Compressive Property and Energy Absorption Capacity of Mg-Ceramic-Ni Foamsat Various Temperatures

Abstract

:1. Introduction

2. Materials and Methods

2.1. Specimen Fabrication

2.2. Compressive Test

2.3. Characterizations

3. Results

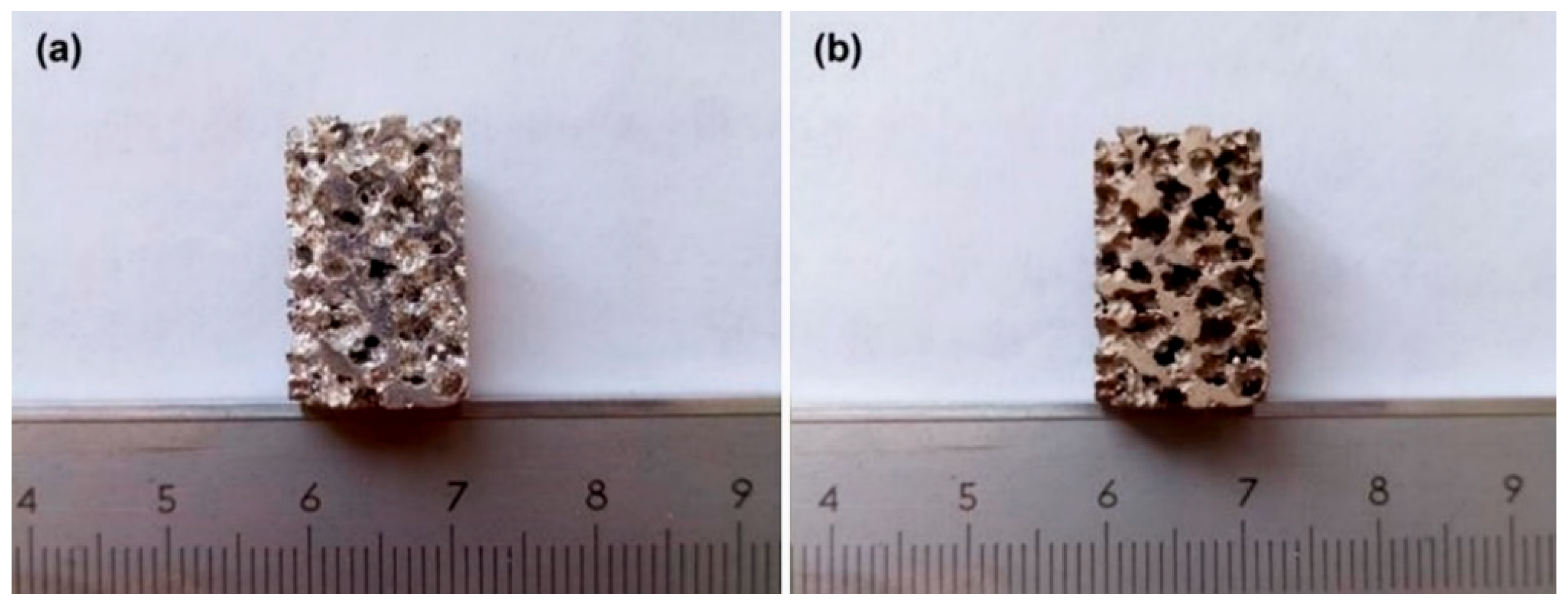

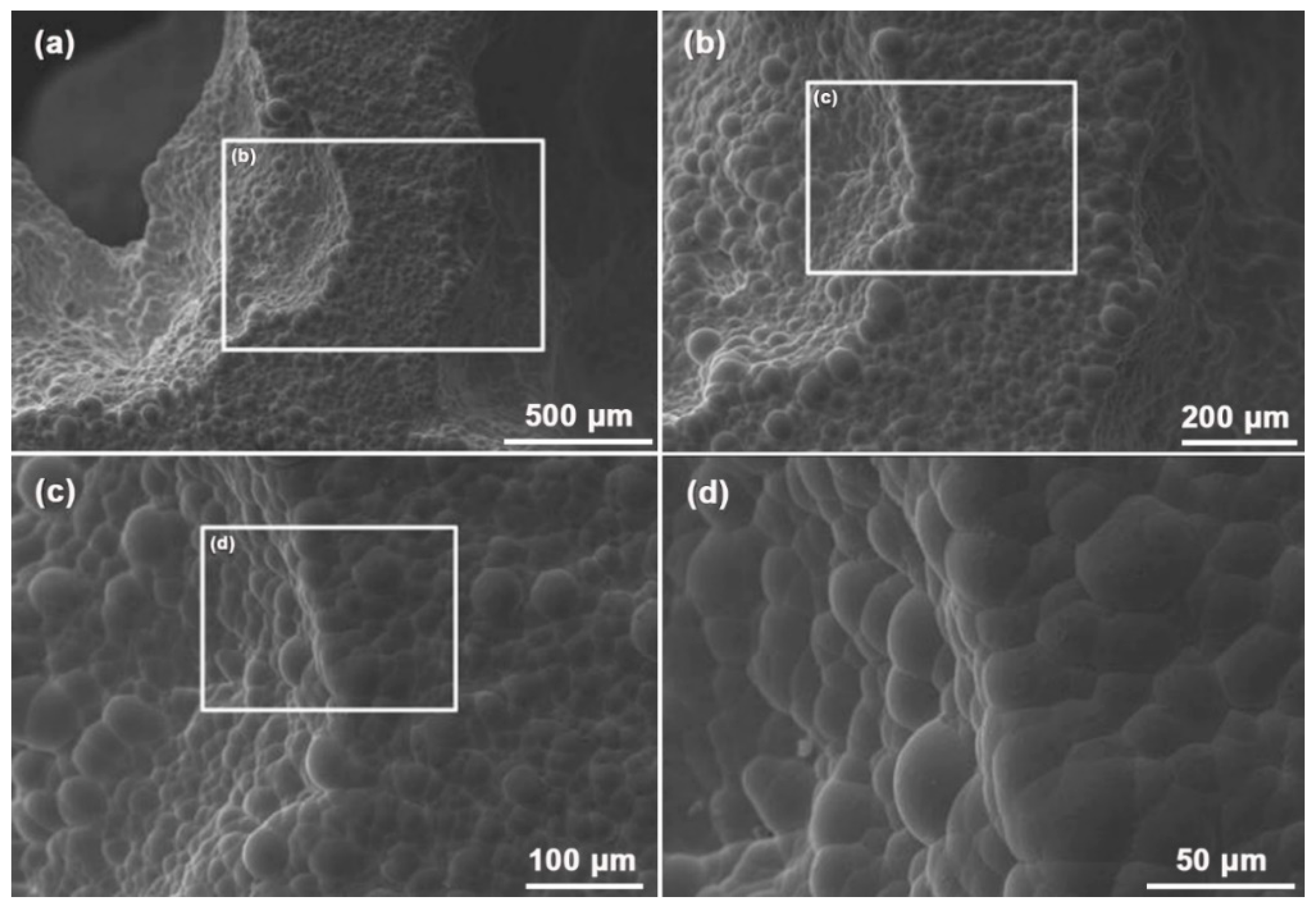

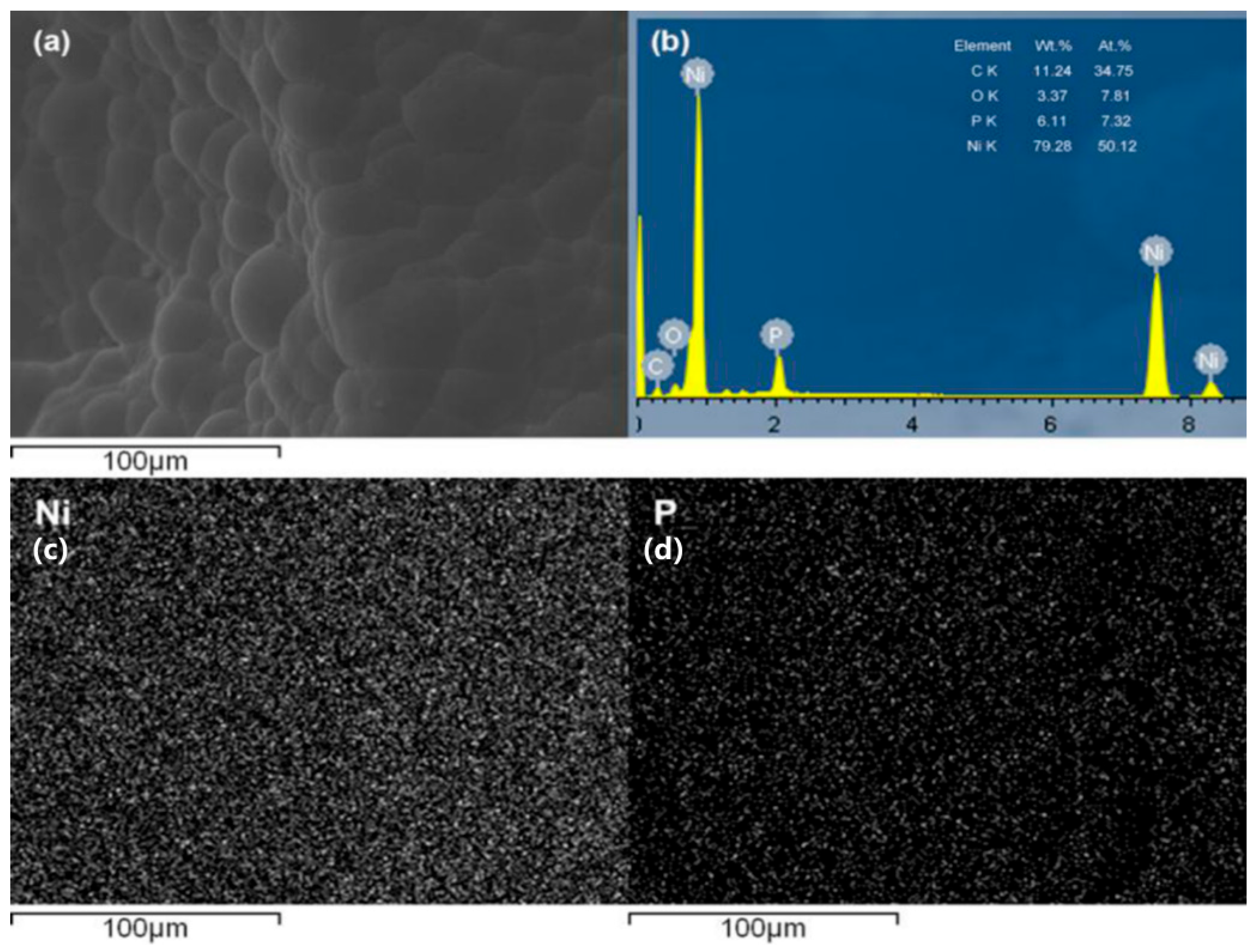

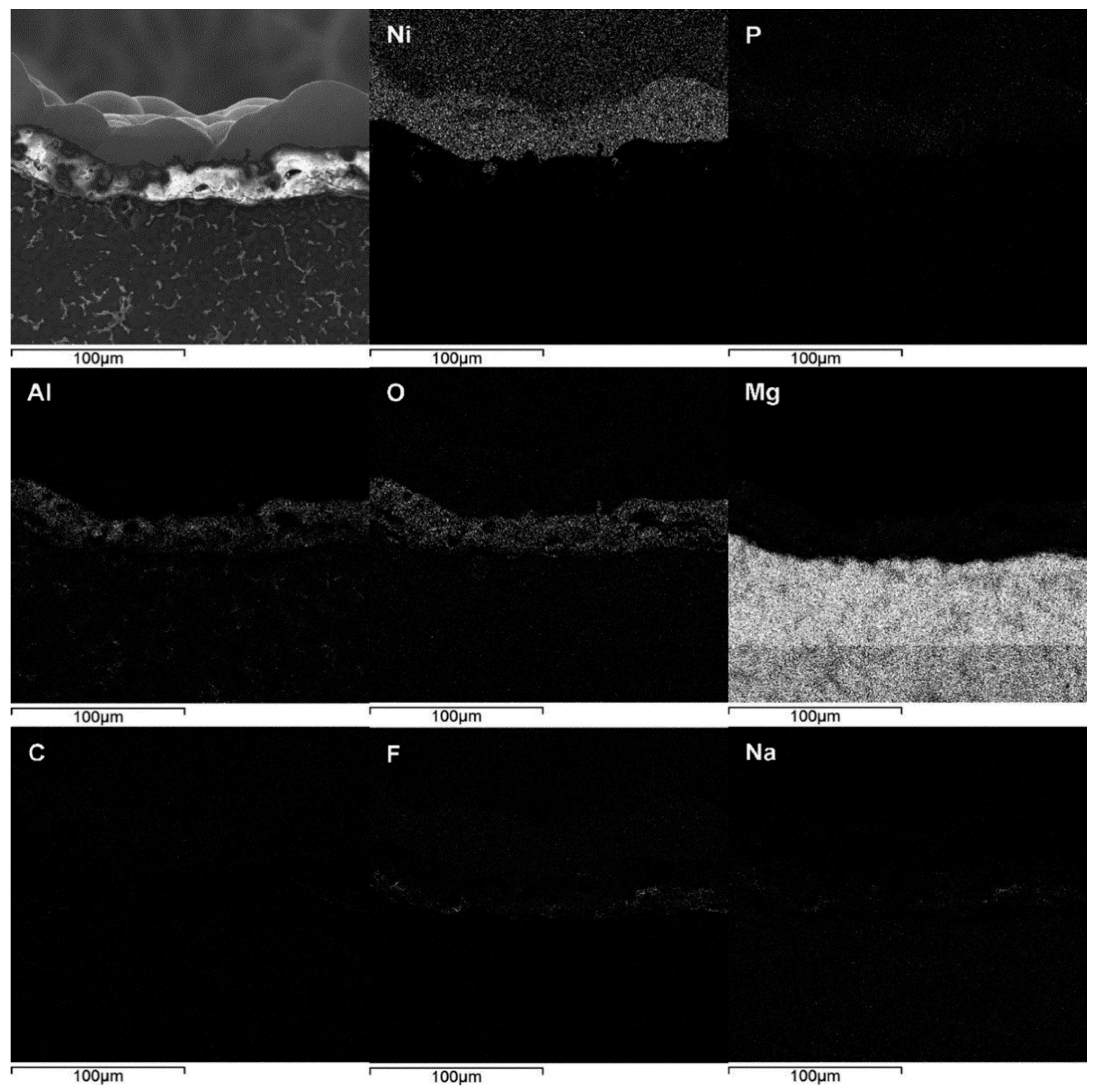

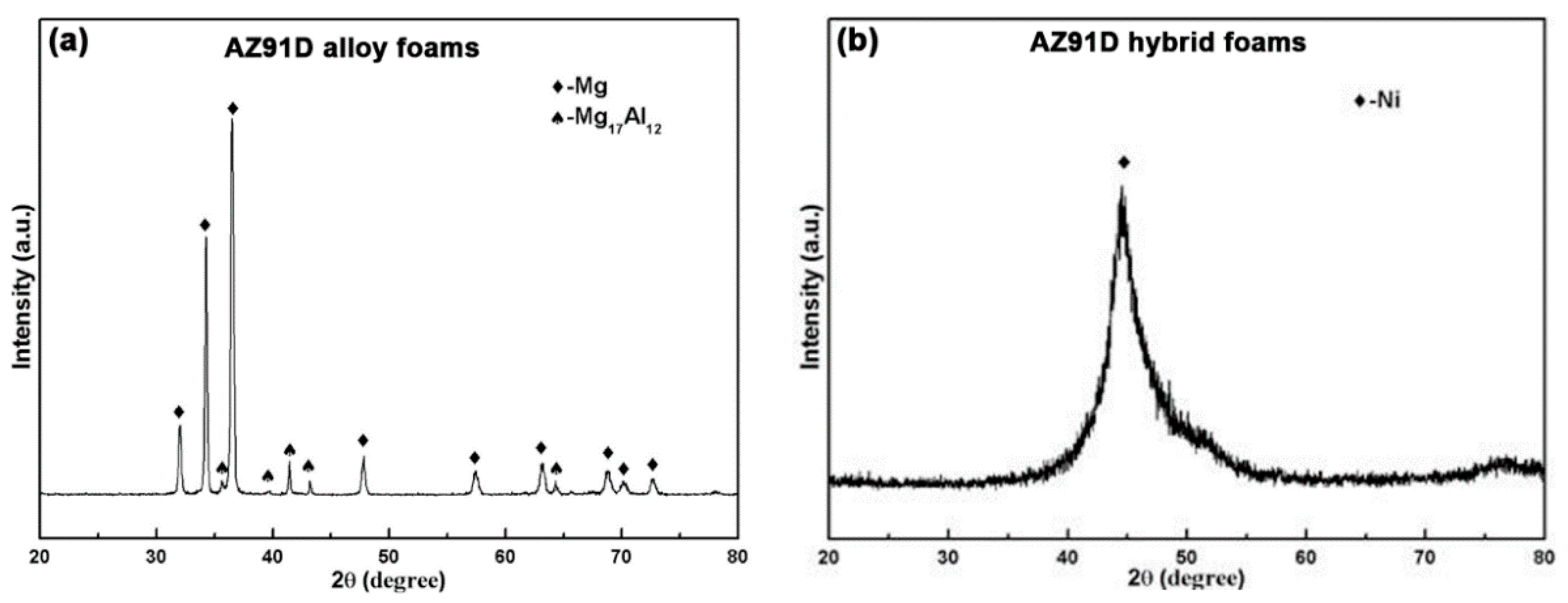

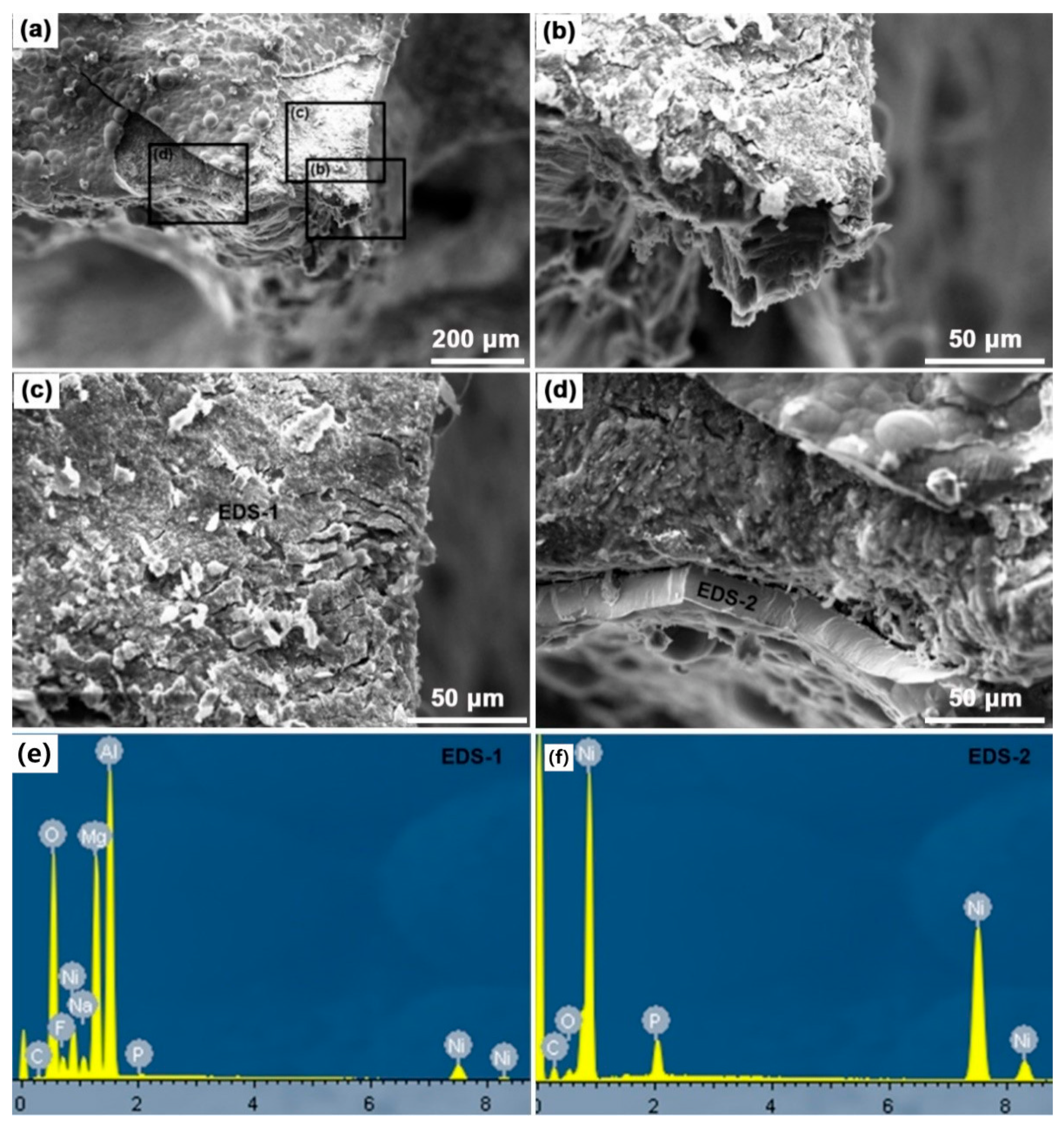

3.1. Macroscopic Morphologiesand Microstructure

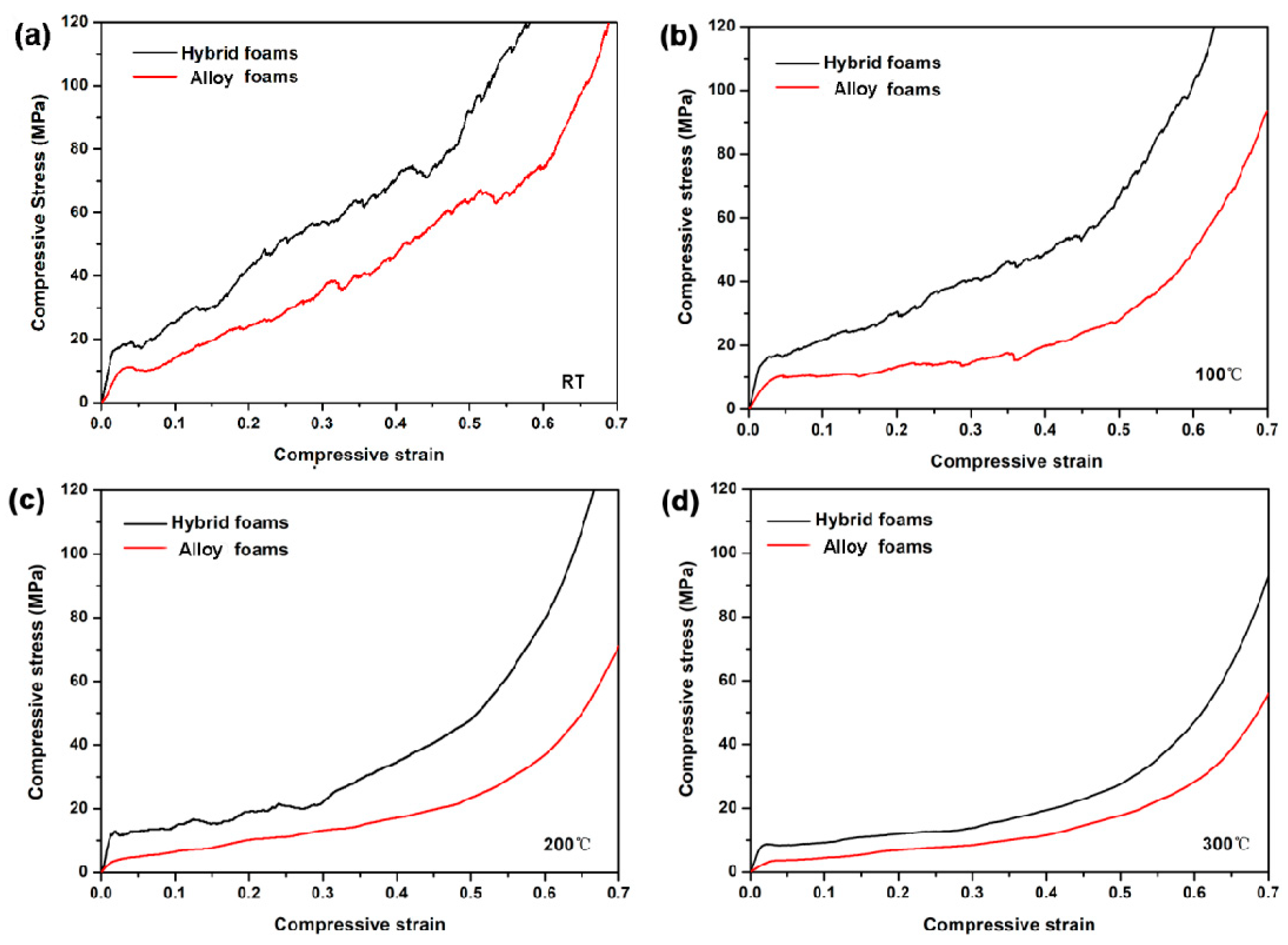

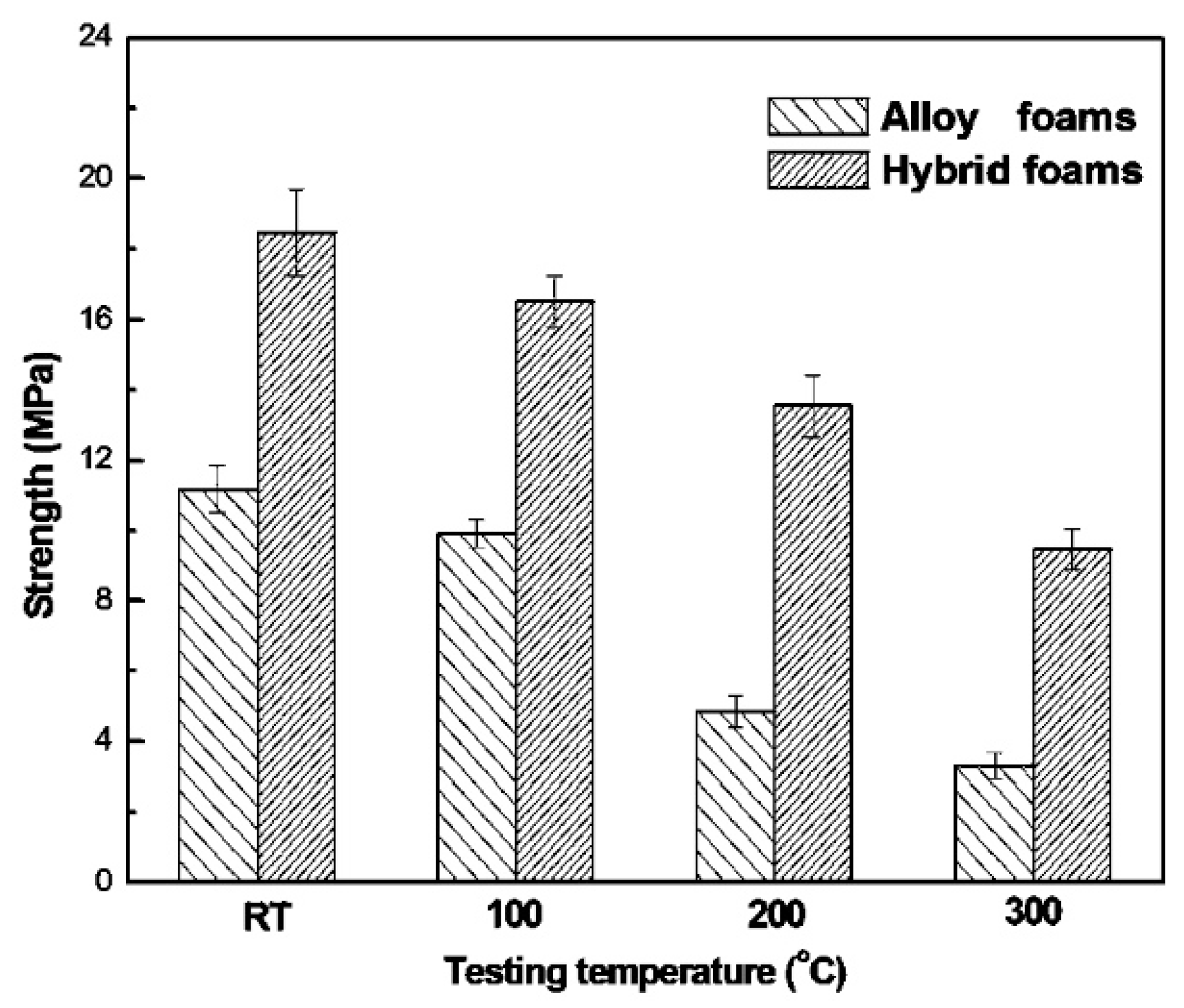

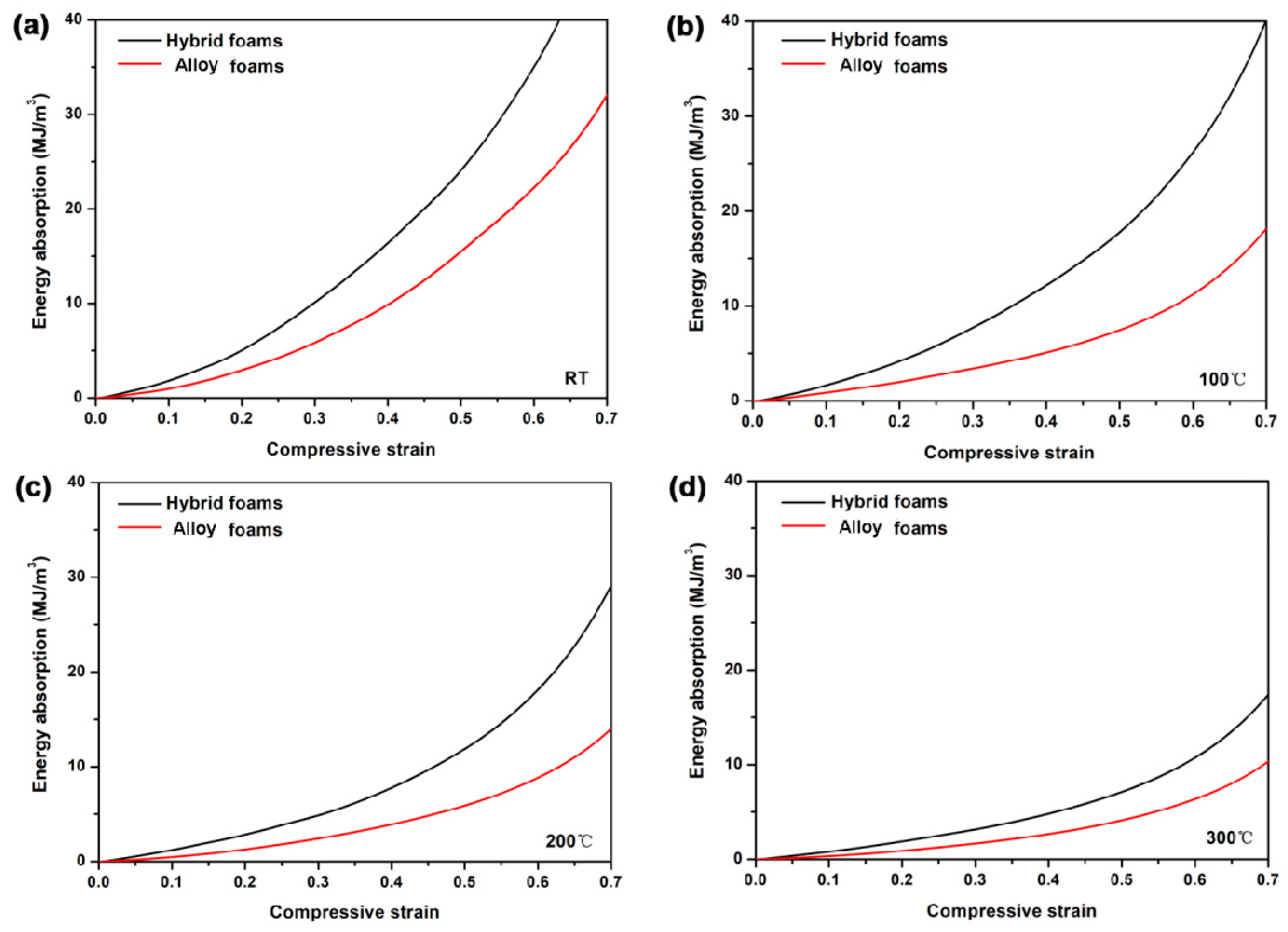

