Development of Hot Working Process Maps for Incompressible TRIP Steel and Zirconia Composites Using Crystal Plasticity-Based Numerical Simulations

Abstract

:1. Introduction

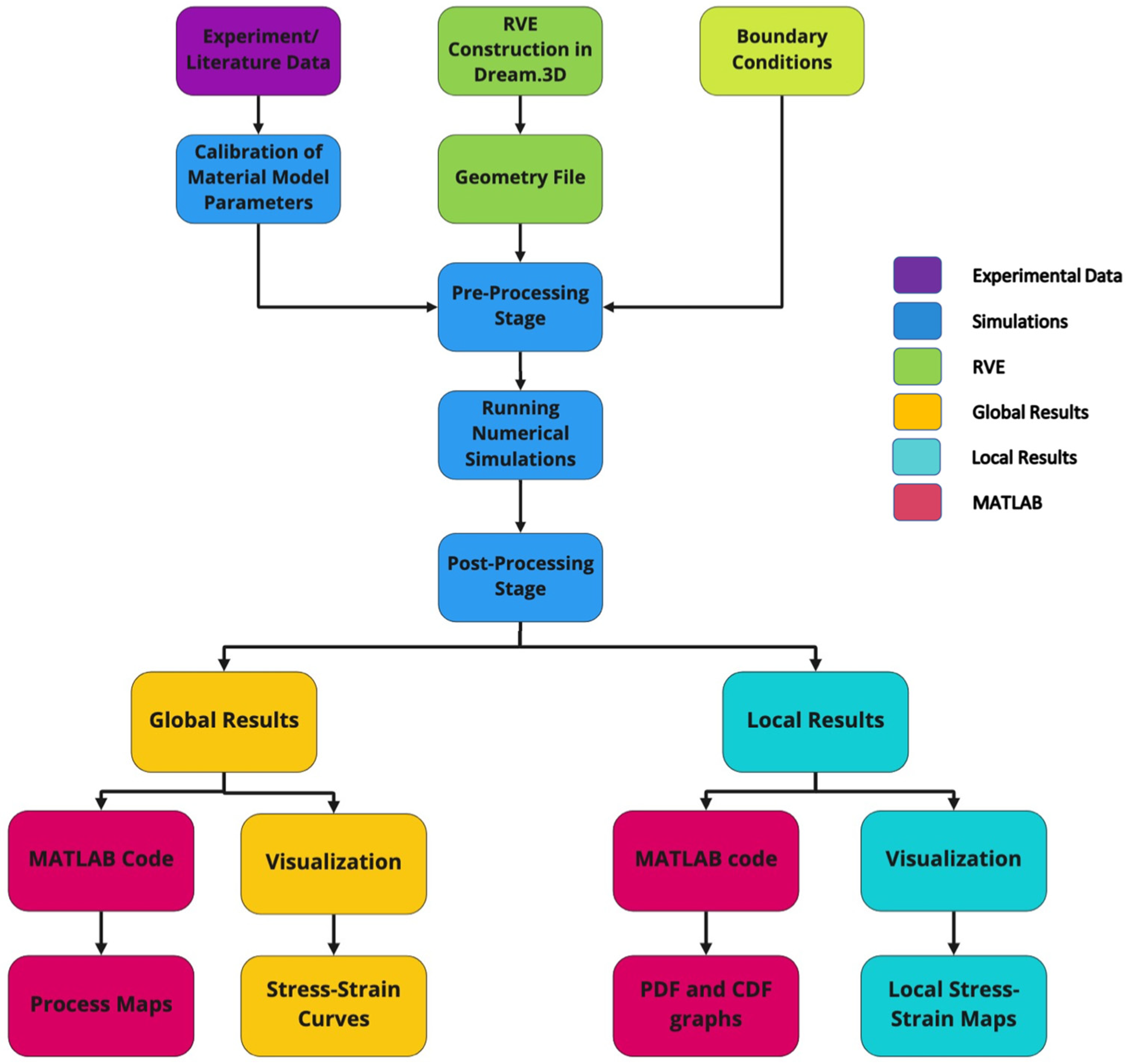

2. Methodology

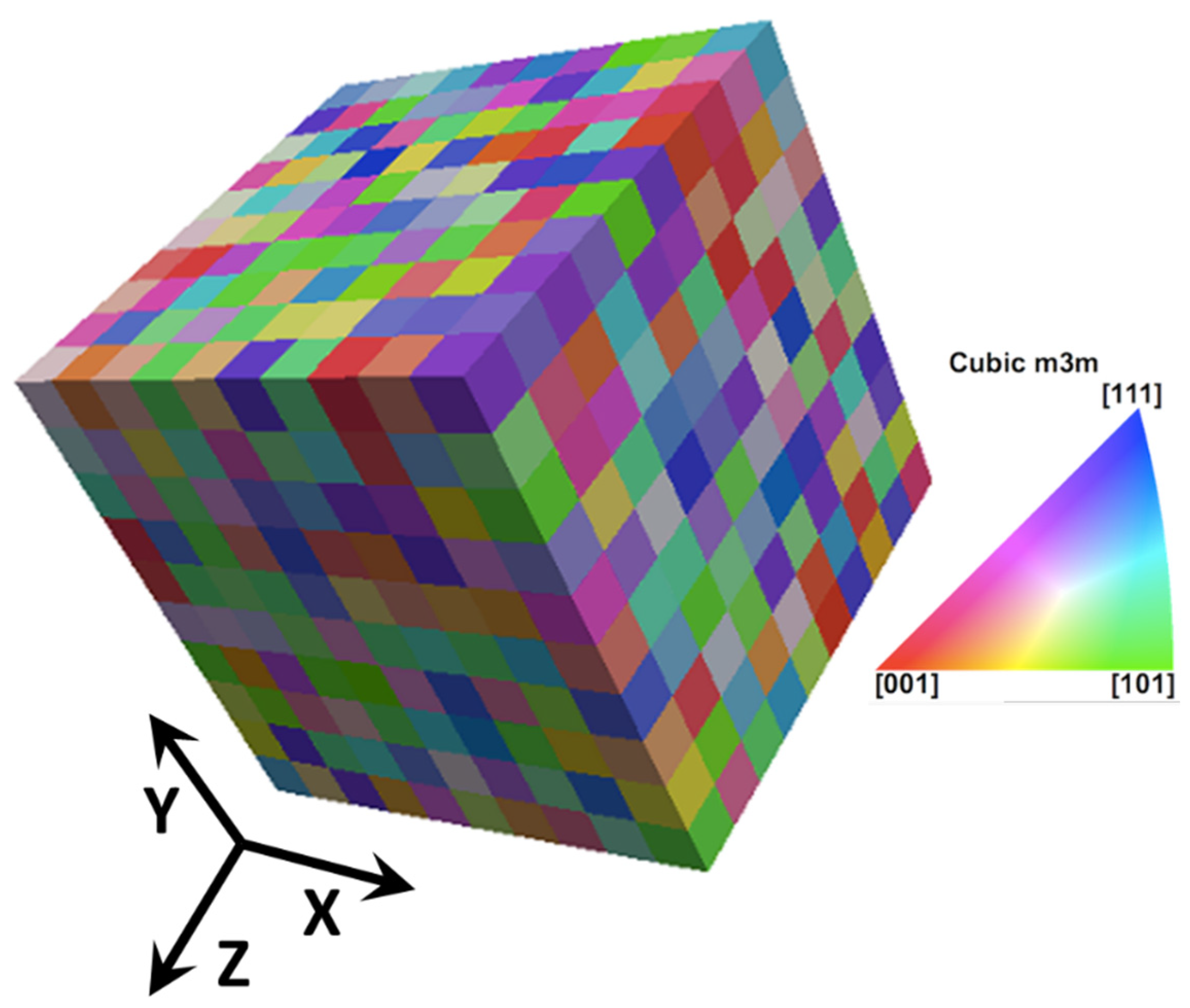

