The Effect of Ce on the Microstructure, Superplasticity, and Mechanical Properties of Al-Mg-Si-Cu Alloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

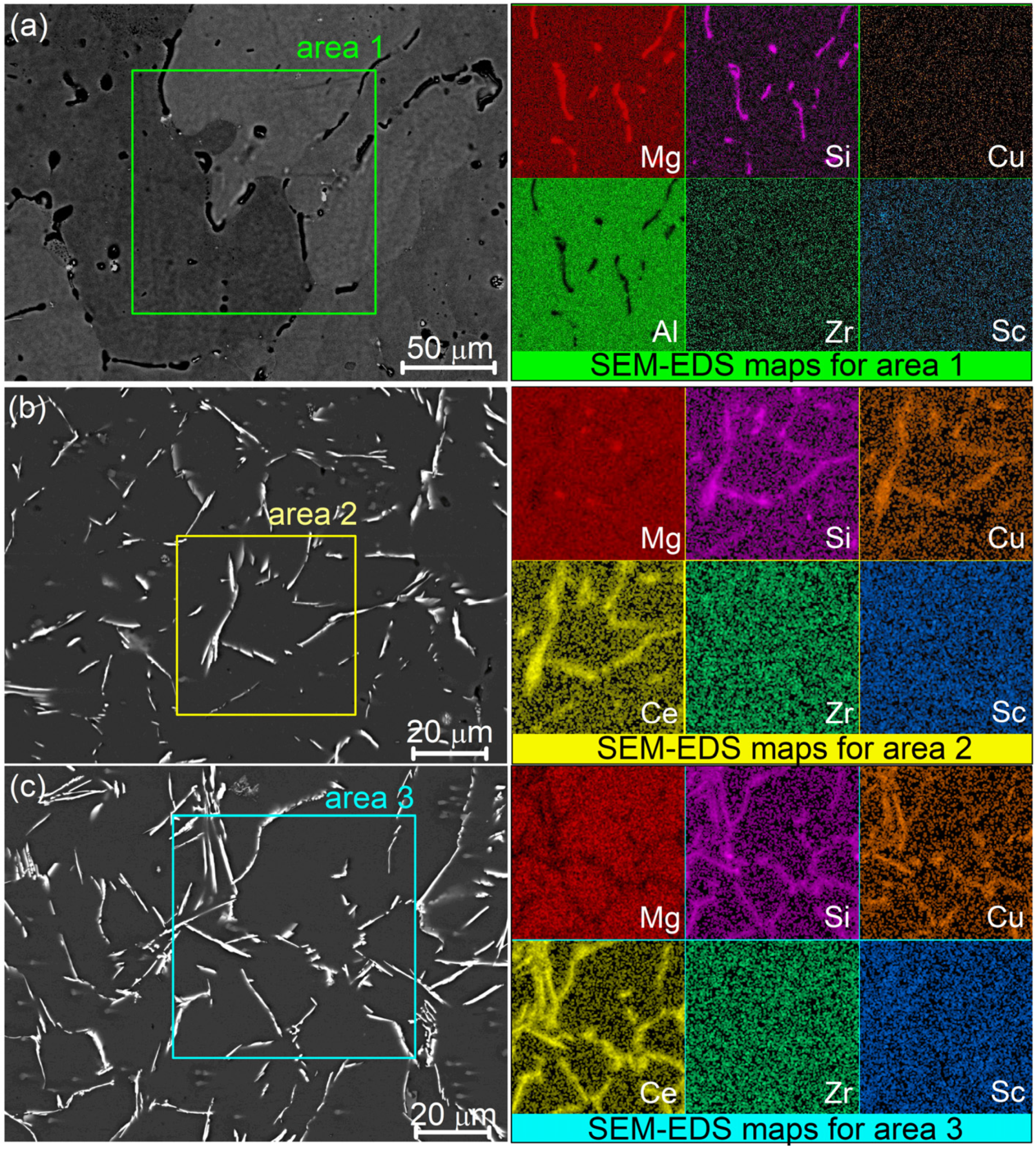

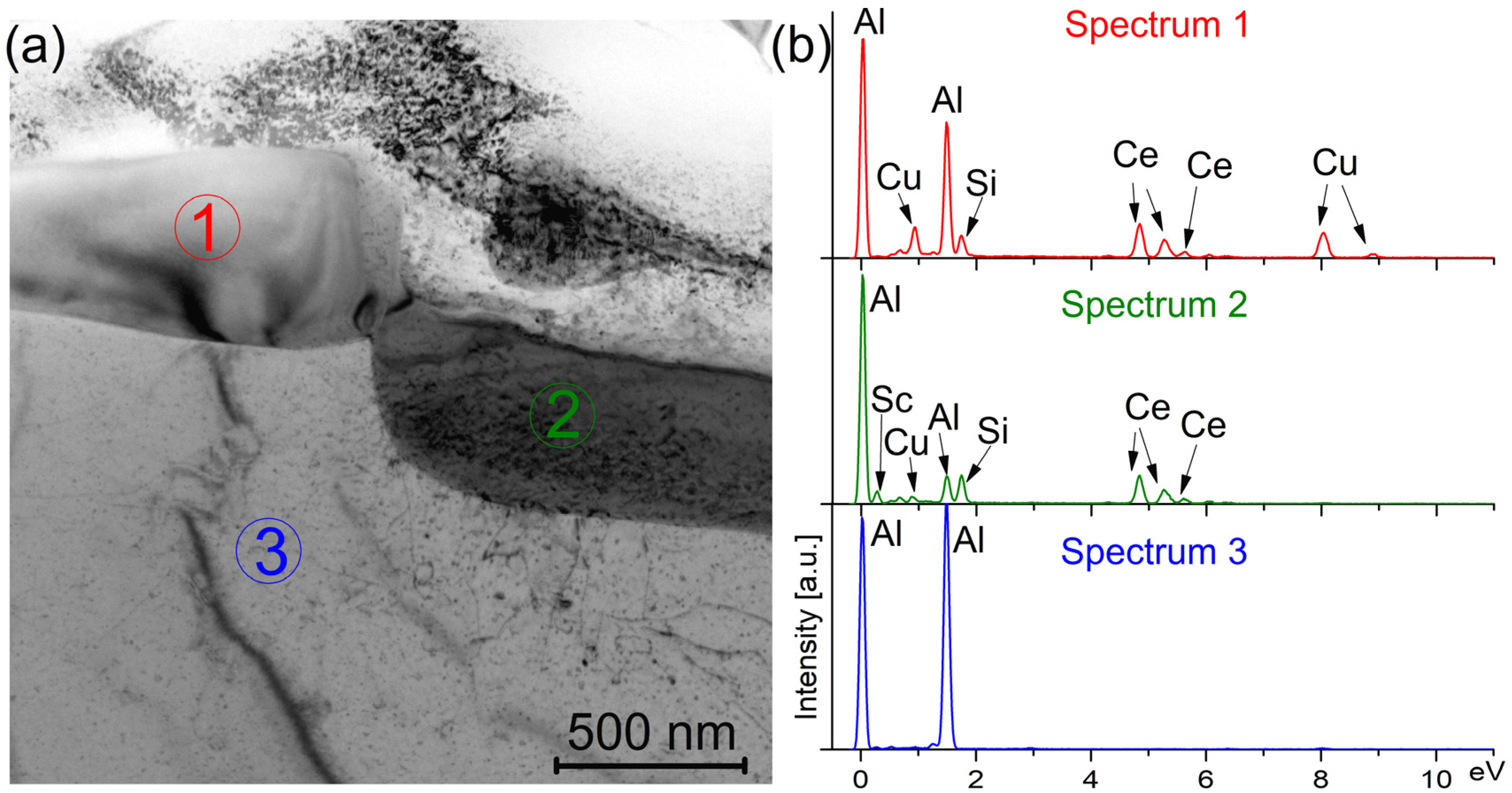

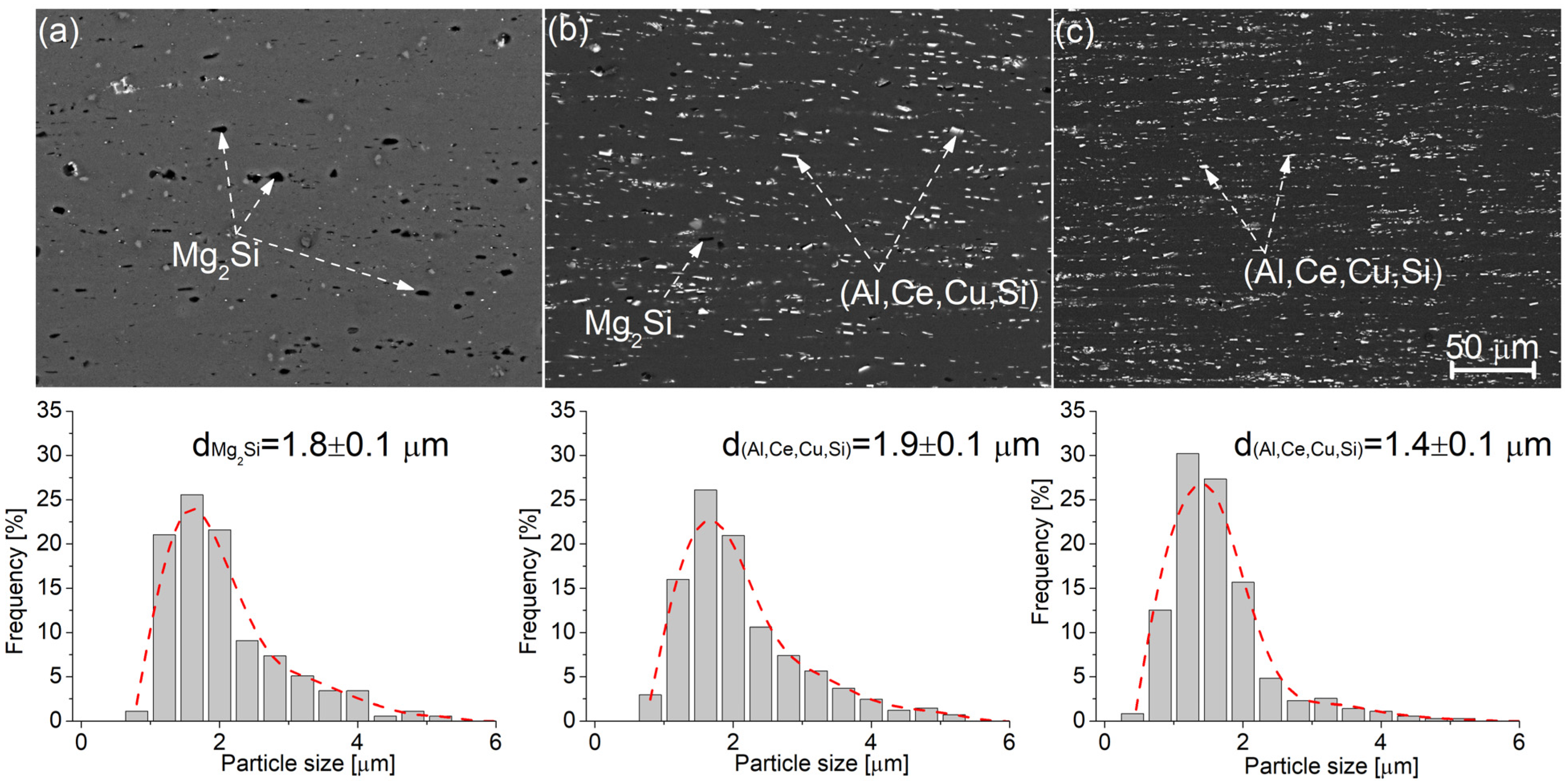

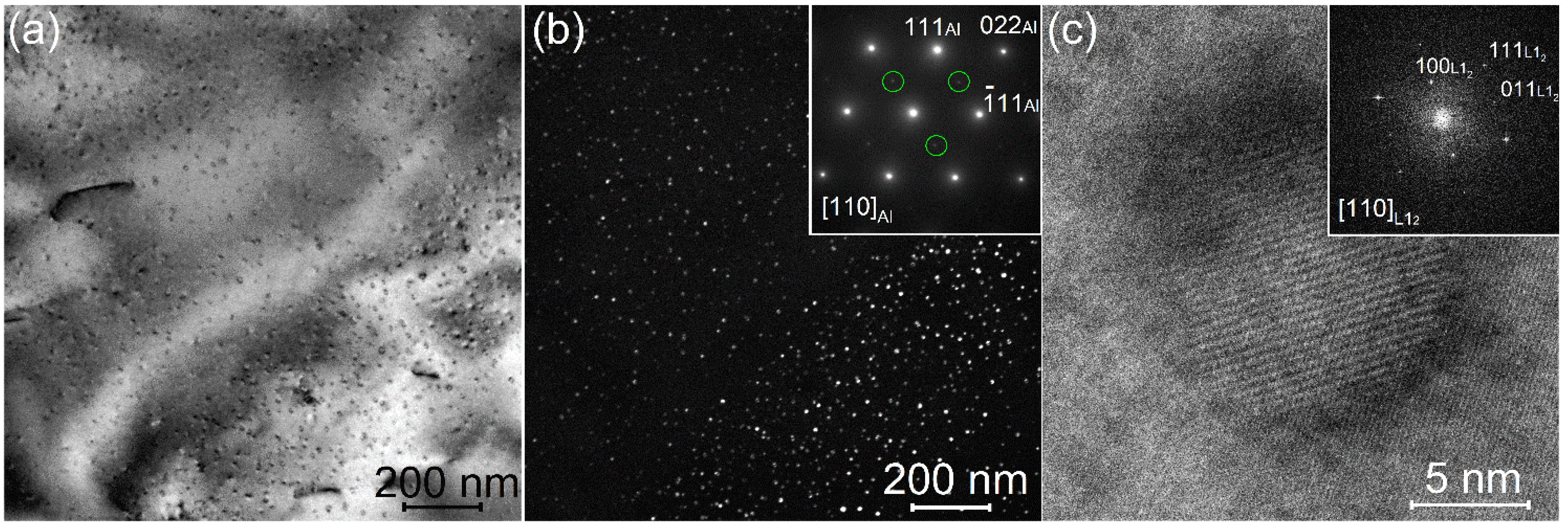

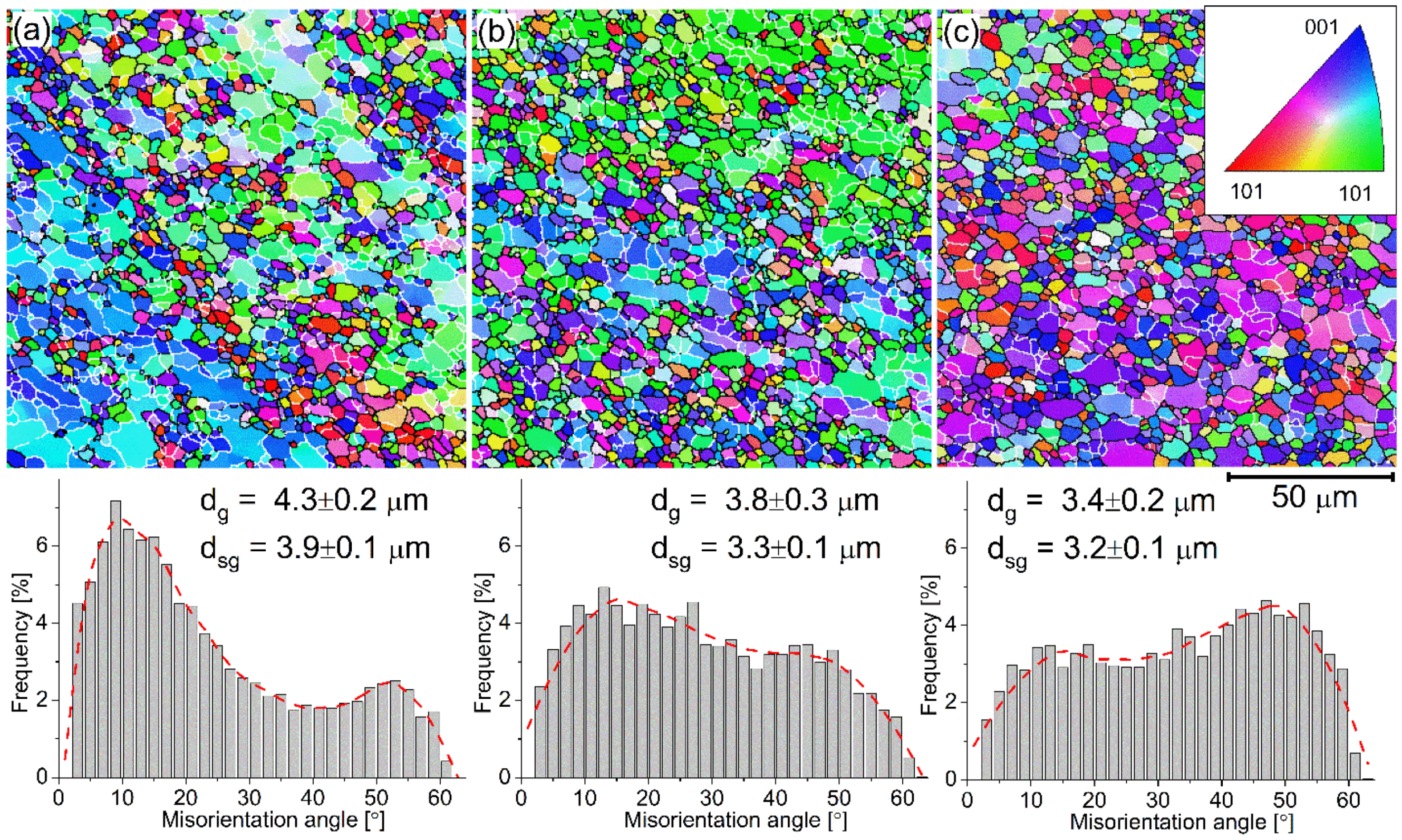

3.1. Microstructural and Phase Composition Analyses

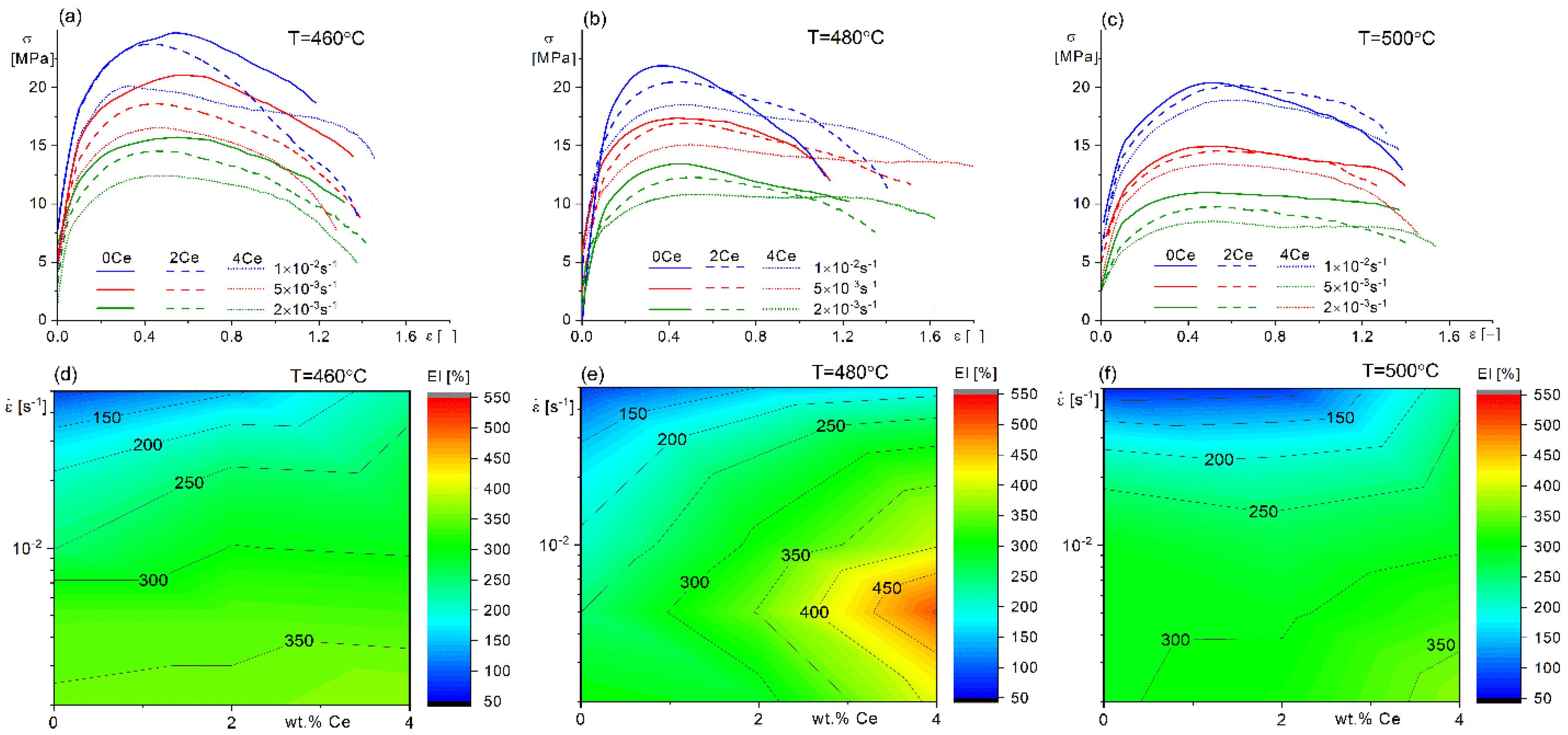

3.2. The Superplastic Deformation Behavior

3.3. Room Temperature Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Staab, T.E.M.; Krause-Rehberg, R.; Hornauer, U.; Zschech, E. Study