Structural FEM Analyses of a Landing Gear Testing Machine

Abstract

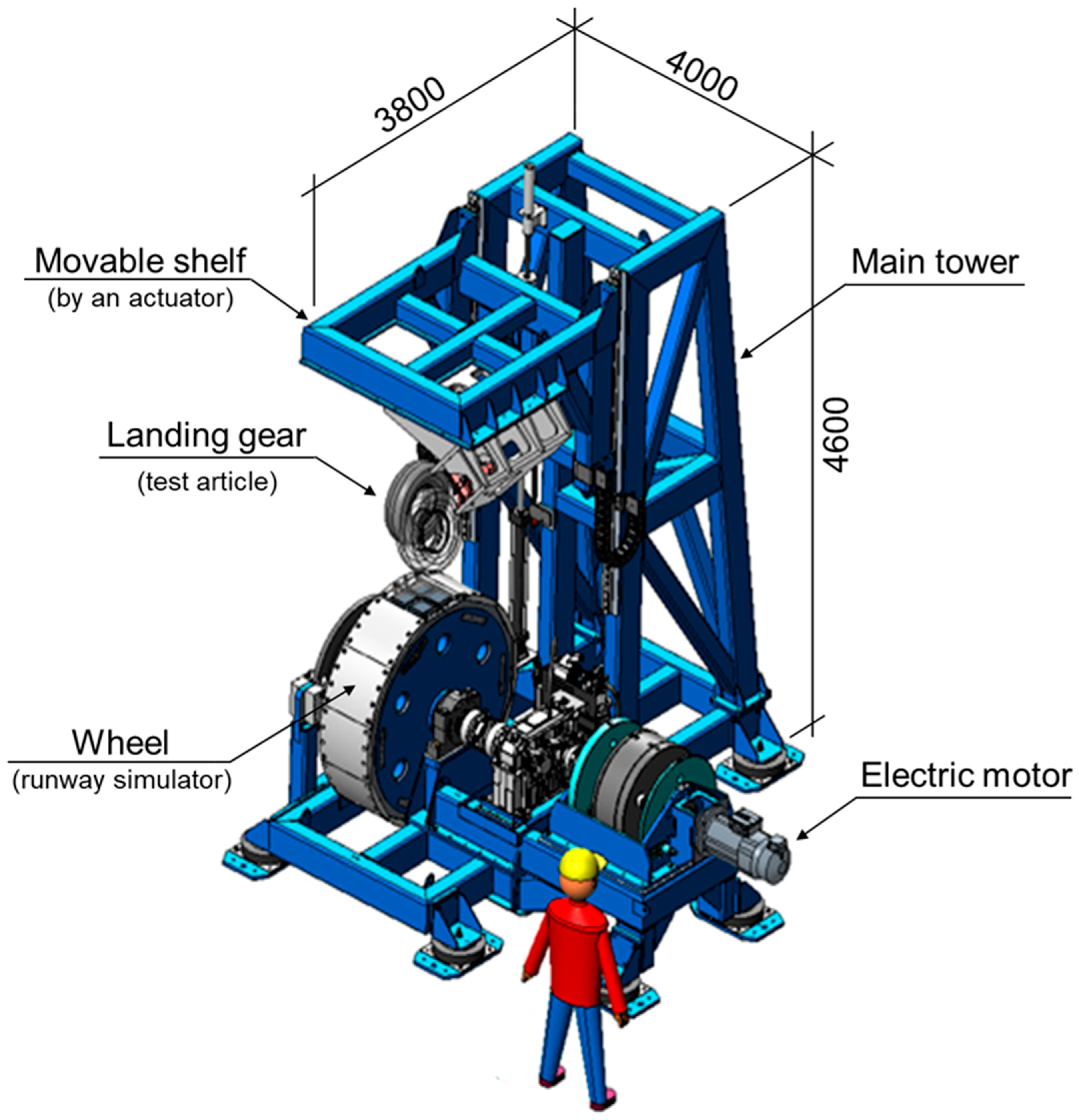

:1. Introduction

