Strain-Controlled Fatigue Behavior of a Nodular Cast Iron in Real Off-Highway Axles: Effects of Casting Skin and Strain Ratio

Abstract

1. Introduction

2. Materials and Methods

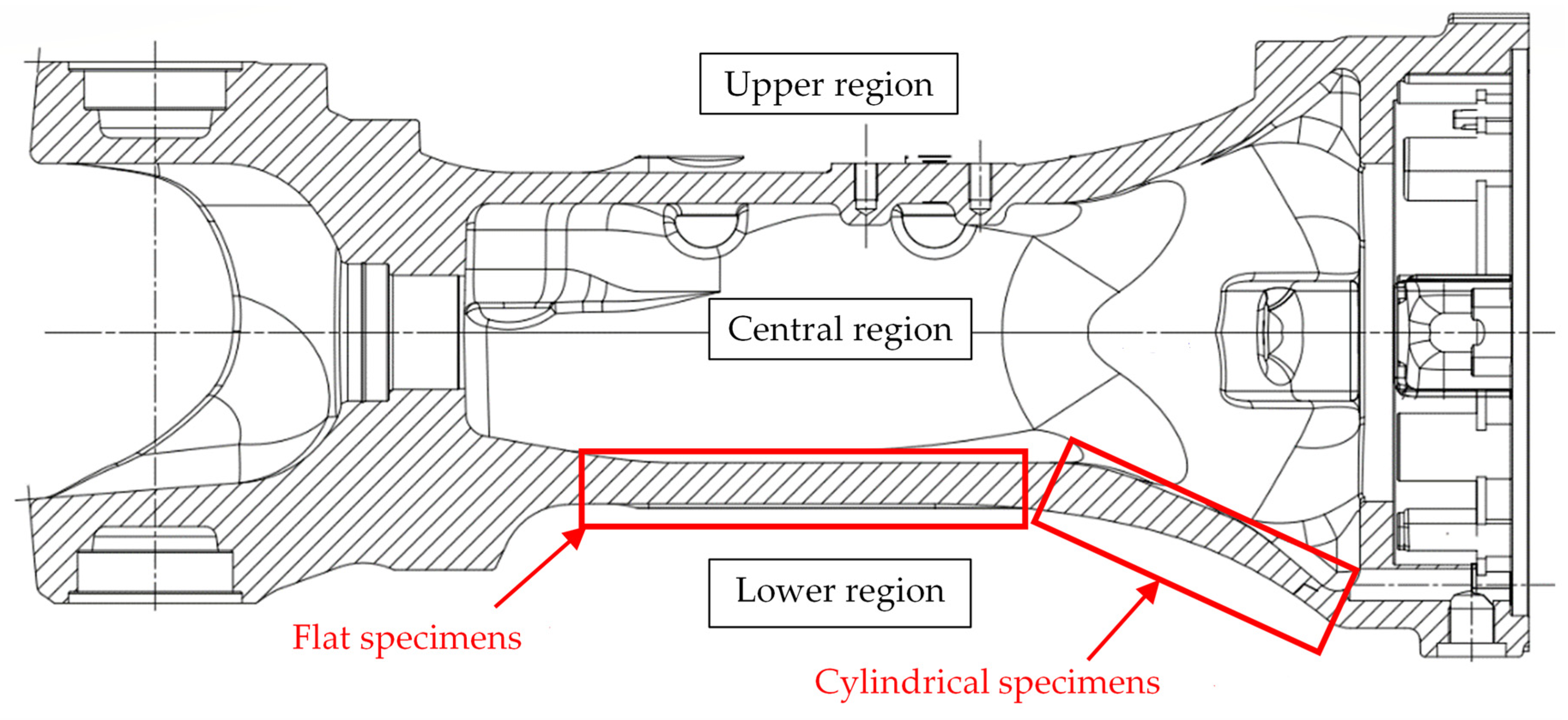

2.1. Specimens’ Position

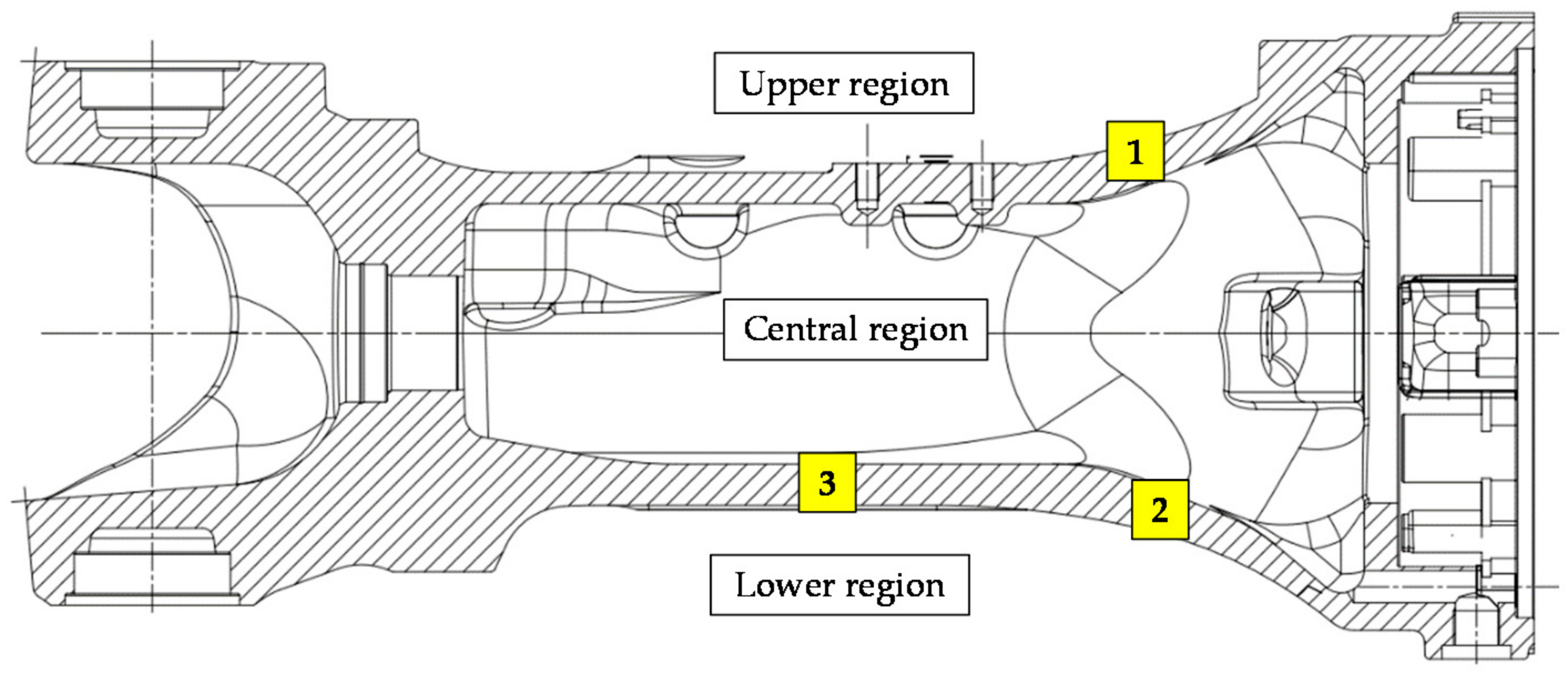

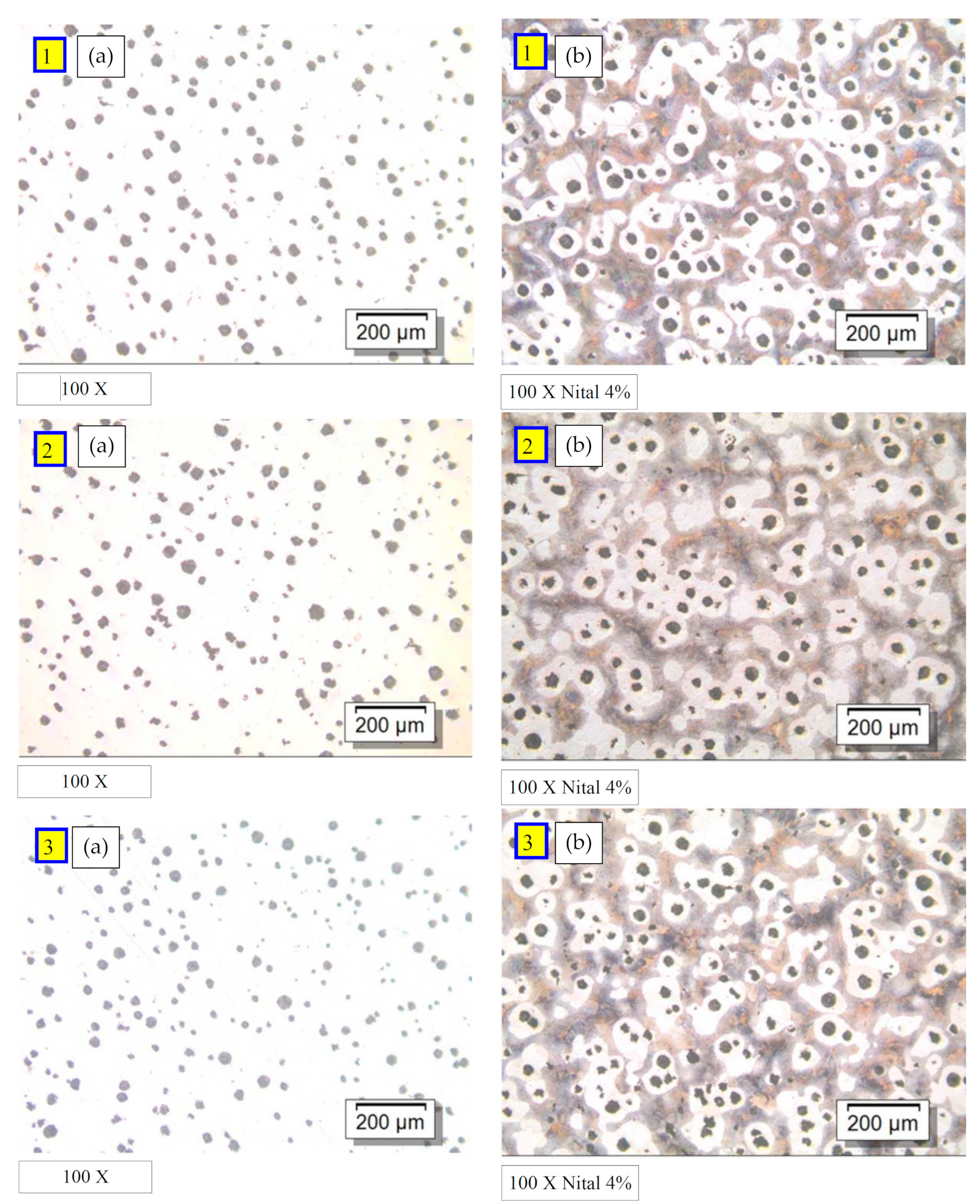

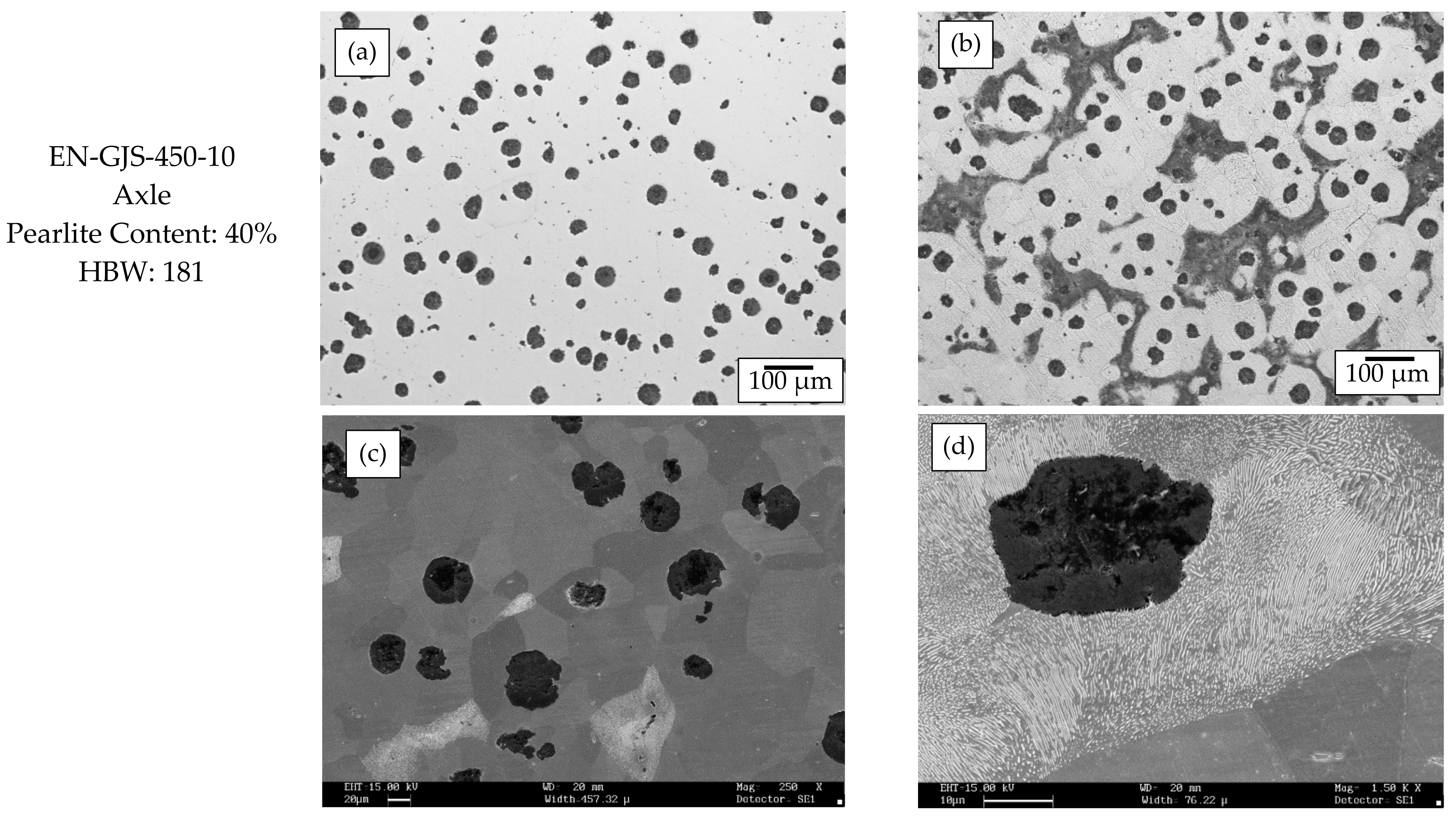

2.2. Metallographic Analyses and Hardness Measurements on the Axle

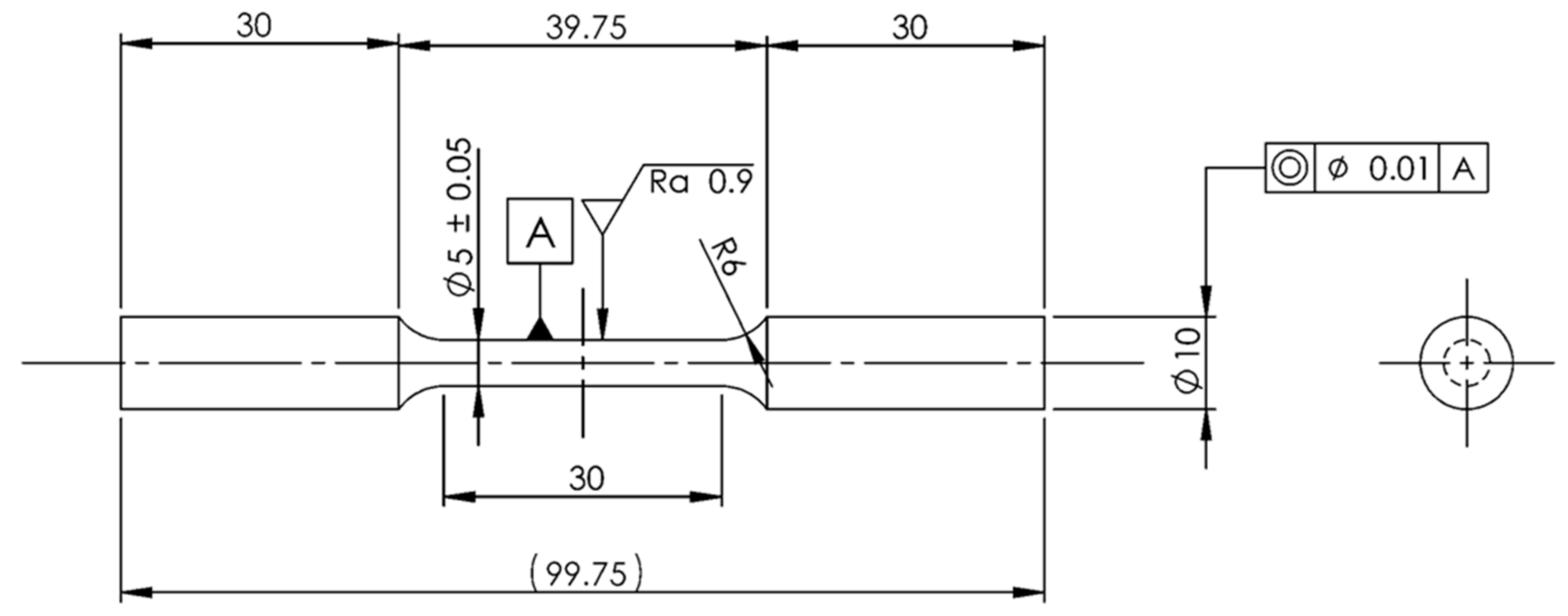

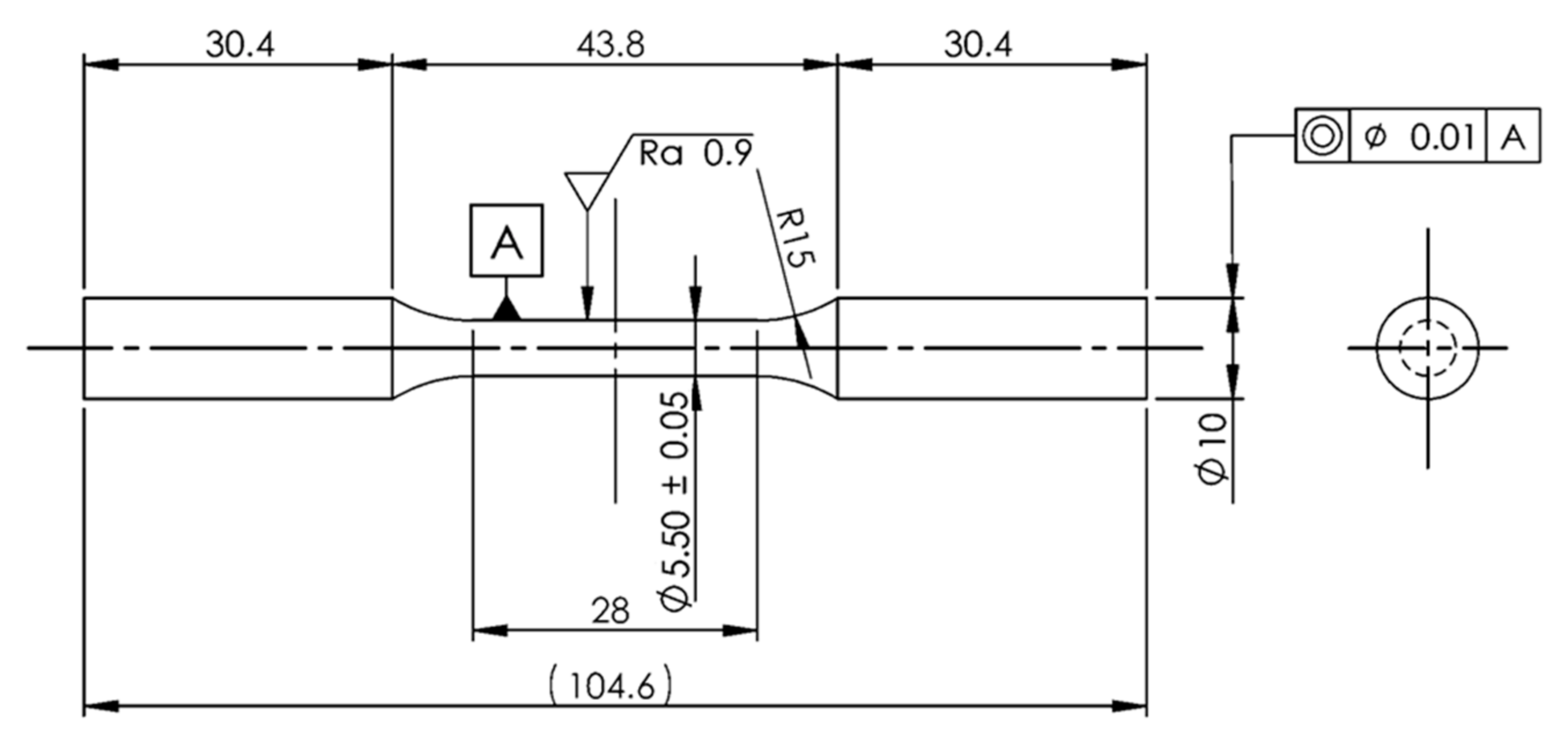

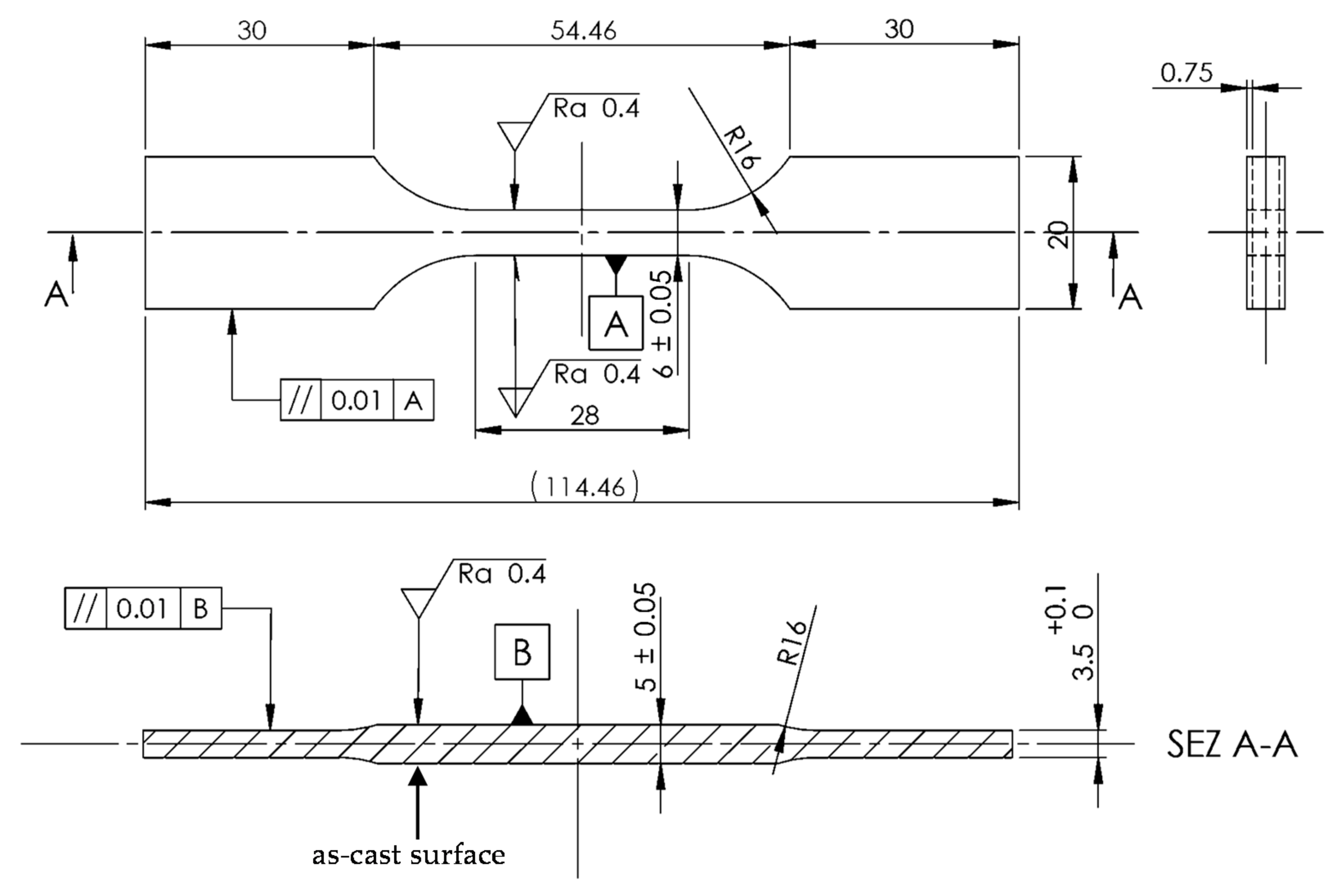

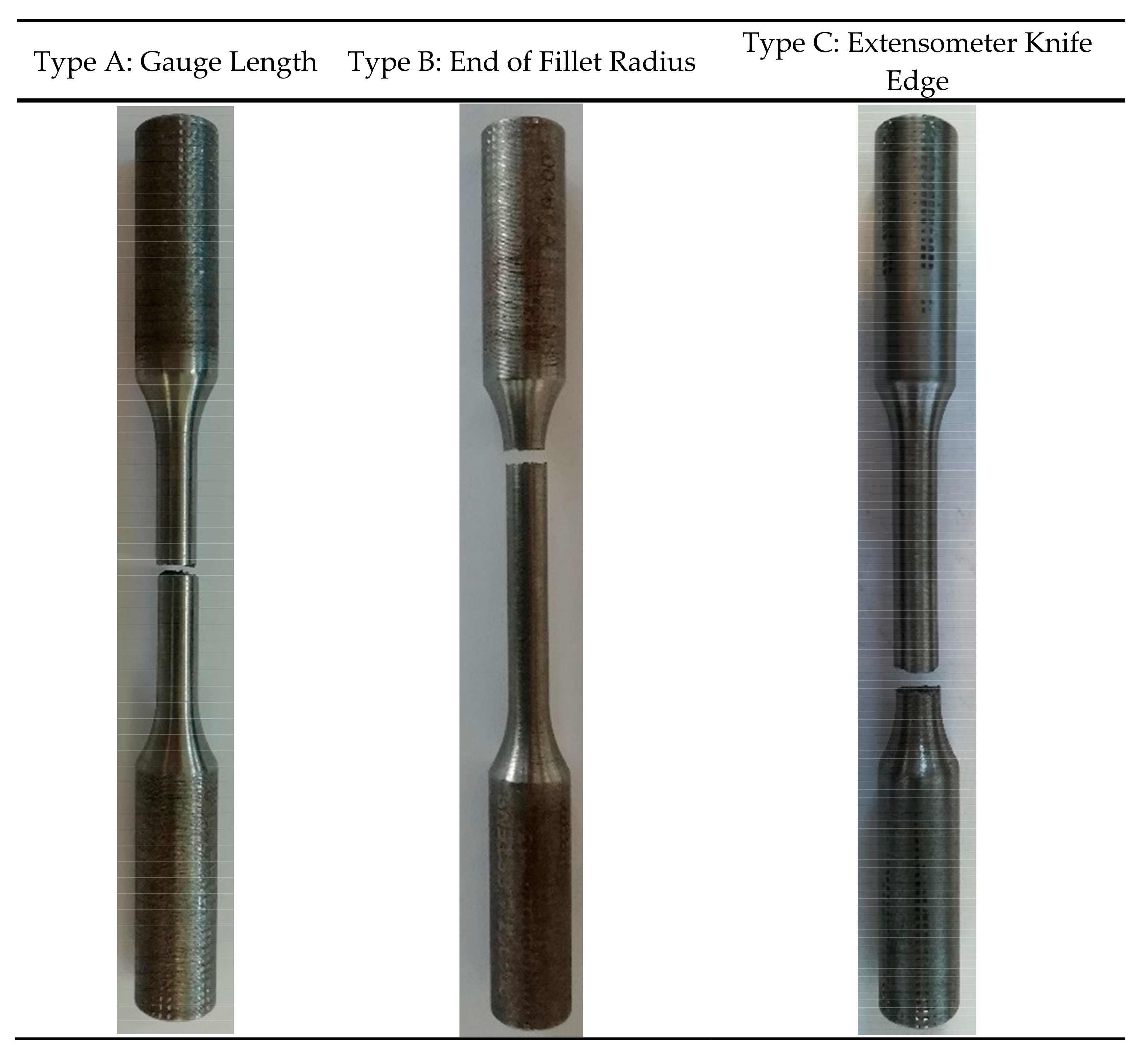

2.3. Static and Fatigue Testing: Parameters and Specimens’ Geometry

3. Results

3.1. Metallographic Analyses and Hardness Measurements on the Tested Samples

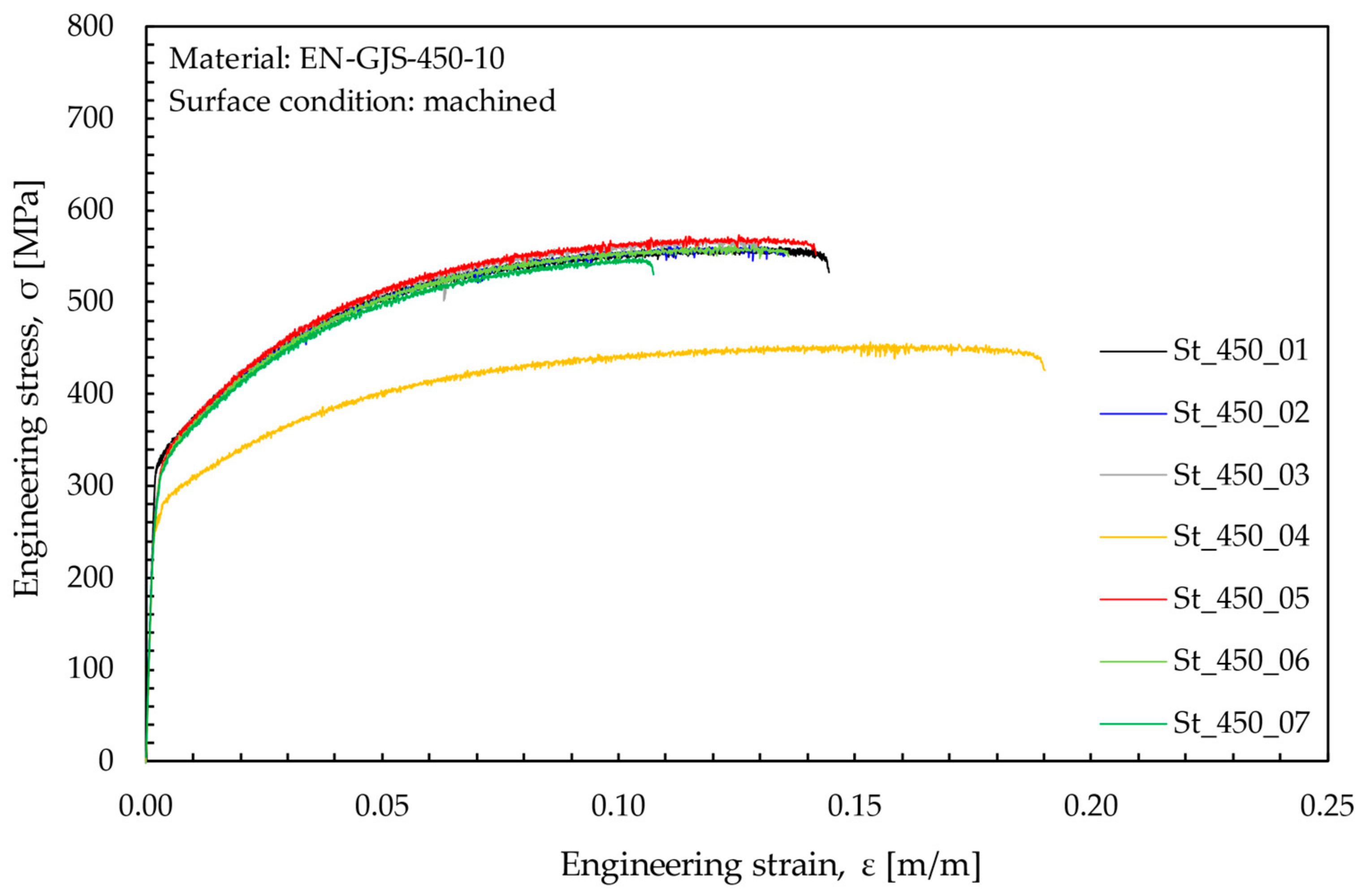

3.2. Static Tensile Test Results