3.2. Compressive Properties

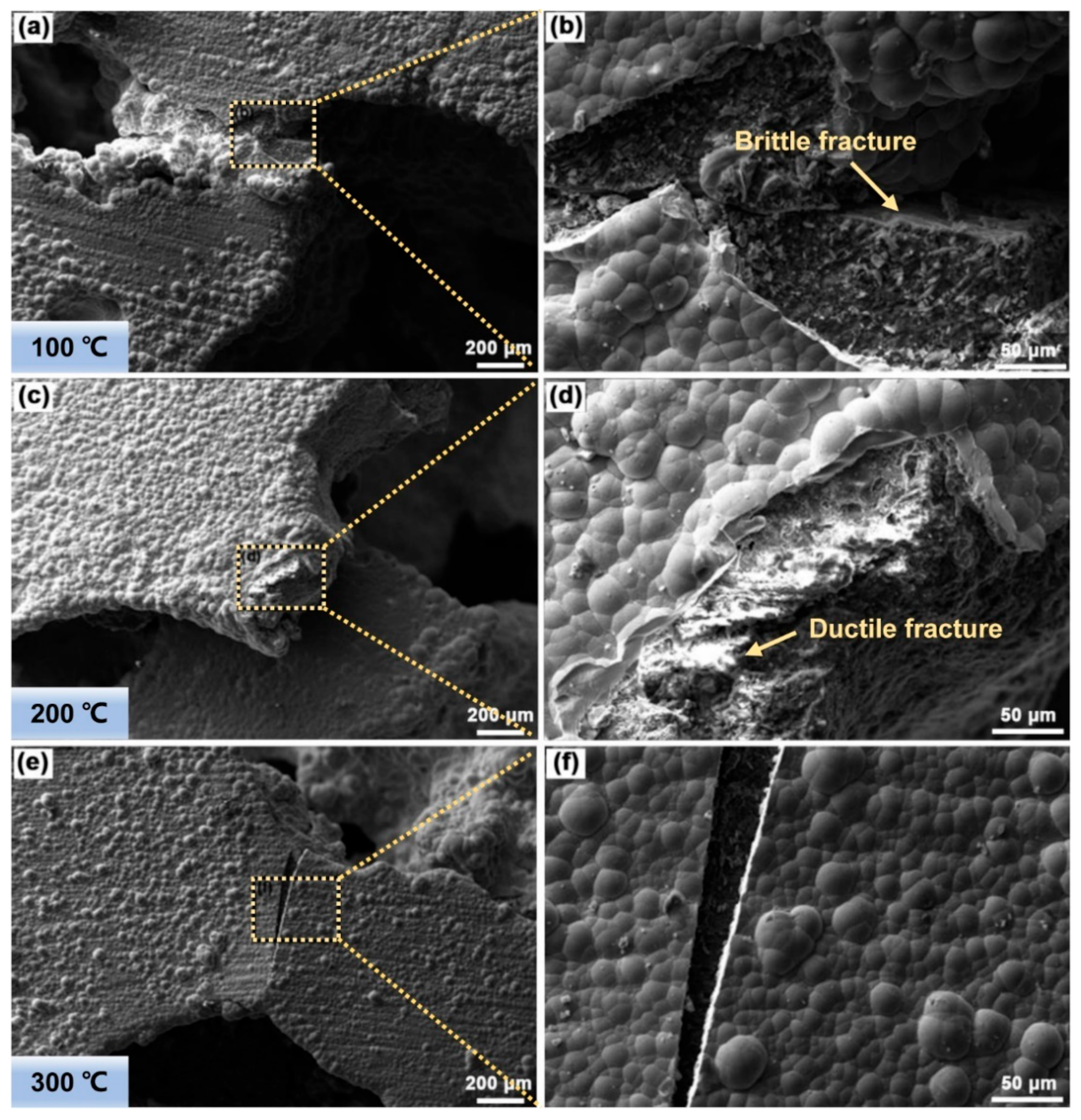

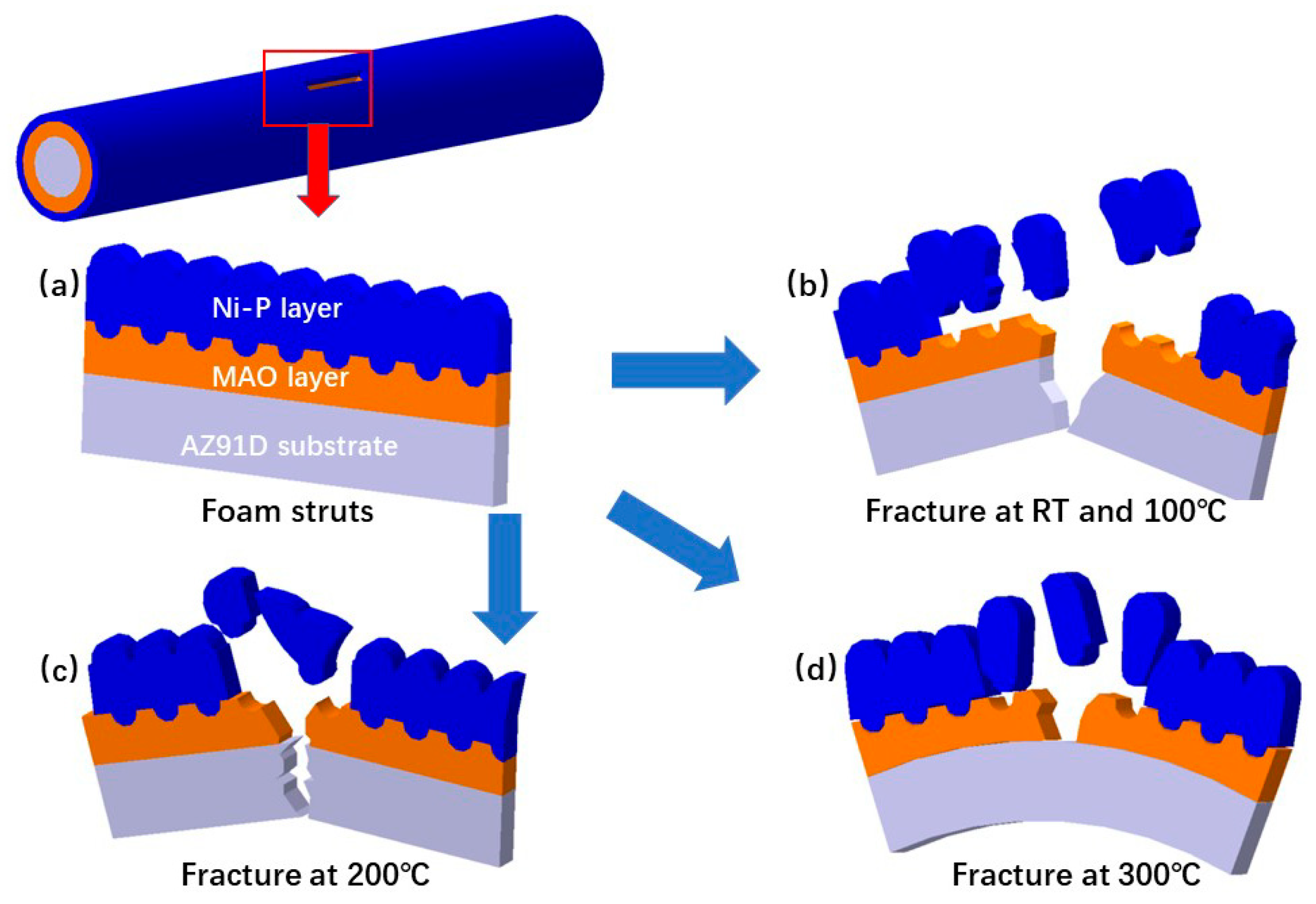

3.3. Deformation Behavior and Failure Modeof the Foam Struts

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Aghion, E.; Perez, Y. Effects of porosity on corrosion resistance of Mg alloy foam produced by powder metallurgy technology. Mater. Charact. 2014, 96, 78–83. [Google Scholar] [CrossRef]

- Jiang, G.; He, G. A new approach to the fabrication of porous magnesium with well-controlled 3D pore structure for orthopedic applications. Mater. Sci. Eng. C 2014, 43, 317–320. [Google Scholar] [CrossRef] [PubMed]

