Abstract

The microstructures and properties of ternary copper-niobium-graphite (Cu-Nb(nano)10-C4, and Cu-Nb(micron)10-C4) composites produced via spark plasma sintering (SPS) technique have been investigated for their potential use as electrical connection materials at high-temperature application. Nowadays, there is much activity in the development of such material all over the world. This study was aimed to compare the effect of adding the nano and micron particles sizes of Nb powders in the microstructures and properties of Cu-Nb-C composites sintered at 700 and 650 °C temperatures. The investigated materials have been produced via the SPS method. The microstructures were observed by electron microscopy technique, the wear test was observed by Anton-Paar TRB3 tribometer, thermal diffusivity was observed by LFA427 NETzschlaser flash device within the temperature of 100–900 °C, and the corrosion test was performed by potentiodynamic polarization. The discoveries have been presented in the manuscript and were discussed with reference to the microstructure development, the composite with nanoparticles sintered at 650 °C displayed closed thermal stabilities as temperature increased, and it recorded a low coefficient of friction and suitable corrosion resistance, which correspond to requirements for electrical contacting materials. The SPS method of production of the composites caused initial microstructure refinement and improved the properties of the composites.

1. Introduction

Copper base composites are considerably used in the domain of present-day electronics stowing, friction, and electrical contacts, aerospace, and rail transportations following their outstanding electrical, thermal, and mechanical properties [1,2]. Niobium and graphite with self-lubrication and better thermal and electrical conductivity are usually added to the copper matrix as an ideal secondary phase. In contrast with traditional fillers such as oxides and graphite particles, additions of graphite and niobium can improve the mechanical performances of copper base composites with little deterioration in their electrical and thermal conductivities due to their exceptional comprehensive performance. As yet, a great number of researchers have made an effort to manufacture copper-graphite [1,3,4,5] and copper-niobium composites by casting or powder metallurgy. There are innumerable studies that have been carried out on copper-niobium alloys and composites [6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26]. Although, it is difficult to obtain a suitable bonding interface between niobium and graphite as the second and third phases in the copper matrix due to their huge differences in density with copper powders. Graphite tends to agglomerate in the copper matrix due to its poor affinity with copper, which renders it difficult to obtain a suitable bonding interface between the two components. Due to a deficiency of wettability along with a high difference of specific gravity values that exist between copper and graphite, it is challenging to annex graphite particles in the matrix of copper rather than agglomerating altogether. Thus, the powder metallurgy approach has been set off as a favored procedure to produce the composite material. There are three major methods (ball milling, compaction, and sintering) used during powder metallurgy, and among them, the most important one is sintering, which offers equal disposition of additive particles in the matrix of copper. Spark plasma sintering technique enables consolidation of powders at about two-thirds of their melting points, and it allows the powder to consolidate within a shorter time. This short sintering time is viewed as an added advantage compared to the conventional sintering technique; similarly, vacuum hot pressing and hot isostatic pressing technique [27]. Not long ago, spark plasma sintering, as the latest and advanced method, has been broadly employed to fabricate metals, alloys, ceramics, and composites as it has numerous benefits, such as short sintering temperature, low sintering time, high relative density, and excellent mechanical properties [1,28,29,30]. Through the spark plasma sintering technique with the help of the joule effect, the electrical current passes through the particles and initiates heat energy straight to the sample. Moreover, applying pressure under high temperatures can cut down the inter space between the material’s particles, thereby improving plastic deformation [31]. On that account, the composite arranged by the spark plasma sintering method would exhibit suitable mechanical properties due to high bonding potential among the particles and little porosity [1,32].

However, the main novelty of this methodology is the possibility of consolidating (sintering) the new composites in a short period of time and at reduced temperatures below their respective melting points. The advantage of this route of production is that it boycotts the immiscibility problems encountered when casting the molten magma of niobium, copper, and graphite since these cannot have mixed together. While the production route we took in this work was able to provide us a well-sintered composited that was consolidated at a temperature far below the melting points of the constituent metallic elements. When compared with earlier reports: The main achievements of this route are the production of well-sintered samples with minimal or no defects and cost-effectiveness due to the short production time it uses.

In the spark plasma sintering technique, the following parameters are used; the sintering temperature, compressive load, heating rate, and dwelling time. In this study, all the sintered parameters were constant except that of sintering temperature, which was at two different temperatures of 650 and 700 °C. The 650 and 700 °C are the maximum sintering (consolidation) temperatures of the admixed powders under the influence of other sintering parameters. However, in this study, the micron-particle size and the milled niobium powders (nanoparticle sizes), nano-platelets of graphite, and micron-particle size of copper were used to prepare a solid solution of Cu-Nb(nano)10-C4, and Cu-Nb(micron)10-C4 composites, and was sintered in two different temperatures of 650 and 700 °C while the other sintering parameters were kept constant in the sintering of the admixed samples. However, we used 86 weight percent of copper powders, 10 weight percent of niobium (nano and microns) metallic powders, and 4 weight percent of graphite powders to prepare the following composites; (a) Cu86-Nb(nano)10-C4, and (b) Cu86-Nb(microns)10-C4. Each of these composites was sintered at two different sintering temperatures of 650 and 700 °C. However, other sintering parameters such as 60 MPa powders pressing load, 50°K/min heating rate, and 5 min of dwelling time were used with sintering temperatures of 650 and 700 °C, respectively, for each composite. The effects of nano and micron-particle size of niobium, as well as variation in sintering temperature, were determined on the microstructures, sintering mechanisms (pressing speed versus sintering temperature and time), microhardness, thermal diffusivity, tribology behavior, and corrosion resistance properties of the composites.

2. Materials and Methodology

2.1. Materials

The metallic powdered materials used in this study are highly pure commercial powders of copper (99% pure, 10% maximum +44 µm), niobium (99.9% pure, −44 µm), and graphite nanoparticle (99.8% pure, 14.43 nm particles sizes) which was supplied by Alfa Aesar, (Industrial Analytical (Pty) Ltd. Vorna Valley, 1686 Republic of South Africa).