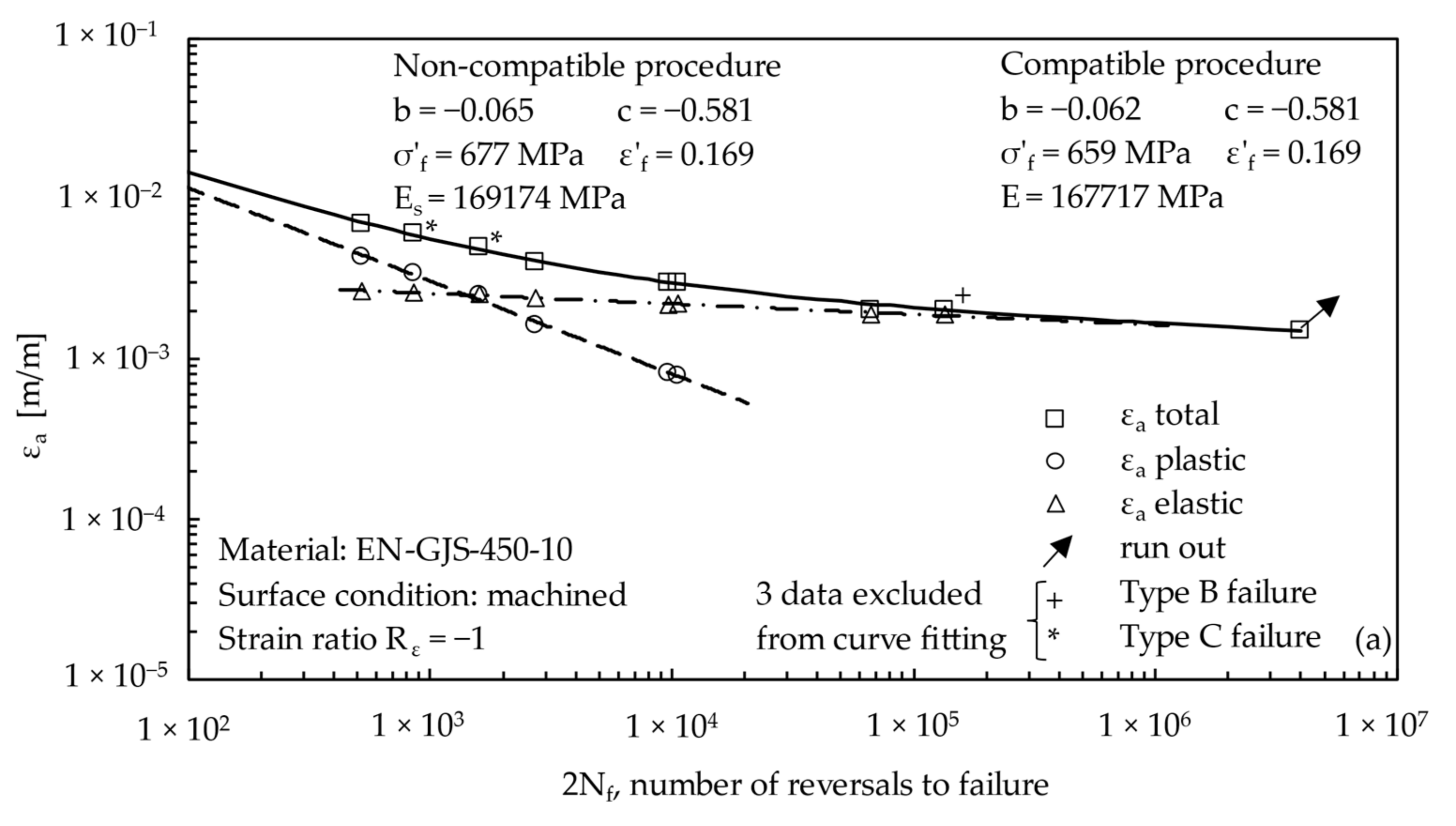

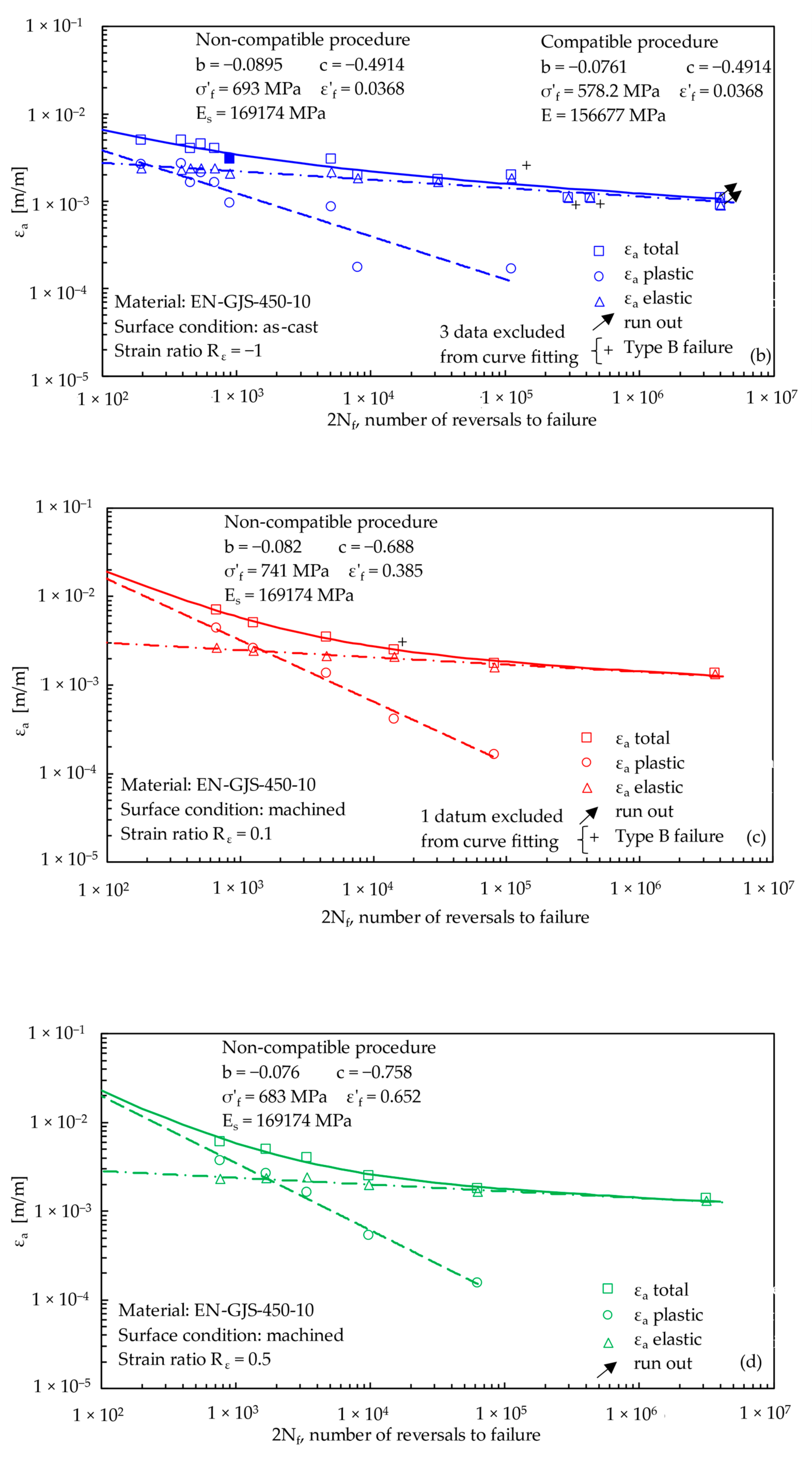

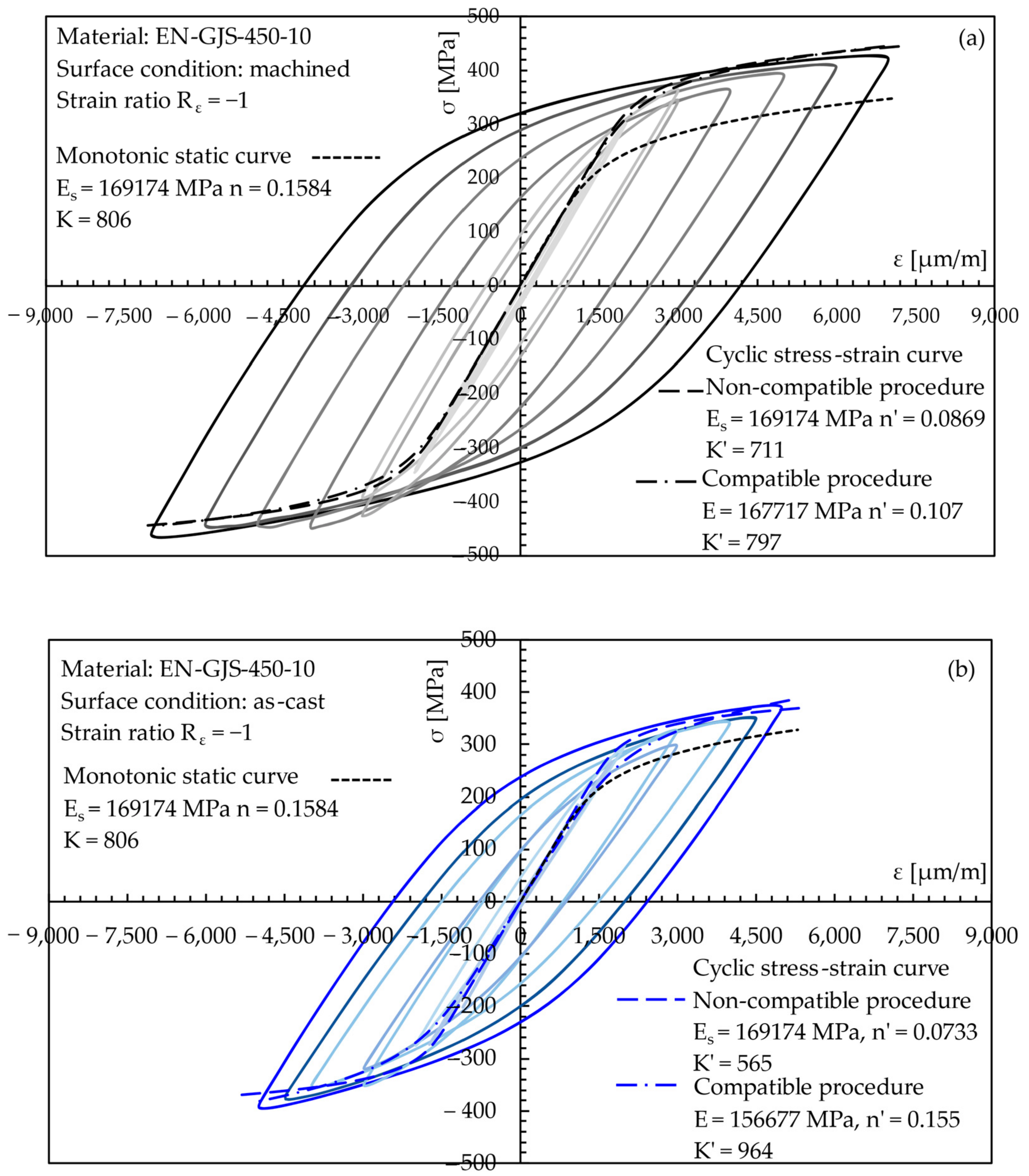

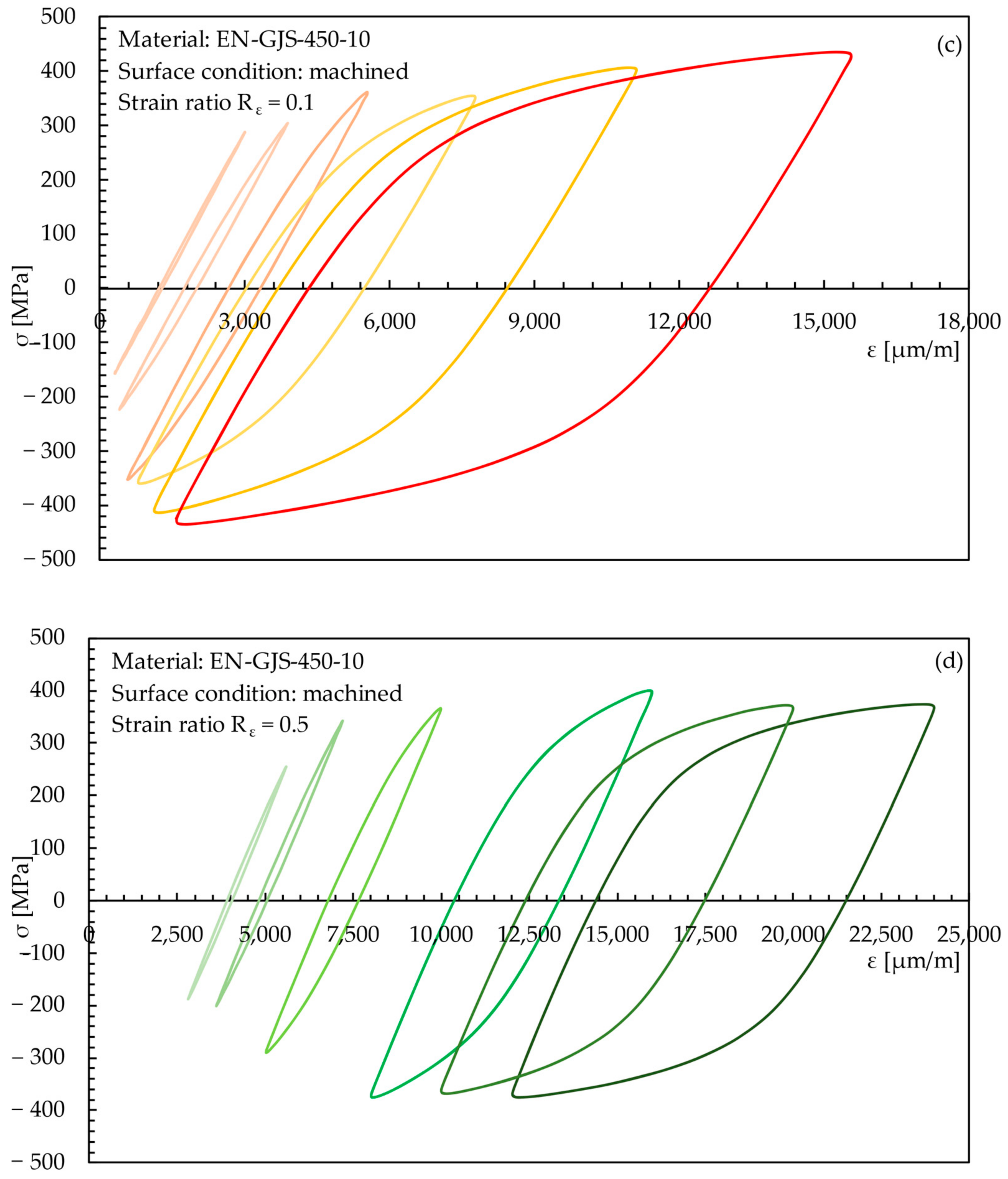

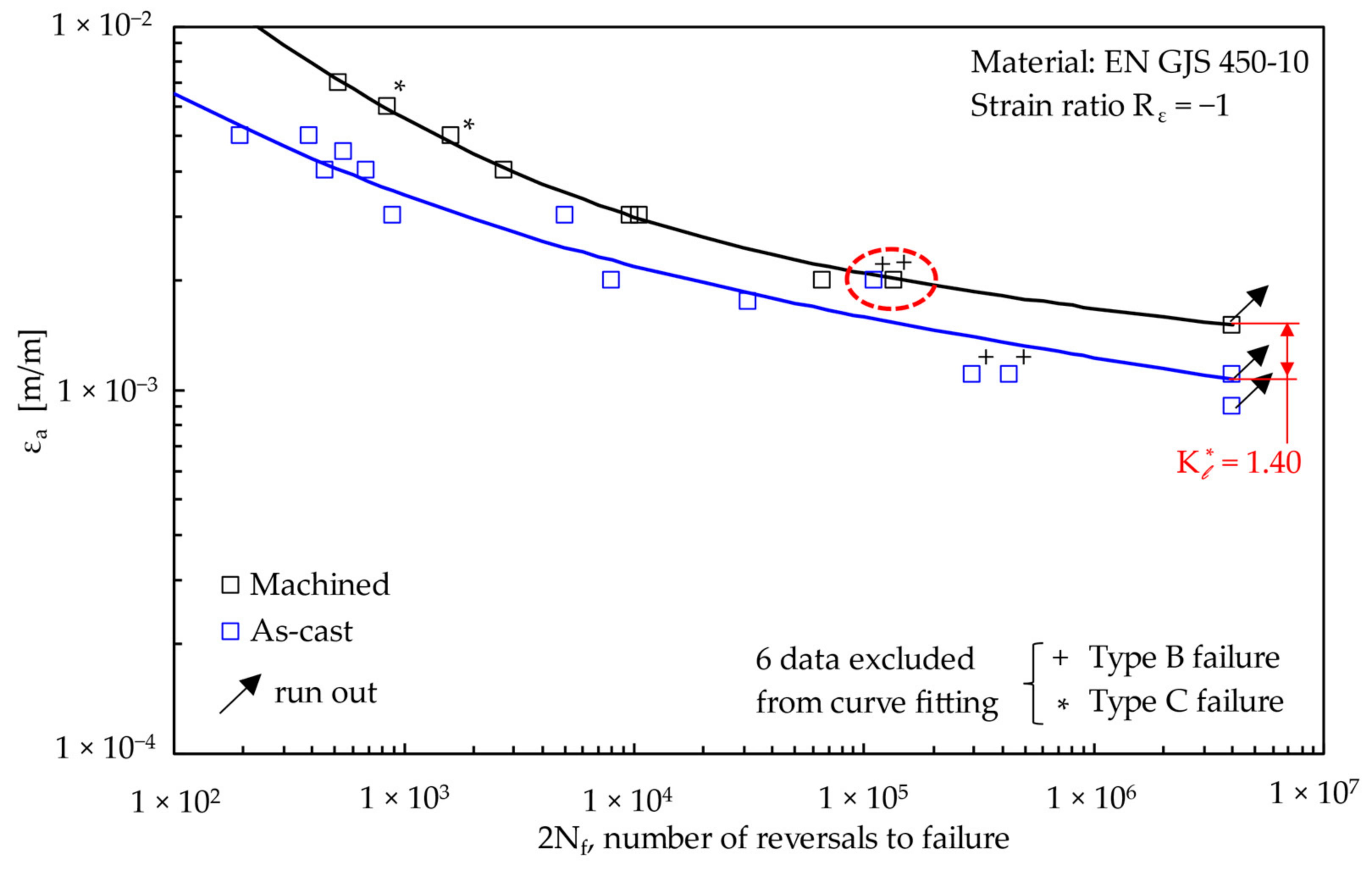

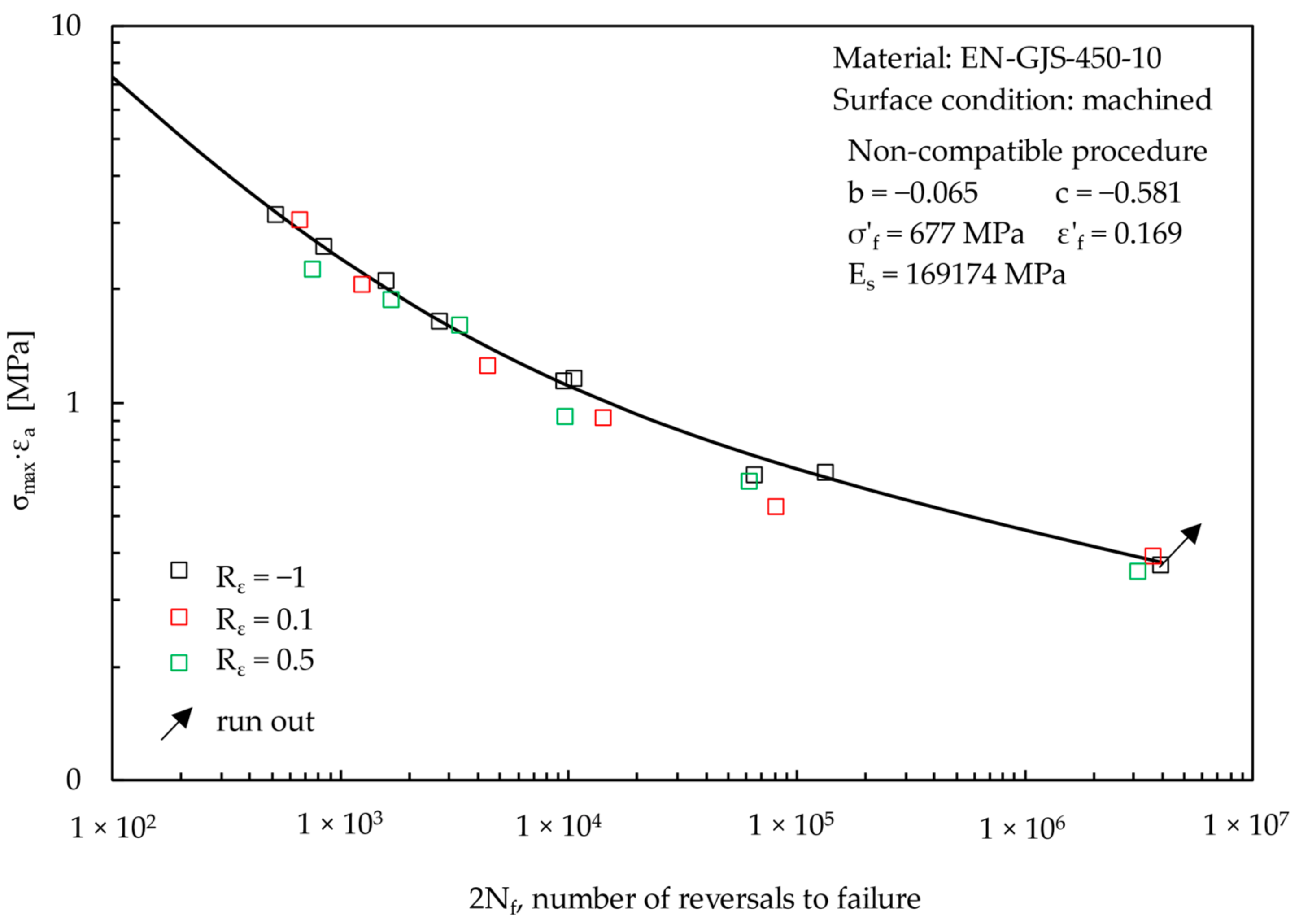

3.3. Strain-Controlled Fatigue Test Results

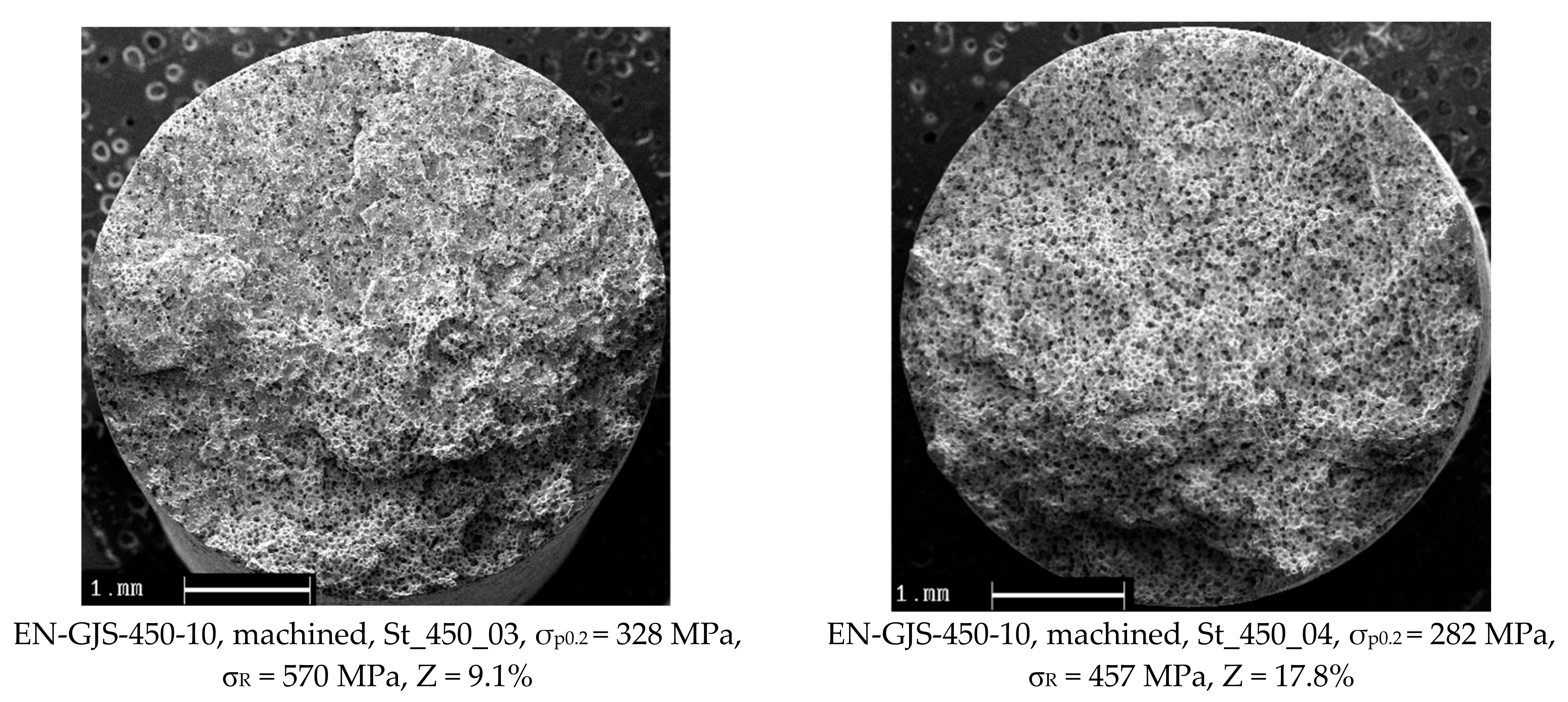

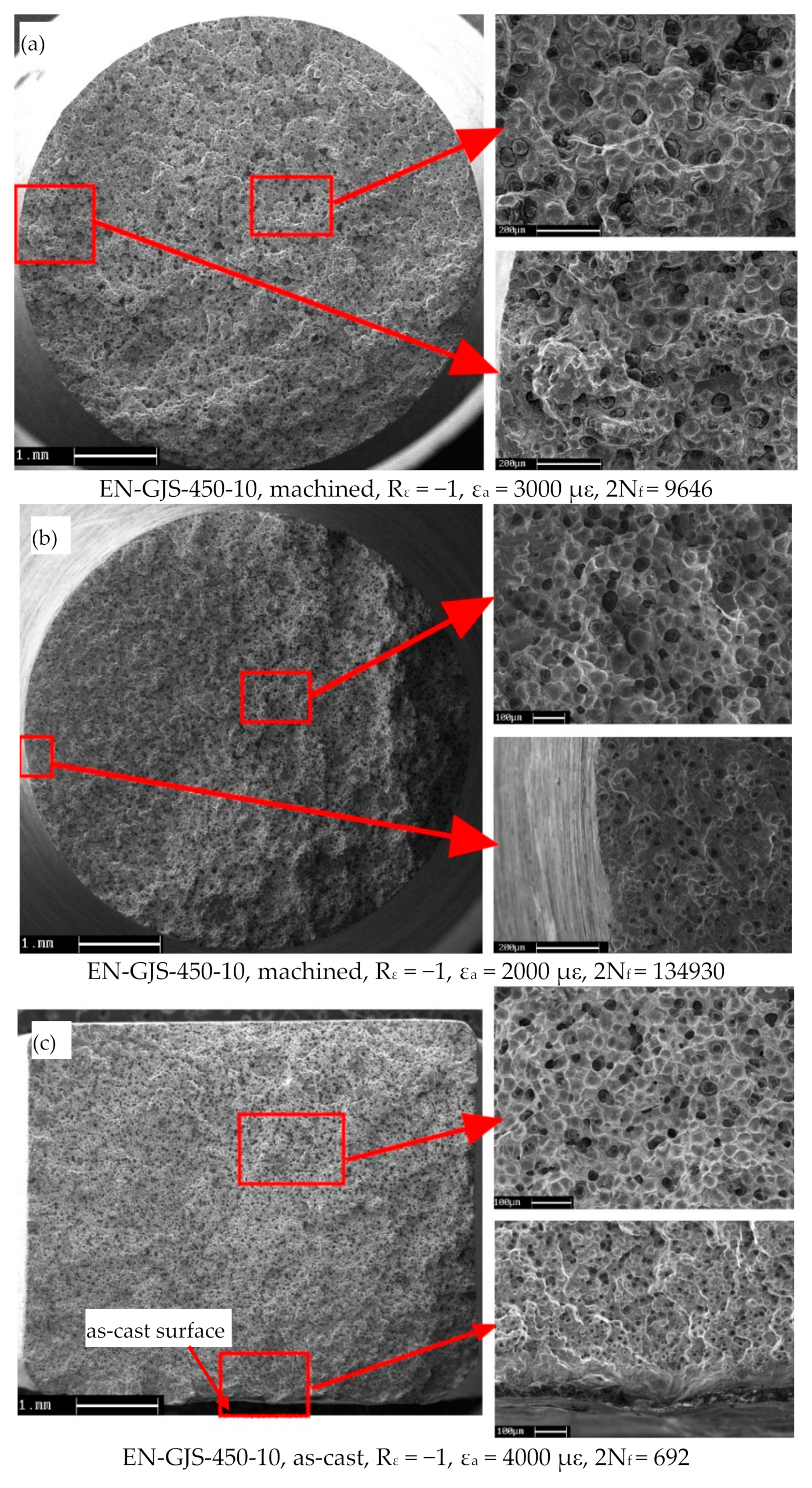

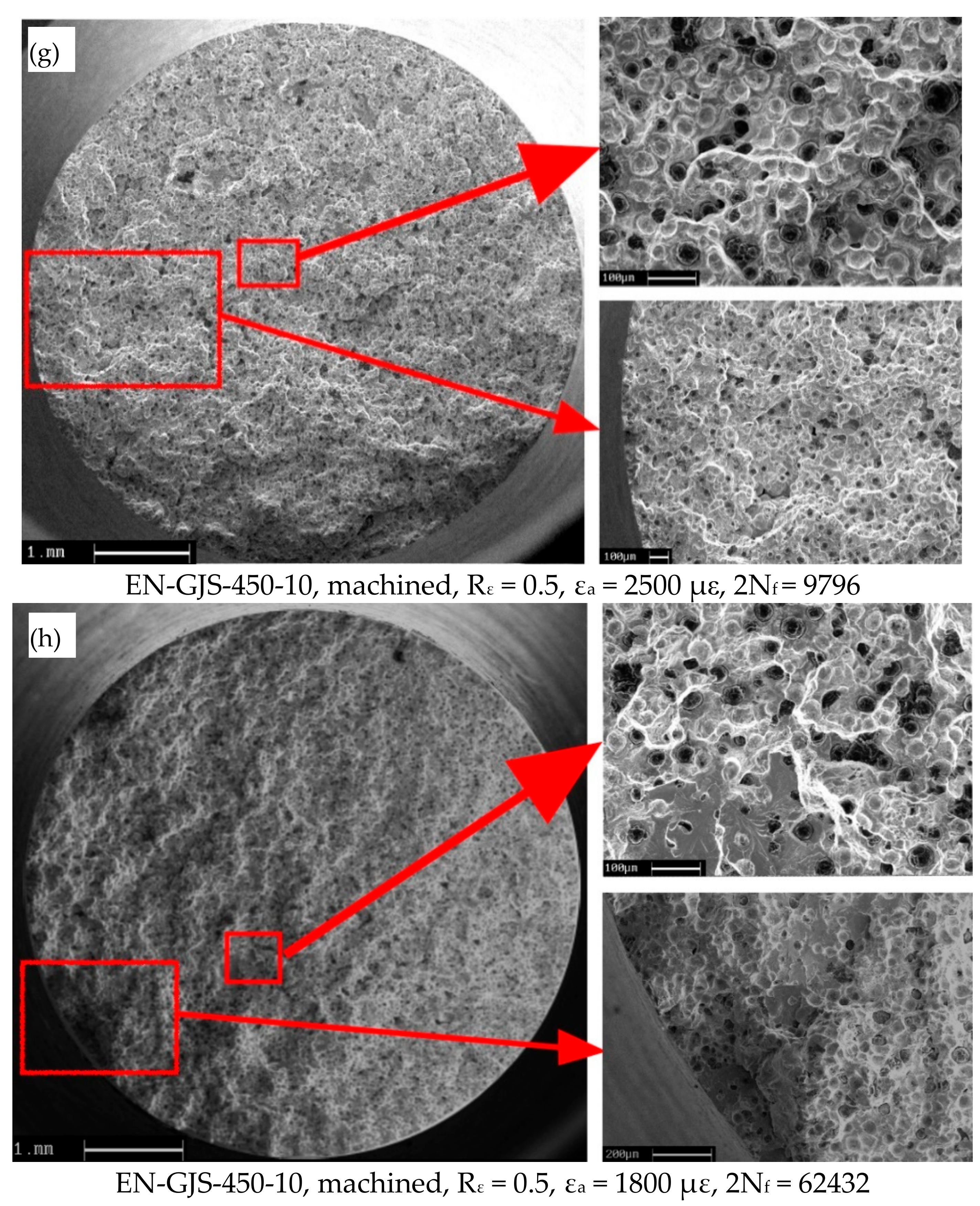

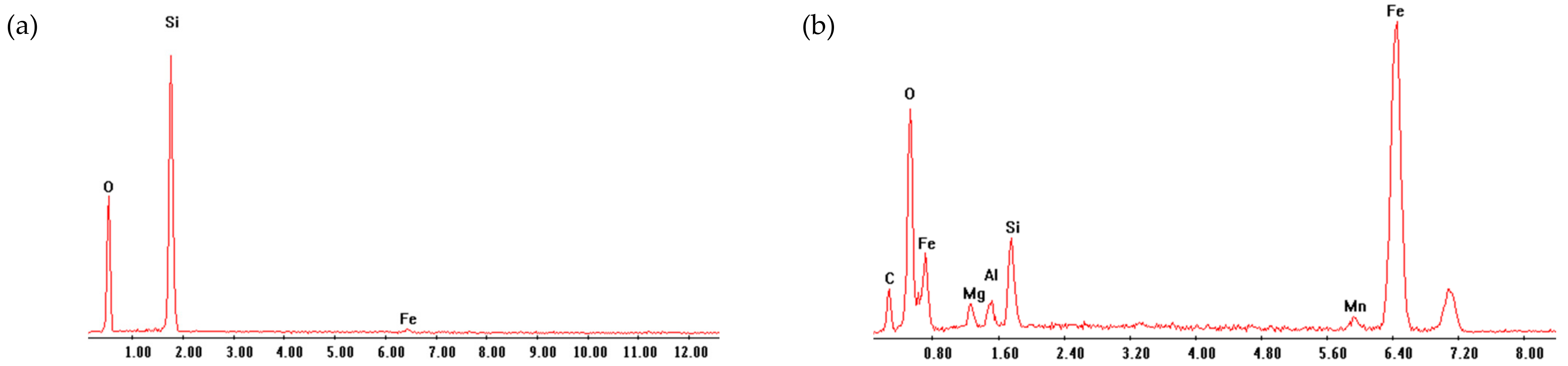

3.4. Failure Location and Fracture Surface Analyses

4. Discussion

- the higher roughness of as-cast surface as compared to the machined one;

- the presence of defects underneath the as-cast surface.

5. Conclusions

- The analysed EN-GJS-450-10 has graphite nodules with regular spheroidal shape dispersed in a matrix consisting of 50% ferrite and 50% pearlite. Specimens tested under static tensile loading