Environmental Failure Behavior Analysis of 7085 High Strength Aluminum Alloy under High Temperature and High Humidity

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Material Examination

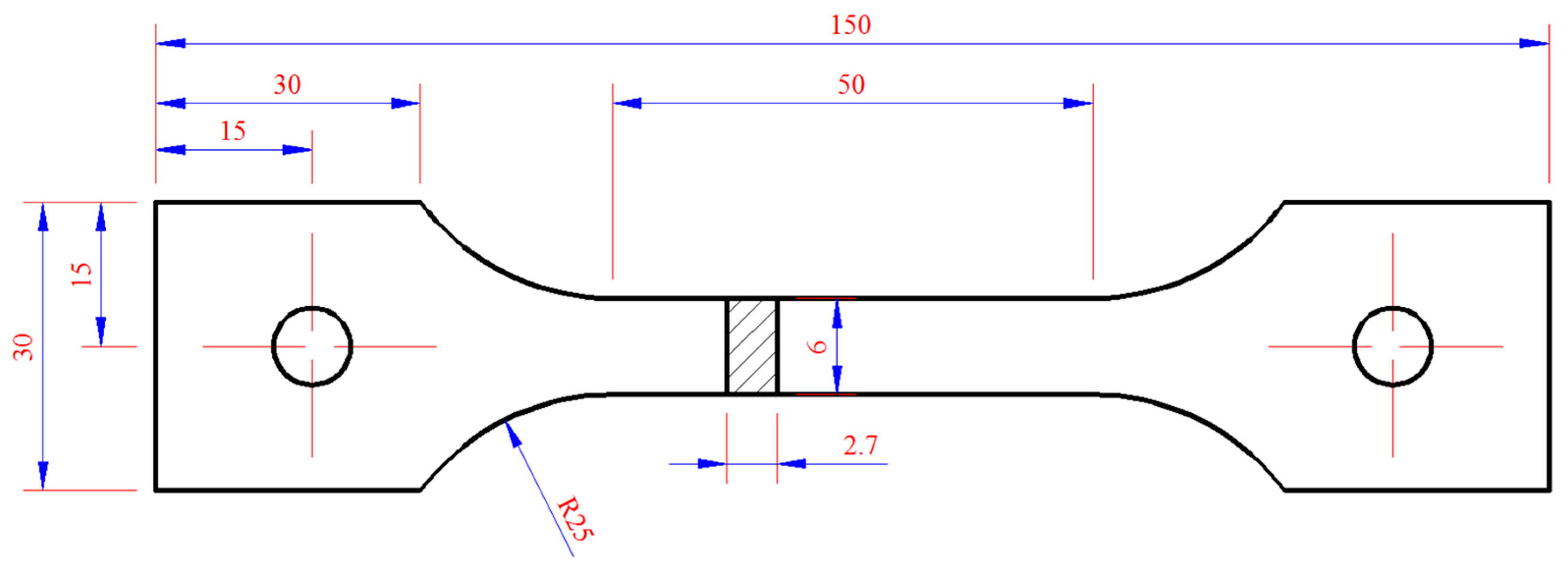

2.2. Fracture Failure Test under Simulated Conditions

3. Results and Discussion

3.1. Traditional Stress Corrosion Susceptibility Analysis