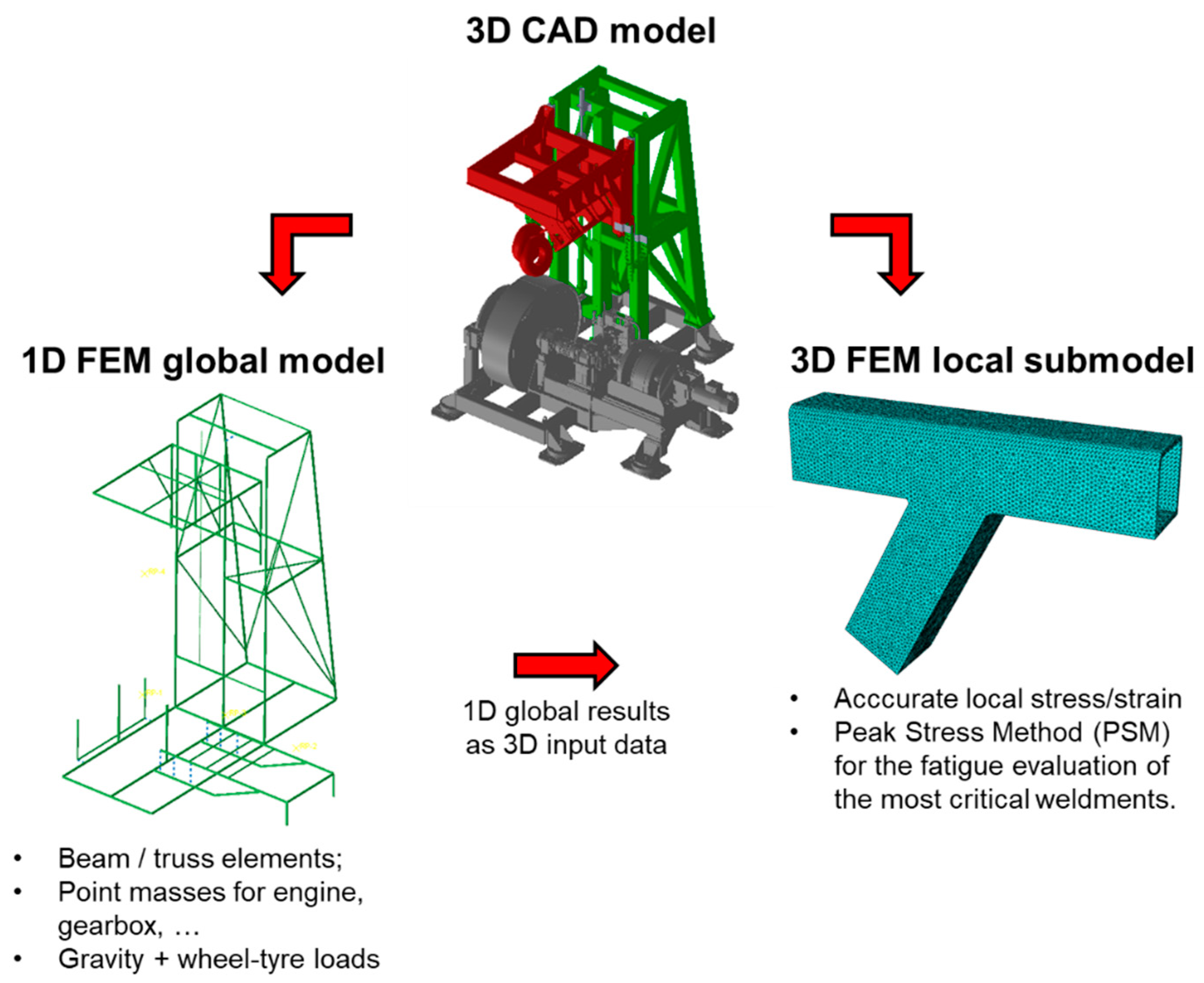

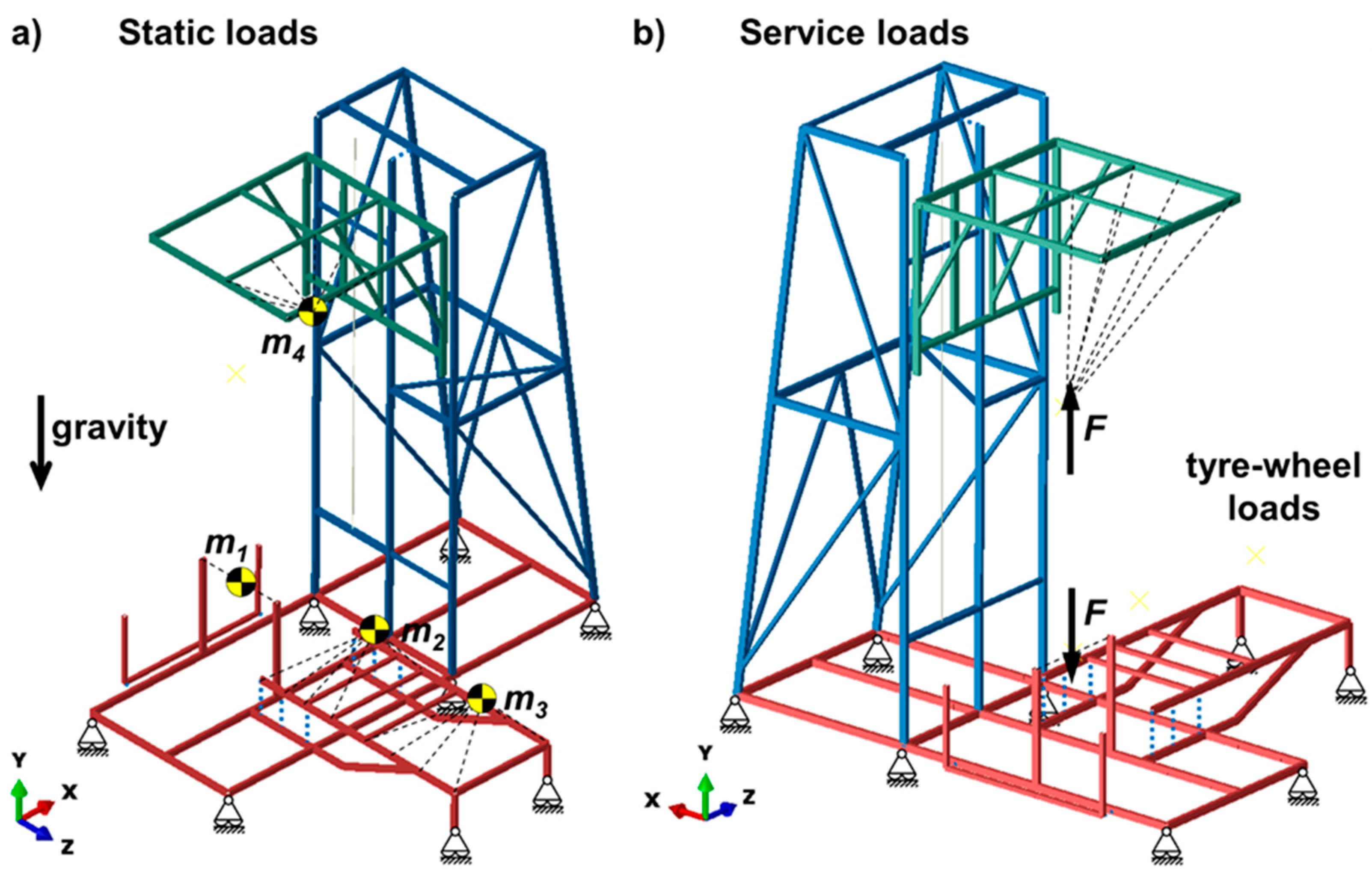

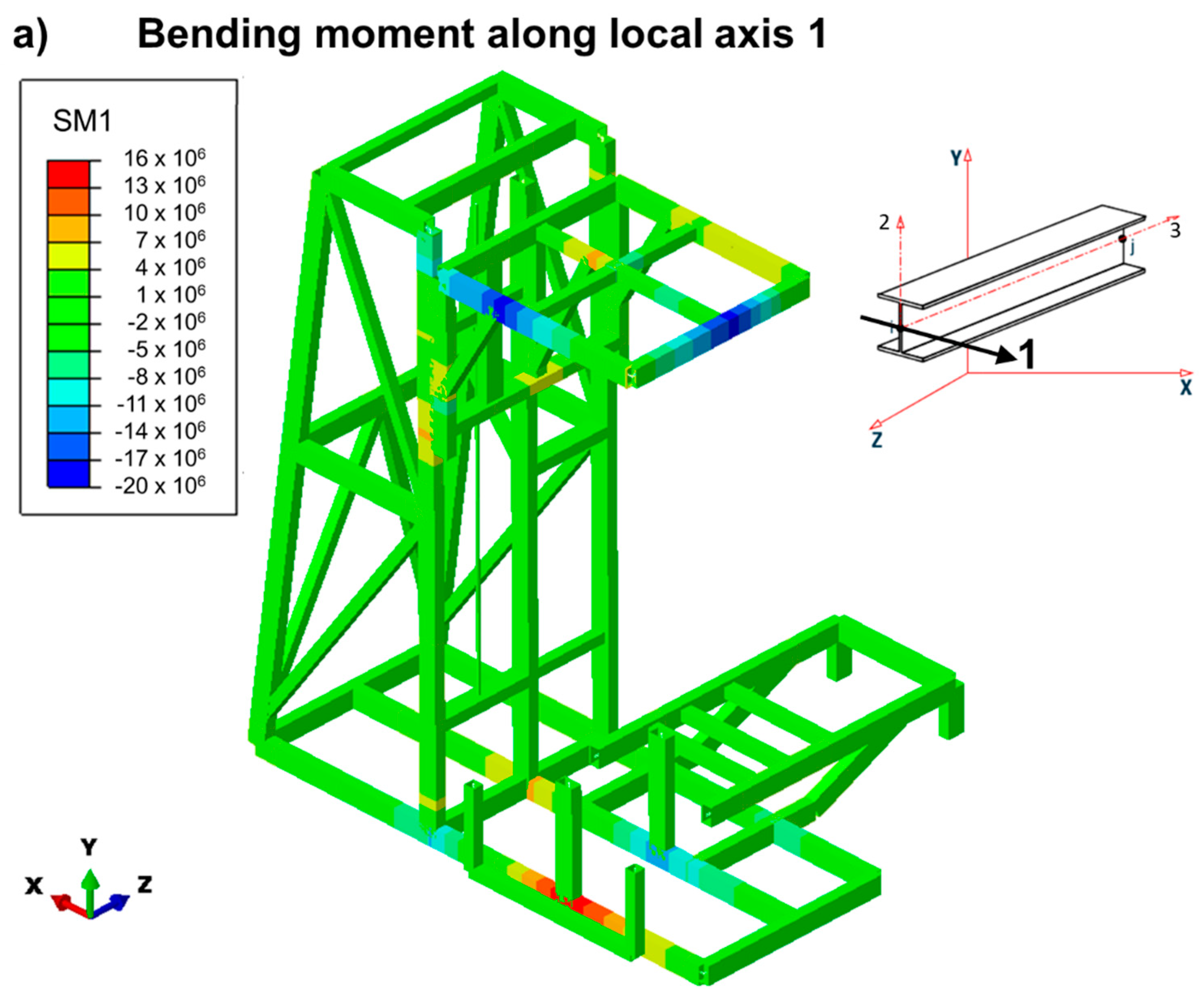

2. Materials and Methods