- Genna, S.; Trocalusci, F.; Ucciardello, N.; Tagliaferri, V. Improving performance of an open cell aluminium foam through electro-deposition of nickel. Materials 2019, 12, 133. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, M.; Feng, Y.; Zhang, J.; Liu, S.; Yang, Q.; Liu, Z.; Li, R.; Meng, J.; Wu, R. Development of extruded Mg-6Er-3Y-1.5Zn-0.4Mn (wt.%) alloy with high strength at elevated temperature. J. Mater. Sci. Technol. 2019, 35, 2365–2374. [Google Scholar] [CrossRef]

- Li, R.; Zhao, D.; Zhang, J.; Li, H.; Dai, Y.; Fang, D. Room temperature yielding phenomenon in extruded or/and aged Mg-14Gd-2Ag-0.5Zr alloy with fine-grained microstructure. Mater. Sci. Eng. A 2020, 787, 139551. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, L.; Liu, S.; Han, Z.; Dong, Z. Effect of Si content on microstructure and compressive properties of open-cell Mg composite foams reinforced by in-situ Mg2Si compounds. Mater. Charact. 2020, 159, 110045. [Google Scholar] [CrossRef]

- Li, Z.; Huang, Y.; Wang, X.; Wang, X.; Wang, D.; Han, F. Enhancement of open cell aluminum foams through thermal evaporating Zn film. Mater. Lett. 2016, 172, 120–124. [Google Scholar] [CrossRef]

- Liu, J.; Qu, Q.; Liu, Y.; Li, R.; Liu, B. Compressive properties of Al-Si-SiC composite foams at elevated temperatures. J. Alloys Compd. 2016, 676, 239–244. [Google Scholar] [CrossRef]

