Simplified Damage Assessment Tool for Rails and Crossings Based on Standard Wear and RCF Models

Abstract

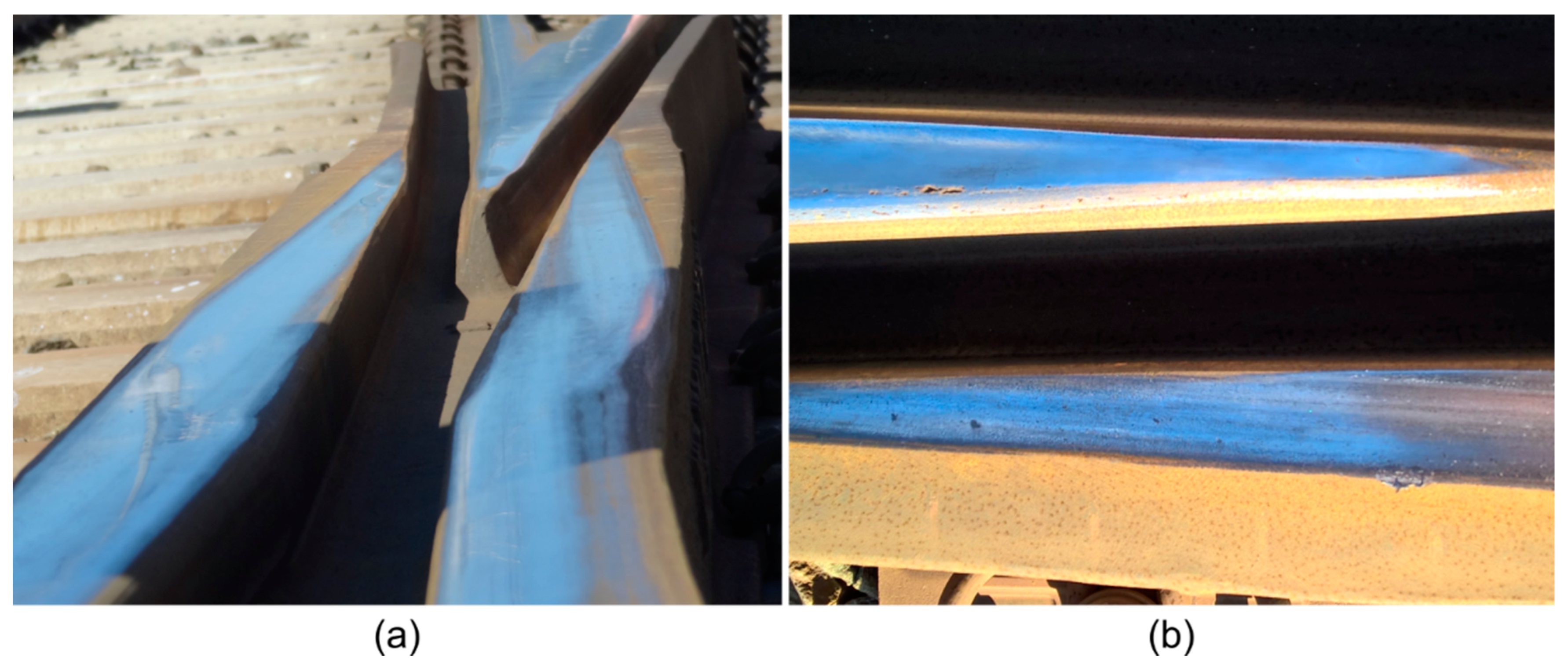

1. Introduction

2. Materials and Methods

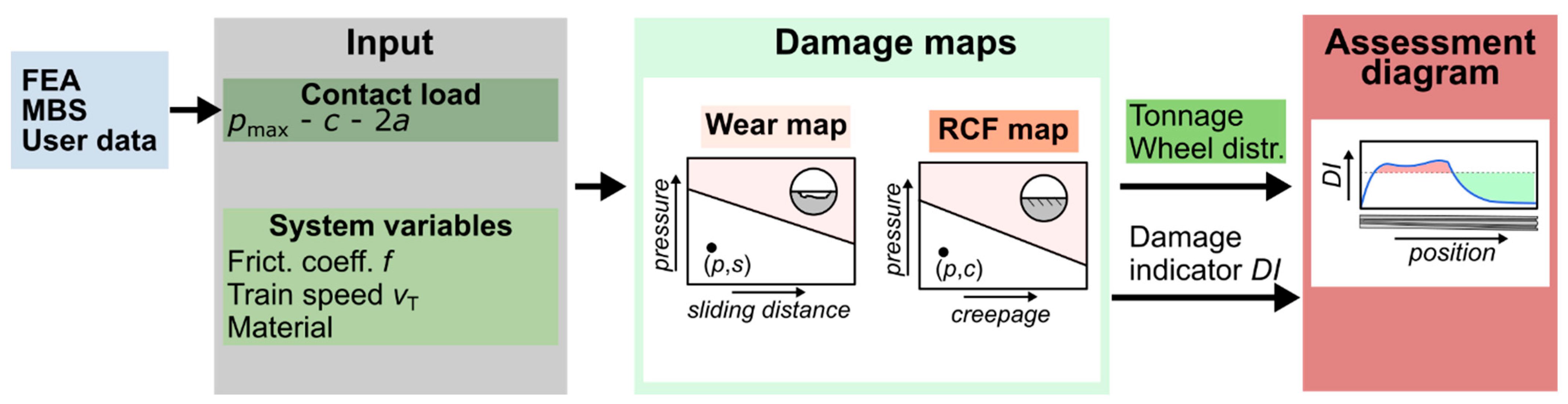

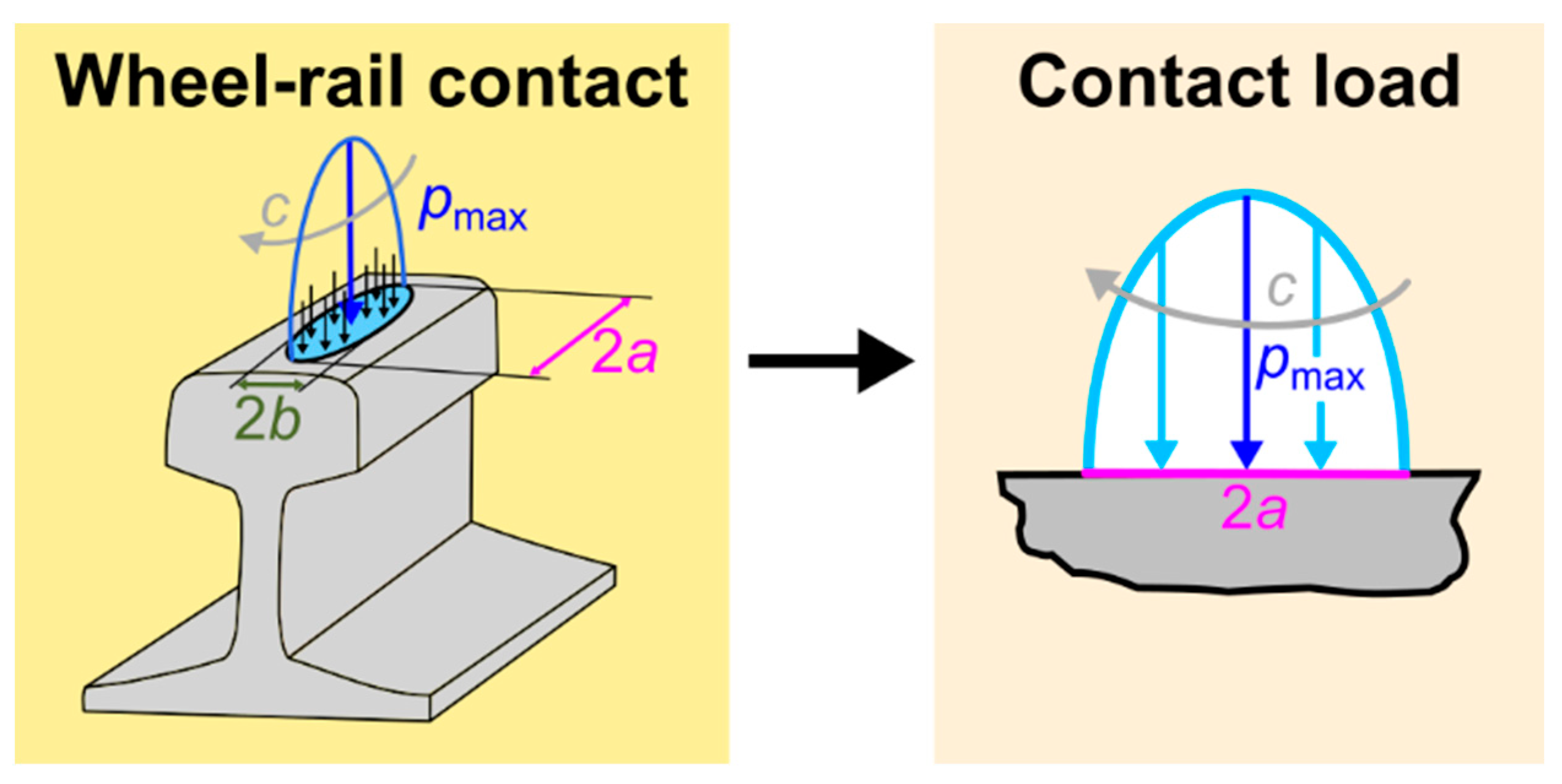

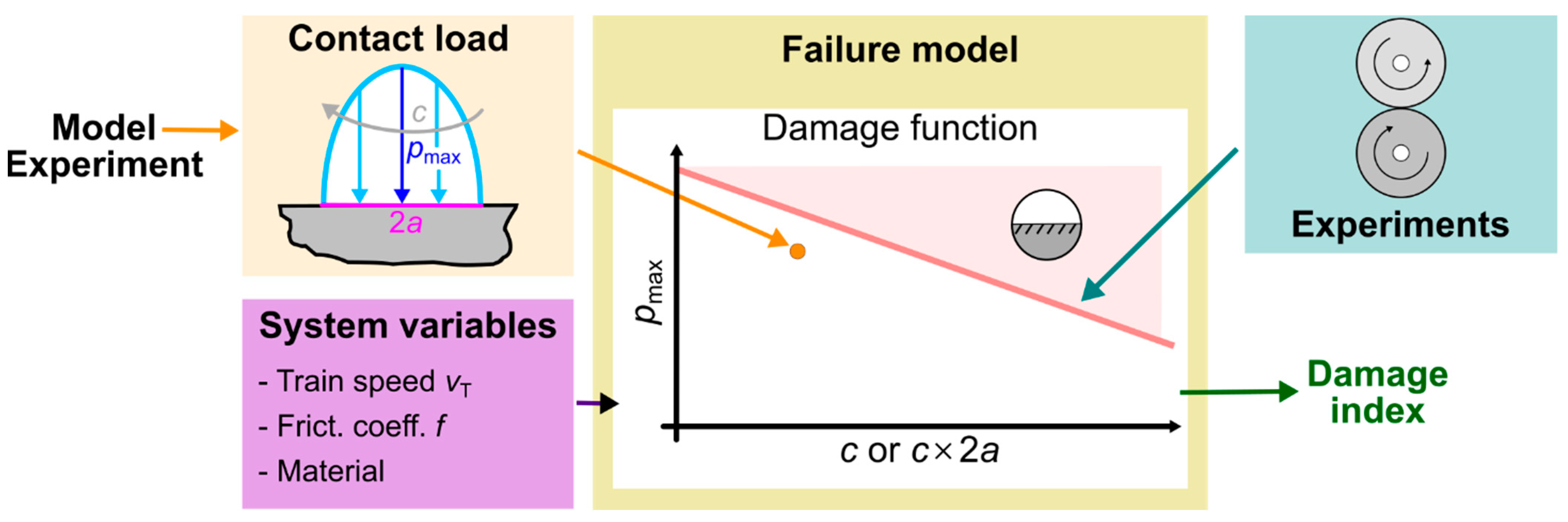

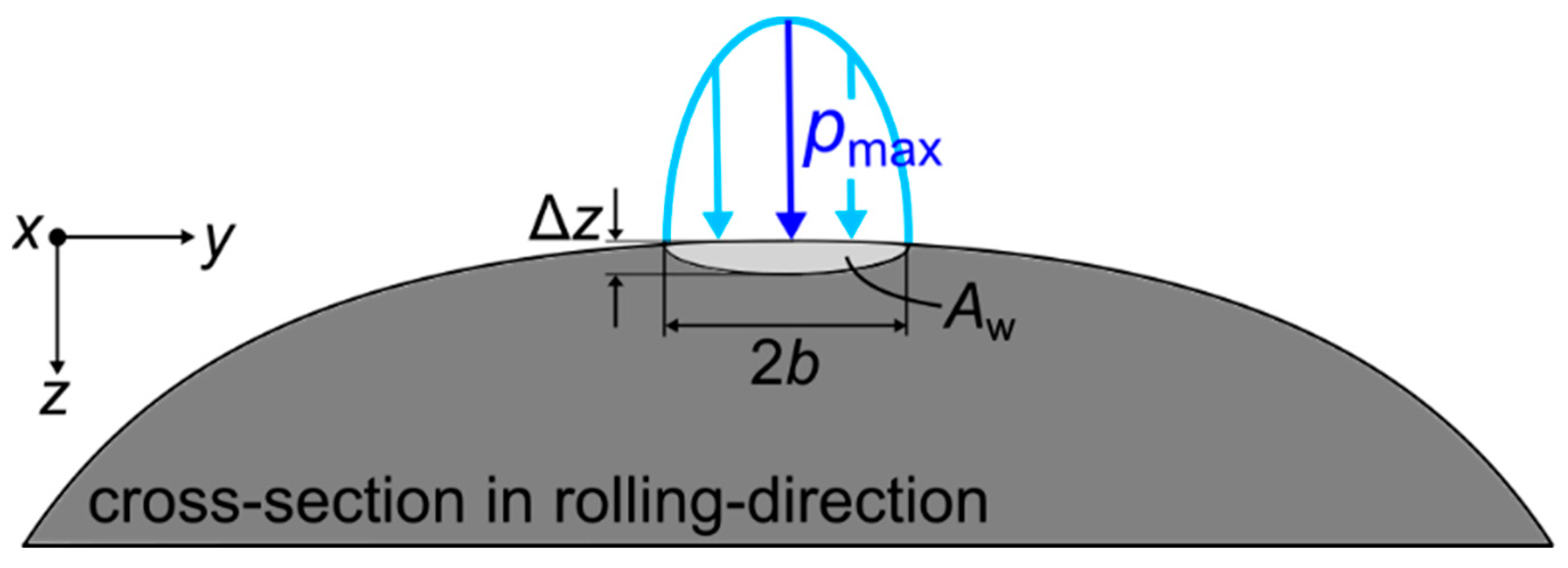

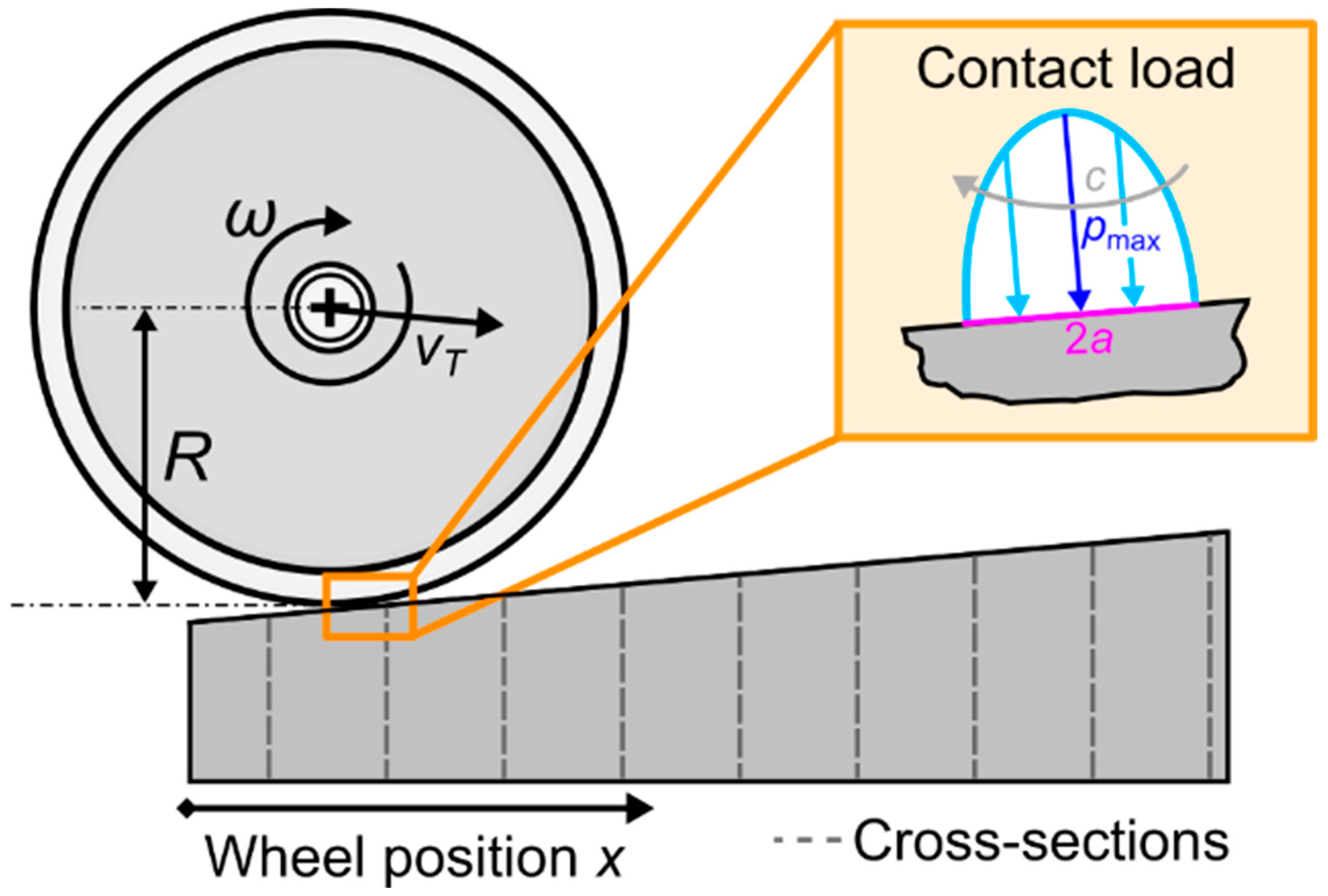

2.1. Simplified Damage Assessment Tool

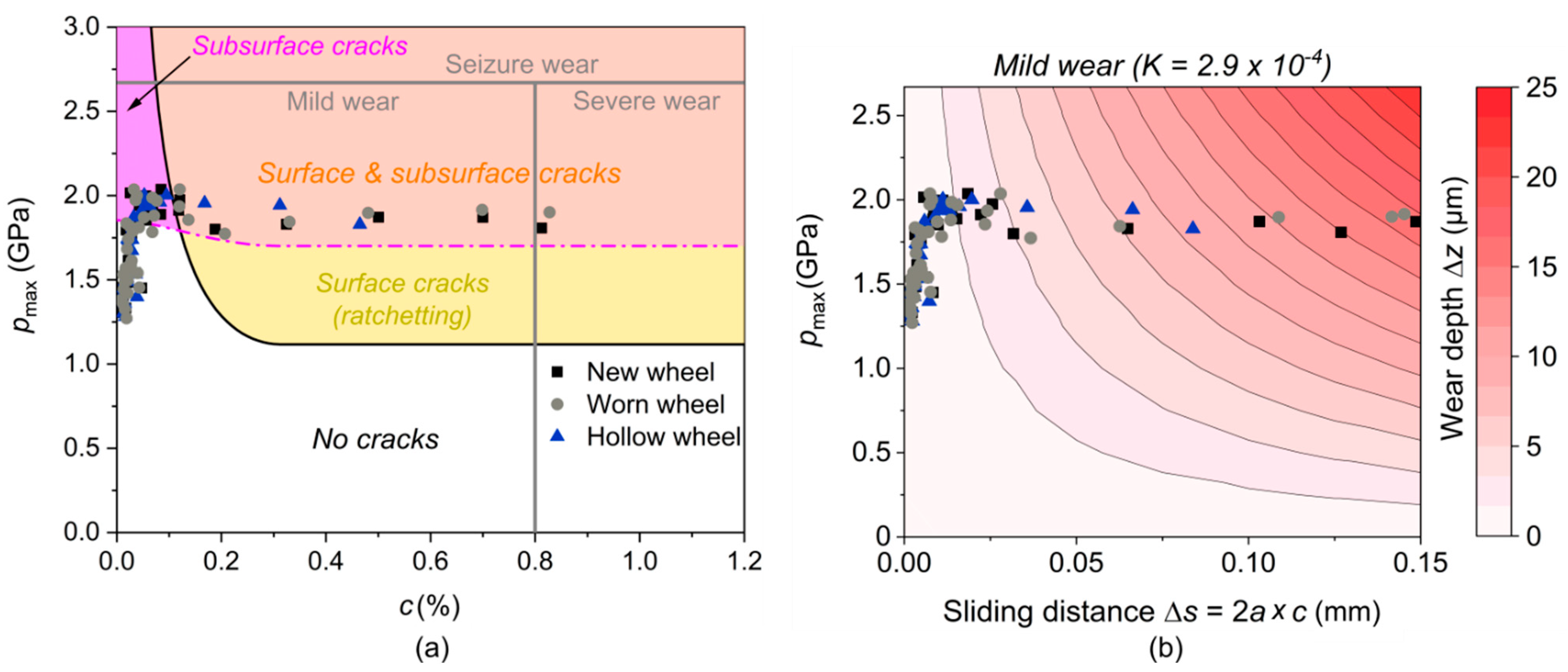

2.1.1. Wear Map

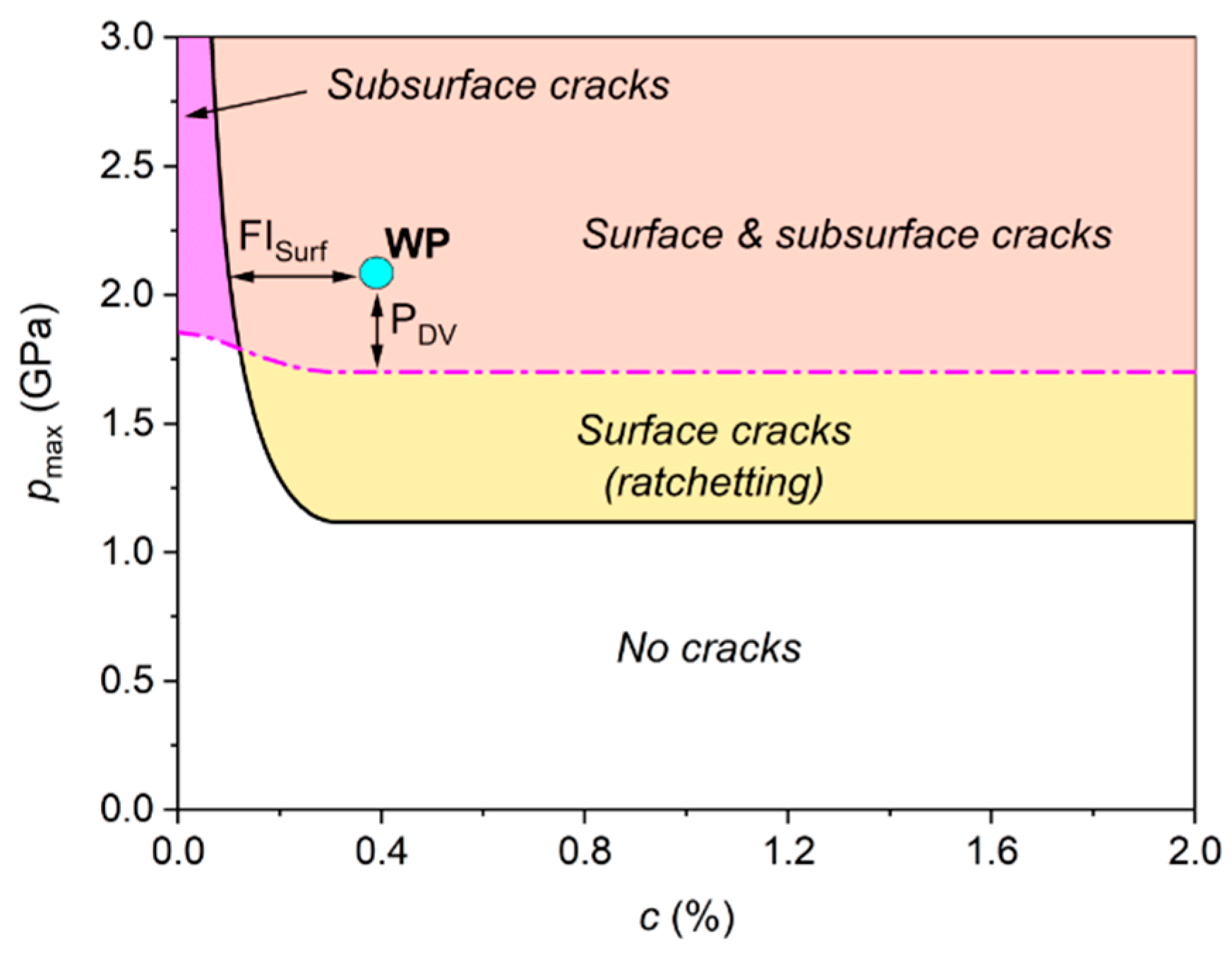

2.1.2. Rolling Contact Fatigue (RCF) Map

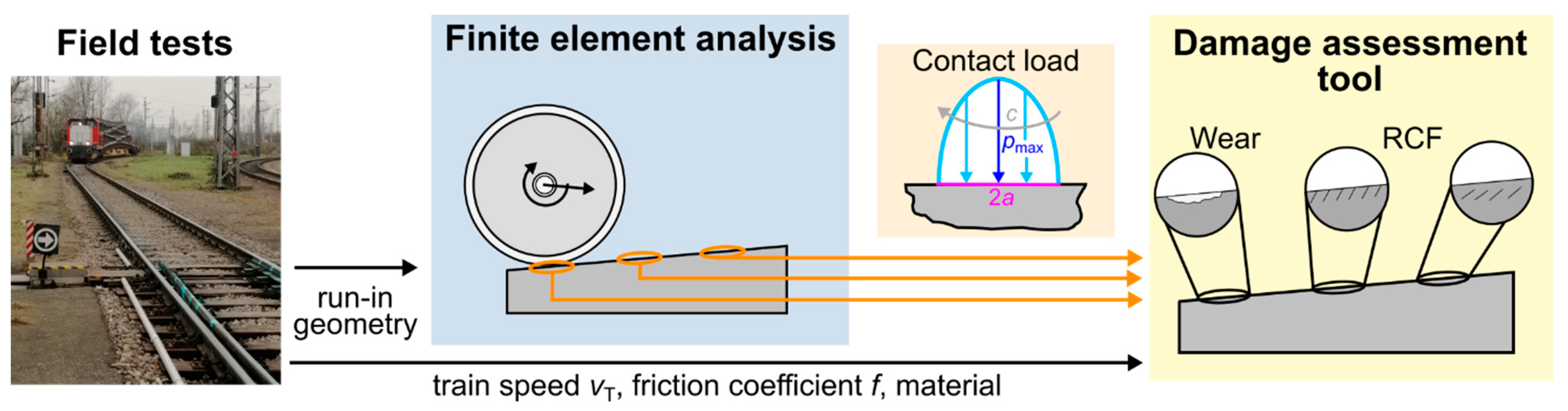

2.2. Case Study: Manganese Crossing Nose

2.2.1. Field Tests

2.2.2. Finite Element Analysis

