On the Registration of Thermographic In Situ Monitoring Data and Computed Tomography Reference Data in the Scope of Defect Prediction in Laser Powder Bed Fusion

Abstract

:1. Introduction

2. Materials and Experimental Procedures

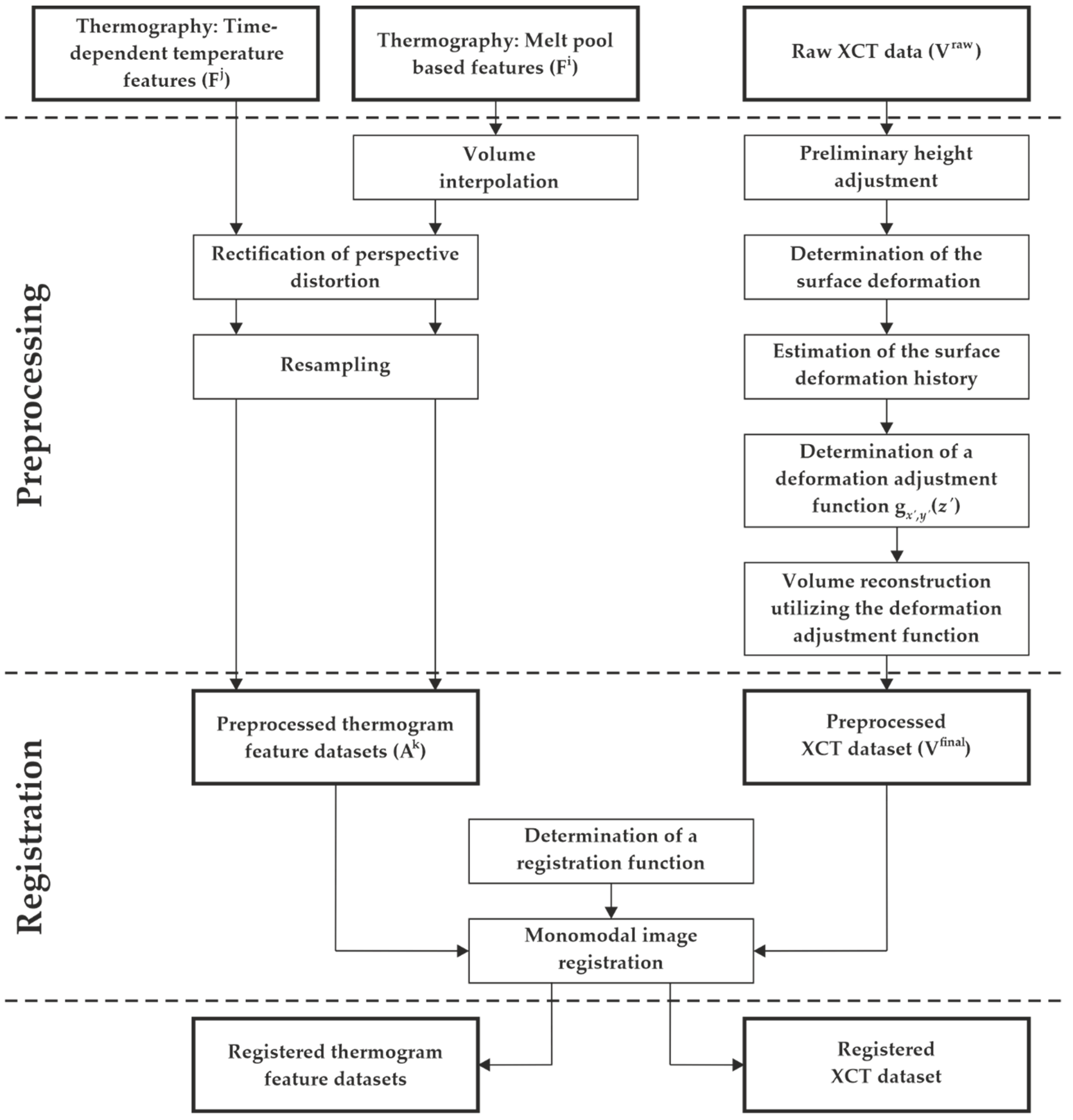

3. Registration Methodology and Results

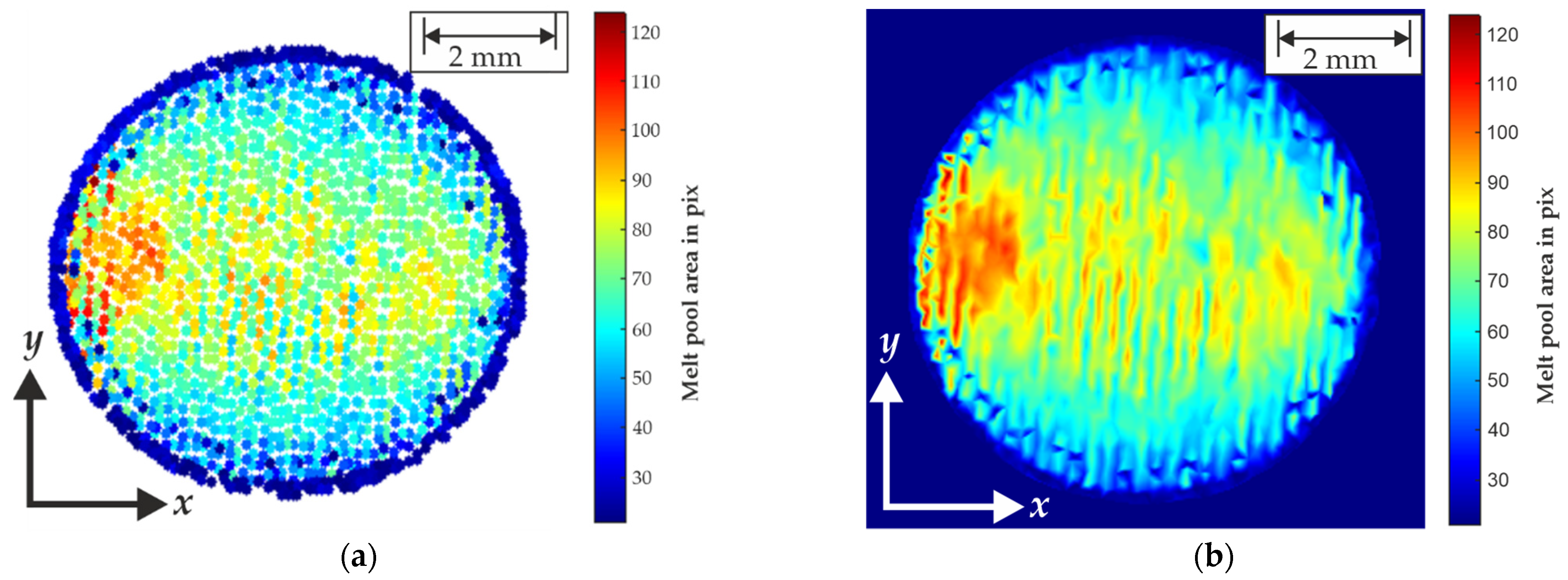

3.1. Preprocessing of Thermogram Feature Dataset

3.2. Preprocessing of XCT Dataset

- Preliminary height adjustment;

- Determination of the surface deformation;

- Estimation of the surface deformation history;

- Determination of a deformation adjustment function;

- Volume reconstruction utilizing the deformation adjustment function.