of artificial aging in AlMgSi (6061) and AlMgSiCu (6013) alloys by Positron Annihilation. J. Mater. Sci. 2006, 41, 1059–1066. [Google Scholar] [CrossRef]

- Miller, W.; Zhuang, L.; Bottema, J.; Wittebrood, A.; De Smet, P.; Haszler, A.; Vieregge, A. Recent development in aluminium alloys for the automotive industry. Mater. Sci. Eng. A 2000, 280, 37–49. [Google Scholar] [CrossRef]

- Heinz, A.; Haszler, A.; Keidel, C.; Moldenhauer, S.; Benedictus, R.; Miller, W. Recent development in aluminium alloys for aerospace applications. Mater. Sci. Eng. A 2000, 280, 102–107. [Google Scholar] [CrossRef]

- Chakrabarti, D.; Laughlin, D.E. Phase relations and precipitation in Al–Mg–Si alloys with Cu additions. Prog. Mater. Sci. 2004, 49, 389–410. [Google Scholar] [CrossRef]

- Yang, W.; Wang, M.; Zhang, R.; Zhang, Q.; Sheng, X. The diffraction patterns from β″ precipitates in 12 orientations in Al–Mg–Si alloy. Scr. Mater. 2010, 62, 705–708. [Google Scholar] [CrossRef]

- Dong, X.; Ji, S. Si poisoning and promotion on the microstructure and mechanical properties of Al–Si–Mg cast alloys. J. Mater. Sci. 2018, 53, 7778–7792. [Google Scholar] [CrossRef] [Green Version]

- Vissers, R.; van Huis, M.A.; Jansen, J.; Zandbergen, H.W.; Marioara, C.D.; Andersen, S.J. The crystal structure of the β′ phase in Al–Mg–Si alloys. Acta Mater. 2007, 55, 3815–3823. [Google Scholar] [CrossRef]

- Chakrabarti, D.J.; Peng, Y.; Laughlin, D.E. Precipitation in Al-Mg-Si Alloys with Cu Additions and the Role of the Q’ and Related Phases. Mater. Sci. Forum 2002, 396–402, 857–862. [Google Scholar] [CrossRef]

- Miao, W.F.; Laughlin, D.E. Effects of Cu content and preaging on precipitation characteristics in aluminum alloy 6022. Metall. Mater. Trans. A 2000, 31, 361–371. [Google Scholar] [CrossRef]

