Damage Evolution Simulations via a Coupled Crystal Plasticity and Cohesive Zone Model for Additively Manufactured Austenitic SS 316L DED Components

Abstract

:1. Introduction

2. Experimental Procedure

2.1. DED-Fabricated SS 316L Cubic Components

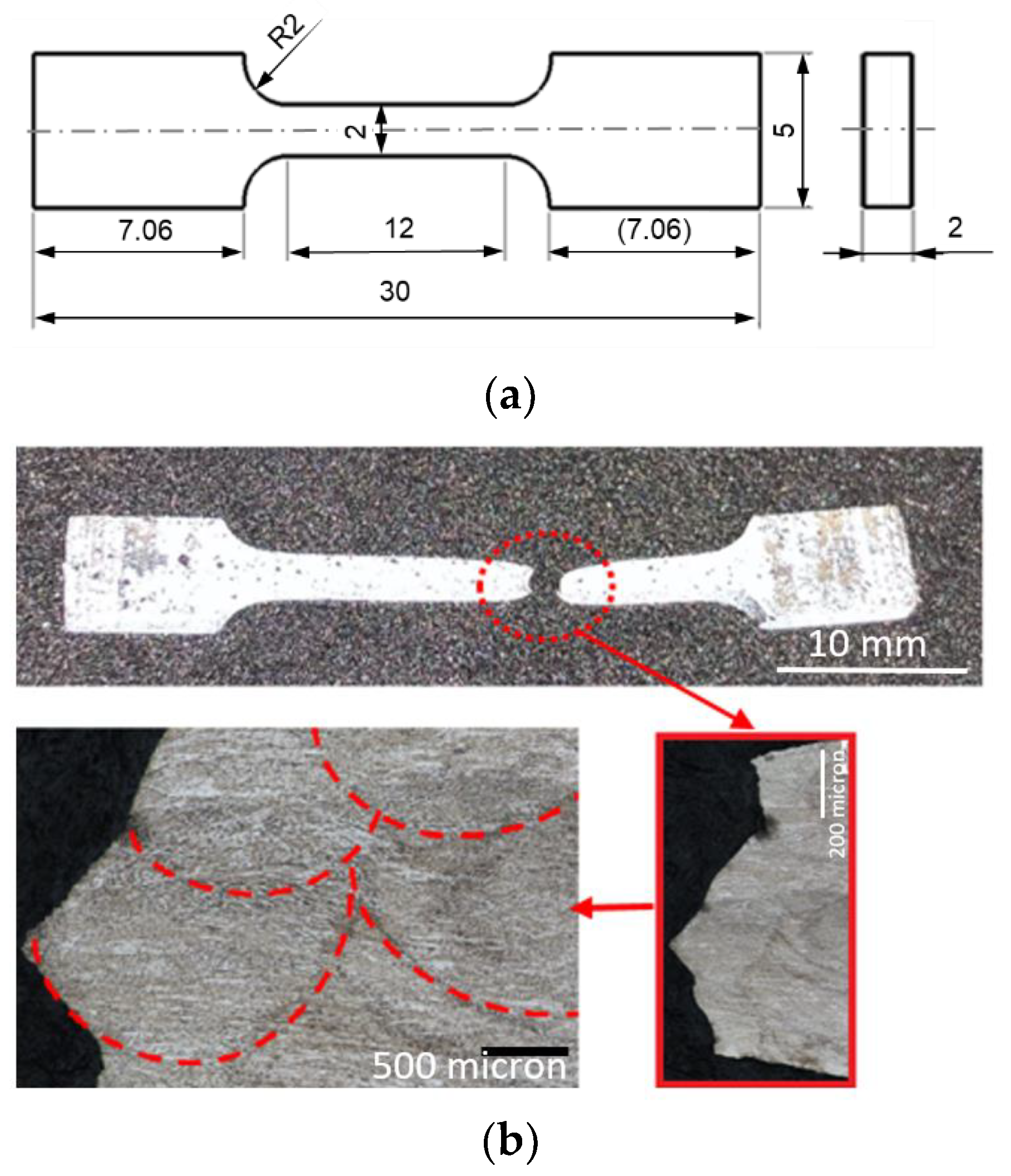

2.2. Tensile Test

3. Numerical Procedure

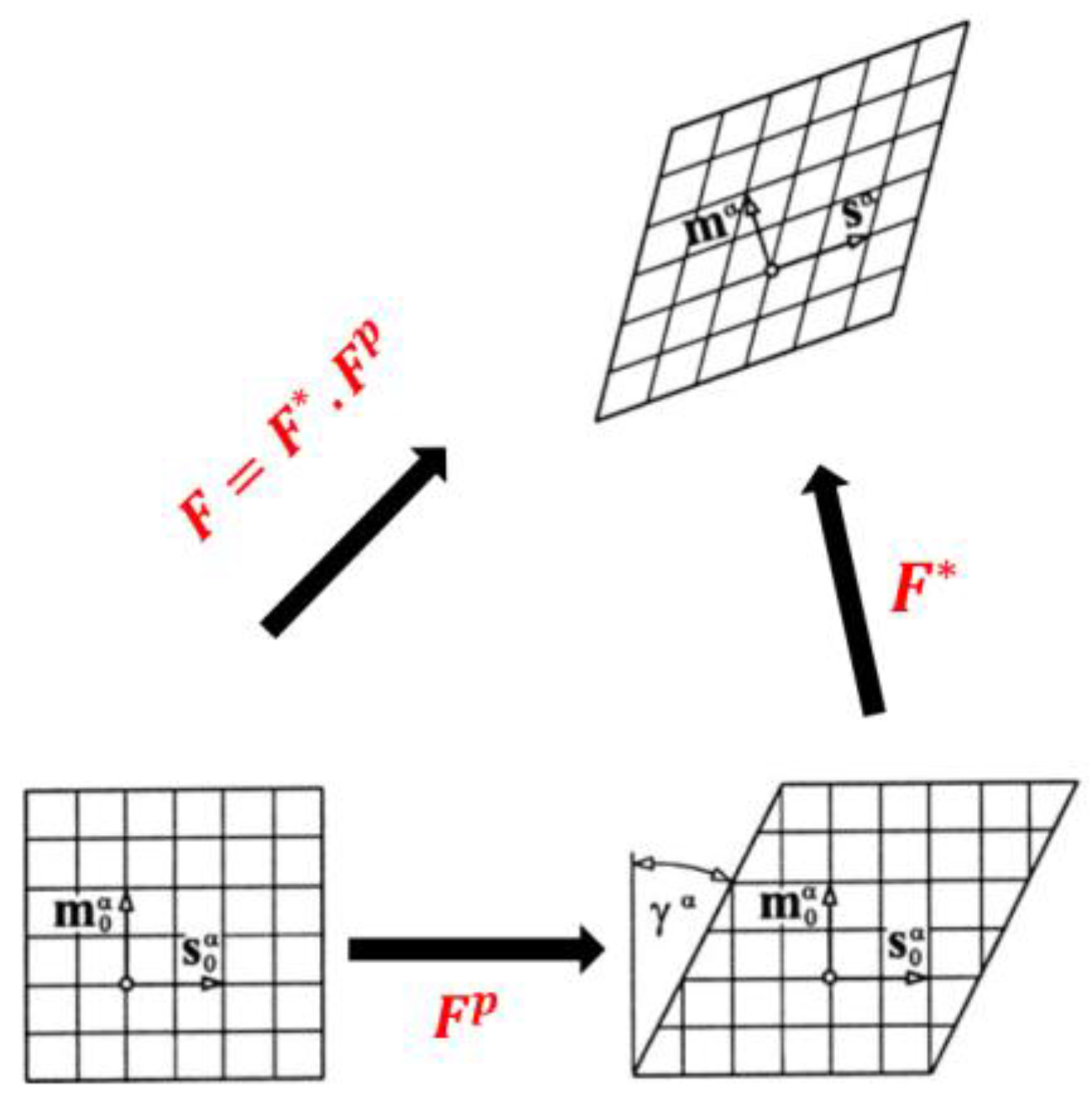

3.1. Classical CP Hypothesis

3.2. Mesoscale Modeling of DED SS 316L

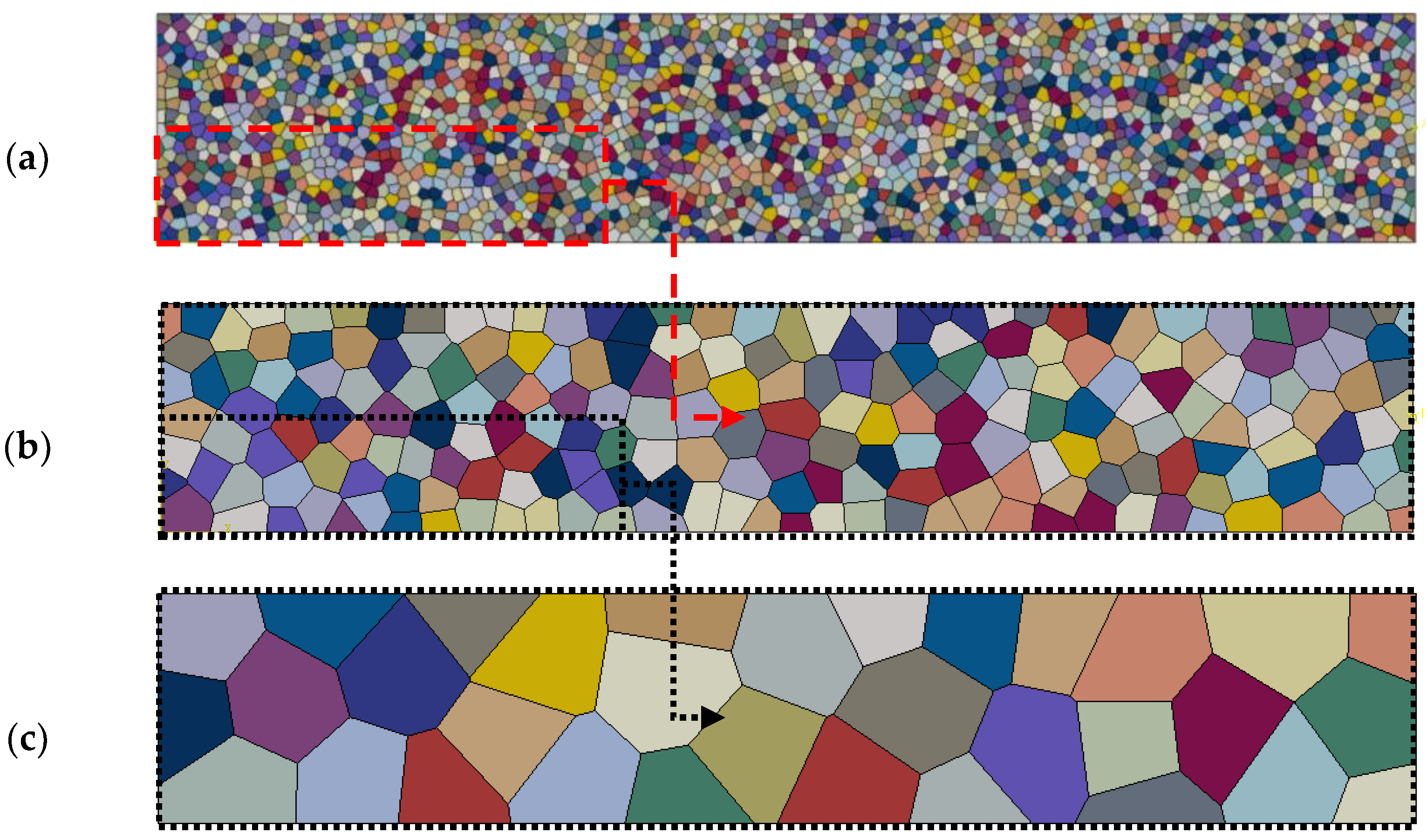

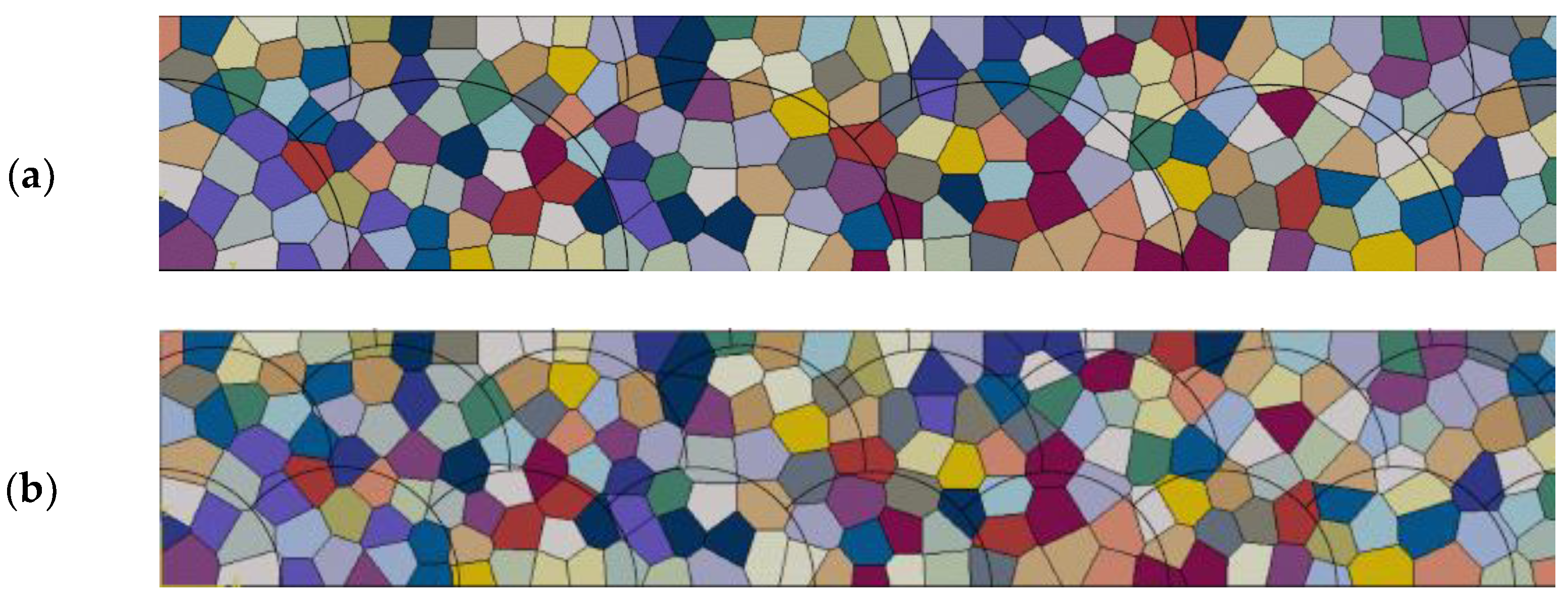

3.2.1. Grain-Scale Modeling Based on Voronoi Tessellation

3.2.2. RVE Size Selection

3.2.3. Melt Pool Modeling

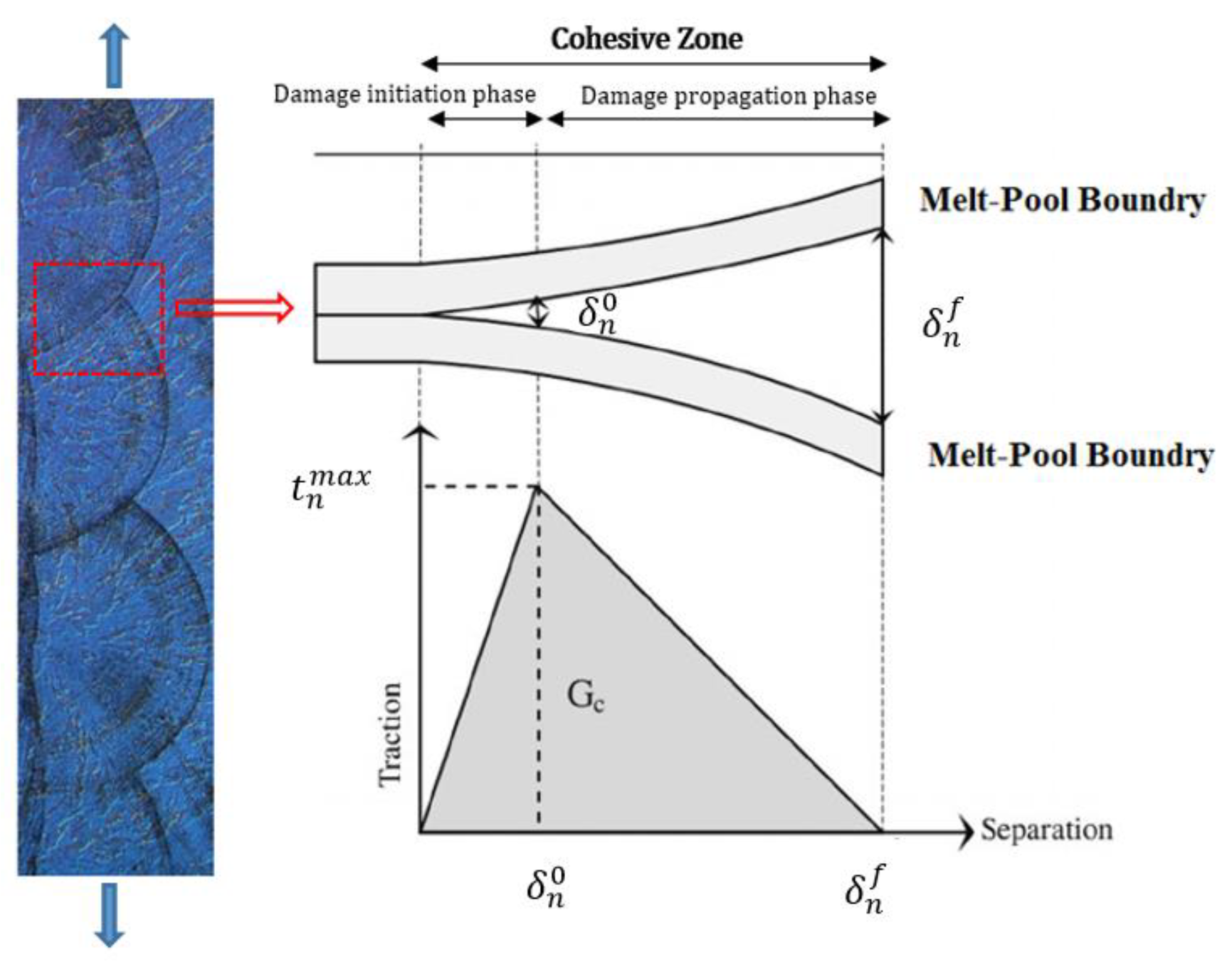

3.2.4. Cohesive Zone Modeling (CZM) for Melt Pool Boundaries

3.3. Finite Element Implementation

4. Result and Discussion

