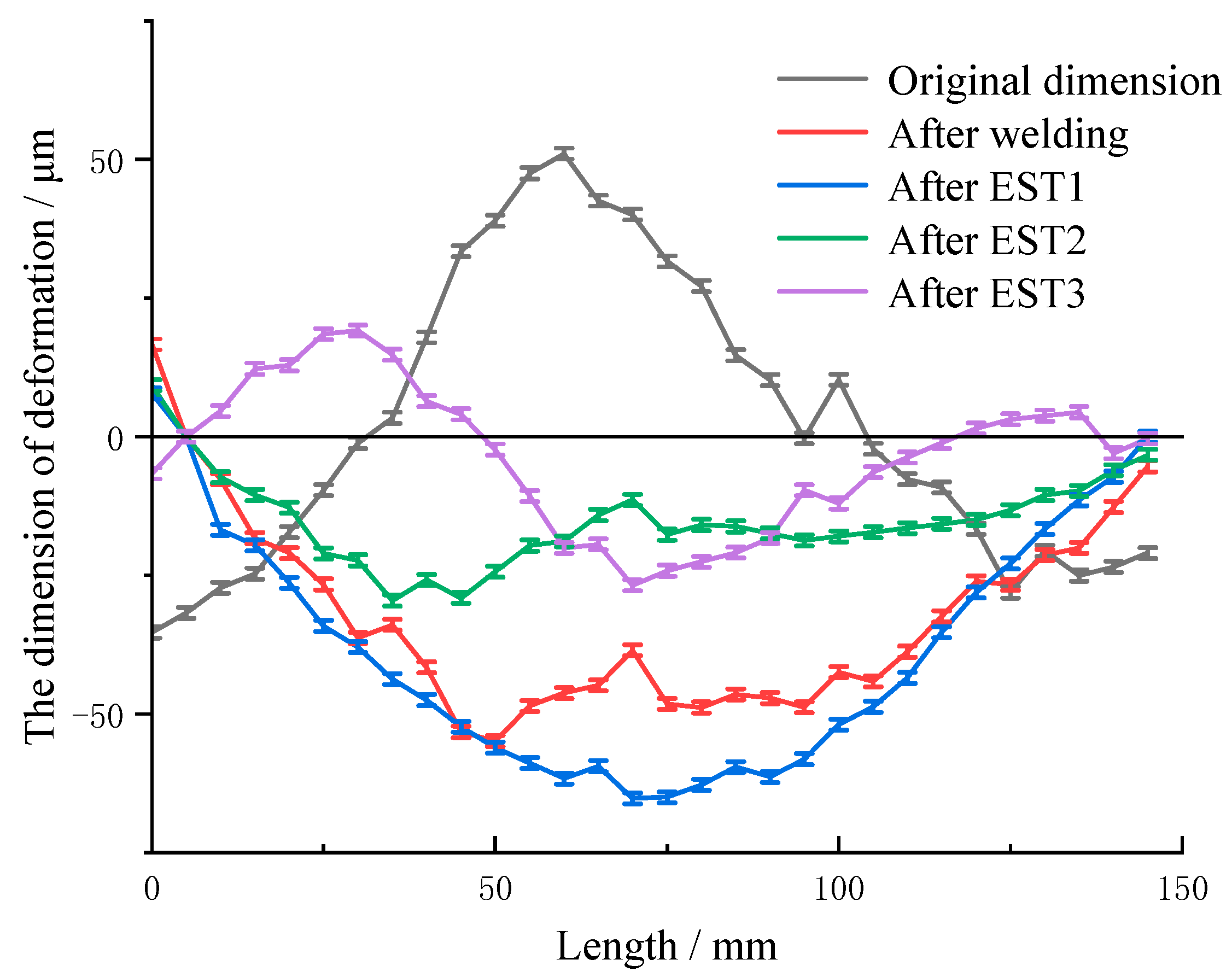

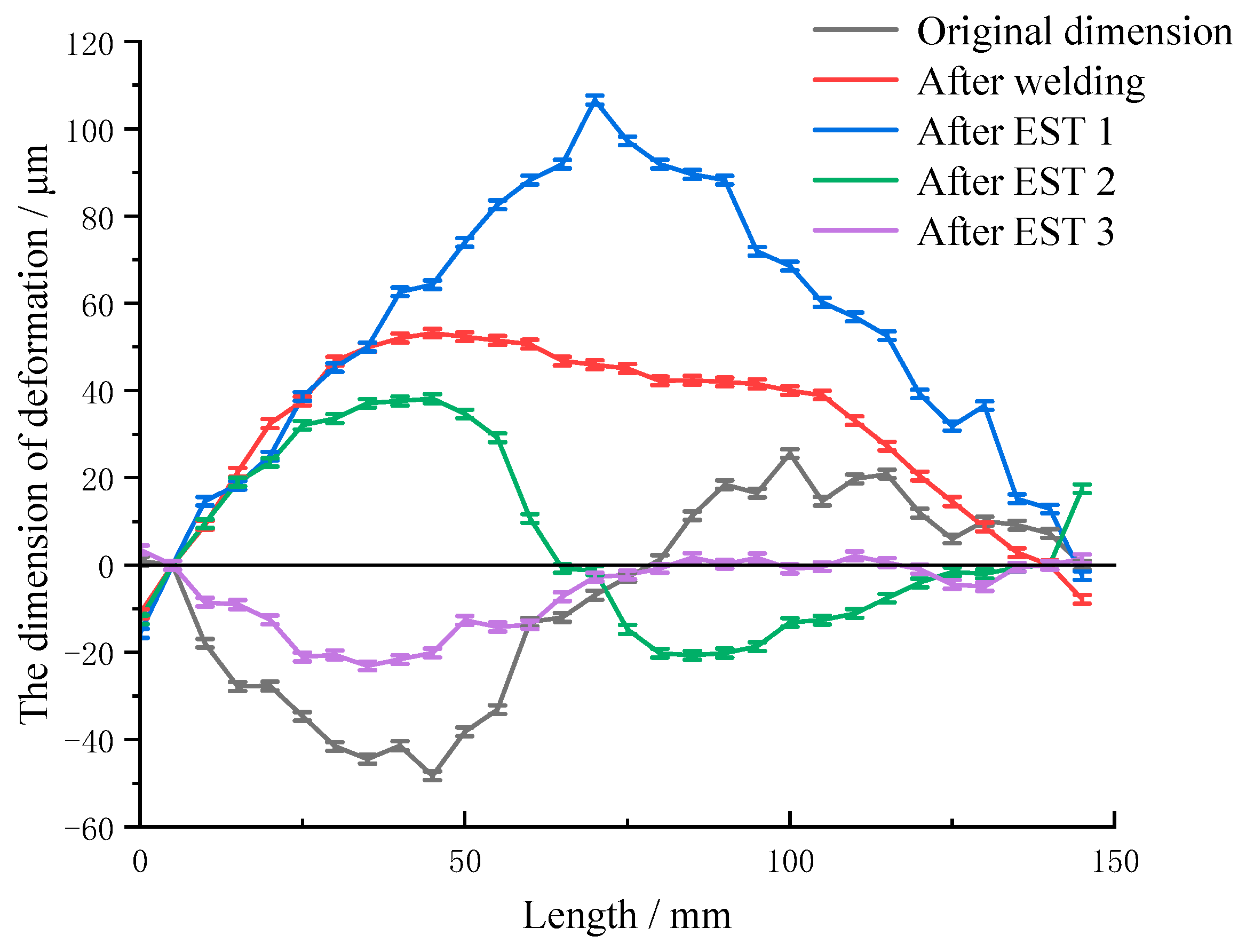

3.2. Geometric Dimension Analysis of the Stress Frame

3.3. Influence of Residual Stress on Geometrical Dimensions

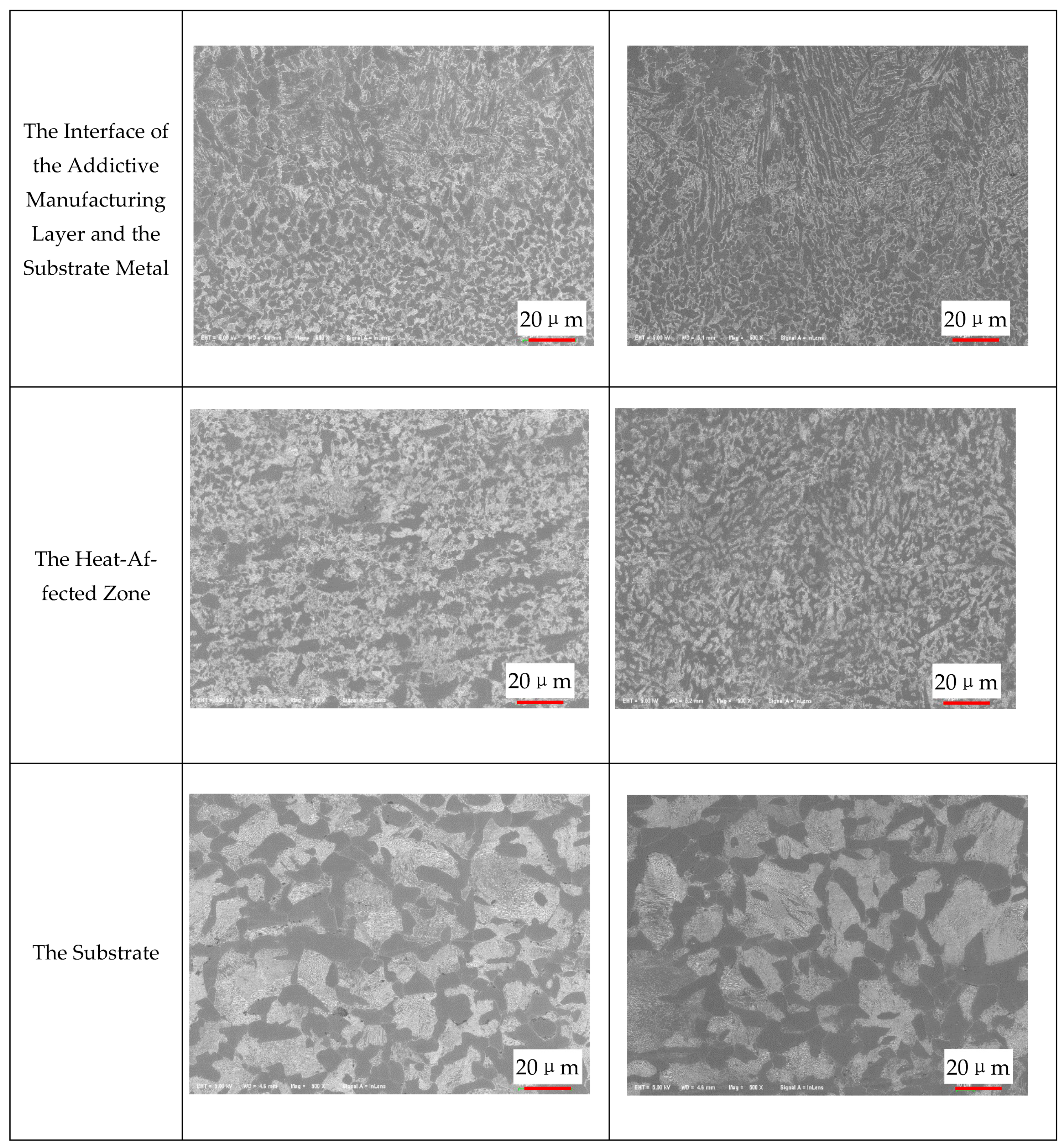

3.4. Effects of the Microstructure of EST on Geometric Dimensions

3.5. Effects of EST on Dislocations

4. Conclusions

- (1)

- After EST, the levelness of the stress frame was basically restored. The residual stress of the additively manufactured components was reduced by 127.6 MPa through EST. The geometric dimensions were ensured for the reduction in the residual stress.

- (2)

- According to SEM and TEM results, the dislocation density of the stress frame in the addictive manufacturing area was reduced, and the dislocation distribution was more homogeneous after EST. This was the reason for the decrease in residual stress and the improvement in the geometric dimensions. At the same time, the microstructure of the stress frame did not change.

- (3)