3.2.1. Preliminary Height Adjustment

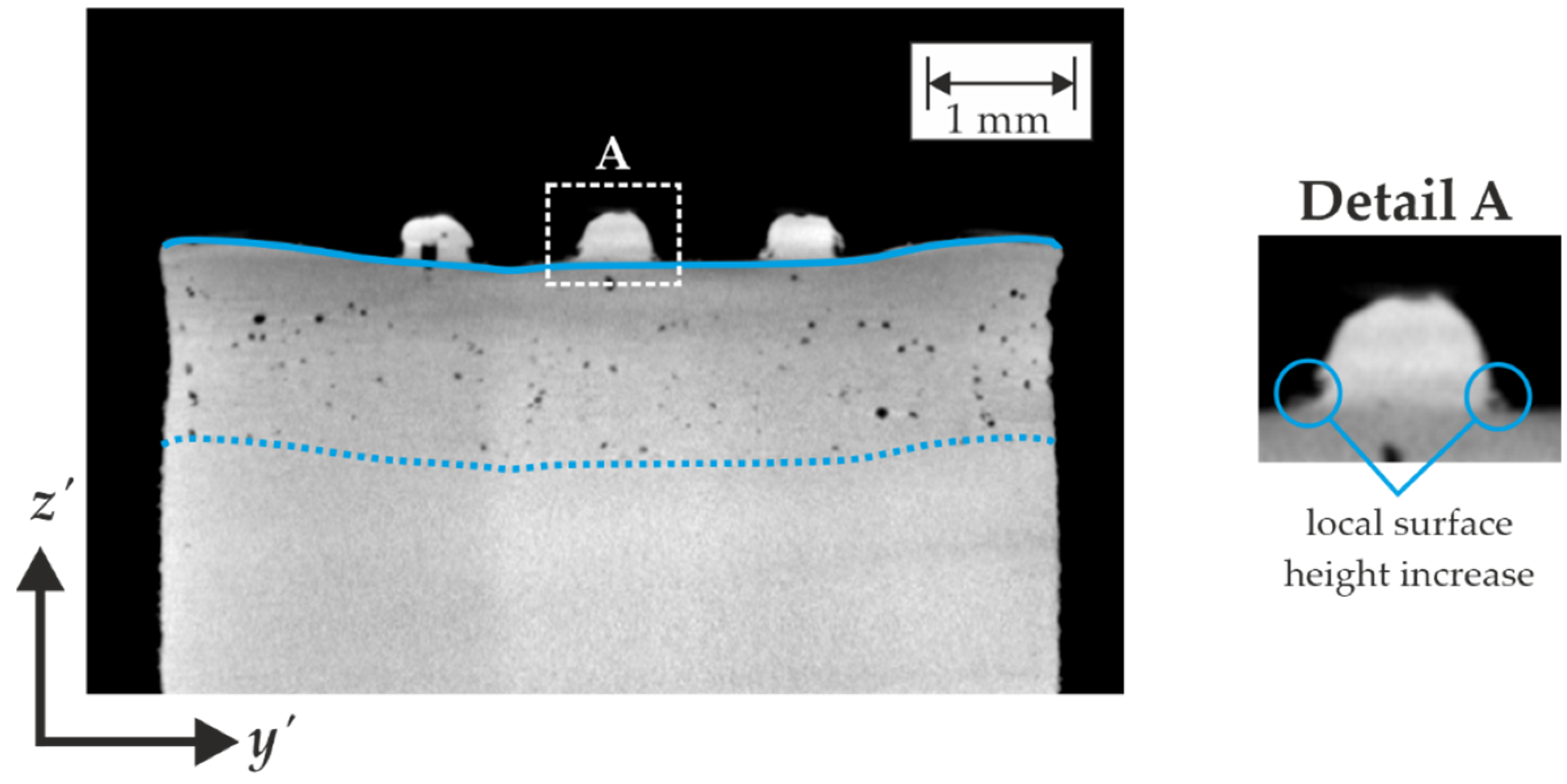

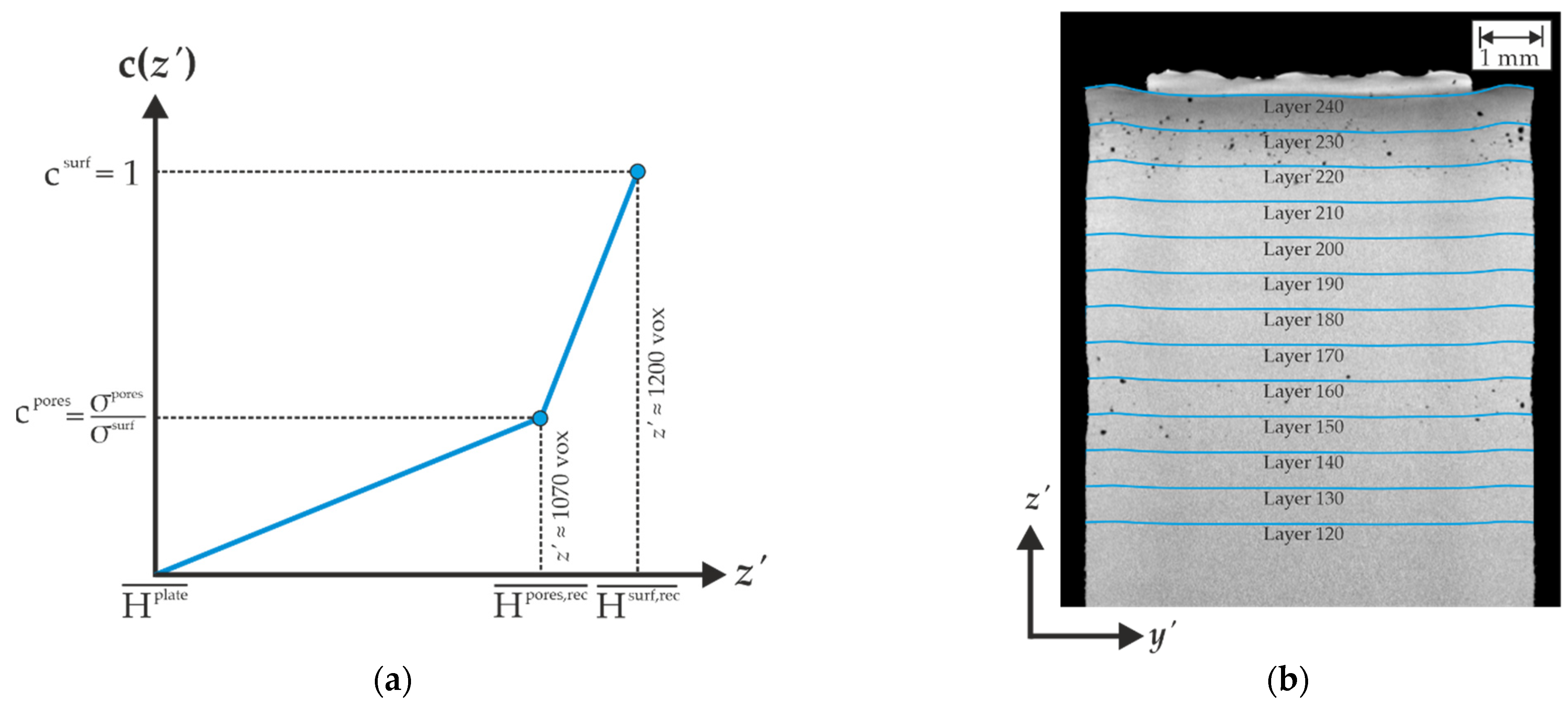

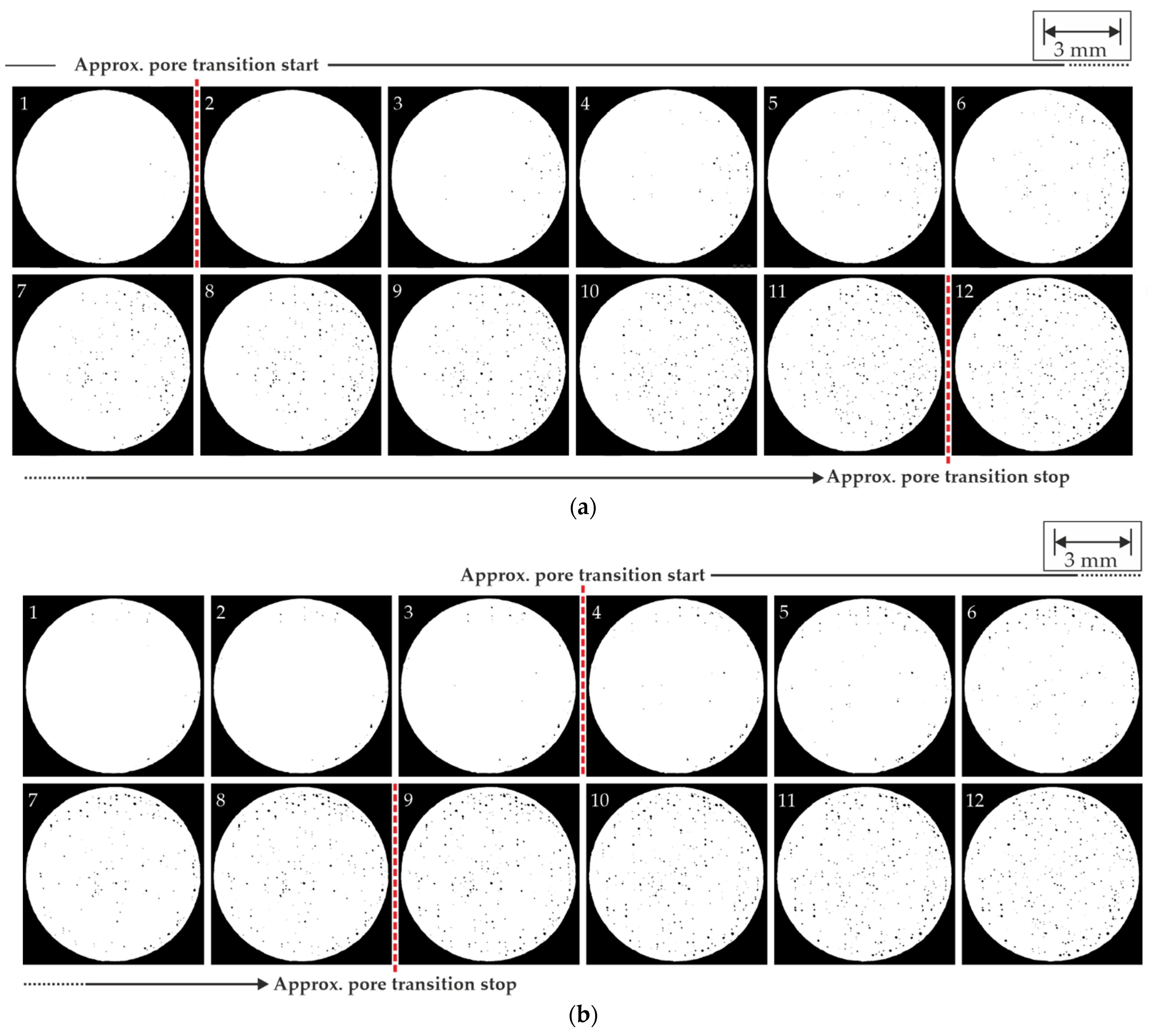

3.2.2. Determination of the Surface Deformation

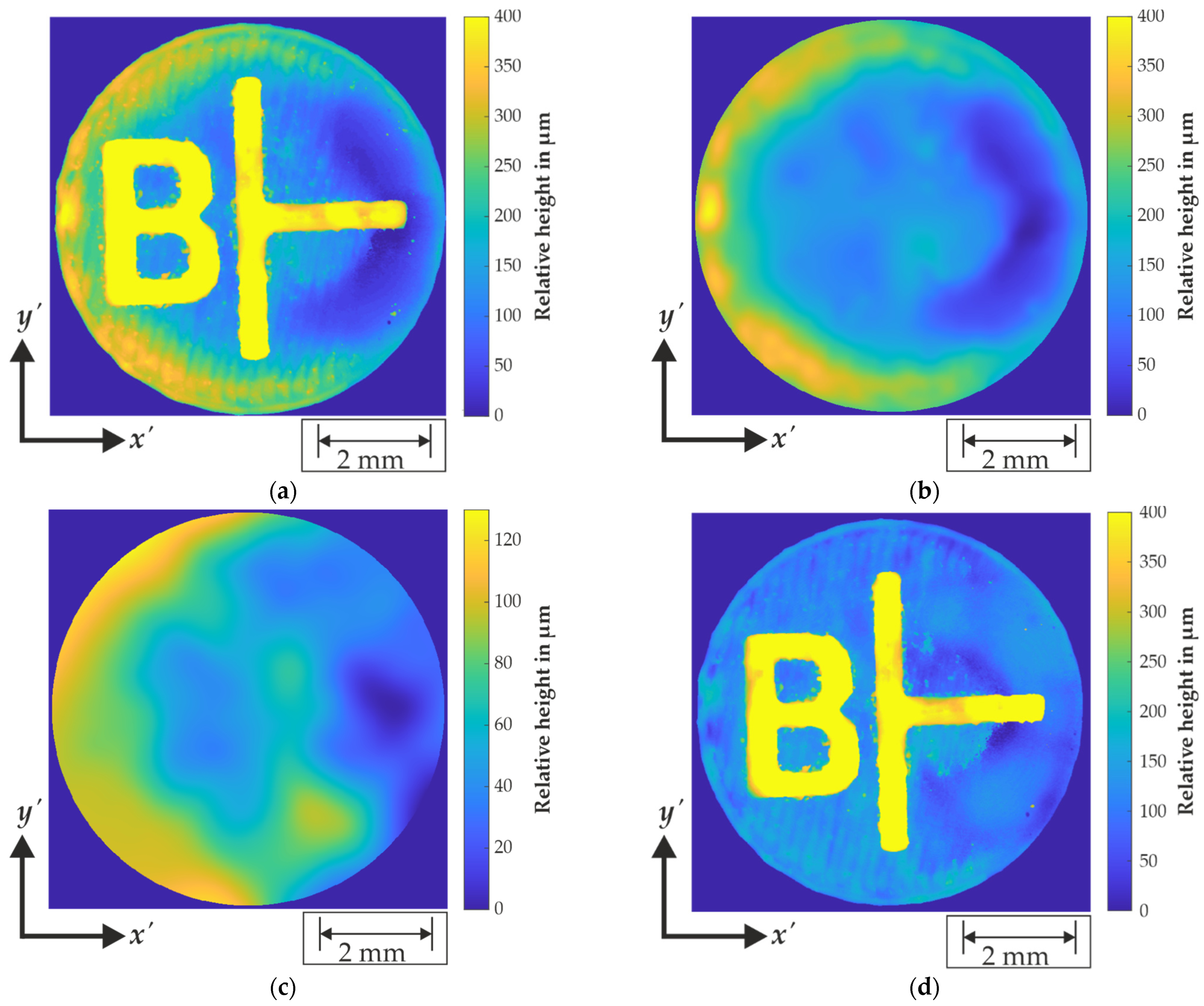

3.2.3. Estimation of the Surface Deformation History

3.2.4. Determination of a Deformation Adjustment Function

3.2.5. Volume Reconstruction Utilizing the Deformation Adjustment Function

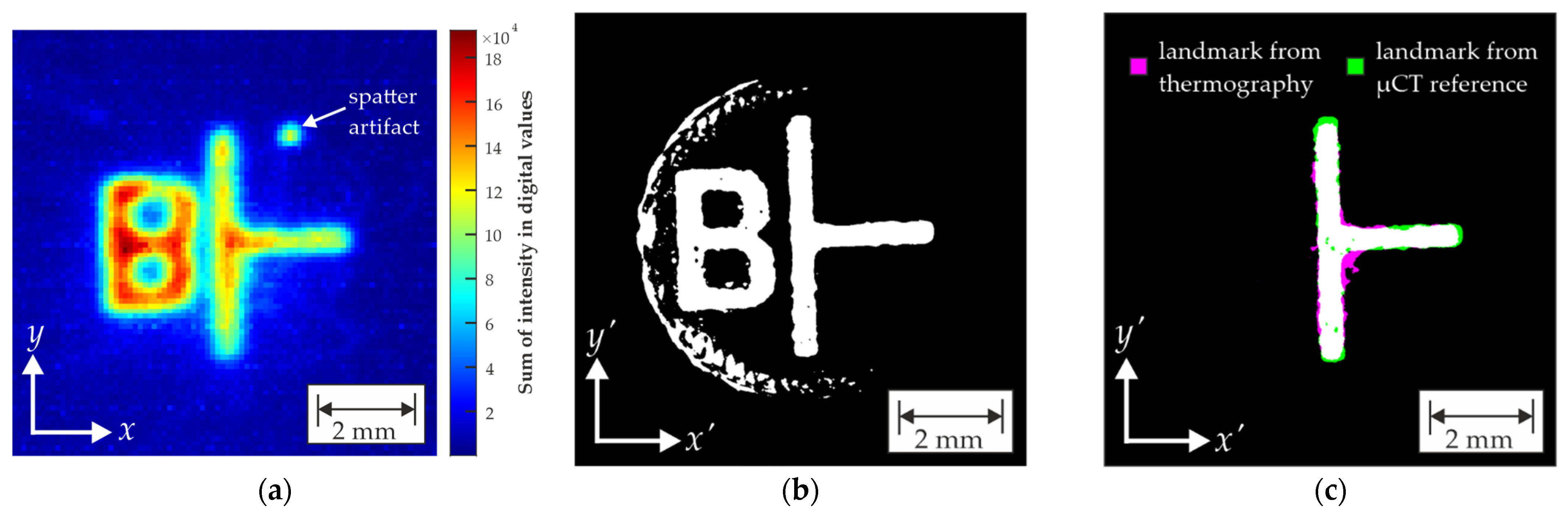

3.3. Image Registration

4. Discussion

5. Conclusions