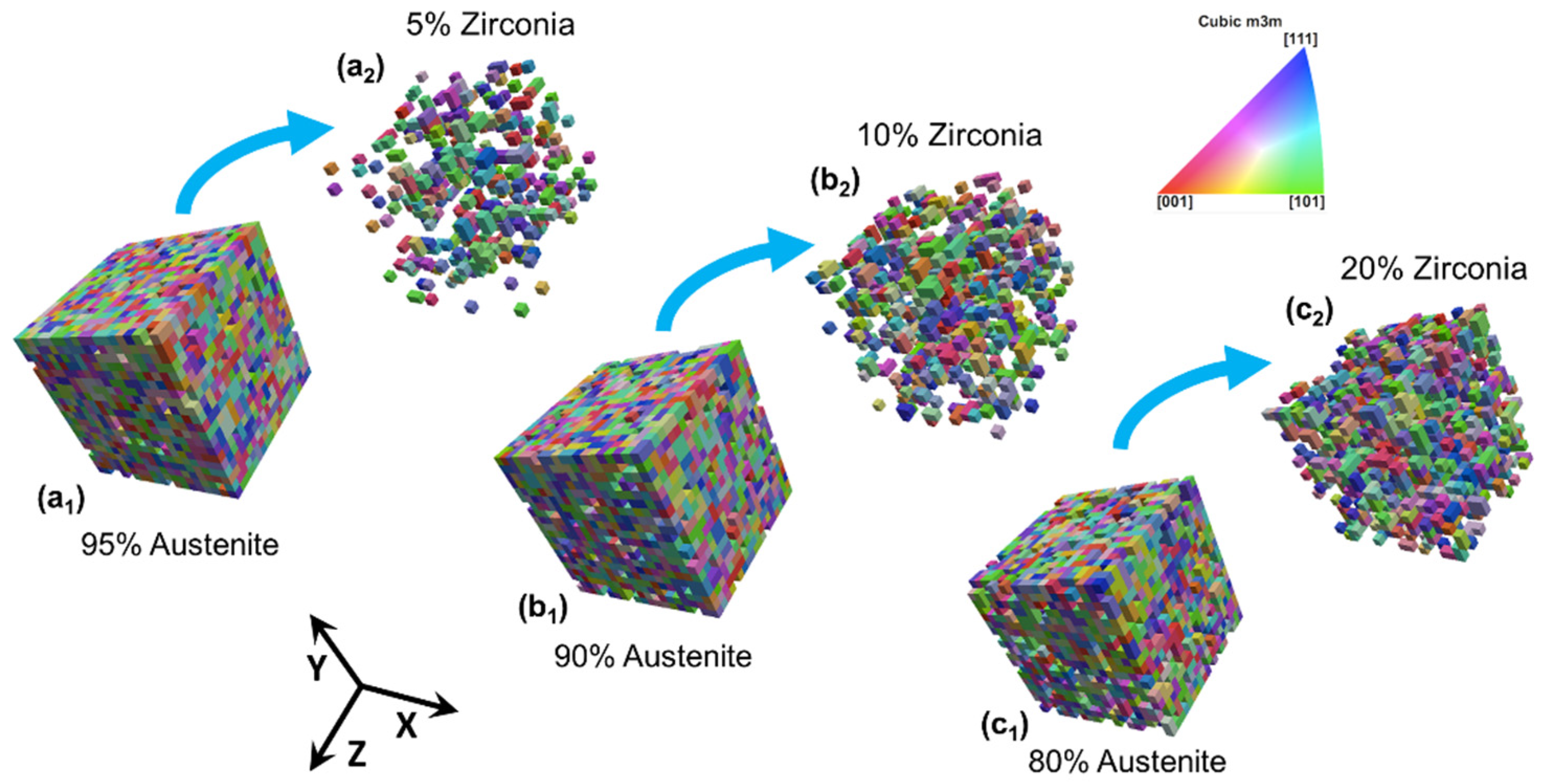

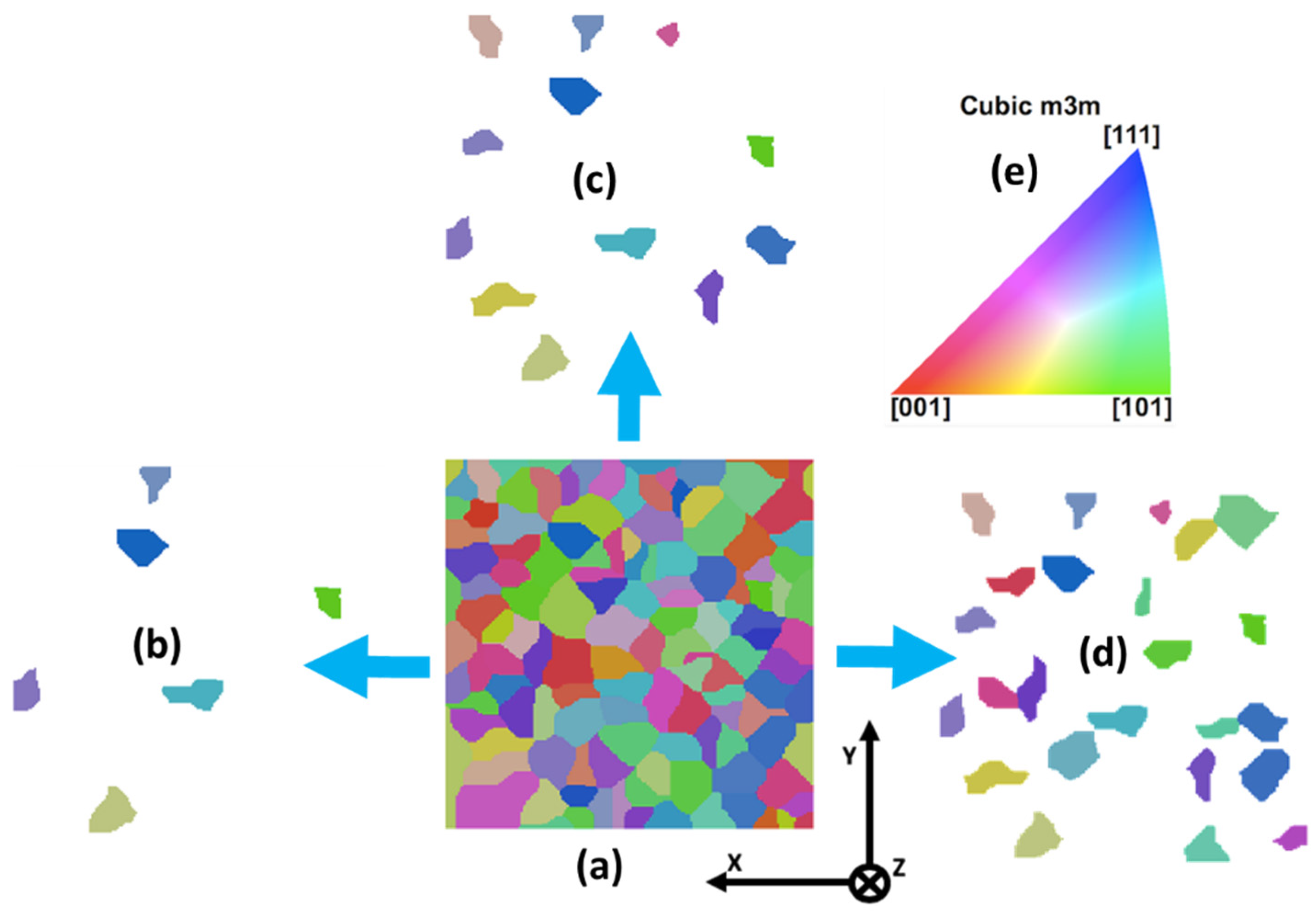

2.1. RVE Construction

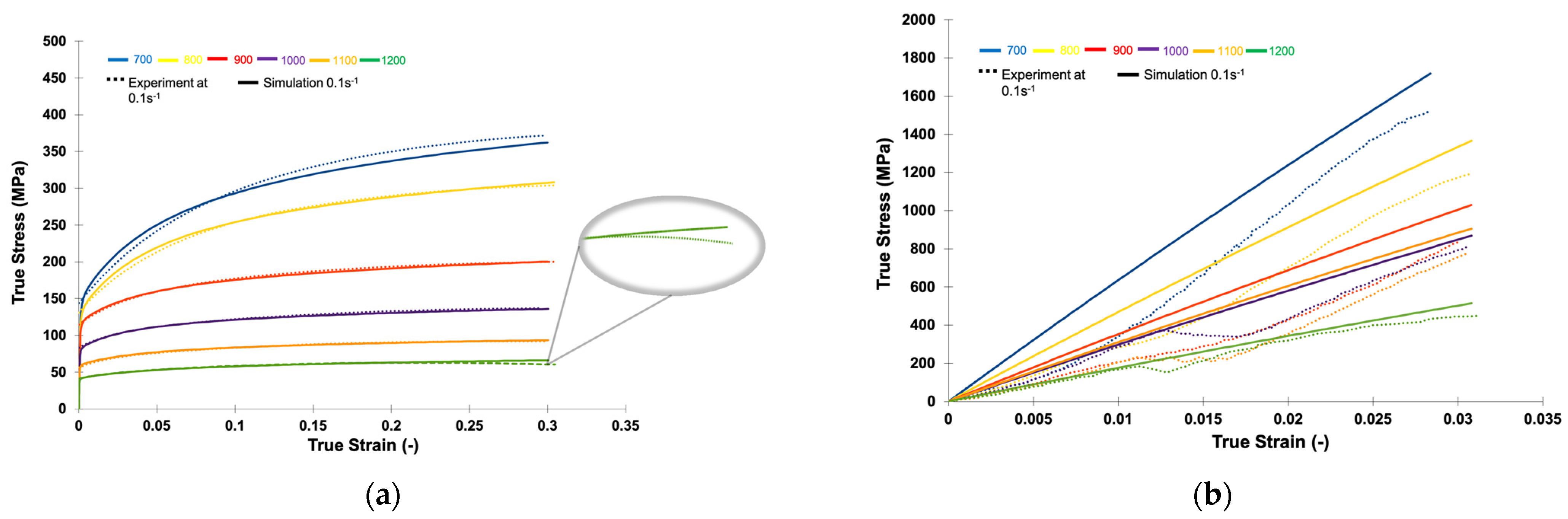

2.2. Material Used and Data Collection

2.3. Boundary Conditions, Processing, and Post-processing

3. Results

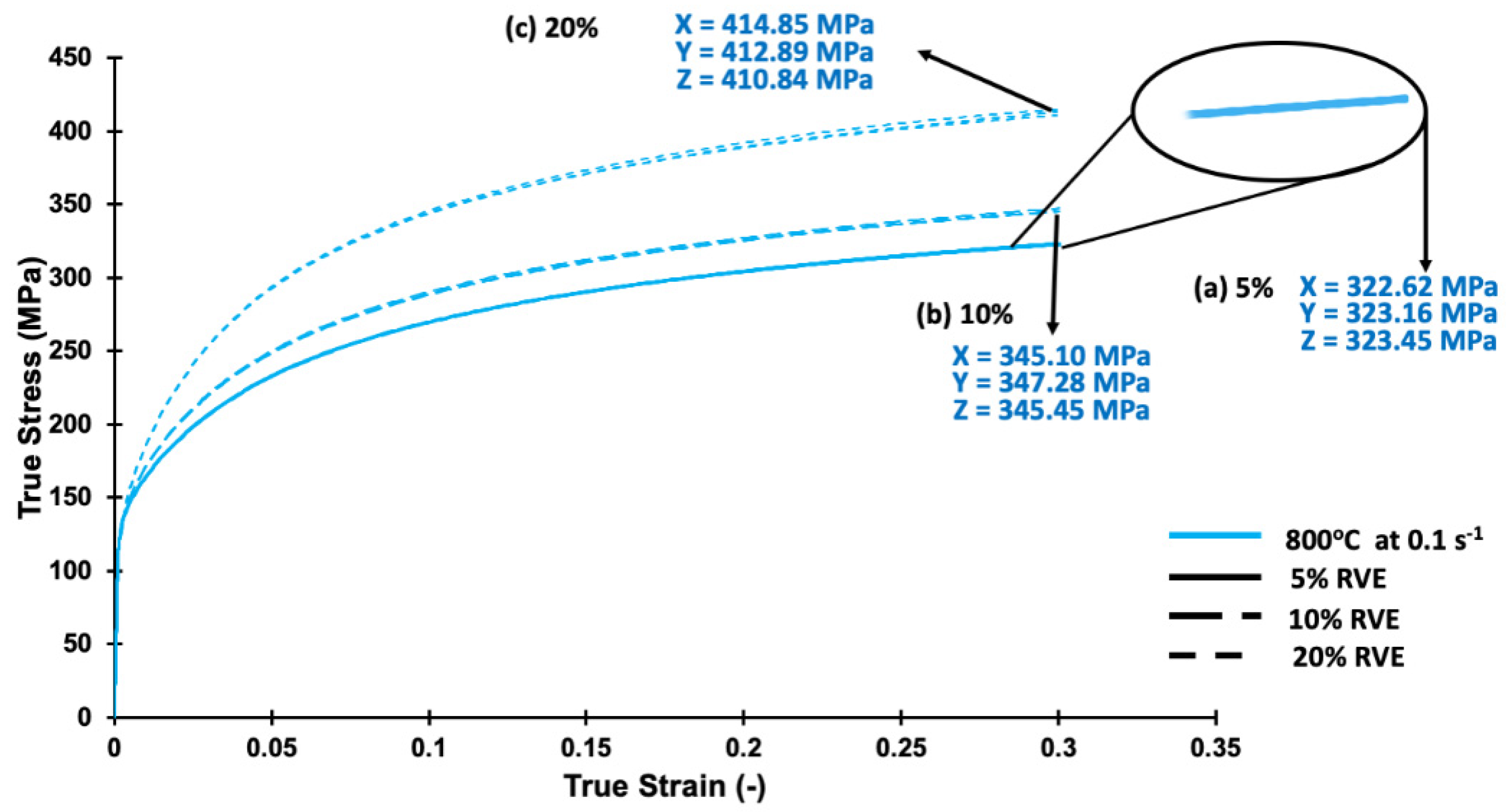

