Annihilation Mechanism of Low-Angle Grain Boundary in Nanocrystalline Metals

Abstract

:1. Introduction

2. Materials and Methods

3. Results

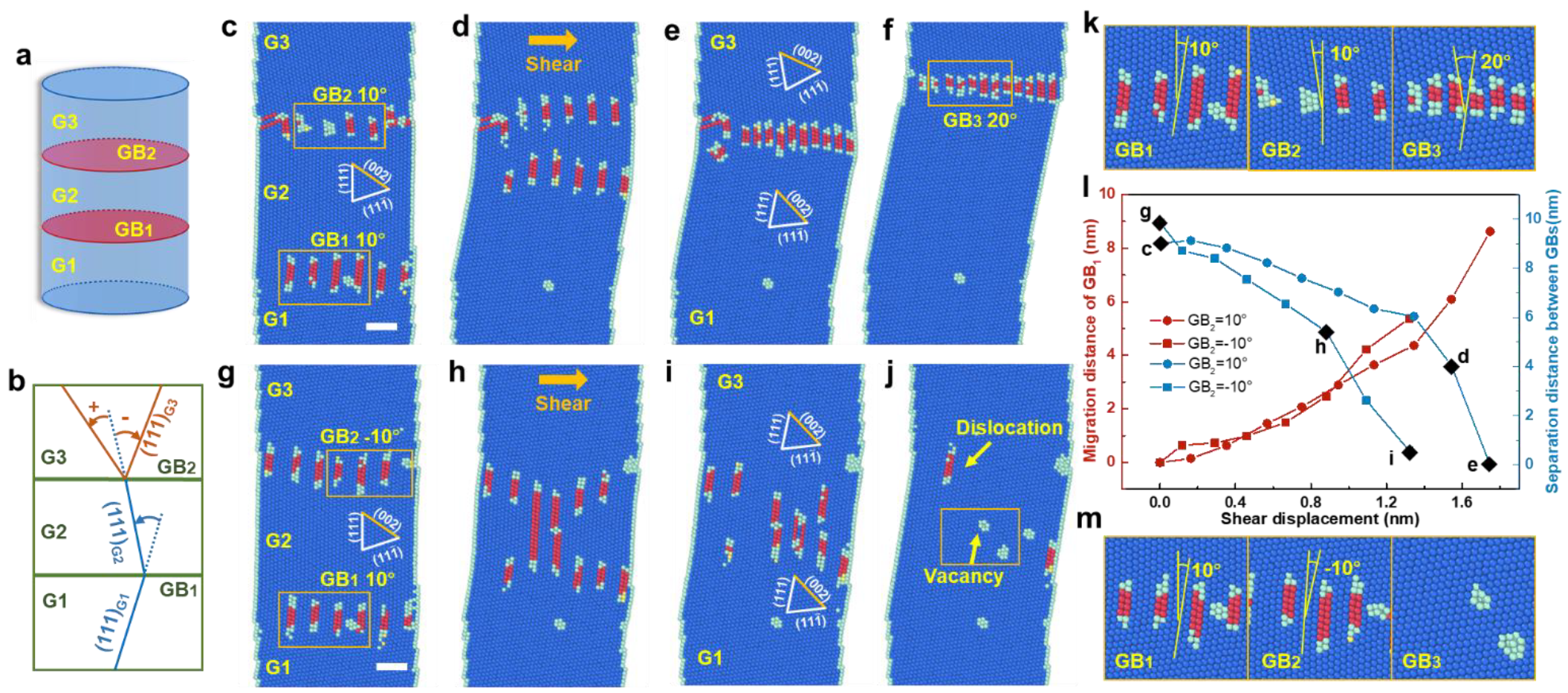

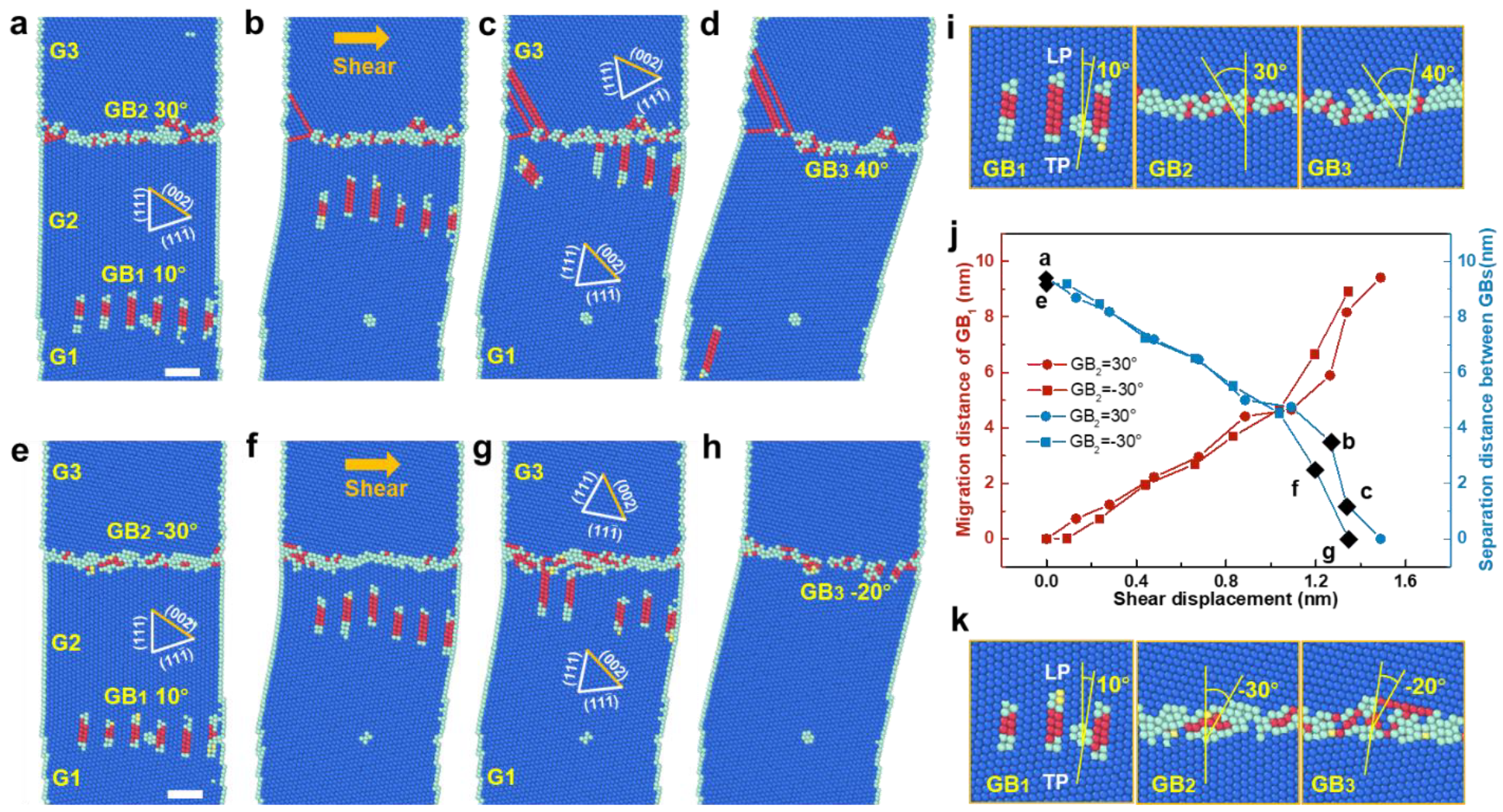

