Development and Implementation of Decision Support Systems for Blast Smelting Control in the Conditions of PrJSC “Kamet-Steel”

Abstract

1. Introduction

2. Materials and Methods

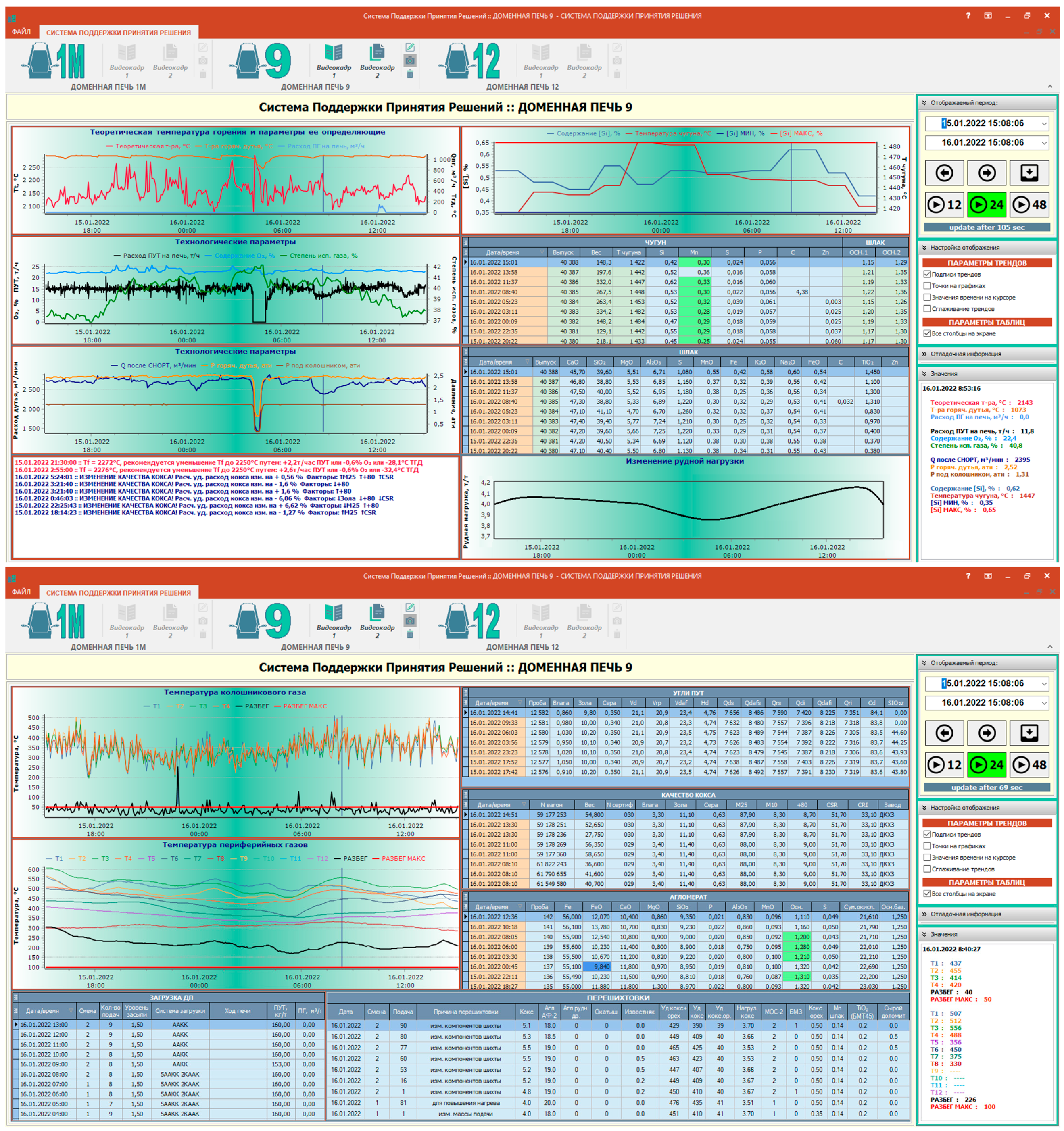

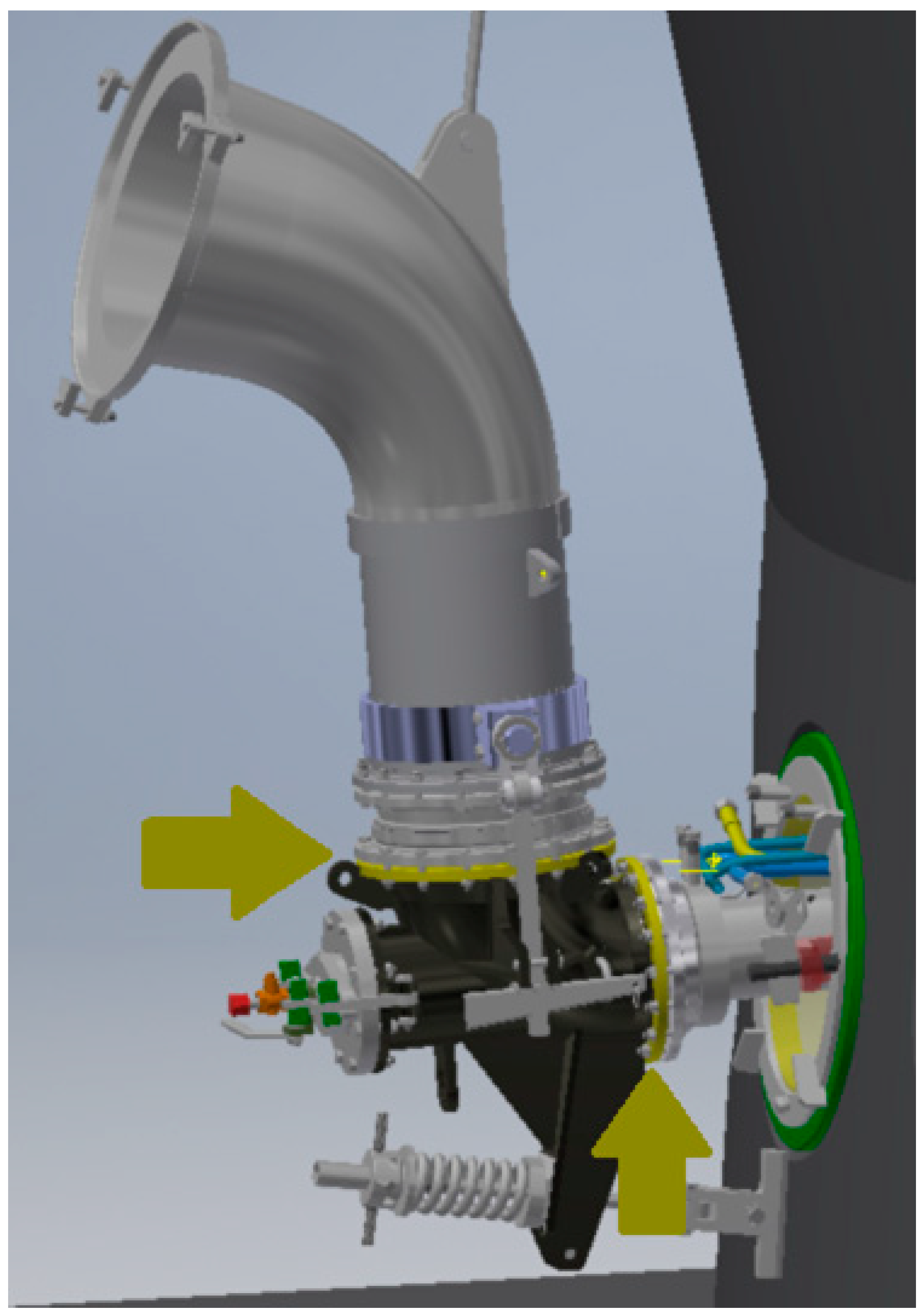

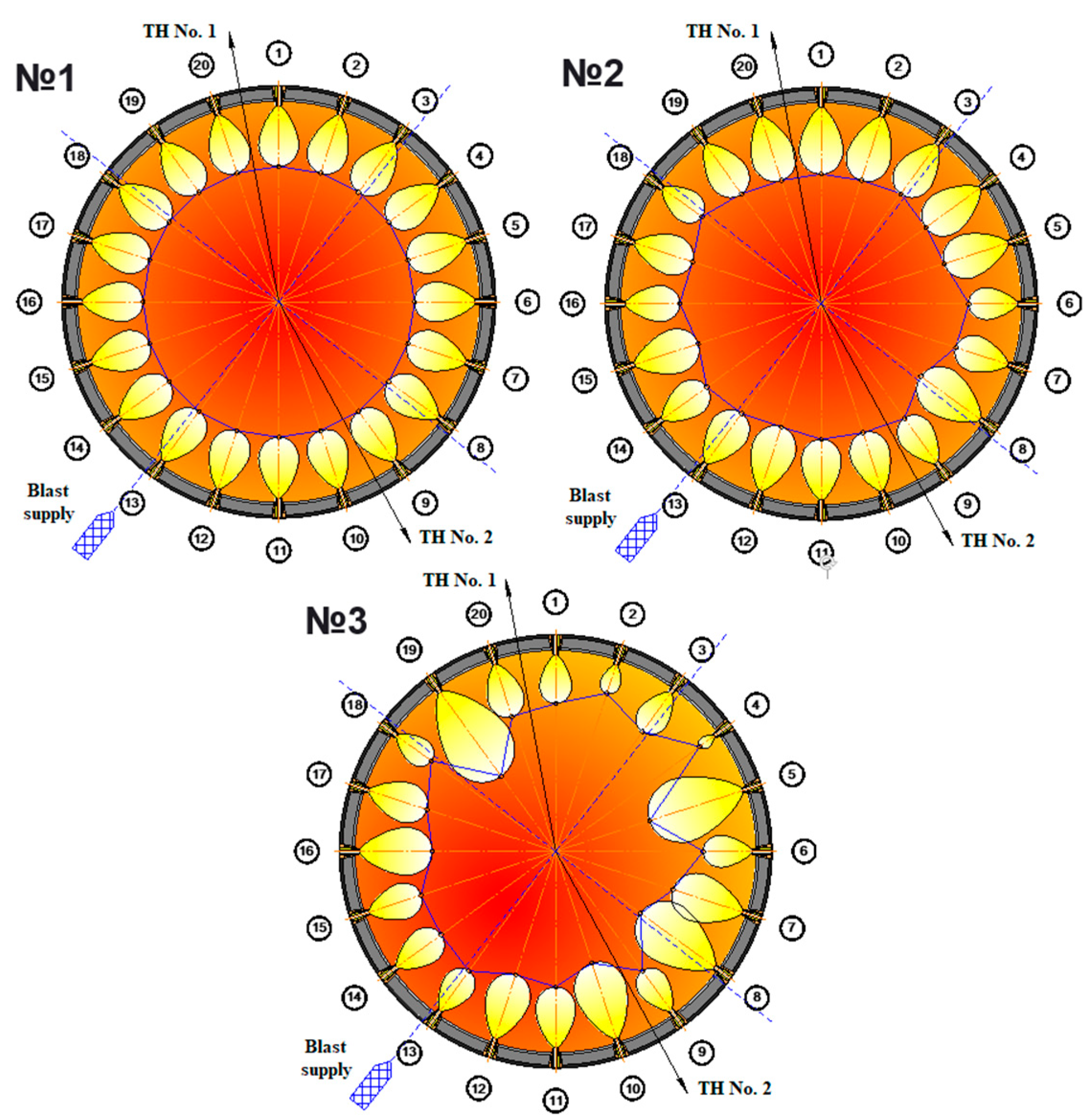

