Environmentally Friendly Recovery of Lithium from Lithium–Sulfur Batteries

Abstract

:1. Introduction

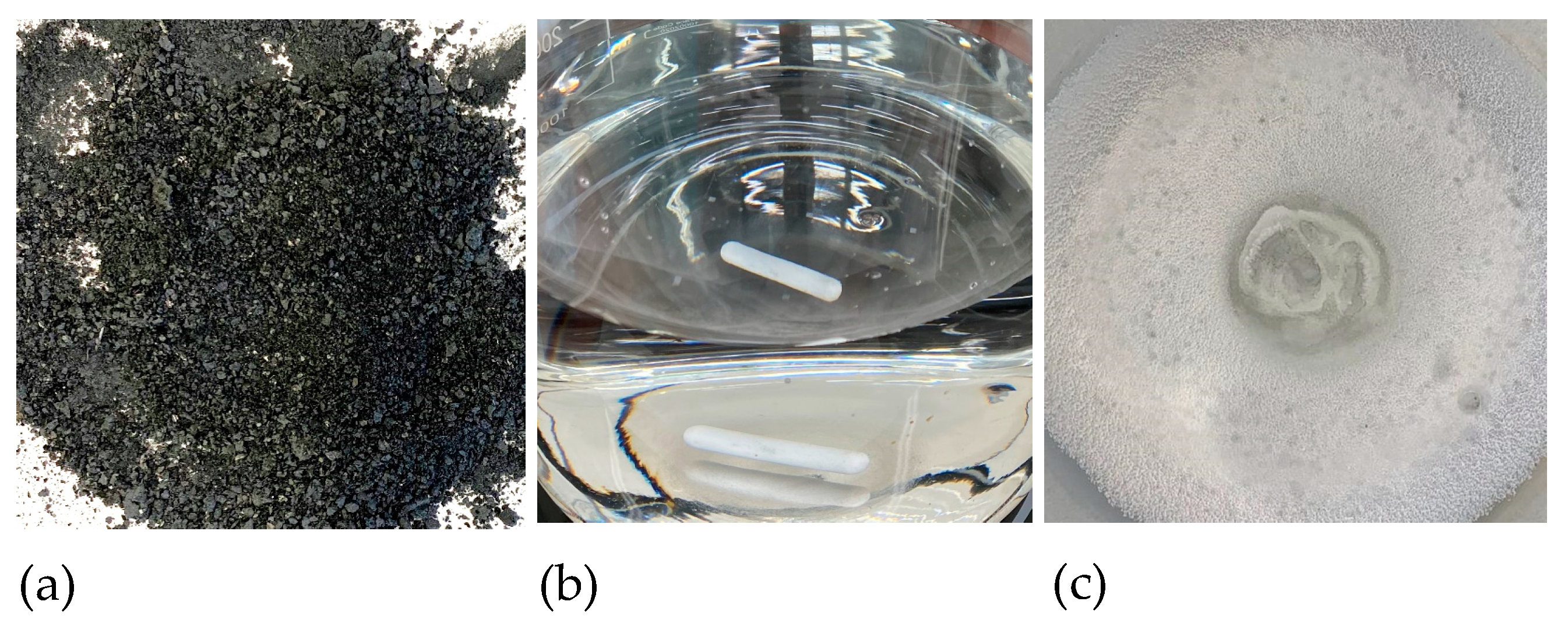

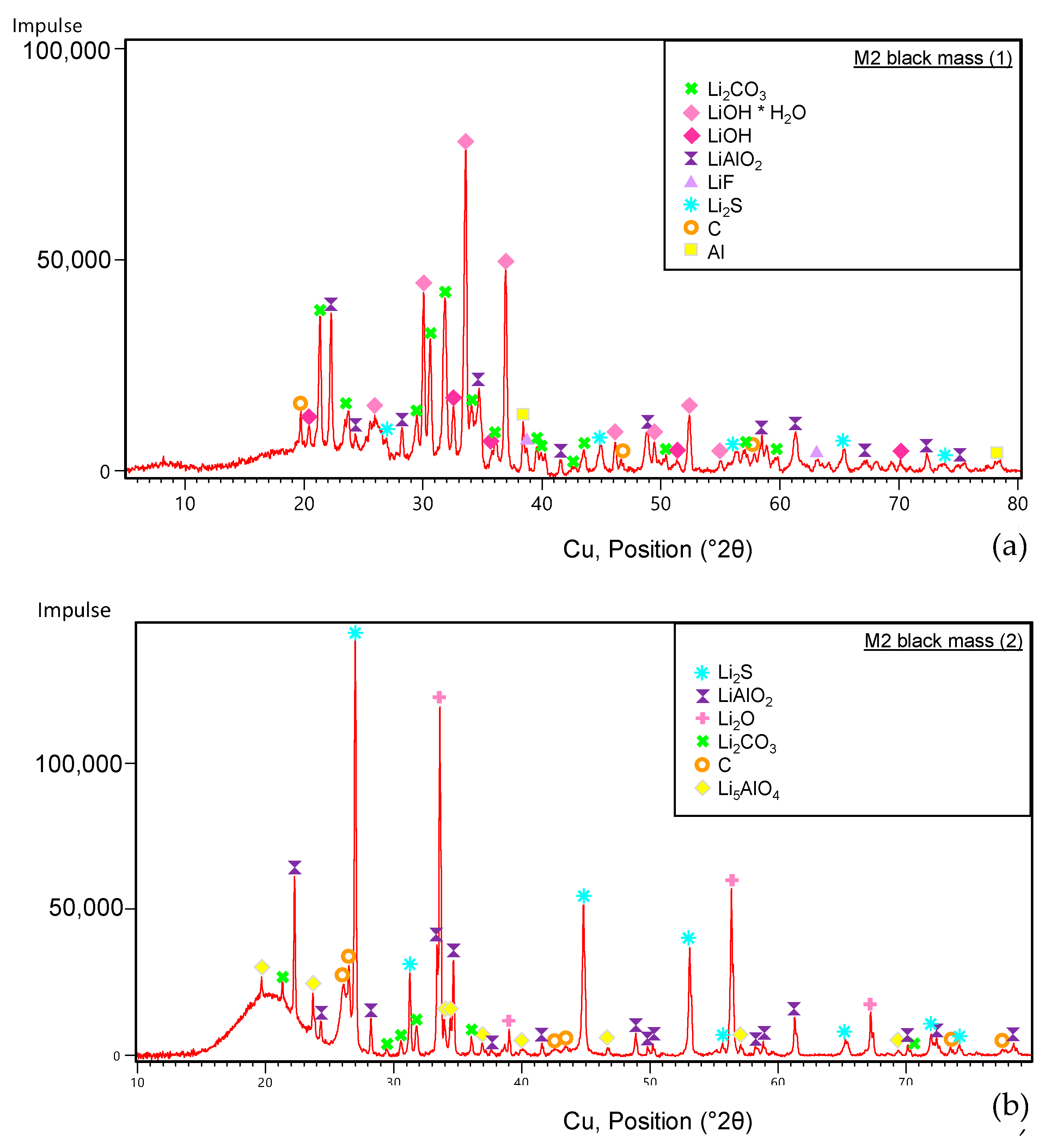

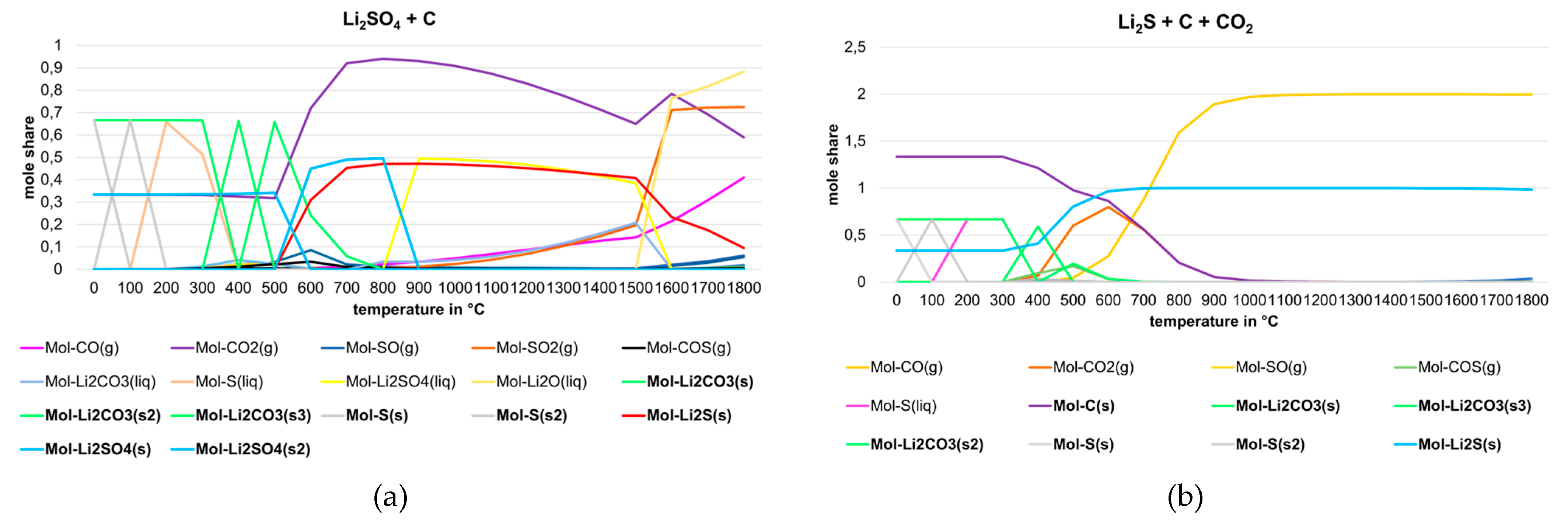

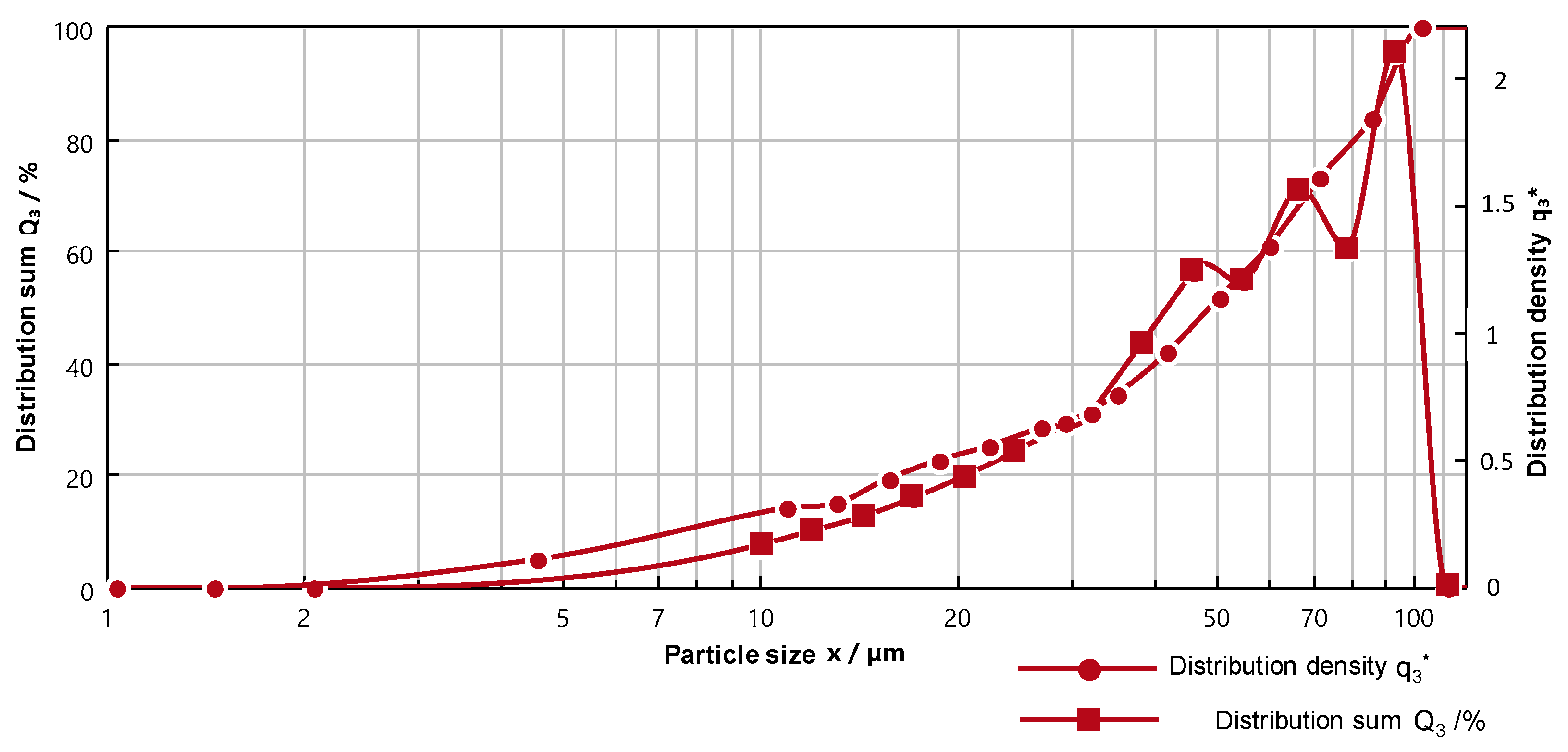

2. Materials and Methods

2.1. Recycling Concept with Thermal Pre-Treatment and Early Stage Li-Recovery (ESLR)

2.2. Material Characterization and Lithium Yield Calculation

3. Results

4. Conclusions

- This is also promoted by the use of metallic lithium in LiS-cells. Li does not have to be liberated from the transition metal oxides in the cathode material in LiBs by means of thermal decomposition. This is in accordance with an increased lithium yield because there are fewer insoluble phases in the thermally treated black mass, which is further exemplified in comparison to [20].

- In addition, there is an increased lithium concentration in LiS cells, which eases the Li-recovery by high yields during recycling, providing an interesting comparison with [20].