- Chauhan, K.P.S. Influence of Heat Treatment on the Mechanical Properties of Aluminium Alloys (6xxx Series): A Literature Review. Int. J. Eng. Res. 2017, 6, 386–389. [Google Scholar] [CrossRef]

- Sotoudeh, K.; Bate, P.S. Diffusion creep and superplasticity in aluminium alloys. Acta Mater. 2010, 58, 1909–1920. [Google Scholar] [CrossRef]

- Bobruk, E.V.; Safargalina, Z.A.; Golubev, O.V.; Baykov, D.; Kazykhanov, V.U. The effect of ultrafine-grained states on superplastic behavior of Al-Mg-Si alloy. Mater. Lett. 2019, 255, 126503. [Google Scholar] [CrossRef]

- Jafarian, H.R.; Mousavi Anijdan, S.H.; Miyamoto, H. Observation of low temperature superplasticity in an ultrafine grained AA6063 alloy. Mater. Sci. Eng. A 2020, 795, 140015. [Google Scholar] [CrossRef]

- Hussain, M.; Nageswara Rao, P.; Jayaganthan, R. Development of Ultrafine-Grained Al–Mg–Si Alloy Through SPD Processing. Metallogr. Microstruct. Anal. 2015, 4, 219–228. [Google Scholar] [CrossRef]

- Troeger, L.P.; Starke, E.A. Particle-stimulated nucleation of recrystallization for grain-size control and superplasticity in an Al–Mg–Si–Cu alloy. Mater. Sci. Eng. A 2000, 293, 19–29. [Google Scholar] [CrossRef]

- Troeger, L.P.; Starke, E.A. Microstructural and mechanical characterization of a superplastic 6xxx aluminum alloy. Mater. Sci. Eng. A 2000, 277, 102–113. [Google Scholar] [CrossRef]

- Wert, J.A.; Paton, N.E.; Hamilton, C.H.; Mahoney, M.W. Grain refinement in 7075 aluminum by thermomechanical processing. Metall. Trans. A 1981, 12, 1267–1276. [Google Scholar] [CrossRef]

- Wang, X.; Li, Q.; Wu, R.; Zhang, X.; Ma, L. A Review on Superplastic Formation Behavior of Al Alloys. Adv. Mater. Sci. Eng. 2018, 2018, 7606140. [Google Scholar] [CrossRef] [Green Version]

- Humphreys, F.J. The nucleation of recrystallization at second phase particles in deformed aluminium. Acta Metall. 1977, 25, 1323–1344. [Google Scholar] [CrossRef]

- Gutierrez-Urrutia, I.; Muñoz-Morris, M.A.; Morris, D.G. Contribution of microstructural parameters to strengthening in an ultrafine-grained Al–7% Si alloy processed by severe deformation. Acta Mater. 2007, 55, 1319–1330. [Google Scholar] [CrossRef] [Green Version]

- Rohrer, G.S. Introduction to Grains, Phases, and Interfaces—An Interpretation of Microstructure. Trans. AIME 1948, vol. 175, pp. 15–51, by C.S. Smith. Metall. Mater. Trans. A 2010, 41, 1063–1100. [Google Scholar] [CrossRef] [Green Version]

- Humphreys, F.J. A unified theory of recovery, recrystallization and grain growth, based on the stability and growth of cellular microstructures—I. The basic model. Acta Mater. 1997, 45, 4231–4240. [Google Scholar] [CrossRef]

- Humphreys, F.J. A unified theory of recovery, recrystallization and grain growth, based on the stability and growth of cellular microstructures—II. The effect of second-phase particles. Acta Mater. 1997, 45, 5031–5039. [Google Scholar] [CrossRef]

- Manohar, P.A.; Ferry, M.; Chandra, T. Five Decades of the Zener Equation. ISIJ Int. 1998, 38, 913–924. [Google Scholar] [CrossRef] [Green Version]

- Mikhaylovskaya, A.V.; Mochugovskiy, A.G.; Kotov, A.D.; Yakovtseva, O.A.; Gorshenkov, M.V.; Portnoy, V.K. Superplasticity of clad aluminium alloy. J. Mater. Process. Technol. 2017, 243, 355–364. [Google Scholar] [CrossRef]

- Portnoy, V.K.; Rylov, D.S.; Levchenko, V.S.; Mikhaylovskaya, A.V. The influence of chromium on the structure and superplasticity of Al–Mg–Mn alloys. J. Alloys Compd. 2013, 581, 313–317. [Google Scholar] [CrossRef]

- Kotov, A.D.; Mikhaylovskaya, A.V.; Kishchik, M.S.; Tsarkov, A.A.; Aksenov, S.A.; Portnoy, V.K. Superplasticity of high-strength Al-based alloys produced by thermomechanical treatment. J. Alloys Compd. 2016, 688, 336–344. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.V.; Kotov, A.D.; Pozdniakov, A.V.; Portnoy, V.K. A high-strength aluminium-based alloy with advanced superplasticity. J. Alloys Compd. 2014, 599, 139–144. [Google Scholar] [CrossRef]

- Humphreys, J.; Rohrer, G.S.; Rollett, A. Grain Growth Following Recrystallization. In Recrystallization and Related Annealing Phenomena; Elsevier: Amsterdam, The Netherlands, 2017; pp. 375–429. ISBN 978-0-08-098235-9. [Google Scholar]

- Mochugovskiy, A.G.; Mikhaylovskaya, A.V.; Tabachkova, N.Y.; Portnoy, V.K. The mechanism of L12 phase precipitation, microstructure and tensile properties of Al-Mg-Er-Zr alloy. Mater. Sci. Eng. A 2019, 744, 195–205. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.V.; Kishchik, A.A.; Kotov, A.D.; Rofman, O.V.; Tabachkova, N.Y. Precipitation behavior and high strain rate superplasticity in a novel fine-grained aluminum based alloy. Mater. Sci. Eng. A 2019, 760, 37–46. [Google Scholar] [CrossRef]

- Kishchik, M.S.; Mikhailovskaya, A.V.; Kotov, A.D.; Drits, A.M.; Portnoy, V.K. Effect of Modes of Heterogenizing Annealing Before Cold Rolling on the Structure and Properties of Sheets from Alloy 1565ch. Met. Sci. Heat Treat. 2019, 61, 228–233. [Google Scholar] [CrossRef]