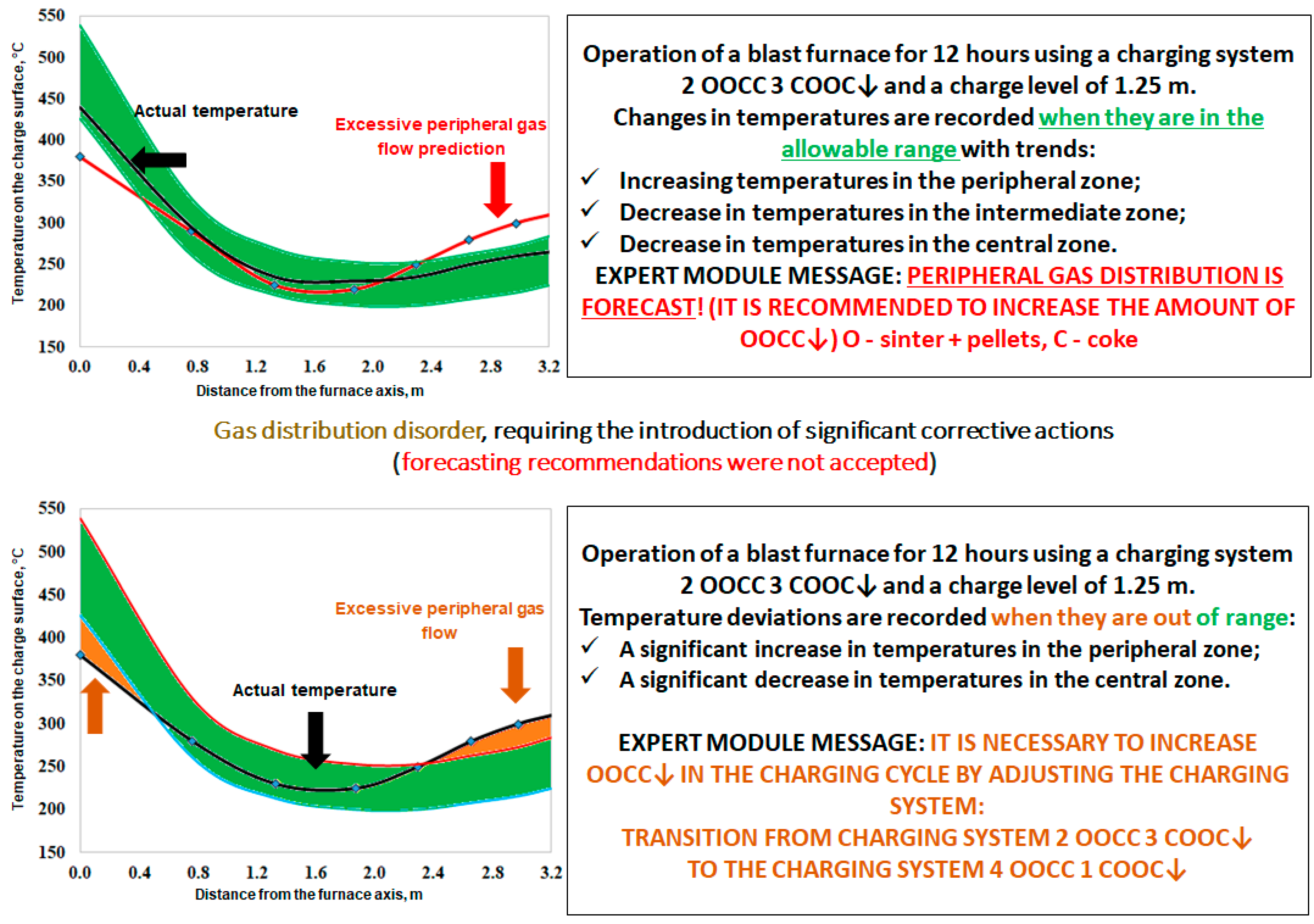

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Semenov, Y.S.; Shumelchik, E.I.; Vishnyakov, V.I.; Nasledov, A.V. Model system for selecting and correcting charging programs for blast furnaces equipped with a bell-less charging apparatu. Metallurgist 2013, 56, 652–657. [Google Scholar] [CrossRef]