3.1. Annihilation at Low-Angle Grain Boundaries

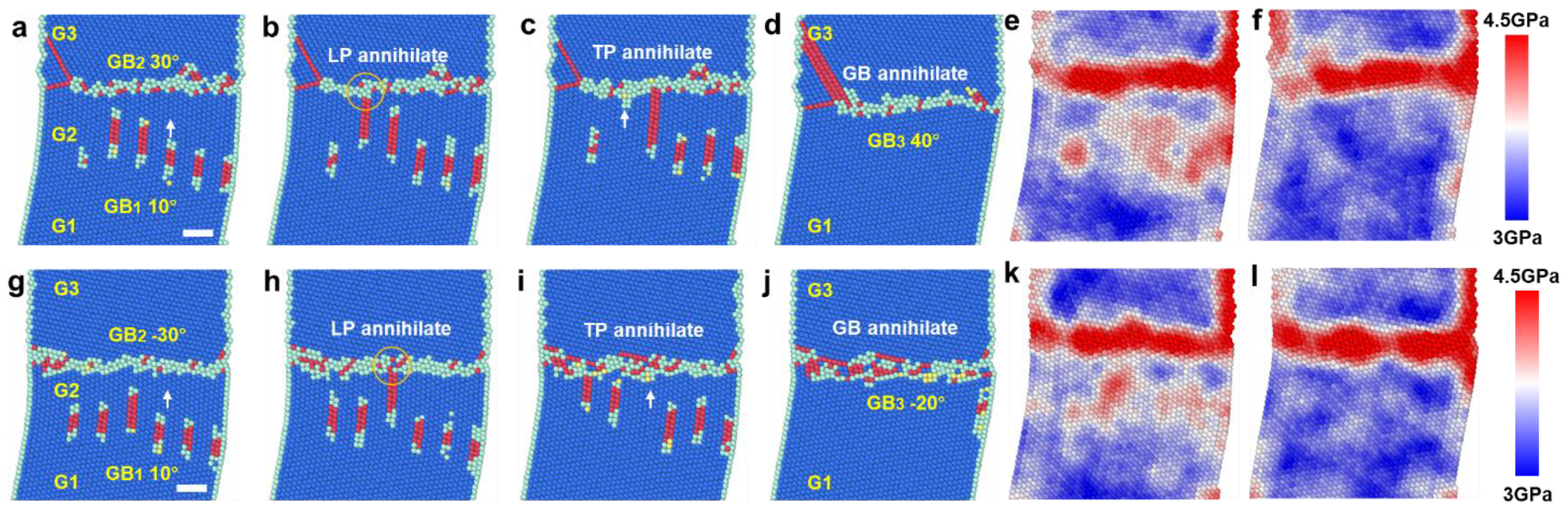

3.2. Annihilation at High-Angle Grain Boundaries

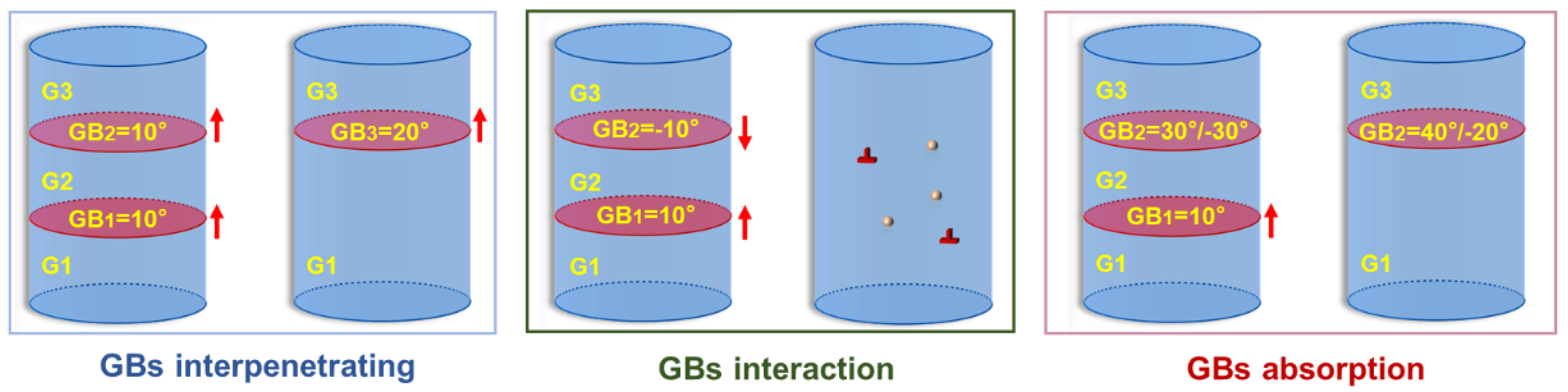

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hu, J.; Shi, Y.N.; Sauvage, X.; Sha, G.; Lu, K. Grain boundary stability governs hardening and softening in extremely fine nanograined metals. Science 2017, 355, 1292–1296. [Google Scholar] [CrossRef] [PubMed]