2.2.3. Damage Assessment Tool: Material Properties

3. Results

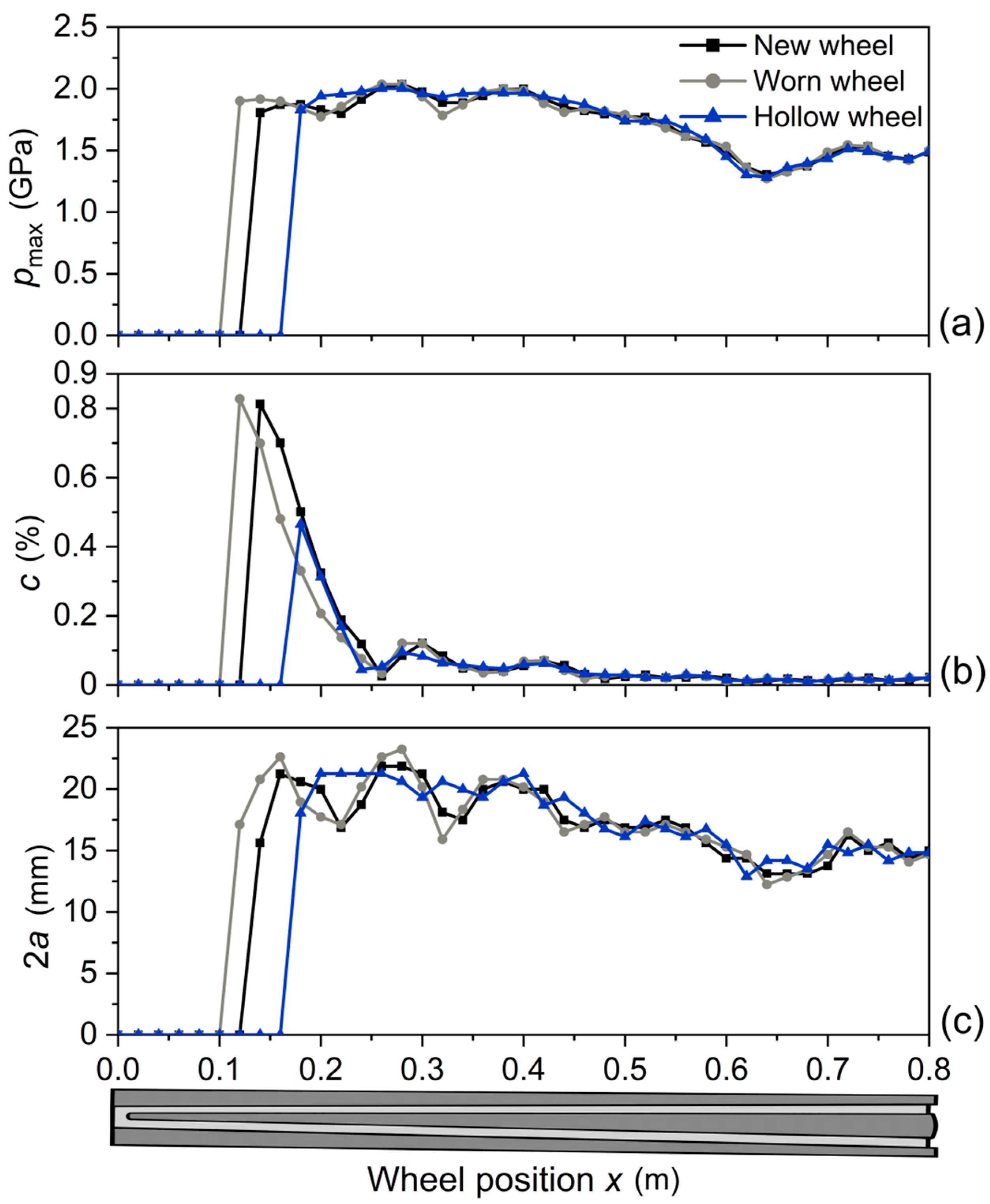

3.1. Contact Loads

3.2. Damage Maps

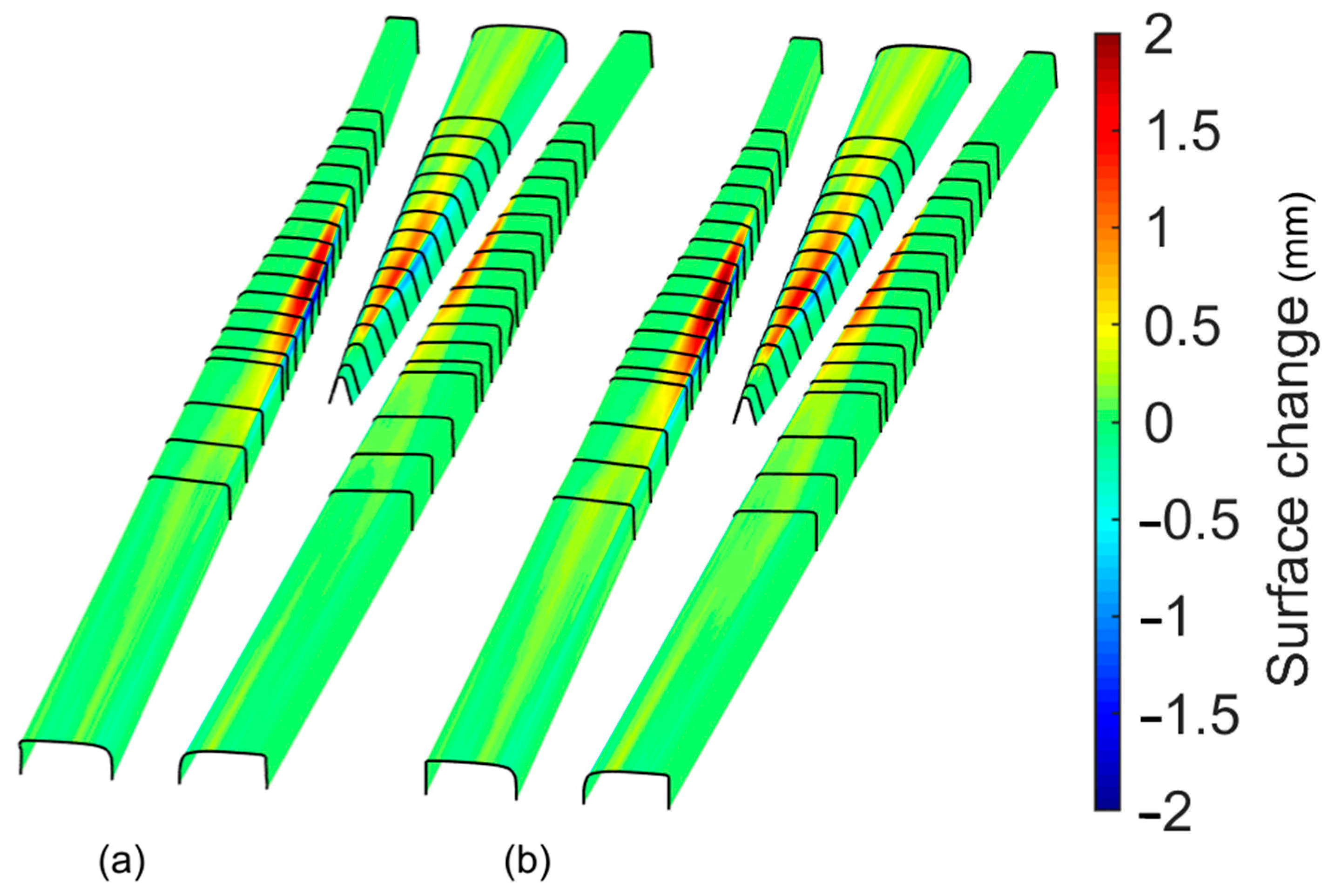

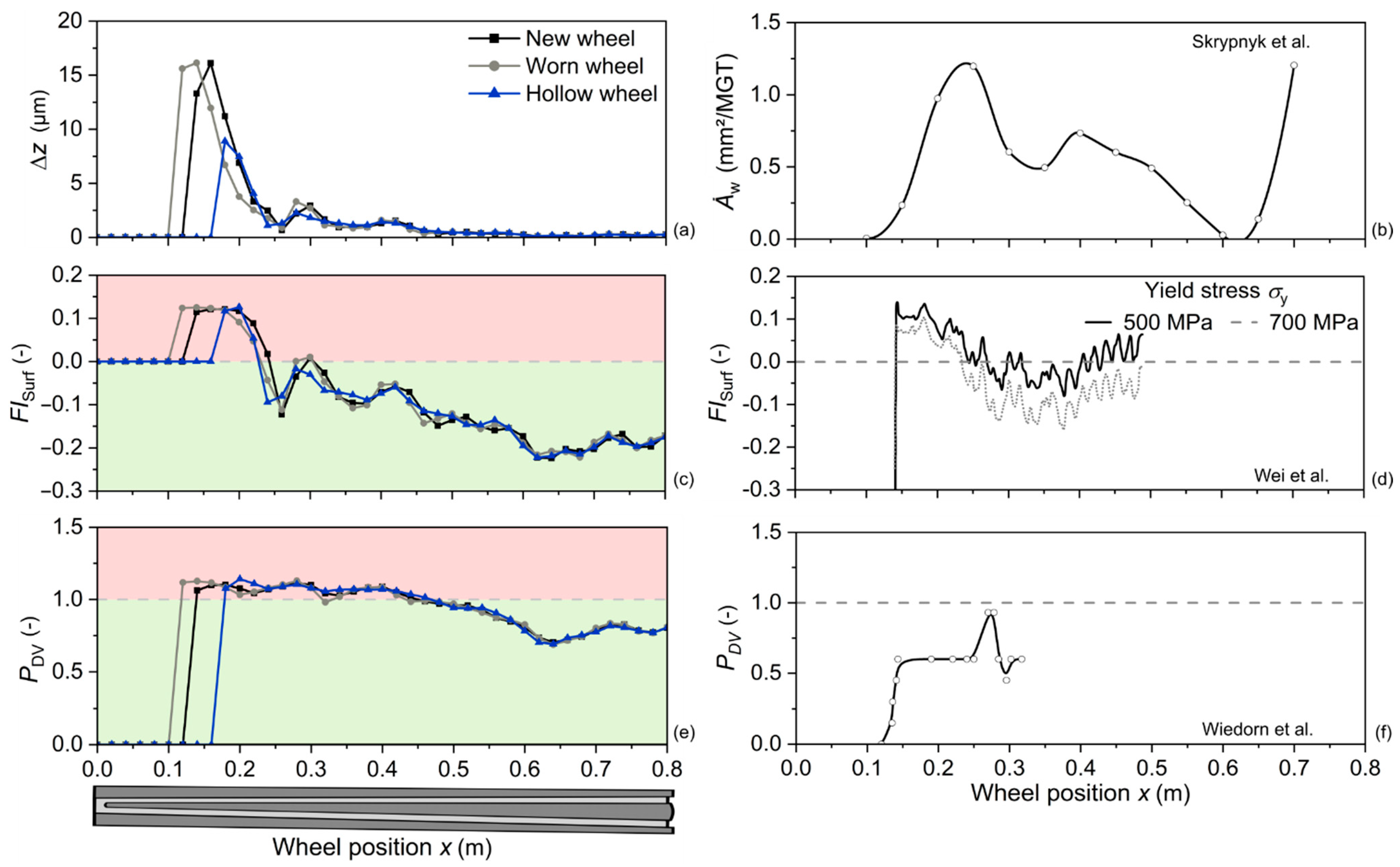

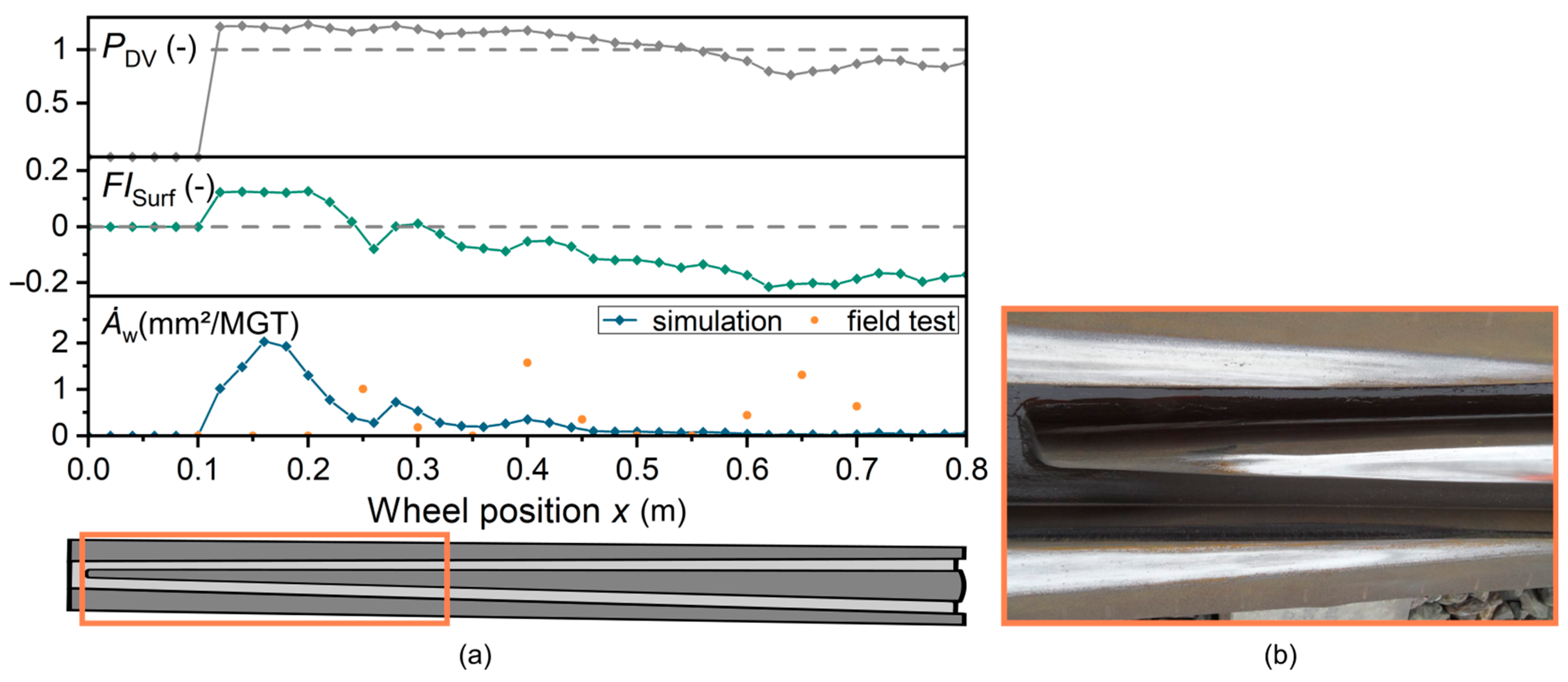

3.3. Evolution of Damage Indicators: Verification

3.4. Accumulated Damage: Validation

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wiedorn, J.; Daves, W.; Ossberger, U.; Ossberger, H.; Pletz, M. Simplified explicit finite element model for the impact of a wheel on a crossing—Validation and parameter study. Tribol. Int. 2017, 111, 254–264. [Google Scholar] [CrossRef]