- Semenov, Y.S.; Shumelchik, E.I.; Horupakha, V.V. Expert Module of the Thermal Probe System for Blast Furnace Charging Control. Steel Transl. 2018, 48, 802–806. [Google Scholar] [CrossRef]

- Semenov, Y.S.; Shumelchik, E.I.; Horupakha, V.V. Blast Furnace Shaft Thermal State Monitoring System. Steel Transl. 2017, 47, 728–731. [Google Scholar] [CrossRef]

- Ivancha, N.G.; Murav’eva, I.G.; Shumel’chik, E.I.; Vishnyakov, V.I.; Semenov, Y.S. Complex Mathematical Model of the Distribution of Multicomponent Charge in a Blast Furnac. Metallurgist 2018, 62, 95–100. [Google Scholar] [CrossRef]

- Gasparini, V.M.; de Castro, L.F.A.; Bitarães Quintas, A. Thermo-chemical model for blast furnace process control with the prediction of carbon consumption. J. Mater. Res. Technol. 2017, 6, 220–222. [Google Scholar] [CrossRef]

- Agrawal, A.; Agarwal, M.K.; Kothari, A.K.; Mallick, S. A mathematical model to control thermal stability of blast furnace using proactive thermal indicator. Ironmak. Steelmak. 2017, 46, 133–140. [Google Scholar] [CrossRef]

- Agrawal, A.; Kothari, A.K.; Kumar, A.; Singh, M.K.; Dubey, S.K.; Ramna, R.V.; Nath, S. Advances in thermal level measurement techniques using mathematical models, statistical models and decision support systems in blast furnace. Metall. Res. Technol. 2019, 116, 16. [Google Scholar] [CrossRef]

- Zhang, L.J.; Zhang, G. A knowledge-based multi-role decision support system for ore blending cost optimization of blast furnace. Eur. J. Oper. Res. 2011, 215, 194–203. [Google Scholar] [CrossRef]

- Wright, B.D.; Zulli, P. Application of decision support system for thermal balance control in the ironmaking blast furnac Chemeca. In Enhancement of Industrial Energy Efficiency and Sustainability; MDPI: Basel, Switzerland, 2020. [Google Scholar]

- Lavrov, V.V.; Spirin, N.A.; Gurin, I.A.; Rybolovlev, V.Y.; Krasnobaev, A.V. Software for decision-making support in blast-furnace operation. Steel Transl. 2017, 47, 538–543. [Google Scholar] [CrossRef]

- Semenov, Y.S.; Podkorytov, A.L.; Shumelchik, E.I.; Horupakha, V.V.; Semion, I.Y.; Orobtsev, I.Y. Decision Support System for Controlling Thermal State of Blast Furnace Smelting. Steel Transl. 2021, 51, 261–266. [Google Scholar] [CrossRef]

- Shumelchyk, Y.; Semenov, Y.; Horupakha, V.; Krot, P.; Hulina, I. Model-Based Decision Support System for the Blast Furnace Charge of Burden Material Nonstationary Systems. Theory Appl. Appl. Cond. Monit. 2021, 18, 340–351. [Google Scholar] [CrossRef]

- Chaika, A.L.; Lebed, V.V.; Kornilov, B.V.; Shumel’chik, E.I.; Karikov, S.A.; Safonov, S.E. Implementation of a Set of Long-Term and Energy-Saving Cast Iron Production Models in Blast Furnaces in Ukrain. Steel Transl. 2021, 51, 201–204. [Google Scholar] [CrossRef]

- Semenov, Y.S.; Shumelchik, E.I.; Horupakha, V.V.; Kuznetsov, A.M.; Zubenko, A.V.; Kovalenko, A.G. Using Thermal Probes to Regulate the Batch Distribution in a Blast Furnace with Pulverized-Coal Injection. Steel Transl. 2017, 47, 389–393. [Google Scholar] [CrossRef]

- Semenov, Y.S.; Shumel’chik, E.I.; Gorupakha, V.V. Efficient Management of the Charging of Blast Furnaces and the Application of Contemporary Means of Control Over the Variable Technological Condition. Metallurgist 2018, 61, 950–958. [Google Scholar] [CrossRef]