- Zhu, T.; Li, J. Ultra-strength materials. Prog. Mater. Sci. 2010, 55, 710–757. [Google Scholar] [CrossRef] [Green Version]

- Srinivasan, V.; Kunjiappan, S.; Palanisamy, P. A brief review of carbon nanotube reinforced metal matrix composites for aerospace and defense applications. Int. Nano Lett. 2021, 11, 321–345. [Google Scholar] [CrossRef]

- Divagar, S.; Vigneshwar, M.; Selvamani, S.T. Impacts of Nano Particles on Fatigue Strength of Aluminum Based Metal Matrix Composites for Aerospace. Mater. Today Proc. 2016, 3, 3734–3739. [Google Scholar] [CrossRef]

- Pan, Q.; Zhou, H.; Lu, Q.; Gao, H.; Lu, L. History-independent cyclic response of nanotwinned metals. Nature 2017, 551, 214–217. [Google Scholar] [CrossRef]

- Ghosh, D.; Shukla, A.K.; Roy, H. Nano Structured Plasma Spray Coating for Wear and High Temperature Corrosion Resistance Applications. J. Inst. Eng. (India) Ser. D 2014, 95, 57–64. [Google Scholar] [CrossRef]

- Li, X.; Wei, Y.; Lu, L.; Lu, K.; Gao, H. Dislocation nucleation governed softening and maximum strength in nano-twinned metals. Nature 2010, 464, 877–880. [Google Scholar] [CrossRef] [Green Version]

- Schiotz, J.; Tolla, F.; Jacobsen, K.W. Softening of nanocrystalline metals at very small grain sizes. Nature 1998, 391, 561–563. [Google Scholar] [CrossRef]

- Langdon, T.G. Grain boundary sliding revisited: Developments in sliding over four decades. J. Mater. Sci. 2006, 41, 597–609. [Google Scholar] [CrossRef]

- Li, Q.; Wang, L.; Teng, J.; Pang, X.; Zou, J. In-situ observation of cooperative grain boundary sliding and migration in the nano-twinned nanocrystalline-Au thin-films. Scr. Mater. 2020, 180, 97–102. [Google Scholar] [CrossRef]

- Thomas, S.L.; Chen, K.; Han, J.; Purohit, P.K.; Srolovitz, D.J. Reconciling grain growth and shear-coupled grain boundary migration. Nat. Commun. 2017, 8, 1764. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, L.; Teng, J.; Liu, P.; Hirata, A.; Ma, E.; Zhang, Z.; Chen, M.; Han, X. Grain rotation mediated by grain boundary dislocations in nanocrystalline platinum. Nat. Commun. 2014, 5, 4402. [Google Scholar] [CrossRef] [PubMed]

- Kumar, K.S.; Van Swygenhoven, H.; Suresh, S. Mechanical behavior of nanocrystalline metals and alloys. Acta Mater. 2003, 51, 5743–5774. [Google Scholar] [CrossRef]

- Cahn, J.W.; Mishin, Y.; Suzuki, A. Coupling grain boundary motion to shear deformation. Acta Mater. 2006, 54, 4953–4975. [Google Scholar] [CrossRef]

- Homer, E.R.; Foiles, S.M.; Holm, E.A.; Olmsted, D.L. Phenomenology of shear-coupled grain boundary motion in symmetric tilt and general grain boundaries. Acta Mater. 2013, 61, 1048–1060. [Google Scholar] [CrossRef]

- Wang, P.; Yang, X.; Peng, D. Molecular dynamics investigation of the grain boundary migration hysteresis of nanocrystalline Ni under cyclic shear loading. Modell. Simul. Mater. Sci. Eng. 2017, 25, 025006. [Google Scholar] [CrossRef]