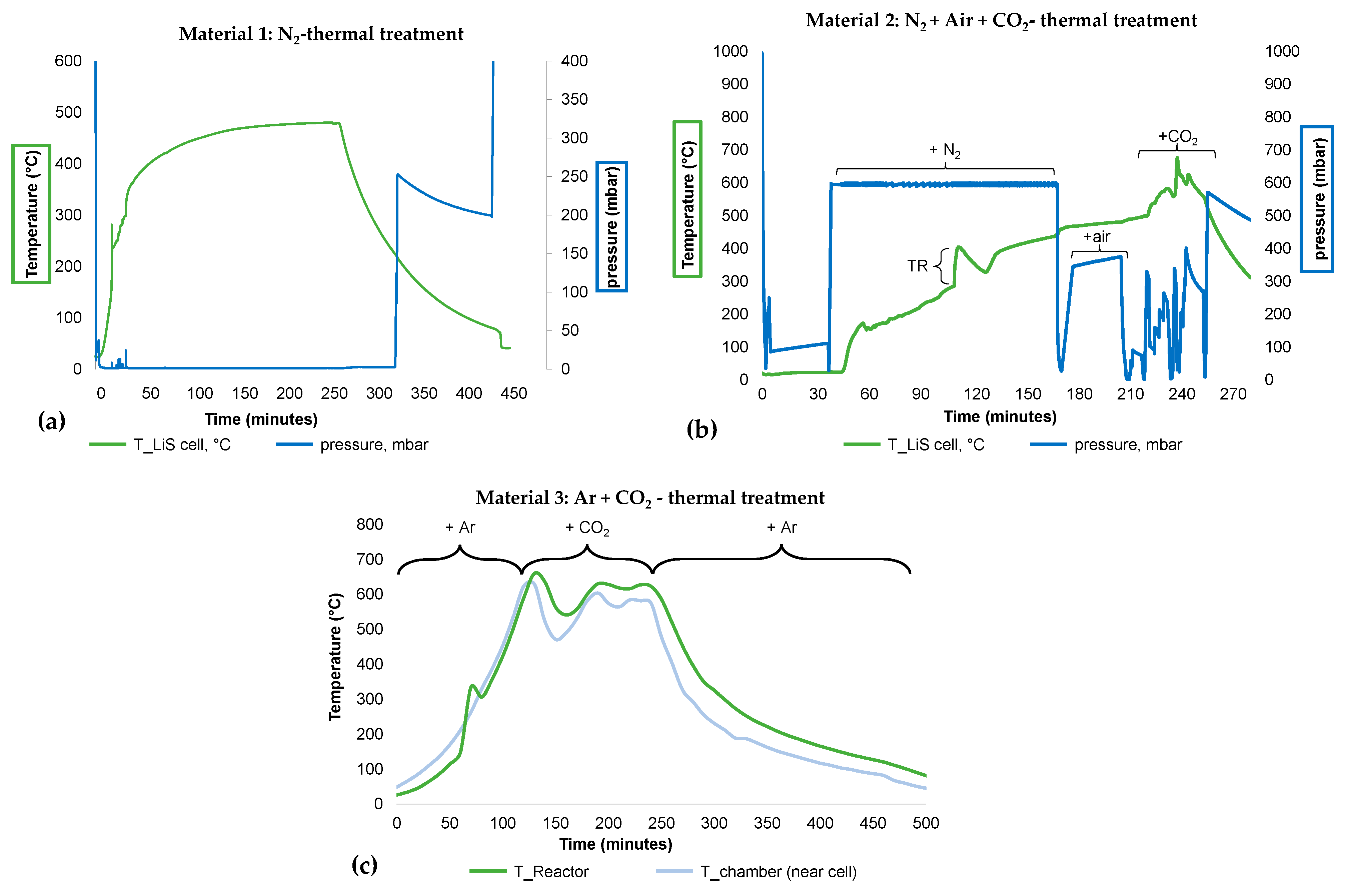

- A thermal pre-treatment specially designed for LiS-cells is necessary in order to achieve full oxidation of Li, otherwise the process safety during recycling is not assured due to the ignition of lithium during crushing of non thermally pre-treated cells, ignitions in the black mass when charging it into aqueous solutions, or ignitions when milling black mass without sufficient thermal pre-treatment.

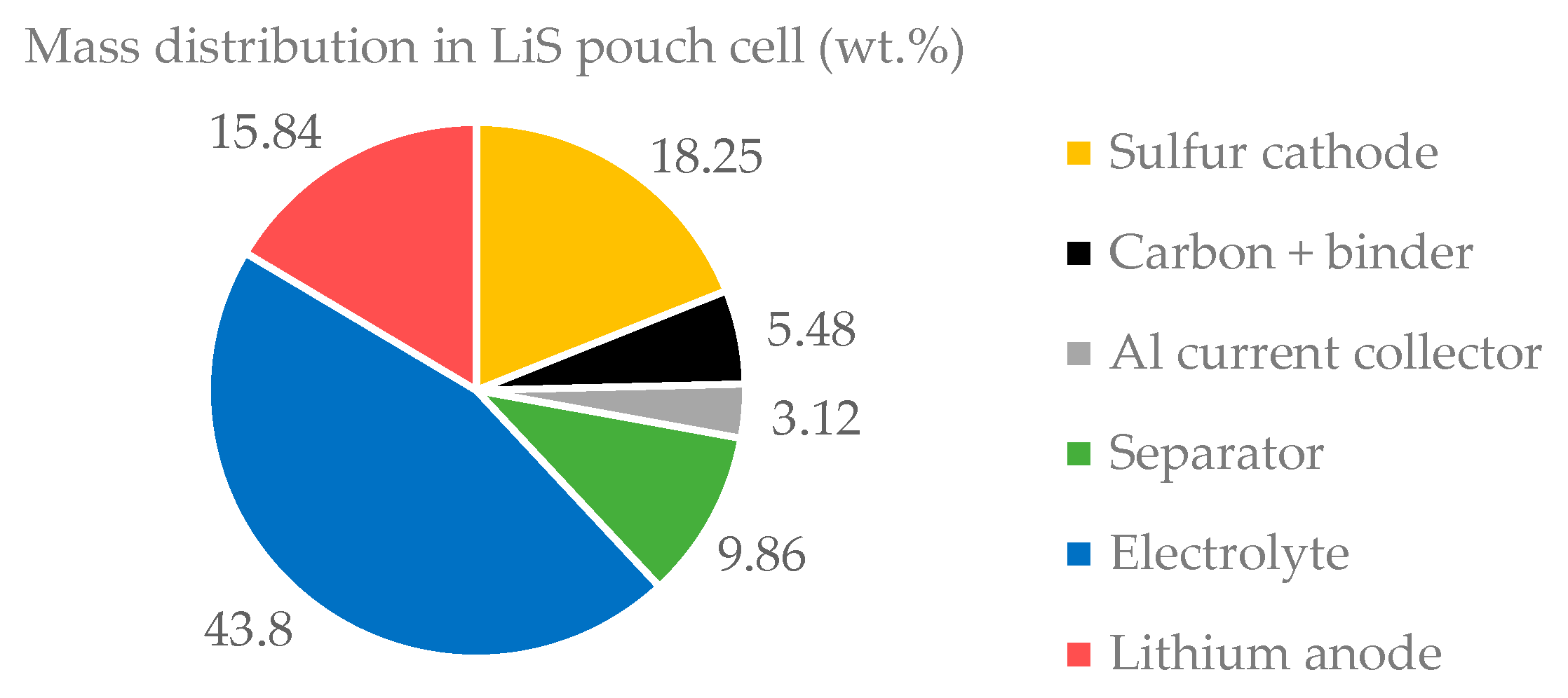

- The intrinsic, monetary value of LiS-cells is largely determined by Li and is generally lower than the value of most LiBs. Because the viability of recycling is challenging, there are lower incentives for recycling. Therefore, a cost-saving recycling process is required for LiS-batteries.

- Connected to that, the Recycling Efficiency demanded by the EU, which is currently 50 wt.% based on a cell level, is not achievable only by recycling Li and Al. Considering the electrolyte, or activated charcoal and sulfur from the cathode material, would be necessary (see this publication in combination with [18]).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Benveniste, G.; Rallo, H.; Casals, L.C.; Merino, A.; Amante, B. Comparison of the state of Lithium-Sulphur and lithium-ion batteries applied to electromobility. J. Environ. Manag. 2018, 226, 1–12. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dörfler, S.; Althues, H.; Härtel, P.; Abendroth, T.; Schumm, B.; Kaskel, S. Challenges and Key Parameters of Lithium-Sulfur Batteries on Pouch Cell Level. Joule 2020, 4, 539–554. [Google Scholar] [CrossRef] [Green Version]

- Samaniego, B.; Carla, E.; O’Neill, L.; Nestoridi, M. High specific energy Lithium Sulfur cell for space application. E3S Web Conf. 2017, 16, 08006. [Google Scholar] [CrossRef] [Green Version]

- Park, J.-W.; Yamauchi, K.; Takashima, E.; Tachikawa, N.; Ueno, K.; Dokko, K.; Watanabe, M. Solvent Effect of Room Temperature Ionic Liquids on Electrochemical Reactions in Lithium–Sulfur Batteries. J. Phys. Chem. C 2013, 117, 4431–4440. [Google Scholar] [CrossRef]

- Agostini, M.; Scrosati, B.; Hassoun, J. An Advanced Lithium-Ion Sulfur Battery for High Energy Storage. Adv. Energy Mater. 2015, 5, 1500481. [Google Scholar] [CrossRef]

- Danner, T.; Latz, A. On the influence of nucleation and growth of S8 and Li2S in lithium-sulfur batteries. Electrochim. Acta 2019, 322, 134719. [Google Scholar] [CrossRef]

- Robinson, J.B.; Xi, K.; Kumar, R.V.; Ferrari, A.C.; Au, H.; Titirici, M.-M.; Parra-Puerto, A.; Kucernak, A.; Fitch, S.D.; Garcia-Araez, N.; et al. 2021 roadmap on lithium sulfur batteries. J. Phys. Energy 2021, 3, 031501. [Google Scholar] [CrossRef]

- Martens, H.; Goldmann, D. Recyclingtechnik: Fachbuch für Lehre und Praxis; 2. Aufl; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2016; ISBN 978-3-658-02786-5. [Google Scholar]

- House, K.Z.; Baclig, A.C.; Ranjan, M.; van Nierop, E.A.; Wilcox, J.; Herzog, H.J. Economic and energetic analysis of capturing CO2 from ambient air. Proc. Natl. Acad. Sci. USA 2011, 108, 20428–20433. [Google Scholar] [CrossRef] [Green Version]

- Dahmus, J.B.; Gutowski, T.G. What gets recycled: An information theory based model for product recycling. Environ. Sci. Technol. 2007, 41, 7543–7550. [Google Scholar] [CrossRef]

- Zhang, S. Liquid electrolyte lithium/sulfur battery: Fundamental chemistry, problems, and solutions. J. Power Sources 2013, 231, 153–162. [Google Scholar] [CrossRef]

- Kommission, E. Mitteilung der Kommission an das Europäische Parlament, den Rat, den Europäischen Wirtschafts- und Sozialausschuss, und den Ausschuss der Regionen. über die Liste kritischer Rohstoffe für die EU 2017. Available online: https://eur-lex.europa.eu/legal-content/DE/TXT/PDF/?uri=CELEX:52017DC0490&from=EN. (accessed on 8 January 2020).

