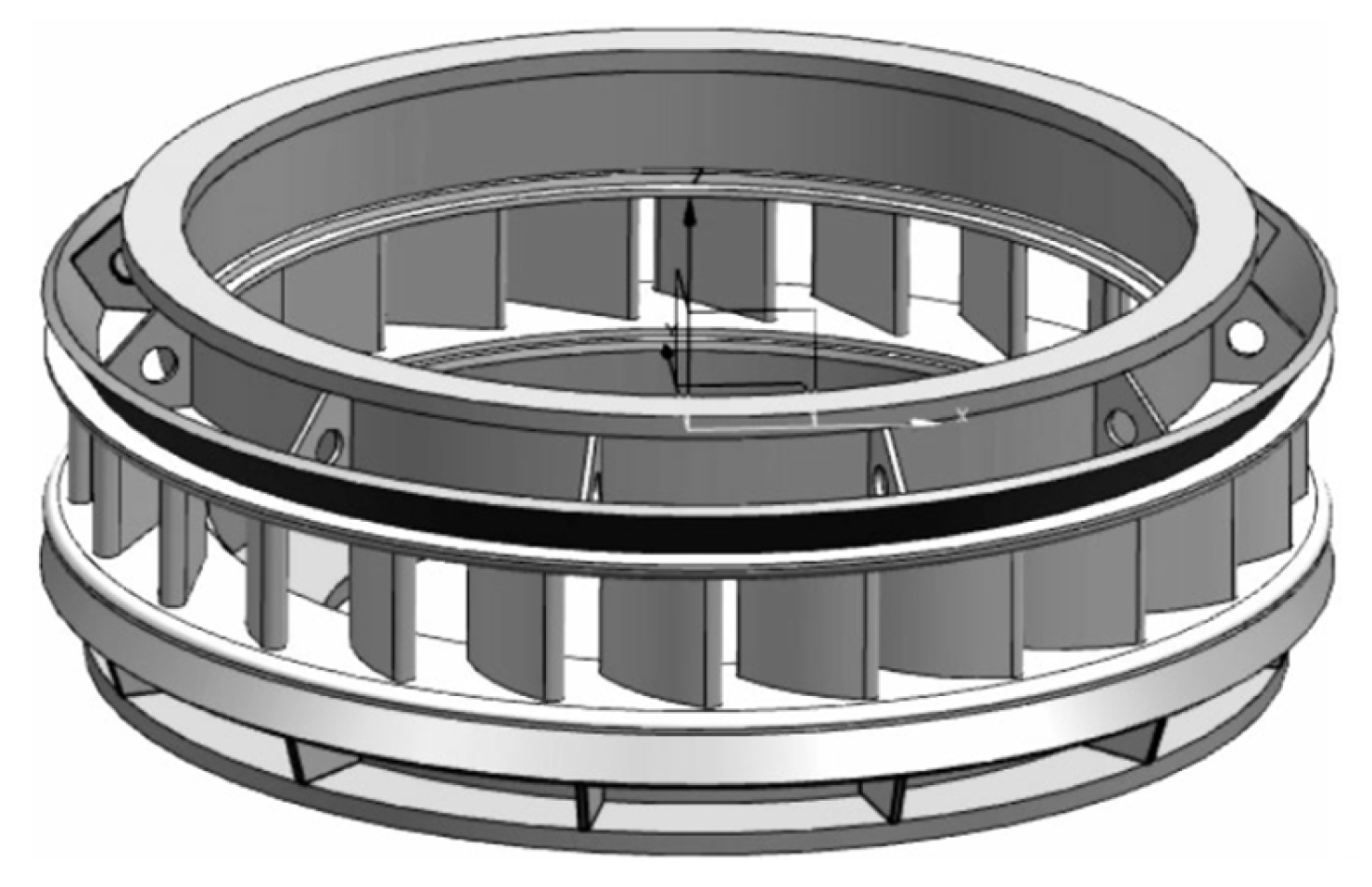

Study on the Heat Treatment Process of SXQ500/550DZ35 Steel QLT for the Seat Ring and Guide Vane of a Hydropower Station

