Melting–Dropping Property of Blast Furnace Charge on the Basis of Its Slag Formation Behavior

Abstract

:1. Introduction

2. Materials and Procedures

2.1. Raw Material

2.2. Experimental Procedure

3. Results and Discussion

3.1. Melting–Dropping Property and Slag Formation Behavior

3.2. Distribution of Iron and Slag in the Graphite Crucible

3.3. Phase-Chemical Composition

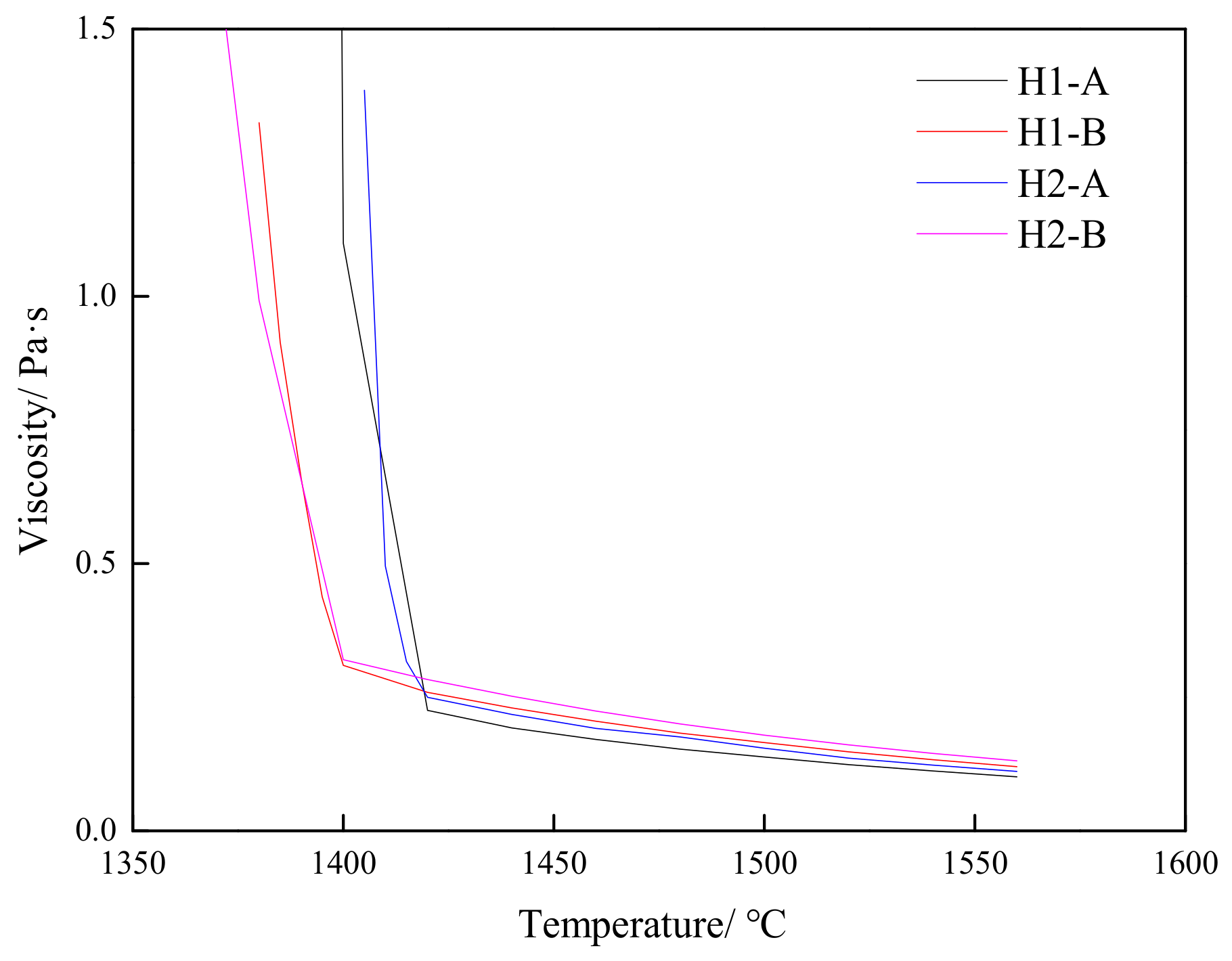

3.4. Melting Property and Mobility of the Slag

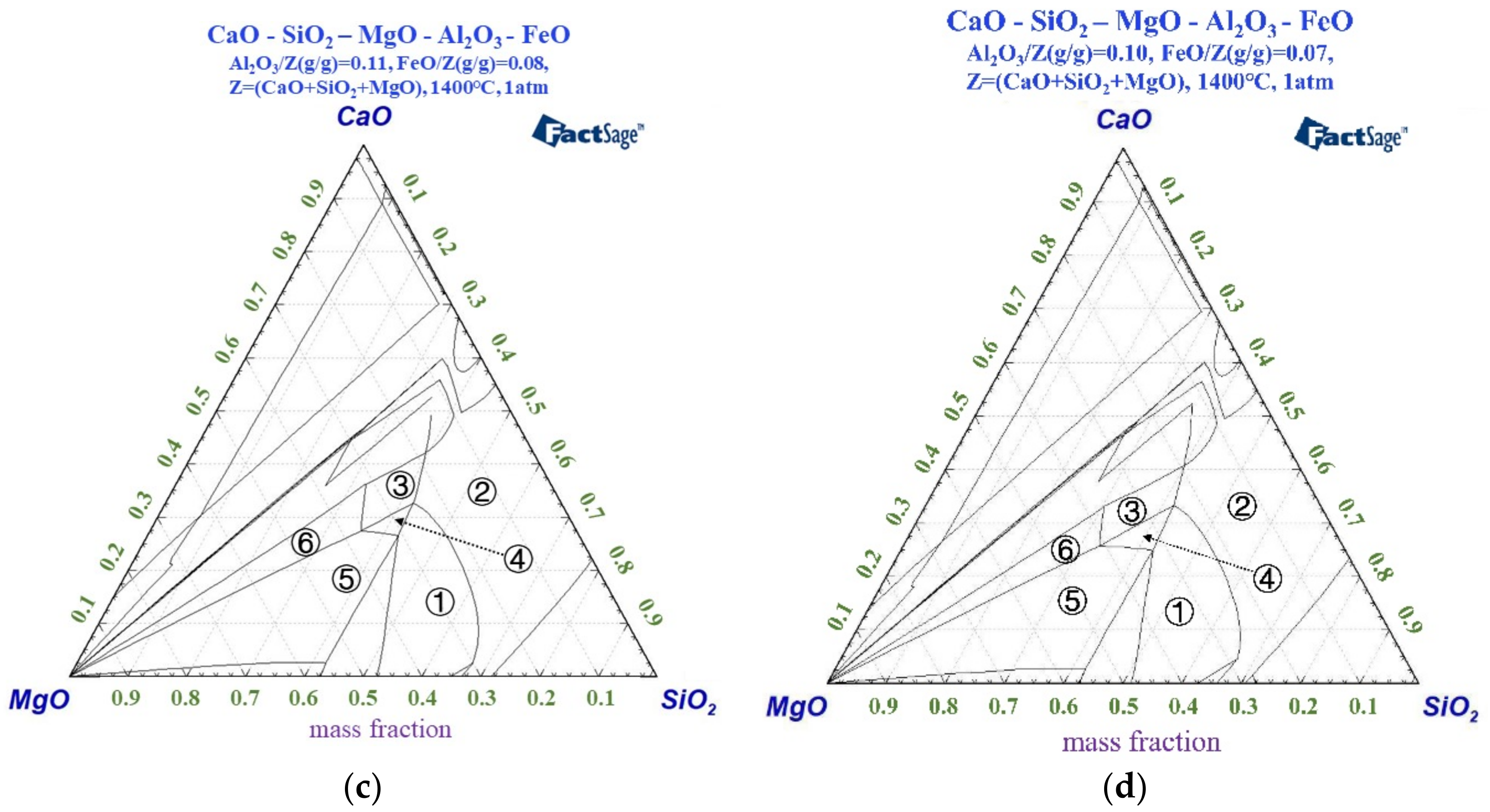

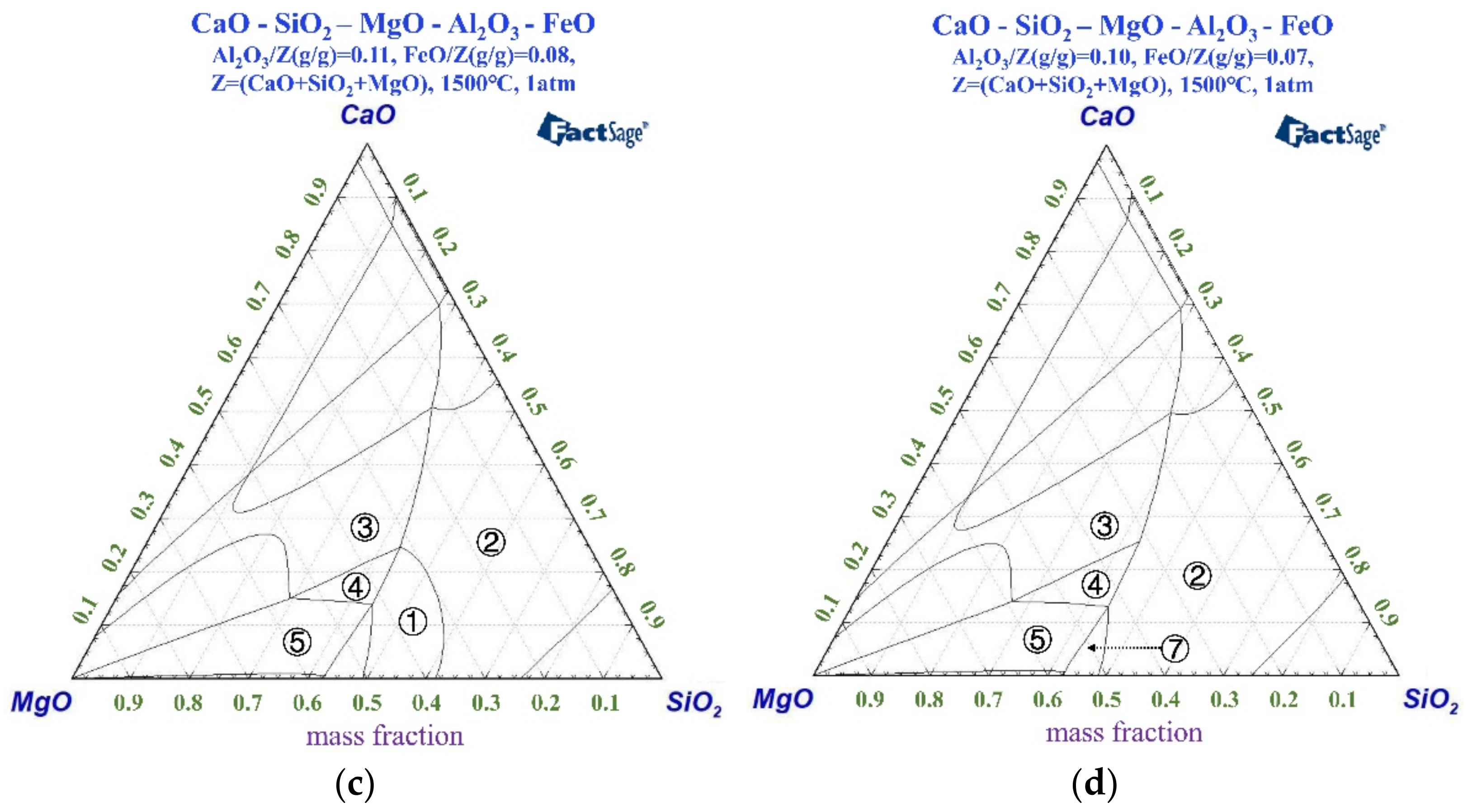

3.5. Theoretical Calculation by FactSage Software

- ①

- Fe(s) + Olivine + Slag-liq

- ②

- Fe(s) + Slag-liq

- ③

- Fe(s) + Monoxide + Slag-liq

- ④