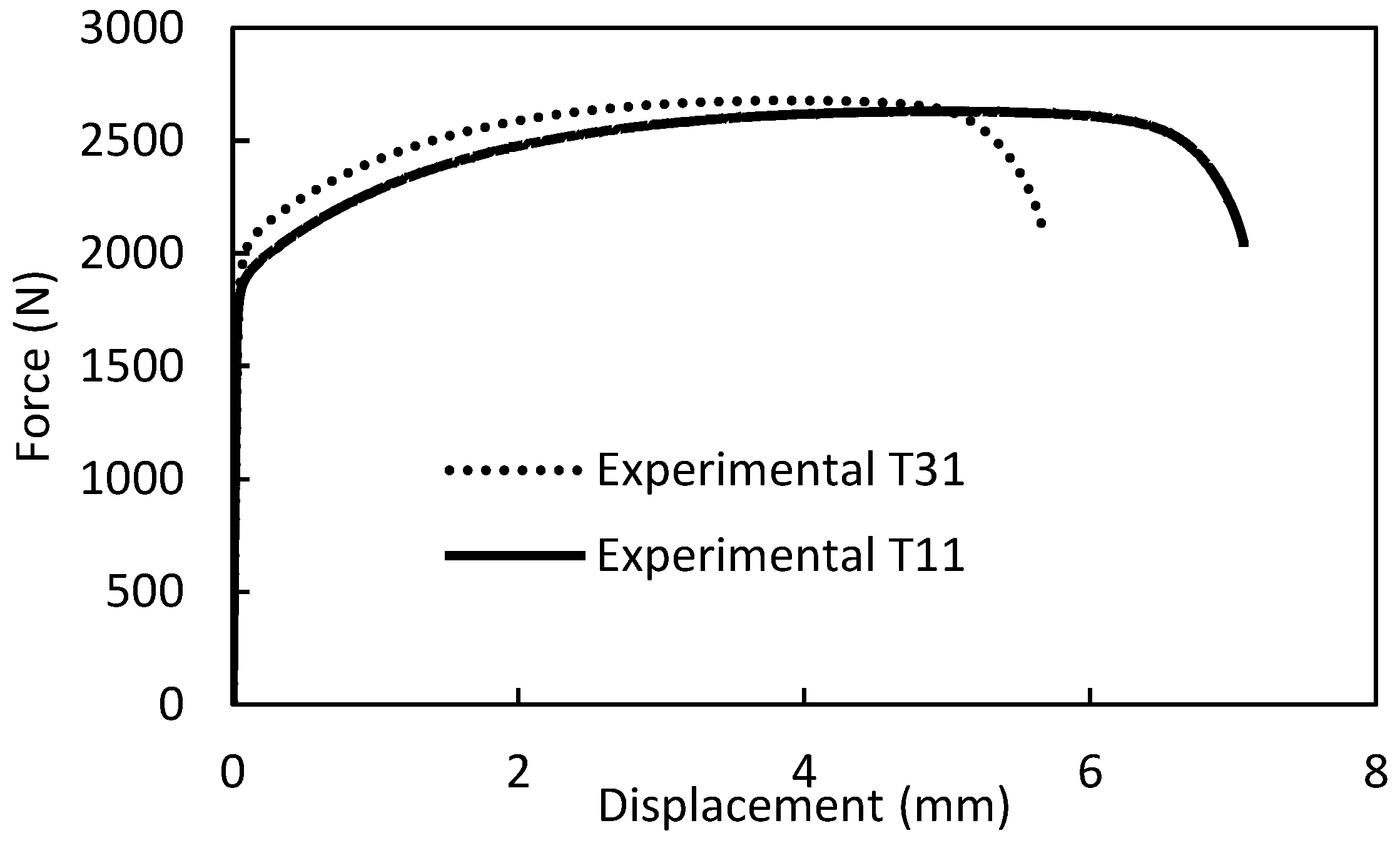

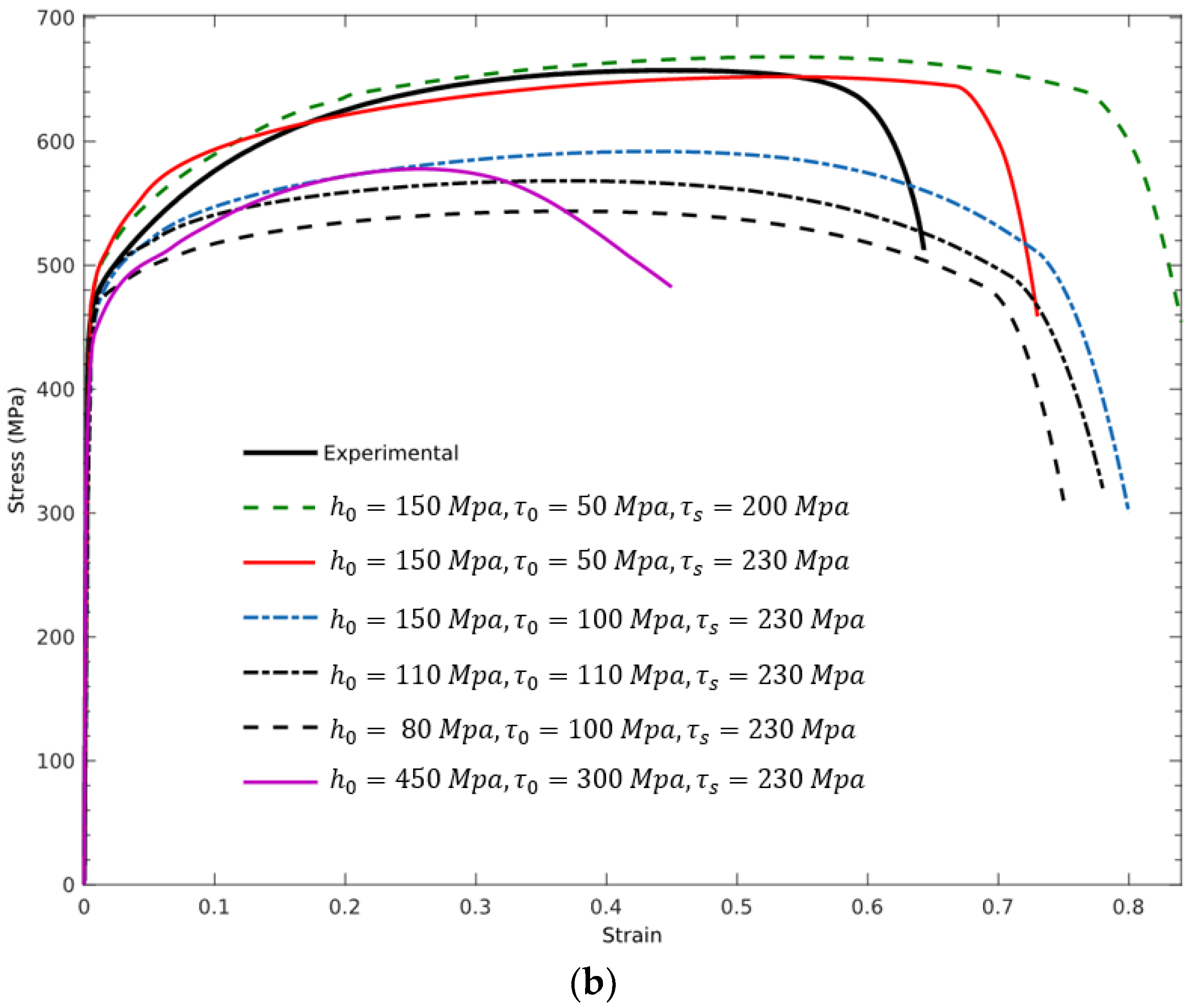

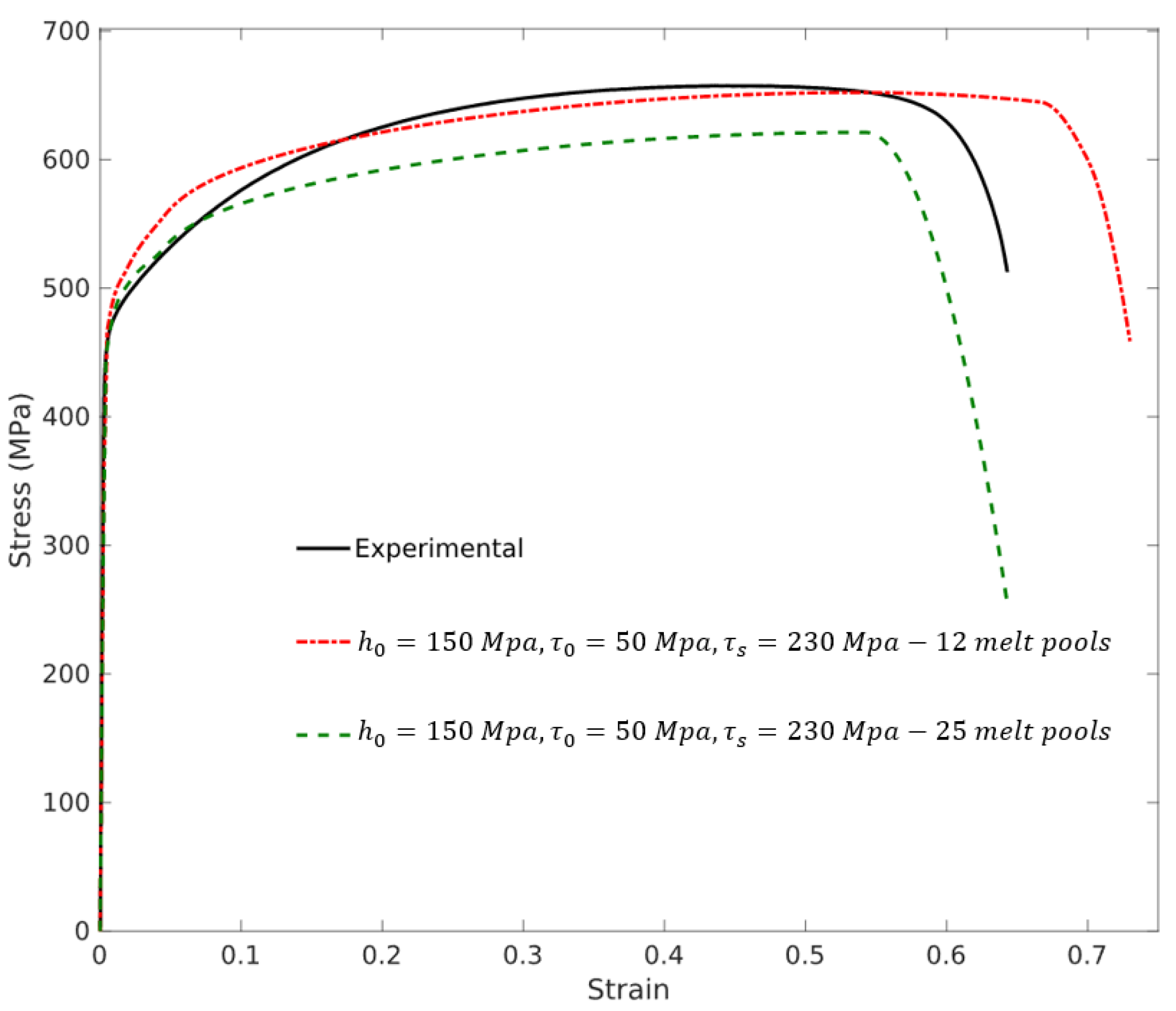

4.1. Calibration of the CP Coefficients

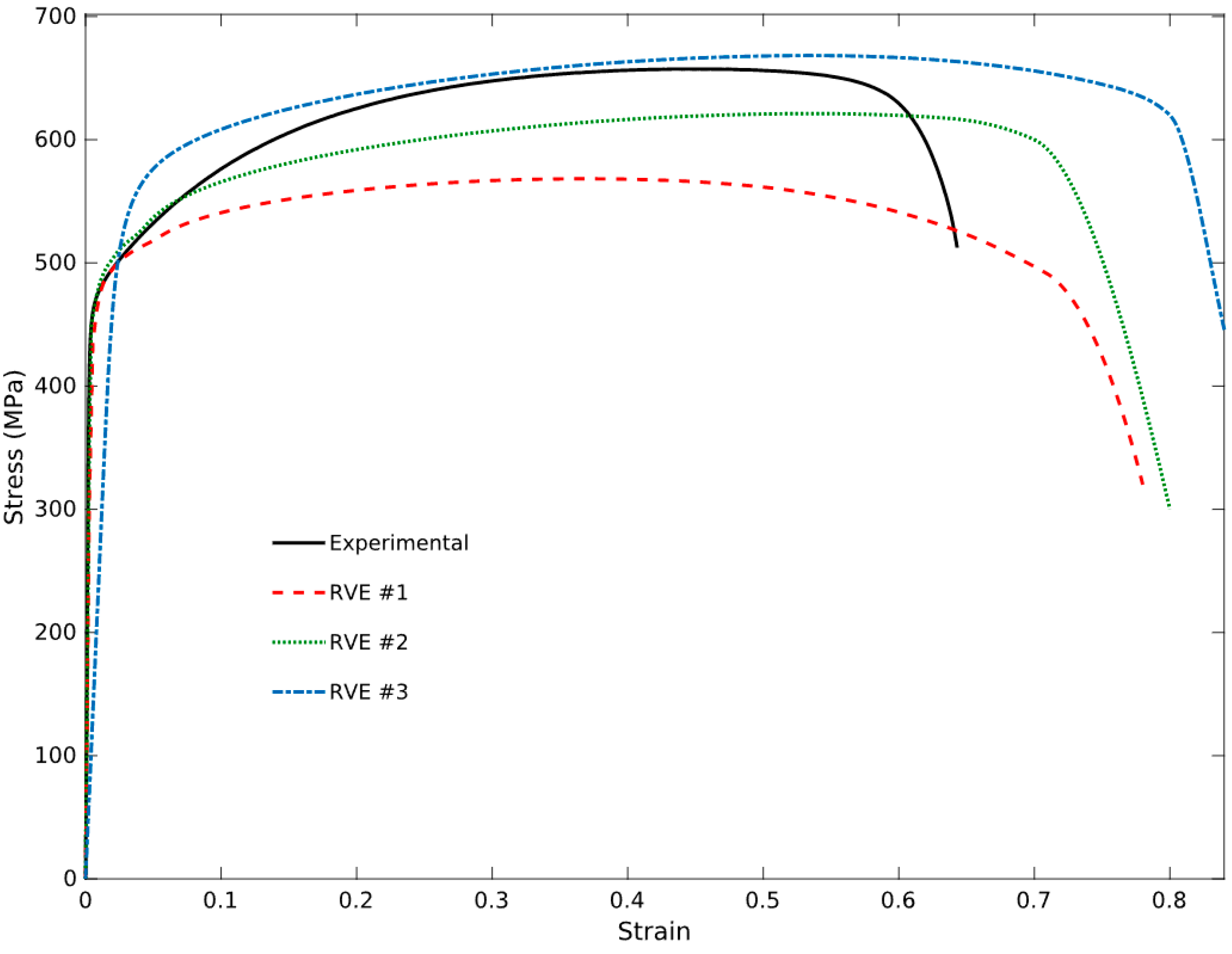

4.2. RVE Size Influence

4.3. Effect of The Melt Pool

4.4. Effect of Damage Evolution on Melt Pool

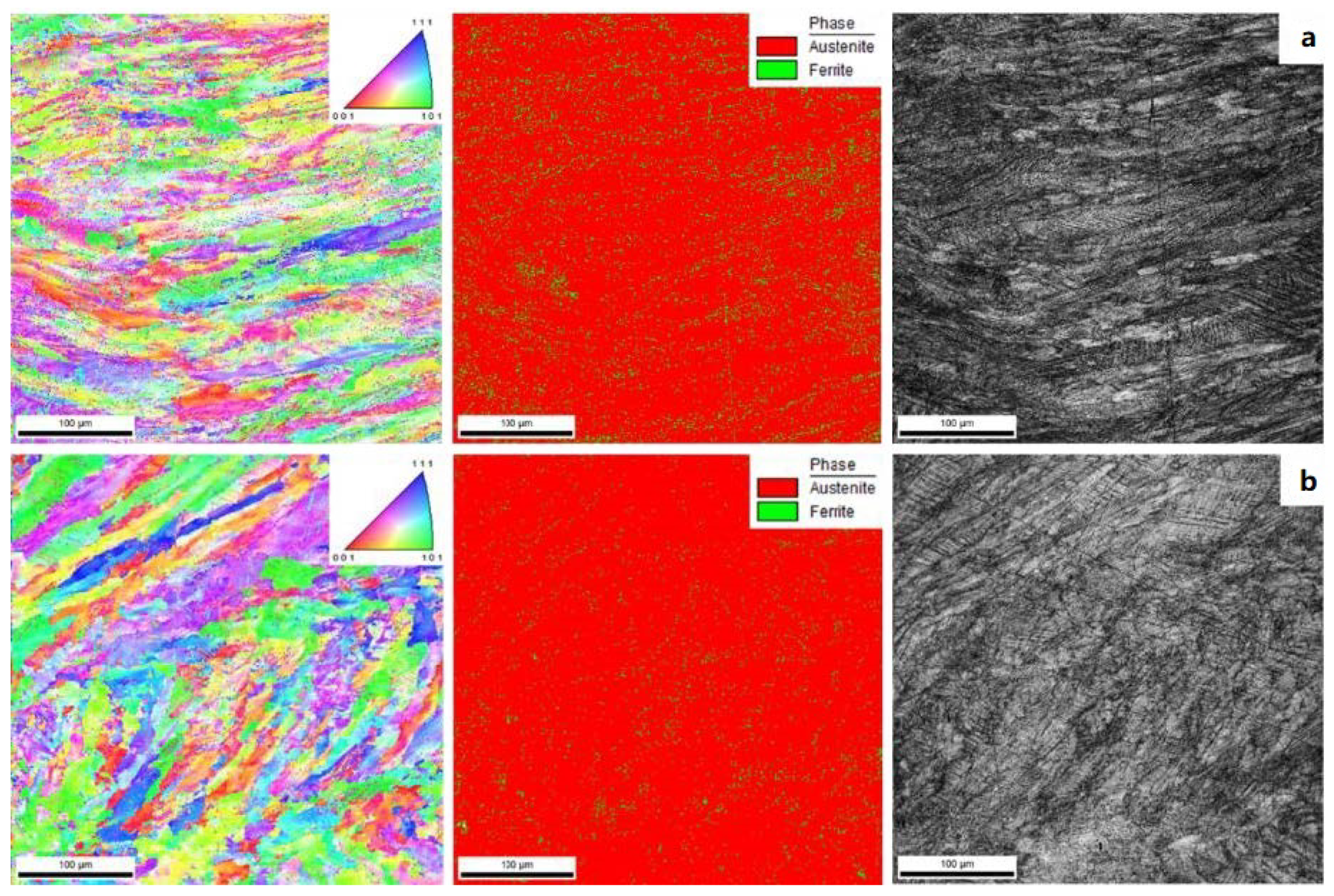

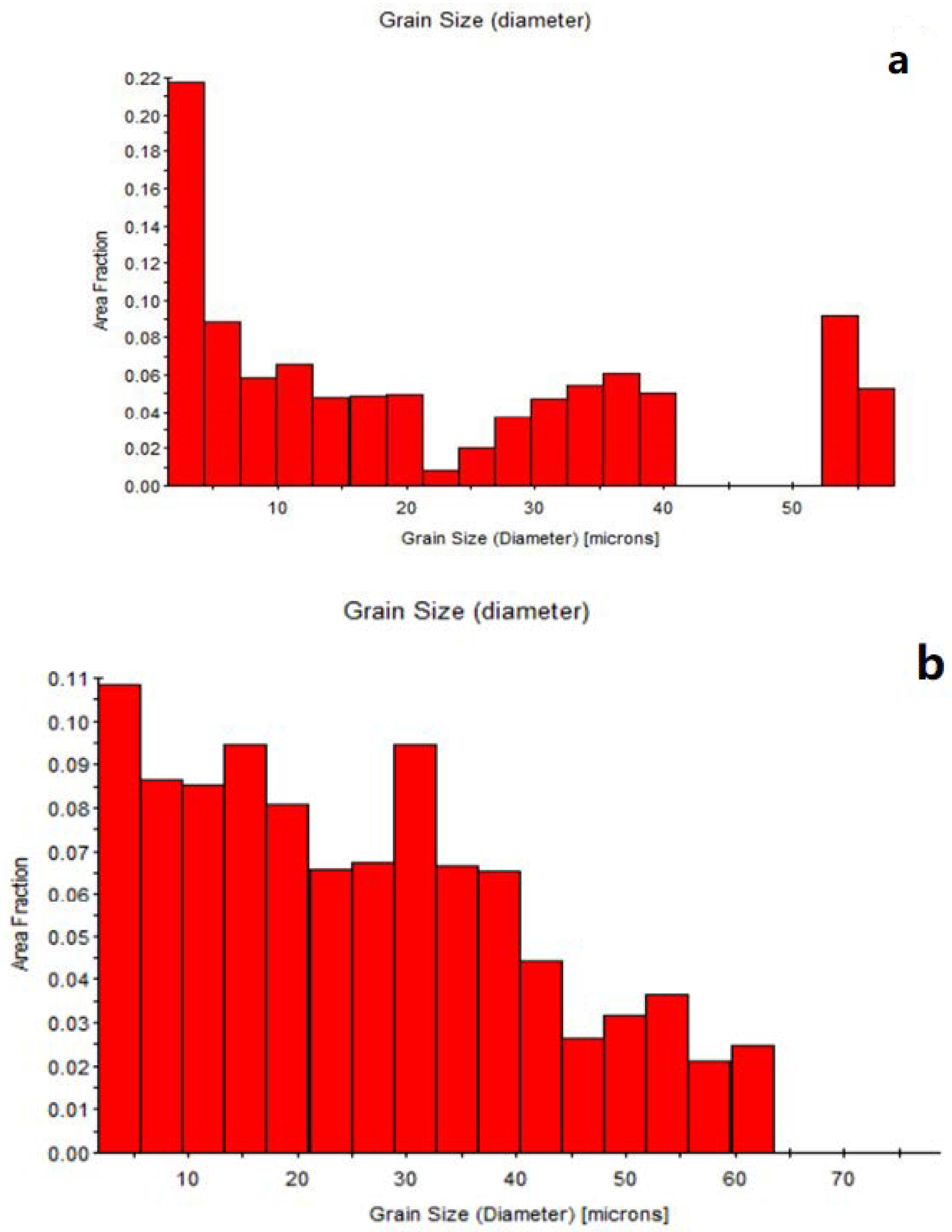

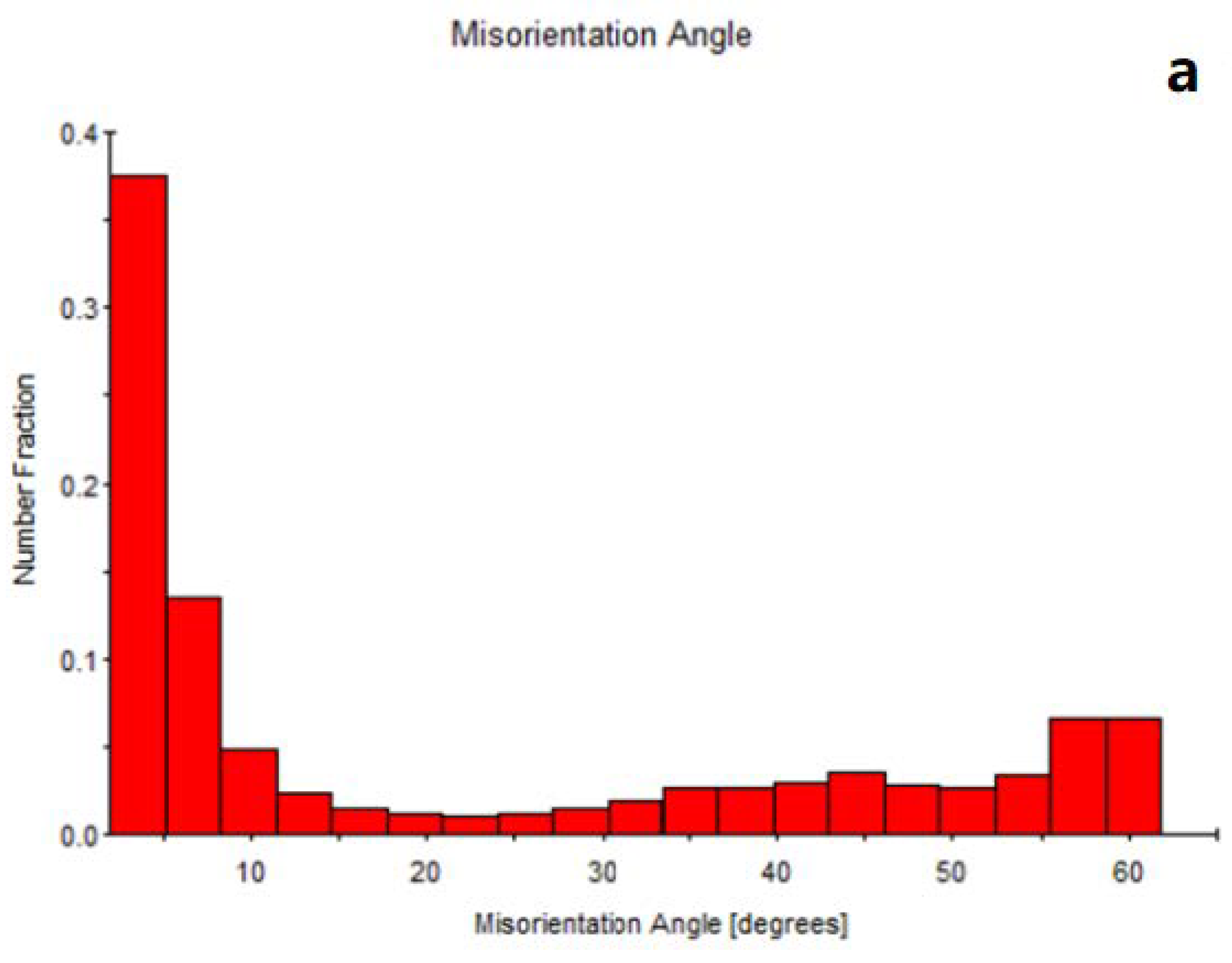

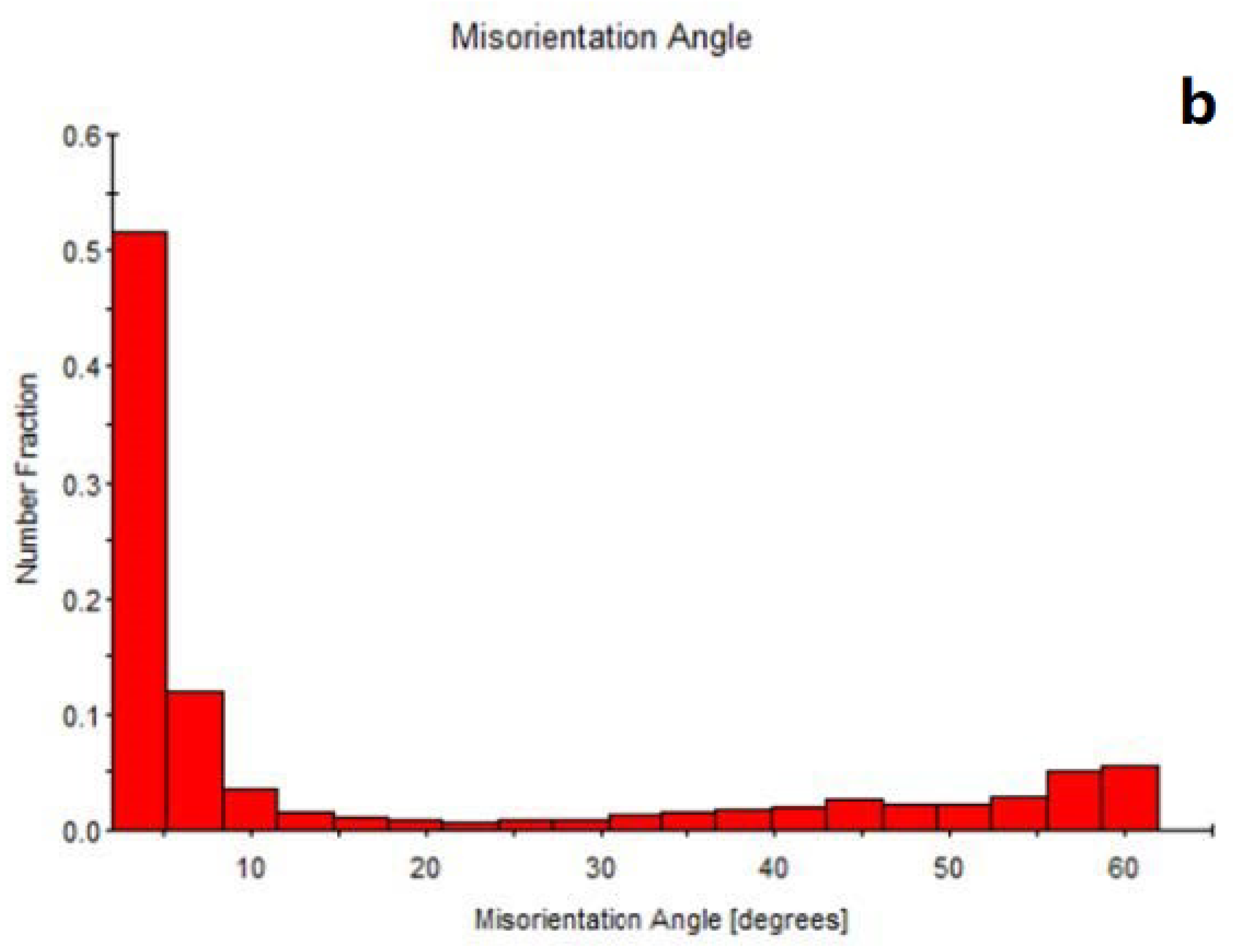

4.5. EBSD Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kim, F.H.; Moylan, S.P. Literature Review of Metal Additive Manufacturing Defects; US Department of Commerce, National Institute of Standards and Technology: Gaithersburg, MD, USA, 2018; pp. 1–17. [Google Scholar]