Abstract

:1. Introduction

2. Experimental Materials and Methods

2.1. Experimental Materials

2.2. Experimental Methods

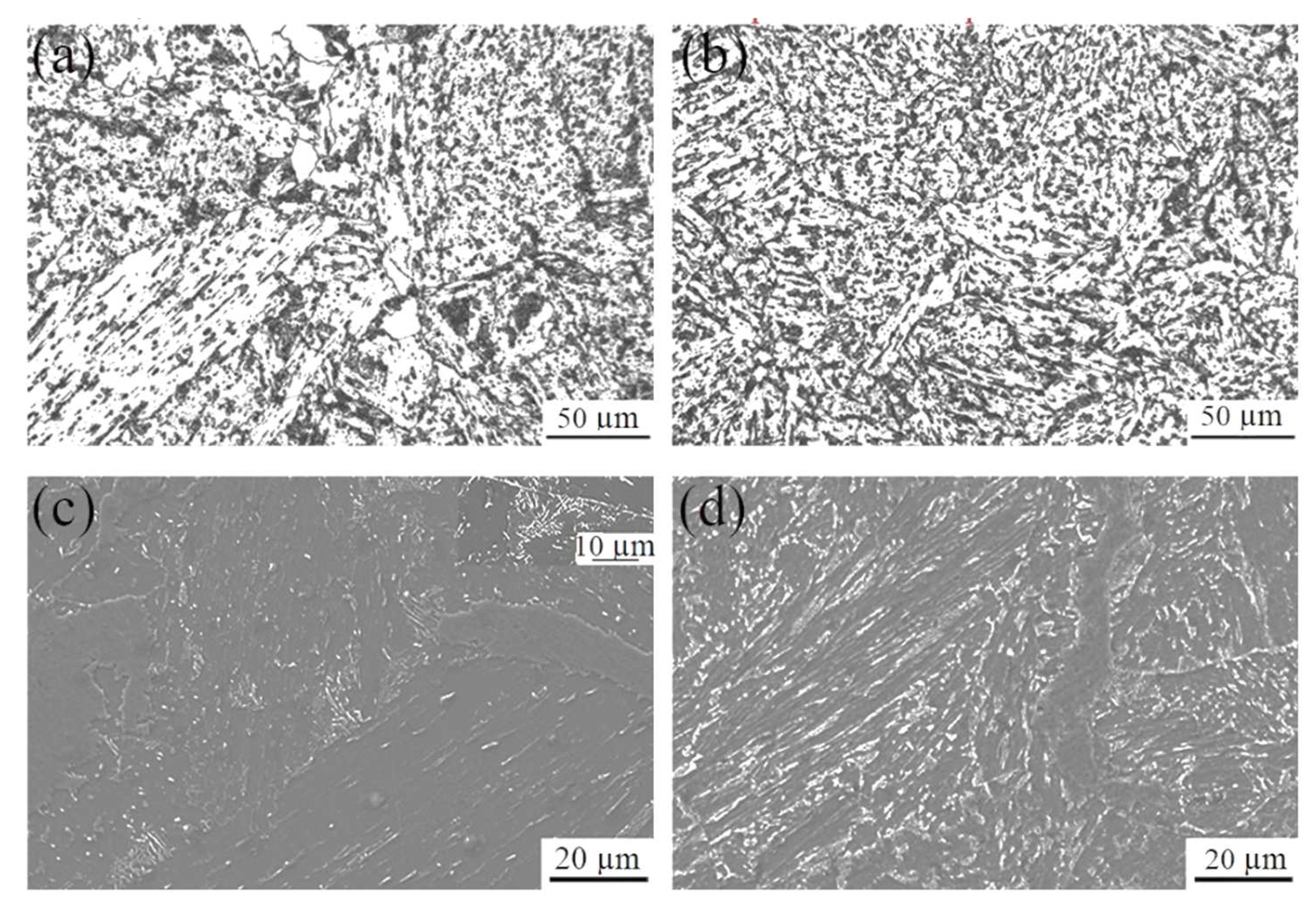

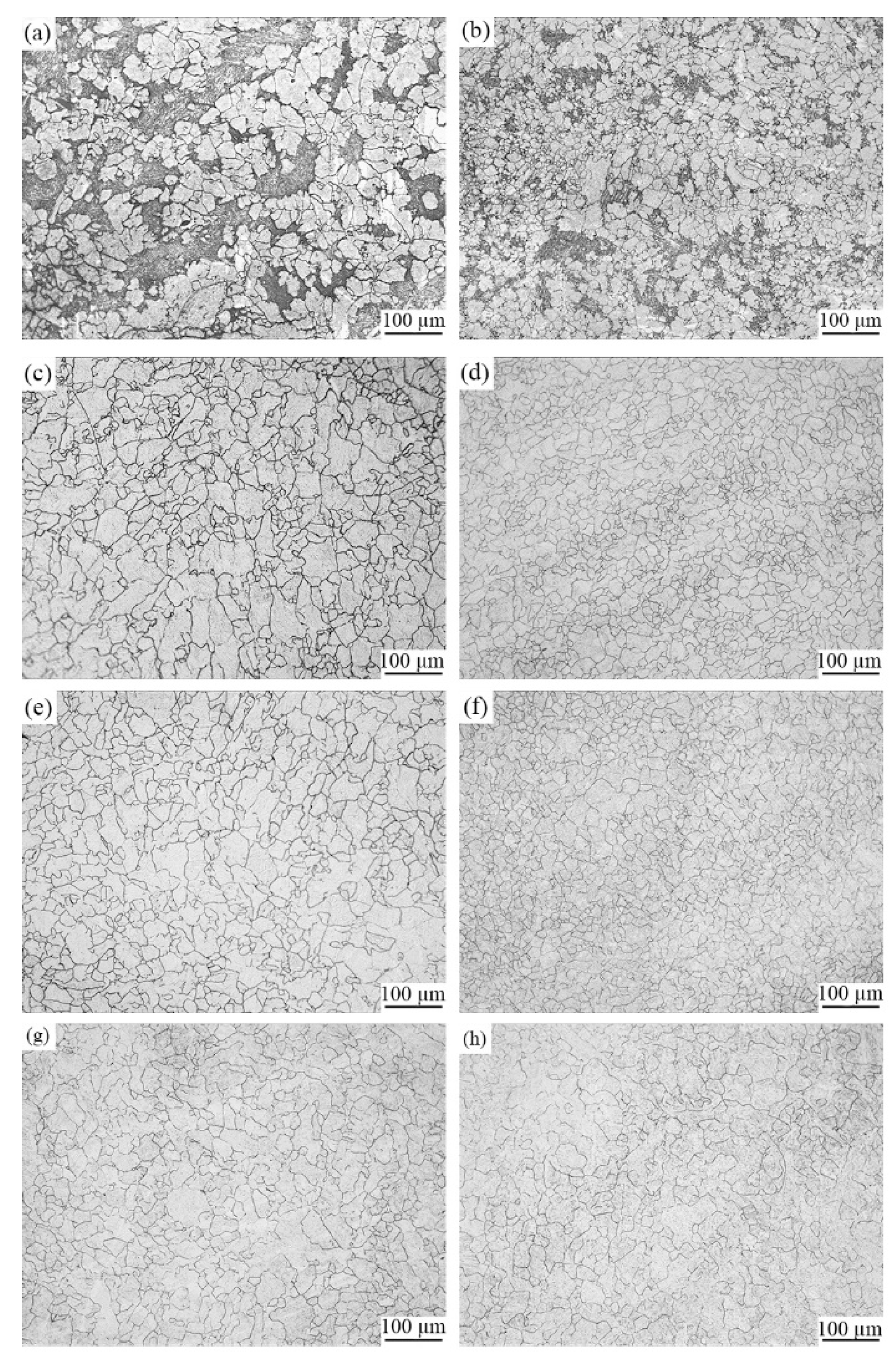