2.2. Methodology

2.2.1. Samples Preparations

A portion of the commercially supplied high purity Nb powders was milled to reduce the particle sizes and later used as nanoparticle sized Nb powder to compare their micron particles sizes counterpart in this study. The highly purity Nb metallic powder with −44 µm was milled to nanoparticle sizes of 14.3 nm using a planetary ball mill (Retsch GmbH, Haan, Germany). For the milling process, 40 g of the as-received Nb powder were packed into two different inured steel receptacles of 125 ML capacity plus steel balls in a ball to powder weight ratio of around 10:1, 80% capacity of the inured steel receptacle was filled with ethanol absolute that assisted as the process guided agent. The receptacles were fastened and weighed to stabilize their weights to circumvent unbalanced in the milling equipment. The powder was wet-milled for 10 h with a speed of 400 rpm, an interval of 15 min, and an interval break of 5 s. After 10 h of milling time, the milled wet powder was recovered through drying in vacutec (RapidvapLabconco, Kansas city, MO, USA). The microns and the nano (milled) particle sizes niobium were used to prepare Cu-Nb(nano-sizes)10-C4 and Cu-Nb(microns-sizes)10-C4 and were separately mixed in an elastic canister employing a turbular mixer at a speed of 72 rpm for 4 h.

2.2.2. Spark Plasma Sintering

FCT Germany sparks plasma sintering machine (Systeme GmbH FCT Group, Frankenblick, Germany), of HHPD-25 model was applied to sinter each of these two admixed powdered composites in the temperatures of 650 and 700 °C under constant sintering parameters, which include: 60 MPa powders pressing load, 50°K/min heating rate, and 5 min of dwelling time. After sintering, all the sintered composites were ground and polished to a mirror surface for further tests. The microstructures of the starting materials and sintered composites were determined with the help of field emission scanning electron microscopy model JSM 7600f JEOL (JEOL, Tokyo, Japan), which was incorporated into the energy dispersive X-ray spectrometer.

2.2.3. Wear Study

The tribological behavior of the 6 sintered composites in a reciprocating dried sliding condition was conducted using an Anton-Paar TRB3 tribometer version 8.1.8 (Anton Paar, Midrand, South Africa) provided with a computer-controlled pin-on-disk arrangement that operated under room temperature. A 6 mm diameter surface of 100Cr6 balls was employed to slide against the tested composites in a countered motion, in a load of 20 N and at a frequency of 15 Hz. The coefficient of friction, µ, was constantly recorded during the sliding operation, and the results were obtained from the tribometer apparatus software (Tribo X, Magdeburg, Germany).

2.2.4. Thermal Diffusivity Study

A thermal diffusivity assessment was carried out with the laser flash system. The experiment was performed at a temperature range of between 100 and 900 °C by the use of the LFA427 NETzschlaser flash apparatus in an Argon environment. The usual geometry of the sintered composite examined was a composite with dimensions of 4 mm thickness and 10 mm diameter. In this method, each of the tested composites was coated with graphite spray to evade the radiation effect. The surfaces of the tested composites were positioned parallel to obtain the correct results. The pulsated laser was situated on the lower face of the composites. An infrared emission sensor examined the increase in temperature as a function of time at the upper face of the composite.

2.2.5. Corrosion Study

Corrosion study of the 4 sintered composites was carried out in a vessel that contained a mole of H2SO4 acid solution as an environment with each tested composite as the working electrode and graphite rod as a counter electrode, and reference electrode (saturated silver/silver chloride). It was further carried out with VersaSTAT 4 with versa studio version 4.9 software (AMETEK Scientific, Berwyn, IL, USA). The potentiodynamic polarization procedure was used to review the general electrochemical behavior of the 4 sintered composites. However, before the scanning, every one of the tested composites was immersed in the electrolyte for about 6 min to permit them to become stable before the open circuit potential measurement, which was performed for 2 h. Every one of the composites tested was scanned at a scan rate of 0.002 volts per second with potential variety from −1.5 to +1.5 volts.

3. Results and Discussions

3.1. Scanning Electron Microscopy of the Starting Materials

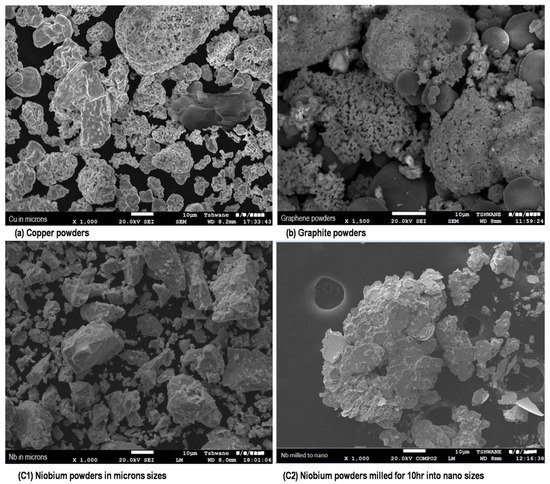

Figure 1a–(c2) revealed the scanning electron microscopy of the starting materials; (Figure 1a) copper powders, (Figure 1b) graphite powders, (Figure 1(c1)) niobium powders in micron-particle sizes, and (Figure 1(c2)) niobium powders in nanoparticle sizes. In Figure 1, it is clear that the shapes of the particles of copper powders appeared irregular (Figure 1a), while graphite powders showed a compacted mass of the particles that are surrounded with ball-shaped particles (Figure 1b,(c1)) illustrate niobium powders in micron-sizes whose particle shapes are seen to be flakes of irregular shapes, and Figure 1(c2) revealed collections of agglomerated niobium nano-powders with irregular shapes.

Figure 1.

Scanning electron microscopy of the starting materials: (a) copper powders, (b) graphite powders, (c1) niobium powders in micron-particle sizes, and (c2) agglomerated niobium powders in nanoparticle sizes.