- Fe(s) + Monoxide + Olivine + Slag-liq

- ⑤

- Fe(s) + Monoxide + Olivine + Slag-liq + Spinel

- ⑥

- Fe(s) + Monoxide + Slag-liq + Spinel

- ⑦

- Fe(s) + Olivine + Slag-liq + Spinel

4. Conclusions

- A positive linear relationship exists between the melting behavior of slag and the melting–dropping property of the corresponding charge. Owing to their poor melting–dropping property, single iron ores are not suitable for BF production.

- It is proposed that the effect is fundamentally dependent on the chemical; the mix charge can result in a concentration gradient of the chemical components at the contact interface, which can improve slag formation at high temperatures and enhance the melting–dropping property of the charging mix.

- It is proposed that the self-softening and melting properties of the lump ores were dramatically improved by interaction between sinters and lump ores; the collocation pattern of lump ores and ratio between lump ores was also optimized, accordant with the interaction. So, the chemical component is the key factor causing the difference in slag formation behavior. An excessive amount of lump ore in the charging mix results in a mix charge with higher Al2O3 content, which causes SiO2 and Al2O3 in the slag to absorb O2– in order to generate (SiO4)4– and (AlO4)5–. In the CaO-SiO2-MgO-Al2O3-FeO slag system, this behavior is likely to form a high-fusion-point phase such as spinel.

