Microstructures and Mechanical Properties of Steels and Alloys Subjected to Large-Strain Cold-to-Warm Deformation

Abstract

1. Introduction

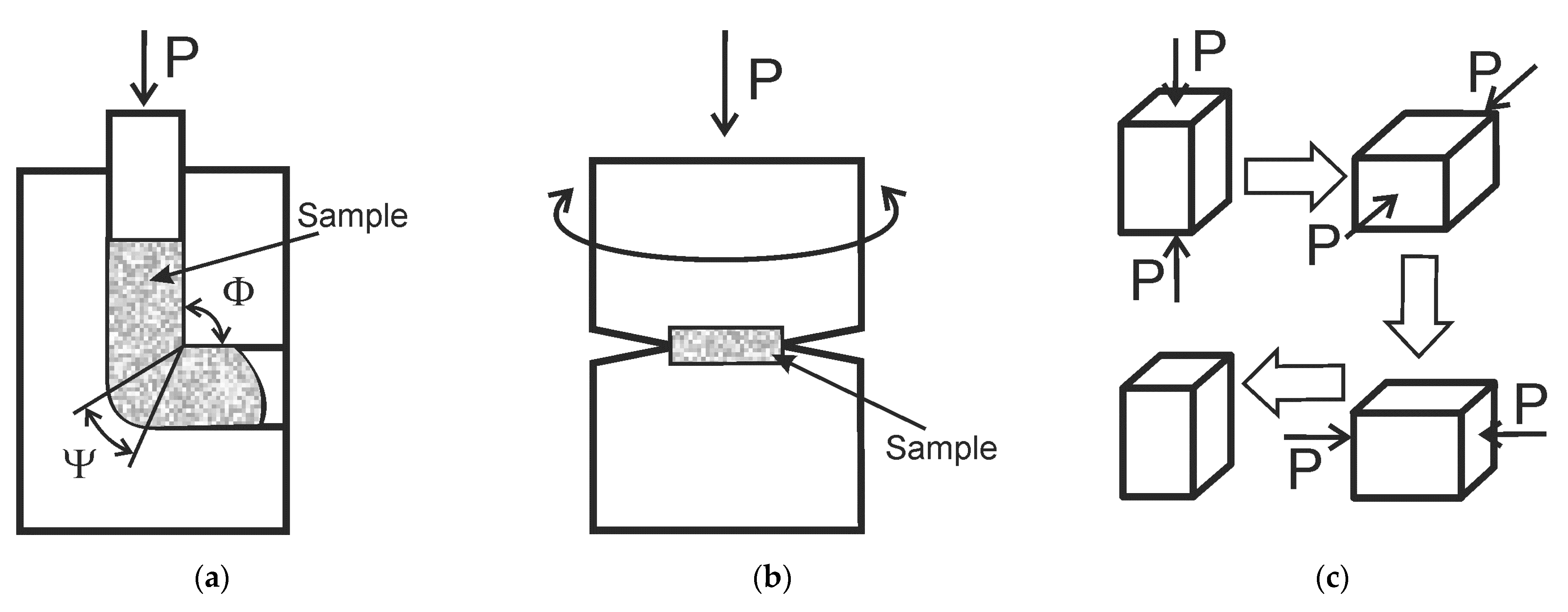

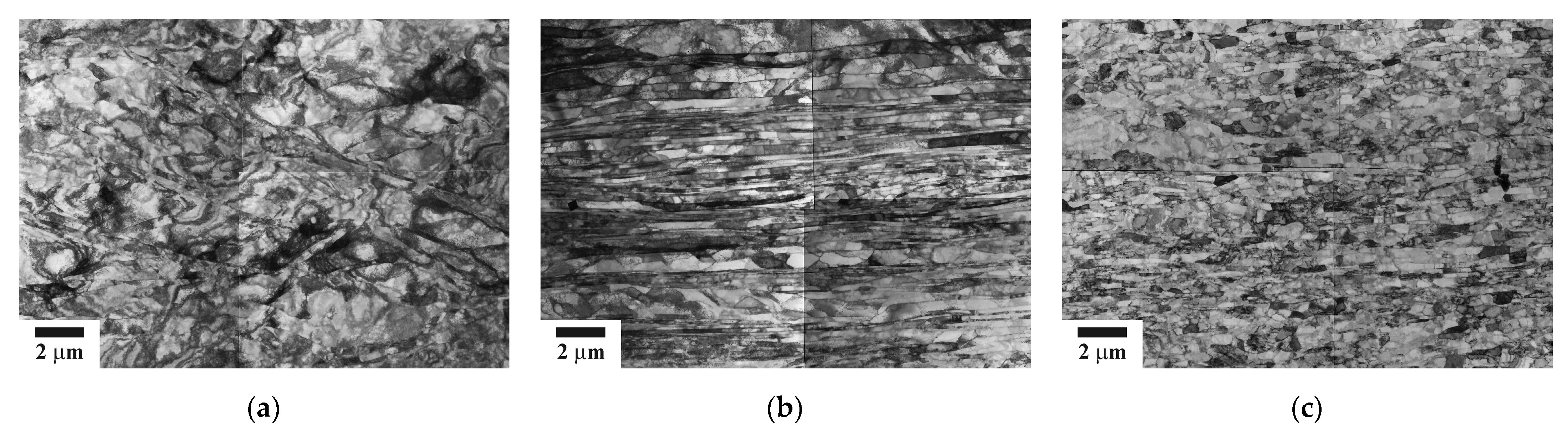

2. Large Strain Deformation

2.1. Processing Methods

2.2. Microstructure Characterization

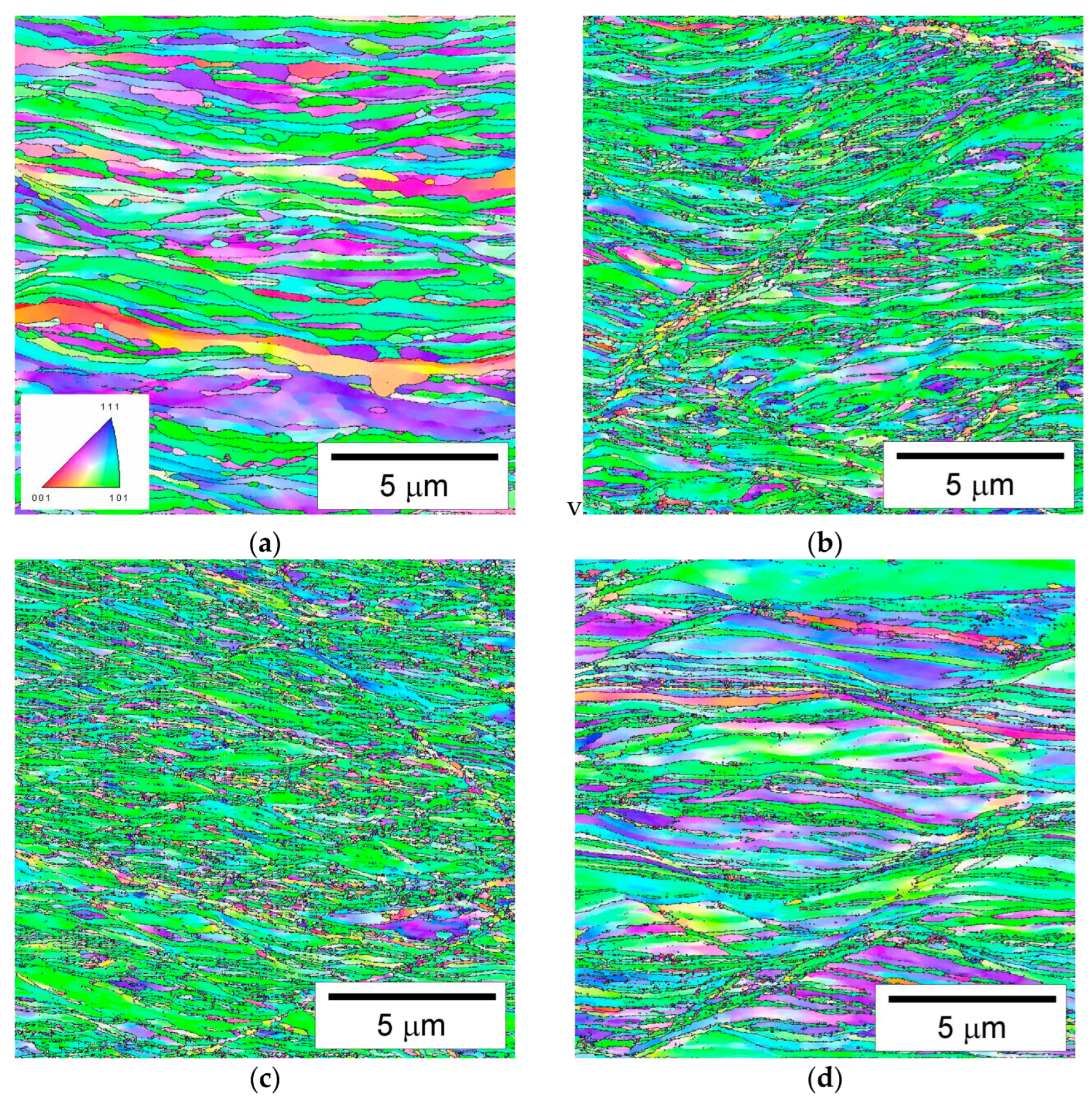

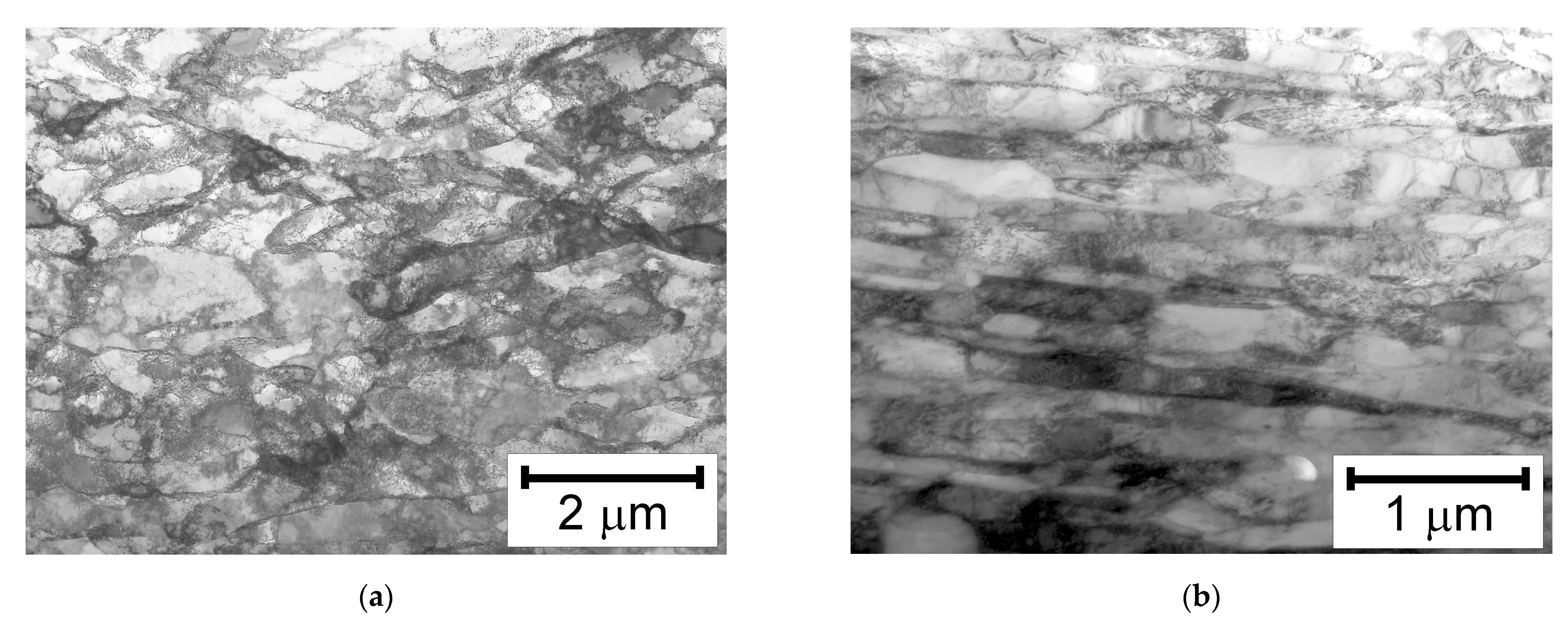

3. Microstructure Evolution

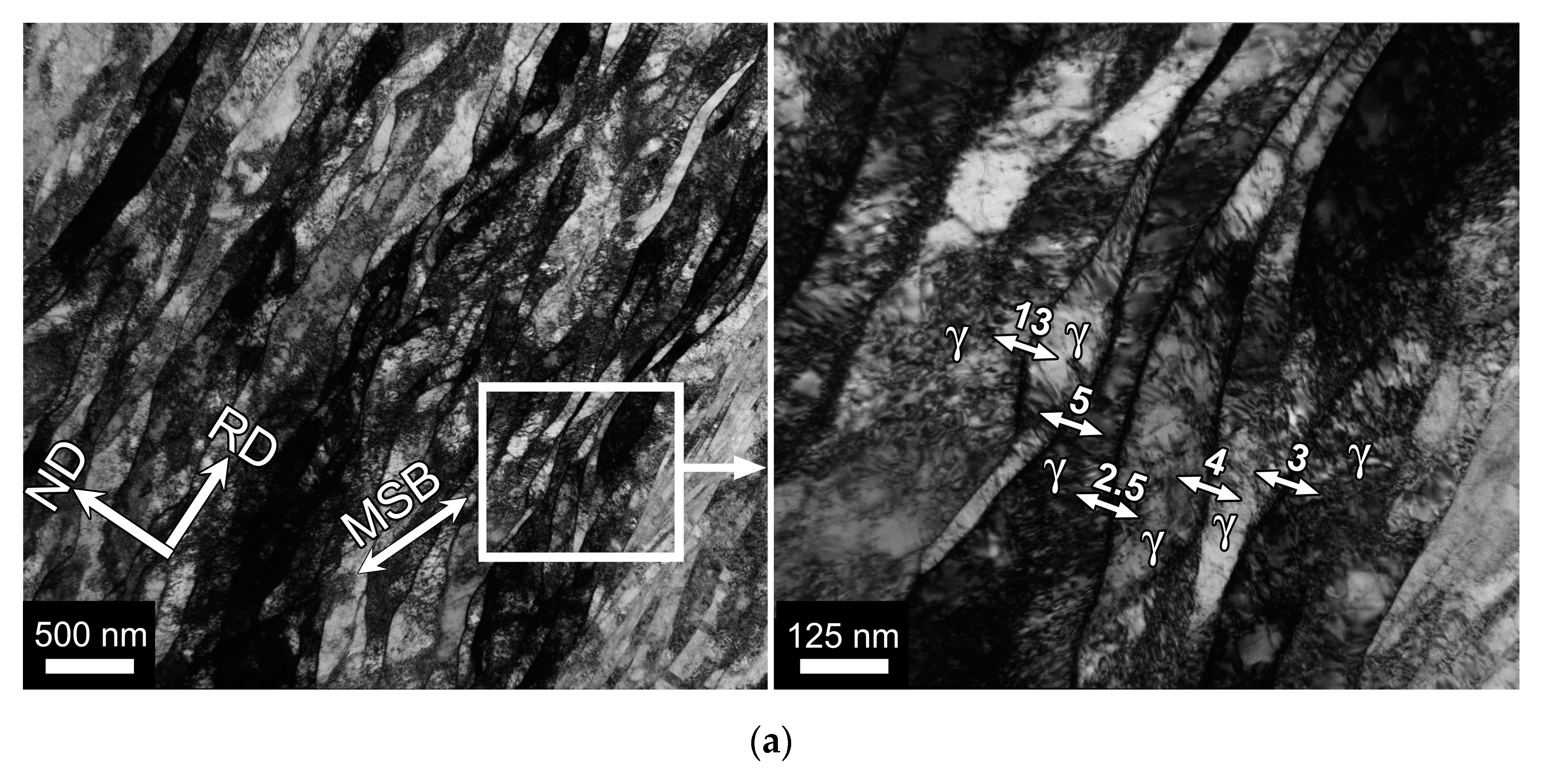

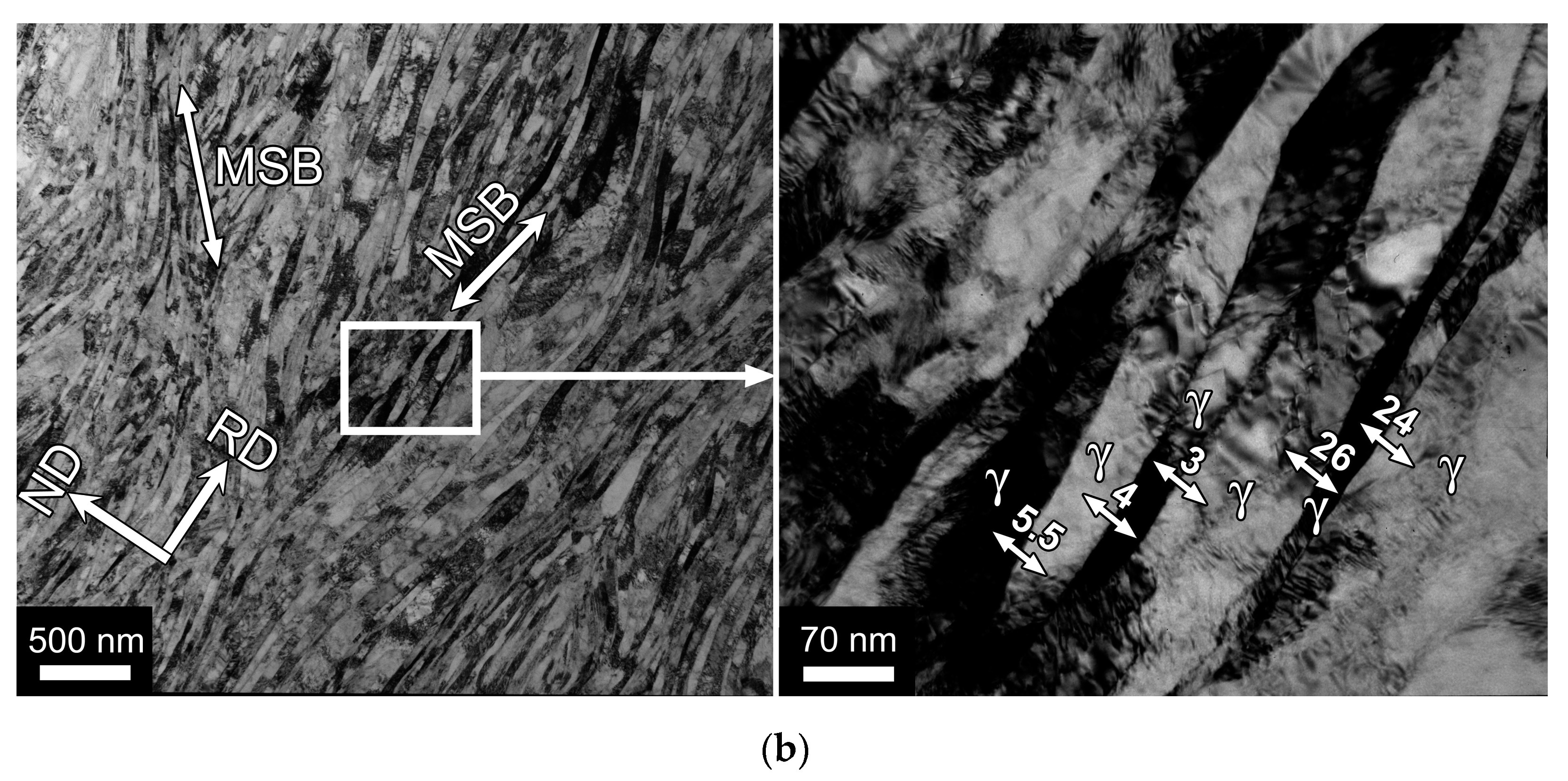

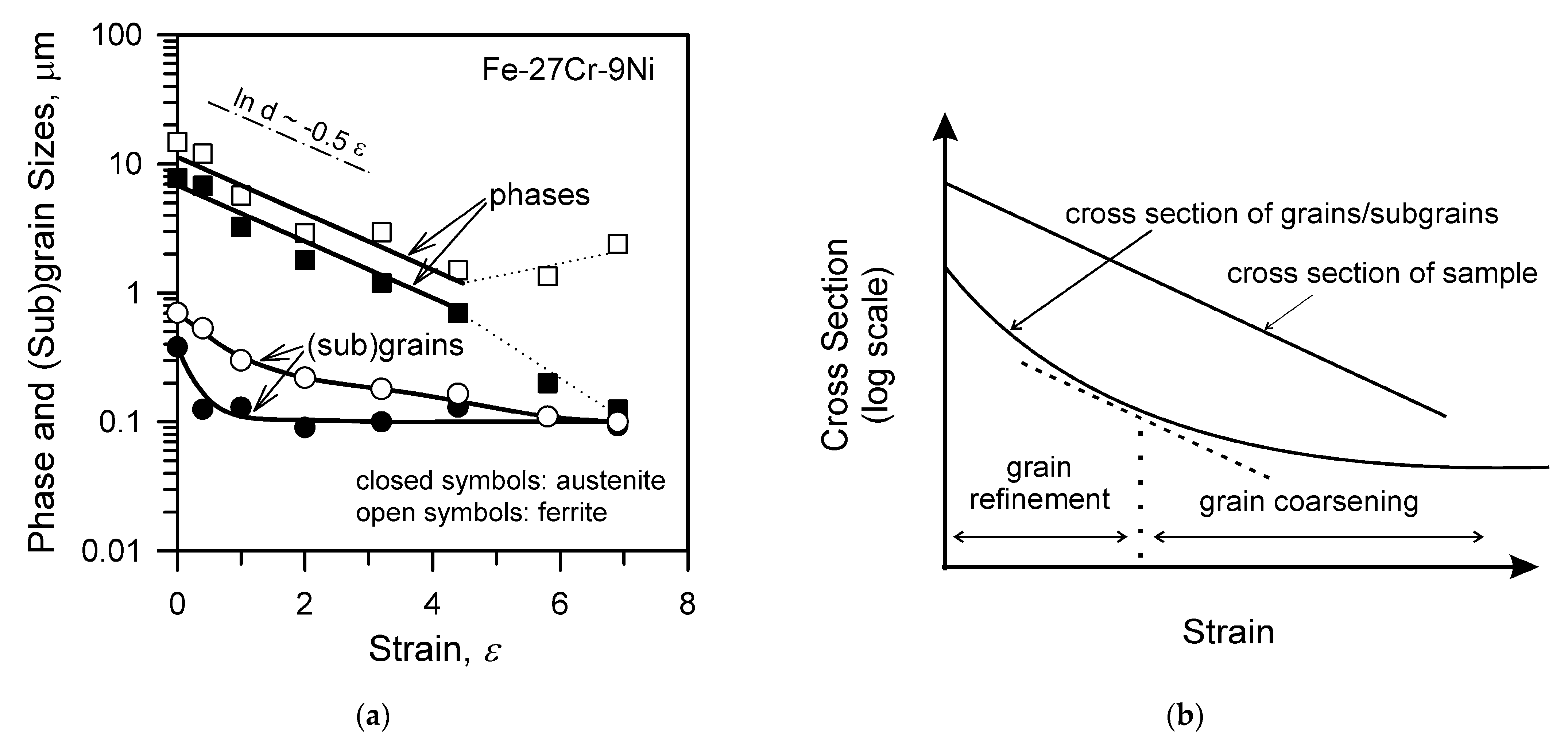

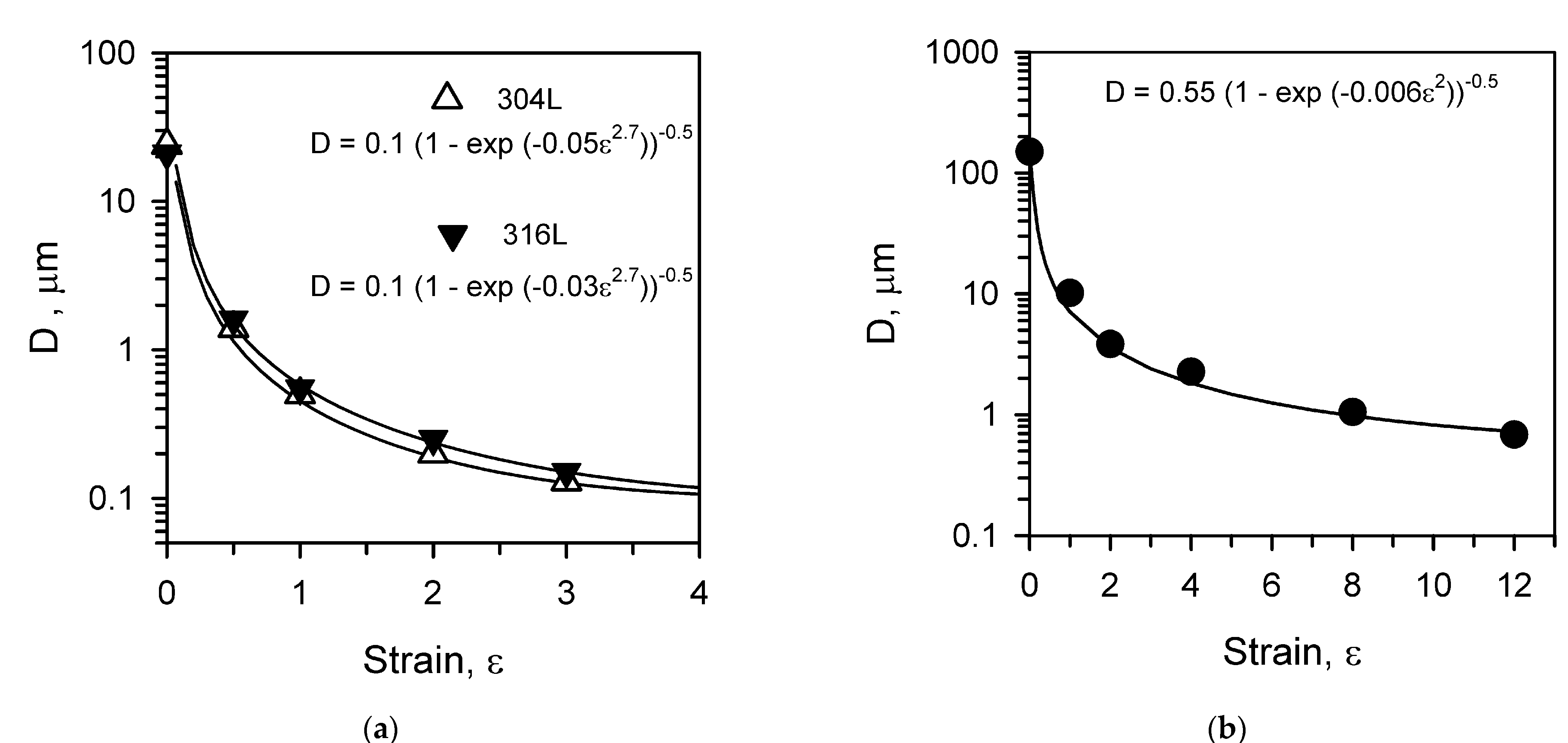

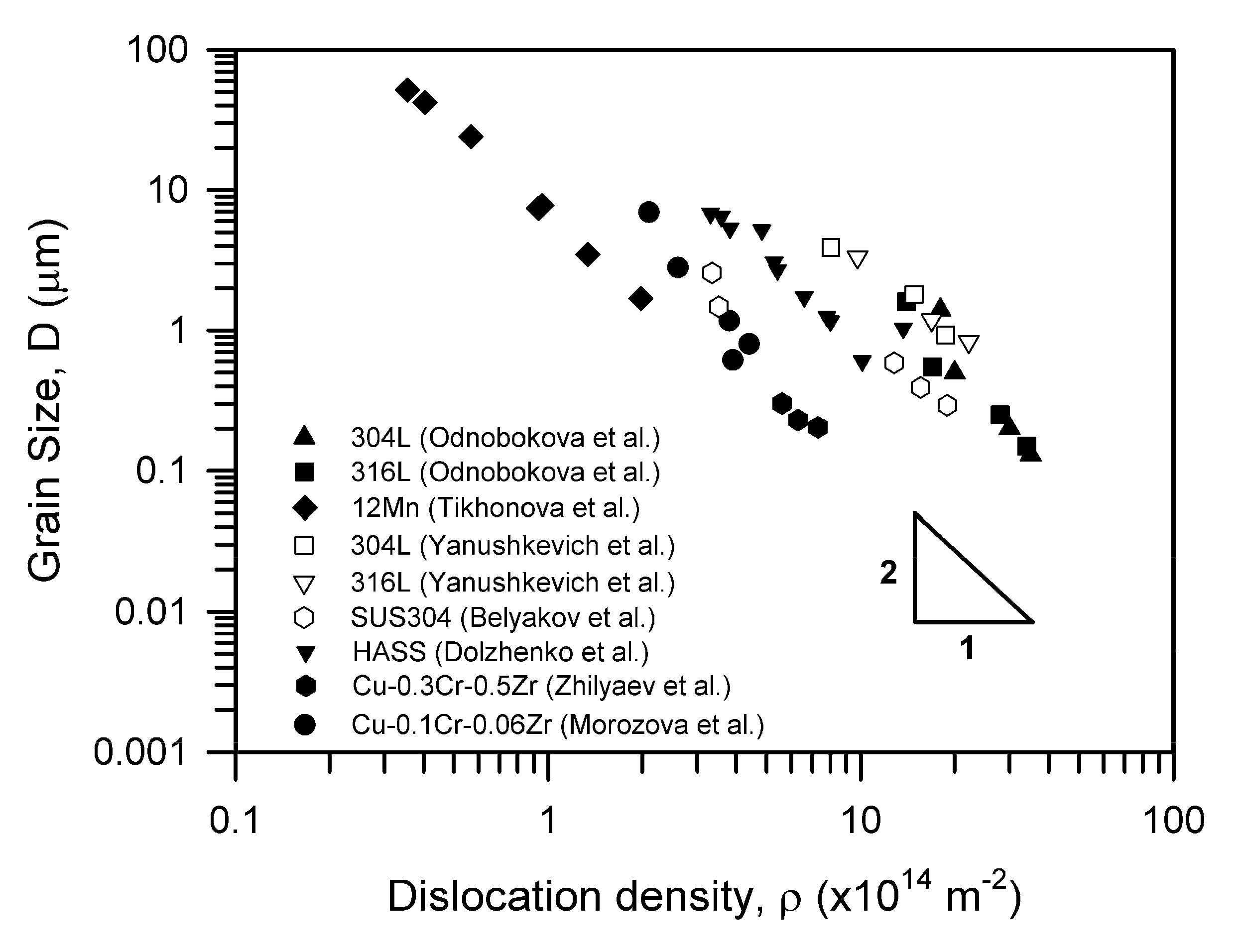

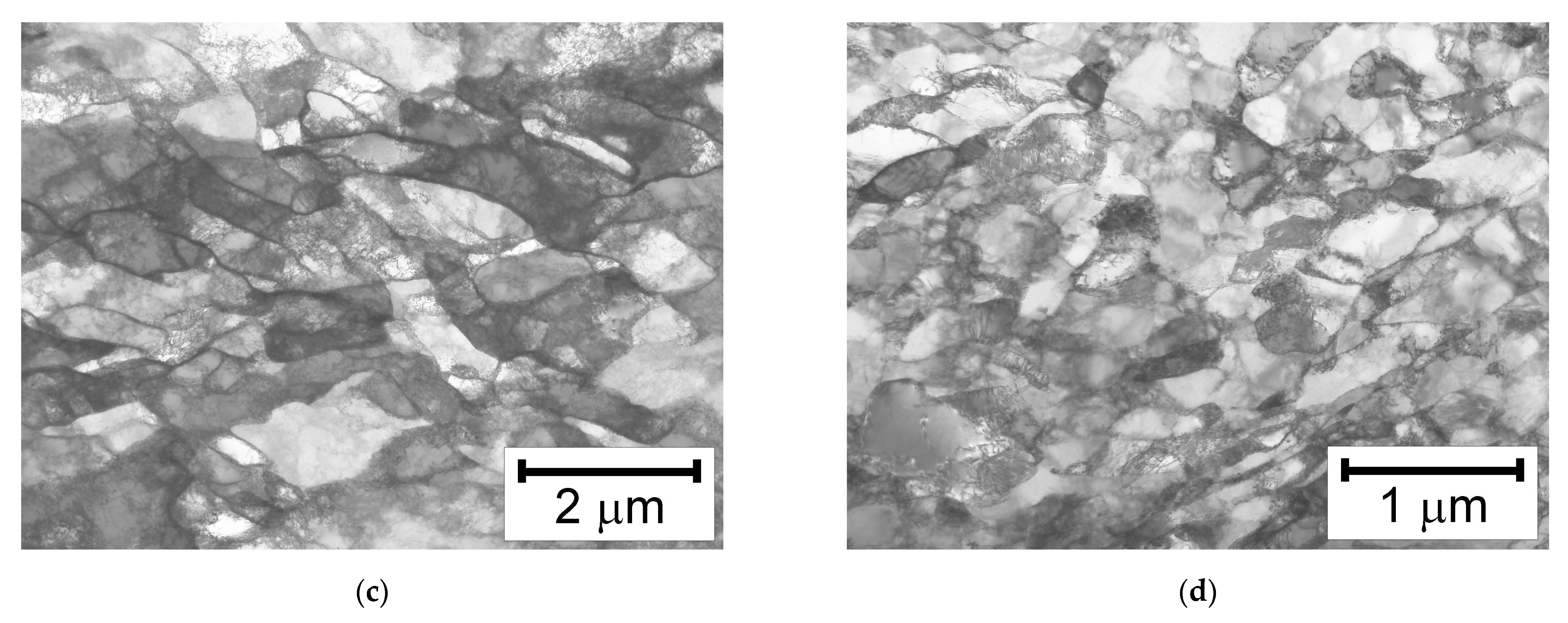

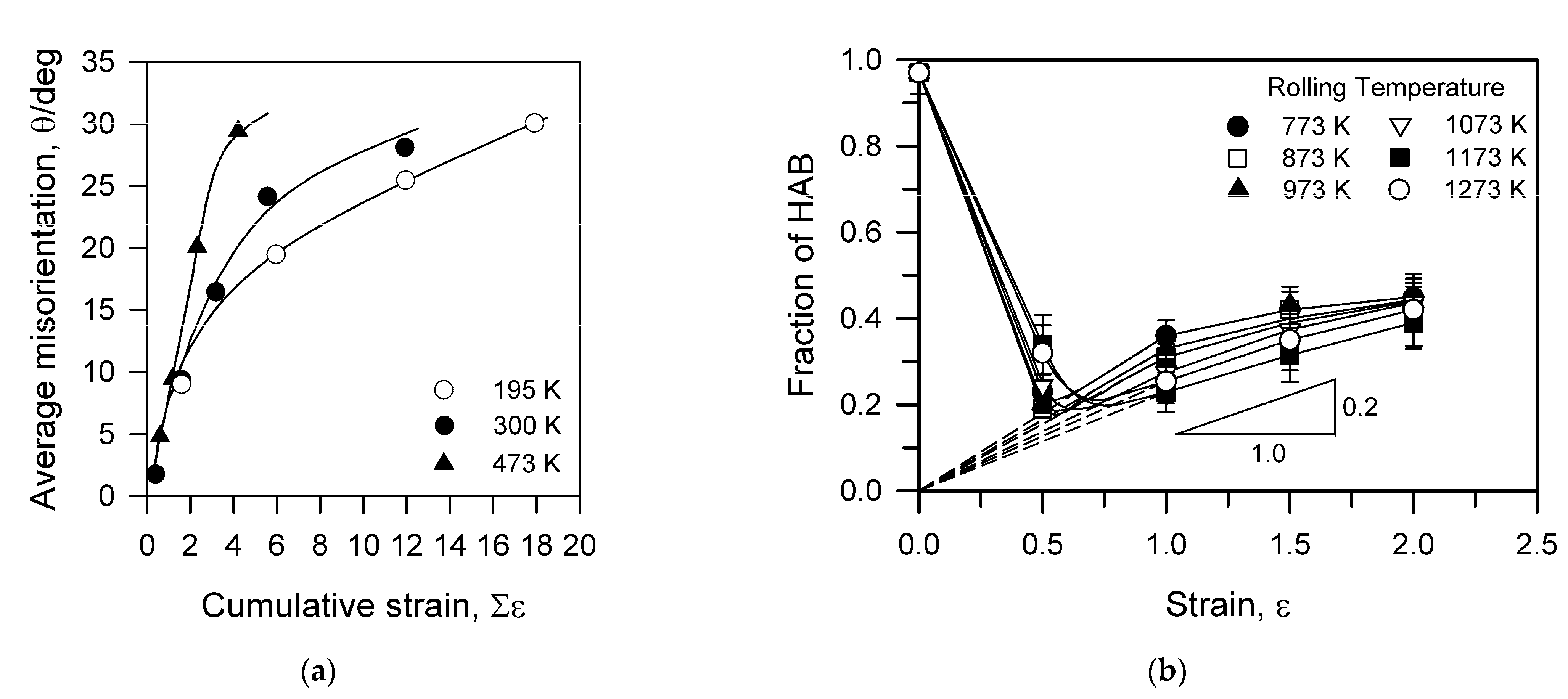

3.1. Grain Size

3.2. Dislocation Density

3.3. Varying the Strain Path

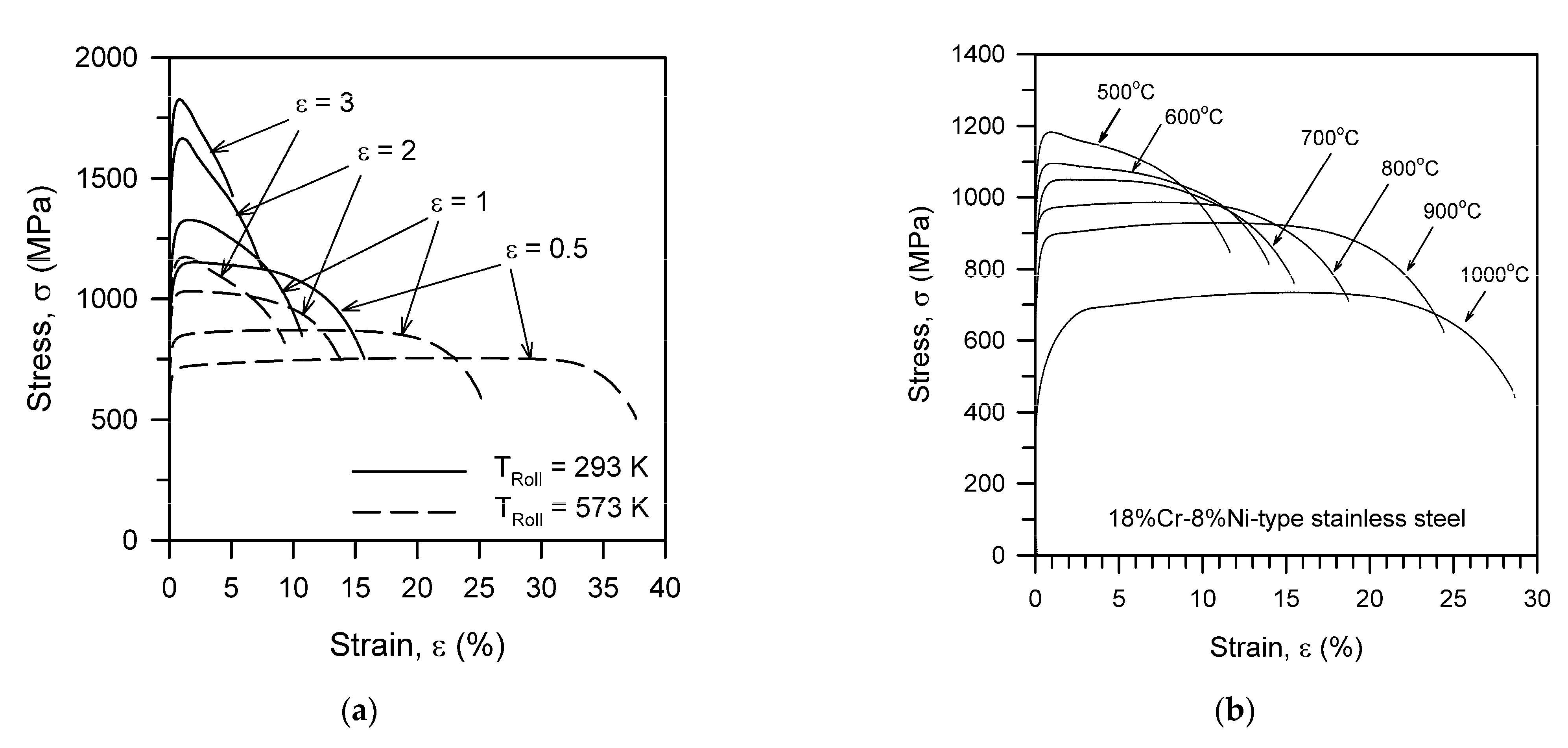

3.4. Temperature Effect

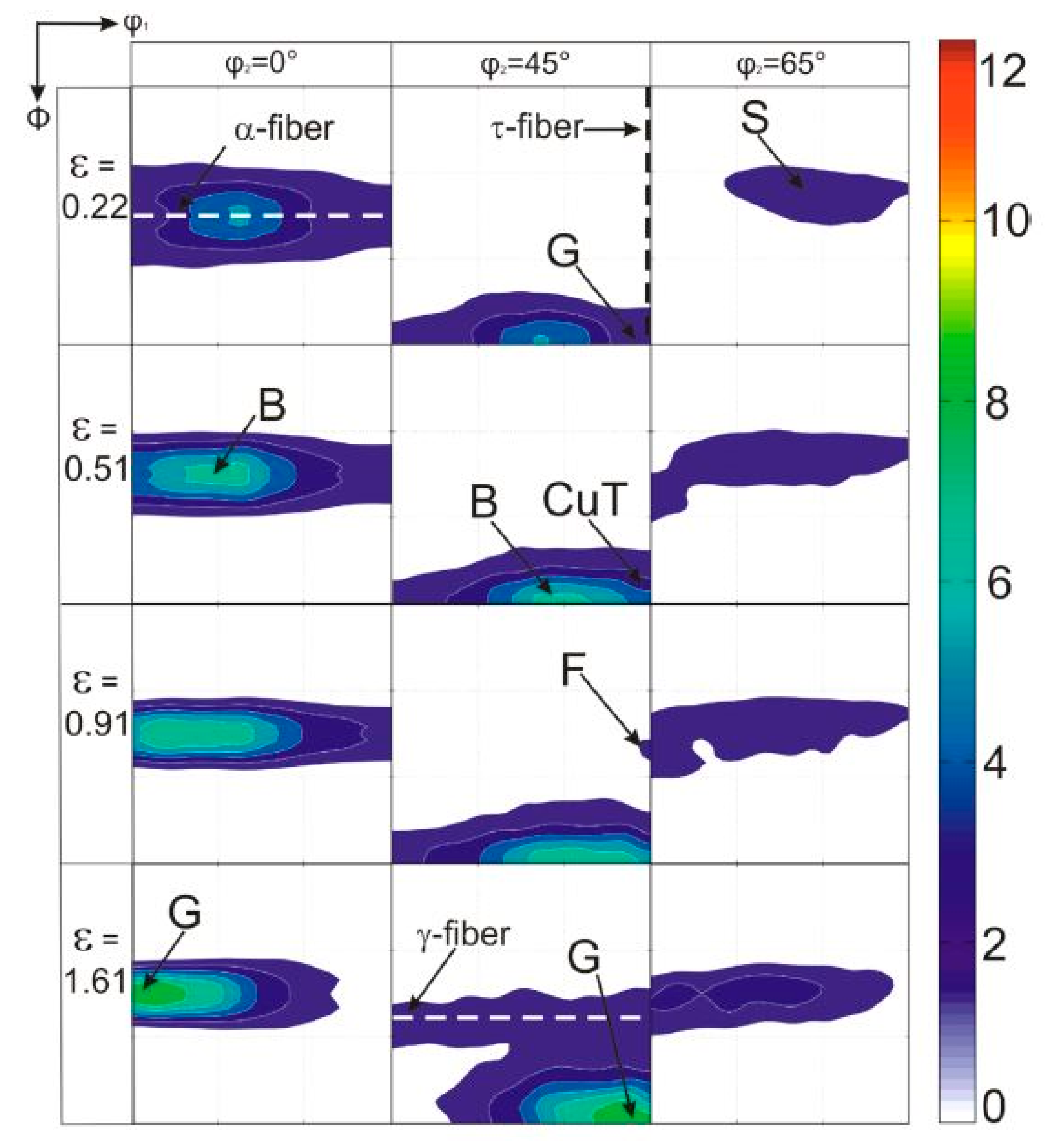

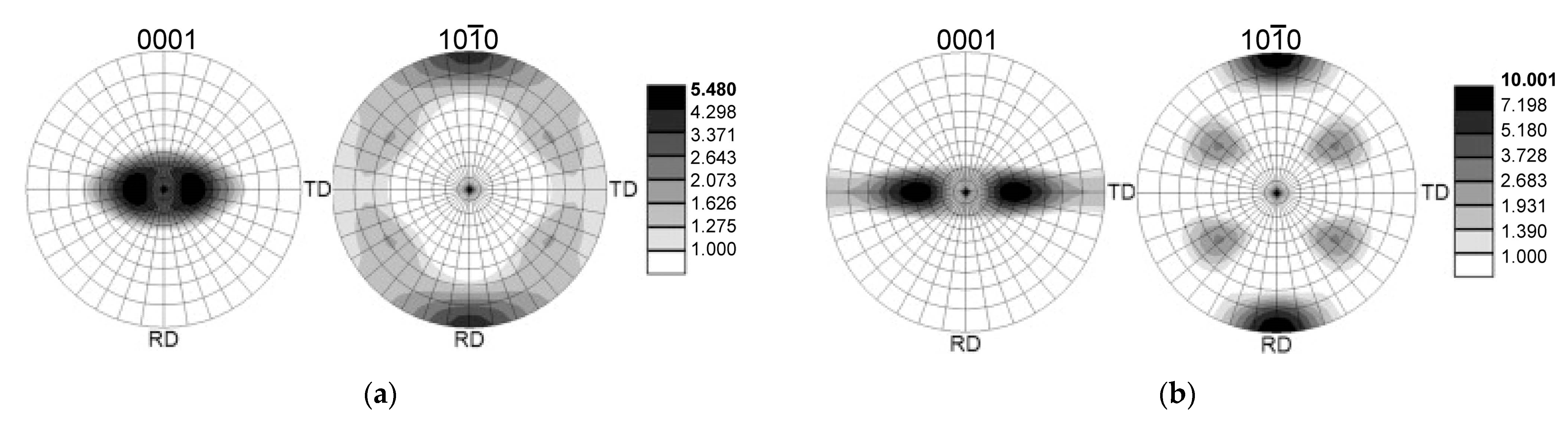

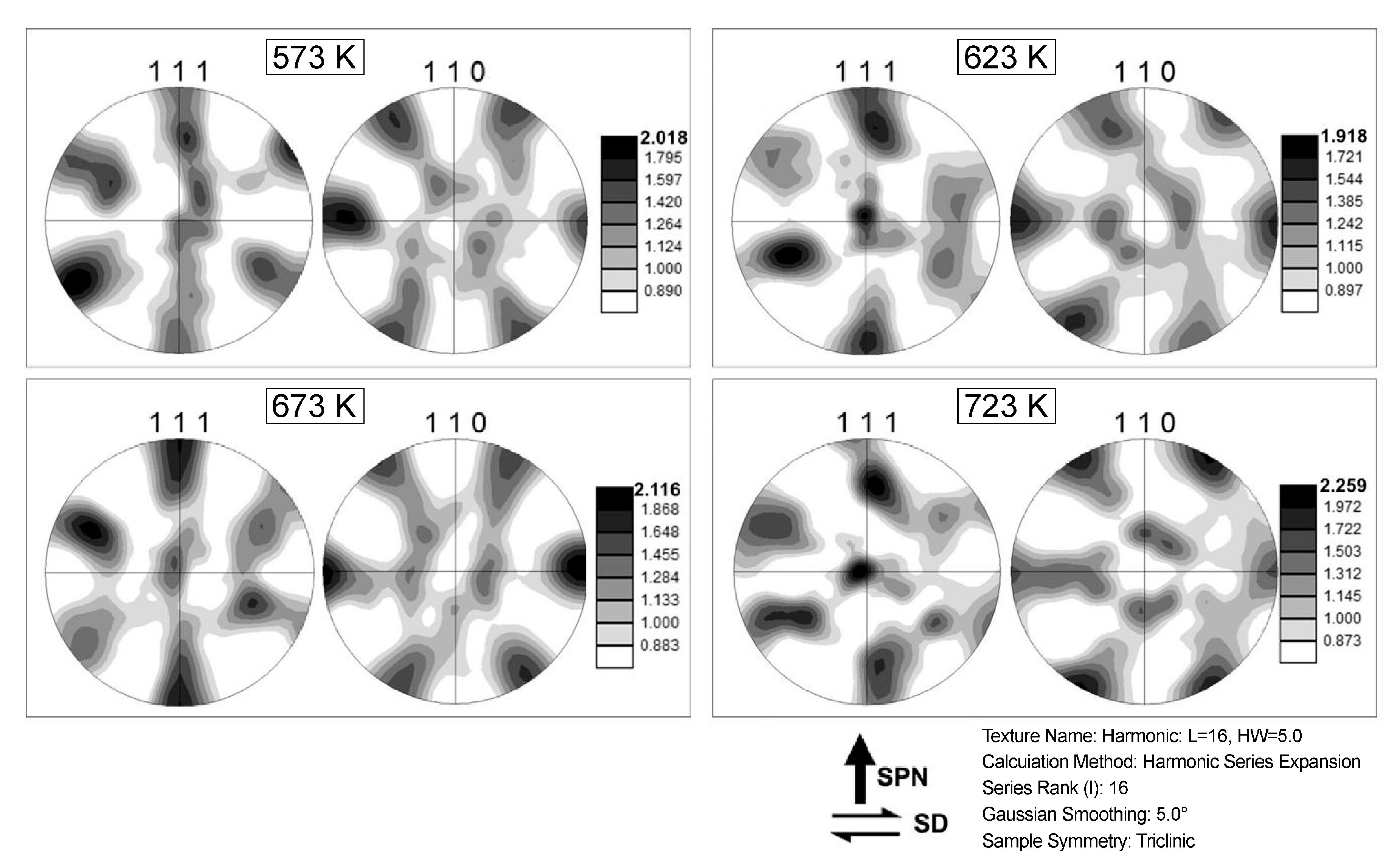

4. Deformation Texture

4.1. Conventional Processing

4.2. Severe Plastic Deformation

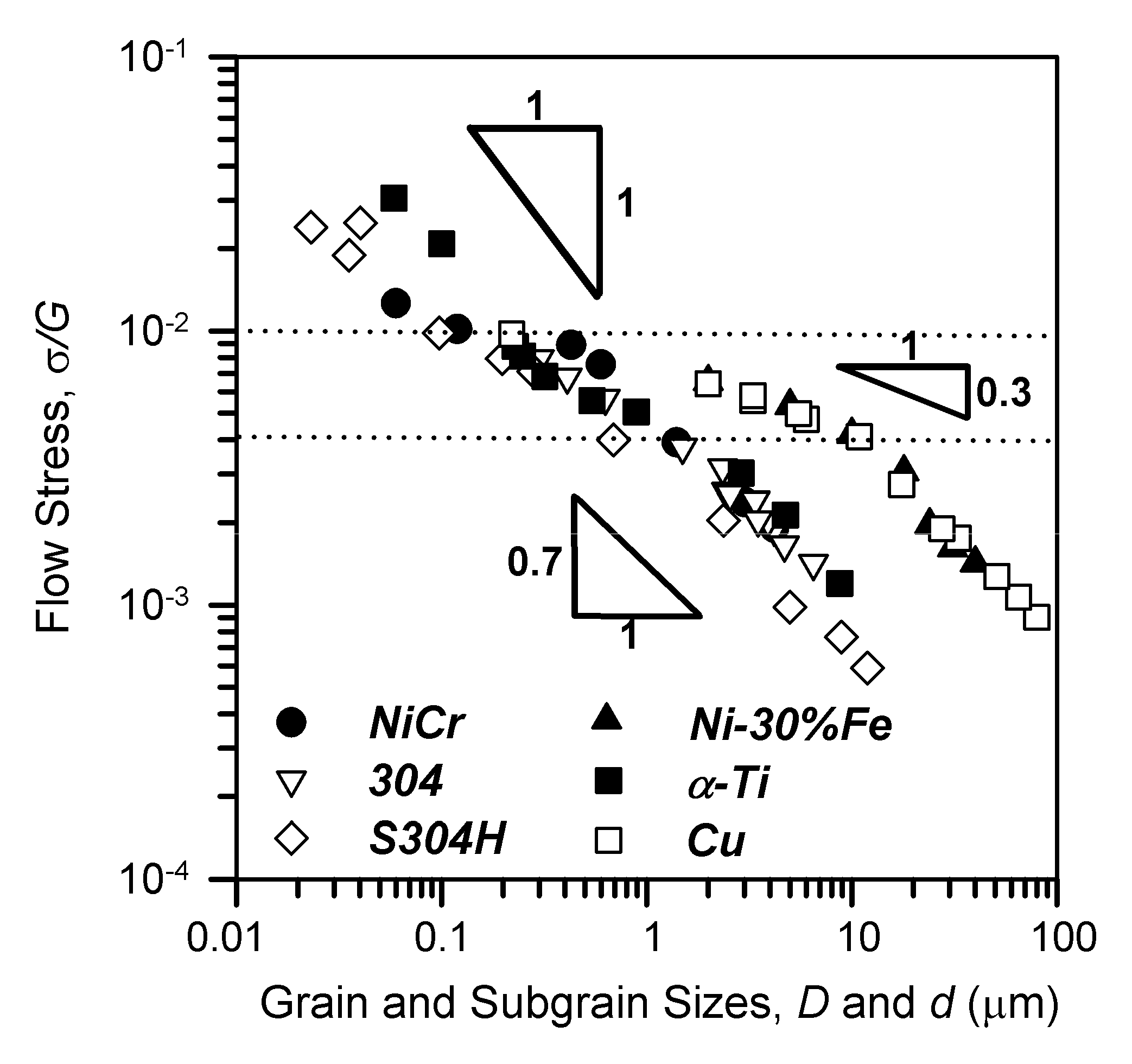

5. Mechanical Properties

6. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dieter, G.E. Mechanical Metallurgy; McGraw-Hill Book Company: New York, NY, USA, 1961; p. 615. [Google Scholar]

- Bernshtein, M.L. Thermomechanical Treatment of Metals and Alloys; Metallurgiya: Moscow, Russia, 1968; p. 1172. [Google Scholar]

- Zhao, J.; Jiang, Z. Thermomechanical processing of advanced high strength steels. Prog. Mater. Sci. 2018, 94, 174–242. [Google Scholar] [CrossRef]