3.2. Sintering Behaviors of the Composites

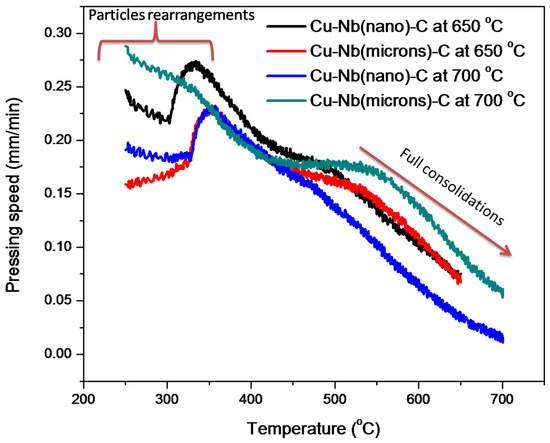

The sintering process takes place inside the spark plasma sintering machine, the ON-OFF direct current (DC) pulsing creates a joule heating point, and the formation of spark discharges is formed in the spaces between the particle surfaces. The sintering temperature is created by the spark discharges. The frequency of the heating process is responsible for the rapid and homogeneous temperature distribution through the sintering powders. The heat is generated during a pulse on the surface of the powder particle, and this is conducted to the volume of the sintered powder during the “pulse off time”. The results presented under this section are the densification mechanisms through which the composites were made. It, therefore, revealed how the admixed powders of the composites were sintered (converted from powders to solid materials) under the influence of heat applied load. Figure 2 shows a line graph that compares the pressing speed of the compressive rod on the powders during sintering over the sintering temperatures of 650 and 700 °C. Suitable mixing of the powders of the constituent elements enhances interfacial connections among the particles during sintering and will guarantee suitable densification. A suitable microstructure mechanical and electrical property can be promoted when a material is fully consolidated since the air spaces in-between the particles will be avoided. This mechanism was applied to demonstrate how quickly the sintering powders can consolidate during sintering. In Figure 2, generally, the composites that contain nanoparticles of niobium (Cu-Nb(nano)-C sintered at 650 °C, Cu-Nb(nano)-C sintered at 700 °C) showed similar behavior but differs toward the end as a result of their differences in sintering temperatures. This shows that after their powders mixed, the nanoparticles were able to stick (maintained their positions) within the particles of other constituent elements in the composite during sintering. However, for the other two samples that contained the same microns-particles of niobium, their behavior was not the same from the beginning of their sintering, but their behavior seemed to be similar after the temperature of about 450 °C to the end. This could be that the microns-particles underwent displacement and rearrangements of the particles under the influence of temperature and pressure.

Figure 2.

A line graph of the pressing speed of the punching rod versus the sintering temperatures of 650 and 700 °C.

In the graph, it can be seen that the pressing speed of the rod on the powders in each of the sintered composites increases between 250 and about 354 °C, except that of Cu-Nb(microns)-C sintered at 700 °C, which was started with the highest speed at lower temperature and decreases as the temperature progressed to 700 °C. The way in which the particles of the constituent element were dispersed in the matrixes of copper and the particle sizes of the powders determines how the heat flow among the particles, which also regulates the speed of the uni-axial force of the pressing rod on the sintering, powders. At the beginning of the sintering temperature (250 °C), the sintered composites attained approximately the following speed: 0.29 mm/min speed was attained by Cu-Nb(microns)-C sintered at 700 °C, the high consolidation speed recorded by the composite could be attributed to the manner in which the constituent powders of the composite were dispersed after the powders mixing, which allowed free pressing of the compressive rod during sintering. While 0.25 mm/min pace was achieved by Cu-Nb(nano)-C sintered at 650 °C, 0.20 mm/min rate was reached by Cu-Nb(nano)-C sintered at 700 °C, and 0.16 mm/min velocity was accomplished by Cu-Nb(microns)-C sintered at 650 °C. At a temperature of about 300 °C, the pressing speed of both Cu-Nb(microns)-C sintered at 650 °C and Cu-Nb(nano)-C sintered at 650 °C experienced the most dramatic increase, but their curves do not share a similar changing tendency. However, at a sintering temperature of about 300 °C, the pressing speed of Cu-Nb(microns)-C sintered at 650 °C increases from 0.18 mm/min to a maximum of 0.23 mm/min at a temperature of about 330 °C, and at a sintering temperature of about 300 °C, the pressing speed of Cu-Nb(nano)-C sintered at 650 °C increases from 0.22 mm/min to the maximum speed of 0.28 mm/min at a temperature of about and 335 °C before a sudden decrease as the temperatures increases. The pressing speed of Cu-Nb(nano)-C at 650 °C was observed to be higher than that of Cu-Nb(microns)-C at 650 °C during the most dramatic increase that occurred at a temperature of about 300 °C. This is because the nanoparticles have large areas of contact than the micron-particle sizes, and this allows a high rate of heat flows into the composite (Cu-Nb(nano)-C), thereby making it softer for easy movement of the compressive rod on the sintering powder when compared with the composite of Cu-Nb(microns)-C. The temperature of the most dramatic increase increases from 300 to 328 °C, and the maximum speed increases for Cu-Nb(nano)-C at 650 °C and Cu-Nb(nano)-C at 700 °C. This can be the temperature range at which the rearrangement and softening of the particles of the powders occurred. While Cu-Nb(nano)-C sintered at 700 °C also experienced a sudden increase in pressing speed, which occurred from 0.19 mm/min to a maximum of about 0.24 mm/min at temperatures between 328 and 353 °C, before it had a sharp fall as temperature increases. Cu-Nb(microns)-C sintered at 700 °C experienced a drop in pressing speed from 0.29 mm/min to 0.18 mm/min at a temperature between 250 and about 434 °C and gradually increased again from 0.18 mm/min at a temperature of 533 °C before it dropped to around 0.05 mm/min at final sintering temperature of 700 °C. However, it is also clear in Figure 2 that the composites with nanoparticles of niobium sintered in both temperatures of 650 and 700 °C recorded the highest peaks, which occurred around 0.28 mm/min at a temperature of 335 °C for Cu-Nb(nano)-C sintered at 650°C and 0.24 mm/min at a temperature of 353 °C for Cu-Nb(nano)-C sintered at 700 °C. The pressing speed curve of Cu-Nb(microns)-C at 700 °C was observed to be different from other samples because the way the particles of the constituent elemental materials were spread in the matrix of copper and how heat flowed among the particles could be attributed to the scenario that occurred in the composite. The observed features in the highest peaks attained among the sintered composites could be that the nanoparticle sizes allowed much heat to penetrate through into the matrixes of the sample, thereby enhancing mass deformations of the powdered particles during sintering in both sintering temperatures of 650 and 700 °C.