- Johansson, A.; Pålsson, B.; Ekh, M.; Nielsen, J.C.O.; Ander, M.K.A.; Brouzoulis, J.; Kassa, E. Simulation of wheel–rail contact and damage in switches & crossings. Wear 2011, 271, 472–481. [Google Scholar] [CrossRef]

- Pletz, M.; Daves, W.; Yao, W.; Ossberger, H. Rolling contact fatigue of three crossing nose materials—Multiscale FE approach. Wear 2014, 314, 69–77. [Google Scholar] [CrossRef]

- Grossoni, I.; Hughes, P.; Bezin, Y.; Bevan, A.; Jaiswal, J. Observed failures at railway turnouts: Failure analysis, possible causes and links to current and future research. Eng. Fail. Anal. 2021, 119, 104987. [Google Scholar] [CrossRef]

- Ekberg, A.; Kabo, E.; Andersson, H. An engineering model for prediction of rolling contact fatigue of railway wheels. Fatigue Fract. Eng. Mater. Struct. 2002, 25, 899–909. [Google Scholar] [CrossRef]

- Magel, E.; Mutton, P.; Ekberg, A.; Kapoor, A. Rolling contact fatigue, wear and broken rail derailments. Wear 2016, 366–367, 249–257. [Google Scholar] [CrossRef]

- Wiedorn, J.; Daves, W.; Ossberger, U.; Ossberger, H.; Pletz, M. Investigation of deformation mechanisms in manganese steel crossings using FE models. Tribol. Int. 2019, 138, 424–434. [Google Scholar] [CrossRef]

- Wiest, M.; Daves, W.; Fischer, F.D.; Ossberger, H. Deformation and damage of a crossing nose due to wheel passages. Wear 2008, 265, 1431–1438. [Google Scholar] [CrossRef]

- Pletz, M.; Daves, W.; Yao, W.; Kubin, W.; Scheriau, S. Multi-scale finite element modeling to describe rolling contact fatigue in a wheel–rail test rig. Tribol. Int. 2014, 80, 147–155. [Google Scholar] [CrossRef]