- Leslie, C.; Hornbogen, E. Physical metallurgy of steels. In Physical Metallurgy; Cahn, R.W., Haasen, P., Eds.; Elsevier: Amsterdam, The Netherlands, 1996; pp. 1555–1620. [Google Scholar]

- Gil Sevilano, J.; van Houtte, P.; Aernoudt, A. Large strain work hardening and textures. Prog. Mater. Sci. 1981, 25, 69–412. [Google Scholar] [CrossRef]

- Zehetbauer, M. Cold work hardening in stages IV and V of F.C.C. metals—II. Model fits and physical results. Acta Metall. Mater. 1993, 41, 589–599. [Google Scholar] [CrossRef]

- Estrin, Y.; Vinogradov, A. Extreme grain refinement by severe plastic deformation: A wealth of challenging science. Acta Mater. 2013, 61, 782–817. [Google Scholar] [CrossRef]

- Vinogradov, A.; Yasnikov, I.S.; Matsuyama, H.; Uchida, M.; Kaneko, Y.; Estrin, Y. Controlling strength and ductility: Dislocation-based model of necking instability and its verification for ultrafine grain 316L steel. Acta Mater. 2016, 106, 295–303. [Google Scholar] [CrossRef]

- McQueen, H.J.; Jonas, J.J. Recovery and recrystallization during high temperature deformation. In Treatise on Materials Science and Technology; Arsenoult, R.J., Ed.; Academic Press: Cambridge, MA, USA, 1975; Volume 6, pp. 393–493. [Google Scholar] [CrossRef]

- Maki, T.; Akasaka, T.; Ohkuno, K.; Tamura, I. Dynamic recrystallization of austenite in 18-8 stainless steels and 18Ni maraging steel. Trans. Iron Steel Jpn. 1982, 22, 253–261. [Google Scholar] [CrossRef]

- Sakai, T.; Jonas, J.J. Dynamic recrystallization—Mechanical and microstructural considerations. Acta Metall. 1984, 32, 189–209. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena; Pergamon Press: Oxford, UK, 1996; p. 363. [Google Scholar]