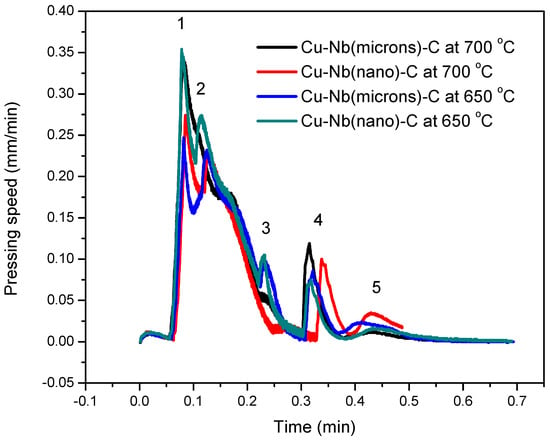

Figure 3 shows how quickly each of the composites would be consolidated (produced) during the spark plasma sintering of the product. It is also a way of considering the production cost of the composite material. If the pressing speed of the consolidating rod takes a longer time to complete the powder densification, it will consume much energy (electric power), which will incur more cost during the course of the production. The result presented in Figure 3 covers the time through which the consolidation of the powders occurred, which did not include the dwelling/cooling time of the process. Figure 3 exhibits the pressing speed of the sintering punch on the powders alongside the sintering time. In the graph, it can be observed that all the sintered composites experienced incredible sharp rises within the time of 0.04 min and 0.06 min from the initial speed to the maximum speed of: 0.35 mm/min for Cu-Nb(nano)-C sintered at 650 °C, 0.33 mm/min for Cu-Nb(microns) sintered at 700 °C, 0.27 mm/min for Cu-Nb(nano)-C sintered at 700 °C, and 0.25 mm/min for Cu-Nb(microns)-C sintered at 650 °C. In Figure 3, it can be seen that each of the sintered samples formed a total of five sharper peaks, which decrease as the pressing speed and time decreases. The final sintering time of Cu-Nb(nano)-C sintered at 700 °C ended at the period of 0.49 min, while others extended to approximately 0.69 min at a speed of 0.002 mm/min. The final sintering time of Cu-Nb(nano)-C at 700 °C was shorter due to the large area of contact that permitted a large flow of heat that facilitated the consolidation of the composite. The peaks formations in the figure might be the points where there is rearrangement of particles of the sintering powders before their consolidations.

Figure 3.

A line graph of the pressing speed of the punching rod versus the sintering time (s).

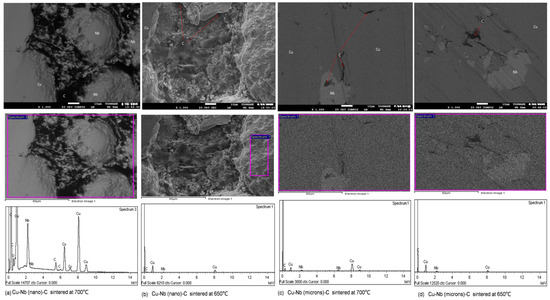

3.3. Scanning Electron Microscopy and Energy Dispersive X-ray Spectrometer of the Sintered Composites

The engineering materials’ properties are determined by their microstructures, which involve the defects, phase, residual stresses, and how these formations are outstretched in the substance. Figure 4a–d shows the scanning electron microscopy and energy dispersive spectrometer of the sintered composites. The energy dispersive spectrometer revealed the elemental compositions (Cu, Nb, and C) that are contained in the selected portions of the scanning electron microscopy images. The results of the spectrometer revealed that the purities of the starting materials were maintained after sintering at 650 and 700 °C by reflecting the phases of each constituent element in the composites. Figure 4a,b show both the scanning electron microscopy and energy dispersive spectrometer of the composites that contained nanoparticle sizes of niobium that was sintered at 700 °C (Figure 4a) and 650 °C (Figure 4b). The area covered by spectrum 3 in Figure 4a showed that all the constituent elements were present in the sample, and all of them were seen to have precipitated in the matrix of copper. It showed high peaks of Cu, C, and Nb with the presence of a small amount of oxygen, O. While in Figure 4b, spectrum 1 showed the presence of all the constituent materials with a high peak of graphite. Figure 4c,d show both the scanning electron microscopy and energy dispersive spectrometer of the composites that contained micron-particle sizes of niobium that was sintered at 700 °C (Figure 4c) and 650 °C (Figure 4d). Spectrum 5 in Figure 4c and spectrum 1 in Figure 4d revealed the presence of all the constituent materials, but they appeared in low peaks. However, it is clear to note that there was no foreign material (s) found in each composite after sintering the admixed powders at 650 and 700 °C. The scanning electron microscopy of the composites that contained nanoparticles of niobium that was sintered in the temperature of 650 and 700 °C (Figure 4a,b) showed huge agglomerations of niobium particles (whitish pigment in the samples), it also showed that there was more precipitation of all the constituent elements compared with the composites that contained micron-particle sizes of niobium (Figure 4c,d). The sintering temperature could not alter the agglomeration of nanoparticles of niobium due to the inadequate dispersion of the nano-powders during mixing, which might be due to the high amount that was loaded (10 wt.%). Most of the challenges encountered in the homogeneous dispersion of nanoparticles are attributed to their well-built contacts between themselves. These effects could cause wide differences in the experimental outcome of some researchers that are working on the nano-composites. These agglomerations of nanoparticles of niobium in Figure 4a,b could be what influenced the similarity that was observed in their graph pathway in Figure 2. In Figure 2, their graph was seen to have started from high speed and slowed down a bit as the temperature increased from 250 °C to about 300 °C before they experienced a sudden rise of pressing speed to their maximum values. That could be the point of particle rearrangement due to the influence of the agglomerations of the nanoparticles. Such a scenario did not occur in the composites that contained micron particles sintered at both 650 and 700 °C. However, the micron-particle size of niobium in the matrix (Figure 4c,d) could not allow the agglomeration to occur, thereby offering sintered composites with microstructures that are more apparently homogeneous than their nanoparticles counterpart (Figure 4a,b). Furthermore, the clustered of the nanoparticles that was observed in Figure 4a,b could be in addition that the mixing time of 4 h was not enough to provide proper dispersions of the particles. The smaller the nanoparticle sizes (dimension less than or/equal to 100 nm), the unchallenging agglomerates are set up, consequently making it very strenuous to disperse in the matrix of the composites (Figure 4a,b). Though graphite nanoplates are assuredly agglomerated during the time of their fabrication process, this is prompted by the van der Waals impacts [33]. However, this might be another factor that could be responsible for the agglomerations of the particles observed in Figure 4a,b, in the composite of Cu-Nb(nano)-C, there are already two different elements with nanoparticles (graphite and niobium) that are mixed with micron particles of copper that were sintered in two different temperatures of 650 and 700 °C.