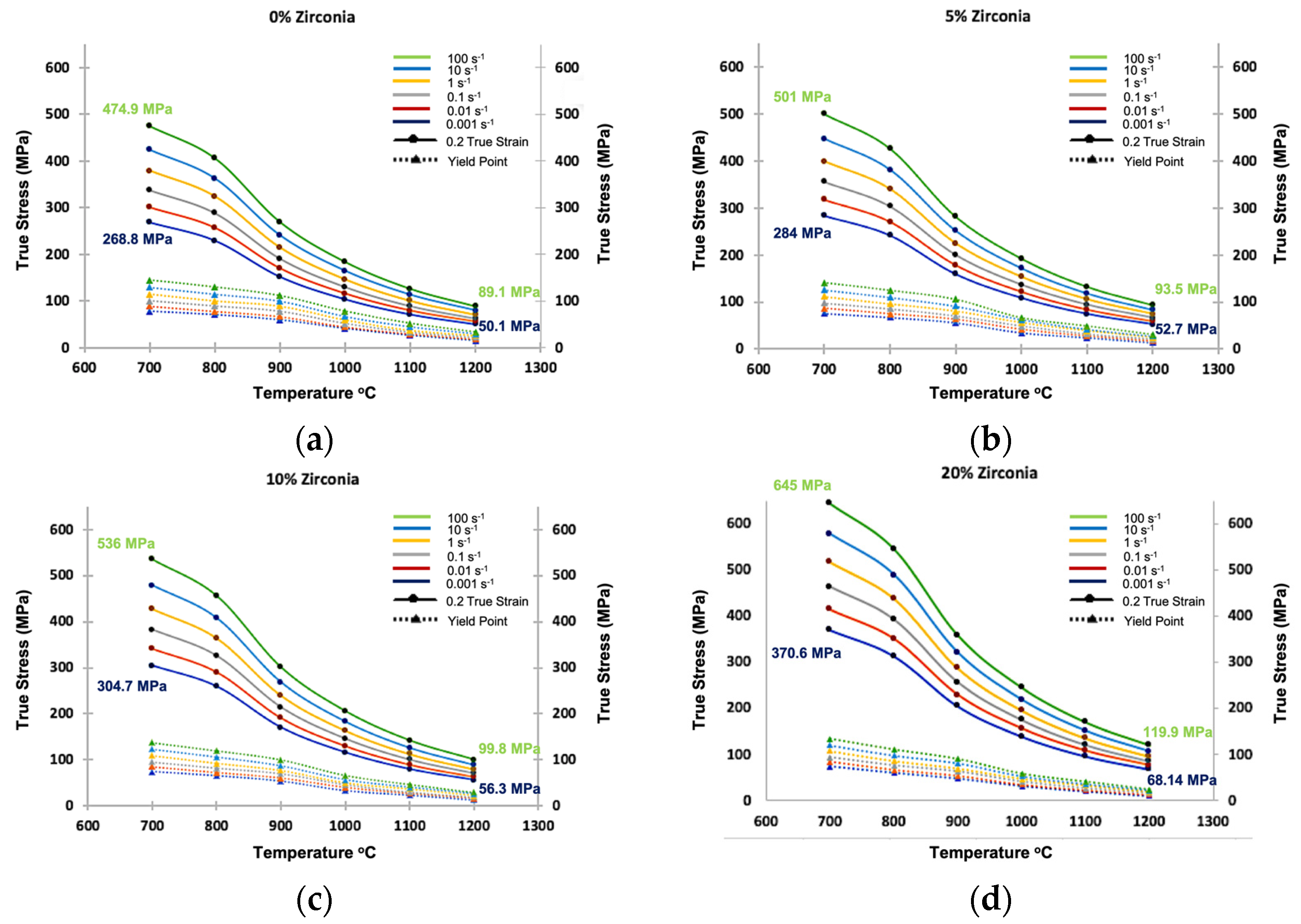

3.1. Deformation Behavior of TRIP Steel Composite

3.1.1. Global Behavior

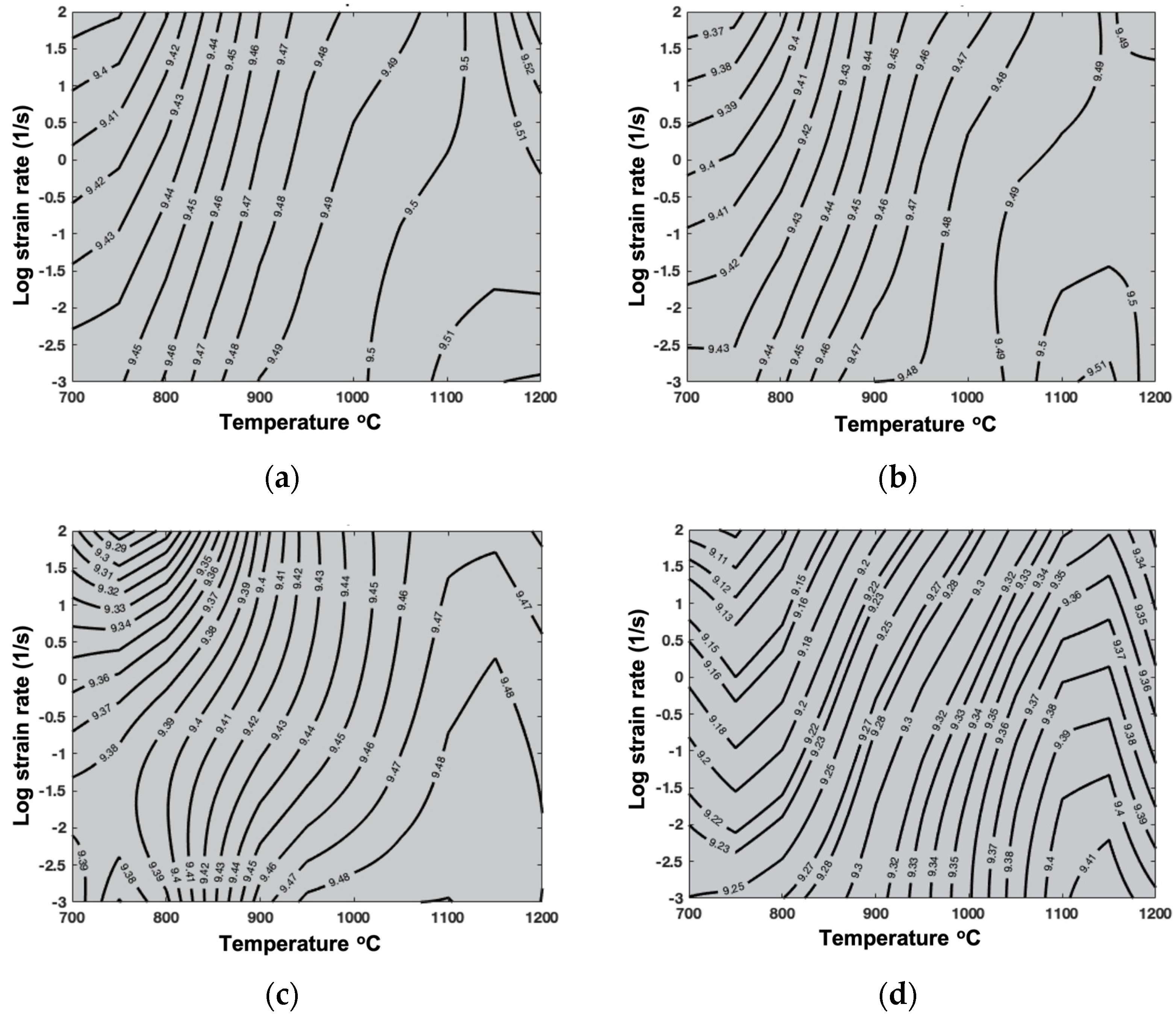

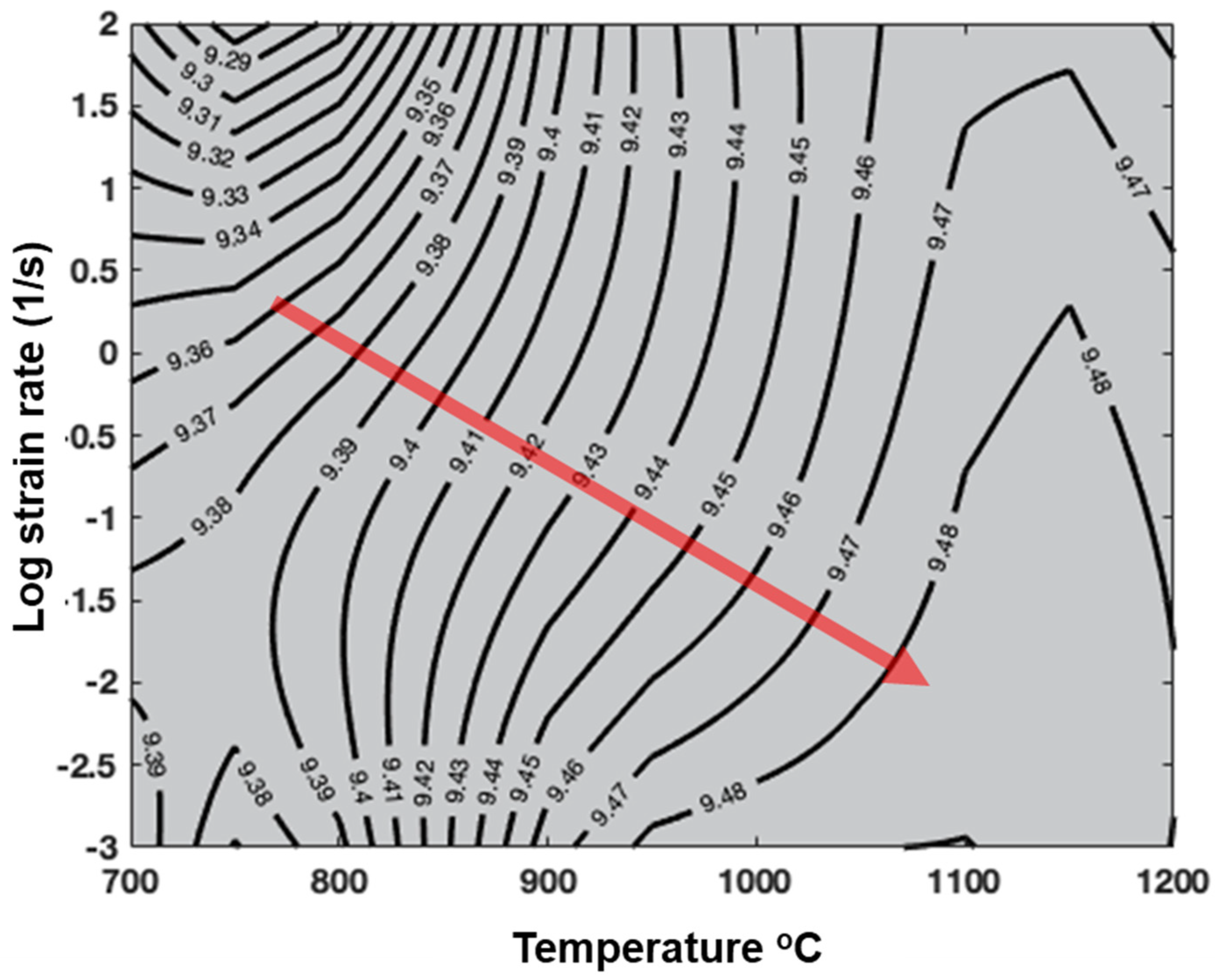

3.1.2. Process Maps

3.2. Local Results

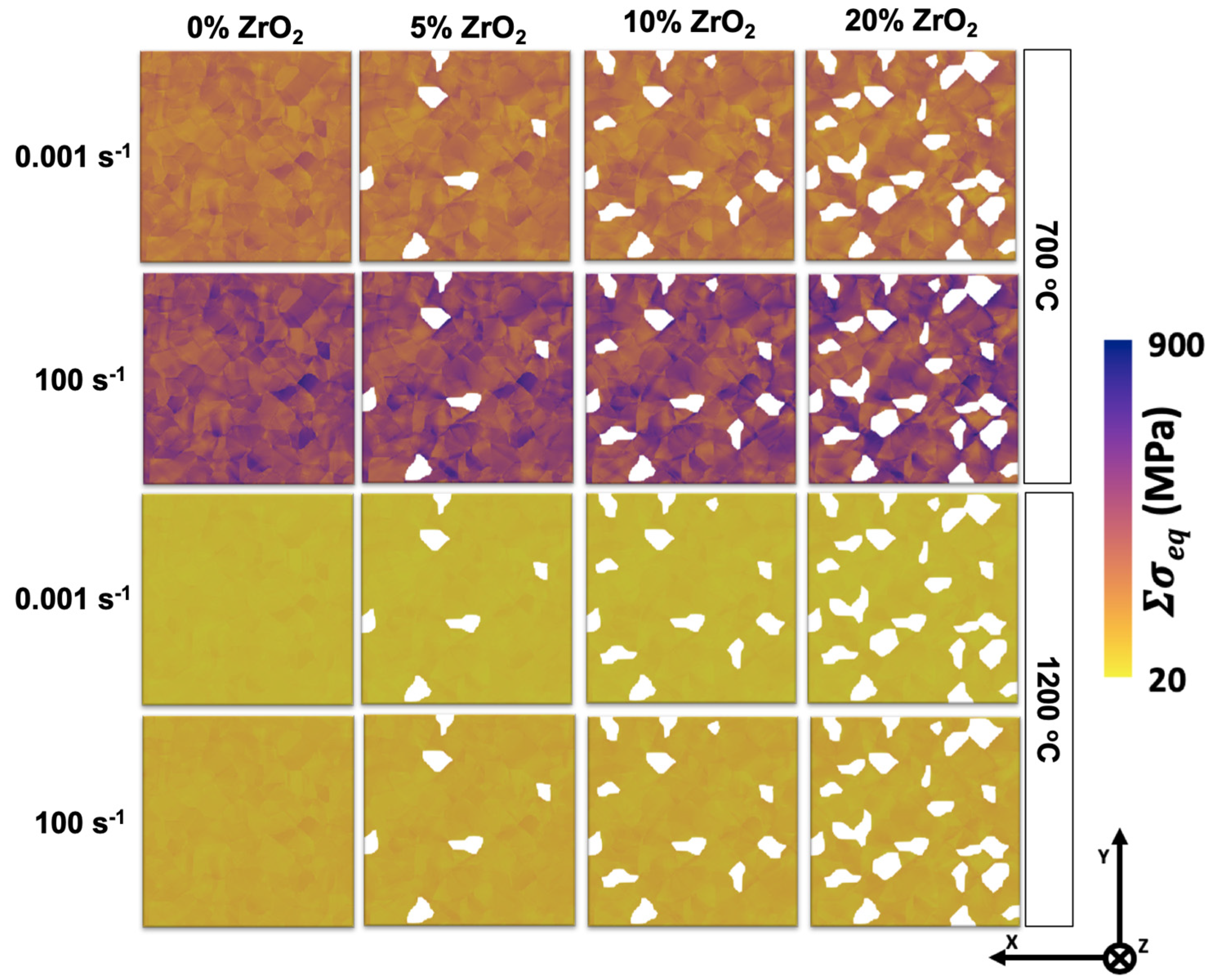

