1. Introduction

The micro-hardness test is a way how to determine the mechanical properties of a small parts of materials. Several authors, such as Sangwal et al. [

1] found that the principle of the Vickers micro-hardness method is identical to the (macro) hardness test, except for a test load lower than 1.691 N (200 g). The micro-hardness can be applied on thin layers of materials, and also to identify the phases in metallography. The independence of the (macro)hardness on the applied load is an advantage of the Vickers test. The form of the Vickers indentation is geometrically similar at all test loads. It is therefore expected that the value of the hardness is constant as long as the tested sample is reasonably homogeneous.

The measured hardness is usually high if a very low load is applied; if a high load is used, the measured hardness decreases. This phenomenon is called a “normal” indentation size effect (ISE). According to Gong et al. [

2], measuring the hardness to characterize materials may result in some unreliable conclusions.

As demonstrated by Tabor [

3], the ambiguity in the measurement of small indentations, especially if pile-up or sink-in effects are present, may result in over- or underestimation of the diagonals’ length. Gubicza et al. [

4] concluded that the existence of ISE can be questioned if it is not possible to guarantee a reliable measurement of the diagonals of the indentations. Similarly, Strand and Jakab-Farkas [

5] consider the biggest source of error to be the measurement of indentations. Most operators can measure indentations with a length accuracy of ±0.5 μm. If the diagonal falls below 20 μm, this inaccuracy can have a significant impact.

In the works of Golanet [

6], Rayar et al. [

7], Kumar et al. [

8], Dusza and Stern [

9], and Michels et al. [

10], there are many examples that point to the fact that “normal” ISE occurs in brittle materials like glass, semiconductors, sintered materials, ceramics ware or organic crystals. Kathavate et al. [

11] studied the ISE of piezoelectric relax or ferroelectric material (PMN-PT). They found that different domain configurations are achieved by selectively annealing, and also affect the values of Meyer’s index. The critical analysis of nanoindentation data reveals that the PSR model provides a satisfactory understanding of the genesis of RISE and ISE considering the elastic resistance of test material and frictional resistance at the indenter facet/test material. Meyer index values for Composite A356 + 6%FA subjected to ECAP (n ranged between 1.9112 and 2.3321), where the cast composite shows normal ISE, while samples machined with ECAP show reverse ISE-RISE, were published by Muslić et al. [

12]. Liu et al. [

13] confirmed the influence of the crystallographic orientation of germanium single crystals on ISE, as did Şahin et al. [

14] for tin and Petrik et al. [

15] for copper. As [

16,

17,

18] prove in their work, the parameters describing ISE are also affected by the method of sample preparation, especially the final surface roughness on which the micro-hardness is measured. Roughness was not measured on the samples used in the presented measurement. Given the standard preparation by pre-measuring the hardness as well as the mirror finish surface of all samples without scratches, we can assume that the potential effect of roughness on the ISE parameters is equal to all samples.

A reverse (inverse, RISE) type of ISE exists, in contrast to “normal” ISE. In the reverse ISE, the apparent micro-hardness increases with increasing testing load. It mostly takes place in materials with plastic deformation. As shown by Sangwal [

19], reverse ISE can be explained by the existence of a distorted zone near the sample—indenter (crystal-medium) interface, the vibration existence of the indenter, the applied energy loss around the indentation, and generation of the cracks.

In the literature, many examples exist, which reveal that the “normal” ISE occurs in brittle materials. On the other hand, the literature is rare on reverse ISE. It mainly concerns reporting for materials passing plastic deformation [

1].

The ground of the ISE is still a topic of debate. It may occur by the testing equipment (the applied load, the measurement device of indentation diagonals [

1,

2,

19]), inner properties of the testing material (load to initiate plastic deformation, indentation elastic recovery, work hardening during indentation, and elastic resistance of the materials [

1,

19,

20], the method tested sample preparation (grinding, polishing, and the resulting residual stress), and possibly other factors (indenter/sample friction, lubrication, and also corrosion) [

2,

21].

The purpose of this paper is to evaluate the influence of the degree/amount of cold plastic deformation (tensile test and compression or upsetting test, thus deformation by tension and pressure) and used load on the micro-hardness and character of the ISE.