Figure 4.

Scanning electron microscopy and energy dispersive spectrometer of; (a) Cu-Nb(nano)-C sintered at 700 °C, and (b) Cu-Nb(nano)-C sintered at 650 °C, (c) Cu-Nb(microns)-C sintered at 700 °C, and (d) Cu-Nb(microns)-C sintered at 650 °C.

Elemental particles color identifications in the SEM images are:

- Cu—lighter black;

- Nb—white;

- C—tick black.

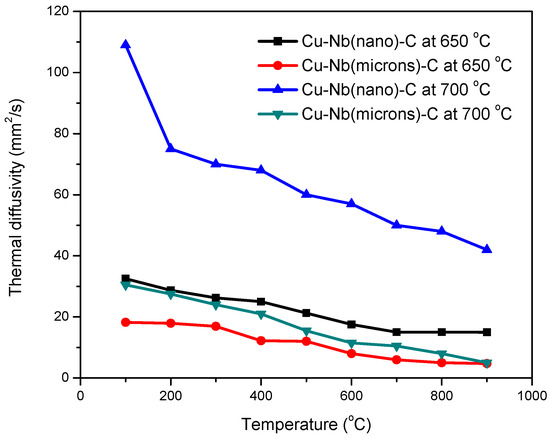

3.4. Thermal Diffusivity Property of the Sintered Composites

Figure 5 is a line graph that depicts the comparison between the thermal diffusivity behaviors of the sintered composites in the temperature range of 100 to 900 °C. It is understandable from the figure that the thermal diffusivity of all the composites decreases as the temperature rise between 100 and 900 °C. The Cu-Nb(nano)-C sintered at 700 °C composites were seen to have the most dramatic changes in their earlier operational temperature and recorded an outstanding property compared with the other composites. The phenomenon could be influenced by the large precipitations of niobium and graphite in the matrix of copper, as can be seen in Figure 4a (the microstructure). The precipitations are the evidence to show that there occurred dissolution of the additives (niobium and graphite) in the matrix of copper, as can be seen in the energy dispersive X-ray spectrometer (EDX) graphs. It was followed by the composites of Cu-Nb(nano)-C sintered at 650 °C, Cu-Nb(micron)-C sintered at 700 °C, and lastly, Cu-Nb(micron)-C sintered at 650 °C. The nanoparticle sizes of niobium promoted a large area of contact (Figure 4a,b) that enhanced thermal conductivity in the composites that contained nanoparticles. At 100 °C, Cu-Nb(nano)-C sintered at 700 °C composites attained around 110 mm2/s highest thermal diffusivity, which suddenly dropped to 75 mm2/s before gradually decreasing as the temperature increases. While at the same initial temperature of 100 °C, about 35 mm2/s diffusivity was attained by Cu-Nb(nano)-C sintered at 650 °C, 32 mm2/s diffusivity was reached by Cu-Nb(micron)-C sintered at 700 °C, and 19 mm2/s diffusivity was achieved by Cu-Nb(micron)-C sintered at 650 °C. Looking at Figure 5, it can be seen that the composite of Cu-Nb(nano)-C sintered at 650 °C and Cu-Nb(micron)-C sintered at 700 °C have a closed thermal diffusivity behavior from their initial operational temperature before diverging at the temperature around 300 °C. However, the higher thermal diffusivity behaviors that were demonstrated by the composites that contained nanoparticles of niobium could be attributed to the influence of the nanoparticles. The wide-reaching surface area to volume ratio attributes of nanoparticles will permit huge transportations of thermal charge carriers to the particles of the other elements within the composites. The presence of nanoparticles will help to modify any void that would have caused electrons diffusion barriers when the thermal charge carriers pass through within the composites, therefore, enhancing the thermal diffusivity of the composites.

Figure 5.

The thermal diffusivity against the temperature of the composites.