3. Results and Discussion

4. Conclusions

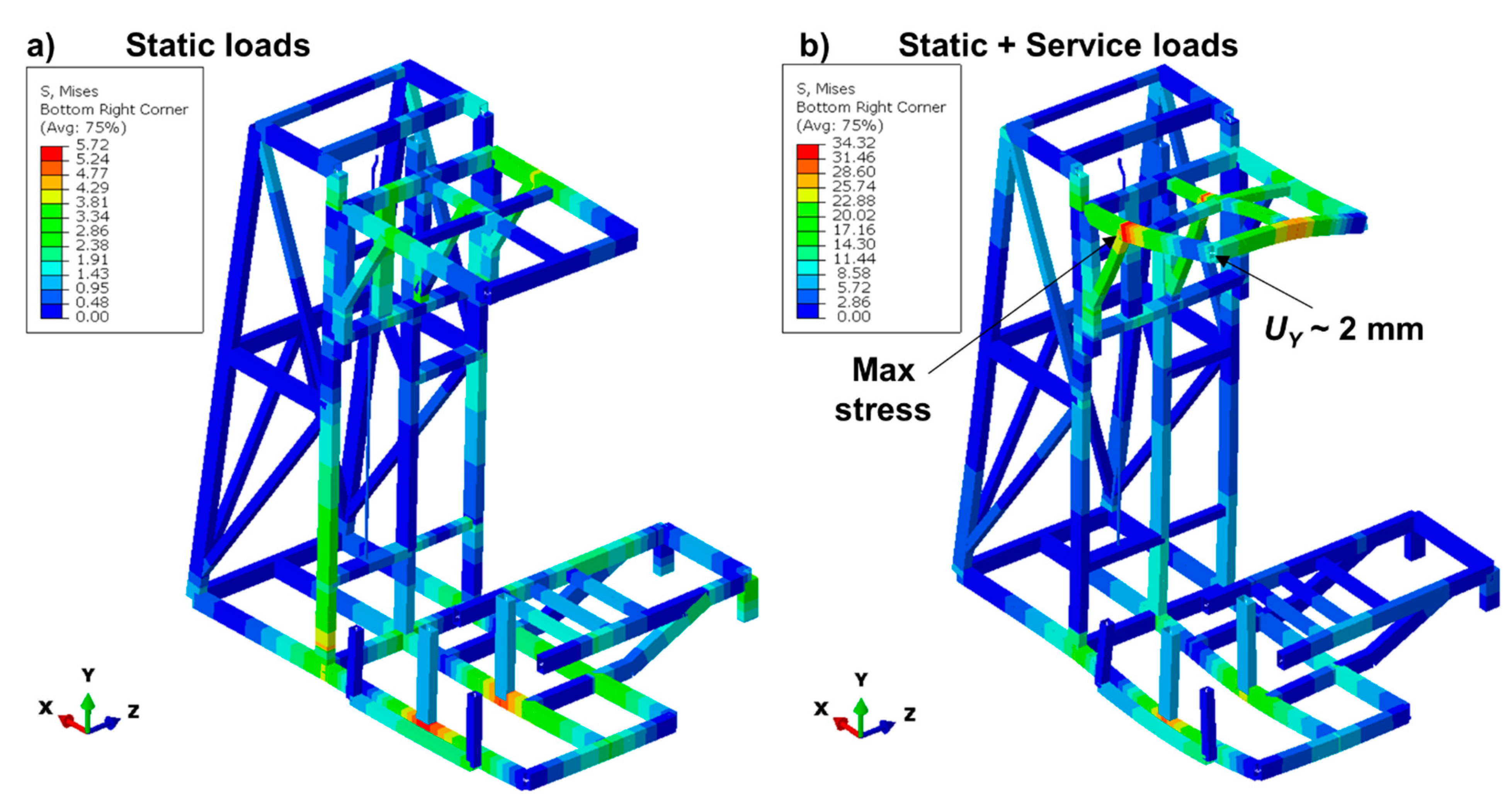

- A 1D model of the whole testing machine made it possible to simulate the global structural response in a fast and simplified way. This model made it possible to calculate the stress, strain, and displacement fields for the whole structure, making it possible to pinpoint the most critical locations to subsequently analyse them in more detail.