- Belyakov, A.; Miura, H.; Sakai, T. Dynamic recrystallization under warm deformation of a 304 type austenitic stainless steel. Mater. Sci. Eng. A 1998, A255, 139–147. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Prangnell, P.B.; Bowen, J.R.; Gholinia, A.; Harris, C. Developing stable fine-grained microstructures by large strain deformation. Phil. Trans. R. Soc. Lond. 1999, 357, 1663–1681. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Islamgaliev, R.K.; Alexandrov, I.V. Bulk nanostructured materials from severe plastic deformation. Progr. Mat. Sci. 2000, 45, 103–189. [Google Scholar] [CrossRef]

- Segal, V.M.; Reznikov, V.I.; Drobyshevskiy, A.E.; Kopylov, V.I. Plastic metal working by simple shear. Russ. Metall. 1981, 1, 115–123. [Google Scholar]

- Saunders, I.; Nutting, J. Deformation of metals to high strains using combination of torsion and compression. Met. Sci. 1984, 18, 571–575. [Google Scholar] [CrossRef]

- Richert, J.; Richert, M. A new method for unlimited deformation of metals and alloys. Aluminium 1986, 62, 604–607. [Google Scholar]

- Saito, Y.; Tsuji, N.; Utsunomiya, H.; Sakai, T.; Hong, R.G. Ultra-fine grained bulk aluminum produced by accumulative roll-bonding (ARB) process. Scr. Mater. 1998, 39, 1221–1227. [Google Scholar] [CrossRef]

- Takaki, S.; Tsuchiyama, T.; Nakashima, K.; Hidaka, H.; Kawasaki, K.; Futamura, Y. Microstructure development of steel during severe plastic deformation. Met. Mater. Int. 2004, 10, 533–539. [Google Scholar] [CrossRef]