- Blengini, G.A.; El Latunussa, C.; Eynard, U.; Torres de Matos, C.; Wittmer, D.M.A.G.; Georgitzikis, K.; Pavel, C.C.; Carrara, S.; Mancini, L.; Unguru, M.; et al. Study on the EU’s List of Critical Raw Materials (2020), Final Report; Publications Office of the European Union: Luxembourg, 2020; ISBN 9789276210498. [Google Scholar]

- Yamaki, J.-I.; Tobishima, S.-I.; Sakurai, Y.; Saito, K.-I.; Hayashi, K. Safety evaluation of rechargeable cells with lithium metal anodes and amorphous V2O5 cathodes. J. Appl. Electrochem. 1997, 28, 135–140. [Google Scholar] [CrossRef]

- Kozen, A.C.; Lin, C.-F.; Pearse, A.J.; Schroeder, M.A.; Han, X.; Hu, L.; Lee, S.-B.; Rubloff, G.W.; Noked, M. Next-Generation Lithium Metal Anode Engineering via Atomic Layer Deposition. ACS Nano 2015, 9, 5884–5892. [Google Scholar] [CrossRef] [PubMed]

- Bognar, N.; Rickert, J.; Mennega, M.; Cerdas, F.; Herrmann, C. Evaluation of the Recyclability of Traction Batteries Using the Concept of Information Theory Entropy. In Cascade Use in Technologies 2018. Internationale Konferenz zur Kaskadennutzung und Kreislaufwirtschaft-Oldenburg 2018; Pehlken, A., Kalverkamp, M.M., Wittstock, R., Eds.; Springer: Berlin/Heidelberg, Germany, 2019; ISBN 978-3-662-57886-5. [Google Scholar]

- HELIS Project Website: HELIS. High Energy Lithium Sulphur Cells and Batteries. European Union’s Horizon 2020 Research and Innovation Programme. 2015. Available online: https://www.helis-project.eu/ (accessed on 15 April 2020).

- Schwich, L.; Sabarny, P.; Friedrich, B. Recycling Potential of Lithium–Sulfur Batteries—A First Concept Using Thermal and Hydrometallurgical Methods. Metals 2020, 10, 1513. [Google Scholar] [CrossRef]

- Abdelbaky, M.; Schwich, L.; Crenna, E.; Peeters, J.R.; Hischier, R.; Friedrich, B.; Dewulf, W. Comparing the environmental performance of industrial recycling routes for lithium nickel-cobalt-manganese oxide 111 vehicle batteries. Procedia CIRP 2021, 98, 97–102. [Google Scholar] [CrossRef]

- Schwich, L.; Schubert, T.; Friedrich, B. Early-Stage Recovery of Lithium from Tailored Thermal Conditioned Black Mass Part I: Mobilizing Lithium via Supercritical CO2-Carbonation. Metals 2021, 11, 177. [Google Scholar] [CrossRef]

- Sloop, S.E.; Parker, R. System and Method for Processing an End-of-Life or Reduced Performance Energy Storage and/or Conversion Device Using a Supercritical Fluid (US 8,067,107 B2). 2011. Available online: https://patentimages.storage.googleapis.com/1f/5d/1b/69963cd0c16466/US8067107.pdf (accessed on 1 April 2020).

- Pavón, S.; Kaiser, D.; Mende, R.; Bertau, M. The COOL-Process—A Selective Approach for Recycling Lithium Batteries. Metals 2021, 11, 259. [Google Scholar] [CrossRef]

- Müller, M.-C.; Pietzner, S.; Vitze, H.; Nickel, V.; Steinbild, M.; Willems, J. Method for Recovering Lithium from Lithium-Sulfur Accumulators (US20170317391A1). 2015. Available online: https://patentimages.storage.googleapis.com/f9/1a/2d/388841f6ddf266/US20170317391A1.pdf. (accessed on 28 November 2020).

- Müller, M.-C.; Pietzner, S.; Vitze, H.; Nickel, V.; Steinbild, M.; Willems, J. Process for Recovering Lithium from Lithium-Sulfur Accumulators (US20190348723A1). 2019. Available online: https://patentimages.storage.googleapis.com/54/f3/ab/0fa4cd4840bdd1/US20190348723A1.pdf (accessed on 28 November 2020).

- Fischedick, M.; Görner, K.; Thomeczek, M. CO2: Abtrennung, Speicherung, Nutzung. In Ganzheitliche Bewertung im Bereich von Energiewirtschaft und Industrie; Springer: Berlin, Germany, 2015; ISBN 9783642195280. [Google Scholar]

- Bernal, J.M.; Lozano, P.; García-Verdugo, E.; Burguete, M.I.; Sánchez-Gómez, G.; López-López, G.; Pucheault, M.; Vaultier, M.; Luis, S.V. Supercritical Synthesis of Biodiesel. Molecules 2012, 17, 8696. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.-P.; Pyo, J.-J.; Ahn, S.-H.; Choi, D.-H.; Lee, B.-W.; Lee, D.-W. A Study on the Recovery of Li2CO3 from Cathode Active Material NCM(LiNiCoMnO2) of Spent Lithium Ion Batteries. J. Korean Powder Met. Inst. 2018, 25, 296–301. [Google Scholar] [CrossRef]

- Xiao, J.; Li, J.; Xu, Z. Novel Approach for in Situ Recovery of Lithium Carbonate from Spent Lithium Ion Batteries Using Vacuum Metallurgy. Environ. Sci. Technol. 2017, 51, 11960–11966. [Google Scholar] [CrossRef]

- Lombardo, G.; Ebin, B.; Steenari, B.-M.; Alemrajabi, M.; Karlsson, I.; Petranikova, M. Comparison of the effects of incineration, vacuum pyrolysis and dynamic pyrolysis on the composition of NMC-lithium battery cathode-material production scraps and separation of the current collector. Resour. Conserv. Recycl. 2020, 164, 105142. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, J.; Li, H.; Chen, Y.; Wang, C. A promising approach for the recovery of high value-added metals from spent lithium-ion batteries. J. Power Sources 2017, 351, 192–199. [Google Scholar] [CrossRef]

- Zhang, J.; Hu, J.; Zhang, W.; Chen, Y.; Wang, C. Efficient and economical recovery of lithium, cobalt, nickel, manganese from cathode scrap of spent lithium-ion batteries. J. Clean. Prod. 2018, 204, 437–446. [Google Scholar] [CrossRef]

- Liu, P.; Xiao, L.; Chen, Y.; Tang, Y.; Wu, J.; Chen, H. Recovering valuable metals from LiNixCoyMn1-x-yO2 cathode materials of spent lithium ion batteries via a combination of reduction roasting and stepwise leaching. J. Alloys Compd. 2018, 783, 743–752. [Google Scholar] [CrossRef]

- Lee, S.-J.; Jang, H.-J.; Son, J.-T. Heat Treatment Process for Recovering Lithium Hydroxide Monohydrate (LiOH·H2O) from Nickel-rich Cathode Materials. Mater. Lett. 2021, 301, 130281. [Google Scholar] [CrossRef]

- Barkholtz, H.M.; Preger, Y.; Ivanov, S.; Langendorf, J.; Torres-Castro, L.; Lamb, J.; Chalamala, B.; Ferreira, S.R. Multi-scale thermal stability study of commercial lithium-ion batteries as a function of cathode chemistry and state-of-charge. J. Power Sources 2019, 435, 226777. [Google Scholar] [CrossRef]

- Vanderbruggen, A.; Schwich, L.; Sabarny, P.; Rudolph, M.; Friedrich, B. Recovery of spheroidized graphite from lithium ion batteries. In Proceedings of the GreenBatt Cluster Meeting 2022, Online, 22 March 2022. [Google Scholar] [CrossRef]

- Vanderbruggen, A.; Gugala, E.; Blannin, R.; Bachmann, K.; Serna-Guerrero, R.; Rudolph, M. Automated mineralogy as a novel approach for the compositional and textural characterization of spent lithium-ion batteries. Miner. Eng. 2021, 169, 106924. [Google Scholar] [CrossRef]

- Vanderbruggen, A.; Sygusch, J.; Rudolph, M.; Serna-Guerrero, R. A contribution to understanding the flotation behavior of lithium metal oxides and spheroidized graphite for lithium-ion battery recycling. Colloids Surfaces A: Physicochem. Eng. Asp. 2021, 626, 127111. [Google Scholar] [CrossRef]

- Engels, P.; Kononova, N.; Khalid, U.; Cerdas, F.; Herrmann, C. Methodology for a combined uncertainty analysis and data quality rating of existing graphite datasets in context of battery LCAs. Procedia CIRP 2022, 105, 577–582. [Google Scholar] [CrossRef]

- Engels, P.; Cerdas, F.; Dettmer, T.; Frey, C.; Hentschel, J.; Herrmann, C.; Mirfabrikikar, T.; Schueler, M. Life cycle assessment of natural graphite production for lithium-ion battery anodes based on industrial primary data. J. Clean. Prod. 2022, 336, 130474. [Google Scholar] [CrossRef]

- Friedrich, B. Ecoliga–Recycling und Resynthese von Kohlenstoffmaterialien aus Lithium-Batterien–Rückgewinnung, Aufbereitung, Wiedereinsatz und Angepasstes Zelldesign. Bundesministerium für Bildung und Forschung. 2021. Available online: https://www.greenbatt-cluster.de/de/projekte/ecoliga/ (accessed on 18 April 2021).