- Fu, J.; Qu, S.; Ding, J.; Song, X.; Fu, M.W. Comparison of the microstructure, mechanical properties and distortion of stainless steel 316 L fabricated by micro and conventional laser powder bed fusion. Addit. Manuf. 2021, 44, 102067. [Google Scholar] [CrossRef]

- Zinovieva, O.; Romanova, V.; Balokhonov, R. Effects of scanning pattern on the grain structure and elastic properties of additively manufactured 316L austenitic stainless steel. Mater. Sci. Eng. A 2022, 832, 142447. [Google Scholar] [CrossRef]

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Wei, H.L.; Elmer, J.W.; Debroy, T. Origin of grain orientation during solidification of an aluminum alloy. Acta Mater. 2016, 115, 123–131. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Lu, F.; Zhang, K.; Nie, P.; Elmi Hosseini, S.R.; Feng, K.; Li, Z. Dendritic microstructure and hot cracking of laser additive manufactured Inconel 718 under improved base cooling. J. Alloys Compd. 2016, 670, 312–321. [Google Scholar] [CrossRef]

- Darabi, R.; Azinpour, E.; Fiorentin, F.K.; Abarca, M.J.; Cesar de Sá, J.; Dzugan, J. Experimental and computational analysis of additively manufactured tensile specimens: Assessment of localized-cooling rate and ductile fracture using the Gurson-Tvergaard-Needleman damage model. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2021, 235, 1430–1442. [Google Scholar] [CrossRef]

- Parimi, L.L.; Ravi, G.; Clark, D.; Attallah, M.M. Microstructural and texture development in direct laser fabricated IN718. Mater. Charact. 2014, 89, 102–111. [Google Scholar] [CrossRef]