- Langdon, T.G.; Furukawa, M.; Nemoto, M.; Horita, Z. Using equal-channel angular pressing for refining grain size. JOM 2000, 52, 30–33. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Langdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Langdon, T.G. Using high-pressure torsion for metal processing: Fundamentals and applications. Prog. Mater. Sci. 2008, 53, 893–979. [Google Scholar] [CrossRef]

- Belyakov, A.; Sakai, T.; Miura, H. Fine-grained structure formation in austenitic stainless steel under multiple deformation at 0.5 Tm. Mater. Trans. JIM 2000, 41, 476–484. [Google Scholar] [CrossRef][Green Version]

- Belyakov, A.; Sakai, T.; Miura, H.; Tsuzaki, K. Grain refinement in copper under large strain deformation. Philos. Mag. A 2001, 81, 2629–2643. [Google Scholar] [CrossRef]

- Ivanisenko, Y.; Lojkowski, W.; Valiev, R.Z.; Fecht, H.-J. The mechanism of formation of nanostructure and dissolution of cementite in a pearlitic steel during high pressure torsion. Acta Mater. 2003, 51, 5555–5570. [Google Scholar] [CrossRef]

- Xu, C.; Furukawa, M.; Horita, Z.; Langdon, T.G. The evolution of homogeneity and grain refinement during equal-channel angular pressing: A model for grain refinement in ECAP. Mater. Sci. Eng. A 2005, A398, 66–76. [Google Scholar] [CrossRef]

- Raab, G.J.; Valiev, R.Z.; Lowe, T.C.; Zhu, Y.T. Continuous processing of ultrafine grained Al by ECAP–Conform. Mater. Sci. Eng. A 2004, A382, 30–34. [Google Scholar] [CrossRef]