- Schwich, L.; Küpers, M.; Finsterbusch, M.; Schreiber, A.; Fattakhova-Rohlfing, D.; Guillon, O.; Friedrich, B. Recycling Strategies for Ceramic All-Solid-State Batteries—Part I: Study on Possible Treatments in Contrast to Li-Ion Battery Recycling. Metals 2020, 10, 1523. [Google Scholar] [CrossRef]

- Haynes, W.M. CRC Handbook of Chemistry and Physics. A Ready-Reference Book of Chemical and Physical Data; 97 Aufl; CRC Press: Boca Raton, FL, USA; London, UK; New York, NY, USA, 2017; ISBN 978-1-4987-5429-3. [Google Scholar]

- Peled, E.; Golodnitsky, D.; Penciner, J. The Anode/Electrolyte Interface. In Handbook of Battery Materials; 2 Aufl; Daniel, C., Besenhard, J.O., Eds.; Wiley-VCH: Weinheim, Germany, 2012; pp. 479–524. ISBN 978-3-527-32695-2. [Google Scholar]

- Tasaki, K.; Goldberg, A.; Lian, J.-J.; Walker, M.; Timmons, A.; Harris, S.J. Solubility of Lithium Salts Formed on the Lithium-Ion Battery Negative Electrode Surface in Organic Solvents. J. Electrochem. Soc. 2009, 156, A1019–A1027. [Google Scholar] [CrossRef]

- Yao, K.P.C.; Kwabi, D.G.; Quinlan, R.A.; Mansour, A.N.; Grimaud, A.; Lee, Y.-L.; Lu, Y.-C.; Shao-Horn, Y. Thermal Stability of Li2O2and Li2O for Li-Air Batteries: In Situ XRD and XPS Studies. J. Electrochem. Soc. 2013, 160, A824–A831. [Google Scholar] [CrossRef]

- Dinh, L.; II, W.M.; Schildbach, M.; LeMay, J.; Siekhaus, W.; Balooch, M. The nature and effects of the thermal stability of lithium hydroxide. J. Nucl. Mater. 2003, 317, 175–188. [Google Scholar] [CrossRef]

- Yang, H.; Zhuang, G.V.; Ross, P.N. Thermal stability of LiPF6 salt and Li-ion battery electrolytes containing LiPF6. J. Power Sources 2006, 161, 573–579. [Google Scholar] [CrossRef] [Green Version]

- Schwedt, G. Chemische Elemente und ihre Spezies. In Mobilität, Bioverfügbarkeit, Toxizität und Analytik, Lehrbuch; Springer Spektrum: Berlin/Heidelberg, Germany, 2018; ISBN 978-3-662-55829-4. [Google Scholar]

- Holmer, M.; Hasler-Sheetal, H. Sulfide intrusion in seagrasses assessed by stable sulfur isotopes—A synthesis of current results. Front. Mar. Sci. 2014, 1, 64. [Google Scholar] [CrossRef] [Green Version]

- Neto, E.S.C.; Aguiar, A.; Rodriguez, R.; Sancinetti, G. Acid Mine Drainage Treatment and Metal Removal Based on a Biological Sulfate-Reducing Process. Braz. J. Chem. Eng. 2018, 35, 543–552. [Google Scholar] [CrossRef] [Green Version]

- Chubarov, A.V.; Maksimenko, V.V.; Belousova, N.V. Investigation of behavior of elemental sulfur in H2O-OH−-CN− solutions. Russ. J. Non-Ferrous Met. 2009, 50, 582–588. [Google Scholar] [CrossRef]

- Tartar, H.V.; Draves, C.Z. Reaction of Sulfur With Alkali and Alkaline Earth Hydroxides in Aqueous Solutions. J. Am. Chem. Soc. 1924, 46, 574–581. [Google Scholar] [CrossRef]

- Zhou, G.; Paek, E.; Hwang, G.S.; Manthiram, A. Long-life Li/polysulphide batteries with high sulphur loading enabled by lightweight three-dimensional nitrogen/sulphur-codoped graphene sponge. Nat. Commun. 2015, 6, 7760. [Google Scholar] [CrossRef]

- Ntuk, U.; Tait, S.; White, E.T.; Steel, K. The precipitation and solubility of aluminium hydroxyfluoride hydrate between 30 and 70 °C. Hydrometallurgy 2015, 155, 79–87. [Google Scholar] [CrossRef]

- Iljina, A.; Baltakys, K.; Baltakys, M.; Siauciunas, R. Neutralization and Removal of Compounds Containing Fluoride Ions From Waste Silica Gel. Rom. J. Mater. 2014, 44, 265–271. [Google Scholar]

- Tang, Y.; Guan, X.; Su, T.; Gao, N.; Wang, J. Fluoride adsorption onto activated alumina: Modeling the effects of pH and some competing ions. Colloids Surfaces A: Physicochem. Eng. Asp. 2009, 337, 33–38. [Google Scholar] [CrossRef]

- Mourabet, M.; El Rhilassi, A.; El Boujaady, H.; Bennani-Ziatni, M.; El Hamri, R.; Taitai, A. Removal of fluoride from aqueous solution by adsorption on Apatitic tricalcium phosphate using Box–Behnken design and desirability function. Appl. Surf. Sci. 2012, 258, 4402–4410. [Google Scholar] [CrossRef]

- Wang, H.; Friedrich, B. Development of a Highly Efficient Hydrometallurgical Recycling Process for Automotive Li–Ion Batteries. J. Sustain. Met. 2015, 1, 168–178. [Google Scholar] [CrossRef] [Green Version]

| Materials | Li | Al | Cu | F | C | S |

|---|---|---|---|---|---|---|

| wt.% | ||||||

| M1 | 20.5 | 25 | 5.2 | 0.63 | 10.7 | 17 |

| M2 | 16 | 13.2 | 0 | 1.76 | 17 | 13.9 |

| M3 | 14.75 | 7.6 | 0.98 | 0.57 | 22.7 | 4.6 |

| Material | Reference Value for Li-Content (wt.%) | Minimal s/l-Ratio (g/mL) | Minimal s/l-Ratio × 2 (g/mL) | Minimal s/l-Ratio × 2.7 (g/mL) |

|---|---|---|---|---|

| M1 | 20 | 1:80 | 1:160 | 1:220 |

| M2/M3 | 30 | +8%: 1:130 | 1:260 | 1:350 |

| Characteristic Species | Li2CO3 | LiF | Li2SO3 | Li2SO4 |

| Overview on Performed Trial Parameters | |||||

|---|---|---|---|---|---|

| Trial | FKC-Washing | Leaching Time, s/l-Ratio, if used: CO2-Use, Leaching Temperature, Additives | Grain Size and Material | Li-Yield | Mean Value (Yield) |

