The Effect of CRITSIMA Process Parameters on the Microstructure Evolution and Element Segregation of Semi-Solid CuSn10P1 Alloy Billet

Abstract

:1. Introduction

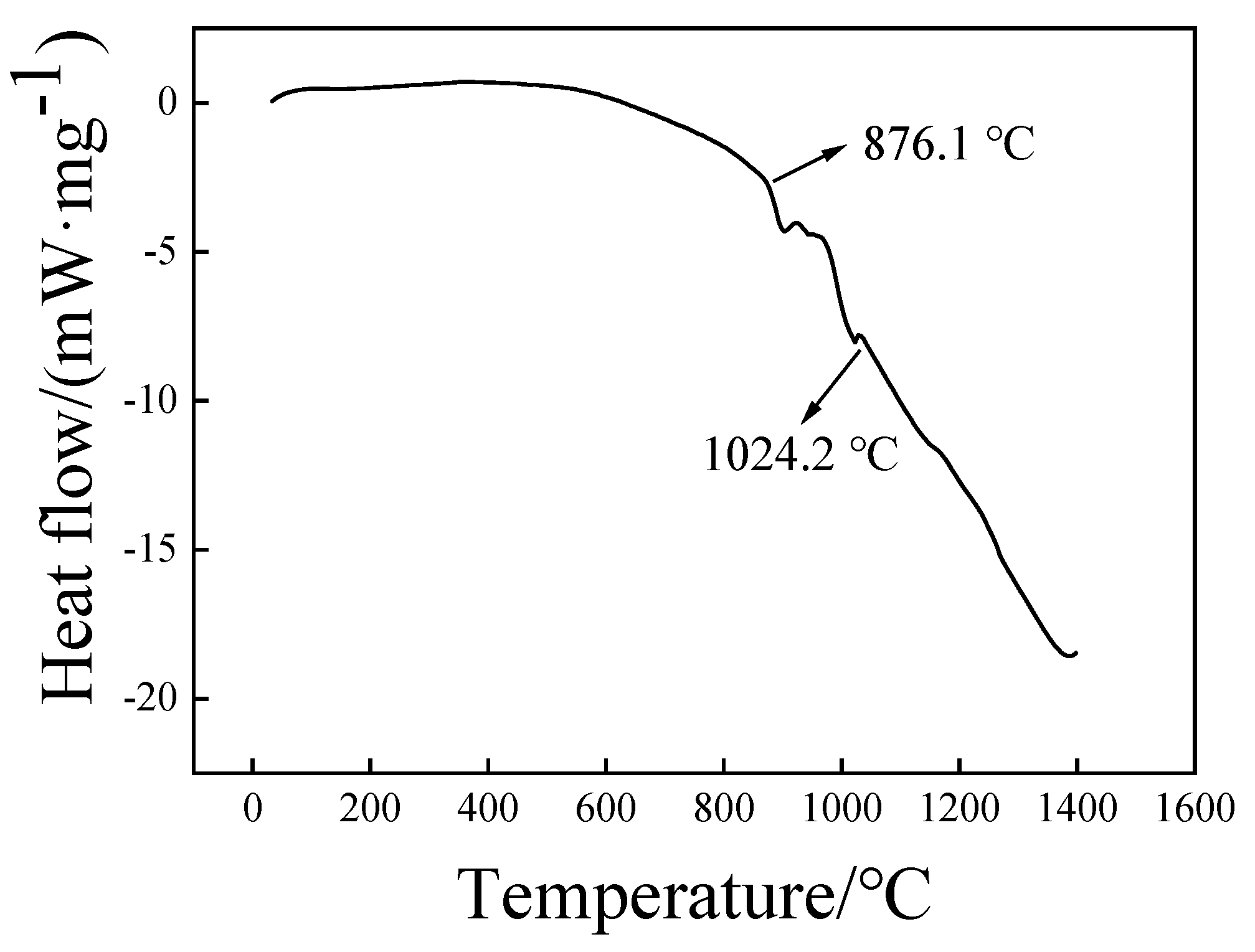

2. Materials and Methods

2.1. Materials

2.2. SIMA, RAP and CRITSIMA Processes

2.3. Observation of Microstructure and Detection of Element Distribution

3. Results and Discussion

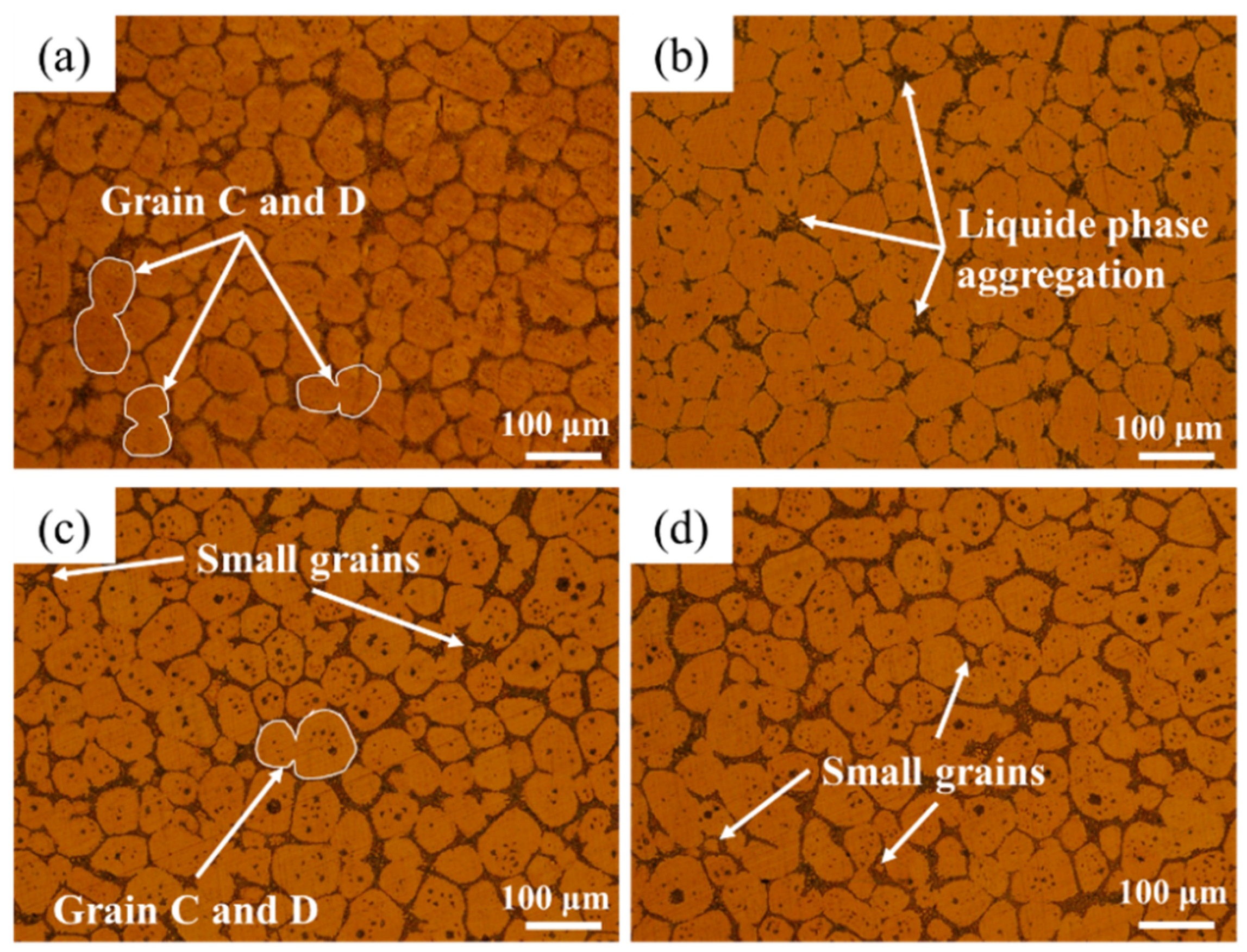

3.1. Effect of Cold Rolling Reduction and Isothermal Time on the Microstructure of Semi-Solid Billet

3.2. Effect of Isothermal Temperature and Isothermal Time on the Microstructure of Semi-Solid Billet

3.3. Coarsening Rate

3.4. Distribution Changes of Elements during Isothermal Treatment

4. Conclusions

- (1)

- The dendrite network microstructure in the as-cast CuSn10P1 copper alloy is destroyed after multi-pass cold rolling, and the dendrite and dendrite walls in the microstructure are broken and fractured. The dendrite direction of fracture is shifted in the same direction by multi-direction rolling. With the increase of cold rolling reduction, the degree of dendrite fragmentation in the microstructure is intensified, and the more stored energy is stored in the microstructure, which provides more energy for the subsequent isothermal treatment process.

- (2)

- The increase of cold rolling reduction can refine the average grain diameter of semi-solid grain. However, when it reaches 40%, the bonding phenomenon of grain is more severe, and the average grain diameter increases. In the isothermal process, the increase of isothermal temperature and the extension of isothermal time will make the grains grow up. When the deformation is 30% and isothermal temperature is 900 °C for 20 min, the average grain diameter, average grain roundness, and liquid fraction are 66.45 μm, 0.7, and 12.78%, respectively.