- Pletz, M.; Daves, W.; Ossberger, H. A wheel set/crossing model regarding impact, sliding and deformation—Explicit finite element approach. Wear 2012, 294–295, 446–456. [Google Scholar] [CrossRef]

- Wiedorn, J.; Daves, W.; Ossberger, U.; Ossberger, H.; Pletz, M. Numerical assessment of materials used in railway crossings by predicting damage initiation—Validation and application. Wear 2018, 414–415, 136–150. [Google Scholar] [CrossRef]

- Kassa, E.; Andersson, C.; Nielsen, J.C.O. Simulation of dynamic interaction between train and railway turnout. Veh. Syst. Dyn. 2006, 44, 247–258. [Google Scholar] [CrossRef]

- Skrypnyk, R.; Ossberger, U.; Pålsson, B.A.; Ekh, M.; Nielsen, J.C.O. Long-term rail profile damage in a railway crossing: Field measurements and numerical simulations. Wear 2021, 472–473, 203331. [Google Scholar] [CrossRef]

- Ossberger, U.; Kollment, W.; Eck, S. Insights towards Condition Monitoring of Fixed Railway Crossings. Procedia Struct. Integr. 2017, 4, 106–114. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and Rubbing of Flat Surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Pombo, J.; Ambrósio, J.; Pereira, M.; Lewis, R.; Dwyer-Joyce, R.; Ariaudo, C.; Kuka, N. Development of a wear prediction tool for steel railway wheels using three alternative wear functions. Wear 2011, 271, 238–245. [Google Scholar] [CrossRef]

- Lewis, R.; Magel, E.; Wang, W.; Olofsson, U.; Lewis, S.; Slatter, T.; Beagles, A. Towards a standard approach for the wear testing of wheel and rail materials. Proc. Inst. Mech. Eng. F J. Rail Rapid Transit 2017, 231, 760–774. [Google Scholar] [CrossRef]

- Wei, Z.; Núñez, A.; Liu, X.; Dollevoet, R.; Li, Z. Multi-criteria evaluation of wheel/rail degradation at railway crossings. Tribol. Int. 2020, 144, 106107. [Google Scholar] [CrossRef]

- Daves, W.; Kráčalík, M.; Scheriau, S. Analysis of crack growth under rolling-sliding contact. Int. J. Fatigue 2019, 121, 63–72. [Google Scholar] [CrossRef]

- Van, K.; Griveau, B. On a new multiaxial fatigue limit criterion—Theory and Application. In Biaxial and Multiaxial Fatigue, EGF 3; Mechanical Engineering Publications, Ltd.: London, UK, 1989; pp. 479–496. [Google Scholar]