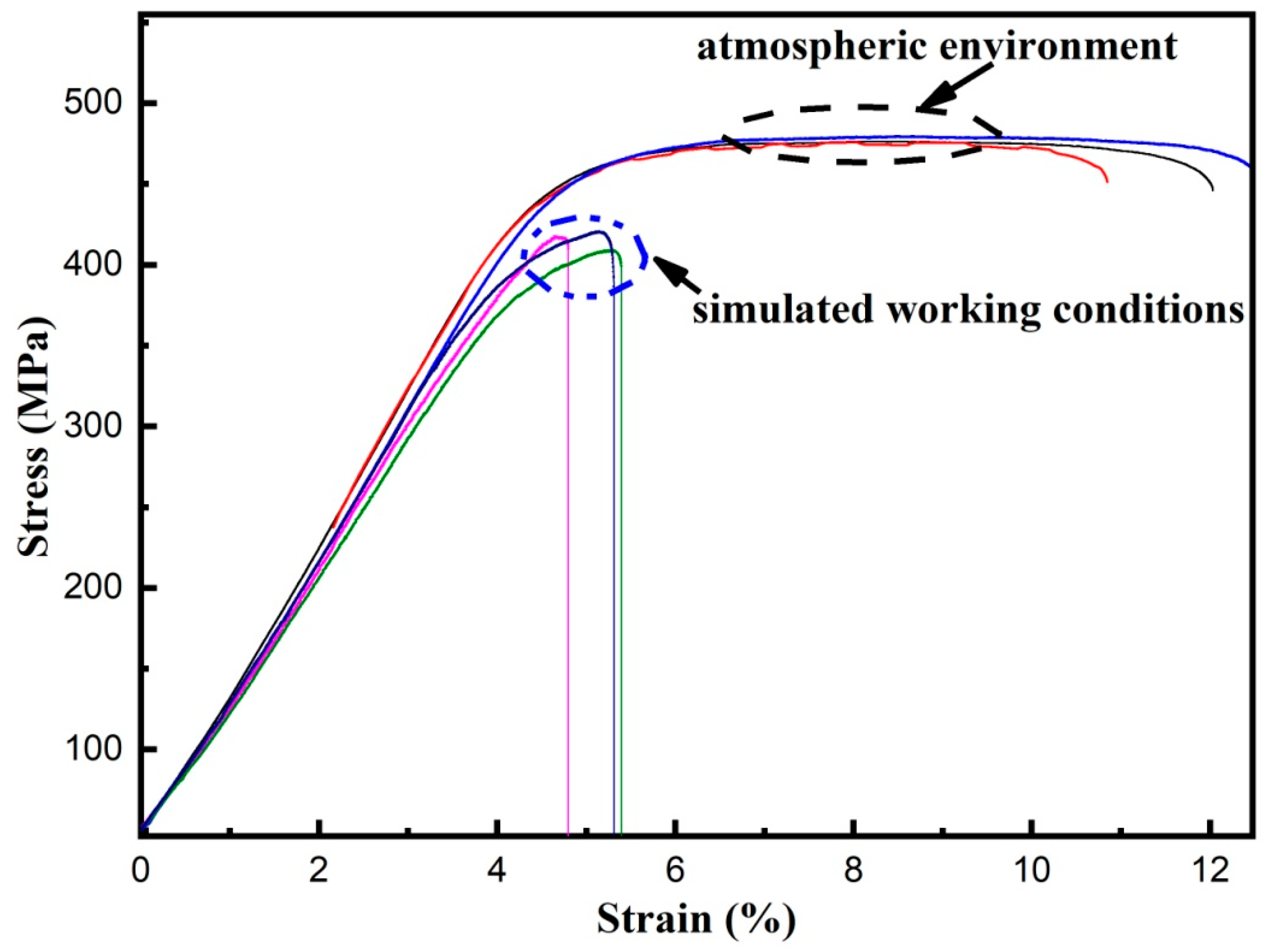

3.2. Test Results under Simulated Environmental Conditions

3.3. Water Quality Analysis

3.4. Elemental Analysis

4. Conclusions

- (1)

- For 7085 high-strength aluminum alloys in a high temperature and high humidity environment, slow stretching has obvious plastic loss behavior, and elongation decreased by about 89.0% compared to blank samples.