| 2.LS.1 | FKC washed | 120 min, 1:80 | >1 mm (CF M1) | 78% | |

| 2.LS.2 | 120 min, 1:160 | >1 mm (CF M1) | 86% | ||

| 2.LS.3 | 120 min, 1:220 | >1 mm (CF M1) | 80% | ||

| 2.LS.4 | FKC not washed | 120 min, 1:80 | >1 mm (CF M1) | 65% | 71% |

| 2.LS.5 | 120 min, 1:80 | >1 mm (CF M1) | 70% | ||

| 2.LS.6 | 120 min, 1:80 | >1 mm (CF M1) | 78% | ||

| 2.LS.7 | 30 min, 1:80 | >1 mm (CF M1) | 75% | 71% | |

| 2.LS.8 | 30 min, 1:80 | >1 mm (CF M1) | 68% | ||

| 2.LS.9 | 30 min, 1:80 | >1 mm (CF M1) | 71% | ||

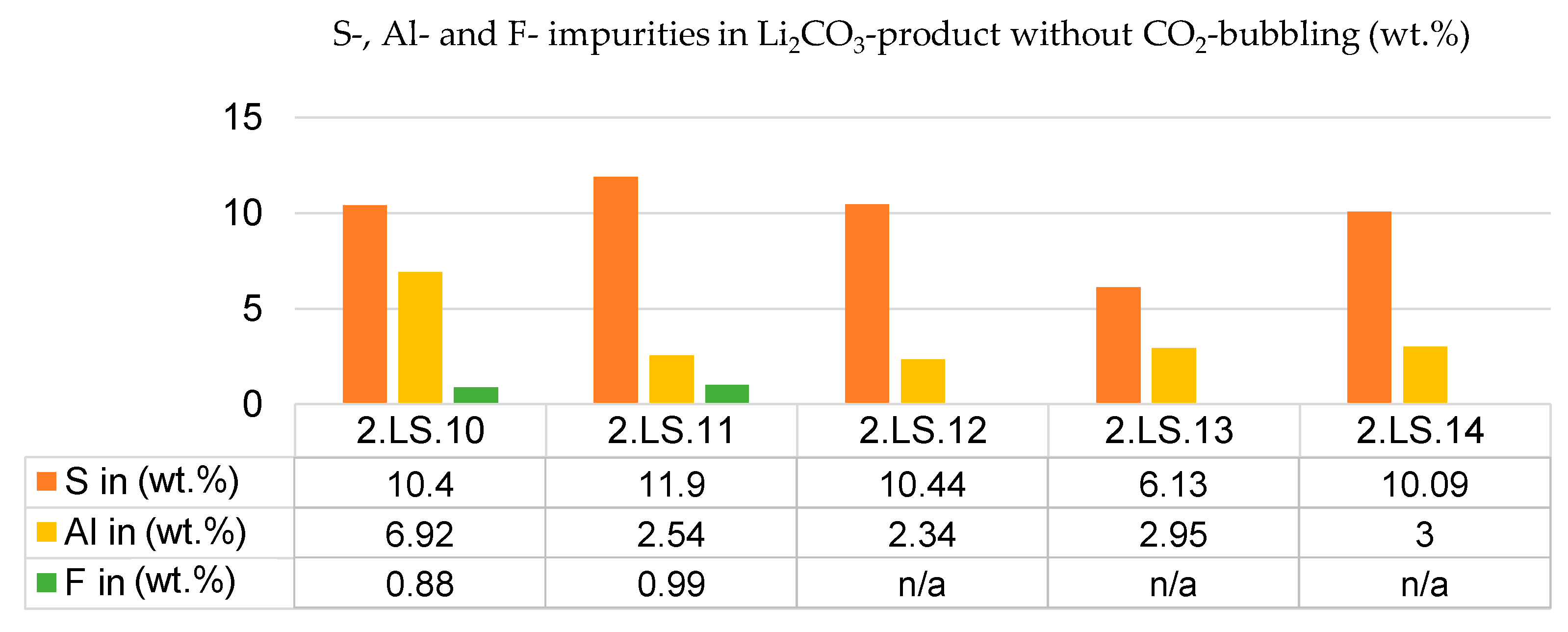

| 2.LS.10 | FKC washed | 120 min, 1:130 | <1 mm (M2) | 72% | 80% (with 2.LS.12) |