Though a high thermal diffusivity rate entails that heat is being transported quickly out of the sample, like in the composites of Cu-Nb(nano)-C sintered at 700 °C, and Cu-Nb(nano)-C sintered at 650 °C. This is because the nanoparticles have large areas of contacts, which allow a high rate of energy flow among the particles of the composite (Cu-Nb(nano)-C), thereby making it easy for the thermal energy to diffuse more in the nano-composite than the composite with microns. The way in which particles of the constituent elements are dispersed in the matrix of copper and the particle sizes will determine the rate at which heat energy can flow in the composite. This might be the mechanism behind the high rate of thermal diffusivity that was observed in the composite of Cu-Nb(nano)-C at 700 °C. Whereas a low thermal diffusivity implies that heat is dispatched slowly (i.e., achievement of thermal equilibrium is being belated) in the composite, as in the case of Cu-Nb(micron)-C sintered at and 700 °C. Therefore, the presence of nanoparticles has caused ample heat dispatched in the composites (Cu-Nb(nano)-C, sintered at 650 and 700 °C), while the presence of micronparticles influences the conservation of heat in the composites (Cu-Nb(micron)-C sintered at 650 and 700 °C). The thermal diffusivity in a composite is connected to the rate at which it arrives at its thermal stability under fluctuating thermal circumstances. Thus, the niobium particles would serve as the thermal control between copper and graphite matrixes, and it manages the massive heat differences that might have existed in the composite. In addition, this will promise a distinguished performance as well as prolong the life span of the material when used in extreme thermal operations. Therefore, the high thermal diffusivity recoded in the composites of Cu-Nb(nano)-C sintered at 700 and 650 °C were revealed in their microstructures (Figure 4a,b), where much graphite and niobium particles were precipitated in the copper matrix. The nanoparticles present in the composites provide a large area of contact among the particles, which promotes thermal diffusivity in the composites.

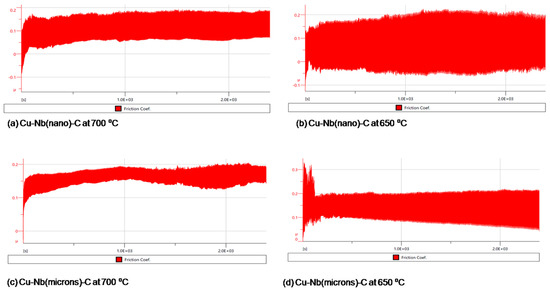

3.5. Tribological Behaviors of the Composites

Figure 6 revealed the coefficient of frictions against sliding time during the comparison of tribological behaviors of the composites under an applied load of 20 N. The maximum coefficient of friction against the sliding time of all the tested composites was determined. Cu-Nb(nano)-C sintered at 700 °C recorded the lowest coefficient of fraction, followed by Cu-Nb(micron)-C sintered at 700 °C, Cu-Nb(nano)-C sintered at 650 °C, and Cu-Nb(micron)-C sintered at 650 °C. Figure 6a shows the coefficient of friction against time for Cu-Nb(nano)-C sintered at 700 °C, which attained a maximum coefficient of friction of around 0.2, and it is the lowest record value among the composites. While Figure 6b shows the graph of the coefficient of friction versus time for Cu-Nb(nano)-C sintered at 650 °C, it attained a maximum coefficient of frictions of about 0.23, which is the third position in the ranking of lowest maximum coefficient of frictions among the composites. Figure 6c shows the coefficient of friction against time for Cu-Nb(micron)-C sintered at 700 °C, which gained a maximum coefficient of friction of 0.21, which is the second of the lowest maximum coefficient of friction among the composites. Figure 6d shows the coefficient of friction versus time for Cu-Nb(micron)-C sintered at 650 °C. It recorded a maximum coefficient of friction around 0.3, which is the highest recorded value among the composites. However, the composites (with either nanoparticle or micron-particle sizes of niobium) that were sintered at 700 °C recorded the lowest coefficient of friction. These implied that sintering at a high temperature of 700 °C favored lower coefficient of friction properties in the composites. These could be a result of the precipitation of niobium and graphite in the matrix of copper elements and can be observed in the microstructure of the composites (Figure 4a,c).

Figure 6.

Coefficient of frictions against sliding time for: (a) Cu-Nb(nano)-C sintered at 700 °C, (b) Cu-Nb(nano)-C sintered at 650 °C, (c) Cu-Nb(micron)-C sintered at 700 °C, and (d) Cu-Nb(micron)-C sintered at 650 °C.

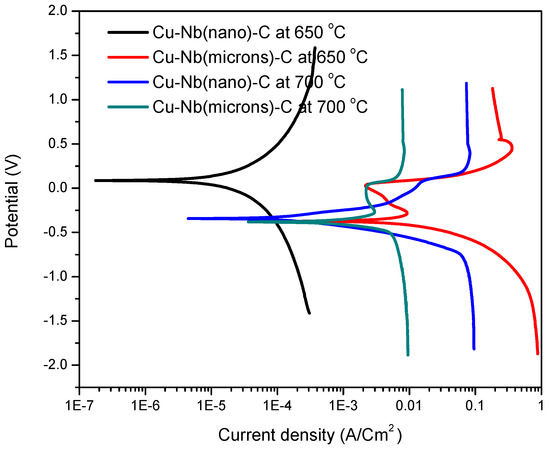

3.6. Corrosion Test (Polarization Test) of the Composites

Figure 7 shows the potential against the current density of the composites under the scan rate of 0.002 V/s with potential variety from −1.5 to +1.5 V in a sulphuric acid environment. In the figure, it is clear that Cu-Nb(nano)-C sintered at 650 °C had outstanding passivity characteristics when compared with the rest of the composites. The observed effect was attributed to the microstructure of the composite (Figure 4b), which showed high precipitations of niobium particles, which the passivity nature could be evidence of formations of a nano oxide layer of niobium in the composite. In addition, it is clear to note that those composites that displayed higher corrosive resistance are the ones with nanoparticles of niobium, both sintered at 650 and 700 °C. Though, every constituent element in this study has suitable corrosive resistance properties. The nanoparticle involvements could enhance the precipitation of niobium in the matrix of the composites, which might have released niobium-rich oxide layers that is responsible for the high passivity traits that were noticed in the composites (Cu-Nb(nano)-C sintered at 650 and 700 °C).

Figure 7.

Potentiodynamic polarization curves of the tested composites in 1 mole of H2SO4 acid solution.