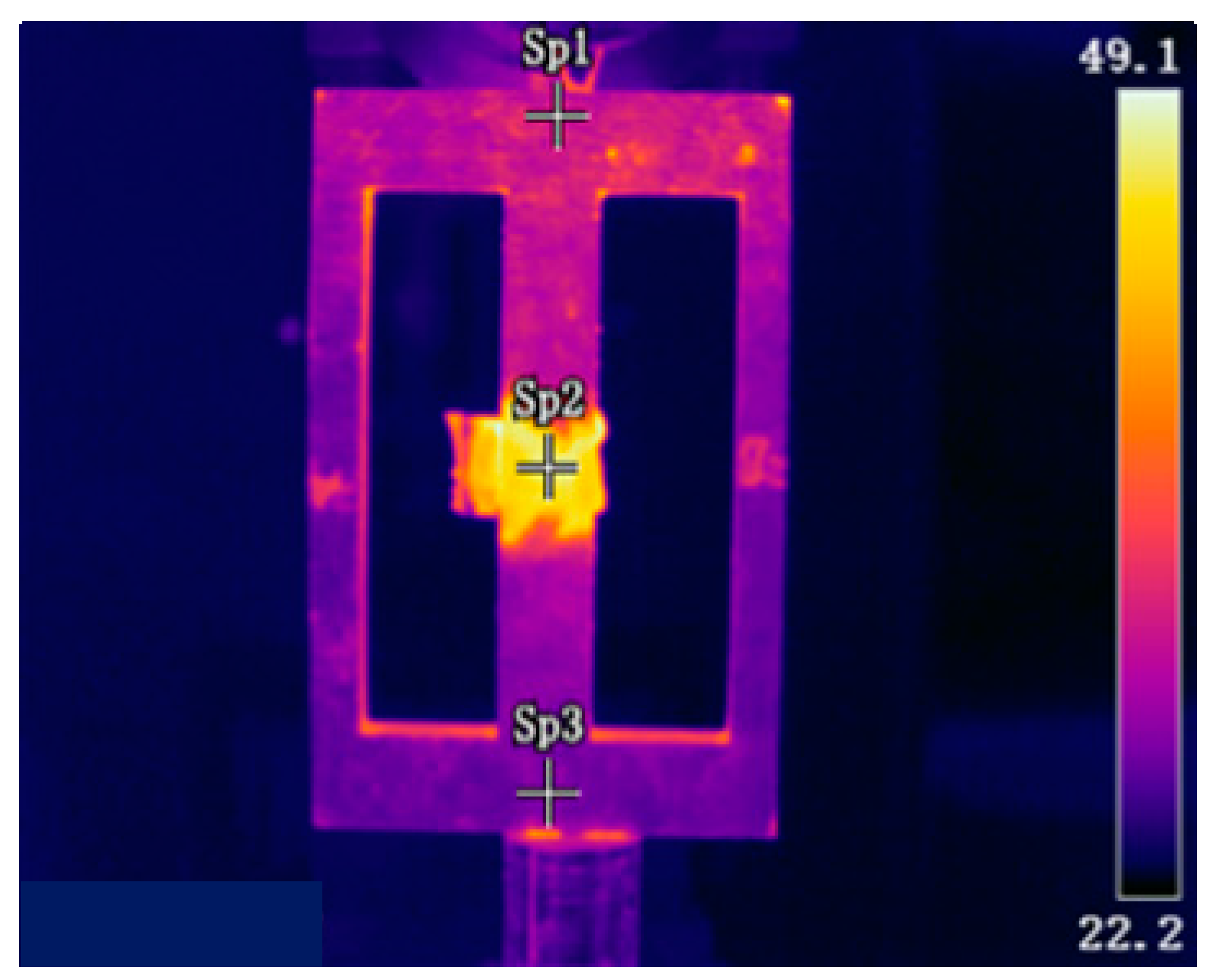

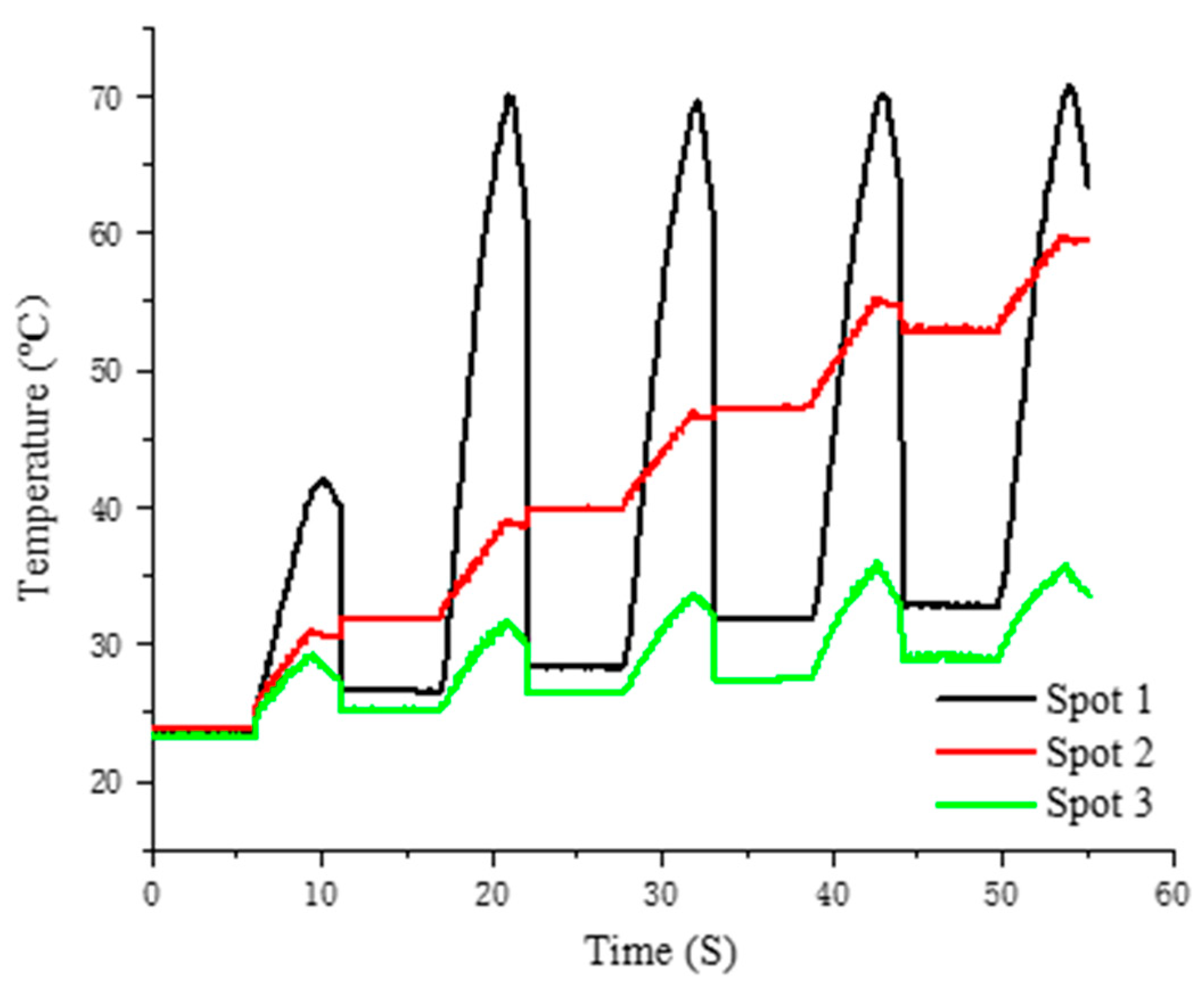

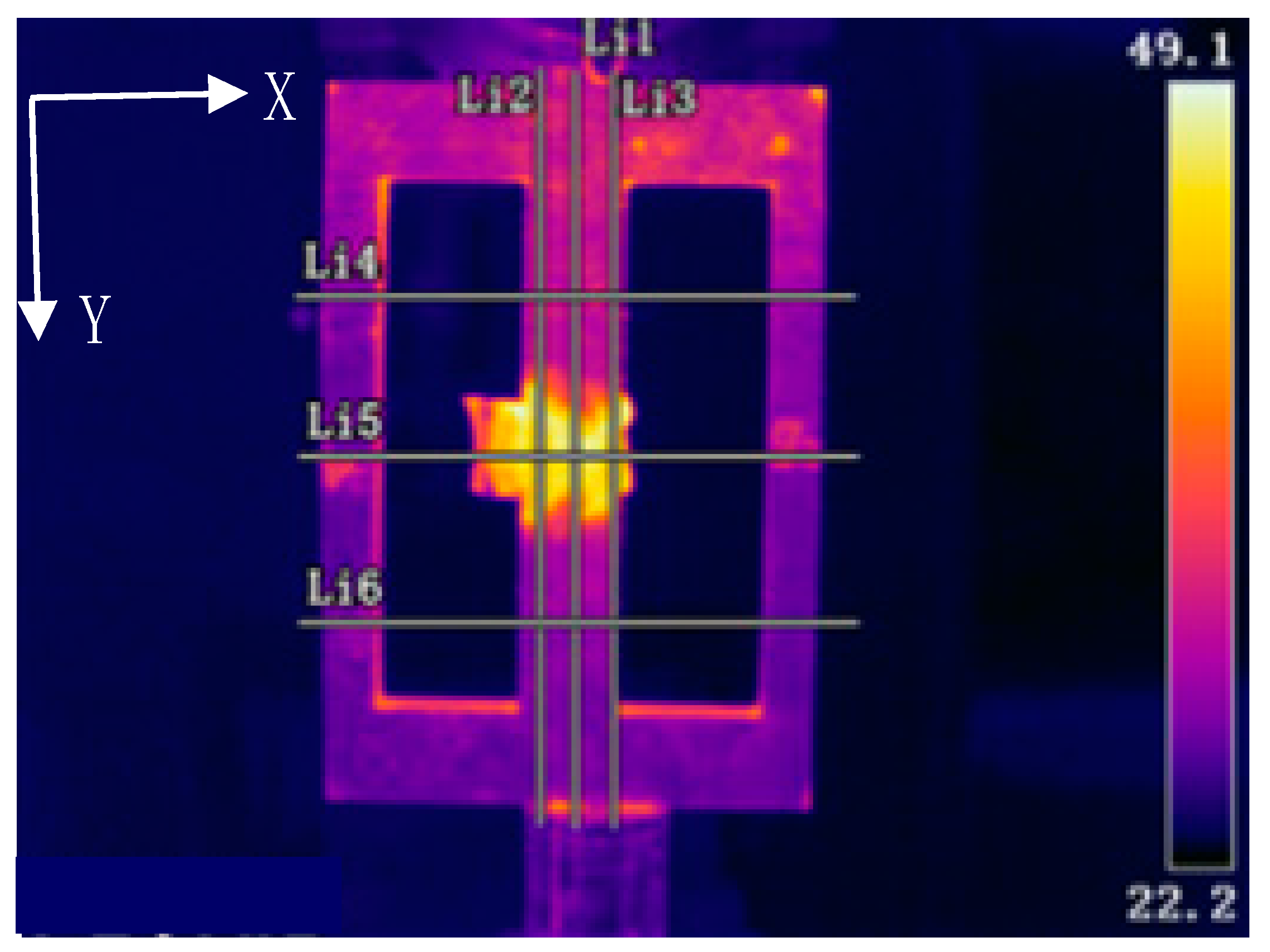

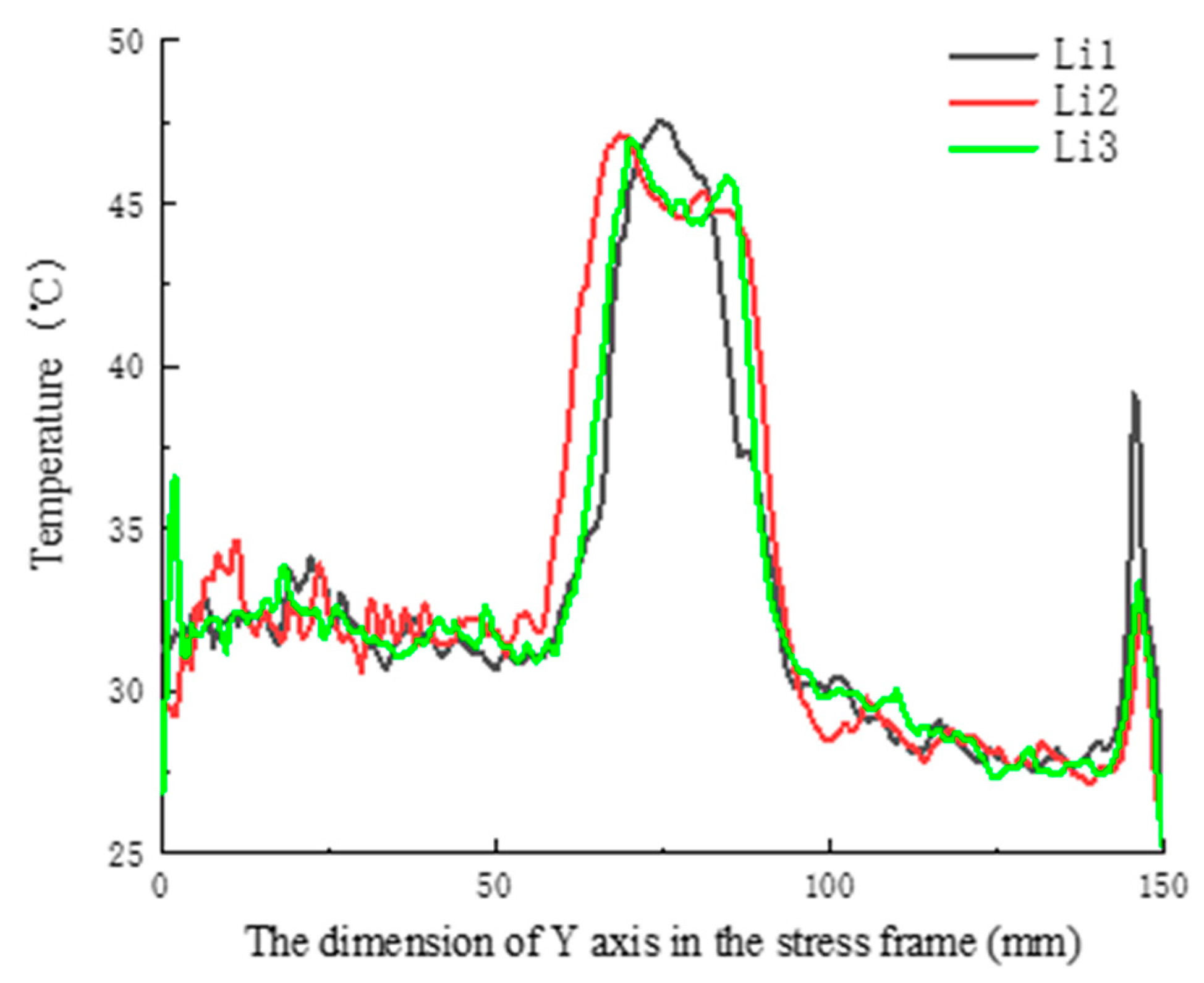

- When the additively manufactured stress frames samples were processed via EST, the temperature of the middle part of the C-pillar was the highest because the microstructure at this area forming during WAAM was different from the substrate, and the EST process further altered the interior structure. The temperature of the substrate in the C-pillar was lower. The substrate temperature decreased gradually under the electroshock pulse when moving from the positive to the negative electrode.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Klocke, F.; Arntz, K.; Teli, M.; Winands, K.; Wegener, M.; Oliari, S. State-of-the-art laser additive manufacturing for hot-work tool steels. Procedia CIRP 2017, 63, 58–63. [Google Scholar] [CrossRef]

- Murathan Kalender, Y.B.; Ersoy, S.; Salman, S. Additive manufacturing and 3d printer technology in aerospace industry. J. Aeronaut. Space Technol. 2020, 13, 10. [Google Scholar]