- Semenov, Y.S. Temperature Distribution of the Gas Flux in Blast Furnace. Steel Transl. 2017, 47, 473–477. [Google Scholar] [CrossRef]

- Tian, J.; Tanaka, A.; Hou, Q.; Chen, X. Radar Detection-based Modeling in a Blast Furnace: A Prediction Model of Burden Surface Shape after Charging. ISIJ Int. 2018, 58, 1999–2008. [Google Scholar] [CrossRef]

- Tian, J.; Tanaka, A.; Hou, Q.; Chen, X. Radar Detection-Based Modeling in a Blast Furnace: A Prediction Model of Burden Surface Descent Speed. Metals 2019, 9, 609. [Google Scholar] [CrossRef]

- Li, M.; Wei, H.; Ge, Y.; Xiao, G.; Yu, Y. A Mathematical Model Combined with Radar Data for Bell-Less Charging of a Blast Furnace. Processes 2020, 8, 239. [Google Scholar] [CrossRef]

- Omori, Y. Blast Furnace Phenomena and Modelling; Elsevier: London, UK, 1987. [Google Scholar]

- Schürmann, E.; Gudenau, H.W.; Peters, K.H. Untersuchung der kohäsiven Zone am Hochofen Schwelgern, Teil I: Erfassung der kohäsiven Zone und ihre Auswirkung auf die Betriebsergebniss. Stahl Eisen 1982, 102, 35–40. [Google Scholar]

- Tovarovskii, I.G. Poznanie Protsessov i Razvitie Tekhnologii Domennoi Plavki (Understanding and Development of Blast Furnace Smelting Technology); Zhurfond: Dnepropetrovsk, Ukraine, 2015; p. 912. (In Russian) [Google Scholar]

- Gao, C.; Jian, L.; Luo, S. Modeling of the thermal state change of blast furnace hearth with support vector machine. IEEE Trans. Ind. Electron. 2012, 59, 1134–1145. [Google Scholar] [CrossRef]

- Han, Y.; Li, J.; Yang, X.L.; Liu, W.X.; Zhang, I.Z. Dynamic Prediction Research of Silicon Content in Hot Metal Driven by Big Data in Blast Furnace Smelting Process under Hadoop Cloud Platform. Complex. Probl. Handled Big Data Technol. 2018, 16, 1577. [Google Scholar] [CrossRef]

- Chen, W.; Wang, B.-X.; Han, H.L. Prediction and control for silicon content in pig iron of blast furnace by integrating artificial neural network with genetic algorithm. Ironmak. Steelmak. 2010, 37, 458–463. [Google Scholar] [CrossRef]

- Saxén, H.; Pettersson, F. Nonlinear Prediction of the Hot Metal Silicon Content in the Blast Furnace. ISIJ Int. 2007, 47, 1732–1737. [Google Scholar] [CrossRef]

- David, S.F.; David, F.F.; Machado, M.L.P. Artificial Neural Network Model for Predict of Silicon Content in Hot Metal Blast Furnace. Mater. Sci. Forum 2016, 869, 572–577. [Google Scholar]

- Bhattacharya, T. Prediction of Silicon Content in Blast Furnace Hot Metal Using Partial Least Squares (PLS). ISIJ Int. 2005, 45, 1943–1945. [Google Scholar] [CrossRef]

- Saxén, H.; Gao, C.; Gao, Z. Data-Driven Time Discrete Models for Dynamic Prediction of the Hot Metal Silicon Content in the Blast Furnace–A Review. IEEE Trans. Ind. Inform. 2013, 9, 2213–2225. [Google Scholar] [CrossRef]

- Li, J.; Hua, C.; Yang, Y.; Guan, X. Fuzzy Classifier Design for Development Tendency of Hot Metal Silicon Content in Blast Furnace. IEEE Trans. Ind. Inform. 2018, 14, 1115–1123. [Google Scholar] [CrossRef]