- (2)

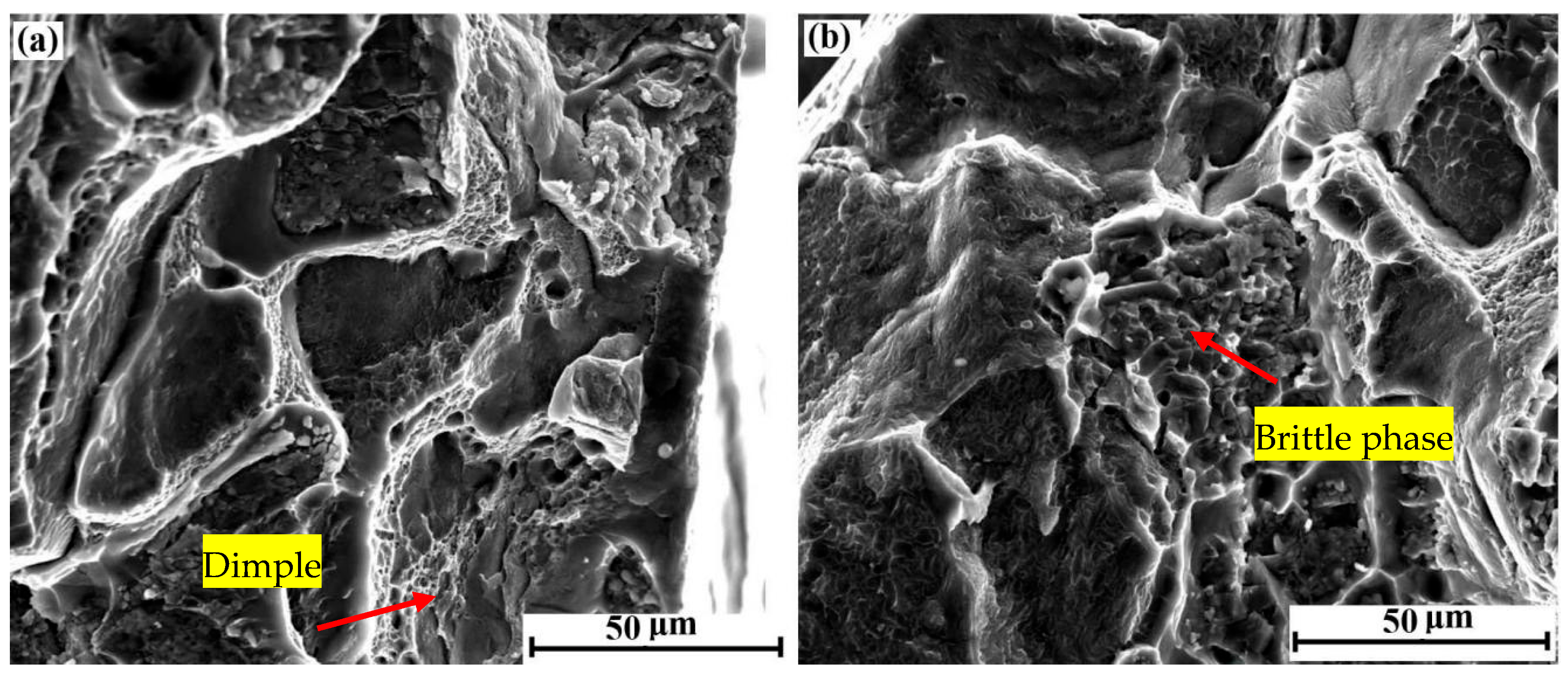

- High-strength aluminum alloys have environmental cracking failure behaviors when used in high temperature and high humidity environments, and this behavior is mainly characterized by brittle fractures.