- Pozdniakov, A.V.; Barkov, R.Y.; Amer, S.M.; Levchenko, V.S.; Kotov, A.D.; Mikhaylovskaya, A.V. Microstructure, mechanical properties and superplasticity of the Al–Cu–Y–Zr alloy. Mater. Sci. Eng. A 2019, 758, 28–35. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.V.; Esmaeili Ghayoumabadi, M.; Mochugovskiy, A.G. Superplasticity and mechanical properties of Al–Mg–Si alloy doped with eutectic-forming Ni and Fe, and dispersoid-forming Sc and Zr elements. Mater. Sci. Eng. A 2021, 817, 141319. [Google Scholar] [CrossRef]

- Mochugovskiy, A.; Kotov, A.; Esmaeili Ghayoumabadi, M.; Yakovtseva, O.; Mikhaylovskaya, A. A High-Strain-Rate Superplasticity of the Al-Mg-Si-Zr-Sc Alloy with Ni Addition. Materials 2021, 14, 2028. [Google Scholar] [CrossRef] [PubMed]

- Murashkin, M.Y.; Sabirov, I.; Medvedev, A.E.; Enikeev, N.A.; Lefebvre, W.; Valiev, R.Z.; Sauvage, X. Mechanical and electrical properties of an ultrafine grained Al–8.5 wt. % RE (RE = 5.4 wt.% Ce, 3.1 wt.% La) alloy processed by severe plastic deformation. Mater. Des. 2016, 90, 433–442. [Google Scholar] [CrossRef]

- Medvedev, A.E.; Murashkin, M.Y.; Enikeev, N.A.; Valiev, R.Z.; Hodgson, P.D.; Lapovok, R. Enhancement of mechanical and electrical properties of Al-RE alloys by optimizing rare-earth concentration and thermo-mechanical treatment. J. Alloys Compd. 2018, 745, 696–704. [Google Scholar] [CrossRef]

- Mogucheva, A.; Zyabkin, D.; Kaibyshev, R. Effect of the Thermomechanical Processing on Microstructure and Properties of an Al-Ce Alloy. Mater. Sci. Forum 2012, 706–709, 361–366. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.V.; Kishchik, A.A.; Tabachkova, N.Y.; Kotov, A.D.; Cheverikin, V.V.; Bazlov, A.I. Microstructural Characterization and Tensile Properties of Al-Mg-Fe-Ce Alloy at Room and Elevated Temperatures. JOM 2020, 72, 1619–1626. [Google Scholar] [CrossRef]

- Stromme, E.T.; Henderson, H.B.; Sims, Z.C.; Kesler, M.S.; Weiss, D.; Ott, R.T.; Meng, F.; Kassoumeh, S.; Evangelista, J.; Begley, G.; et al. Ageless Aluminum-Cerium-Based Alloys in High-Volume Die Casting for Improved Energy Efficiency. JOM 2018, 70, 866–871. [Google Scholar] [CrossRef] [Green Version]

- Sims, Z.C.; Weiss, D.; McCall, S.K.; McGuire, M.A.; Ott, R.T.; Geer, T.; Rios, O.; Turchi, P.A.E. Cerium-Based, Intermetallic-Strengthened Aluminum Casting Alloy: High-Volume Co-product Development. JOM 2016, 68, 1940–1947. [Google Scholar] [CrossRef]

- Weiss, D. High Performance Aluminum Casting Alloys for Engine Applications; SAE: Warrendale, PA, USA, 2016. [Google Scholar]

- Belov, N.A.; Khvan, A.V.; Alabin, A.N. Microstructure and Phase Composition of Al-Ce-Cu Alloys in the Al-Rich Corner. Mater. Sci. Forum 2006, 519–521, 395–400. [Google Scholar] [CrossRef]

- Belov, N.A.; Naumova, E.A.; Eskin, D.G. Casting alloys of the Al–Ce–Ni system: Microstructural approach to alloy design. Mater. Sci. Eng. A 1999, 271, 134–142. [Google Scholar] [CrossRef]

- Belov, N.A.; Khvan, A.V. The ternary Al–Ce–Cu phase diagram in the aluminum-rich corner. Acta Mater. 2007, 55, 5473–5482. [Google Scholar] [CrossRef]

- Gröbner, J.; Mirković, D.; Schmid-Fetzer, R. Thermodynamic aspects of the constitution, grain refining, and solidification enthalpies of Al-Ce-Si alloys. Metall. Mater. Trans. A 2004, 35, 3349–3362. [Google Scholar] [CrossRef]

- Vončina, M.; Kores, S.; Mrvar, P.; Medved, J. Effect of Ce on solidification and mechanical properties of A360 alloy. J. Alloys Compd. 2011, 509, 7349–7355. [Google Scholar] [CrossRef]

- Zhang, Z.; Bian, X.; Wang, Y. Microstructural characterization and microhardness of rapidly solidified Al–Ce alloys. Z. Met. 2002, 93, 578–584. [Google Scholar] [CrossRef]

- Glazoff, M.V.; Khvan, A.V.; Zolotorevsky, V.S.; Belov, N.A.; Dinsdale, A.T. Industrial and Perspective Casting Alloys. In Casting Aluminum Alloys; Elsevier: Amsterdam, The Netherlands, 2019; pp. 405–510. [Google Scholar]

- Tolley, A.; Radmilovic, V.; Dahmen, U. Segregation in Al3(Sc,Zr) precipitates in Al–Sc–Zr alloys. Scr. Mater. 2005, 52, 621–625. [Google Scholar] [CrossRef]

- Fuller, C.; Murray, J.; Seidman, D. Temporal evolution of the nanostructure of Al(Sc,Zr) alloys: Part I—Chemical compositions of Al(ScZr) precipitates. Acta Mater. 2005, 53, 5401–5413. [Google Scholar] [CrossRef]

- Clouet, E. Excess solvent in precipitates. Nat. Mater. 2018, 17, 1060–1061. [Google Scholar] [CrossRef] [PubMed]