4. Conclusions

This study demonstrated two major facts: (a) the effect of particle size variations (nanoparticles and micron-particle sizes), and (b) the effect of sintering temperature variation (650 and 700 °C), while other SPS parameters were kept constant. The significance of our work is that we have been able to produce novelty composites materials of great potential using the spark plasma sintering technique. In addition, we have shown that variation in particle sizes and sintering temperatures have an effect on the production of these new products. The unfamiliarity in this work is the production of new ternate copper-niobium-graphite conglomeration through the use of micron-particle size and nanoparticle size of niobium and nanoparticle size of graphite with copper as based material. The practical application could be on the nano-engineered materials in high-efficiency electrical connection materials at the high-temperature application in the field of electronics, aircraft engines, automotive, etc. The outcome of the study can be summarized as follows:

- (1)

- The microstructures of the composites with nanoparticles of niobium showed agglomeration of niobium and graphite and were largely precipitated in the matrix of copper at sintering temperatures of 650 and 700 °C (Figure 4a,b);

- (2)

- The composites with nanoparticles of niobium recorded the highest thermal diffusivity irrespective of their sintered temperatures. This was as a result of a large area of contacts of nanoparticles which granted high thermal diffusivity in the composites;

- (3)

- The composites sintered at 700 °C recorded the lowest coefficient of friction values over the composites sintered at 650 °C. Composites with nanoparticles of niobium sintered at 700 °C recorded the lowest coefficient of friction. The reason could be the result of the high precipitation of niobium particles, which helped the composite to withstand the abrasion effect when it was subjected to wear. The large precipitation of niobium in the matrix of the composite can be seen in the microstructure of the composite (Figure 4a,c);

- (4)

- The composite Cu-Nb(nano)-C sintered at 650 °C had an outstanding passivity characteristic than the other composites. This could be attributed to the microstructure of the composite, which revealed large precipitations of niobium (Figure 4b). In addition, the passivity nature could be evidence of the existence of nano oxide layers of niobium in the composite.

Author Contributions

A.A.E.: Conceptualization, Methodology, Writing an original draft. E.R.S.: Supervisor, validation, editorial. W.K.K.: Visualization, Investigation. J.S.: Visualization, Investigation. J.M.N.: Supervision. I.D.I.: Visualization. All authors have read and agreed to the published version of the manuscript.

Funding

Department of Science and Technology (DST), South Africa.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors acknowledge Tshwane University of Technology and the department of science and technology (DST) South Africa for financial support.

Conflicts of Interest

The authors proclaimed that they have no known contending financial interests or personal relationships that could have appeared to affect the work delineated in this paper.

References

- Liu, J.; Sun, K.; Zeng, L.; Wang, J.; Xiao, X.; Liu, J.; Guo, C.; Ding, Y. Microstructure and Properties of Copper–Graphite Composites Fabricated by Spark Plasma Sintering Based on Two-Step Mixing. Metals 2020, 10, 1506. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, L.; Wei, D.; Wu, P.; Cao, J.; Shijia, C.; Qu, X.; Fu, K. Effect of graphite type on the contact plateaus and friction properties of copper-based friction material for high-speed railway train. Wear 2019, 432, 202927. [Google Scholar] [CrossRef]

- Anil Kumar, R.; Krishna Kumar, R.; Radhika, N. Mechanical and wear properties of functionally graded Cu-11Ni-4Si/graphite composite. Silicon 2019, 11, 2613–2624. [Google Scholar] [CrossRef]

- Nageswaran, G.; Natarajan, S.; Ramkumar, K. Synthesis, structural characterization, mechanical and wear behaviour of Cu-TiO2-Gr hybrid composite through stir casting technique. J. Alloys Compd. 2018, 768, 733–741. [Google Scholar] [CrossRef]

- Singh, M.K.; Gautam, R.K. Mechanical and electrical behaviour of developed copper based hybrid composites. Mater. Today Proc. 2018, 5, 5692–5700. [Google Scholar] [CrossRef]

- Abad, M.; Parker, S.; Kiener, D.; Primorac, M.-M.; Hosemann, P. Microstructure and mechanical properties of CuxNb1−x alloys prepared by ball milling and high pressure torsion compacting. J. Alloys Compd. 2015, 630, 117–125. [Google Scholar] [CrossRef]

- Banerjee, R.; Bose, S.; Genc, A.; Ayyub, P. The microstructure and electrical transport properties of immiscible copper-niobium alloy thin films. J. Appl. Phys. 2008, 103, 033511. [Google Scholar] [CrossRef]

- Botcharova, E.; Heilmaier, M.; Freudenberger, J.; Drew, G.; Kudashow, D.; Martin, U.; Schultz, L. Supersaturated solid solution of niobium in copper by mechanical alloying. J. Alloys Compd. 2003, 351, 119–125. [Google Scholar] [CrossRef]

- Deng, L.; Han, K.; Hartwig, K.T.; Siegrist, T.M.; Dong, L.; Sun, Z.; Yang, X.; Liu, Q. Hardness, electrical resistivity, and modeling of in situ Cu–Nbmicrocomposites. J. Alloys Compd. 2014, 602, 331–338. [Google Scholar] [CrossRef]

- Deng, L.; Han, K.; Wang, B.; Yang, X.; Liu, Q. Thermal stability of Cu–Nbmicrocomposite wires. Acta Mater. 2015, 101, 181–188. [Google Scholar] [CrossRef]

- Deng, L.; Yang, X.; Han, K.; Lu, Y.; Liang, M.; Liu, Q. Microstructure and texture evolution of Cu–Nb composite wires. Mater. Charact. 2013, 81, 124–133. [Google Scholar] [CrossRef]

- Eze, A.; Jamiru, T.; Sadiku, E.R.; Diouf, S.; Durowoju, M.O.; Ibrahim, I.; Kupolati, W.K. Electrical conductivity of Cu and Cu-2vol.% Nb powders and the effect of varying sintering temperatures on their mechanical properties using spark plasma sintering. Silicon 2017, 9, 855–865. [Google Scholar] [CrossRef]