| 2.LS.11 | 120 min, 1:260 | <1 mm (M2) | 40% | ||

| 2.LS.12 | 120 min, 1:130 | <1 mm (M2) | 87% | ||

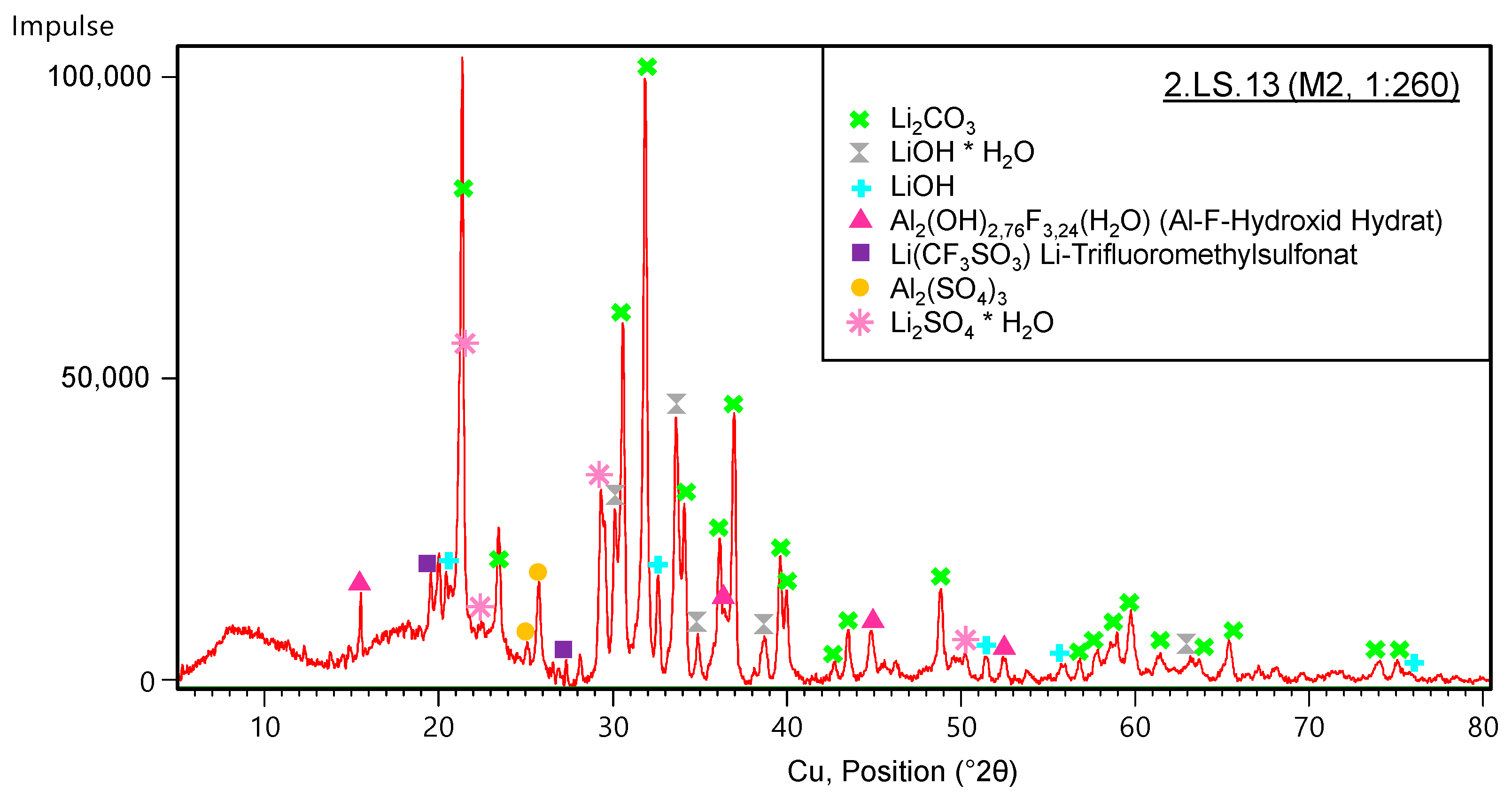

| 2.LS.13 | 120 min, 1:260 | <1 mm (M2) | 81% | ||

| 2.LS.14 | 120 min, 1:350 | <1 mm (M2) | 87% | ||

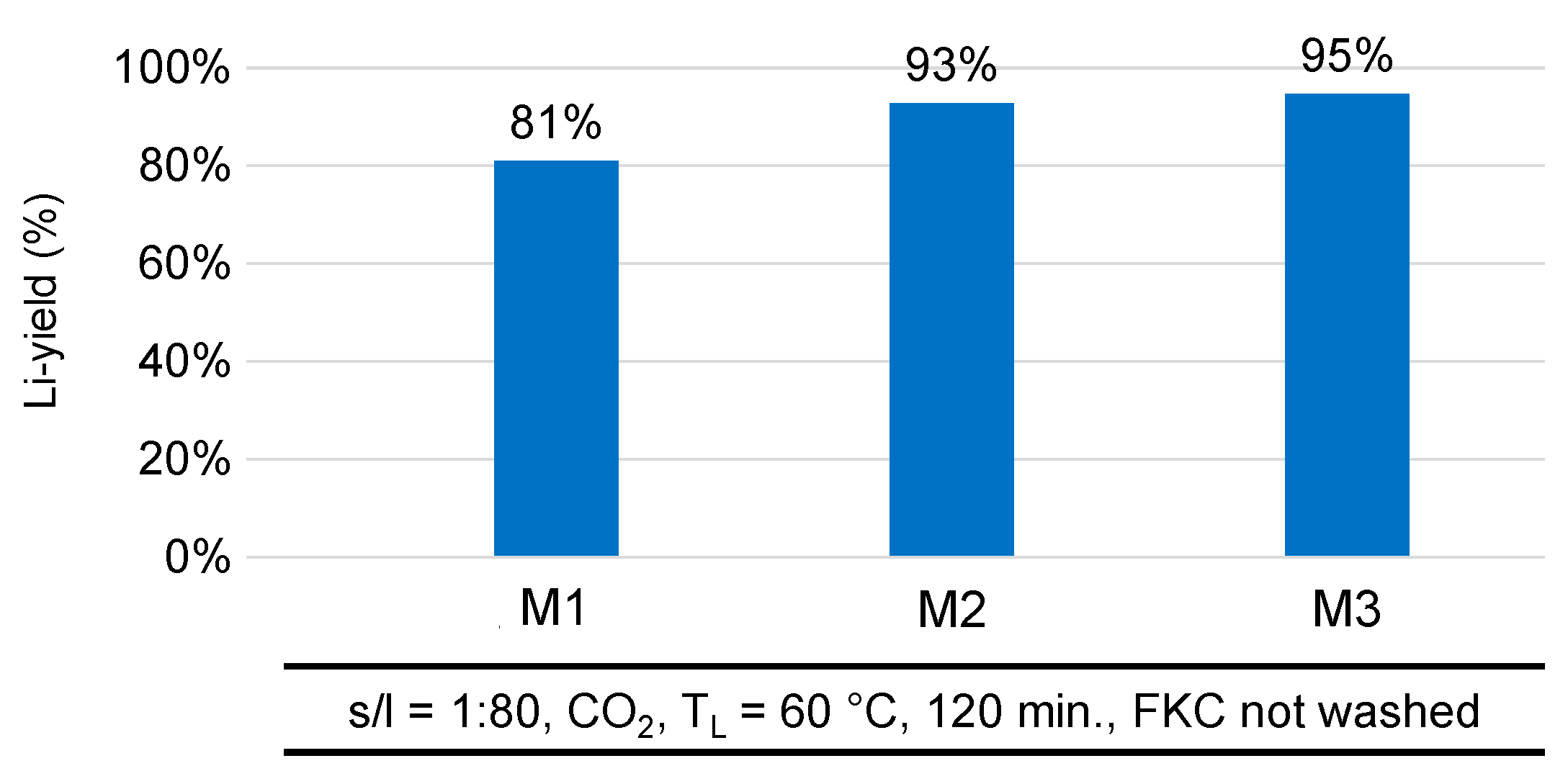

| 2.LS.15 | FKC not washed | 120 min, 1:80, CO2, 60 °C | <1 mm (FF M1) | 80% | 81% |