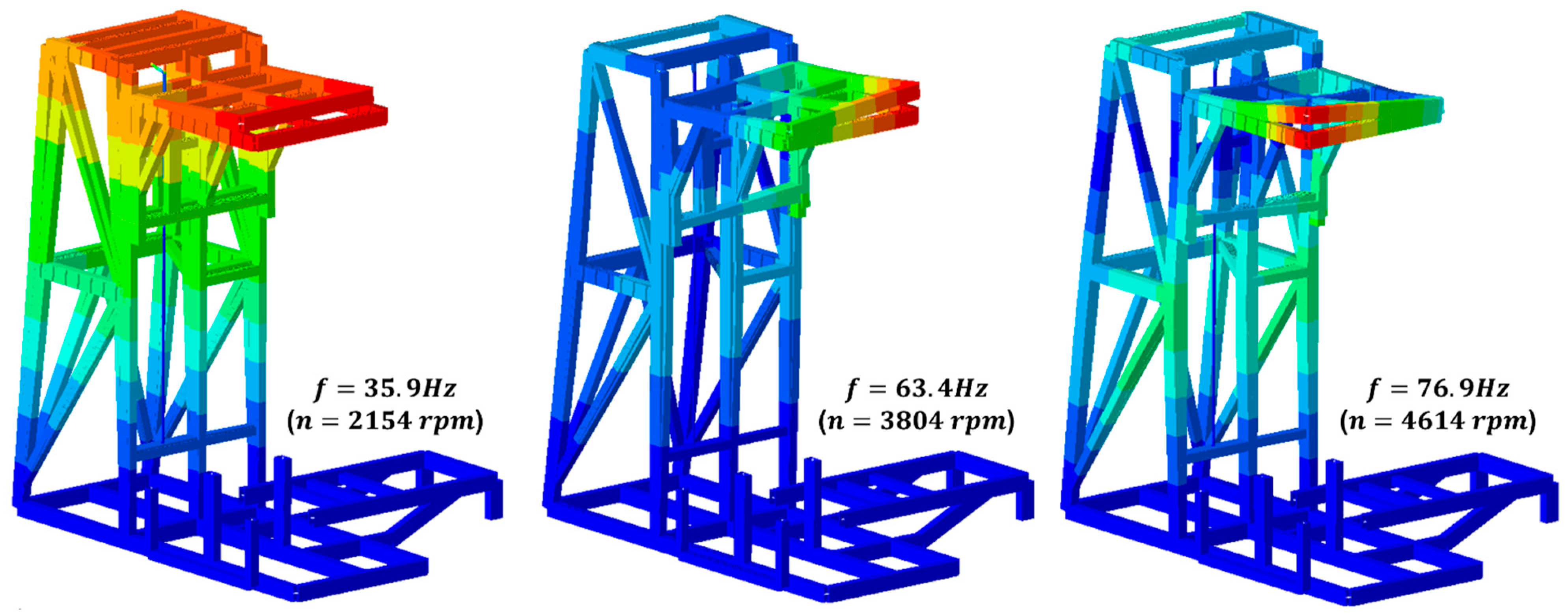

- A modal analysis was performed on the 1D model so to evaluate the performances of the structure against the heavy dynamic loads acting during the tests. Some rotational speeds of the wheel representing potentially critical conditions were calculated. Although the wheel rotation does not induce rotary bending on the structure during the operation of the machine, these operating conditions should be avoided so as to limit resonance issues.

- Based on the 1D model results, a full 3D FEM model was built up to investigate the most stressed position in more detail. Details of fillets and weldments were added to this model, and the accurate 3D local stress–strain field was recreated from the 1D global data. The Peak Stress Method was developed with this model so as to quantify that the most critical weldments were safe from fatigue.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fei, C.; Liu, H.; Zhu, Z.; An, L.; Li, S.; Lu, C. Whole-process design and experimental validation of landing gear lower drag stay with global/local linked driven optimization strategy. Chin. J. Aeronaut. 2021, 34, 318–328. [Google Scholar] [CrossRef]

- Citarella, R.G.; Cricrì, G.; Armentani, E. Multiple Crack Propagation with Dual Boundary Element Method in Stiffened and Reinforced Full Scale Aeronautic Panels. In Key Engineering Materials; Trans Tech Publications: Bach, Switzerland, 2013; Volume 560, pp. 129–155. [Google Scholar] [CrossRef]