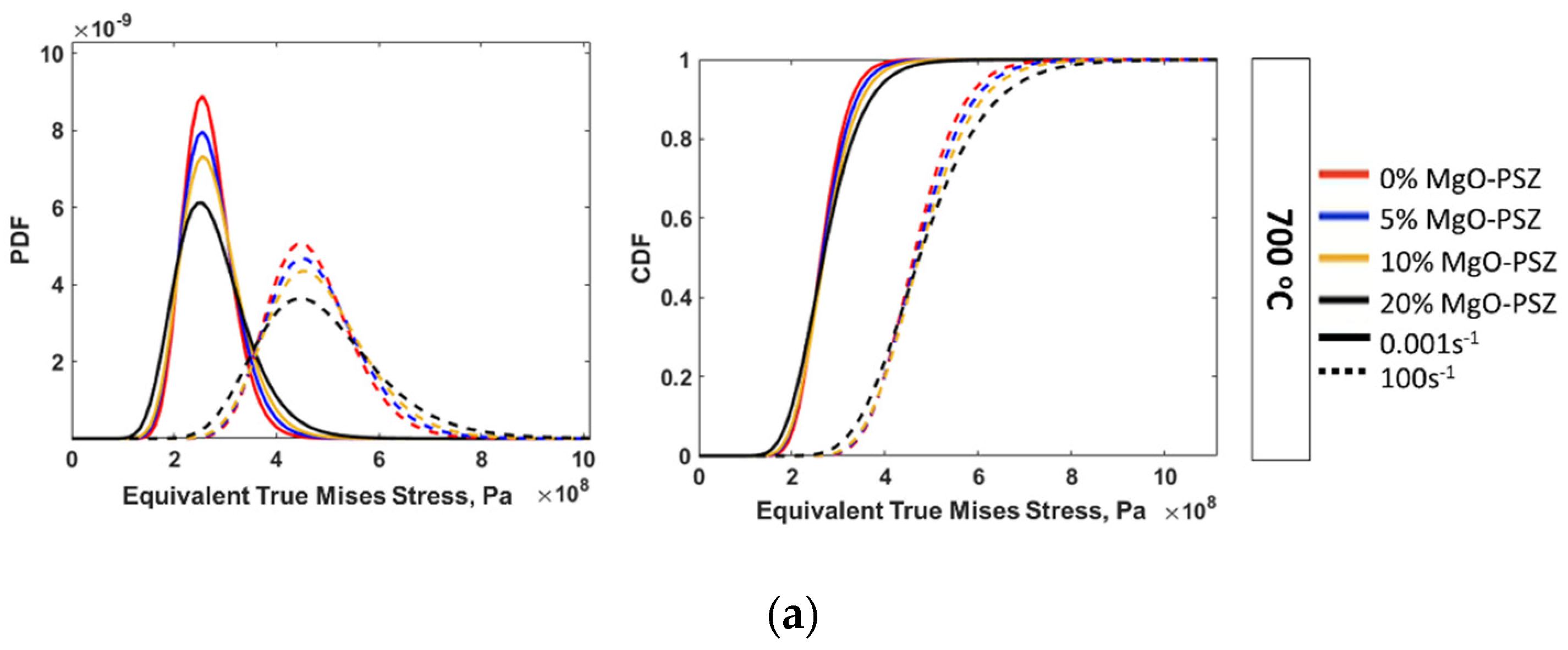

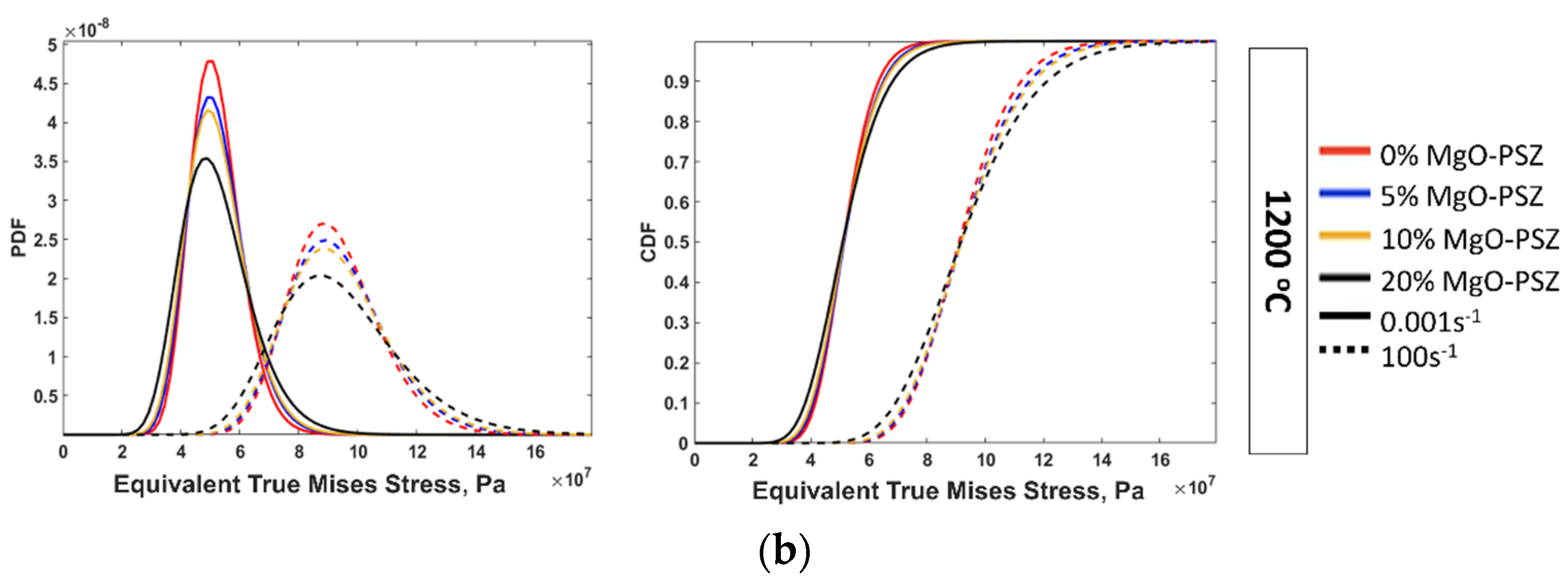

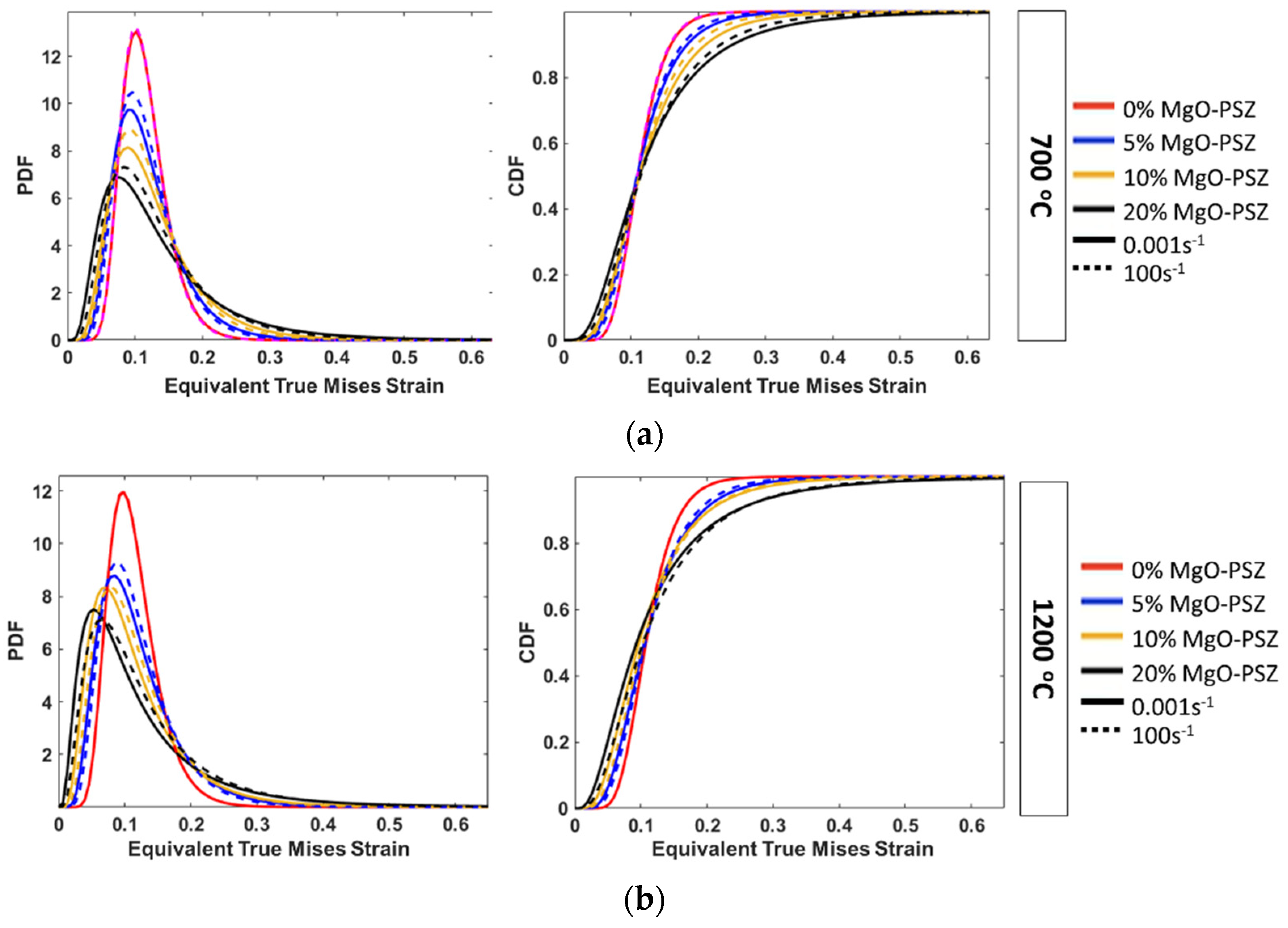

3.2.1. Local Stress and Strain Maps

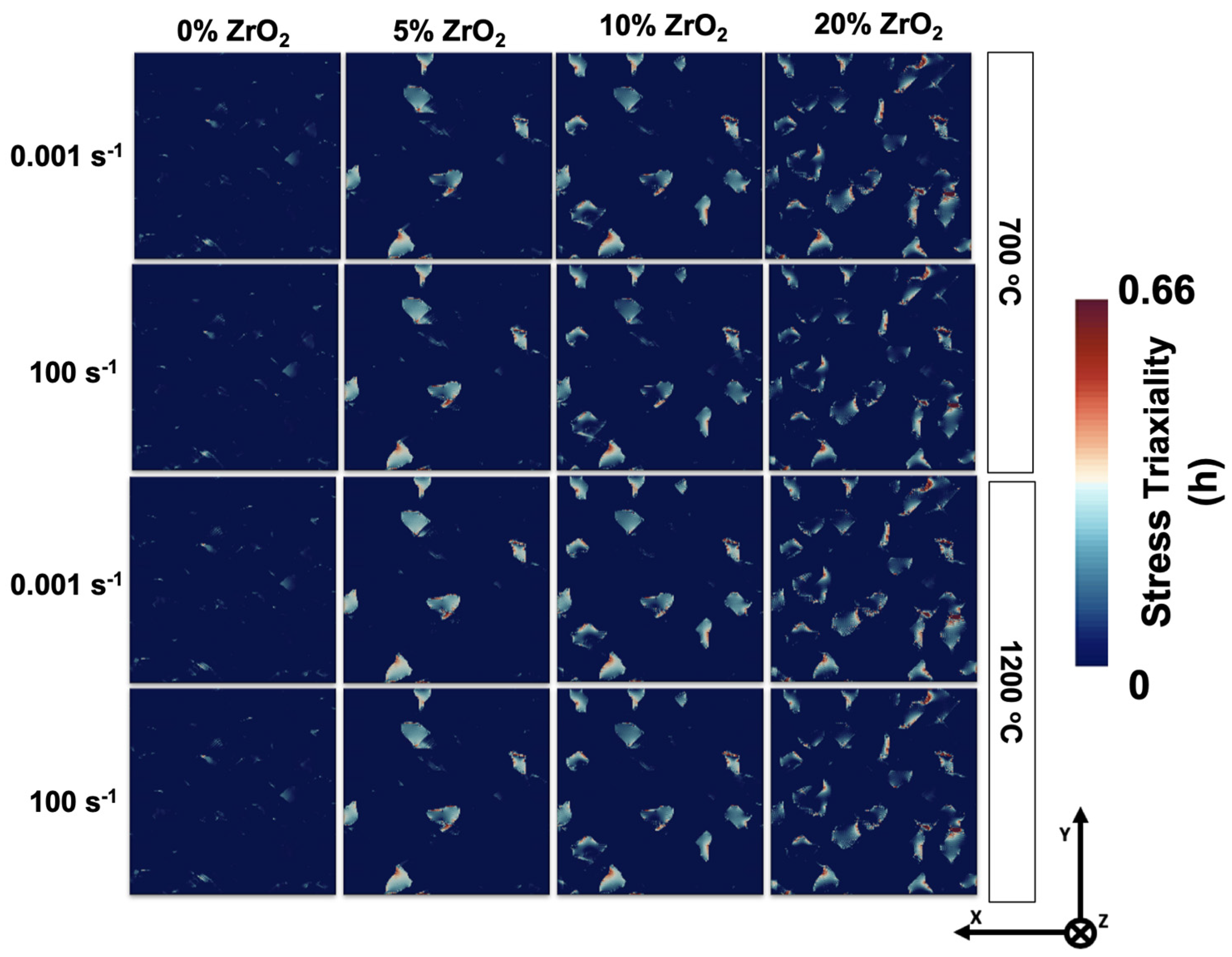

3.2.2. Local Stress Triaxiality Map

4. Discussion

5. Conclusions

- The proposed methodology for creating process maps might assist researchers in estimating process maps of zirconia-reinforced TRIP steel MMCs based on virtual laboratory setups with different microstructural attributes.

- In this study, isotropic 3D 20 × 20 × 20 RVEs were proposed for global deformation behavior with 5%, 10%, and 20% second-phase particles. These RVEs behaved isotopically and yielded simulation results independent of the geometry and mesh dependence. Such RVEs might be used for calibrating model parameters by other researchers.