- Li, J.; Hua, C.; Yang, Y.; Guan, X. Bayesian Block Structure Sparse Based T–S Fuzzy Modeling for Dynamic Prediction of Hot Metal Silicon Content in the Blast Furnace. IEEE Trans. Ind. Inform. 2018, 65, 4933–4942. [Google Scholar] [CrossRef]

- Li, J.; Hua, C.; Yang, Y.; Guan, X. Data-Driven Bayesian-Based Takagi-Sugeno Fuzzy Modeling for Dynamic Prediction of Hot Metal Silicon Content in Blast Furnace. IEEE Trans. Ind. Inform. 2020, 52, 1087–1099. [Google Scholar] [CrossRef]

- Shirshov, M.Y.; Druzhkov, V.G. Improving the automatic blast distribution in blast furnace. Steel Transl. 2015; 45, 49–53. [Google Scholar]

- Motta, B.E.; Souza, L. Hot Blast Flow Measurement in Blast Furnace in Straight Pipe. Mod. Instrum. 2013, 2, 68–73. [Google Scholar] [CrossRef][Green Version]

- Semenov, Y.S.; Horupakha, V.V.; Shumelchik, E.I.; Alter, M.A. Blast Furnace Operation Improvement by Forming Uniform Circular Distribution of Raceway’s Thermal Mod AISTech. In Proceedings of the Iron and Steel Technology Conference, Nashville, TN, USA, 29 June–1 July 2021; pp. 184–192. [Google Scholar] [CrossRef]

- Agrawal, A.; Tiwari, K.; Kumar, S. Technological advancements in evaluating the performance of the pulverized coal injection through tuyeres in blast furnace. Metall. Res. Technol. 2020, 117, 611. [Google Scholar] [CrossRef]

- Liu, S.; Zhou, Z.; Dong, K.; Yu, A.; Pinson, D.; Tsalapatis, J. Numerical investigation of burden distribution in a blast furnace. Steel Res. Int. 2015, 86, 651–661. [Google Scholar] [CrossRef]

- Chibwe, D.K. Optimised Burden Delivery for Blast Furnace Operations. Ph.D. Thesis, University of Newcastle, Newcastle, Australia, 2019. [Google Scholar]

- Chibwe, D.K.; Evans, G.M.; Doroodchi, E.; Monaghan, J.; Pinson, D.J.; Chew, S.J. Charge material distribution behaviour in blast furnace charging system. Powder Technol. 2020, 366, 22–35. [Google Scholar] [CrossRef]

- Park, J.; Jung, H.; Jo, M.; Oh, H.; Han, J. Mathematical modeling of the burden distribution in the blast furnace shaft. Met. Mater. Int. 2011, 17, 485–496. [Google Scholar] [CrossRef]

- Mitra, T. Modeling of Burden Distribution in the Blast Furnace. Ph.D. Thesis, Abo Akademi University, Turku/Abo, Finland, 2016. [Google Scholar]

- Mitra, T.; Saxen, H. Simulation of burden distribution and charging in an ironmaking blast furnace. IFAC-Pap. Online 2015, 48, 183–188. [Google Scholar] [CrossRef]

- Yang, Y.; Yin, Y.; Wunsch, D.; Zhang, S.; Chen, X.; Li, X.; Cheng, S.; Wu, M.; Liu, K.Z. Development of blast furnace burden distribution process modeling and control. ISIJ Int. 2017, 57, 1350–1363. [Google Scholar] [CrossRef]

- Zhu, Q.; Lu, L.; Yin, Y.X.; Chen, X.Z. Burden distribution calculation of bell-less top of blast furnace based on multi-radar data. J. Iron Steel Res. Int. 2013, 20, 33–37. [Google Scholar] [CrossRef]

- Ivko, V.V.; Krupii, V.G.; Rudenko, Y. Analysis of the effectiveness of flushing materials for fight against cluttering the hearth of blast furnace. Metall. Gornorudn. Promyshlennost 2009, 3, 17–19. (In Russian) [Google Scholar]