- Dirks, B.; Enblom, R. Prediction model for wheel profile wear and rolling contact fatigue. Wear 2011, 271, 210–217. [Google Scholar] [CrossRef]

- Mazzù, A.; Petrogalli, C.; Faccoli, M. An integrated model for competitive damage mechanisms assessment in railway wheel steels. Wear 2015, 322–323, 181–191. [Google Scholar] [CrossRef]

- Karttunen, K.; Kabo, E.; Ekberg, A. Estimation of gauge corner and flange root degradation from rail, wheel and track geometries. Wear 2016, 366–367, 294–302. [Google Scholar] [CrossRef]

- Boyacioglu, P.; Bevan, A. Prediction of rail damage using a combination of Shakedown Map and wheel-rail contact energy. Wear 2020, 460–461, 203457. [Google Scholar] [CrossRef]

- Nielsen, J.C.O.; Pålsson, B.A.; Torstensson, P.T. Switch panel design based on simulation of accumulated rail damage in a railway turnout. Wear 2016, 366–367, 241–248. [Google Scholar] [CrossRef]

- Ma, X.; Wang, P.; Xu, J.; Chen, R.; Wang, J. Assessment of non-Hertzian wheel-rail contact models for numerical simulation of rail damages in switch panel of railway turnout. Wear 2019, 432–433, 102912. [Google Scholar] [CrossRef]

- Zani, N.; Ekh, M.; Ekberg, A.; Mazzù, A. Application of a semianalytical strain assessment and multiaxial fatigue analysis to compare rolling contact fatigue in twin-disk and full-scale wheel/rail contact conditions. Fatigue Fract. Eng. Mater. Struct. 2021, 37, 478. [Google Scholar] [CrossRef]

- Meyer, K.A.; Skrypnyk, R.; Pletz, M. Efficient 3d finite element modeling of cyclic elasto-plastic rolling contact. Tribol. Int. 2021, 161, 107053. [Google Scholar] [CrossRef]

- Daves, W.; Kubin, W.; Scheriau, S.; Pletz, M. A finite element model to simulate the physical mechanisms of wear and crack initiation in wheel/rail contact. Wear 2016, 366–367, 78–83. [Google Scholar] [CrossRef]

- Jendel, T. Prediction of wheel profile wear—Comparisons with field measurements. Wear 2002, 253, 89–99. [Google Scholar] [CrossRef]

- Johnson, K.L. Contact Mechanics; Cambridge University Press: Cambridge, UK; New York, NY, USA; Port Melbourne, Australia; Madrid, Spain; Cape Town, South Africa, 1985; ISBN 0521255767. [Google Scholar]

- Cremona, M.A.; Liu, B.; Hu, Y.; Bruni, S.; Lewis, R. Predicting railway wheel wear under uncertainty of wear coefficient, using universal kriging. Reliab. Eng. Syst. 2016, 154, 49–59. [Google Scholar] [CrossRef]

- Schelle, H. Radverschleissreduzierung für Eine Güterzuglokomotive Durch Optimierte Spurführung. Ph.D. Thesis, Technische Universität Berlin, Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Besson, J.; Cailletaud, G.; Chaboche, J.-L.; Forest, S. Non-Linear Mechanics of Materials; Springer Science+Business Media B.V: Dordrecht, The Netherlands, 2010; ISBN 978-90-481-3355-0. [Google Scholar]

- Enblom, R. Deterioration mechanisms in the wheel–rail interface with focus on wear prediction: A literature review. Veh. Syst. Dyn. 2009, 47, 661–700. [Google Scholar] [CrossRef]

- Vollebregt, E.; Six, K.; Polach, O. Challenges and progress in the understanding and modelling of the wheel–rail creep forces. Veh. Syst. Dyn. 2021, 59, 1026–1068. [Google Scholar] [CrossRef]

- Wiedorn, J.; Daves, W.; Ossberger, U.; Ossberger, H.; Pletz, M. Finite element model for predicting the initiation of subsurface damage in railway crossings—A parametric study. Proc. Inst. Mech. Eng. F J. Rail Rapid Transit 2019, 233, 614–628. [Google Scholar] [CrossRef]

- Dassault Systèmes. Abaqus 2019 User Manual; Dassault Systèmes: Vélizy-Villacoublay, France, 2019. [Google Scholar]

| Property | Elastic (Wheel) | Mn13 (Crossing Nose) |

|---|---|---|

| Young’s modulus (GPa) | 210 | 201 |

| Poisson’s ratio (-) | 0.3 | 0.3 |

| Density (kg/m3) | 7800 | 7800 |

| R0 (MPa) | - | 580 |

| Q (MPa) | - | 300 |

| B (-) | - | 10 |

| C1 (MPa) | - | 700,000 |

| D1 (-) | - | 4000 |

| C2 (MPa) | - | 70,000 |

| D2 (-) | - | 800 |

| C3 (MPa) | - | 350 |

| D3 (-) | - | 1 |

| Damage Mechanism | Property | Magnitude | Ref. |

|---|---|---|---|

| Wear (dry contact) | Wear coefficient (K) for mild wear (-) | 2.9 × 10−4 | [13] |

| Hardness (H) (GPa) | 3.33 | [37] | |

| RCF | Yield stress (σy) (MPa) | 580 | [13] |

| Wheel rolling radius (R) (m) | 0.476 | [1] | |

| Friction coefficient (f) (dry wheel/rail friction) (-) | 0.3 | [1] | |

| Shear–torsion fatigue limit (τf) (MPa) | 278 | [1] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schnalzger, G.; Daves, W.; Maierhofer, J.; Ossberger, U.; Ossberger, H.; Bucher, C.; Pletz, M. Simplified Damage Assessment Tool for Rails and Crossings Based on Standard Wear and RCF Models. Metals 2022, 12, 2169. https://doi.org/10.3390/met12122169

Schnalzger G, Daves W, Maierhofer J, Ossberger U, Ossberger H, Bucher C, Pletz M. Simplified Damage Assessment Tool for Rails and Crossings Based on Standard Wear and RCF Models. Metals. 2022; 12(12):2169. https://doi.org/10.3390/met12122169

Chicago/Turabian StyleSchnalzger, Georg, Werner Daves, Jürgen Maierhofer, Uwe Ossberger, Heinz Ossberger, Christian Bucher, and Martin Pletz. 2022. "Simplified Damage Assessment Tool for Rails and Crossings Based on Standard Wear and RCF Models" Metals 12, no. 12: 2169. https://doi.org/10.3390/met12122169

APA StyleSchnalzger, G., Daves, W., Maierhofer, J., Ossberger, U., Ossberger, H., Bucher, C., & Pletz, M. (2022). Simplified Damage Assessment Tool for Rails and Crossings Based on Standard Wear and RCF Models. Metals, 12(12), 2169. https://doi.org/10.3390/met12122169