- Zerbst, U.; Bruno, G.; Buffiere, J.-Y.; Wegener, T.; Niendorf, T.; Wu, T.; Zhang, X.; Kashaev, N.; Meneghetti, G.; Hrabe, N.; et al. Damage tolerant design of additively manufactured metallic components subjected to cyclic loading: State of the art and challenges. Prog. Mater. Sci. 2021, 121, 100786. [Google Scholar] [CrossRef]

- Francois, M.M.; Sun, A.; King, W.E.; Henson, N.J.; Tourret, D.; Bronkhorst, C.A.; Carlson, N.N.; Newman, C.K.; Haut, T.; Bakosi, J.; et al. Modeling of additive manufacturing processes for metals: Challenges and opportunities. Curr. Opin. Solid State Mater. Sci. 2017, 21, 198–206. [Google Scholar] [CrossRef]

- Antony, K.; Arivazhagan, N.; Senthilkumaran, K. Numerical and experimental investigations on laser melting of stainless steel 316L metal powders. J. Manuf. Process. 2014, 16, 345–355. [Google Scholar] [CrossRef]

- Zheng, B.; Haley, J.C.; Yang, N.; Yee, J.; Terrassa, K.W.; Zhou, Y.; Lavernia, E.J.; Schoenung, J.M. On the evolution of microstructure and defect control in 316L SS components fabricated via directed energy deposition. Mater. Sci. Eng. A 2019, 764, 138243. [Google Scholar] [CrossRef]

- Foroozmehr, A.; Badrossamay, M.; Foroozmehr, E.; Golabi, S. Finite Element Simulation of Selective Laser Melting process considering Optical Penetration Depth of laser in powder bed. Mater. Des. 2016, 89, 255–263. [Google Scholar] [CrossRef]

- Keller, T.; Lindwall, G.; Ghosh, S.; Ma, L.; Lane, B.M.; Zhang, F.; Kattner, U.R.; Lass, E.A.; Heigel, J.C.; Idell, Y.; et al. Application of finite element, phase-field, and CALPHAD-based methods to additive manufacturing of Ni-based superalloys. Acta Mater. 2017, 139, 244–253. [Google Scholar] [CrossRef] [PubMed]

- Oh, W.J.; Lee, W.J.; Kim, M.S.; Jeon, J.B.; Shim, D.S. Repairing additive-manufactured 316L stainless steel using direct energy deposition. Opt. Laser Technol. 2019, 117, 6–17. [Google Scholar] [CrossRef]

- Azinpour, E.; Darabi, R.; Cesar de Sa, J.; Santos, A.; Hodek, J.; Dzugan, J. Fracture analysis in directed energy deposition (DED) manufactured 316L stainless steel using a phase-field approach. Finite Elem. Anal. Des. 2020, 177, 103417. [Google Scholar] [CrossRef]

- Aversa, A.; Saboori, A.; Librera, E.; de Chirico, M.; Biamino, S.; Lombardi, M.; Fino, P. The role of Directed Energy Deposition atmosphere mode on the microstructure and mechanical properties of 316L samples. Addit. Manuf. 2020, 34, 101274. [Google Scholar] [CrossRef]