- Lump ores are easy to reduce at lower temperatures. The mix charge containing fewer lump ore retains more FeO, providing free-moving Fe2+ and O2– in the Si-O network. Al2O3 in slag absorbs O2– to generate (AlO6)5–. The main phases in the slag are feldspathic, causing variations in fluidity.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Elices, M.; Guinea, G.V.; Gómez, J.; Planas, J. The Cohesive Zone Model: Advantages, Limitations and Challenges. Eng. Fract. Mech. 2002, 69, 137–163. [Google Scholar] [CrossRef]

- Nomura, S.; Higuchi, K.; Kunitomo, K.; Naito, M. Reaction Behavior of Formed Iron Coke and Its Effect on Decreasing Thermal Reserve Zone Temperature in Blast Furnace. ISIJ Int. 2010, 50, 1388–1395. [Google Scholar] [CrossRef] [Green Version]

- Shi, P.Y.; Zhou, P.; Fu, D.; Zhou, C.Q. Mathematical model for burden distribution in blast furnace. Ironmak. Steelmak. 2016, 43, 74–81. [Google Scholar] [CrossRef]

- Committee on Reaction within Blast Furnace. Dissection of Quenched Blast Furnaces. In Blast Furnace Phenomena and Modelling; Springer: Amsterdam, The Netherlands, 1987. [Google Scholar]

- Yu, Y.; Saxén, H. Experimental and DEM Study of Segregation of Ternary Size Particles in a Blast Furnace Top Bunker Model. Chem. Eng. Sci. 2010, 65, 5237–5250. [Google Scholar] [CrossRef]

- Yang, W.; Zhou, Z.; Pinson, D.; Yu, A. A New Approach for Studying Softening and Melting Behavior of Particles in a Blast Furnace Cohesive Zone. Metall. Mater. Trans. B 2015, 46, 977–992. [Google Scholar] [CrossRef]

- Liu, X.; Wu, S.; Huang, W.; Zhang, K.; Du, K. Influence of High Temperature Interaction between Iron Ores on the Formation Behavior of Primary Slags. ISIJ Int. 2014, 54, 2089–2096. [Google Scholar] [CrossRef] [Green Version]

- Wu, S.L.; Xu, H.F.; Tian, Y.Q. Evaluation of Lump Ores for Use in Modern Blast Furnaces as Part of Mixed Burden Practice. Ironmak. Steelmak. 2009, 36, 19–23. [Google Scholar] [CrossRef]

- Wu, S.L.; Su, B.; Liu, X.L.; Kou, M.Y. Optimisation of the Blast Furnace Burden Based on Its Primary Slag Formation Behavior. Ironmak. Steelmak. 2016, 45, 50–57. [Google Scholar] [CrossRef]

- Wei, H.U.; Shusen, C.; Wenxuan, X.U.; Bang, J.W. Effect of Particle Size on Burden Distribution of Stock Surface and Permeability of Burden Layer in Blast Furnace. J. Iron Steel Res. 2018, 30, 769–775. [Google Scholar]

- Gupta, P.K.; Rao, A.S.; Sekhar, V.R.; Ranjan, M.; Naha, T.K. Burden Distribution Control and Its optimisation under High Pellet Operation. Ironmak. Steelmak. 2013, 37, 235–239. [Google Scholar] [CrossRef]

- Umadevi, T.; Brahmacharyulu, A.; Sah, R.; Mahapatra, P.C. Influence of Sinter Grate Suction Pressure (Flame Front Speed) on microstructure, productivity and quality of Iron Ore Sinter. Ironmak. Steelmak. 2014, 41, 410–417. [Google Scholar] [CrossRef]

- Long, C.; Xue, Q.; Guo, W.; She, X.; Wang, J. Study on the interaction behavior between lump and sinter under the condition of oxygen blast furnace. Ironmak. Steelmak. 2016, 43, 458–464. [Google Scholar]

- Wu, S.; Han, H.L.; Tao, W.Z.; Xu, H.F.; Wang, H.W. Increasing Proportion of Natural Lump Ores in Blast Furnace. Iron Steel 2009, 44, 12–16. [Google Scholar]