- (3)

- With the increase of cold rolling reduction, stored energy increases, and grain consolidation and growth rate are accelerated. Therefore, the grain coarsening rate coefficient K increases gradually. With the increase of isothermal temperature, the increase of the liquid phase makes the grain melting rate more than the coarsening rate. Therefore, the grain coarsening rate coefficient K decreases gradually.

- (4)

- Element segregation exists in both as-cast and semi-solid microstructure of CuSn10P1 alloy. Sn and P accumulate in the secondary phase of the as-cast microstructure. Sn and P accumulate in the intergranular microstructure of the semi-solid microstructure. Isothermal treatment can improve the segregation of Sn and P to a certain extent, but cannot eliminate the segregation of elements.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Spencer, D.B.; Mehrabian, R.; Flemings, M.C. Rheological behavior of Sn-15 pct Pb in the crystallization range. Met. Mater. Trans. A 1972, 3, 1925–1932. [Google Scholar] [CrossRef]

- Flemings, M.C. Behavior of metal alloys in the semi-solid state. Metall. Trans. B 1991, 3, 269–293. [Google Scholar] [CrossRef]

- Guan, R.G.; Tie, D. A Review on Grain Refinement of Aluminum Alloys: Progresses, Challenges and Prospects. Acta Metall. Sin. 2017, 5, 409–432. [Google Scholar] [CrossRef]

- Atkinson, H.V. Modelling the Semi-solid Processing of Metallic Alloys. J. Cheminf. 2005, 3, 341–412. [Google Scholar]

- Qi, M.F.; Kang, Y.L.; Zhou, B.; Zhu, G.M.; Zhang, H.H. Microstructure and Properties of Forced Convection Stirring Rheological Die Casting AZ91D Magnesium Alloy. Acta Metall. Sin. 2015, 6, 9. [Google Scholar]

- Rogal, Ł. Semi-solid processing of the CoCrCuFeNi high entropy alloy. Mater. Des. 2017, 119, 406–416. [Google Scholar] [CrossRef]

- Niitsu, C.K.; Chaussê, D.F.C.; Suk-Chun, M.; Rian, D.; Rubens, C. In-situ microstructural observation of Ti-Cu alloys for semi-solid processing. Mater. Charact. 2018, 145, 10–19. [Google Scholar]

- Jiang, J.; Atkinson, H.; Wang, Y. Microstructure and Mechanical Properties of 7005 Aluminum Alloy Components Formed by Thixoforming. J. Mater. Sci. Technol. 2017, 33, 379–388. [Google Scholar] [CrossRef]

- Chayong, S.; Atkinson, H.V.; Kapranos, P. Thixoforming 7075 aluminium alloys. J. Mater. Sci. Eng. A 2005, 390, 3–12. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Y.B.; Cao, Z.Y.; Zhang, Y.F.; Zhang, Q.Q. Effects of isothermal process parameters on the microstructure of semi-solid AZ91D alloy produced by SIMA. J. Mater. Process. Technol. 2009, 2, 792–797. [Google Scholar] [CrossRef]

- Jiang, J.F.; Peng, Q.C.; Shan, W.W.; Luo, S.J. Preparation of AZ91D semi-solid billet by new SIMA method. Spec. Cast. Nonferrous Alloy. 2005, 12, 4. [Google Scholar]

- Zhai, Q.Y.; Yuan, S.; Jiang, B.L. Semi-solid microstructure characteristics of AZ91 magnesium alloy by SIMA method. Trans. Nonferrous Met. Soc. China 2005, 1, 123–128. [Google Scholar]

- Yao, L.Y.; Yuan, S.; Wang, W.X.; Jiang, B.L.; Tang, W.T. Characteristics of compression deformation and semi-solid isothermal structure of AZ91D magnesium alloy treated by SIMA method. Trans. Nonferrous Met. Soc. China 2004, 4, 660–664. [Google Scholar]

- Fu, J.; Wang, S.; Wang, K. Influencing factors of the coarsening behaviors for 7075 aluminum alloy in the semi-solid state. J. Mater. Sci. 2018, 13, 9790–9805. [Google Scholar] [CrossRef]

- Flemings, M.C.; Riek, R.G.; Young, K.P. Rheocasting. Mater. Sci. Eng. 1976, 25, 103–117. [Google Scholar] [CrossRef]

- Cao, M.; Wang, Z.; Zhang, Q. Microstructure-dependent mechanical properties of semi-solid copper alloys. J. Alloy. Compd. 2017, 715, 413–420. [Google Scholar] [CrossRef]

- Cao, M.; Zhang, Q.; Huang, K.; Wang, X.J.; Chang, B.T.; Cai, L. Microstructural evolution and deformation behavior of copper alloy during rheoforging process. J. Mater. Sci. Technol. 2020, 7, 19–29. [Google Scholar] [CrossRef]