- Luo, X.M.; Zhang, B.; Zhu, X.F.; Zhou, Y.T.; Xiao, T.Y.; Zhang, G.P. Local-structure-affected behavior during self-driven grain boundary migration. MRS Commun. 2016, 6, 85–91. [Google Scholar] [CrossRef]

- Yu, T.; Hughes, D.A.; Hansen, N.; Huang, X. In situ observation of triple junction motion during recovery of heavily deformed aluminum. Acta Mater. 2015, 86, 269–278. [Google Scholar] [CrossRef] [Green Version]

- Ovid’ko, I. Triple junction nanocracks in deformed nanocrystalline materials. Acta Mater. 2004, 52, 1201–1209. [Google Scholar] [CrossRef]

- Kacher, J.; Eftink, B.P.; Cui, B.; Robertson, I.M. Dislocation interactions with grain boundaries. Curr. Opin. Solid State Mater. Sci. 2014, 18, 227–243. [Google Scholar] [CrossRef]

- Dake, J.M.; Oddershede, J.; Sorensen, H.O.; Werz, T.; Shatto, J.C.; Uesugi, K.; Schmidt, S.; Krill, C.E., III. Direct observation of grain rotations during coarsening of a semisolid Al-Cu alloy. Proc. Natl. Acad. Sci. USA 2016, 113, E5998–E6006. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aleshin, A.N. Role of grain-boundary diffusion in the grain growth in nanocrystalline nickel. Russ. Metall. (Metally) 2008, 2008, 286–293. [Google Scholar] [CrossRef]

- Ni, H.; Zhu, J.; Wang, Z.; Lv, H.; Su, Y.; Zhang, X. A brief overview on grain growth of bulk electrodeposited nanocrystalline nickel and nickel-iron alloys. Rev. Adv. Mater. Sci. 2019, 58, 98–106. [Google Scholar] [CrossRef]

- Sauzay, M.; Brillet, H.; Monnet, I.; Mottot, M.; Barcelo, F.; Fournier, B.; Pineau, A. Cyclically induced softening due to low-angle boundary annihilation in a martensitic steel. Mater. Sci. Eng. A 2005, 400–401, 241–244. [Google Scholar] [CrossRef]

- Plimpton, S. Fast Parallel Algorithms for Short-Range Molecular Dynamics. J. Comp. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Grochola, G.; Russo, S.P.; Snook, I.K. On fitting a gold embedded atom method potential using the force matching method. J. Chem. Phys. 2005, 123, 204719. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO—The Open Visualization Tool. Modell. Simul. Mater. Sci. Eng. 2010, 18, 015012. [Google Scholar] [CrossRef]

- Pan, J.; Cocks, A.; Kucherenko, S. Finite element formulation of coupled grain-boundary and surface diffusion with grain-boundary migration. Proc. R. Soc. A Math. Phys. Eng. Sci. 1997, 453, 2161–2184. [Google Scholar] [CrossRef]

- Wang, H. On the annihilation of dislocation dipoles in metals. AIMS Mater. Sci. 2017, 4, 1231–1239. [Google Scholar] [CrossRef]

- Kondo, S.; Mitsuma, T.; Shibata, N.; Ikuhara, Y. Direct observation of individual dislocation interaction processes with grain boundaries. Sci. Adv. 2016, 2, e1501926. [Google Scholar] [CrossRef] [Green Version]

- Yuk, J.M.; Jeong, M.; Kim, S.Y.; Seo, H.K.; Kim, J.; Lee, J.Y. In situ atomic imaging of coalescence of Au nanoparticles on graphene: Rotation and grain boundary migration. Chem. Commun. 2013, 49, 11479–11481. [Google Scholar] [CrossRef] [PubMed]

- Fomin, E.V.; Mayer, A.E. Slip of low-angle tilt grain boundary (110) in FCC metals at perpendicular shear. Int. J. Plast. 2020, 134, 102843. [Google Scholar] [CrossRef]