3. Effect of Original Structure and Intermediate Quenching Temperature on Austenite Grain Size

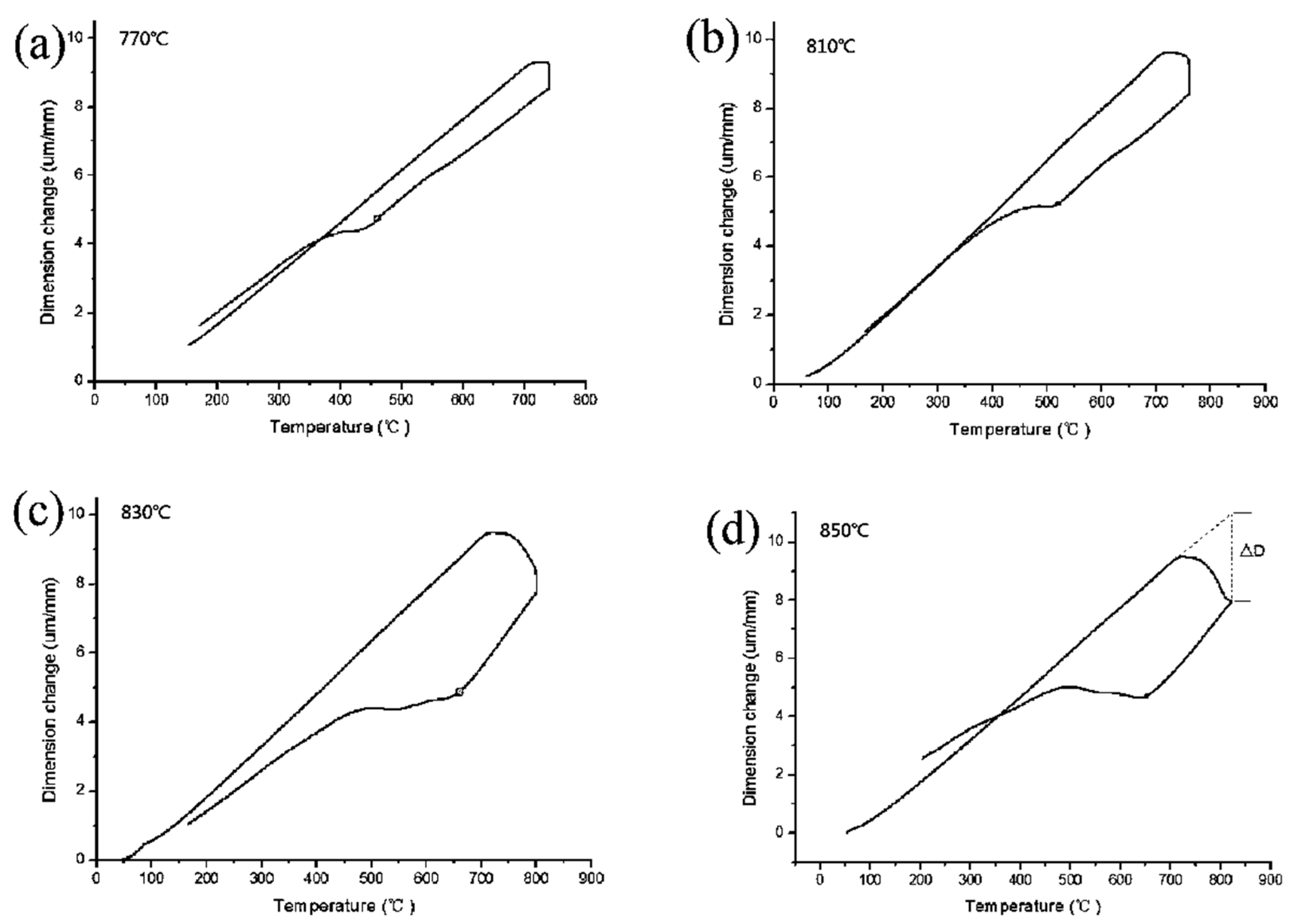

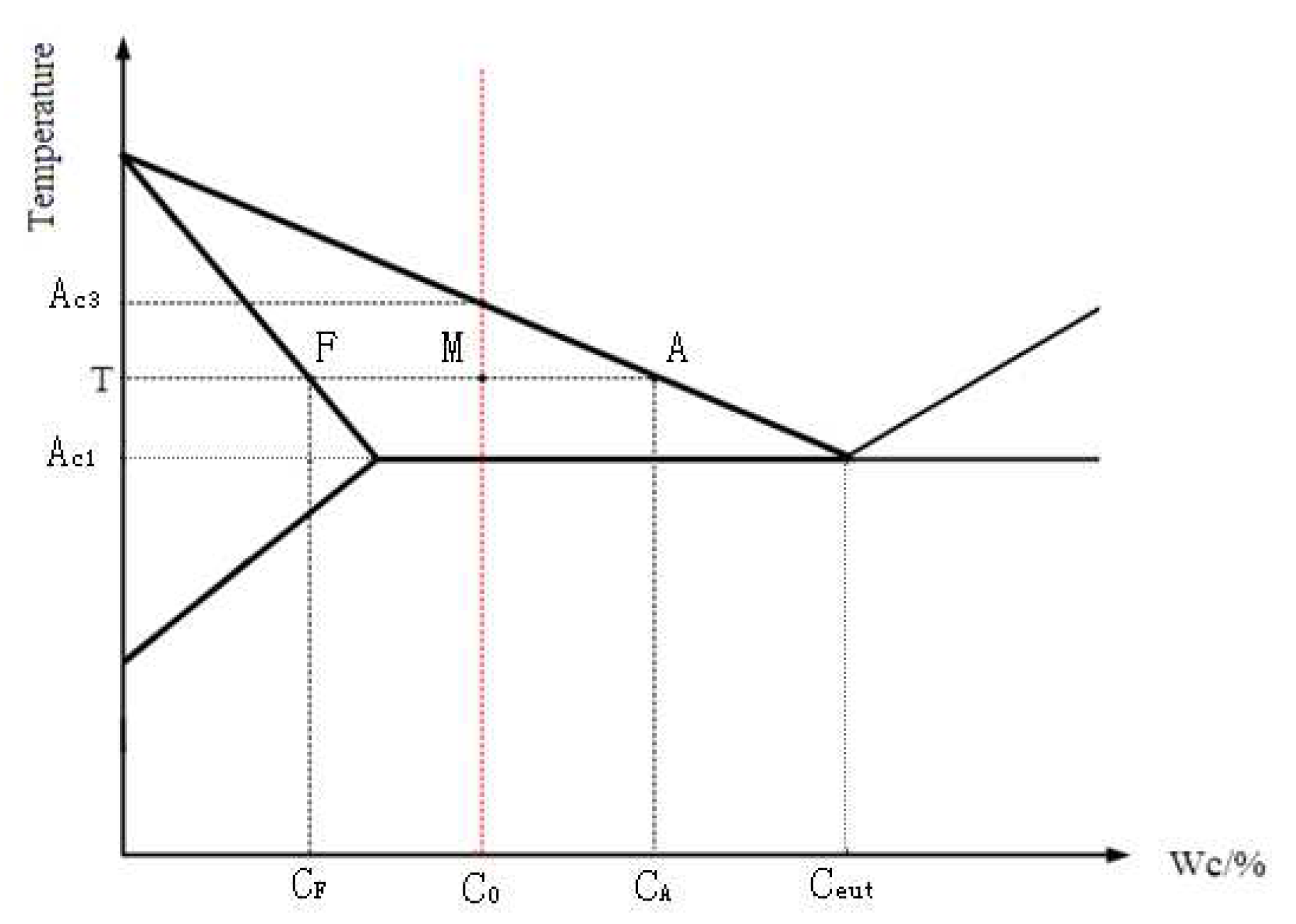

4. Effect of Sub-Temperature Quenching Temperature on Austenite Conversion

5. Effect of Sub-Temperature Quenching Temperature on Carbon Content in Austenite

6. Microstructure Change in SXQ500/550DZ35 Steel during the QLT Heat Treatment Process

7. Effect of Heat Treatment Process on Properties of QLT

8. Conclusions

- (1)