- (3)

- The environmental failure behavior of 7085 aluminum alloy can be attributed to the combined effect of stress and hydrogen interaction, which is different from traditional stress corrosion cracking behavior.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, J. Advanced aluminum and hybrid aerostructures for future aircraft. Mater. Sci. Forum 2006, 519, 1233–1238. [Google Scholar] [CrossRef]

- Zhou, B.; Liu, B.; Zhang, S. The Advancement of 7XXX Series Aluminum Alloys for Aircraft Structures: A Review. Metals 2021, 11, 718. [Google Scholar] [CrossRef]

- Heinz, A.; Haszler, A.; Keidel, C.; Moldenhauer, S.; Benedictus, R.; Miller, W.S. Recent development in aluminium alloys for aerospace applications. Mater. Sci. Eng. A 2000, 280, 102–107. [Google Scholar] [CrossRef]

- Williams, J.C.; Starke, E.A. Progress in structural materials for aerospace systems11The Golden Jubilee Issue—Selected topics in Materials Science and Engineering: Past, Present and Future, edited by S. Suresh. Acta Mater. 2003, 51, 5775–5799. [Google Scholar] [CrossRef]

- Braun, R. Transgranular environment-induced cracking of 7050 aluminium alloy under cyclic loading conditions at low frequencies. Int. J. Fatigue 2008, 30, 1827–1837. [Google Scholar] [CrossRef]

- Kannan, M.B.; Raja, V.S.; Mukhopadhyay, A.K.; Schmuki, P. Environmentally assisted cracking behavior of peak-aged 7010 aluminum alloy containing scandium. Metall. Mater. Trans. A 2005, 36, 3257–3262. [Google Scholar] [CrossRef]

- Lynch, S.P. Environmentally assisted cracking: Overview of evidence for an adsorption-induced localised-slip process. Acta Metall. 1988, 36, 2639–2661. [Google Scholar] [CrossRef]

- Bakare, A.K.; Shaikh, A.A.; Kale, S.S. Comparison of SCC behaviour of crack in thin aluminium structure with and without single sided composite patch repair. Eng. Fail. Anal. 2020, 118, 104781–104787. [Google Scholar] [CrossRef]

- Rout, P.K.; Ghosh, K.S. Effect of microstructural features on stress corrosion cracking behaviour of 7017 and 7150 aluminium alloy. Mater. Today Proc. 2018, 5, 2391–2400. [Google Scholar] [CrossRef]

- Gupta, R.K.; Ramkumar, P.; Ghosh, B.R. Investigation of internal cracks in aluminium alloy AA7075 forging. Eng. Fail. Anal. 2006, 13, 1–8. [Google Scholar] [CrossRef]

- Rao, A.C.U.; Vasu, V.; Govindaraju, M.; Srinadh, K.V.S. Stress corrosion cracking behaviour of 7xxx aluminum alloys: A literature review. Trans. Nonferrous Met. Soc. China 2016, 26, 1447–1471. [Google Scholar] [CrossRef]

- Oliveira, A.F.; de Barros, M.C.; Cardoso, K.R.; Travessa, D.N. The effect of RRA on the strength and SCC resistance on AA7050 and AA7150 aluminium alloys. Mater. Sci. Eng. A 2004, 379, 321–326. [Google Scholar] [CrossRef]

- Yue, T.M.; Yan, L.J.; Dong, C.F.; Chan, C.P. Stress corrosion cracking behaviour of laser treated aluminium alloy 7075 using a slow strain rate test. Mater. Sci. Technol. 2013, 21, 961–966. [Google Scholar] [CrossRef]

- Rout, P.K.; Ghosh, M.M.; Ghosh, K.S. Influence of Aging Treatments on Alterations of Microstructural Features and Stress Corrosion Cracking Behavior of an Al-Zn-Mg Alloy. J. Mater. Eng. Perform. 2015, 24, 2792–2805. [Google Scholar] [CrossRef]

- Song, R.G.; Dietzel, W.; Zhang, B.J.; Liu, W.J.; Tseng, M.K.; Atrens, A. Stress corrosion cracking and hydrogen embrittlement of an Al–Zn–Mg–Cu alloy. Acta Mater. 2004, 52, 4727–4743. [Google Scholar] [CrossRef]

- Zhang, C.X.; Jiang, X.Y.; Sun, Y.; Long, D. Research on Helicopter Environmental Worthiness in Southeast Coastal Areas. Equip. Environ. Eng. 2009, 6, 66–71. [Google Scholar]