- Shen, X.; Gao, K.; Dong, S. Simulation and analysis of electron beam welding residual stress in thin-walled high-temperature alloy aeroengine structures. Int. J. Adv. Manuf. Technol. 2020, 107, 3953–3966. [Google Scholar] [CrossRef]

- AMondal, A.K.; Lohit, A.; Biswas, P.; Bag, S.; Das, M. Prediction of weld-induced distortion of large structure using equivalent load technique. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 232, 499–512. [Google Scholar] [CrossRef]

- Yilmaz, A.F.; Günay, M. Investigation of Mechanical strength and distortion in submerged arc welding of ah36 ship steel plate. J. Ship Prod. Des. 2017, 33, 335–341. [Google Scholar] [CrossRef]

- Rathinasuriyan, C.; Kumar, V.S.S. Experimental investigation of weld characteristics on submerged friction stir welded 6061-T6 aluminum alloy. J. Mech. Sci. Technol. 2017, 31, 3925–3933. [Google Scholar] [CrossRef]

- Akhtar, N.; Afzal, M.; Khan, M.A.; Hussain, M.; Ali, M.N. Assessment of cold deformation effects on yield-to-tensile ratio and dimensional stability of an aluminium alloy extruded tube. In Proceedings of the 2017 14th International Bhurban Conference on Applied Sciences & Technology (IBCAST), Islamabad, Pakistan, 10–14 January 2017; pp. 29–33. [Google Scholar]

- Song, Y.; Ding, X.; Xiao, L.; Zhao, X.; Cai, Z.; Guo, L.; Li, Y.; Zheng, Z. Effects of two-stage aging on the dimensional stability of Al-Cu-Mg alloy. J. Alloys Compd. 2017, 701, 508–514. [Google Scholar] [CrossRef]

- Tu, X.; Xiao, L.; Zhao, X.; Cai, Z.; Peng, Z.; Wei, D. Effects of thermal-cold cycling on the dimensional stability of TiC reinforced steel matrix composite. Mater. Lett. 2020, 279, 128483. [Google Scholar] [CrossRef]

- Singla, A.K.; Singh, J.; Sharma, V.S. Processing of materials at cryogenic temperature and its implications in manufacturing: A review. Mater. Manuf. Process. 2018, 33, 1603–1640. [Google Scholar] [CrossRef]

- Guo, H.; Zeng, X.; Fan, J.; Zhang, H.; Zhang, Q.; Li, W.; Dong, H.; Xu, B. Effect of electropulsing treatment on static recrystallization behavior of cold-rolled magnesium alloy ZK60 with different reductions. J. Mater. Sci. Technol. 2019, 35, 1113–1120. [Google Scholar] [CrossRef]

- Räbiger, D.; Zhang, Y.; Galindo, V.; Franke, S.; Willers, B.; Eckert, S. The relevance of melt convection to grain refinement in Al–Si alloys solidified under the impact of electric currents. Acta Mater. 2014, 79, 327–338. [Google Scholar] [CrossRef]

- Yiu, P.; Chen, Y.; Chu, J.; Chang, S.; Bei, H.; Jang, J.; Hsueh, C. Rapid relaxation and embrittlement of Zr-based bulk metallic glasses by electropulsing. Intermetallics 2013, 34, 43–48. [Google Scholar] [CrossRef]

- Kim, M.-J.; Lee, K.; Oh, K.H.; Choi, I.-S.; Yu, H.-H.; Hong, S.-T.; Han, H.N. Electric current-induced annealing during uniaxial tension of aluminum alloy. Scr. Mater. 2014, 75, 58–61. [Google Scholar] [CrossRef]

- Pan, L.; Wang, B.; Xu, Z. Effects of electropulsing treatment on residual stresses of high elastic cobalt-base alloy ISO 5832-7. J. Alloys Compd. 2019, 792, 994–999. [Google Scholar] [CrossRef]

- Pan, L.; He, W.; Gu, B. Effects of electric current pulses on mechanical properties and microstructures of as-quenched medium carbon steel. Mater. Sci. Eng. A 2016, 662, 404–411. [Google Scholar] [CrossRef]

- Xiang, S.; Zhang, X. Dislocation structure evolution under electroplastic effect. Mater. Sci. Eng. A 2019, 761, 138026. [Google Scholar] [CrossRef]

- Wang, F.; Qian, D.; Hua, L.; Mao, H.; Xie, L. Voids healing and carbide refinement of cold rolled M50 bearing steel by electropulsing treatment. Sci. Rep. 2019, 9, 11315. [Google Scholar] [CrossRef]

- Yang, C.L.; Yang, H.J.; Zhang, Z.J.; Zhang, Z.F. Recovery of tensile properties of twinning-induced plasticity steel via electropulsing induced void healing. Scr. Mater. 2018, 147, 88–92. [Google Scholar] [CrossRef]