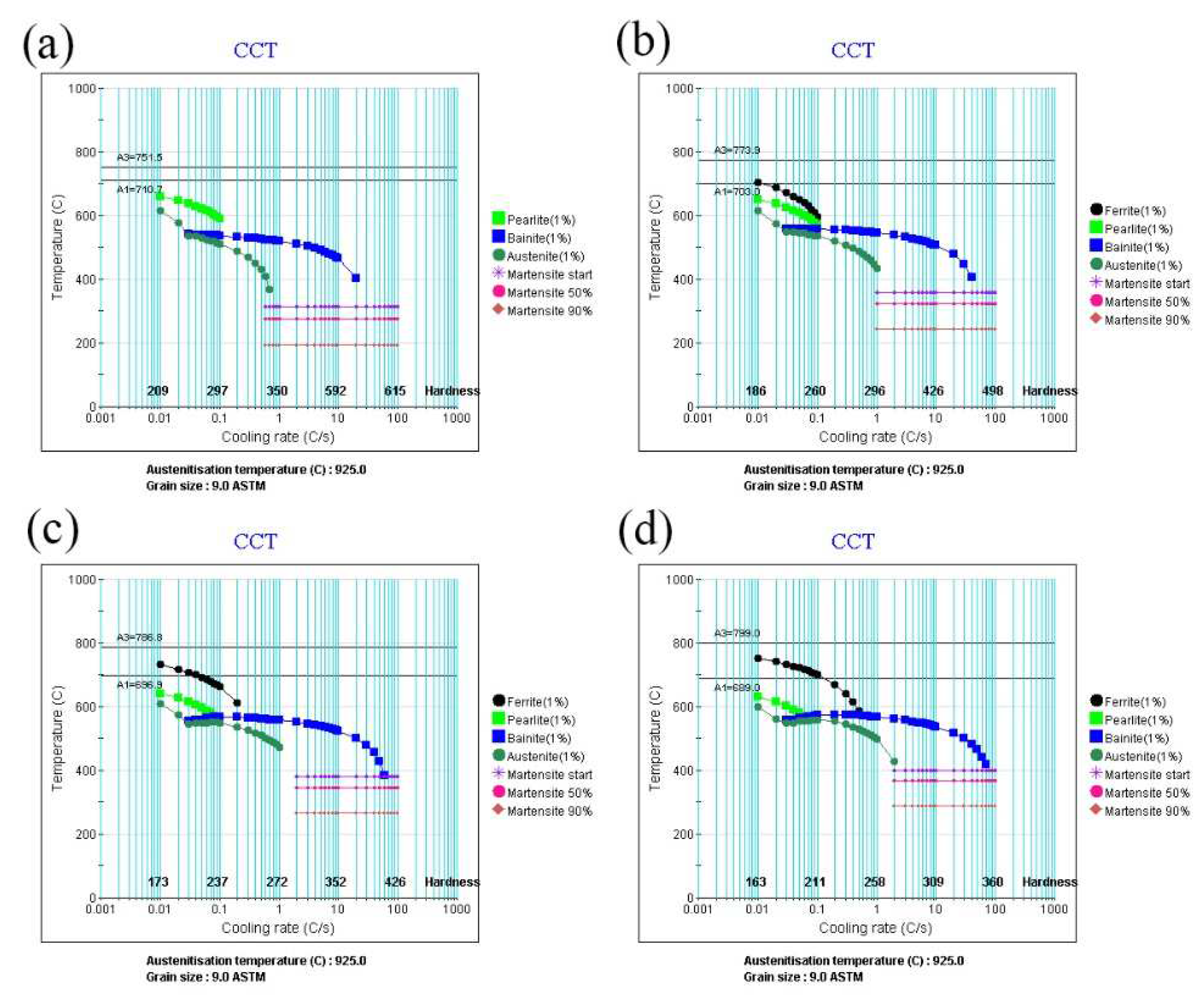

- The thermal expansion tests of AR and Q state samples were carried out using a DIL805L thermal dilatometer. The heating rate below 600 °C was 10 °C/s. The heating rate above 600 °C was 0.05 °C/s (simulating industrial production). The steel was heated to 770 °C, 810 °C, 830 °C, 850 °C, 870 °C, and 920 °C, respectively. The Ac1 = 744 °C and Ac3 = 847 °C of the steel were obtained, and the heat preservation coefficient of 2.2 min/mm was obtained according to the industrial production heat preservation coefficient. There are two ways of cooling: water quenching to room temperature, cooling at 30 °C/min, and grinding and polishing the metallographic samples. The comparison of austenite grain size at different temperatures was obtained under a LEICADMRX metallographic microscope to analyze the effect of the original structure and sub-temperature quenching temperature on austenite grain size. The sample cooled at 30 °C/min simulated the change in austenite transformation during the heating and cooling of SXQ500/550DZ35 in the two-phase zone, calculated the change law of carbon content in austenite according to lever law, and analyzed the influence of carbon content in austenite on phase transformation products. When the carbon content was 0.110%, the bainite transition temperature was 573.13 °C, and the critical cooling rate of F was 0.5 °C/s. When the carbon content was 0.163%, the bainite transition temperature was 563.38 °C, and the critical cooling rate of F was 0.2 °C/s. When the carbon content was 0.225%, the bainite transition point was 550.98 °C, and the critical cooling rate of F was 0.1 °C/s. When carbon content was 0.348%, bainite began to shift to 527.35 °C, and even 0.01 °C/s cooling did not produce F. The visible two-phase zone temperature affected the uniformity of the main components of the austenitic and carbon enrichment degree and influenced the high and low transformation points, resulting in the same cooling rate for different phase transformation points and transformation products.