- Liu, J.; Shi, S.; Zheng, Z.; Huang, K.; Yan, Y. Characterization and compressive properties of Ni/Mg hybrid foams. Mater. Sci. Eng. A 2017, 708, 329–335. [Google Scholar] [CrossRef]

- Movahedi, N.; Habibolahzadeh, A. Effect of plasma electrolytic oxidation treatment on corrosion behavior of closed-cell Al-A356 alloy foam. Mater. Lett. 2016, 164, 558–561. [Google Scholar] [CrossRef]

- Rúa, J.M.; Zuleta, A.A.; Ramírez, J.; Fernández-Morales, P. Micro-arc oxidation coating on porous magnesium foam and its potential biomedical applications. Surf. Coat. Technol. 2019, 360, 213–221. [Google Scholar] [CrossRef]

- Abdulla, T.; Yerokhin, A.; Goodall, R. Enhancement in specific strength of open-cell aluminium foams through plasma electrolytic oxidation treatment. Scr. Mater. 2014, 75, 38–41. [Google Scholar] [CrossRef]

- Abdulla, T.; Yerokhin, A.; Goodall, R. Effect of Plasma Electrolytic Oxidation coating on the specific strength of open-cell aluminium foams. Mater. Des. 2011, 32, 3742–3749. [Google Scholar] [CrossRef]

- Wang, X.; Wang, X.; Wang, D.; Zhao, M.; Han, F. A novel approach to fabricate Zn coating on Mg foam through a modified thermal evaporation technique. J. Mater. Sci. Technol. 2018, 34, 1558–1563. [Google Scholar] [CrossRef]

- Song, Z.; Xie, Z.; Yu, G.; Hu, B.; He, X.; Zhang, X. A novel palladium-free surface activation process for electroless nickel deposition on micro-arc oxidation film of AZ91D Mg alloy. J. Alloys Compd. 2015, 623, 274–281. [Google Scholar] [CrossRef]

- Zhang, W.; Jiang, Z.; Li, G.; Jiang, Q.; Lian, J. Electroless Ni-P/Ni-B duplex coatings for improving the hardness and the corrosion resistance of AZ91D magnesium alloy. Appl. Surf. Sci. 2008, 254, 4949–4955. [Google Scholar] [CrossRef]

- Ezhilselvi, V.; Balaraju, J.N.; Subramanian, S. Chromate and HF free pretreatment for MAO/electroless nickel coating on AZ31B magnesium alloy. Surf. Coat. Technol. 2017, 325, 270–276. [Google Scholar] [CrossRef]