- Eze, A.A. Production of Binary Copper-Titanium and Copper-Niobium Alloys for Trolley Wire Applications Using Spark Plasma Sintering Techniques Spark Plasma Sintering Techniques; Tshwane University of Technology: Pretoria, South Africa, 2016. [Google Scholar]

- Eze, A.A. Development of a New Copper-niobium Based Composite Trolley Cable for Electric Trains. Ph.D. Thesis, Tshwane University of Technology, Pretoria, South Africa, 2019. [Google Scholar]

- Eze, A.A.; Jamiru, T.; Sadiku, E.R.; Durowoju, M.O.; Kupolati, W.K.; Ibrahim, I.D. Considering the use of niobium and titanium to enhance electrical and mechanical properties of copper at higher operational temperature application. SN Appl. Sci. 2019, 1, 74. [Google Scholar] [CrossRef] [Green Version]

- Głuchowski, W.; Rdzawski, Z.; Stobrawa, J.; Marszowski, K. Microstructure and properties of Cu-Nb wire composites. Arch. Metall. Mater. 2014, 59, 35–40. [Google Scholar] [CrossRef] [Green Version]

- Gu, T.; Medy, J.-R.; Volpi, F.; Castelnau, O.; Forest, S.; Hervé-Luanco, E.; Lecouturier, F.; Proudhon, H.; Renault, P.-O.; Thilly, L. Multiscale modeling of the anisotropic electrical conductivity of architectured and nanostructured Cu-Nb composite wires and experimental comparison. Acta Mater. 2017, 141, 131–141. [Google Scholar] [CrossRef] [Green Version]

- Lei, R.; Wang, M.; Li, Z.; Wei, H.; Yang, W.; Jia, Y.; Gong, S. Structure evolution and solid solubility extension of copper–niobium powders during mechanical alloying. Mater. Sci. Eng. A 2011, 528, 4475–4481. [Google Scholar] [CrossRef]

- Lei, R.-S.; Wang, M.-P.; Guo, M.-X.; Li, Z.; Dong, Q.-Y. Microstructure evolution and thermal stability of nanocrystalline Cu-Nb alloys during heat treatment. Trans. Nonferrous Met. Soc. China 2009, 19, 272–276. [Google Scholar] [CrossRef]

- Li, D.; Robinson, M.; Rathz, T.; Williams, G. Liquidus temperatures and solidification behavior in the copper–niobium system. Acta Mater. 1998, 46, 3849–3855. [Google Scholar] [CrossRef]

- Liang, M.; Lu, Y.; Sun, L.; Xu, X.; Wang, P.; Liu, G.; Li, C. Investigation on recrystallization of Cu-Nb micro-composites by the method of resistance. Phys. Procedia 2013, 45, 105–108. [Google Scholar] [CrossRef] [Green Version]

- Mitchell, T.E.; Lu, Y.C.; Griffin, A.J., Jr.; Nastasi, M.; Kung, H. Structure and mechanical properties of copper/niobium multilayers. J. Am. Ceram. Soc. 1997, 80, 1673–1676. [Google Scholar] [CrossRef]

- Munitz, A.; Bamberger, M.; Venkert, A.; Landau, P.; Abbaschian, R. Phase selection in supercooled Cu–Nb alloys. J. Mater. Sci. 2009, 44, 64. [Google Scholar] [CrossRef]

- Schelle, R.F. Phase Relationships in the Copper-Niobium Alloy System; Ames Lab.: Ames, IA, USA, 1971. [Google Scholar]

- Sharma, I.; Chakraborty, S.; Majumdar, S.; Bidaye, A.; Suri, A. A study on preparation of copper–niobium composite by aluminothermic reduction of mixed oxides. J. Alloys Compd. 2002, 336, 247–252. [Google Scholar] [CrossRef]

- Shikov, A.; Pantsyrnyi, V.I.; Vorob’Eva, A.E.; Sud’Ev, S.V.; Khlebova, N.E.; Silaev, A.K.; Belyakov, N.A. Copper-niobium high-strength and high-conductivity winding wires for pulsed magnets. Met. Sci. Heat Treat. 2002, 44, 491–495. [Google Scholar] [CrossRef]

- Mizuuchi, K.; Inoue, K.; Agari, Y. Trend of the development of metal-based heat dissipative materials. Microelectron. Reliab. 2017, 79, 5–19. [Google Scholar] [CrossRef]

- Ghayebloo, M.; Alizadeh, P.; Melo, R. Fabrication of ZrO2-Bearing lithium-silicate glass-ceramics by pressureless sintering and spark plasma sintering. J. Mech. Behav. Biomed. Mater. 2020, 105, 103709. [Google Scholar] [CrossRef] [PubMed]

- Ogunbiyi, O.; Jamiru, T.; Sadiku, R.; Adesina, O.; Beneke, L.; Adegbola, T.A. Spark plasma sintering of nickel and nickel based alloys: A Review. Procedia Manuf. 2019, 35, 1324–1329. [Google Scholar] [CrossRef]

- Shkodich, N.; Spasova, M.; Farle, M.; Kovalev, D.; Nepapushev, A.; Kuskov, K.; Vergunova, Y.; Scheck, Y.; Rogachev, A. Structural evolution and magnetic properties of high-entropy CuCrFeTiNi alloys prepared by high-energy ball milling and spark plasma sintering. J. Alloys Compd. 2020, 816, 152611. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, Y.; Jiang, Y.; Zhou, R. Mechanical behaviors of porous Ti with high porosity and large pore size prepared by one-step spark plasma sintering technique. Vacuum 2015, 122, 187–194. [Google Scholar] [CrossRef]

- Dash, K.; Ray, B.C.; Chaira, D. Synthesis and characterization of copper–alumina metal matrix composite by conventional and spark plasma sintering. J. Alloys Compd. 2012, 516, 78–84. [Google Scholar] [CrossRef]

- Chen, F.; Ying, J.M.; Wang, Y.F.; Du, S.Y.; Liu, Z.P.; Huang, Q. Effects of graphene content on the microstructure and properties of copper matrix composites. Carbon 2016, 96, 836–842. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).