- Yakovtseva, O.A.; Sitkina, M.N.; Kotov, A.D.; Rofman, O.V.; Mikhaylovskaya, A.V. Experimental study of the superplastic deformation mechanisms of high-strength aluminum-based alloy. Mater. Sci. Eng. A 2020, 788, 139639. [Google Scholar] [CrossRef]

- Lee, S.; Utsunomiya, A.; Akamatsu, H.; Neishi, K.; Furukawa, M.; Horita, Z.; Langdon, T. Influence of scandium and zirconium on grain stability and superplastic ductilities in ultrafine-grained Al–Mg alloys. Acta Mater. 2002, 50, 553–564. [Google Scholar] [CrossRef]

- Kumar, A.; Mukhopadhyay, A.K.; Prasad, K.S. Superplastic behaviour of Al–Zn–Mg–Cu–Zr alloy AA7010 containing Sc. Mater. Sci. Eng. A 2010, 527, 854–857. [Google Scholar] [CrossRef]

- Avtokratova, E.; Sitdikov, O.; Markushev, M.; Mulyukov, R. Extraordinary high-strain rate superplasticity of severely deformed Al–Mg–Sc–Zr alloy. Mater. Sci. Eng. A 2012, 538, 386–390. [Google Scholar] [CrossRef]

- Mochugovskiy, A.; Mikhaylovskaya, A.V.; Mufalo, W.; Portnoy, V.K. Superplasticity of Al-Mg-Zr Alloy. Defect Diffus. Forum 2018, 385, 114–119. [Google Scholar] [CrossRef]

- Mochugovskiy, A.G.; Mikhaylovskaya, A.V.; Zadorognyy, M.Y.; Golovin, I.S. Effect of heat treatment on the grain size control, superplasticity, internal friction, and mechanical properties of zirconium-bearing aluminum-based alloy. J. Alloys Compd. 2021, 856, 157455. [Google Scholar] [CrossRef]

- Mochugovskiy, A.G.; Mikhaylovskaya, A.V. Comparison of precipitation kinetics and mechanical properties in Zr and Sc-bearing aluminum-based alloys. Mater. Lett. 2020, 275, 128096. [Google Scholar] [CrossRef]

- Belov, N.A.; Alabin, A.N.; Eskin, D.G.; Istomin-Kastrovskii, V.V. Optimization of hardening of Al–Zr–Sc cast alloys. J. Mater. Sci. 2006, 41, 5890–5899. [Google Scholar] [CrossRef]

- Seidman, D.N.; Marquis, E.A.; Dunand, D.C. Precipitation strengthening at ambient and elevated temperatures of heat-treatable Al(Sc) alloys. Acta Mater. 2002, 50, 4021–4035. [Google Scholar] [CrossRef]

- Chao, R.; Guan, X.; Guan, R.; Tie, D.; Lian, C.; Wang, X.; Zhang, J. Effect of Zr and Sc on mechanical properties and electrical conductivities of Al wires. Trans. Nonferrous Met. Soc. China 2014, 24, 3164–3169. [Google Scholar] [CrossRef]

- Filatov, Y.; Yelagin, V.; Zakharov, V. New Al–Mg–Sc alloys. Mater. Sci. Eng. A 2000, 280, 97–101. [Google Scholar] [CrossRef]

- Tzeng, Y.-C.; Chung, C.-Y.; Chien, H.-C. Effects of trace amounts of Zr and Sc on the recrystallization behavior and mechanical properties of Al-4.5Zn-1.6Mg alloys. Mater. Lett. 2018, 228, 270–272. [Google Scholar] [CrossRef]

- He, Y.; Zhang, X.; You, J. Effect of minor Sc and Zr on microstructure and mechanical properties of Al-Zn-Mg-Cu alloy. Trans. Nonferrous Met. Soc. China 2006, 16, 1228–1235. [Google Scholar] [CrossRef]

- Lityńska-Dobrzyńska, L. Precipitation of Phases in Al-Mg-Si-Cu Alloy with Sc and Zr Additions during Heat Treatment. Solid State Phenom. 2007, 130, 163–166. [Google Scholar] [CrossRef]

- Dumbre, J.; Kairy, S.K.; Anber, E.; Langan, T.; Taheri, M.L.; Dorin, T.; Birbilis, N. Understanding the formation of (Al,Si)3Sc and V-phase (AlSc2Si2) in Al-Si-Sc alloys via ex situ heat treatments and in situ transmission electron microscopy studies. J. Alloys Compd. 2021, 861, 158511. [Google Scholar] [CrossRef]

- Vo, N.Q.; Dunand, D.C.; Seidman, D.N. Improving aging and creep resistance in a dilute Al–Sc alloy by microalloying with Si, Zr and Er. Acta Mater. 2014, 63, 73–85. [Google Scholar] [CrossRef]

- Ratchev, P.; Verlinden, B.; Van Houtte, P. Effect of preheat temperature on the orientation relationship of (Mn,Fe)Al6 precipitates in an AA 5182 Aluminium—Magnesium alloy. Acta Metall. Mater. 1995, 43, 621–629. [Google Scholar] [CrossRef]

- Esmaeili Ghayoumabadi, M.; Mochugovskiy, A.G.; Tabachkova, N.Y.; Mikhaylovskaya, A.V. The influence of minor additions of Y, Sc and Zr on the microstructural evolution, superplastic behavior, and tensile properties of AA6013 alloy. J. Alloys Compd. 2021, 900, 163477. [Google Scholar] [CrossRef]

- Pancholi, V.; Kashyap, B. Effect of local strain distribution on concurrent microstructural evolution during superplastic deformation of Al–Li 8090 alloy. Mater. Sci. Eng. A 2003, 351, 174–182. [Google Scholar] [CrossRef]

- Mukhopadhyay, A.K.; Kumar, A.; Raveendra, S.; Samajdar, I. Development of grain structure during superplastic deformation of an Al–Zn–Mg–Cu–Zr alloy containing Sc. Scr. Mater. 2011, 64, 386–389. [Google Scholar] [CrossRef]

- Myshlyaev, M.; Mironov, S.; Korznikova, G.; Konkova, T.; Korznikova, E.; Aletdinov, A.; Khalikova, G. EBSD study of superplastically strained Al-Mg-Li alloy. Mater. Lett. 2020, 275, 128063. [Google Scholar] [CrossRef]