- Tanskanen, P.A.; Huttunen, S.M.; Mannila, P.H.; Härkki, J.J. Experimental Simulations of Primary Slag Formation in Blast Furnace. Ironmak. Steelmak. 2013, 29, 281–286. [Google Scholar] [CrossRef]

- Hino, M.; Nagasaka, T.; Katsumata, A.; Higuchi, K.I.; Yamaguchi, K.; Kon-No, N. Simulation of Primary-Slag Melting Behavior in the Cohesive Zone of a Blast Furnace, Considering the Effect of Al2O3, FetO, and Basicity in the Sinter Ore. Metall. Mater. Trans. B 1999, 30, 671–683. [Google Scholar] [CrossRef]

| Sample | T[Fe] | FeO | SiO2 | CaO | MgO | Al2O3 | R2 |

|---|---|---|---|---|---|---|---|

| S-1 | 58.52 | 9.33 | 4.85 | 9.04 | 1.27 | 1.99 | 1.86 |

| S-2 | 57.20 | 9.10 | 5.06 | 10.25 | 1.88 | 1.33 | 2.02 |

| P-1 | 66.53 | 0.32 | 2.02 | 1.49 | 0.16 | 0.59 | 0.73 |

| P-2 | 66.82 | 0.41 | 2.25 | 1.08 | 0.11 | 0.53 | 0.48 |

| O-1 | 63.39 | 0.48 | 3.14 | 0.04 | 0.06 | 1.25 | 0.01 |

| H1-A | 67.36 | 6.25 | 4.30 | 6.24 | 0.88 | 1.69 | 1.45 |

| H1-B | 60.55 | 6.22 | 4.15 | 6.01 | 0.85 | 1.66 | 1.44 |

| H2-A | 59.85 | 6.06 | 4.23 | 6.87 | 1.26 | 1.20 | 1.62 |

| H2-B | 59.70 | 6.07 | 4.29 | 6.80 | 1.25 | 1.23 | 1.58 |

| Sample | S-1 | P-1 | P-2 | O-1 |

|---|---|---|---|---|

| H1-A | 65 | 10 | 5 | 20 |

| H1-B | 65 | 5 | 5 | 25 |

| H2-A | 65 | 10 | 5 | 20 |

| H2-B | 65 | 5 | 5 | 25 |

| Sample | Deformation | Softening | Hemispherical Fusion | Flow |

|---|---|---|---|---|

| S-1 | 1312 | 1369 | 1388 | 1422 |

| S-2 | 1337 | 1373 | 1396 | 1441 |

| P-1 | 1184 | 1200 | 1222 | 1234 |

| P-2 | 1116 | 1139 | 1234 | 1318 |

| O-1 | 1088 | 1096 | 1109 | 1123 |

| H1-A | 1218 | 1311 | 1317 | 1324 |

| H1-B | 1204 | 1303 | 1312 | 1329 |

| H2-A | 1224 | 1324 | 1332 | 1345 |

| H2-B | 1210 | 1316 | 1323 | 1335 |

| Sample | CaO | SiO2 | MgO | Al2O3 | FeO | R2 |

|---|---|---|---|---|---|---|

| H1-A | 44.05 | 32.16 | 6.27 | 8.95 | 8.57 | 1.3 |

| H1-B | 43.05 | 35.09 | 6.50 | 8.70 | 6.66 | 1.2 |

| H2-A | 45.12 | 32.93 | 6.18 | 9.30 | 6.47 | 1.3 |

| H2-B | 42.75 | 36.65 | 6.48 | 8.35 | 5.77 | 1.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Diao, J.; Xie, B.; Qi, C.; Du, P. Melting–Dropping Property of Blast Furnace Charge on the Basis of Its Slag Formation Behavior. Metals 2022, 12, 987. https://doi.org/10.3390/met12060987

Wang Y, Diao J, Xie B, Qi C, Du P. Melting–Dropping Property of Blast Furnace Charge on the Basis of Its Slag Formation Behavior. Metals. 2022; 12(6):987. https://doi.org/10.3390/met12060987

Chicago/Turabian StyleWang, Yonghong, Jiang Diao, Bing Xie, Chenglin Qi, and Ping Du. 2022. "Melting–Dropping Property of Blast Furnace Charge on the Basis of Its Slag Formation Behavior" Metals 12, no. 6: 987. https://doi.org/10.3390/met12060987

APA StyleWang, Y., Diao, J., Xie, B., Qi, C., & Du, P. (2022). Melting–Dropping Property of Blast Furnace Charge on the Basis of Its Slag Formation Behavior. Metals, 12(6), 987. https://doi.org/10.3390/met12060987