- (2)

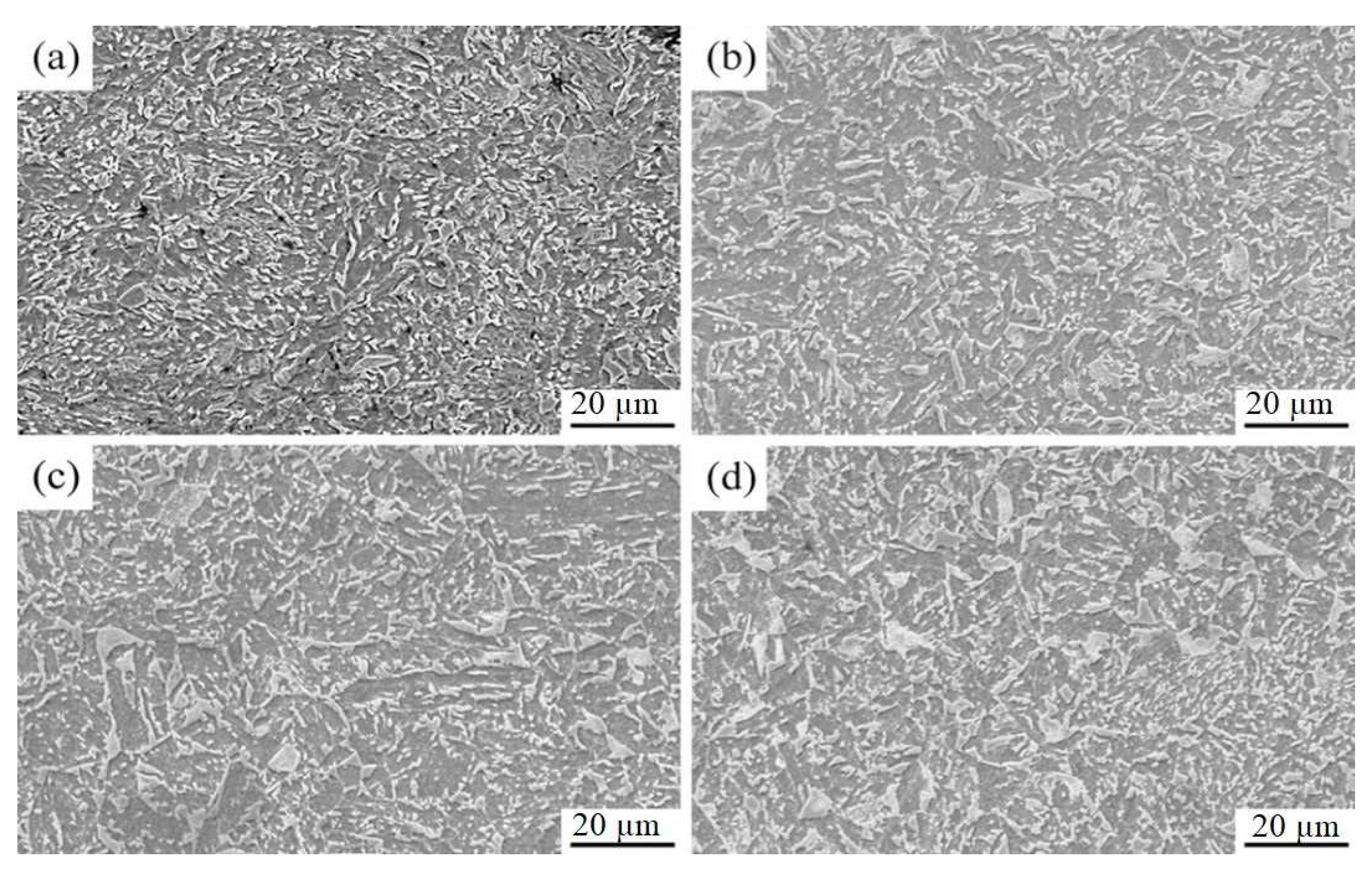

- In the original microstructure, the distribution of carbon elements in the rolled R state was not as uniform as that in the Q state. Under the condition of the same intertemperature quenching, the original austenite in the Q state had a smaller grain size, and the lower the intertemperature quenching, the more uneven the components in austenite were. Carbon enrichment made the supercooled austenite more stable, and the CCT curve shifted to the right, which reduced the transition point. Thus, different transformation points and transformation products were obtained at the same cooling rate, which effectively solved the problem of coarse and uneven bainite structure caused by the insufficient cooling rate of extra-thick plates. The microstructure after secondary quenching (subtemperature) was BF + “island” microstructure, and the “island” microstructure had a relatively low austenitization temperature in the two-phase zone, resulting in local carbon concentration fluctuations. Therefore, the formed “island” microstructure may be two or more mixed tissues of F, M, and M/A due to different components and processes. The finer the original microstructure was and the larger the carbide dispersion, the smaller the austenite grains obtained. Moreover, after repeating Q + nL + T, the microstructure was uniform and fine, and the impact toughness was more stable.