exhibited an almost flat fracture surface and provided a proof stress σp,02 equal to 328 MPa, an ultimate tensile strength σR equal to 538 MPa, and an elongation after fracture A% and a reduction of area Z% equal to 12.9% and 10%, respectively.

- Concerning the fatigue behaviour, the experimental data were fitted by the Manson–Coffin equation according to the common practice, as well as to a recent procedure, which assures, strictly speaking, the compatibility conditions between stress-strain-life data.

- The analysis of the half fatigue life hysteresis loops shows that the stress ratio Rσ was different from the nominal strain ratio Rε. In particular, it ranged between -1.36 and −0.76 when Rε = −1, between −1.02 and −0.55 when Rε = 0.1, and between −1 and −0.59 when Rε = 0.5. Moreover, the comparison of the cyclic stress-strain curve with the monotonic static curve highlighted that the tested material exhibited a hardening behavior.

- The analysis of the fracture surfaces shows that machined specimens exhibited crack initiation from the surface, while as-cast specimens failed in most cases from the as-cast surface or from sub-surface defects, such as silicon oxides. A reduction coefficient Kl* has been defined to account for the high-cycle downgrading effect of the casting skin. At 2Nf = 4∙106 reversals to failure and with reference to a strain ratio Rε = −1, Kl* was equal to 1.40.

- Finally, it has been observed that the higher the strain ratio, the shorter the fatigue life for a given strain amplitude. Experimental fatigue data generated from machined specimens tested under different strain ratios, from −1 to 0.5, have been successfully correlated by using a Smith–Watson–Topper (SWT) expression, previously fitted only on experimental results relevant to Rε = −1.