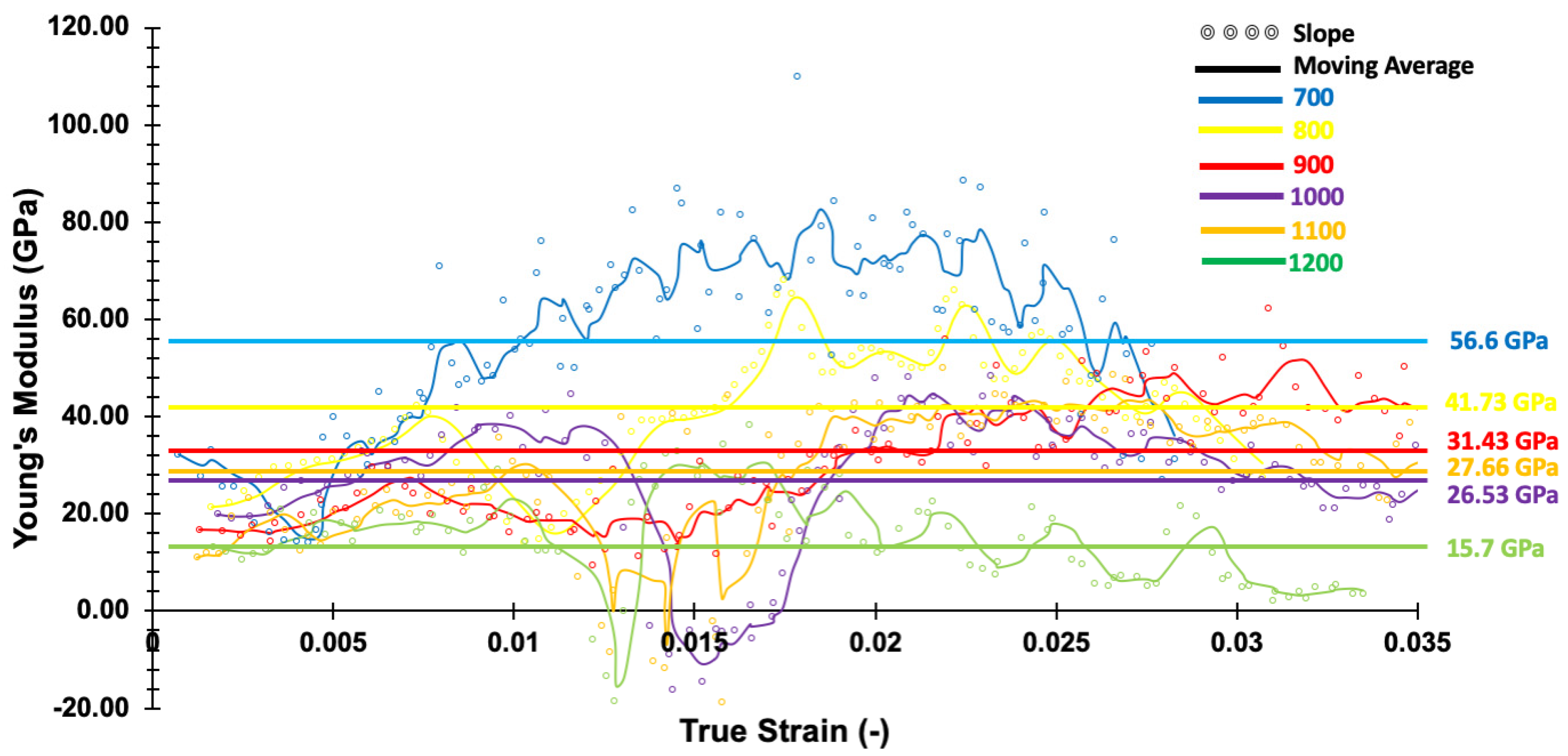

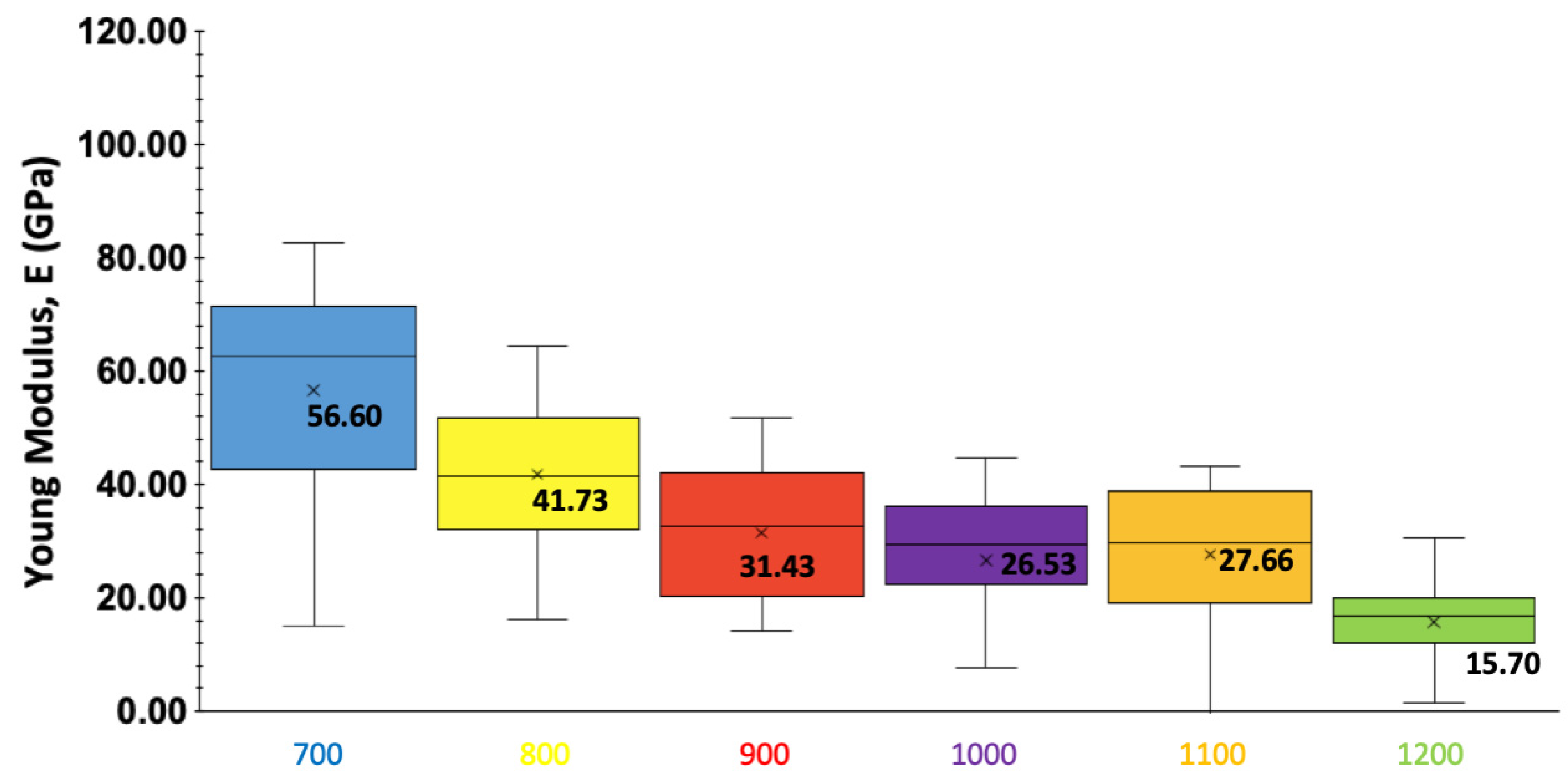

- The modulus of elasticity for zirconia particles at different temperatures was determined by performing statistical analyses on the experimental data. For this, a four-point moving average of the experimentally determined slope values was selected from the entire dataset in the elastic zone. Although the identified values had a similar slope, they deviated from experimental observations significantly at temperatures below 900 °C.

- At 0.2 strain, the value of global true stress was 30% higher for the composite containing 20% zirconia compared to the value of global true stress of pure TRIP steel matrix at all temperatures.

- The phenomenological power law did not exhibit the experimentally observed dynamic softening behavior, which is why the identified process maps did not reflect the zones of instability. This limitation might be addressed in future studies by the inclusion of dynamic softening and recrystallization in this formulation.

- By performing qualitative analysis, we found that the efficiency of power dissipation decreased with an increase in the zirconia concentration, which reduced its formability.

- For comparing the inclusion of zirconia particles, statistical analysis of the simulation results presented as PDFs and CDFs for each material might be helpful. By performing this analysis, we found that the corresponding stress and strain heterogeneity increased significantly as the number of zirconia inclusions in a fixed steel matrix increased.

- The zirconia particles exhibited the highest stress–strain partitioning at the ceramic/matrix interface, which probably caused interface decohesion in this material. The zirconia particles experienced the highest stress and the least strain during deformation.

- The local stress triaxiality maps showed that increasing the percentage of zirconia in the composite increased the value of the stress triaxiality factor. This corresponded to an increase in the hydrostatic stress in the material, which might cause faster evolution of local damage.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Acronym | |

| Symbol | Description |

| 2D | Two-Dimensional |

| 3D | Three-Dimensional |

| CP | Crystal Plasticity |

| CPFEM | Crystal Plasticity Finite Element Method |

| CPU | Central Processing Unit |

| CDF | Cumulative Distribution Function |

| DAMASK | Düsseldorf Advanced Materials Simulation Kit |

| DMM | Dynamic Material Model |

| DRX | Dynamic Recrystallization |

| FFT | Fast Fourier Transform |

| GHz | Giga Hertz |

| MMC | Metal Matrix Composite |

| MPa | Mega Pascal |

| Probability Density Function | |

| PF | Phase Field |

| RVE | Representative Volume Element |

| TRIP | Transformation Induced Plasticity |

Appendix A

Appendix A.1. Phenomenological Power Law

Appendix A.2. Dynamic Material Model

Appendix B. Zirconia Material Model Parameters Calculations

References

- Miracle, D. Metal matrix composites–from science to technological significance. Compos. Sci. Technol. 2005, 65, 2526–2540. [Google Scholar] [CrossRef]

- Weigelt, C.; Aneziris, C.; Ehinger, D.; Eckner, R.; Krüger, L.; Ullrich, C.; Rafaja, D. Effect of zirconia and aluminium titanate on the mechanical properties of transformation-induced plasticity-matrix composite materials. J. Compos. Mater. 2015, 49, 3567–3579. [Google Scholar] [CrossRef]

- Springer, P.; Prahl, U. Characterisation of mechanical behavior of 18CrNiMo7-6 steel with and without nb under warm forging conditions through processing maps analysis. J. Mater. Process. Technol. 2016, 237, 216–234. [Google Scholar] [CrossRef]

- Prasad, Y.; Gegel, H.; Doraivelu, S.; Malas, J.; Morgan, J.; Lark, K.; Barker, D. Modeling of dynamic material behavior in hot deformation: Forging of Ti-6242. Metall. Trans. A 1984, 15, 1883–1892. [Google Scholar] [CrossRef]

- Li, J.; Li, F.; An, Y. Characterization of Hot Deformation Behavior for Pure Aluminum Using 3D Processing Maps. High Temp. Mater. Process. 2018, 37, 929–942. [Google Scholar] [CrossRef]

- Qayyum, F.; Guk, S.; Kawalla, R.; Prahl, U. On Attempting to Create a Virtual Laboratory for Application-Oriented Microstructural Optimization of Multi-Phase Materials. Appl. Sci. 2021, 11, 1506. [Google Scholar] [CrossRef]

- Bruschi, S.; Altan, T.; Banabic, D.; Bariani, P.; Brosius, A.; Cao, J.; Ghiotti, A.; Khraisheh, M.; Merklein, M.; Tekkaya, A. Testing and modelling of material behaviour and formability in sheet metal forming. CIRP Ann. 2014, 63, 727–749. [Google Scholar] [CrossRef]

- Eisenlohr, P.; Diehl, M.; Lebensohn, R.A.; Roters, F. A spectral method solution to crystal elasto-viscoplasticity at finite strains. Int. J. Plast. 2013, 46, 37–53. [Google Scholar] [CrossRef]

- Roters, F.; Eisenlohr, P.; Hantcherli, L.; Tjahjanto, D.D.; Bieler, T.R.; Raabe, D. Overview of constitutive laws, kinematics, homogenization and multiscale methods in crystal plasticity finite-element modeling: Theory, experiments, applications. Acta Mater. 2010, 58, 1152–1211. [Google Scholar] [CrossRef]

- Roters, F.; Eisenlohr, P.; Kords, C.; Tjahjanto, D.; Diehl, M.; Raabe, D. DAMASK: The Düsseldorf Advanced MAterial Simulation Kit for studying crystal plasticity using an FE based or a spectral numerical solver. Procedia Iutam 2012, 3, 3–10. [Google Scholar] [CrossRef]

- Zhang, H.; Diehl, M.; Roters, F.; Raabe, D. A virtual laboratory using high resolution crystal plasticity simulations to determine the initial yield surface for sheet metal forming operations. Int. J. Plast. 2016, 80, 111–138. [Google Scholar] [CrossRef]

- Roters, F.; Diehl, M.; Shanthraj, P.; Eisenlohr, P.; Reuber, C.; Wong, S.L.; Maiti, T.; Ebrahimi, A.; Hochrainer, T.; Fabritius, H.-O. DAMASK–The Düsseldorf Advanced Material Simulation Kit for modeling multi-physics crystal plasticity, thermal, and damage phenomena from the single crystal up to the component scale. Comput. Mater. Sci. 2019, 158, 420–478. [Google Scholar] [CrossRef]

- Qayyum, F.; Umar, M.; Guk, S.; Schmidtchen, M.; Kawalla, R.; Prahl, U. Effect of the 3rd Dimension within the Representative Volume Element (RVE) on Damage Initiation and Propagation during Full-Phase Numerical Simulations of Single and Multi-Phase Steels. Materials 2020, 14, 42. [Google Scholar] [CrossRef]