- Bishop, G.H.; Harrison, R.J.; Kwok, T.; Yip, S. Computer molecular dynamics simulation studies of grain-boundary structures. II. Migration, sliding, and annihilation in a two-dimensional solid. J. Appl. Phys. 1982, 53, 5609–5616. [Google Scholar] [CrossRef]

- Mompiou, F.; Legros, M.; Radetic, T.; Dahmen, U.; Gianola, D.S.; Hemker, K.J. In situ TEM observation of grain annihilation in tricrystalline aluminum films. Acta Mater. 2012, 60, 2209–2218. [Google Scholar] [CrossRef]

- Jin, M.; Minor, A.M.; Stach, E.A.; Morris, J.W. Direct observation of deformation-induced grain growth during the nanoindentation of ultrafine-grained Al at room temperature. Acta Mater. 2004, 52, 5381–5387. [Google Scholar] [CrossRef]

- Gianola, D.S.; Van Petegem, S.; Legros, M.; Brandstetter, S.; Van Swygenhoven, H.; Hemker, K.J. Stress-assisted discontinuous grain growth and its effect on the deformation behavior of nanocrystalline aluminum thin films. Acta Mater. 2006, 54, 2253–2263. [Google Scholar] [CrossRef]

- Zhang, K.; Weertman, J.R.; Eastman, J.A. Rapid stress-driven grain coarsening in nanocrystalline Cu at ambient and cryogenic temperatures. Appl. Phys. Lett. 2005, 87, 061921. [Google Scholar] [CrossRef]

- Zhu, Q.; Huang, Q.; Guang, C.; An, X.; Mao, S.X.; Yang, W.; Zhang, Z.; Gao, H.; Zhou, H.; Wang, J. Metallic nanocrystals with low angle grain boundary for controllable plastic reversibility. Nat. Commun. 2020, 11, 3100. [Google Scholar] [CrossRef]

- Yuan, Y.; Li, X.; Yang, W. Low-angle grain boundary structures and size effects of nickel nanolaminated structures. J. Mech. Phys. Solids 2019, 130, 280–296. [Google Scholar] [CrossRef]

- Mendelev, M.I.; Srolovitz, D.J. Impurity effects on grain boundary migration. Modell. Simul. Mater. Sci. Eng. 2002, 10, R79. [Google Scholar] [CrossRef]

- Aramfard, M.; Deng, C. Influences of triple junctions on stress-assisted grain boundary motion in nanocrystalline materials. Modell. Simul. Mater. Sci. Eng. 2014, 22, 055012. [Google Scholar] [CrossRef]

- Niu, L.L.; Peng, Q.; Gao, F.; Chen, Z.; Zhang, Y.; Lu, G.H. Effects of interstitial defects on stress-driven grain boundary migration in bcc tungsten. J. Nucl. Mater. 2018, 512, 246–251. [Google Scholar] [CrossRef]

- Chen, D.; Xu, S.; Kulkarni, Y. Atomistic mechanism for vacancy-enhanced grain boundary migration. Phys. Rev. Mater. 2020, 4, 33602. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, G.; Huang, Q.; Chen, Y.; Yu, X.; Zhou, H. Annihilation Mechanism of Low-Angle Grain Boundary in Nanocrystalline Metals. Metals 2022, 12, 451. https://doi.org/10.3390/met12030451

Zhou G, Huang Q, Chen Y, Yu X, Zhou H. Annihilation Mechanism of Low-Angle Grain Boundary in Nanocrystalline Metals. Metals. 2022; 12(3):451. https://doi.org/10.3390/met12030451

Chicago/Turabian StyleZhou, Guofeng, Qishan Huang, Yingbin Chen, Xiongqing Yu, and Haofei Zhou. 2022. "Annihilation Mechanism of Low-Angle Grain Boundary in Nanocrystalline Metals" Metals 12, no. 3: 451. https://doi.org/10.3390/met12030451

APA StyleZhou, G., Huang, Q., Chen, Y., Yu, X., & Zhou, H. (2022). Annihilation Mechanism of Low-Angle Grain Boundary in Nanocrystalline Metals. Metals, 12(3), 451. https://doi.org/10.3390/met12030451