- Thermally induced warping and solidification shrinkage, especially in the form of surface deformations, are a major challenge for the image registration because it prevents the application of simple registration methods. In this study, it was demonstrated that the distribution of boundary keyhole pores within the observed specimen can be utilized to reconstruct the surface deformation for a specific point in time within the manufacturing. Furthermore, it was shown that an adjustment function based on the approximated surface deformation history enables the adjustment of the part deformation and the application of a simple 3D image-to-image registration.

- The geometrical references that were included in the specimen design proved to be very beneficial for the data registration. The surrounding staircase structure provided information for the preliminary adjustment of the vertical part shrinkage. The cross label added on the specimen top could be utilized to generate a registration function. A drawback of this structure was its disruptive influence during the reconstruction of the top surface information.

- The performed registration resulted in a translation error of 23 μm ± 12 μm and a scaling error of 21 μm ± 8 μm (rigid model in section 3). These errors are significantly lower than the spatial resolution achieved by the IR camera. From the utilization of the adjustment function, it was found that high improvement was achieved in comparison to the unadjusted dataset. Based on these findings, it is possible for the first time to consider the registration accuracy in irregularity prediction modeling.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Al Rashid, A.; Khan, S.A.; Al-Ghamdi, S.G.; Koç, M. Additive Manufacturing: Technology, Applications, Markets, and Opportunities for the Built Environment. Autom. Constr. 2020, 118, 103268. [Google Scholar] [CrossRef]