- Tsuji, N.; Saito, Y.; Lee, S.-H.; Minamino, Y. ARB (Accumulative Roll-Bonding) and other new techniques to produce bulk ultrafine grained materials. Adv. Eng. Mater. 2003, 5, 338–344. [Google Scholar] [CrossRef]

- Zherebtsov, S.V.; Salishchev, G.A.; Galeyev, R.M. Formation of submicrocrystalline structure in titanium and its alloy under severe plastic deformation. Defect Diffus. Forum 2002, 208–209, 237–240. [Google Scholar] [CrossRef]

- Shrivastava, S.C.; Jonas, J.J.; Canova, G. Equivalent strain in large deformation testing: Theoretical and practical considerations. J. Mech. Phys. Solids 1982, 30, 75–90. [Google Scholar] [CrossRef]

- Kimura, Y.; Takaki, S. Microstructural changes during annealing of work-hardened mechanically milled metallic powders. Mater. Trans. JIM 1995, 36, 289–296. [Google Scholar] [CrossRef][Green Version]

- Koch, C.C. Synthesis of nanostructured materials by mechanical milling: Problems and opportunities. Nanostruct. Mater. 1997, 9, 13–22. [Google Scholar] [CrossRef]

- Huang, J.Y.; Zhu, Y.T.; Jiang, H.; Lowe, T.C. Microstructures and dislocation configurations in nanostructured Cu processed by repetitive corrugation and straightening. Acta Mater. 2001, 49, 1497–1505. [Google Scholar] [CrossRef]

- Suh, D.W.; Torizuka, S.; Ohmori, A.; Inoue, T.; Nagai, K. Dynamic restoration process of Ni–30Fe alloy during hot deformation. ISIJ Int. 2002, 42, 432–439. [Google Scholar] [CrossRef]

- Takayama, Y.; Miura, T.; Kato, H.; Watanabe, H. Microstructural and textural evolution by continuous cyclic bending and annealing in a high purity titanium. Mater. Trans. 2004, 45, 2826–2831. [Google Scholar] [CrossRef][Green Version]