- Song, X.; Wang, F.; Qian, D.; Hua, L. Tailoring the residual stress and mechanical properties by electroshocking treatment in cold rolled M50 steel. Mater. Sci. Eng. A 2020, 780, 139171. [Google Scholar] [CrossRef]

- Xie, L.; Liu, C.; Song, Y.; Guo, H.; Wang, Z.; Hua, L.; Wang, L.; Zhang, L.-C. Evaluation of microstructure variation of TC11 alloy after electroshocking treatment. J. Mater. Res. Technol. 2020, 9, 2455–2466. [Google Scholar] [CrossRef]

- Xie, L.; Guo, H.; Song, Y.; Liu, C.; Wang, Z.; Hua, L.; Wang, L.; Zhang, L.-C. Effects of electroshock treatment on microstructure evolution and texture distribution of near-β titanium alloy manufactured by directed energy deposition. Mater. Charact. 2020, 161, 110137. [Google Scholar] [CrossRef]

- Jung, J.; Ju, Y.; Morita, Y.; Toku, Y. Enhancement of fatigue life of aluminum alloy affected by the density of pulsed electric current. Int. J. Fatigue 2017, 103, 419–425. [Google Scholar] [CrossRef]

- Liang, C.-L.; Lin, K.-L. The microstructure and property variations of metals induced by electric current treatment: A review. Mater. Charact. 2018, 145, 545–555. [Google Scholar] [CrossRef]

- Balc, N.; Strnad, G.; Cazacu, R.; Chetan, P.; Gaz Florea, A.S.; Peti, F. Effect of phosphate/fluoride electrolytes on mass and dimensional stability of anodization bath manufactured by FDM. MATEC Web Conf. 2017, 137, 02012. [Google Scholar]

- Kocks, U.F. Laws for work-hardening and low-temperature creep. J. Eng. Mater. Technol. 1976, 98, 76–85. [Google Scholar] [CrossRef]

- Mecking, H.; Kocks, U.F. Kinetics of flow and strain-hardening. Acta Metall. 1981, 29, 1865–1875. [Google Scholar] [CrossRef]

- Williamson, G.K.; Hall, W.H. X-ray line broadening from filed aluminium and wolfram. Acta Metall. 1953, 1, 22–31. [Google Scholar] [CrossRef]

| C | Si | Mn | S | P |

|---|---|---|---|---|

| 0.42–0.50 | 0.17–0.37 | 0.50–0.80 | ≤0.035 | ≤0.035 |

| C | Mn | Si | Ni | Cr |

|---|---|---|---|---|

| 0.06–0.15 | 1.40–1.85 | 0.08-1.85 | ≤0.15 | ≤0.15 |

| Group Number | EST Number | Treatment Position | Current Intensity/A |

|---|---|---|---|

| 1 | 1 | 1 | 70 |

| 2 | 2 | 70 | |

| 3 | 3 | 70 | |

| 4 | 4 | 70 | |

| 5 | 5 | 70 | |

| 2 | 6 | 1 | 90 |

| 7 | 2 | 90 | |

| 8 | 3 | 90 | |

| 9 | 4 | 90 | |

| 10 | 5 | 90 | |

| 3 | 11 | 1 | 110 |

| 12 | 2 | 110 | |

| 13 | 3 | 110 | |

| 14 | 4 | 110 | |

| 15 | 5 | 110 |

| Number of Test Point | After EDM Cutting /MPa | After Additive Manufacturing /MPa | After Electroshock Treatment/MPa |

|---|---|---|---|

| 1# | 218 | 186 | 76 |

| 2# | 23 | −137 | −14 |

| 3# | 234 | 303 | 165 |

| 4# | 180 | 228 | 72 |

| 5# | 171 | 203 | 102 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, M.; Hu, Z.; Qin, X. Effects of Electroshock Treatment on Residual Stress and the Geometric Dimensions of Components Fabricated with Wire Arc Additive Manufacturing. Metals 2022, 12, 1434. https://doi.org/10.3390/met12091434

Wu M, Hu Z, Qin X. Effects of Electroshock Treatment on Residual Stress and the Geometric Dimensions of Components Fabricated with Wire Arc Additive Manufacturing. Metals. 2022; 12(9):1434. https://doi.org/10.3390/met12091434

Chicago/Turabian StyleWu, Min, Zeqi Hu, and Xunpeng Qin. 2022. "Effects of Electroshock Treatment on Residual Stress and the Geometric Dimensions of Components Fabricated with Wire Arc Additive Manufacturing" Metals 12, no. 9: 1434. https://doi.org/10.3390/met12091434

APA StyleWu, M., Hu, Z., & Qin, X. (2022). Effects of Electroshock Treatment on Residual Stress and the Geometric Dimensions of Components Fabricated with Wire Arc Additive Manufacturing. Metals, 12(9), 1434. https://doi.org/10.3390/met12091434