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Borsato, T.; Berto, F.; Ferro, P.; Carollo, C. Effect of in-mould inoculant composition on microstructure and fatigue behaviour of heavy section ductile iron castings. Procedia Struct. Integr. 2016, 2, 3150–3157. [Google Scholar] [CrossRef]

- Konečná, R.; Kokavec, M.; Nicoletto, G. Surface conditions and the fatigue behavior of nodular cast iron. Procedia Eng. 2011, 10, 2538–2543. [Google Scholar] [CrossRef]

- Benam, A.S. Effect of Shot Peening on the High-Cycle Fatigue Behavior of High-Strength Cast Iron with Nodular Graphite. Met. Sci. Heat Treat. 2017, 58, 568–571. [Google Scholar] [CrossRef]

- Meyer, N.; Fatemi, A.; McCutcheon, S.; Havard, B.; Fairchilds, W. Fatigue Behavior of Cast Iron Including Mean Stress Effects. SAE Int. J. Mater. Manuf. 2015, 8, 425–434. [Google Scholar] [CrossRef]

- Shirani, M.; Härkegård, G. Large scale axial fatigue testing of ductile cast iron for heavy section wind turbine components. Eng. Fail. Anal. 2011, 18, 1496–1510. [Google Scholar] [CrossRef]

- Shirani, M.; Härkegård, G. Fatigue life distribution and size effect in ductile cast iron for wind turbine components. Eng. Fail. Anal. 2011, 18, 12–24. [Google Scholar] [CrossRef]

- Clement, P.; Angeli, J.P.; Pineau, A. Short crack behaviour in nodular cast iron. Fatigue Fract. Eng. Mater. Struct. 1984, 7, 251–265. [Google Scholar] [CrossRef]

- Agha, H.Y.; Beranger, A.-S.; Billardon, R.; Hild, F. High-cycle fatigue behaviour of spheroidal graphite cast iron. Fatigue Fract. Eng. Mater. Struct. 1998, 21, 287–296. [Google Scholar] [CrossRef]

- Yamabe, J.; Kobayashi, M. Influence of casting surfaces on fatigue strength of ductile cast iron. Fatigue Fract. Eng. Mater. Struct. 2006, 29, 403–415. [Google Scholar] [CrossRef]

- Zambrano, H.R.; Härkegård, G.; Stärk, K.F. Fracture toughness and growth of short and long fatigue cracks in ductile cast iron EN-GJS-400-18-LT. Fatigue Fract. Eng. Mater. Struct. 2011, 35, 374–388. [Google Scholar] [CrossRef]

- Shirani, M.; Härkegård, G.; Morin, N. Fatigue life prediction of components made of spheroidal graphite cast iron. Procedia Eng. 2010, 2, 1125–1130. [Google Scholar] [CrossRef]

- Nadot, Y. Influence of casting defects on the fatigue limit of nodular cast iron. Int. J. Fatigue 2004, 26, 311–319. [Google Scholar] [CrossRef]

- SAE J 1099; Technical Report on Low Cycle Fatigue Properties: Ferrous and Non Ferrous Materials. SAE International: Warrendale, PA, USA, 2002.