- Qayyum, F.; Guk, S.; Prüger, S.; Schmidtchen, M.; Saenko, I.; Kiefer, B.; Kawalla, R.; Prahl, U. Investigating the local deformation and transformation behavior of sintered X3CrMnNi16-7-6 TRIP steel using a calibrated crystal plasticity-based numerical simulation model. Int. J. Mater. Res. 2020, 111, 392–404. [Google Scholar] [CrossRef]

- Qayyum, F.; Chaudhry, A.A.; Guk, S.; Schmidtchen, M.; Kawalla, R.; Prahl, U. Effect of 3D Representative Volume Element (RVE) Thickness on Stress and Strain Partitioning in Crystal Plasticity Simulations of Multi-Phase Materials. Crystals 2020, 10, 944. [Google Scholar] [CrossRef]

- Khan, U.; Hussain, A.; Shah, M.; Shuaib, M.; Qayyum, F. Investigation of Mechanical Properties Based on Grain Growth and Microstructure Evolution of Alumina Ceramics during Two Step Sintering Process; IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2016; p. 012046. [Google Scholar]

- Kirschner, M.; Guk, S.; Kawalla, R.; Prahl, U. Further Development of Process Maps for TRIP Matrix Composites during Powder Forging; Materials Science Forum; Trans. Tech. Publications: Stafa-Zurich, Switzerland, 2019; pp. 15–23. [Google Scholar]

- Decker, S. Entwicklung der Mikrostruktur und der Mechanischen Eigenschaften eines Mg-PSZ-Partikelverstärkten TRIP-Matrix-Composits während Spark Plasma Sintering; Logos Verlag Berlin GmbH: Berlin, Germany, 2015. [Google Scholar]

- Reckziegel, A. Properties and Applications of High-Performance Ceramics Made of Zirconia; Aliaxis Utilities and Industry: Mannheim, Germany, 2015. [Google Scholar]

- Martin, S.; Decker, S.; Krüger, L.; Martin, U.; Rafaja, D. Microstructure Changes in TRIP Steel/Mg-PSZ Composites Induced by Low Compressive Deformation. Adv. Eng. Mater. 2013, 15, 600–608. [Google Scholar] [CrossRef]

- Groeber, M.A.; Jackson, M.A. DREAM.3D: A Digital Representation Environment for the Analysis of Microstructure in 3D. Integr. Mater. Manuf. Innov. 2014, 3, 56–72. [Google Scholar] [CrossRef] [Green Version]

- Prasad, Y.; Rao, K.; Sasidhar, S. Hot Working Guide: A Compendium of Processing Maps; ASM International: Almere, The Netherlands, 2015. [Google Scholar]

- Ahrens, J.; Geveci, B.; Law, C. Paraview: An End-User Tool for Large Data Visualization; Los Alamos National Laboratory: Los Alamos, NM, USA, 2005. [Google Scholar]

- Kirschner, M.; Guk, S.; Kawalla, R.; Prahl, U. Powder Forging of Presintered TRIP-Matrix Composites. In Austenitic TRIP/TWIP Steels and Steel-Zirconia Composites; Springer: Berlin/Heidelberg, Germany, 2020; pp. 223–255. [Google Scholar]

- Qayyum, F.; Guk, S.; Schmidtchen, M.; Kawalla, R.; Prahl, U. Modeling the local deformation and transformation behavior of cast X8CrMnNi16-6-6 TRIP steel and 10% Mg-PSZ composite using a continuum mechanics-based crystal plasticity model. Crystals 2020, 10, 221. [Google Scholar] [CrossRef] [Green Version]

- Reyes-Morel, P.E.; Chen, I.W. Stress-Biased Anisotropic Microcracking in Zirconia Polycrystals. J. Am. Ceram. Soc. 1990, 73, 1026–1033. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Y.; Zeng, W.; Feng, F.; Sun, Y.; Han, Y.; Zhou, Y. Characterization of hot deformation behavior of as-cast TC21 titanium alloy using processing map. Mater. Sci. Eng. A 2011, 528, 1757–1763. [Google Scholar] [CrossRef]

- Landes, J.D.; McCabe, D.E. Fracture Mechanics: Twenty-Fourth Volume; ASTM International: Philadelphia, PA, USA, 1994; Volume 1207. [Google Scholar]

- Giglio, M.; Manes, A.; Vigano, F. Ductile fracture locus of Ti–6Al–4V titanium alloy. Int. J. Mech. Sci. 2012, 54, 121–135. [Google Scholar] [CrossRef]

- Zhao, P.; Song En Low, T.; Wang, Y.; Niezgoda, S.R. An integrated full-field model of concurrent plastic deformation and microstructure evolution: Application to 3D simulation of dynamic recrystallization in polycrystalline copper. Int. J. Plast. 2016, 80, 38–55. [Google Scholar] [CrossRef]

- Guk, S.; Milisova, D.; Pranke, K. Influence of Deformation Conditions on the Microstructure and Formability of Sintered Mg-PSZ Reinforced TRIP-Matrix-Composites; Key Engineering Materials; Trans. Tech. Publications: Stafa-Zurich, Switzerland, 2016; pp. 86–96. [Google Scholar]

- Ziegler, H. Progress in Solid Mechanics; Sneddon, I.N., Hill, R., Eds.; North-Holland Publishing Company: New York, NY, USA, 1963. [Google Scholar]

- Pabst, W.; Ticha, G.; Gregorová, E. Effective elastic properties of alumina-zirconia composite ceramics-Part 3. Calculation of elastic moduli of polycrystalline alumina and zirconia from monocrystal data. Ceram. Silik. 2004, 48, 41–48. [Google Scholar]

- Vliet, K. Mechanical Behavior of Materials; v. 3.22; Massachusetts Institute of Technology: Cambridge, MA, USA, 2008. [Google Scholar]

| TRIP Steel | C | Si | Mn | S | Cr | Mo | Ni | N | Al | Nb | Ti |

|---|---|---|---|---|---|---|---|---|---|---|---|

| wt.% | 0.03 | 1.0 | 7.2 | <0.01 | 16.3 | <0.01 | 6.6 | 0.09 | 0.04 | 0.021 | <0.01 |

| Zirconia | ZrO2 | HfO2 | MgO | SiO2 | Al2O3 | CaO | TiO2 | Y2O3 | |||

| wt.% | bal. | 1.85 | 3.25 | 0.1 | 1.58 | 0.06 | 0.13 | 0.13 |

| Parameter Definition | Symbol | 700 °C | 800 °C | 900 °C | 1000 °C | 1100 °C | 1200 °C | Unit |

|---|---|---|---|---|---|---|---|---|

| First elastic stiffness constant with normal strain | C11 | 124.8 | GPa | |||||

| Second elastic stiffness constant with normal strain | C12 | 53.5 | GPa | |||||

| First, elastic stiffness constant with shear strain | C44 | 35.7 | GPa | |||||

| Initial shear resistance on [111] | So [111] | 46 | 41 | 36 | 25 | 18 | 12.5 | MPa |

| Saturation shear resistance on [111] | S∞ [111] | 120 | 100 | 63 | 42 | 29 | 21 | MPa |

| Slip hardening parameter | ho | 850 | 830 | 780 | 685 | 440 | 220 | MPa |

| Stress exponent | n | 20 | - | |||||

| Curve fitting parameter | w | 2.5 | - | |||||

| Parameter Definition | Symbol | 700 °C | 800 °C | 900 °C | 1000 °C | 1100 °C | 1200 °C | Unit |

|---|---|---|---|---|---|---|---|---|

| Young’s Modulus | E | 56.6 | 41.73 | 31.43 | 26.53 | 27.66 | 15.7 | GPa |

| Poisson’s Ratio Value | v | 0.3 | - | |||||

| First elastic stiffness constant with normal strain | C11 | 76.19 | 56.18 | 42.31 | 35.71 | 37.23 | 21.13 | GPa |

| Second elastic stiffness constant with normal strain | C12 | 32.65 | 24.08 | 18.13 | 15.31 | 15.96 | 9.06 | GPa |

| First, elastic stiffness constant with shear strain | C44 | 21.77 | 16.05 | 12.09 | 10.20 | 10.64 | 6.04 | GPa |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, M.; Qayyum, F.; Tseng, S.; Guk, S.; Overhagen, C.; Chao, C.; Prahl, U. Development of Hot Working Process Maps for Incompressible TRIP Steel and Zirconia Composites Using Crystal Plasticity-Based Numerical Simulations. Metals 2022, 12, 2174. https://doi.org/10.3390/met12122174

Ali M, Qayyum F, Tseng S, Guk S, Overhagen C, Chao C, Prahl U. Development of Hot Working Process Maps for Incompressible TRIP Steel and Zirconia Composites Using Crystal Plasticity-Based Numerical Simulations. Metals. 2022; 12(12):2174. https://doi.org/10.3390/met12122174

Chicago/Turabian StyleAli, Muhammad, Faisal Qayyum, ShaoChen Tseng, Sergey Guk, Christian Overhagen, ChingKong Chao, and Ulrich Prahl. 2022. "Development of Hot Working Process Maps for Incompressible TRIP Steel and Zirconia Composites Using Crystal Plasticity-Based Numerical Simulations" Metals 12, no. 12: 2174. https://doi.org/10.3390/met12122174

APA StyleAli, M., Qayyum, F., Tseng, S., Guk, S., Overhagen, C., Chao, C., & Prahl, U. (2022). Development of Hot Working Process Maps for Incompressible TRIP Steel and Zirconia Composites Using Crystal Plasticity-Based Numerical Simulations. Metals, 12(12), 2174. https://doi.org/10.3390/met12122174