| 2.LS.16 | 120 min, 1:80, CO2, 60 °C | <1 mm (FF M1) | 81% | ||

| 2.LS.17 | 120 min, 1:80, CO2, 60 °C | >1 mm (CF M1) | 73% | 73% | |

| 2.LS.18 | 120 min, 1:80, CO2, 60 °C | >1 mm (CF M1) | 72% | ||

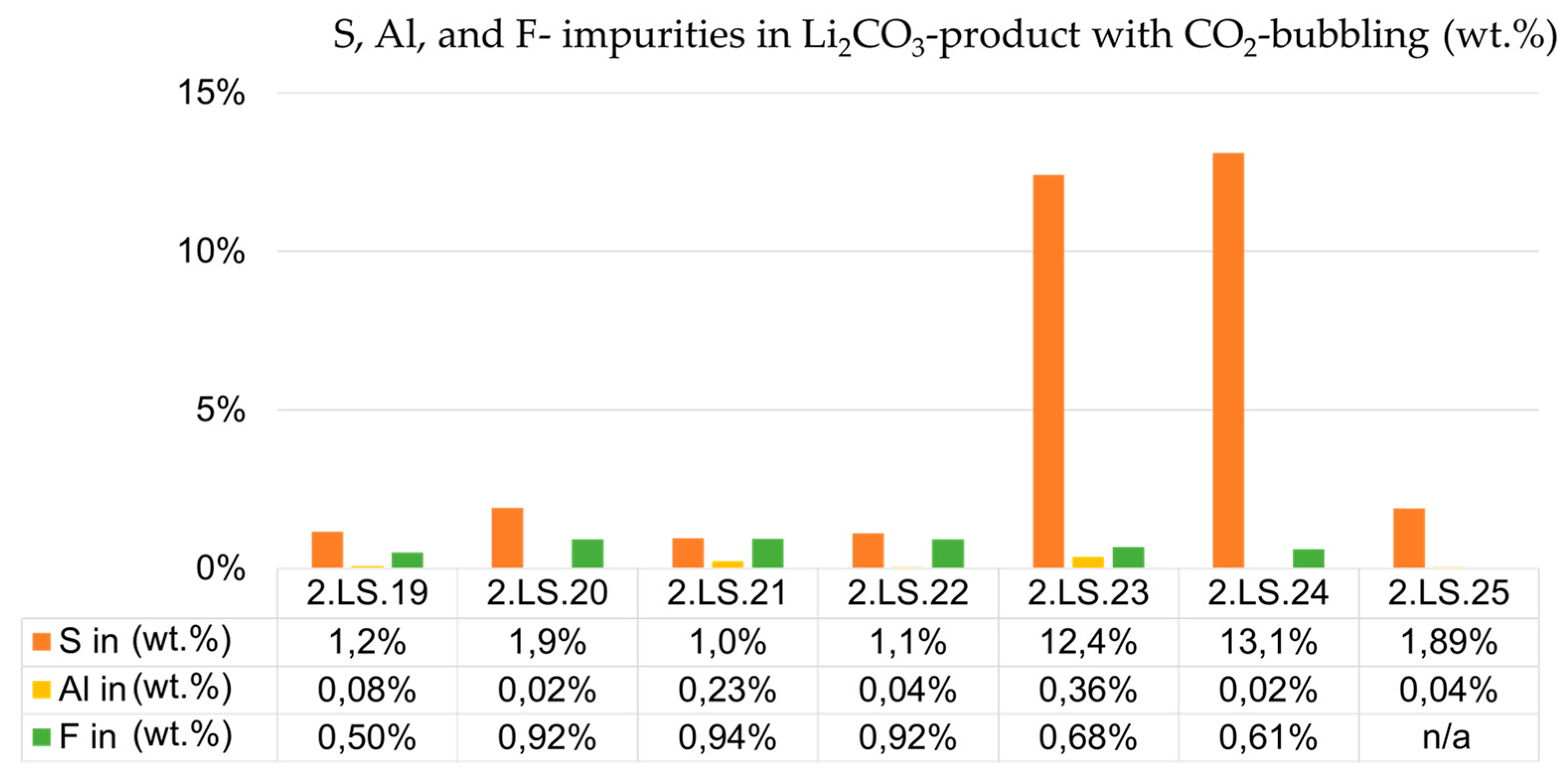

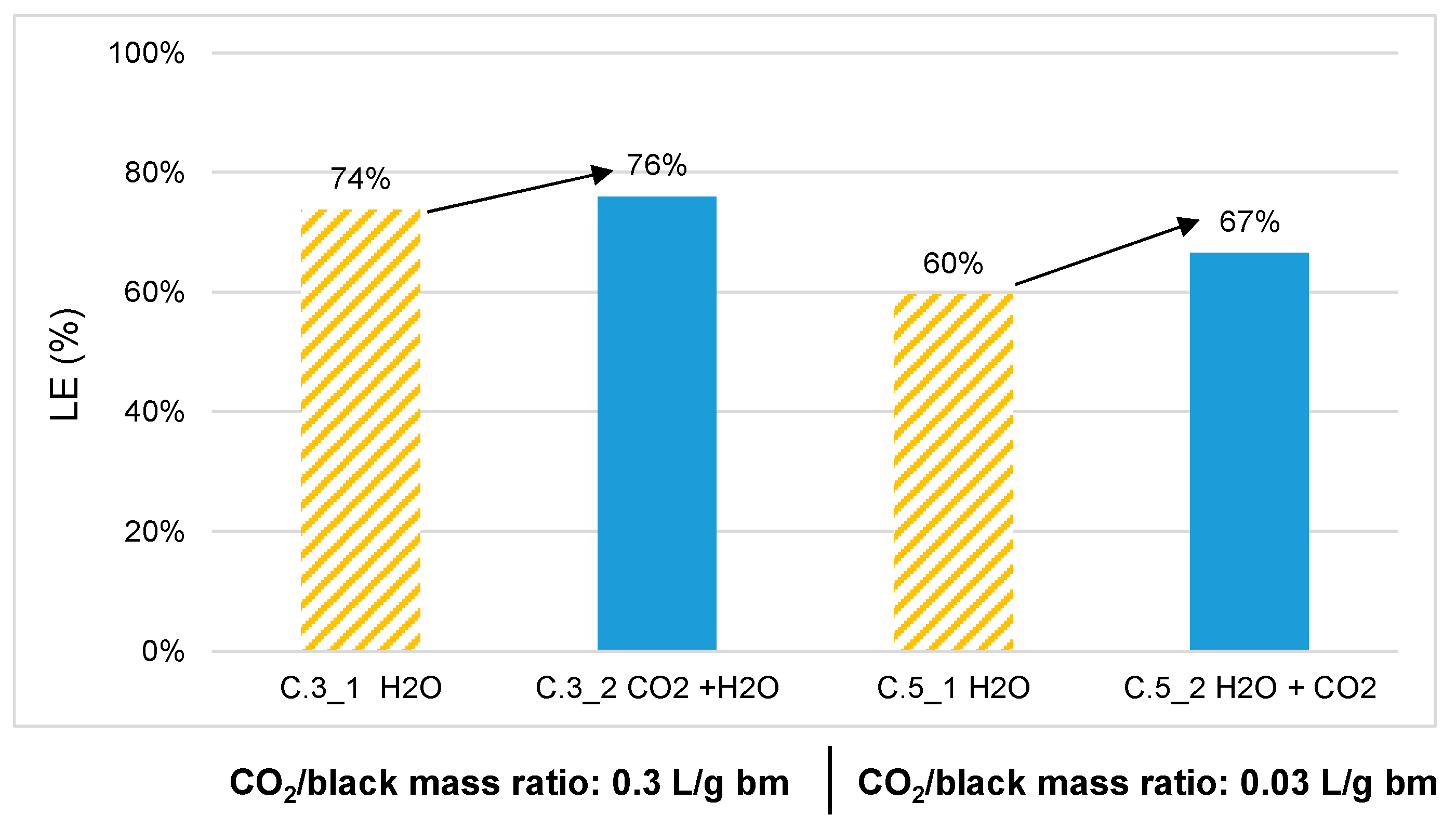

| 2.LS.19 | FKC washed | 120 min, 1:130, CO2, RT | <1 mm (M2) | 79% | |

| 2.LS.20 | 120 min, 1:130, CO2, 60 °C | <1 mm (M2) | 87% | ||

| 2.LS.21 | 120 min, 1:260, CO2, RT | <1 mm (M2) | 88% | ||

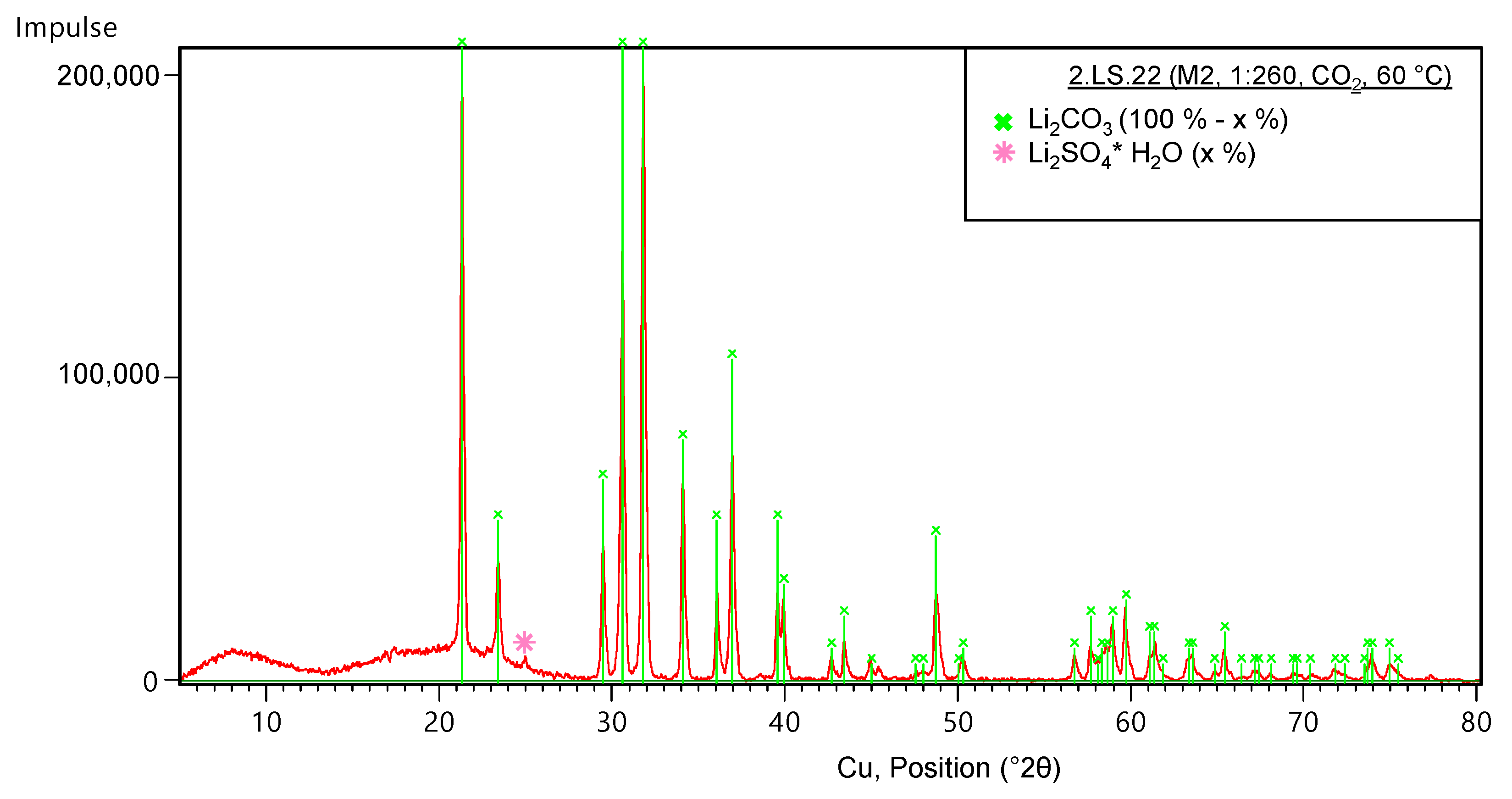

| 2.LS.22 | 120 min, 1:260, CO2, 60 °C | <1 mm (M2) | 92% | ||

| 2.LS.23 | 120 min, 1:260, CO2, RT, + H2O2 | <1 mm (M2) | 91% | ||

| 2.LS.24 | 120 min, 1:260, CO2, 60 °C, + H2O2 | <1 mm (M2) | 91% | ||

| 2.LS.25 | 120 min, 1:350, CO2, 60 °C | <1 mm (M2) | 87% | ||

| Trial | FKC-Washing | Leaching Time, s/l-Ratio, Grain Size | Leaching Temperature and CO2-Use/Flowrate |

|---|---|---|---|

| 2.LS.26 (M1) 2.LS.27 (M2) 2.LS.28 (M3) | FKC not washed | 120 min, 1:80, <1 mm | 60 °C, CO2-gas (2.5 L/min) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schwich, L.; Friedrich, B. Environmentally Friendly Recovery of Lithium from Lithium–Sulfur Batteries. Metals 2022, 12, 1108. https://doi.org/10.3390/met12071108

Schwich L, Friedrich B. Environmentally Friendly Recovery of Lithium from Lithium–Sulfur Batteries. Metals. 2022; 12(7):1108. https://doi.org/10.3390/met12071108

Chicago/Turabian StyleSchwich, Lilian, and Bernd Friedrich. 2022. "Environmentally Friendly Recovery of Lithium from Lithium–Sulfur Batteries" Metals 12, no. 7: 1108. https://doi.org/10.3390/met12071108

APA StyleSchwich, L., & Friedrich, B. (2022). Environmentally Friendly Recovery of Lithium from Lithium–Sulfur Batteries. Metals, 12(7), 1108. https://doi.org/10.3390/met12071108