- Brandes, E.A.; Brook, G.B. Smithells Metals Reference Book; Elsevier: Amsterdam, The Netherlands, 1992; ISBN 9780080517308. [Google Scholar]

- Zener, C.; Hollomon, J.H. Effect of Strain Rate Upon Plastic Flow of Steel. J. Appl. Phys. 1944, 15, 22–32. [Google Scholar] [CrossRef]

- Sellars, C.M.; McTegart, W.J. On the mechanism of hot deformation. Acta Metall. 1966, 14, 1136–1138. [Google Scholar] [CrossRef]

- Chen, L.; Zhao, G.; Yu, J.; Zhang, W. Constitutive analysis of homogenized 7005 aluminum alloy at evaluated temperature for extrusion process. Mater. Des. 2015, 66, 129–136. [Google Scholar] [CrossRef]

- Yang, J.; Wu, J.; Zhang, Q.; Han, R.; Wang, K. The simple hyperbolic-sine equation for superplastic deformation and parameters optimization. J. Mater. Res. Technol. 2020, 9, 10819–10829. [Google Scholar] [CrossRef]

- Ruano, O.A.; Sherby, O.D. On constitutive equations for various diffusion-controlled creep mechanisms. Rev. Phys. Appl. 1988, 23, 625–637. [Google Scholar] [CrossRef]

- Kawasaki, M.; Balasubramanian, N.; Langdon, T.G. Flow mechanisms in ultrafine-grained metals with an emphasis on superplasticity. Mater. Sci. Eng. A 2011, 528, 6624–6629. [Google Scholar] [CrossRef]

- Kotov, A.D.; Mikhaylovskaya, A.V.; Portnoy, V.K. Effect of the solid-solution composition on the superplasticity characteristics of Al-Zn-Mg-Cu-Ni-Zr Alloys. Phys. Met. Metallogr. 2014, 115, 730–735. [Google Scholar] [CrossRef]

- Kaneko, R.S.; Bakow, L.; Lee, E.W. Aluminum alloy 6013 sheet for new U.S. Navy aircraft. JOM 1990, 42, 16–18. [Google Scholar] [CrossRef]

| Alloy | Mg | Si | Cu | Ce | Sc | Zr | Al |

|---|---|---|---|---|---|---|---|

| 0Ce | 1.2 | 0.7 | 1.0 | - | 0.10 | 0.2 | bal. |

| 2Ce | 1.2 | 0.7 | 1.0 | 2.0 | 0.10 | 0.2 | bal. |

| 4Ce | 1.2 | 0.7 | 1.0 | 4.0 | 0.10 | 0.2 | bal. |

| Al | Mg | Si | Cu | Ce | Sc | Zr | |

|---|---|---|---|---|---|---|---|

| Spectrum 1 | 43.40 | 0.54 | 7.90 | 26.40 | 21.40 | 0.10 | 0.02 |

| Spectrum 2 | 43.50 | 0.17 | 24.20 | 2.50 | 29.40 | 0.18 | 0.11 |

| Spectrum 3 | 97.72 | 1.60 | 0.03 | 0.50 | - | 0.12 | 0.15 |

| Strain [%] | Q1 [kJ/mol] | n1/m | lnA1 | Q2 [kJ/mol] | β [MPa−1] | lnA2 | Q3 [kJ/mol] | n2 | lnA3 |

|---|---|---|---|---|---|---|---|---|---|

| 0Ce | 98 ± 4 | 2.89/0.34 | 2.1 | 100 ± 5 | 0.16 | 7.8 | 100 ± 7 | 2.21 | 10.3 |

| 2Ce | 92 ± 3 | 2.72/0.37 | 1.9 | 98 ± 7 | 0.17 | 7.4 | 96 ± 7 | 2.06 | 9.5 |

| 4Ce | 67 ± 8 | 2.46/0.40 | 1.1 | 70 ± 10 | 0.18 | 3.1 | 69 ± 8 | 1.87 | 5.2 |

| SST at 520 °C (20 min) | SST and Aging at 180 °C for 8 h | |||||||

|---|---|---|---|---|---|---|---|---|

| Alloy | HV | YS [MPa] | UTS [MPa] | El [%] | HV | YS [MPa] | UTS [MPa] | El [%] |

| 0Ce | 65 ± 2 | 140 ± 1 | 256 ± 3 | 20 ± 2 | 126 ± 3 | 367 ± 1 | 420 ± 4 | 9 ± 1 |

| 2Ce | 68 ± 3 | 150 ± 2 | 255 ± 5 | 15 ± 1 | 102 ± 2 | 281 ± 2 | 324 ± 2 | 10 ± 1 |

| 4Ce | 72 ± 3 | 160 ± 1 | 250 ± 5 | 11 ± 2 | 74 ± 2 | 192 ± 7 | 260 ± 10 | 13 ± 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mochugovskiy, A.G.; Prosviryakov, A.S.; Tabachkova, N.Y.; Mikhaylovskaya, A.V. The Effect of Ce on the Microstructure, Superplasticity, and Mechanical Properties of Al-Mg-Si-Cu Alloy. Metals 2022, 12, 512. https://doi.org/10.3390/met12030512

Mochugovskiy AG, Prosviryakov AS, Tabachkova NY, Mikhaylovskaya AV. The Effect of Ce on the Microstructure, Superplasticity, and Mechanical Properties of Al-Mg-Si-Cu Alloy. Metals. 2022; 12(3):512. https://doi.org/10.3390/met12030512

Chicago/Turabian StyleMochugovskiy, Andrey G., Alexey S. Prosviryakov, Nataliya Yu. Tabachkova, and Anastasia V. Mikhaylovskaya. 2022. "The Effect of Ce on the Microstructure, Superplasticity, and Mechanical Properties of Al-Mg-Si-Cu Alloy" Metals 12, no. 3: 512. https://doi.org/10.3390/met12030512

APA StyleMochugovskiy, A. G., Prosviryakov, A. S., Tabachkova, N. Y., & Mikhaylovskaya, A. V. (2022). The Effect of Ce on the Microstructure, Superplasticity, and Mechanical Properties of Al-Mg-Si-Cu Alloy. Metals, 12(3), 512. https://doi.org/10.3390/met12030512