- Toth, L.S.; Arzaghi, M.; Fundenberger, J.J.; Beausir, B.; Bouaziz, O.; Arruffat-Massion, R. Severe plastic deformation of metals by high-pressure tube twisting. Scr. Mater. 2009, 60, 175–177. [Google Scholar] [CrossRef]

- Wadsworth, J.; Sherby, O.D. On the bulat—Damascus steels revisited. Prog. Mater. Sci. 1980, 25, 35–68. [Google Scholar] [CrossRef]

- Salishchev, G.A.; Valiakhmetov, O.R.; Galeyev, R.M. Formation of submicrocrystalline structure in the titanium alloy VT8 and its influence on mechanical properties. J. Mater. Sci. 1993, 28, 2898–2902. [Google Scholar] [CrossRef]

- Belyakov, A.; Gao, W.; Miura, H.; Sakai, T. Strain induced grain evolution in polycrystalline copper during warm deformation. Metall. Mater. Trans. A 1998, 29A, 2957–2965. [Google Scholar] [CrossRef]

- Belyakov, A.; Kimura, Y.; Adachi, Y.; Tsuzaki, K. Microstructure evolution in ferritic stainless steels during large strain deformation. Mater. Trans. 2004, 45, 2812–2821. [Google Scholar] [CrossRef]

- Williams, D.B.; Carter, C.B. Transmission Electron Microscopy; Plenum Press: New York, NY, USA, 1996; p. 730. [Google Scholar]

- Belyakov, A.; Dudova, N.; Tikhonova, M.; Sakai, T.; Tsuzaki, K.; Kaibyshev, R. Dynamic recrystallization mechanisms operating under different processing conditions. Mater. Sci. Forum 2012, 706–709, 2704–2709. [Google Scholar] [CrossRef]

- Humphreys, F.J. Quantitative metallography by electron backscattered diffraction. J. Microsc. 1999, 195, 170–185. [Google Scholar] [CrossRef]

- Schwartz, A.J.; Kumar, M.; Adams, B.L.; Field, D.P. Electron. Backscatter Diffraction in Materials Science; Springer: New York, NY, USA, 2009; p. 406. [Google Scholar]

- Zisman, A.; Zolotorevsky, N.; Petrov, S.; Hlusova, E.; Yashina, E. Panoramic crys-tallographic analysis of structure evolution in low-carbon martensitic steel under tempering. Metal Sci. Heat Treat. 2018, 60, 142–149. [Google Scholar] [CrossRef]

- Calcagnotto, M.; Ponge, D.; Demir, E.; Raabe, D. Orientation gradients and geometrically necessary dislocations in ultrafine grained dual-phase steels studied by 2D and 3D EBSD. Mater. Sci. Eng. A 2010, A527, 2738–2746. [Google Scholar] [CrossRef]

- Konijnenberg, P.J.; Zaefferer, S.; Raabe, D. Assessment of geometrically necessary dislocation levels derived by 3D EBSD. Acta Mater. 2015, 99, 402–414. [Google Scholar] [CrossRef]

- Ermakova, N.Y.; Zolotorevsky, N.Y.; Titovets, Y.F. Quantitative X-ray analysis of deformation microtexture within individual grains. Mater. Sci. Forum 2005, 495–497, 983–988. [Google Scholar] [CrossRef]

- Sauvage, X.; Enikeev, N.; Valiev, R.; Nasedkina, Y.; Murashkin, M. Atomic-scale analysis of the segregation and precipitation mechanisms in a severely deformed Al–Mg alloy. Acta Mater. 2014, 72, 125–136. [Google Scholar] [CrossRef]

- Belyakov, A.; Tsuzaki, K.; Kimura, Y.; Kimura, Y.; Mishima, Y. Comparative study on microstructure evolution upon unidirectional and multidirectional cold working in an Fe—15%Cr ferritic alloy. Mater. Sci. Eng. A 2007, A456, 323–331. [Google Scholar] [CrossRef]

- Tikhonova, M.; Shakhova, I.; Kaibyshev, R.; Belyakov, A. Effect of SPD processing technique on grain refinement and properties of an austenitic stainless steel. Mater. Sci. Forum 2017, 879, 1957–1962. [Google Scholar] [CrossRef]

- Belyakov, A.; Tsuzaki, K.; Kimura, Y. Regularities of deformation microstructures in ferritic stainless steels during large strain cold working. ISIJ Int. 2008, 48, 1071–1079. [Google Scholar] [CrossRef]

- Sakai, T.; Belyakov, A.; Miura, H. Ultrafine grain refinement in ferritic stainless steel during severe plastic deformation. Metall. Mater. Trans. A 2008, 39A, 2206–2214. [Google Scholar] [CrossRef]

- Odnobokova, M.; Belyakov, A.; Kaibyshev, R. Effect of severe cold or warm deformation on microstructure evolution and tensile behavior of a 316L stainless steel. Adv. Eng. Mater. 2015, 17, 1812–1820. [Google Scholar] [CrossRef]

- Belyakov, A.; Murayama, M.; Sakai, Y.; Tsuzaki, K.; Okubo, M.; Eto, M.; Kimura, T. Development of a high-strength high-conductivity Cu-Ni-P alloy, Part II: Processing by severe deformation. J. Electr. Mater. 2006, 35, 2000–2008. [Google Scholar] [CrossRef]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef]

- Hornbogen, E.; Koster, U. Recrystallization of two-phase alloys. In Recrystallization of Metallic Materials; Haessner, F., Ed.; Riederer-Verlag GmbH: Stuttgart, Germany, 1978; pp. 159–194. [Google Scholar]

- Gardner, K.J.; Grimes, R. Recrystallization during hot deformation of aluminium alloys. Met. Sci. 1979, 13, 216–222. [Google Scholar] [CrossRef]

- Maki, T.; Okaguchi, S.; Tamura, I. Dynamic recrystallization in ferritic stainless steel. In Strength of Metals and Alloys (ICSMA 6); Gifkins, R.C., Ed.; Pergamon Press: Oxford, UK, 1982; pp. 529–534. [Google Scholar] [CrossRef]

- Belyakov, A.; Kaibyshev, R.; Sakai, T. New grain formation during warm deformation of ferritic stainless steel. Metall. Mater. Trans. A 1998, 29A, 161–167. [Google Scholar] [CrossRef]

- Galiev, A.; Kaibyshev, R.; Gottstein, G. Correlation of plastic deformation and dynamic recrystallization in magnesium alloy ZK60. Acta Mater. 2001, 49, 1199–1207. [Google Scholar] [CrossRef]

- Sitdikov, O.; Kaibyshev, R. Dynamic recrystallization in pure magnesium. Mater. Trans. 2001, 42, 1928–1937. [Google Scholar] [CrossRef]

- Rybin, V.V. Large Plastic Deformations and Destruction of Metals; Metallurgia: Moscow, Russia, 1987; p. 224. [Google Scholar] [CrossRef][Green Version]

- Tikhonova, M.; Kaibyshev, R.; Fang, X.; Wang, W.; Belyakov, A. Grain boundary assembles developed in an austenitic stainless steel during large strain warm working. Mater. Character 2012, 70, 14–20. [Google Scholar] [CrossRef]

- Tikhonova, M.; Belyakov, A.; Kaibyshev, R. Strain-induced grain evolution in an austenitic stainless steel under warm multiple forging. Mater. Sci. Eng. A 2013, A564, 413–422. [Google Scholar] [CrossRef]

- Shakhova, I.; Yanushkevich, Z.; Fedorova, I.; Belyakov, A.; Kaibyshev, R. Grain refinement in a Cu-Cr-Zr alloy during multidirectional forging. Mater. Sci. Eng. A 2014, A606, 380–389. [Google Scholar] [CrossRef]

- Kuhlmann-Wilsdorf, D.; Hansen, N. Geometrically necessary, incidental and subgrain boundaries. Scr. Metall. Mater. 1991, 25, 1557–1562. [Google Scholar] [CrossRef]

- Belyakov, A.; Kimura, Y.; Tsuzaki, K. Microstructure evolution in dual phase stainless steel during severe deformation. Acta Mater. 2006, 54, 2521–2532. [Google Scholar] [CrossRef]

- Yu, T.; Hansen, N.; Huang, X. Linking recovery and recrystallization through triple junction motion in aluminum cold rolled to a large strain. Acta Mater. 2013, 61, 6577–6586. [Google Scholar] [CrossRef]

- Renk, O.; Hohenwarter, A.; Wurster, S.; Pippan, R. Direct evidence for grain boundary motion as the dominant restoration mechanism in the steady-state regime of extremely cold-rolled copper. Acta Mater. 2014, 77, 401–410. [Google Scholar] [CrossRef] [PubMed]

- Toth, L.S.; Estrin, Y.; Lapovok, R.; Gu, C. A model of grain fragmentation based on lattice curvature. Acta Mater. 2010, 58, 1782–1794. [Google Scholar] [CrossRef]

- Belyakov, A.; Tsuzaki, K.; Miura, H.; Sakai, T. Effect of initial microstructures on grain refinement in a stainless steel by large strain deformation. Acta Mater. 2003, 51, 847–861. [Google Scholar] [CrossRef]

- Morozova, A.; Kaibyshev, R. Grain refinement and strengthening of a Cu–0.1Cr–0.06Zr alloy subjected to equal channel angular pressing. Philos. Mag. 2017, 97, 2053–2076. [Google Scholar] [CrossRef]

- Odnobokova, M.; Belyakov, A.; Enikeev, N.; Kaibyshev, R.; Valiev, R.Z. Microstructural changes and strengthening of austenitic stainless steels during rolling at 473 K. Metals 2020, 10, 1614. [Google Scholar] [CrossRef]

- Beladi, H.; Cizek, P.; Hodgson, P.D. Dynamic recrystallization of austenite in Ni-30 Pct Fe model alloy: Microstructure and texture evolution. Metall. Mater. Trans. A 2009, 40A, 1175–1189. [Google Scholar] [CrossRef]

- Dudova, N.; Belyakov, A.; Sakai, T.; Kaibyshev, R. Dynamic recrystallization mechanisms operating in a Ni–20%Cr alloy under hot-to-warm working. Acta Mater. 2010, 58, 3624–3632. [Google Scholar] [CrossRef]

- Belyakov, A.; Zherebtsov, S.; Salishchev, G. Three-stage relationship between flow stress and dynamic grain size in titanium in a wide temperature interval. Mater. Sci. Eng. A 2015, A628, 104–109. [Google Scholar] [CrossRef]

- Tikhonova, M.; Enikeev, N.; Valiev, R.Z.; Belyakov, A.; Kaibyshev, R. Submicrocrystalline Austenitic Stainless Steel Processed by Cold or Warm High Pressure Torsion. Mater. Sci. Forum 2016, 838–839, 398–403. [Google Scholar] [CrossRef]

- Gholizadeh, R.; Shibata, A.; Tsuji, N. Global view for grain refinement in ultra-low-C IF steel during high-strain deformation at various temperatures and strain rates. Materialia 2019, 6, 100262. [Google Scholar] [CrossRef]

- Young, C.M.; Sherby, O.D. Subgrain formation and subgrain-boundary strengthening in iron-based materials. J. Iron Steel Inst. 1973, 211, 640–647. [Google Scholar]

- Taylor, G.I. The mechanism of plastic deformation of crystals. Part I.—Theoretical. Proc. R. Soc. Lond. A 1934, 145, 362–387. [Google Scholar] [CrossRef]

- Hansen, N. Polycrystalline strengthening. Metall. Trans. A 1985, 16A, 2167–2190. [Google Scholar] [CrossRef]

- Hansen, N.; Huang, X. Microstructure and flow stress of polycrystals and single crystals. Acta Mater. 1998, 46, 1827–1836. [Google Scholar] [CrossRef]

- Mecking, H.; Kocks, U.F. Kinetics of flow and strain-hardening. Acta Metall. 1981, 29, 1865–1875. [Google Scholar] [CrossRef]

- Estrin, Y.; Mecking, H. A unified phenomenological description of work hardening and creep based on one-parameter models. Acta Metall. 1984, 32, 57–70. [Google Scholar] [CrossRef]

- Jonas, J.J.; Quelennec, X.; Jiang, L.; Martin, E. The Avrami kinetics of dynamic recrystallization. Acta Mater. 2009, 57, 2748–2756. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Shakhova, I.; Morozova, A.; Belyakov, A.; Kaibyshev, R. Grain refinement kinetics and strengthening mechanisms in Cu–0.3Cr–0.5Zr alloy subjected to intense plastic deformation. Mater. Sci. Eng. A 2016, A654, 131–142. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Korznikov, A.V.; Mulyukov, R.R. Structure and properties of ultrafine-grained materials produced by severe plastic deformation. Mater. Sci. Eng. A 1993, A168, 141–148. [Google Scholar] [CrossRef]