- Tapia, G.; Elwany, A. A Review on Process Monitoring and Control in Metal-Based Additive Manufacturing. J. Manuf. Sci. Eng. 2014, 136, 060801. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Fritsch, T.; Farahbod-Sternahl, L.; Serrano-Muñoz, I.; Léonard, F.; Haberland, C.; Bruno, G. 3d Computed Tomography Quantifies the Dependence of Bulk Porosity, Surface Roughness, and Re-Entrant Features on Build Angle in Additively Manufactured In625 Lattice Struts. Adv. Eng. Mater. 2021, 2021, 2100689. [Google Scholar] [CrossRef]

- McCann, R.; Obeidi, M.A.; Hughes, C.; McCarthy, É.; Egan, D.S.; Vijayaraghavan, R.K.; Joshi, A.M.; Acinas Garzon, V.; Dowling, D.P.; McNally, P.J.; et al. In-Situ Sensing, Process Monitoring; Machine Control in Laser Powder Bed Fusion: A Review. Addit. Manuf. 2021, 45, 102058. [Google Scholar] [CrossRef]

- Lough, C.S.; Liu, T.; Wang, X.; Brown, B.; Landers, R.G.; Bristow, D.A.; Drallmeier, J.A.; Kinzel, E.C. Local Prediction of Laser Powder Bed Fusion Porosity by Short-Wave Infrared Imaging Thermal Feature Porosity Probability Maps. J. Mater. Processing Technol. 2022, 302, 117473. [Google Scholar] [CrossRef]

- Ulbricht, A.; Mohr, G.; Altenburg, S.J.; Oster, S.; Maierhofer, C.; Bruno, G. Can Potential Defects in Lpbf Be Healed from the Laser Exposure of Subsequent Layers? A Quantitative Study. Metals 2021, 11, 1012. [Google Scholar] [CrossRef]

- Grasso, M.; Remani, A.; Dickins, A.; Colosimo, B.M.; Leach, R.K. In-Situ Measurement and Monitoring Methods for Metal Powder Bed Fusion: An Updated Review. Meas. Sci. Technol. 2021, 32, 112001. [Google Scholar] [CrossRef]

- Oliveira, F.P.; Tavares, J.M. Medical Image Registration: A Review. Comput. Methods Biomech. Biomed. Eng. 2014, 17, 73–93. [Google Scholar] [CrossRef]

- Gao, Z.; Gu, B.; Lin, J. Monomodal Image Registration Using Mutual Information Based Methods. Image Vis. Comput. 2008, 26, 164–173. [Google Scholar] [CrossRef]

- Klein, S.; Staring, M.; Murphy, K.; Viergever, M.A.; Pluim, J.P. Elastix: A Toolbox for Intensity-Based Medical Image Registration. IEEE Trans. Med. Imaging 2010, 29, 196–205. [Google Scholar] [CrossRef] [PubMed]

- Alpert, N.M.; Berdichevsky, D.; Levin, Z.; Morris, E.D.; Fischman, A.J. Improved Methods for Image Registration. Neuroimage 1996, 3, 10–18. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Guo, W.G.; Tian, Q.; Guo, S.; Guo, Y. A Physics-Driven Deep Learning Model for Process-Porosity Causal Relationship and Porosity Prediction with Interpretability in Laser Metal Deposition. CIRP Ann. 2020, 69, 205–208. [Google Scholar] [CrossRef]

- Sinclair, L.; Leung, C.L.A.; Marussi, S.; Clark, S.J.; Chen, Y.; Olbinado, M.P.; Rack, A.; Gardy, J.; Baxter, G.J.; Lee, P.D. In Situ Radiographic and Ex Situ Tomographic Analysis of Pore Interactions During Multilayer Builds in Laser Powder Bed Fusion. Addit. Manuf. 2020, 36, 101512. [Google Scholar] [CrossRef]

- Mohr, G.; Nowakowski, S.; Altenburg, S.J.; Maierhofer, C.; Hilgenberg, K. Experimental Determination of the Emissivity of Powder Layers and Bulk Material in Laser Powder Bed Fusion Using Infrared Thermography and Thermocouples. Metals 2020, 10, 1546. [Google Scholar] [CrossRef]

- Feldkamp, L.A.; Davis, L.C.; Kress, J.W. Practical Cone-Beam Algorithm. J. Opt. Soc. Am. A 1984, 1, 612–619. [Google Scholar] [CrossRef] [Green Version]

- Schörner, K.; Goldammer, M.; Stephan, J. Scatter Correction by Modulation of Primary Radiation in Industrial X-Ray Ct: Beam-Hardening Effects and Their Correction. In Proceedings of the International Symposium on Digital Industrial Radiology and Computed Tomography—Mo.3.2, Berlin, Germany, 20–22 June 2011. [Google Scholar]

- Ametova, E.; Ferrucci, M.; Dewulf, W. A Tool for Reducing Cone-Beam Artifacts in Computed Tomography Data. In Proceedings of the 7th Conference on Industrial Computed Tomography (iCT 2017), Leuven, Belgium, 7–9 February 2017. [Google Scholar]

- Roche, R.C.; Abel, R.A.; Johnson, K.G.; Perry, C.T. Quantification of Porosity in Acropora Pulchra (Brook 1891) Using X-ray Micro-Computed Tomography Techniques. J. Exp. Mar. Biol. Ecol. 2010, 396, 1–9. [Google Scholar] [CrossRef]

- Shah, P.; Racasan, R.; Bills, P. Comparison of Different Additive Manufacturing Methods Using Computed Tomography. Case Stud. Nondestruct. Test. Eval. 2016, 6, 69–78. [Google Scholar] [CrossRef] [Green Version]