- Rodgers, T.M.; Madison, J.D.; Tikare, V. Simulation of metal additive manufacturing microstructures using kinetic Monte Carlo. Comput. Mater. Sci. 2017, 135, 78–89. [Google Scholar] [CrossRef]

- Froes, F.; Boyer, R. Additive Manufacturing for the Aerospace Industry; Elsevier: Amsterdam, The Netherlands, 2019; ISBN 9780128140635. [Google Scholar]

- Ahmadi, A.; Mirzaeifar, R.; Moghaddam, N.S.; Turabi, A.S.; Karaca, H.E.; Elahinia, M. Effect of manufacturing parameters on mechanical properties of 316L stainless steel parts fabricated by selective laser melting: A computational framework. Mater. Des. 2016, 112, 328–338. [Google Scholar] [CrossRef]

- Taheri Andani, M.; Ghodrati, M.; Karamooz-Ravari, M.R.; Mirzaeifar, R.; Ni, J. Damage modeling of metallic alloys made by additive manufacturing. Mater. Sci. Eng. A 2019, 743, 656–664. [Google Scholar] [CrossRef]

- Taheri Andani, M.; Karamooz-Ravari, M.R.; Mirzaeifar, R.; Ni, J. Micromechanics modeling of metallic alloys 3D printed by selective laser melting. Mater. Des. 2018, 137, 204–213. [Google Scholar] [CrossRef]

- Bhujangrao, T.; Veiga, F.; Suárez, A.; Iriondo, E.; Mata, F.G. High-temperature mechanical properties of IN718 alloy: Comparison of additive manufactured and wrought samples. Crystals 2020, 10, 689. [Google Scholar] [CrossRef]

- Melzer, D.; Džugan, J.; Koukolíková, M.; Rzepa, S.; Vavřík, J. Structural integrity and mechanical properties of the functionally graded material based on 316L/IN718 processed by DED technology. Mater. Sci. Eng. A 2021, 811, 141038. [Google Scholar] [CrossRef]

- Darabi, R.; Ferreira, A.; Azinpour, E.; de Sa, J.C.; Reis, A. Thermal study of a cladding layer of Inconel 625 in Directed Energy Deposition (DED) process using a phase-field model. Int. J. Adv. Manuf. Technol. 2022, 119, 3975–3993. [Google Scholar] [CrossRef]

- Churyumov, A.Y.; Medvedeva, S.V.; Mamzurina, O.I.; Kazakova, A.A.; Churyumova, T.A. United approach to modelling of the hot deformation behavior, fracture, and microstructure evolution of austenitic stainless AISI 316Ti steel. Appl. Sci. 2021, 11, 3204. [Google Scholar] [CrossRef]

- Darabi, R.; Azinpour, E. Fracture Prediction Based on Evaluation of Initial Porosity Induced By Direct Energy Deposition. Eur. J. Comput. Mech. 2021, 29, 223–254. [Google Scholar] [CrossRef]

- Taylor, G.I. Taylor_1938.pdf. Journal of the Institute of Metals 1938, 62, 307–324. [Google Scholar]

- Hill, R.; Rice, J.R. Constitutive analysis of elastic-plastic crystals at arbitrary strain. J. Mech. Phys. Solids 1972, 20, 401–413. [Google Scholar] [CrossRef]

- Rice, J.R. Inelastic constitutive relations for solids: An internal-variable theory and its application to metal plasticity. J. Mech. Phys. Solids 1971, 19, 433–455. [Google Scholar] [CrossRef]

- Habibi, M.; Darabi, R.; Sa, J.C.; Reis, A. An innovation in finite element simulation via crystal plasticity assessment of grain morphology effect on sheet metal formability. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2021, 235, 1937–1951. [Google Scholar] [CrossRef]

- Zhang, P.; Karimpour, M.; Balint, D.; Lin, J. Three-dimensional virtual grain structure generation with grain size control. Mech. Mater. 2012, 55, 89–101. [Google Scholar] [CrossRef]

- Shifeng, W.; Shuai, L.; Qingsong, W.; Yan, C.; Sheng, Z.; Yusheng, S. Effect of molten pool boundaries on the mechanical properties of selective laser melting parts. J. Mater. Process. Technol. 2014, 214, 2660–2667. [Google Scholar] [CrossRef]

- Huang, Y. A User-Material Subroutine Incorporating Single crystal Plasticity in the ABAQUS Finite Element Program; Mech Report 178; Harvard University: Cambridge, MA, USA, 1991. [Google Scholar]

- Chua, C.K.; Wong, C.H.; Yeong, W.Y. Roadmap on Additive Manufacturing Standards. In Standards, Quality Control, and Measurement Sciences in 3D Printing and Additive Manufacturing; Academic Press: Cambridge, MA, USA, 2017; pp. 31–55. [Google Scholar] [CrossRef]

- Rocha, A.V.M.; Akhavan-Safar, A.; Carbas, R.; Marques, E.A.S.; Goyal, R.; El-zein, M.; da Silva, L.F.M. Numerical analysis of mixed-mode fatigue crack growth of adhesive joints using CZM. Theor. Appl. Fract. Mech. 2020, 106, 102493. [Google Scholar] [CrossRef]

- Simonovski, I. Material properties calibration for 316L steel using polycrystalline model. In Proceedings of the 13th International Conference on Nuclear Engineering Abstracts, Beijing, China, 16–20 May 2005; pp. 1–8. [Google Scholar]

- Guo, Q.; Zhao, C.; Qu, M.; Xiong, L.; Escano, L.I.; Hojjatzadeh, S.M.H.; Parab, N.D.; Fezzaa, K.; Everhart, W.; Sun, T.; et al. In-situ characterization and quantification of melt pool variation under constant input energy density in laser powder bed fusion additive manufacturing process. Addit. Manuf. 2019, 28, 600–609. [Google Scholar] [CrossRef]

- Zhong, Y.; Liu, L.; Wikman, S.; Cui, D.; Shen, Z. Intragranular cellular segregation network structure strengthening 316L stainless steel prepared by selective laser melting. J. Nucl. Mater. 2016, 470, 170–178. [Google Scholar] [CrossRef]

- Davies, E.R. Introduction to texture analysis. In Handbook of Texture Analysis; Imperial College Press: London, UK, 2008; ISBN 9781848161160. [Google Scholar]

| Material | . | . | |||

| SS 316L | 20 | 0.001 | 150 | 230 | 50 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Darabi, R.; Azinpour, E.; Ferreira, A.; de Sa, J.C.; Reis, A.; Dzugan, J. Damage Evolution Simulations via a Coupled Crystal Plasticity and Cohesive Zone Model for Additively Manufactured Austenitic SS 316L DED Components. Metals 2022, 12, 1096. https://doi.org/10.3390/met12071096

Darabi R, Azinpour E, Ferreira A, de Sa JC, Reis A, Dzugan J. Damage Evolution Simulations via a Coupled Crystal Plasticity and Cohesive Zone Model for Additively Manufactured Austenitic SS 316L DED Components. Metals. 2022; 12(7):1096. https://doi.org/10.3390/met12071096

Chicago/Turabian StyleDarabi, Roya, Erfan Azinpour, Andre Ferreira, Jose Cesar de Sa, Ana Reis, and Jan Dzugan. 2022. "Damage Evolution Simulations via a Coupled Crystal Plasticity and Cohesive Zone Model for Additively Manufactured Austenitic SS 316L DED Components" Metals 12, no. 7: 1096. https://doi.org/10.3390/met12071096

APA StyleDarabi, R., Azinpour, E., Ferreira, A., de Sa, J. C., Reis, A., & Dzugan, J. (2022). Damage Evolution Simulations via a Coupled Crystal Plasticity and Cohesive Zone Model for Additively Manufactured Austenitic SS 316L DED Components. Metals, 12(7), 1096. https://doi.org/10.3390/met12071096