- Petrenec, M.; Tesařová, H.; Beran, P.; Šmíd, M.; Roupcová, P. Comparison of low cycle fatigue of ductile cast irons with different matrix alloyed with nickel. Procedia Eng. 2010, 2, 2307–2316. [Google Scholar] [CrossRef][Green Version]

- Šamec, B.; Potrč, I.; Šraml, M. Low cycle fatigue of nodular cast iron used for railway brake discs. Eng. Fail. Anal. 2011, 18, 1424–1434. [Google Scholar] [CrossRef]

- Meneghetti, G.; Ricotta, M.; Masaggia, S.; Atzori, B. Comparison of the low-cycle and medium-cycle fatigue behaviour of ferritic, pearlitic, isothermed and austempered ductile irons. Fatigue Fract. Eng. Mater. Struct. 2013, 36, 913–929. [Google Scholar] [CrossRef]

- Boonmee, S.; Stefanescu, D.M. Effect of Casting Skin on Fatigue Properties of CG Iron. Int. J. Met. 2013, 7, 15–26. [Google Scholar] [CrossRef]

- Nasu, S.; Fujita, S.; Furusato, N.; Yamada, S.; Hiratsuka, S. Effect of Casting Skin Condition on Fatigue Strength of Gray Cast Iron. Int. J. Met. 2016, 11, 155–161. [Google Scholar] [CrossRef]

- Rehmer, B.; Skrotzki, B.; Glaubitz, S. Influence of casting skin on the fatigue lifetime of ferritic ductile cast iron. Mater. Test. 2016, 59, 5–10. [Google Scholar] [CrossRef]

- Nain, P.K.S. The Effect of Remaining Casting Skin on Cast Iron Components Fatigue Strength. Int. J. Eng. Res. Comput. Sci. Eng. 2017, 4, 157–165. [Google Scholar]

- Gróza, M.; Váradi, K. Fatigue Design of Ferritic-Pearlitic Nodular Cast Iron Components with Surface Discontinuities. Stroj. Vestn. J. Mech. Eng. 2018, 64, 373–382. [Google Scholar] [CrossRef]

- Lundberg, M.; Peng, R.L.; Ahmad, M.; Bäckström, D.; Vuoristo, T.; Johansson, S. Fatigue Strength of Machined and Shot Peened Grey Cast Iron. Adv. Mater. Res. 2014, 891–892, 30–35. [Google Scholar] [CrossRef]

- Bergner, K.; Bleicher, C.; Wagener, R. Influence of remaining casting skin on the fatigue strength of cast iron components. Procedia Struct. Integr. 2019, 18, 792–801. [Google Scholar] [CrossRef]

- Bergner, K.; Hesseler, J.; Bleicher, C. Fatigue analysis of cast iron components considering the influence of casting skin. Procedia Struct. Integr. 2019, 19, 140–149. [Google Scholar] [CrossRef]

- Anca, D.; Chisamera, M.; Stan, S.; Stan, I.; Riposan, I. Sulfur and Oxygen Effects on High-Si Ductile Iron Casting Skin Formation. Coatings 2020, 10, 618. [Google Scholar] [CrossRef]

- Dowling, N.E. Mechanical Behavior of Materials—Engineering Methods for Deformation, Fracture and Fatigue, 4th ed.; Pearson: Harlow, UK, 2013. [Google Scholar]

- Sonsino, C.M. Light-weight design chances using high-strength steels. Mater. Werkst. 2007, 38, 9–22. [Google Scholar] [CrossRef]

- Hübner, P.; Pusch, G.; Krodel, L. Fatigue Behaviour of Cast Iron with Globular Graphite. Adv. Eng. Mater. 2004, 6, 541–544. [Google Scholar] [CrossRef]

- Bleicher, C.; Wagener, R.; Kaufmann, H.; Melz, T. Fatigue strength of nodular cast iron with regard to heavy-wall applications. Mater. Test. 2015, 57, 723–731. [Google Scholar] [CrossRef]

- Bleicher, C.; Wagener, R.; Kaufmann, H.; Melz, T. Influence of Different Load Histories on the Cyclic Material Behavior of Nodular Cast Iron for Thick-Walled Application. In Proceedings of the International Offshore and Polar Engineering Conference, San Francisco, CA, USA, 25–30 June 2017. [Google Scholar]

- Heinrietz, A.; Hesseler, J. An approach for the fatigue estimation of porous cast iron based on non-destructive testing results. MATEC Web Conf. 2014, 12, 05001. [Google Scholar] [CrossRef]

- ISO/TR 945-3:2016; Microstructure of Cast Irons, Part1: Graphite Classification by Visual Analysis. International Organization for Standardization (ISO): Geneva, Switzerland, 2016.

- ISO 6506-1:2014; Metallic Materials—Brinell Hardness Test. International Organization for Standardization (ISO): Geneva, Switzerland, 2014.

- ISO 6892-1:2016; Metallic Materials—Tensile Testing. International Organization for Standardization (ISO): Geneva, Switzerland, 2016.

- ISO 12106:2017; Metallic Materials—Fatigue Testing—Axial-Strain-Controlled Method. International Organization for Standardization (ISO): Geneva, Switzerland, 2017.

- ASTM E 606-04; Standard Practice for Strain-Controlled Fatigue Testing. ASTM International: West Conshohocken, PA, USA, 2004.

- EN 1563:2018; Founding—Spheroidal Graphite Cast Irons. European Standard, 2018. Available online: https://standards.iteh.ai/catalog/standards/cen/e04bc999-3e91-4f24-855b-06dd6cf1d728/en-1563-2018 (accessed on 10 January 2022).

- Toktaş, G.; Tayanç, M.; Toktaş, A. Effect of matrix structure on the impact properties of an alloyed ductile iron. Mater. Charact. 2006, 57, 290–299. [Google Scholar] [CrossRef]

- Aristizabal, R.; Druschitz, A.; Druschitz, E.; Bragg, R.; Hubbard, C.; Watkins, T.; Ostrander, M. Intercritically Austempered Ductile Iron. In Proceedings of the American Foundry Society Transactions, Schaumburg, IL, USA, 5–8 April 2011; pp. 1–6. [Google Scholar]

- Durmuş, A.; Aydın, H.; Tutar, M.; Bayram, A.; Yiğit, K. Effect of the microstructure on the notched tensile strength of as-cast and austempered ductile cast irons. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2012, 226, 2214–2229. [Google Scholar] [CrossRef]

- Angella, G.; Donnini, R.; Ripamonti, D.; Górny, M.; Zanardi, F. The Role of Microstructure on the Tensile Plastic Behaviour of Ductile Iron GJS 400 Produced through Different Cooling Rates—Part II: Tensile Modelling. Metals 2019, 9, 1019. [Google Scholar] [CrossRef]

- Basquin, O.H. The exponential law of endurance tests. Am. Soc. Test Mater. Proc. 1910, 10, 625–630. [Google Scholar]

- Manson, S.S. Behavior of Materials under Conditions of Thermal Stress. Report No. NACA TN-2933; Nasa: Washington, DC, USA, 1945. [Google Scholar]

- Coffin, L.F. A study of the effect of cyclic thermal stresses on a ductile metal. Trans. ASME 1954, 76, 931–950. [Google Scholar]

- Morrow, J. Cyclic Plastic Strain Energy and Fatigue of Metals. In Internal Friction, Damping, and Cyclic Plasticity; ASTM International: West Conshohocken, PA, USA, 1965; pp. 43–45. [Google Scholar]

- Niesłony, A.; El Dsoki, C.; Kaufmann, H.; Krug, P. New method for evaluation of the Manson–Coffin–Basquin and Ramberg–Osgood equations with respect to compatibility. Int. J. Fatigue 2008, 30, 1967–1977. [Google Scholar] [CrossRef]

- Atzori, B.; Meneghetti, G.; Ricotta, M. A Three Dimensional Graphical Aid for Fatigue Data Analysis. Key Eng. Mater. 2011, 488–489, 755–758. [Google Scholar] [CrossRef]

- Williams, C.; Lee, Y.-L.; Rilly, J. A practical method for statistical analysis of strain–life fatigue data. Int. J. Fatigue 2002, 25, 427–436. [Google Scholar] [CrossRef]

- ASTM E739-10 (2010); Standard Practice for Statistical Analysis of Linear or Linearized Stress-Life (S-N) and Strain-Life (ε-N) Fatigue Data. ASTM International: West Conshohocken, PA, USA, 2015.

- Smith, R.; Watson, P.; Topper, T. A stress–strain function for the fatigue of metal. J. Mater. 1970, 5, 767–778. [Google Scholar]

| Region | Shape # and Size * of Graphite Nodules | Matrix Composition |

|---|---|---|

| 1 | VI-7 Spheroidal graphite | ferritic (50%)–pearlitic (50%) |

| 2 | VI-6/7 Spheroidal graphite | ferritic (50%)–pearlitic (50%) |

| 3 | VI-7 Spheroidal graphite | ferritic (50%)–pearlitic (50%) |

| Region | HBW—Test 1 | HBW—Test 2 | HBW—Test 3 | HBW—Average | HBW—Standard Deviation |

|---|---|---|---|---|---|

| 1 | 182 | 182 | 183 | 182.3 | 0.577 |

| 2 | 182 | 184 | 183 | 183.0 | 1.000 |

| 3 | 185 | 187 | 187 | 186.3 | 1.155 |

| Material | Raw Component | Specimen Surface | Test | Specimen Geometry | Rε | N° Tests | f [Hz] | Rate [mm/min] | Failure Criterion |

|---|---|---|---|---|---|---|---|---|---|

| EN-GJS-450-10 | Off-highway axle | machined | Static | Figure 4 | n.a. | 7 | n.a. | 0.5 | separation |

| Fatigue * | Figure 5 | −1 0.1 0.5 | 10 6 6 | 0.2–18 0.2–15 0.2–15 | n.a. n.a. n.a. | separation separation separation | |||

| as-cast | Fatigue * | Figure 6 | −1 | 15 | 0.2–18 | n.a. | separation |

| Material | Raw Component | Pearlite Content | HBW |

|---|---|---|---|

| EN-GJS-450-10 | off-highway axle | 20–50% | 170–206 |

| Material | Raw Component | Parameter | Es | σp0.2 | σR | A | Z | K | n |

|---|---|---|---|---|---|---|---|---|---|

| (MPa) | (MPa) | (MPa) | (%) | (%) | (MPa) | (/) | |||

| EN-GJS-450-10 | off-highway axle | Average value | 169,174 | 328 | 563 | 12.9 | 10 | 806 | 0.1584 |

| Standard deviation | 2383 | 4 | 9 | 1.3 | 1 | 26 | 0.0113 |

| Material | Raw Component | Specimen Surface | Test | Rε | N° Tests | Type A | Type B | Type C | Run Out |

|---|---|---|---|---|---|---|---|---|---|

| EN-GJS-450-10 | off-highway axle | machined | Static | n.a. | 7 | 6 | 0 | 1 | n.a. |

| Fatigue * | −1 0.1 0.5 | 10 6 6 | 6 5 6 | 1 1 0 | 2 0 0 | 1 0 0 | |||

| as-cast | Fatigue * | −1 | 14 | 9 | 3 | 0 | 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scacco, F.; Campagnolo, A.; Franceschi, M.; Meneghetti, G. Strain-Controlled Fatigue Behavior of a Nodular Cast Iron in Real Off-Highway Axles: Effects of Casting Skin and Strain Ratio. Metals 2022, 12, 426. https://doi.org/10.3390/met12030426

Scacco F, Campagnolo A, Franceschi M, Meneghetti G. Strain-Controlled Fatigue Behavior of a Nodular Cast Iron in Real Off-Highway Axles: Effects of Casting Skin and Strain Ratio. Metals. 2022; 12(3):426. https://doi.org/10.3390/met12030426

Chicago/Turabian StyleScacco, Federico, Alberto Campagnolo, Mattia Franceschi, and Giovanni Meneghetti. 2022. "Strain-Controlled Fatigue Behavior of a Nodular Cast Iron in Real Off-Highway Axles: Effects of Casting Skin and Strain Ratio" Metals 12, no. 3: 426. https://doi.org/10.3390/met12030426

APA StyleScacco, F., Campagnolo, A., Franceschi, M., & Meneghetti, G. (2022). Strain-Controlled Fatigue Behavior of a Nodular Cast Iron in Real Off-Highway Axles: Effects of Casting Skin and Strain Ratio. Metals, 12(3), 426. https://doi.org/10.3390/met12030426