- Mireles, J.; Ridwan, S.; Morton, P.A.; Hinojos, A.; Wicker, R.B. Analysis and Correction of Defects within Parts Fabricated Using Powder Bed Fusion Technology. Surf. Topogr. Metrol. Prop. 2015, 3, 034002. [Google Scholar] [CrossRef]

- Lough, C.S.; Wang, X.; Smith, C.C.; Landers, R.G.; Bristow, D.A.; Drallmeier, J.A.; Brown, B.; Kinzel, E.C. Correlation of Swir Imaging with Lpbf 304l Stainless Steel Part Properties. Addit. Manuf. 2020, 35, 101359. [Google Scholar] [CrossRef]

- Coeck, S.; Bisht, M.; Plas, J.; Verbist, F. Prediction of Lack of Fusion Porosity in Selective Laser Melting Based on Melt Pool Monitoring Data. Addit. Manuf. 2019, 25, 347–356. [Google Scholar] [CrossRef]

- Forien, J.-B.; Calta, N.P.; DePond, P.J.; Guss, G.M.; Roehling, T.T.; Matthews, M.J. Detecting Keyhole Pore Defects and Monitoring Process Signatures During Laser Powder Bed Fusion: A Correlation between in Situ Pyrometry and Ex Situ X-ray Radiography. Addit. Manuf. 2020, 35, 101336. [Google Scholar] [CrossRef]

- Mohr, G.; Altenburg, S.J.; Ulbricht, A.; Heinrich, P.; Baum, D.; Maierhofer, C.; Hilgenberg, K. In-Situ Defect Detection in Laser Powder Bed Fusion by Using Thermography and Optical Tomography—Comparison to Computed Tomography. Metals 2020, 10, 103. [Google Scholar] [CrossRef] [Green Version]

- Taherkhani, K.; Sheydaeian, E.; Eischer, C.; Otto, M.; Toyserkani, E. Development of a Defect-Detection Platform Using Photodiode Signals Collected from the Melt Pool of Laser Powder-Bed Fusion. Addit. Manuf. 2021, 46, 102152. [Google Scholar] [CrossRef]

- Gobert, C.; Reutzel, E.W.; Petrich, J.; Nassar, A.R.; Phoha, S. Application of Supervised Machine Learning for Defect Detection During Metallic Powder Bed Fusion Additive Manufacturing Using High Resolution Imaging. Addit. Manuf. 2018, 21, 517–528. [Google Scholar] [CrossRef]

- Oster, S.; Maierhofer, C.; Mohr, G.; Hilgenberg, K.; Ulbricht, A.; Altenburg, S.J. Investigation of the Thermal History of L-Pbf Metal Parts by Feature Extraction from in-Situ Swir Thermography. In Proceedings of the Thermosense: Thermal Infrared Applications XLIII, online, 12–16 April 2021; p. 117430C. [Google Scholar] [CrossRef]

- Scheuschner, N.; Strasse, A.; Altenburg, S.J.; Gumenyuk, A.; Maierhofer, C. In-Situ Thermographic Monitoring of the Laser Metal Deposition Process. In Proceedings of the II International Conference on Simulation for Additive Manufacturing, Pavia, Italy, 11–13 September 2019. [Google Scholar]

- Herman, G.T. Correction for Beam Hardening in Computed Tomography. Phys. Med. Biol. 1997, 24, 81–106. [Google Scholar] [CrossRef]

- Schindelin, J.; Arganda-Carreras, I.; Frise, E.; Kaynig, V.; Longair, M.; Pietzsch, T.; Preibisch, S.; Rueden, C.; Saalfeld, S.; Schmid, B.; et al. Fiji: An Open-Source Platform for Biological-Image Analysis. Nat. Methods 2012, 9, 676–682. [Google Scholar] [CrossRef] [Green Version]

- Chernov, N. Circle Fit (Pratt Method). Available online: https://www.mathworks.com/matlabcentral/fileexchange/22643-circle-fit-pratt-method (accessed on 1 November 2021).

- Phansalkar, N.; More, S.; Sabale, A.; Madhuri, J. Adaptive Local Thresholding for Detection of Nuclei in Diversity Stained Cytology Images. In Proceedings of the 2011 International Conference on Communications and Signal Processing, Kerala, India, 10–12 February 2011. [Google Scholar] [CrossRef]

- Markelj, P.; Tomazevic, D.; Likar, B.; Pernus, F. A Review of 3d/2d Registration Methods for Image-Guided Interventions. Med. Image Anal. 2012, 16, 642–661. [Google Scholar] [CrossRef]

- Kiekens, K.; Welkenhuyzen, F.; Tan, Y.; Bleys, P.; Voet, A.; Kruth, J.P.; Dewulf, W. A Test Object with Parallel Grooves for Calibration and Accuracy Assessment of Industrial Computed Tomography (Ct) Metrology. Meas. Sci. Technol. 2011, 22, 115502. [Google Scholar] [CrossRef]

- D’Errico, J. Surface Fitting Using Gridfit. Available online: https://www.mathworks.com/matlabcentral/fileexchange/8998-surface-fitting-using-gridfit (accessed on 5 July 2021).