- Citarella, R.; Giannella, V.; Lepore, M.; Dhondt, G. Dual boundary element method and finite element method for mixed-mode crack propagation simulations in a cracked hollow shaft. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 84–98. [Google Scholar] [CrossRef]

- Sepe, R.; Greco, A.; De Luca, A.; Armentani, E.; Berto, F. Experimental and FEM numerical assessment of multiaxial fatigue failure criteria for a rolling Stock’s seats structure. Eng. Fail. Anal. 2019, 102, 303–317. [Google Scholar] [CrossRef]

- Caputo, F.; De Luca, A.; Greco, A.; Marro, A.; Apicella, A.; Sepe, R.; Armentani, E. Established Numerical Techniques for the Structural Analysis of a Regional Aircraft Landing Gear. Adv. Mater. Sci. Eng. 2018, 2018, 8536581. [Google Scholar] [CrossRef] [Green Version]

- Ferraiuolo, M.; Leo, M.; Citarella, R. On the Adoption of Global/Local Approaches for the Thermomechanical Analysis and Design of Liquid Rocket Engines. Appl. Sci. 2020, 10, 7664. [Google Scholar] [CrossRef]

- Giannella, V.; Citarella, R.; Fellinger, J.; Esposito, R. LCF assessment on heat shield components of nuclear fusion experiment “Wendelstein 7-X” by critical plane criteria. Procedia Struct. Integr. 2018, 8, 318–331. [Google Scholar] [CrossRef]

- Ferraiuolo, M.; Perrella, M.; Giannella, V.; Citarella, R. Thermal–Mechanical FEM Analyses of a Liquid Rocket Engines Thrust Chamber. Appl. Sci. 2022, 12, 3443. [Google Scholar] [CrossRef]

- Giannella, V.; Fellinger, J.; Perrella, M.; Citarella, R. Fatigue life assessment in lateral support element of a magnet for nuclear fusion experiment “Wendelstein 7-X”. Eng. Fract. Mech. 2017, 178, 243–257. [Google Scholar] [CrossRef] [Green Version]

- Giannella, V.; Perrella, M.; Citarella, R. Efficient FEM-DBEM coupled approach for crack propagation simulations. Theor. Appl. Fract. Mech. 2017, 91, 76–85. [Google Scholar] [CrossRef]

- Citarella, R.; Lepore, M.A.; Fellinger, J.; Bykov, V.; Schauer, F. Coupled FEM-DBEM method to assess crack growth in magnet system of Wendelstein 7-X. Frat. Integrità Strutt. 2013, 7, 92–103. [Google Scholar] [CrossRef] [Green Version]

- Meneghetti, G.; Campagnolo, A.; Visentin, A.; Avalle, M.; Benedetti, M.; Bighelli, A.; Castagnetti, D.; Chiocca, A.; Collini, L.; De Agostinis, M.; et al. Rapid evaluation of notch stress intensity factors using the peak stress method with 3D tetrahedral finite element models: Comparison of commercial codes. Fatigue Fract. Eng. Mater. Struct. 2022, 45, 1005–1034. [Google Scholar] [CrossRef]

- Meneghetti, G. The use of peak stresses for fatigue strength assessments of welded lap joints and cover plates with toe and root failures. Eng. Fract. Mech. 2012, 89, 40–51. [Google Scholar] [CrossRef]

- Meneghetti, G. The peak stress method applied to fatigue assessments of steel and aluminium fillet-welded joints subjected to mode I loading. Fatigue Fract. Eng. Mater. Struct. 2008, 31, 346–369. [Google Scholar] [CrossRef]

- Sepe, R.; Wiebesiek, J.; Sonsino, C.M. Numerical and experimental validation of residual stresses of laser-welded joints and their influence on the fatigue behaviour. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 1126–1141. [Google Scholar] [CrossRef]