- (3)

- Finally, QLT (925 °C + 830 °C + 640 °C) steel had better strength, toughness, and lower yield ratio. The staggered microstructure of bainite and ferrite in QLT steel was similar to that of “fiber reinforced composites”. The bainite on the grain boundary in the structure played the role of strengthening the grain boundary and improving the properties. The interface between ferrite and bainite was highly coherent, there was no formation of brittle carbides on the interface, and it was not easy to produce local stress concentration. The soft ferrite phase not only reduced the yield–strength ratio but also prevented crack propagation and further improved the impact toughness. In conclusion, a large number of ferrite/bainite grain boundaries can effectively prevent crack propagation in steel.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhu, S.; Tang, Z.; Xu, S.; Li, Z.; Kang, W.; Yuan, J.; Yang, Y.; Li, L.; Zhang, T.; Zhu, X.; et al. A Kind of Construction Steel Plate and Its Production Method. China Patent No.cn109930071b, 28 April 2020. [Google Scholar]

- Shi, L. Study on Phase Transformation Behavior and Two Phase Heat Treatment Process of Low Alloy High Strength Steel. Ph.D. Thesis, Tianjin University, Tianjin, China, 2014. [Google Scholar]

- Zhang, Y.; Wang, R.; Niu, C. Sub temperature quenching and strengthening toughening of hypoeutectoid steel. Hot Work. Technol. 2011, 40, 163–166. [Google Scholar]

- Lin, J.; Liu, J.; Tian, S. Innovative application and development of mesh belt furnace of Dalian Shengjie company. Met. Process. (Hot Process.) 2014, 2, 47–49. [Google Scholar]

- Zhang, Y.; Wang, F.; Tang, Z.; Wang, L. Austenite grain growth behavior and its influencing factors of sxq500/550D steel. Met. Heat Treat. 2019, 44, 110–118. [Google Scholar]

- Sun, D.; Wu, C.; Xie, J. Research and development status and Prospect of bainitic steel. Mech. Eng. Mater. 2003, 6, 4–7. [Google Scholar]

- Li, B.; Chu, S.; Ren, X. Application of non quenched and tempered steel in sucker rod production in China. Baogang Sci. Technol. 2008, 5, 1–4. [Google Scholar]

- Fang, H.; Feng, C.; Zheng, Y.; Yang, Z.; Bai, B. Creation and development of new Mn Series Air Cooled Bainitic Steel. Heat Treat. 2008, 3, 2–19. [Google Scholar]

- Yan, X. Heat Treatment Process, Microstructure and Properties of HSLA100 Steel for Hull Structure. Ph.D. Thesis, Wuhan University of Science and Technology, Wuhan, China, 2015. [Google Scholar]

- Zhang, Y.; Zhang, J.; Pan, H.; Yu, T.; Guo, Z. Effect of process parameters on Microstructure and properties of corrosion resistant steel 12cucrniv. J. Iron Steel Res. 2015, 27, 55–62. [Google Scholar]

- Li, R. Study on Microstructure Transformation and Temperature Simulation of 700MPa High Strength Automobile Structural Steel. Master’s Thesis, Inner Mongolia University of Science and Technology, Baotou, China, 2019. [Google Scholar]

- Liuz, Z.; Li, W.; Yang, D.; Cheng, J.; Jian, Z. Effect of normalizing treatment at different temperatures on Microstructure and properties of zg20crmnsini2mo. J. Xi’an Univ. Technol. 2017, 37, 665–670. [Google Scholar]

- Yang, D.; Liu, Y.; Zhou, L.; Li, Y.; Jing, Y.; Yang, W. Effect of heat treatment process on mechanical properties of 27SiMn Steel. J. Beijing Univ. Sci. Technol. 2012, 34, 34–38. [Google Scholar]

- Zuo, X.; Chen, Y.; Wang, M.; Li, Y.; Wang, H.; Wang, Z. Microstructure and properties of ferrite/martensite dual phase steel. J. Mater. Heat Treat. 2010, 31, 29–34. [Google Scholar]

- Zhao, S. Kinetics of Bainite Nucleation and Growth in Medium and Low Carbon Steel. Ph.D. Thesis, Shanghai Jiaotong University, Shanghai, China, 2007. [Google Scholar]

- Wang, J.; Yang, Z.; Bai, B.; Fang, H.; Feng, Y.; Xu, H. Effect of Austenite Deformation on Microstructure and strength and toughness of grain boundary type ferrite/granular bainite multiphase steel. Acta Metall. Sin. 2004, 3, 263–269. [Google Scholar]

- Wang, J.; Kang, Y.; Yang, S.; Wang, Y. Effect of cooling rate after rolling on Microstructure and properties of low carbon bainitic steel. J. Plast. Eng. 2007, 5, 116–119. [Google Scholar]

- Wu, B. Effect of Heat Treatment Process on Microstructure and Properties of New Bainitic Steel. Master’s Thesis, Central South University, Changsha, China, 2005. [Google Scholar]