- Hojjatzadeh, S.M.H.; Parab, N.D.; Guo, Q.; Qu, M.; Xiong, L.; Zhao, C.; Escano, L.I.; Fezzaa, K.; Everhart, W.; Sun, T.; et al. Direct Observation of Pore Formation Mechanisms During Lpbf Additive Manufacturing Process and High Energy Density Laser Welding. Int. J. Mach. Tools Manuf. 2020, 153, 103555. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Y.; Chia, H.Y.; Yan, W. Mechanism of Keyhole Pore Formation in Metal Additive Manufacturing. Npj Comput. Mater. 2022, 8, 22. [Google Scholar] [CrossRef]

- Ertay, D.S.; Ma, H.; Vlasea, M. Correlative Beam Path; Pore Defect Space Analysis for Modulated Powder Bed Laser Fusion Process. In Proceedings of the 2018 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 13–15 August 2018. [Google Scholar] [CrossRef]

- Du Plessis, A. Effects of Process Parameters on Porosity in Laser Powder Bed Fusion Revealed by X-ray Tomography. Addit. Manuf. 2019, 30, 100871. [Google Scholar] [CrossRef]

- Jost, E.W.; Miers, J.C.; Robbins, A.; Moore, D.G.; Saldana, C. Effects of Spatial Energy Distribution-Induced Porosity on Mechanical Properties of Laser Powder Bed Fusion 316l Stainless Steel. Addit. Manuf. 2021, 39, 101875. [Google Scholar] [CrossRef]

| Section | Layer Count | Laser Power P in W | Scan Velocity v in mm/s | VED in J/mm3 |

|---|---|---|---|---|

| 1 | 1–60 | 275 | 700 | 65.45 |

| 2 | 61–80 | 275 | 560 | 81.84 (+25%) |

| 3 | 81–140 | 275 | 700 | 65.45 |

| 4 | 141–160 | 275 | 467 | 98.21 (+50%) |

| 5 | 161–220 | 275 | 700 | 65.45 |

| 6 | 221–240 | 275 | 400 | 114.45 (+75%) |

| Feature Class | Feature |

|---|---|

| Melt pool-based features 1 | Area |

| Length | |

| Width | |

| Eccentricity | |

| Perimeter | |

| Mean temperature | |

| Maximum temperature | |

| Time-dependent temperature features | Time over threshold of 1200 K |

| Time over threshold of 1680 K | |

| Time over threshold of 2400 K |

| Dataset | Source | Content | Dimensions | Voxel Size in μm3 |

|---|---|---|---|---|

| Fi | SWIR camera | Values of i-th melt pool-based feature | 3 × nmp,l × 240 | 100 × 100 × 50 |

| Fj | SWIR camera | Values of j-th time-dependent temperature features | 90 × 90 × 240 | 100 × 100 × 50 |

| Ak | SWIR camera | Preprocessed and interpolated values of k-th feature | 935 × 980 × 1200 | 10 × 10 × 10 |

| Vraw | XCT | Density information (raw) | 2024 × 2024 × 2024 | 10 × 10 × 10 |

| Vproc | XCT | Density information (cropped, increased contrast) | 711 × 711 × 1260 | 10 × 10 × 10 |

| Vproc,bin | XCT | Porosity information (cropped) | 711 × 711 × 1260 | 10 × 10 × 10 |

| Vfinal | XCT | Porosity information (cropped, adjusted to CAD) | 711 × 711 × 1200 | 10 × 10 × 10 |

| Transformation Model (Including Degrees of Freedom) | Section | ΔD in μm | σΔD in μm | ΔR in μm | σΔR in μm |

|---|---|---|---|---|---|

| Rigid (translation and rotation) | 1 | 23 | ±12 | 21 | ±8 |

| 2 | 42 | ±20 | 38 | ±6 | |

| 3 | 23 | ±11 | 25 | ±7 | |

| 4 | 65 | ±29 | 59 | ±11 | |

| 5 | 25 | ±12 | 30 | ±11 | |

| 6 | 80 | ±31 | 57 | ±23 | |

| Translation (translation) | 1 | 27 | ±13 | 19 | ±8 |

| 2 | 43 | ±19 | 37 | ±5 | |

| 3 | 29 | ±12 | 23 | ±7 | |

| 4 | 53 | ±22 | 55 | ±9 | |

| 5 | 27 | ±12 | 28 | ±10 | |

| 6 | 64 | ±27 | 55 | ±23 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oster, S.; Fritsch, T.; Ulbricht, A.; Mohr, G.; Bruno, G.; Maierhofer, C.; Altenburg, S.J. On the Registration of Thermographic In Situ Monitoring Data and Computed Tomography Reference Data in the Scope of Defect Prediction in Laser Powder Bed Fusion. Metals 2022, 12, 947. https://doi.org/10.3390/met12060947

Oster S, Fritsch T, Ulbricht A, Mohr G, Bruno G, Maierhofer C, Altenburg SJ. On the Registration of Thermographic In Situ Monitoring Data and Computed Tomography Reference Data in the Scope of Defect Prediction in Laser Powder Bed Fusion. Metals. 2022; 12(6):947. https://doi.org/10.3390/met12060947

Chicago/Turabian StyleOster, Simon, Tobias Fritsch, Alexander Ulbricht, Gunther Mohr, Giovanni Bruno, Christiane Maierhofer, and Simon J. Altenburg. 2022. "On the Registration of Thermographic In Situ Monitoring Data and Computed Tomography Reference Data in the Scope of Defect Prediction in Laser Powder Bed Fusion" Metals 12, no. 6: 947. https://doi.org/10.3390/met12060947

APA StyleOster, S., Fritsch, T., Ulbricht, A., Mohr, G., Bruno, G., Maierhofer, C., & Altenburg, S. J. (2022). On the Registration of Thermographic In Situ Monitoring Data and Computed Tomography Reference Data in the Scope of Defect Prediction in Laser Powder Bed Fusion. Metals, 12(6), 947. https://doi.org/10.3390/met12060947