- Li, R.; Li, H.; Zhao, D.; Dai, Y.; Fang, D.; Zhang, J.; Zong, L.; Sun, J. High strength commercial AZ91D alloy with a uniformly fine-grained structure processed by conventional extrusion. Mater. Sci. Eng. A 2020, 780, 139193. [Google Scholar] [CrossRef]

- Zhang, L.; Ye, B.; Liao, W.; Zhou, H.; Guo, W.; Wang, Q.; Jiang, H.; Ding, W. Microstructure evolution and mechanical properties of AZ91D magnesium alloy processed by repetitive upsetting. Mater. Sci. Eng. A 2015, 641, 62–70. [Google Scholar] [CrossRef]

- Banhart, J.; Baumeister, J. Deformation characteristics of metal foams. J. Mater. Sci. 1998, 33, 1431–1440. [Google Scholar] [CrossRef]

- Thornton, P.H.; Magee, C.L. Deformation characteristics of zinc foam. Metall. Trans. A 1975, 6, 1801–1807. [Google Scholar] [CrossRef]

- Jappes, J.; Ramamoorthy, B.; Nair, P. A study on the influence of process parameters on efficiency and crystallinity of electroless Ni-P deposits. J. Mater. Process. Technol. 2005, 169, 308–313. [Google Scholar] [CrossRef]

- Ly, X.N.; Yang, S. Influence of current mode on microstructure and corrosion behavior of micro-arc oxidation (MAO) biodegradable Mg-Zn-Ca alloy in Hank’s solution. Surf. Coat. Technol. 2019, 358, 331–339. [Google Scholar] [CrossRef]

- Hussein, R.O.; Nie, X.; Northwood, D.O. An investigation of ceramic coating growth mechanisms in plasma electrolytic oxidation (PEO) processing. Electrochim. Acta 2013, 112, 111–119. [Google Scholar] [CrossRef]

- Yang, D.; Hu, Z.; Chen, W.; Lu, J.; Chen, J.; Wang, H.; Wang, L.; Jiang, J.; Ma, A. Fabrication of Mg-Al alloy foam with close-cell structure by powder metallurgy approach and its mechanical properties. J. Manuf. Process. 2016, 22, 290–296. [Google Scholar] [CrossRef]

- Florek, R.; Simančík, F.; Nosko, M.; Harnúšková, J. Compression test evaluation method for aluminium foam parts of different alloys and densities. Powder Metall. Prog. 2010, 10, 207–212. [Google Scholar]

- Liu, J.; Si, F.; Zhu, X.; Liu, Y.; Zhang, J.; Liu, Y.; Zhang, C. Compressive properties of open-cell Al hybrid foams at different temperatures. Materials 2017, 10, 98. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.; Pan, W.; Si, F.; Huang, K.; Liu, Y.; Liu, J. Enhanced compressive property of Al composite foams at elevated temperatures via plasma electrolytic oxidation. Metals 2018, 8, 118. [Google Scholar] [CrossRef] [Green Version]

- Sahu, S.; Goel, M.D.; Mondal, D.P.; Das, S. High temperature compressive deformation behavior of ZA27-SiC foam. Mater. Sci. Eng. A 2014, 607, 162–172. [Google Scholar] [CrossRef]

- Lu, X.; Zhang, Z.; Du, H.; Luo, H.; Mu, Y.; Xu, J. Compressive behavior of Mg alloy foams at elevated temperature. J. Alloys Compd. 2019, 797, 727–734. [Google Scholar] [CrossRef]

- Shi, B.; Zhao, L.; Chen, D.; Li, C.; Dong, Y.; Wu, D.; Chen, R.; Ke, W. Characterization of a novel 14H-LPSO structure and related elevated-temperature mechanical behaviors in an extruded Mg-Y-Zn-Cu alloy. Mater. Sci. Eng. A 2020, 772, 138786. [Google Scholar] [CrossRef]

- Feng, Y.; Zhang, J.; Qin, P.; Liu, S.; Yang, Q.; Meng, J.; Wu, R.; Xie, J. Characterization of elevated-temperature high strength and decent thermal conductivity extruded Mg-Er-Y-Zn alloy containing nano-spaced stacking faults. Mater. Charact. 2019, 155, 109823. [Google Scholar] [CrossRef]

- Bi, G.; Fang, D.; Zhao, L.; Lian, J.; Jiang, Q.; Jiang, Z. An elevated temperature Mg-Dy-Zn alloy with long period stacking ordered phase by extrusion. Mater. Sci. Eng. A 2011, 528, 3609–3614. [Google Scholar] [CrossRef]

- Regev, M.; Aghion, E.; Rosen, A. Creep studies of AZ91D pressure die casting. Mater. Sci. Eng. A 1997, 234, 123–126. [Google Scholar] [CrossRef]

| Composition | Concentration (g/L) | Process Conditions |

|---|---|---|

| NaAlO2 | 10 g/L | Stirring |

| KF | 4 g/L | |

| Na3C6H5O7·2H2O | 3 g/L | |

| NaOH | 1 g/L |

| Composition | Concentration (g/L) | Process Conditions |

|---|---|---|

| NiSO4·6H2O | 20 g/L | 2–3 h |

| NaH2PO2·H2O | 18 g/L | |

| CH3COONa | 17 g/L | |

| NH4HF2 | 10 g/L | |

| Stabilizer | Appropriate content | |

| NH3·H2O | Appropriate content |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, S.; Sun, W.; Zhang, X.; Zhu, X.; Liu, J. Compressive Property and Energy Absorption Capacity of Mg-Ceramic-Ni Foamsat Various Temperatures. Metals 2022, 12, 689. https://doi.org/10.3390/met12040689

Shi S, Sun W, Zhang X, Zhu X, Liu J. Compressive Property and Energy Absorption Capacity of Mg-Ceramic-Ni Foamsat Various Temperatures. Metals. 2022; 12(4):689. https://doi.org/10.3390/met12040689

Chicago/Turabian StyleShi, Shouquan, Weibo Sun, Xiaoru Zhang, Xianyong Zhu, and Jiaan Liu. 2022. "Compressive Property and Energy Absorption Capacity of Mg-Ceramic-Ni Foamsat Various Temperatures" Metals 12, no. 4: 689. https://doi.org/10.3390/met12040689

APA StyleShi, S., Sun, W., Zhang, X., Zhu, X., & Liu, J. (2022). Compressive Property and Energy Absorption Capacity of Mg-Ceramic-Ni Foamsat Various Temperatures. Metals, 12(4), 689. https://doi.org/10.3390/met12040689