| C | Si | Mn | P | S | V | Ti | Als |

|---|---|---|---|---|---|---|---|

| 0.11 | 0.12 | 1.18 | 0.009 | 0.001 | 0.042 | 0.004 | 0.019 |

| Cr | Mo | Nb | Ni | Cu | B | N | O |

| 0.506 | 0.386 | 0.035 | 1.380 | 0.020 | 0.0003 | 0.0058 | 0.005 |

| State | Temperature/°C | D/μm | S | %RA | 95%CI | G | 95%CL | G ± 95%CL |

|---|---|---|---|---|---|---|---|---|

| AR state | 770 | 15.15 | 5.89 | 3.57 | 7.31 | 8.79 | 0.10 | 8.79 ± 0.10 |

| 810 | 15.50 | 4.71 | 2.92 | 5.85 | 8.72 | 0.08 | 8.72 ± 0.08 | |

| 830 | 16.58 | 2.86 | 1.90 | 3.56 | 8.53 | 0.06 | 8.53 ± 0.06 | |

| 850 | 17.38 | 3.21 | 2.23 | 3.98 | 8.40 | 0.06 | 8.40 ± 0.06 | |

| 870 | 18.32 | 11.61 | 8.51 | 14.41 | 8.24 | 0.25 | 8.24 ± 0.25 | |

| Q state | 770 | 9.39 | 4.09 | 3.82 | 5.07 | 10.18 | 0.11 | 10.18 ± 0.11 |

| 810 | 9.93 | 6.73 | 6.65 | 8.36 | 10.02 | 0.16 | 10.02 ± 0.16 | |

| 830 | 10.67 | 5.50 | 5.84 | 6.82 | 9.81 | 0.14 | 9.81 ± 0.14 | |

| 850 | 11.90 | 6.68 | 7.92 | 8.30 | 9.50 | 018 | 9.50 ± 0.18 | |

| 870 | 16.84 | 5.05 | 8.47 | 6.27 | 8.50 | 0.25 | 8.50 ± 0.25 |

| Temperature range (°C) | 770~810 | 810~830 | 830~850 | 850~870 |

| The growth rate (μm/°C) | 0.0135 | 0.037 | 0.0615 | 0.247 |

| Temperature/°C | 770 | 810 | 830 | 850 |

| Proportion of undissolved ferrite/% | 14.13 | 10.4 | 8.67 | 0 |

| Temperature (°C) | 744 | 755 | 765 | 770 | 785 | 795 | 805 | 810 | 825 | 830 | 850 |

| CA(Wt%) | 0.429 | 0.395 | 0.364 | 0.348 | 0.302 | 0.271 | 0.240 | 0.225 | 0.178 | 0.163 | 0.110 |

| Q State Sample Number | Sub-Temperature Quenching Temperature/°C | Tempering Temperature/°C | Tensile Strength Rm/MPa | Yield Strength Re/MPa | Elongation After Fracture A/% | Impact Work/J (−20 °C) |

|---|---|---|---|---|---|---|

| 1-1 | 770 | 610 | 704.1 | 365.3 | 21.0 | 107.2 |

| 1-2 | 770 | 640 | 695.4 | 516.1 | 23.7 | 97.28 |

| 1-3 | 770 | 670 | 684.8 | 447.5 | 24.2 | 55.1 |

| 2-1 | 810 | 610 | 754.0 | 619.5 | 21.4 | 183.2 |

| 2-2 | 810 | 640 | 717.2 | 587.1 | 21.5 | 197.4 |

| 2-3 | 810 | 670 | 688.5 | 519.6 | 23.2 | 177.3 |

| 3-1 | 830 | 610 | 758.3 | 623.0 | 19.8 | 206.4 |

| 3-2 | 830 | 640 | 715.0 | 592.1 | 21.2 | 250.3 |

| 3-3 | 830 | 670 | 673.9 | 542.0 | 21.4 | 202.2 |

| 4-1 | 850 | 610 | 772.4 | 649.4 | 20.0 | 160.7 |

| 4-2 | 850 | 640 | 743.2 | 631.5 | 19.4 | 211.1 |

| 4-3 | 850 | 670 | 703.3 | 561.6 | 24.2 | 161.4 |

| 5-1 | - | 610 | 747.3 | 639.6 | 19.5 | 117.6 |

| 5-2 | - | 640 | 726.2 | 625.9 | 22.2 | 158.6 |

| 5-3 | - | 670 | 687.9 | 590.4 | 21.7 | 196.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, Z.; Wang, F.; Guo, R.; Xu, S.; Li, Z.; Zhang, Y. Study on the Heat Treatment Process of SXQ500/550DZ35 Steel QLT for the Seat Ring and Guide Vane of a Hydropower Station. Metals 2022, 12, 2084. https://doi.org/10.3390/met12122084

Tang Z, Wang F, Guo R, Xu S, Li Z, Zhang Y. Study on the Heat Treatment Process of SXQ500/550DZ35 Steel QLT for the Seat Ring and Guide Vane of a Hydropower Station. Metals. 2022; 12(12):2084. https://doi.org/10.3390/met12122084

Chicago/Turabian StyleTang, Zhenglei, Fuming Wang, Ran Guo, Shaopu Xu, Zhongbo Li, and Yang Zhang. 2022. "Study on the Heat Treatment Process of SXQ500/550DZ35 Steel QLT for the Seat Ring and Guide Vane of a Hydropower Station" Metals 12, no. 12: 2084. https://doi.org/10.3390/met12122084

APA StyleTang, Z., Wang, F., Guo, R., Xu, S., Li, Z., & Zhang, Y. (2022). Study on the Heat Treatment Process of SXQ500/550DZ35 Steel QLT for the Seat Ring and Guide Vane of a Hydropower Station. Metals, 12(12), 2084. https://doi.org/10.3390/met12122084