- Belyakov, A.; Sakai, T.; Miura, H.; Kaibyshev, R. Substructures and internal stresses developed under warm severe deformation of austenitic stainless steel. Scripta Mater. 2000, 42, 319–325. [Google Scholar] [CrossRef]

- Belyakov, A.; Sakai, T.; Miura, H.; Kaibyshev, R. Strain-induced submicrocrystalline grains developed in austenitic stainless steel under severe warm deformation. Philos. Mag. Lett. 2000, 80, 711–718. [Google Scholar] [CrossRef]

- Romanov, A.E.; Vladimirov, V.I. Disclinations in crystalline solids. In Dislocation in Solids; Nabarro, F.R.N., Ed.; Elsevier Science: Amsterdam, The Netherlands, 1992; Volume 9, pp. 191–402. [Google Scholar]

- Rybin, V.V.; Zisman, A.A.; Zolotorevsky, N.Y. Junction disclinations in plastically deformed crystals. Acta Mater. 1993, 41, 2211–2217. [Google Scholar] [CrossRef]

- Zisman, A. Model for partitioning slip patterns at triple junctions of grains. Int. J. Eng. Sci. 2017, 116, 155–164. [Google Scholar] [CrossRef]

- Belyakov, A.; Sakai, T.; Miura, H.; Kaibyshev, R. Grain refinement under multiple warm deformation in 304 type austenitic stainless steel. ISIJ Int. 1999, 39, 592–599. [Google Scholar] [CrossRef]

- Yanushkevich, Z.; Dobatkin, S.V.; Belyakov, A.; Kaibyshev, R. Hall-Petch relationship for austenitic stainless steels processed by large strain warm rolling. Acta Mater. 2017, 136, 39–48. [Google Scholar] [CrossRef]

- Morozova, A.; Mishnev, R.; Belyakov, A.; Kaibyshev, R. Microstructure and properties of fine grained Cu-Cr-Zr alloys after thermo-mechanical treatments. Rev. Adv. Mater. Sci. 2018, 54, 56–92. [Google Scholar] [CrossRef]

- Tikhonova, M.; Torganchuk, V.; Brasche, F.; Molodov, D.A.; Belyakov, A.; Kaibyshev, R. Effect of warm to hot rolling on microstructure, texture and mechanical properties of an advanced medium-Mn steel. Metall. Mater. Trans. A 2019, 50A, 4245–4256. [Google Scholar] [CrossRef]

- Dolzhenko, P.; Tikhonova, M.; Kaibyshev, R.; Belyakov, A. Peculiarities of DRX in a highly-alloyed austenitic stainless steel. Materials 2021, 14, 4004. [Google Scholar] [CrossRef]

- Tsuji, N.; Ueji, R.; Minamino, Y.; Saito, Y. A new and simple process to obtain nano-structured bulk low-carbon steel with superior mechanical property. Scr. Mater. 2002, 46, 305–310. [Google Scholar] [CrossRef]

- Korshunov, A.A.; Enikeev, F.U.; Mazurski, M.I.; Salishchev, G.A.; Dmitriev, O.V.; Muravlev, A.V.; Chistyakov, P.V. Grain-structure refinement in titanium alloy under different loading schedules. J. Mater. Sci. 1996, 31, 4635–4639. [Google Scholar] [CrossRef]

- Goloborodko, A.; Sitdikov, O.; Kaibyshev, R.; Miura, H.; Sakai, T. Effect of pressing temperature on fine-grained structure formation in 7475 aluminum alloy during ECAP. Mater. Sci. Eng. A 2004, A381, 121–128. [Google Scholar] [CrossRef]

- Narayana Murty, S.V.S.; Torizuka, S.; Nagai, K. Ferrite grain size formed by large strain-high Z deformation in a 0.15C steel. Mater. Trans. 2005, 46, 2454–2460. [Google Scholar] [CrossRef][Green Version]

- Iwahashi, Y.; Horita, Z.; Nemoto, M.; Langdon, T.G. An investigation of microstructural evolution during equal-channel angular pressing. Acta Mater. 1997, 45, 4733–4741. [Google Scholar] [CrossRef]

- Iwahashi, Y.; Horita, Z.; Nemoto, M.; Langdon, T.G. The process of grain refinement in equal-channel angular pressing. Acta Mater. 1998, 46, 3317–3331. [Google Scholar] [CrossRef]

- Tikhonova, M.; Dolzhenko, P.; Kaibyshev, R.; Belyakov, A. Grain boundary assemblies in dynamically-recrystallized austenitic stainless steel. Metals 2016, 6, 268. [Google Scholar] [CrossRef]

- Jafari, M.; Najafizadeh, A. Correlation between Zener-Hollomon parameter and necklace DRX during hot deformation of 316 stainless steel. Mater. Sci. Eng. A 2009, A501, 16–25. [Google Scholar] [CrossRef]

- Beladi, H.; Cizek, P.; Hodgson, P.D. On the characteristics of substructure development through dynamic recrystallization. Acta Mater. 2010, 58, 3531–3541. [Google Scholar] [CrossRef]

- Belyakov, A.; Tikhonova, M.; Yanushkevich, Z.; Kaibyshev, R. Regularities of grain refinement in an austenitic stainless steel during multiple warm working. Mater. Sci. Forum 2013, 753, 411–416. [Google Scholar] [CrossRef]

- Yanushkevich, Z.; Lugovskaya, A.; Belyakov, A.; Kaibyshev, R. Deformation microstructures and tensile properties of an austenitic stainless steel subjected to multiple warm rolling. Mater. Sci. Eng. A 2016, A667, 279–285. [Google Scholar] [CrossRef]

- Dolzhenko, A.; Pydrin, A.; Gaidar, S.; Kaibyshev, R.; Belyakov, A. Microstructure and strengthening mechanisms in an hsla steel subjected to tempforming. Metals 2022, 12, 48. [Google Scholar] [CrossRef]

- Ryan, N.D.; McQueen, H.J.; Jonas, J.J. The deformation behavior of types 304, 316, and 317 austenitic stainless steels during hot torsion. Can. Metall. Q. 1983, 22, 369–378. [Google Scholar] [CrossRef]

- Ryan, N.D.; McQueen, H.J. Dynamic softening mechanisms in 304 austenitic stainless steel. Can. Metall. Q. 1990, 29, 147–162. [Google Scholar] [CrossRef]

- Tikhonova, M.; Kaibyshev, R.; Belyakov, A. Microstructure and mechanical properties of austenitic stainless steels after dynamic and post-dynamic recrystallization treatment. Adv. Eng. Mater. 2018, 20, 1700960. [Google Scholar] [CrossRef]

- Bay, B.; Hansen, N.; Hughes, D.A.; Kuhlmann-Wilsdorf, D. Evolution of f.c.c. deformation structures in polyslip. Acta Metall. Mater. 1992, 40, 205–219. [Google Scholar] [CrossRef]

- Kobayashi, C.; Sakai, T.; Belyakov, A.; Miura, H. Ultrafine grain development in copper during multi-directional forging at 195 K. Philos. Mag. Lett. 2007, 87, 751–766. [Google Scholar] [CrossRef]

- Tsuzaki, K.; Xiaoxu, H.; Maki, T. Mechanism of dynamic continuous recrystallization during superplastic deformation in a microduplex stainless steel. Acta Mater. 1996, 44, 4491–4499. [Google Scholar] [CrossRef]

- Qing, L.; Xiaoxu, H.; Mei, Y.; Jinfeng, Y. On deformation-induced continuous recrystallization in a superplastic AlLiCuMgZr alloy. Acta Metall. Mater. 1992, 40, 1753–1762. [Google Scholar] [CrossRef]

- Yanushkevich, Z.; Belyakov, A.; Kaibyshev, R. Microstructural evolution of a 304-type austenitic stainless steel during rolling at temperatures of 773–1273 K. Acta Mater. 2015, 82, 244–254. [Google Scholar] [CrossRef]

- Sakai, T.; Miura, H. Ultrafine grain formation in aluminum alloys during hot severe plastic deformation. Mater. Sci. Forum 2012, 706–709, 1829–1834. [Google Scholar] [CrossRef]

- Blum, W.; Zhu, Q.; Markel, R.; McQueen, H.J. Geometric dynamic recrystallization in hot torsion of Al–5Mg–0.6Mn (AA5083). Mater. Sci. Eng. A 1996, A205, 23–30. [Google Scholar] [CrossRef]

- Hirsch, J.; Lucke, K. Mechanism of deformation and development of rolling textures in polycrystalline f.c.c. metals—I. Description of rolling texture development in homogeneous CuZn alloys. Acta Metall. Mater. 1988, 36, 2863–2882. [Google Scholar] [CrossRef]

- Hirsch, J.; Lucke, K.; Hatherly, M. Mechanism of deformation and development of rolling textures in polycrystalline f.c.c. metals—III. The influence of slip inhomogeneities and twinning. Acta Metall. Mater. 1988, 36, 2905–2927. [Google Scholar] [CrossRef]

- Konkova, T.; Mironov, S.; Korznikov, A.; Semiatin, S.L. Structural response of pure copper to cryogenic rolling. Acta Mater. 2010, 58, 5262–5273. [Google Scholar] [CrossRef]

- Haase, C.; Barrales-Mora, L.A.; Roters, F.; Molodov, D.A.; Gottstein, G. Applying the texture analysis for optimizing thermomechanical treatment of high manganese twinning-induced plasticity steel. Acta Mater. 2014, 80, 327–340. [Google Scholar] [CrossRef]

- Konkova, T.; Mironov, S.; Korznikov, A.V.; Korznikova, G.; Myshlyaev, M.M.; Semiatin, S.L. Grain structure evolution during cryogenic rolling of alpha brass. J. All. Comp. 2015, 629, 140–147. [Google Scholar] [CrossRef]

- Odnobokova, M.; Belyakov, A.; Kaibyshev, R. Grain refinement and strengthening of austenitic stainless steels during large strain cold rolling. Philos. Mag. 2019, 99, 531–556. [Google Scholar] [CrossRef]

- Yanushkevich, Z.; Belyakov, A.; Haase, C.; Molodov, D.A.; Kaibyshev, R. Structural/textural changes and strengthening of an advanced high-Mn steel subjected to cold rolling. Mater. Sci. Eng. A 2016, A651, 763–773. [Google Scholar] [CrossRef]

- Ray, R.K.; Jonas, J.J.; Hook, R.E. Cold rolling and annealing textures in low carbon and extra low carbon steels. Int. Mater. Rev. 1994, 39, 129–172. [Google Scholar] [CrossRef]

- Wenk, H.-R.; Houtte, P.V. Texture and anisotropy. Rep. Prog. Phys. 2004, 67, 1367–1428. [Google Scholar] [CrossRef]

- Kestens, L.A.I.; Pirgazi, H. Texture formation in metal alloys with cubic crystal structures. Mater. Sci. Technol. 2016, 32, 1303–1315. [Google Scholar] [CrossRef]

- Zherebtsov, S.V.; Dyakonov, G.S.; Salem, A.A.; Malysheva, S.P.; Salishchev, G.A.; Semiatin, S.L. Evolution of grain and subgrain structure during cold rolling of commercial-purity titanium. Mater. Sci Eng. A 2011, A528, 3474–3479. [Google Scholar] [CrossRef]

- Dyakonov, G.S.; Mironov, S.; Zherebtsov, S.V.; Malysheva, S.P.; Salishchev, G.A.; Salem, A.A.; Semiatin, S.L. Grain-structure development in heavily cold-rolled alpha-titanium. Mater. Sci. Eng. A 2014, A607, 145–154. [Google Scholar] [CrossRef]

- Zherebtsov, S.V.; Dyakonov, G.S.; Salishchev, G.A.; Salem, A.A.; Semiatin, S.L. The influence of grain size on twinning and microstructure refinement during cold rolling of commercial-purity titanium. Metall. Mat. Trans. A 2016, 47A, 5101–5113. [Google Scholar] [CrossRef]

- Li, S.; Beyerlein, I.J.; Bourke, M.A.M. Texture formation during equal channel angular extrusion of fcc and bcc materials: Comparison with simple shear. Mater. Sci. Eng. A 2005, A394, 66–77. [Google Scholar] [CrossRef]

- Beyerlein, I.J.; Tóth, L.S. Texture evolution in equal-channel angular extrusion. Prog. Mater. Sci. 2009, 54, 427–510. [Google Scholar] [CrossRef]

- Kulitskiy, V.; Malopheyev, S.; Mironov, S.; Kaibyshev, R. Grain refinement in an Al-Mg-Sc alloy: Equal channel angular pressing versus friction-stir processing. Mater. Sci. Eng. A 2016, A674, 480–490. [Google Scholar] [CrossRef]