- Kurunov, I.F.; Bol’shakova, O.G. Briquets for washing blast furnace. Metallurgist 2007, 51, 253–261. [Google Scholar] [CrossRef]

- Kurunov, I.F.; Shcheglov, E.M.; Emel’yanov, V.L.; Titov, V.N.; Bol’Shakova, O.G. Washing the hearth of blast furnaces with briquets made from scale. Metallurgist 2007, 51, 306–311. [Google Scholar] [CrossRef]

- Semenov, Y.S.; Horupakha, V.V.; Shumelchik, Y.I. Measures for Preventing Disruption in the Blast Furnace Operation under Use of Pulverized Coal. Steel Transl. 2020, 50, 100–106. [Google Scholar] [CrossRef]

- Semenov, Y.S.; Horupakha, V.V.; Alter, M.A.; Vashchenko, S.V.; Khudyakov, A.Y.; Shumelchik, E.I. Efficiency of Washing Blast Furnace Hearth in case of Pulverized Coal Injection. In Proceedings of the AISTech–Iron and Steel Technology Conference, Pittsburgh, PA, USA, 16–18 May 2022; pp. 219–230. [Google Scholar] [CrossRef]

- Kanaev, V.V.; Kobeza, I.I.; Buzoverya, M.T. Control of blast distribution on air blast furnace tuyere. Metall. Gornorudn. Promyshlennost 1995, 2, 69–71. (In Russian) [Google Scholar]

- Bol’shakov, V.I.; Shuliko, S.T.; Kanaev, V.V.; Shutylev, F.M.; Loginov, V.N. Investigation of gas Distribution in a Large–Volume Blast Furnace. Steel Transl. 1999, 29, 1–5. [Google Scholar]

- Bol’shakov, V.I.; Shuliko, S.T.; Kanaev, V.V. Study of the charge and gas–flow distributions in a large blast furnace with a bell-less charging apparature. Metallurgist 1997, 41, 389–390. [Google Scholar] [CrossRef]

- Bolshakov, V.I.; Semenov, Y.S.; Kuznetsov, A.M. The Experience of the Implementation of Modern Blast Furnace Equipped with Bell-Less Top Charging Device under Conditions of Changing Quality of Charge Material. Metall. Min. Ind. 2013, 5, 56–64. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Semenov, Y.S.; Shumelchyk, Y.I.; Horupakha, V.V.; Semion, I.Y.; Vashchenko, S.V.; Khudyakov, O.Y.; Chychov, I.V.; Hulina, I.H.; Zakharov, R.H. Development and Implementation of Decision Support Systems for Blast Smelting Control in the Conditions of PrJSC “Kamet-Steel”. Metals 2022, 12, 985. https://doi.org/10.3390/met12060985

Semenov YS, Shumelchyk YI, Horupakha VV, Semion IY, Vashchenko SV, Khudyakov OY, Chychov IV, Hulina IH, Zakharov RH. Development and Implementation of Decision Support Systems for Blast Smelting Control in the Conditions of PrJSC “Kamet-Steel”. Metals. 2022; 12(6):985. https://doi.org/10.3390/met12060985

Chicago/Turabian StyleSemenov, Yurii S., Yevhen I. Shumelchyk, Viktor V. Horupakha, Igor Y. Semion, Sergii V. Vashchenko, Oleksandr Y. Khudyakov, Igor V. Chychov, Iryna H. Hulina, and Rostyslav H. Zakharov. 2022. "Development and Implementation of Decision Support Systems for Blast Smelting Control in the Conditions of PrJSC “Kamet-Steel”" Metals 12, no. 6: 985. https://doi.org/10.3390/met12060985

APA StyleSemenov, Y. S., Shumelchyk, Y. I., Horupakha, V. V., Semion, I. Y., Vashchenko, S. V., Khudyakov, O. Y., Chychov, I. V., Hulina, I. H., & Zakharov, R. H. (2022). Development and Implementation of Decision Support Systems for Blast Smelting Control in the Conditions of PrJSC “Kamet-Steel”. Metals, 12(6), 985. https://doi.org/10.3390/met12060985