- Li, D.F. Corrosion and Protection of Aircraft Structure. Equip. Environ. Eng. 2016, 13, 57–62. [Google Scholar]

- China Aeronautic Corporation. HB7235-1995 Slow Strain Rate Stress Corrosion Test Method; China Aeronautic Corporation: Beijing, China, 1995. [Google Scholar]

- Zhao, H.; Chakraborty, P.; Ponge, D. Hydrogen trapping and embrittlement in high-strength Al alloys. Nature 2022, 602, 437–441. [Google Scholar] [CrossRef]

- Yang, X.; Luo, X.; Zhang, X.; Chen, J.; Gao, L. Characterization of hydrogen in a high strength aluminum alloy. Mater. Test. 2020, 62, 962–964. [Google Scholar] [CrossRef]

- Hamada, S.; Ohnishi, K.; Nishikawa, H.-A.; Oda, Y.; Noguchi, H. SIMS analysis of low content hydrogen in commercially pure titanium. J. Mater. Sci. 2009, 44, 5692–5696. [Google Scholar] [CrossRef]

- Sobol, O.; Holzlechner, G.; Nolze Wirth, T.; Eliezer, D.; Boellinghaus, T.; Unger, W.E.S. Time-of-Flight Secondary Ion Mass Spectrometry (ToF-SIMS) imaging of deuterium assisted cracking in a 2205 duplex stainless steel micro-structure. Mater. Sci. Eng. A 2016, 676, 271–277. [Google Scholar] [CrossRef]

| Test Conditions | Average Strength (MPa) | Average Elongation (%) | ISSRT (%) |

|---|---|---|---|

| 35 °C 3.5% NaCl | 490 | 5.2 | 2.83 |

| 35 °C dry air | 499 | 6.1 |

| Test Condition (Slow Strain Rate of 10−7 1/s) | Average Time (h) | Average Strength (MPa) | Average Elongation (%) | ISSRT (%) |

|---|---|---|---|---|

| Temperature 70 °C, humidity 85% | 77.8 ± 2.8 | 414 ± 3.0 | 0.8 ± 0.07 | 18.56 |

| Atmosphere | 166.3 ± 6.7 | 477 ± 1.3 | 7.3 ± 0.5 |

| Water Quality | Cl− (ppm) | SO42− (ppm) | F− (ppm) |

|---|---|---|---|

| High purity water | 0.026 ± 0.002 | 0.0054 ± 0.0005 | 0.0091 ± 0.0008 |

| Tap water | 25.91 ± 0.3 | 87.13 ± 1.0 | 0.198 ± 0.005 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, X.; Zhang, X.; Liu, Y.; Li, X.; Chen, J.; Zhang, X.; Gao, L. Environmental Failure Behavior Analysis of 7085 High Strength Aluminum Alloy under High Temperature and High Humidity. Metals 2022, 12, 968. https://doi.org/10.3390/met12060968

Yang X, Zhang X, Liu Y, Li X, Chen J, Zhang X, Gao L. Environmental Failure Behavior Analysis of 7085 High Strength Aluminum Alloy under High Temperature and High Humidity. Metals. 2022; 12(6):968. https://doi.org/10.3390/met12060968

Chicago/Turabian StyleYang, Xiao, Xianfeng Zhang, Yan Liu, Xuefeng Li, Jieming Chen, Xinyao Zhang, and Lingqing Gao. 2022. "Environmental Failure Behavior Analysis of 7085 High Strength Aluminum Alloy under High Temperature and High Humidity" Metals 12, no. 6: 968. https://doi.org/10.3390/met12060968

APA StyleYang, X., Zhang, X., Liu, Y., Li, X., Chen, J., Zhang, X., & Gao, L. (2022). Environmental Failure Behavior Analysis of 7085 High Strength Aluminum Alloy under High Temperature and High Humidity. Metals, 12(6), 968. https://doi.org/10.3390/met12060968