- Li, S.; Gazder, A.A.; Beyerlein, I.J.; Pereloma, E.V.; Davies, C.H.J. Effect of processing route on microstructure and texture development in equal channel angular extrusion of interstitial-free steel. Acta Mater. 2006, 54, 1087–1100. [Google Scholar] [CrossRef]

- Yanushkevich, Z.; Mogucheva, A.; Tikhonova, M.; Belyakov, A.; Kaibyshev, R. Structural strengthening of an austenitic stainless steel subjected to warm-to-hot working. Mater. Charact. 2011, 62, 432–437. [Google Scholar] [CrossRef]

- Dyakonov, G.S.; Mironov, S.; Semenova, I.P.; Valiev, R.Z.; Semiatin, S.L. Microstructure evolution and strengthening mechanisms in commercial purity titanium subjected to equal channel angular pressing. Mater. Sci. Eng. A 2017, A701, 289–301. [Google Scholar] [CrossRef]

- Zherebtsov, S.; Yurchenko, N.; Shaysultanov, D.; Tikhonovsky, M.; Salishchev, G.; Stepanov, N. Microstructure and mechanical properties evolution in HfNbTaTiZr refractory high-entropy alloy during cold rolling. Adv. Eng. Mater. 2020, 22, 2000105. [Google Scholar] [CrossRef]

- Belyakov, A.; Tikhonova, M.; Dolzhenko, P.; Sakai, T.; Kaibyshev, R. On kinetics of grain refinement and strengthening by dynamic recrystallization. Adv. Eng. Mater. 2019, 21, 1800104. [Google Scholar] [CrossRef]

- Dolzhenko, P.; Tikhonova, M.; Sakai, T.; Belyakov, A.; Kaibyshev, R. Dynamic recrystallization in austenitic stainless steel during hot working with decreasing deformation temperature. Mater. Perform. Charact. 2019, 8, 808–820. [Google Scholar] [CrossRef]

- Torganchuk, V.; Vysotskiy, I.; Malopheyev, S.; Mironov, S.; Kaibyshev, R. Microstructure evolution and strengthening mechanisms in friction-stir welded TWIP steel. Mater. Sci. Eng. A 2019, A746, 248–258. [Google Scholar] [CrossRef]

- Hall, E.O. The deformation and ageing of mild steel: III Discussion of results. Proc. Phys. Soc. B 1951, 64, 747. [Google Scholar] [CrossRef]

- Petch, N.J. The cleavage strength of polycrystals. J. Iron Steel Inst. 1953, 174, 25–28. [Google Scholar]

- Schneibel, J.H.; Heilmaier, M. Hall-Petch breakdown at elevated temperatures. Mater. Trans. 2014, 55, 44–51. [Google Scholar] [CrossRef]

- Belyakov, A.; Odnobokova, M.; Shakhova, I.; Kaibyshev, R. Regularities of microstructure evolution and strengthening mechanisms of austenitic stainless steels subjected to large strain cold working. Mater. Sci. Forum 2017, 879, 224–229. [Google Scholar] [CrossRef]

- Takaki, S.; Akama, D.; Nakada, N.; Tsuchiyama, T. Effect of grain boundary segregation of interstitial elements on Hall–Petch coefficient in steels. Mater. Trans. 2014, 55, 28–34. [Google Scholar] [CrossRef]

- Thompson, A.W. Substructure strengthening mechanisms. Metall. Trans. A 1977, 8A, 833–842. [Google Scholar] [CrossRef]

- Estrin, Y.; Toth, L.S.; Molinari, A.; Brechet, Y. A dislocation density model for all hardening stages in large strain deformation. Acta Mater. 1998, 46, 5509–5522. [Google Scholar] [CrossRef]

- Miller, A.K.; Sherby, O.D. On subgrain strengthening at high and low temperatures. Scr. Metall. 1976, 10, 311–317. [Google Scholar] [CrossRef]

- Abson, D.J.; Jonas, J.J. The Hall-Petch relation and high-temperature subgrains. Met. Sci. J. 1979, 4, 24–28. [Google Scholar] [CrossRef]

- Hughes, D.A.; Hansen, N. Microstructure and strength of nickel at large strains. Acta Mater. 2000, 48, 2985–3004. [Google Scholar] [CrossRef]

- Hansen, N. Hall–Petch relation and boundary strengthening. Scr. Mater. 2004, 51, 801–806. [Google Scholar] [CrossRef]

- Harrell, T.J.; Topping, T.D.; Wen, H.; Hu, T.; Schoenung, J.M.; Lavernia, E.J. Microstructure and strengthening mechanisms in an ultrafine grained Al-Mg-Sc alloy produced by powder metallurgy. Metall. Mater. Trans. A 2014, 45A, 6329–6343. [Google Scholar] [CrossRef]

- Tanaka, Y.; Takaki, S.; Tsuchiyama, T.; Uemori, R. Effect of grain size on the yield stress of cold worked iron. ISIJ Int. 2018, 58, 1927–1933. [Google Scholar] [CrossRef]

- Starink, M.J. Dislocation versus grain boundary strengthening in SPD processed metals: Non-causal relation between grain size and strength of deformed polycrystals. Mater. Sci. Eng. A 2017, A705, 42–46. [Google Scholar] [CrossRef]

- Dolzhenko, A.; Kaibyshev, R.; Belyakov, A. Tempforming as an advanced processing method for carbon steels. Metals 2020, 10, 1566. [Google Scholar] [CrossRef]

- Mukherjee, J.K. Thermomechanical ausforming technique for producing substitute ultra high strength steels. In Proceedings of the Symposium on Metallurgy of Substitute Ferrous & Non-Ferrous Alloys, Jamshedpur, India, 27–30 April 1966; National Metallurgy Laboratory: Jamshedpur, India, 1966; pp. 156–161. Available online: http://eprints.nmlindia.org/3137 (accessed on 2 February 2022).

- Schaller, F.W.; Schmatz, D.J. The inheritance of defects by martensite. Acta Metall. 1963, 11, 1193–1194. [Google Scholar] [CrossRef]

- Kimura, Y.; Inoue, T.; Yin, F.; Tsuzaki, K. Inverse temperature dependence of toughness in an ultrafine grain-structure steel. Science 2008, 320, 1057–1060. [Google Scholar] [CrossRef]

- Kimura, Y.; Inoue, T. Mechanical property of ultrafine elongated grain structure steel processed by warm tempforming and its application to ultra-high-strength bolt. ISIJ Int. 2020, 60, 1108–1126. [Google Scholar] [CrossRef]

- Dolzhenko, A.; Yanushkevich, Z.; Nikulin, S.A.; Belyakov, A.; Kaibyshev, R. Impact toughness of an S700MC-type steel: Tempforming vs ausforming. Mater. Sci. Eng. A 2018, A723, 259–268. [Google Scholar] [CrossRef]

- Dolzhenko, A.; Yanushkevich, Z.; Kopteva, K.; Belyakov, A.; Kaibyshev, R. Effect of tempforming temperature on the microstructure and mechanical properties of a high-strength low-carbon steel. In Proceedings of the International Conference on Metallurgy and Materials, Conference Proceedings, Brno, Czech Republic, 22–24 May 2019; pp. 632–637. [Google Scholar] [CrossRef]

- Dolzhenko, A.S.; Dolzhenko, P.D.; Belyakov, A.N.; Kaibyshev, R.O. Microstructure and impact toughness of high-strength low-alloy steel after tempforming. Phys. Met. Metallogr. 2021, 122, 1014–1022. [Google Scholar] [CrossRef]

- Kaibyshev, O.A. Superplasticity of Alloys, Intermetallics and Ceramics; Springer: Berlin, Germany, 1992; p. 317. [Google Scholar] [CrossRef]

- Zherebtsov, S.V.; Kudryavtsev, E.A.; Salishchev, G.A.; Straumal, B.B.; Semiatin, S.L. Microstructure evolution and mechanical behavior of ultrafine Ti-6Al-4V during low-temperature superplastic deformation. Acta Mater. 2016, 121, 152–163. [Google Scholar] [CrossRef]

- Higashi, K. Positive exponent superplasticity in advanced aluminum alloys with nano or near-nano scale grained structures. Mater. Sci. Eng. A 1993, A166, 109–118. [Google Scholar] [CrossRef]

| Component | {hkl} <uvw> | Euler Angles | ||

|---|---|---|---|---|

| φ1 | Φ | φ2 | ||

| Brass (B) | {111}<112> | 55 | 90 | 45 |

| Goss (G) | {011}<100> | 90 | 90 | 45 |

| S | {123}<634> | 59 | 37 | 63 |

| Copper (Cu) | {112}<111> | 90 | 35 | 45 |

| Rotated Goss (RtG) | {011}<110> | 0 | 90 | 45 |

| E | {111}<110> | 0/60 | 55 | 45 |

| F | {111}<211> | 30/90 | 55 | 45 |

| ζ-fiber | <110> parallel to ND | |||

| γ-fiber | <111> parallel to ND | |||

| τ-fiber | <110> parallel to TD | |||

| Component | {hkl} <uvw> | Euler Angles | ||

|---|---|---|---|---|

| φ1 | Φ | φ2 | ||

| Cube (C) | {001}<100> | 45 | 0 | 45 |

| Rotated cube (H) | {001}<110> | 0/90 | 0 | 45 |

| I* | {223}<110> | 0 | 43 | 45 |

| E | {111}<110> | 0/60 | 55 | 45 |

| F | {111}<211> | 30/90 | 55 | 45 |

| Goss (G) | {110}<001> | 90 | 90 | 45 |

| η-fiber | <001> parallel to ND | |||

| α-fiber | <110> parallel to RD | |||

| γ-fiber | <111> parallel to ND | |||

| Notation | {hkl} <uvw> | Euler Angles | ||

|---|---|---|---|---|

| φ1 | Φ | φ2 | ||

| A1* | (1 1 1) [ 2] | 35.26/215.26 | 45 | 0/90 |

| 125.26 | 90 | 45 | ||

| A2* | (1 1 1) [1 1 ] | 144.74 | 45 | 0/90 |

| 54.74/234.74 | 90 | 45 | ||

| A | (1 1) [1 1 0] | 0 | 35.26 | 45 |

| ( 1 ) [ 0] | 180 | 35.26 | 45 | |

| B | (1 2) [1 1 0] | 0/120/240 | 54.74 | 45 |

| ( 1 ) [ 0] | 60/180 | 54.74 | 45 | |

| C | {0 0 1} <1 1 0> | 90/270 | 45 | 0/90 |

| 0/180 | 90 | 45 | ||

| Notation | {hkl} <uvw> | Euler Angles | ||

|---|---|---|---|---|

| φ1 | Φ | φ2 | ||

| D1 | ( 2) [1 1 1] | 54.74/2334.74 | 45 | 0/90 |

| 144.74 | 90 | 45 | ||

| D2 | (1 1 ) [1 1 1] | 125.26 | 45 | 0/90 |

| 35.26/215.26 | 90 | 45 | ||

| E | (1 1 0) [1 1] | 90 | 35.26 | 45 |

| ( 0) [ 1 ] | 270 | 35.26 | 45 | |

| J | (1 1 0) [1 2] | 90/120 | 54.74 | 45 |

| ( 0) [ 1 ] | 30/150/270 | 54.74 | 45 | |

| F | {1 1 0} <0 0 1> | 0/180 | 45 | 0/90 |

| 90/270 | 90 | 45 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dolzhenko, A.; Tikhonova, M.; Kaibyshev, R.; Belyakov, A. Microstructures and Mechanical Properties of Steels and Alloys Subjected to Large-Strain Cold-to-Warm Deformation. Metals 2022, 12, 454. https://doi.org/10.3390/met12030454

Dolzhenko A, Tikhonova M, Kaibyshev R, Belyakov A. Microstructures and Mechanical Properties of Steels and Alloys Subjected to Large-Strain Cold-to-Warm Deformation. Metals. 2022; 12(3):454. https://doi.org/10.3390/met12030454

Chicago/Turabian StyleDolzhenko, Anastasiia, Marina Tikhonova, Rustam Kaibyshev, and Andrey Belyakov. 2022. "Microstructures and Mechanical Properties of Steels and Alloys Subjected to Large-Strain Cold-to-Warm Deformation" Metals 12, no. 3: 454. https://doi.org/10.3390/met12030454

APA StyleDolzhenko, A., Tikhonova, M., Kaibyshev, R., & Belyakov, A. (2022). Microstructures and Mechanical Properties of Steels and Alloys Subjected to Large-Strain Cold-to-Warm Deformation. Metals, 12(3), 454. https://doi.org/10.3390/met12030454