- Youn, J.I.; Kim, Y.J. Application of Semi-Solid Process for Production of the Induction Motor Squirrel Cage. Solid State Phenom. 2006, 116–117, 730–733. [Google Scholar] [CrossRef]

- Shao, B.; Liu, D.H.; Zhu, L. Research on the Microstructure of QSn7-0.2 Copper Alloy Semi-solid Extrusion Forming. Foundry Technol. 2017, 12, 4. [Google Scholar]

- Chen, Y.N.; Huo, Y.Z.; Zhao, Y.P.; Song, X.D.; Zhao, Y.Q.; Bi, C.C.; Liao, L. How does Cu content affect the semi-solid forgeability and mechanical properties of Ti-Cu alloys after forging? Rare Met. Mater. Eng. 2016, 6, 7. [Google Scholar]

- Young, K.P.; Kyonka, C.P.; Courtois, C.A. Fine Grained Metal Composition. U.S. Patent 4,415,374, 15 November 1983. [Google Scholar]

- Kirkwood, D.H.T.U.; Sellars, C.M.T.; Elias, B.L.G.; Sheffield, U. Thixotropic Materials. U.S. Patent 5,133,811, 28 July 1992. [Google Scholar]

- Wang, J.; Xiao, H.; Wu, L.B.; Hu, H.L.; Lu, D.H.; Zhou, R.F.; Zhou, R. Deformation characteristic of semi-solid ZCuSn10 copper alloy during isothermal compression. Rare Met. 2016, 8, 620–626. [Google Scholar] [CrossRef]

- Seo, P.K.; Kang, C.G. The effect of raw material fabrication process on microstructural characteristics in reheating process for semi-solid forming. J. Mater. Process. Technol. 2005, 162, 402–409. [Google Scholar] [CrossRef]

- Jiang, J.; Xiao, G.; Wang, Y.; Qi, Y. Microstructure evolution of wrought nickel based superalloy GH4037 in the semi-solid state. Mater. Charact. 2018, 141, 229–237. [Google Scholar] [CrossRef]

- Jiang, J.; Wang, Y.; Xiao, G.; Nie, X. Comparison of microstructural evolution of 7075 aluminum alloy fabricated by SIMA and RAP. J. Mater. Process. Technol. 2016, 238, 361–372. [Google Scholar] [CrossRef]

- Jiang, J.F.; Zhang, Y.H.; Liu, Y.Z.; Wang, Y.; Xiao, G.F.; Zhang, Y. Research on AlSi7Mg Alloy Semi-solid Billet Prepared by RAP Method. Acta Metall. Sin. 2021, 6, 14. [Google Scholar]

| Sn | P | Fe | Pb | Cu |

|---|---|---|---|---|

| 10.2 | 0.9 | 0.02 | 0.05 | Bal. |

| Element | As-Cast | Semi-Solid | |||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 1 | 2 | 3 | |

| Cu | 96.86 | 68.68 | 88.87 | 85.78 | 96.13 | 91.98 | 75.48 |

| Sn | 2.99 | 31.32 | 10.68 | - | 3.55 | 7.71 | 19.23 |

| P | 0.15 | - | 0.45 | 14.22 | 0.32 | 3.17 | 5.29 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Chen, L.; Xiao, H.; Zhou, Y.; Chen, H.; Duan, Z. The Effect of CRITSIMA Process Parameters on the Microstructure Evolution and Element Segregation of Semi-Solid CuSn10P1 Alloy Billet. Metals 2022, 12, 487. https://doi.org/10.3390/met12030487

Zhang X, Chen L, Xiao H, Zhou Y, Chen H, Duan Z. The Effect of CRITSIMA Process Parameters on the Microstructure Evolution and Element Segregation of Semi-Solid CuSn10P1 Alloy Billet. Metals. 2022; 12(3):487. https://doi.org/10.3390/met12030487

Chicago/Turabian StyleZhang, Xiongchao, Lei Chen, Han Xiao, Yuhang Zhou, Hao Chen, and Zhike Duan. 2022. "The Effect of CRITSIMA Process Parameters on the Microstructure Evolution and Element Segregation of Semi-Solid CuSn10P1 Alloy Billet" Metals 12, no. 3: 487. https://doi.org/10.3390/met12030487

APA StyleZhang, X., Chen, L., Xiao, H., Zhou, Y., Chen, H., & Duan, Z. (2022). The Effect of CRITSIMA Process Parameters on the Microstructure Evolution and Element Segregation of Semi-Solid CuSn10P1 Alloy Billet. Metals, 12(3), 487. https://doi.org/10.3390/met12030487