- Perić, M.; Tonković, Z.; Rodić, A.; Surjak, M.; Garašić, I.; Boras, I.; Švaić, S. Numerical analysis and experimental investigation of welding residual stresses and distortions in a T-joint fillet weld. Mater. Des. 2014, 53, 1052–1063. [Google Scholar] [CrossRef]

- Sepe, R.; De Luca, A.; Greco, A.; Armentani, E. Numerical evaluation of temperature fields and residual stresses in butt weld joints and comparison with experimental measurements. Fatigue Fract. Eng. Mater. Struct. 2021, 44, 182–198. [Google Scholar] [CrossRef]

- Sepe, R.; Giannella, V.; Greco, A.; De Luca, A. FEM Simulation and Experimental Tests on the SMAW Welding of a Dissimilar T-Joint. Metals 2021, 11, 1016. [Google Scholar] [CrossRef]

- Armentani, E.; Caputo, F.; Esposito, L.; Giannella, V.; Citarella, R. Multibody Simulation for the Vibration Analysis of a Turbocharged Diesel Engine. Appl. Sci. 2018, 8, 1192. [Google Scholar] [CrossRef] [Green Version]

- Giannella, V.; Sepe, R.; Citarella, R.; Armentani, E. FEM Modelling Approaches of Bolt Connections for the Dynamic Analyses of an Automotive Engine. Appl. Sci. 2021, 11, 4343. [Google Scholar] [CrossRef]

- Armentani, E.; Giannella, V.; Citarella, R.; Parente, A.; Pirelli, M. Substructuring of a Petrol Engine: Dynamic Characterization and Experimental Validation. Appl. Sci. 2019, 9, 4969. [Google Scholar] [CrossRef] [Green Version]

- Citarella, R.; Federico, L. Advances in Vibroacoustics and Aeroacustics of Aerospace and Automotive Systems. Appl. Sci. 2018, 8, 366. [Google Scholar] [CrossRef] [Green Version]

- Citarella, R.; Federico, L.; Barbarino, M. Aeroacustic and Vibroacoustic Advancement in Aerospace and Automotive Systems. Appl. Sci. 2020, 10, 3853. [Google Scholar] [CrossRef]

- Meneghetti, G.; Campagnolo, A. The Peak Stress Method to assess the fatigue strength of welded joints using linear elastic finite element analyses. Procedia Eng. 2018, 213, 392–402. [Google Scholar] [CrossRef]

- Livieri, P.; Lazzarin, P. Fatigue strength of steel and aluminium welded joints based on generalised stress intensity factors and local strain energy values. Int. J. Fract. 2005, 133, 247–276. [Google Scholar] [CrossRef]

- De Martin, A.; Jacazio, G.; Sorli, M. Simulation of Runway Irregularities in a Novel Test Rig for Fully Electrical Landing Gear Systems. Aerospace 2022, 9, 114. [Google Scholar] [CrossRef]

| Young’s Modulus E (GPa) | Poisson’s Ratio ν (–) | Mass Density ρ (kg/m3) | ||

|---|---|---|---|---|

| 210 | 0.33 | >275 | >410 | 7900 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Giannella, V.; Baglivo, G.; Giordano, R.; Sepe, R.; Citarella, R. Structural FEM Analyses of a Landing Gear Testing Machine. Metals 2022, 12, 937. https://doi.org/10.3390/met12060937

Giannella V, Baglivo G, Giordano R, Sepe R, Citarella R. Structural FEM Analyses of a Landing Gear Testing Machine. Metals. 2022; 12(6):937. https://doi.org/10.3390/met12060937

Chicago/Turabian StyleGiannella, Venanzio, Giovanni Baglivo, Rosario Giordano, Raffaele Sepe, and Roberto Citarella. 2022. "Structural FEM Analyses of a Landing Gear Testing Machine" Metals 12, no. 6: 937. https://doi.org/10.3390/met12060937

APA StyleGiannella, V., Baglivo, G., Giordano, R., Sepe, R., & Citarella, R. (2022). Structural FEM Analyses of a Landing Gear Testing Machine. Metals, 12(6), 937. https://doi.org/10.3390/met12060937