2. Materials and Methods

“Commercially pure” aluminum was used as the experimental material. It is a malleable alloy that is formed by rolling, pressing, forging, and other operations. It is widely used in various branches of industry, especially as a conductor in electrical engineering. As an experimental material, it was used primarily for single-phase structure and deformation strengthening by cold working. The authors were somewhat inspired by the contribution [

22], in which the authors, unfortunately, did not use the measurement of hardness. The tested material is 99.5% aluminum (more detail in the standards STN 42 4004 or EN AW 1350) in the form of a rod with a diameter ∅ of 9 mm. The presence of secondary (Fe, Mn, Cu, Cr, Mo, Pb, Si, V, Sn, Zn in the range from 0.1–0.01%) and trace (Ag, Ti in the range from 0.01–0.00001%) elements was determined by semi-quantitative spectral analysis by the spectrograph PGS-2. The rod was annealed for an hour at a temperature of 400 °C and slowly cooled in the furnace to ensure the homogeneity of the structure and to remove stress. After heat treatment, two tensile test samples and cylinders (15 mm × ∅ 9 mm) for compression (upset) test were turned. The tester 200 kN Zwick-Extensometer was used for both tests. For the tensile test, the mean strain rate

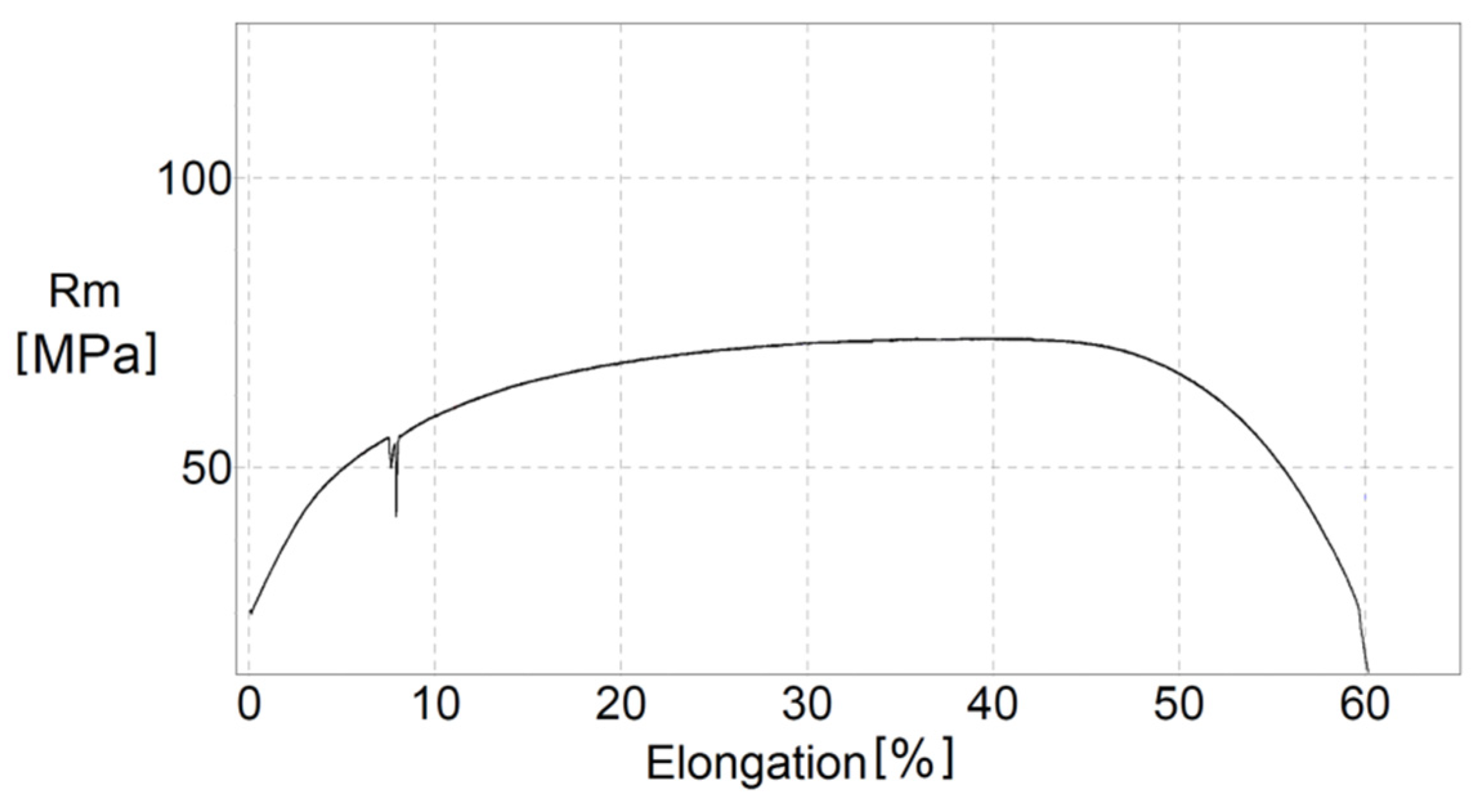

. The ultimate tensile strength UTS is 73 MPa, yield tensile strength YS 25 MPa, elongation TE 59.7%, and reduction of the area/contraction Z is 90.7%. The stress-strain curve is shown in

Figure 1. Relative expanded uncertainty U

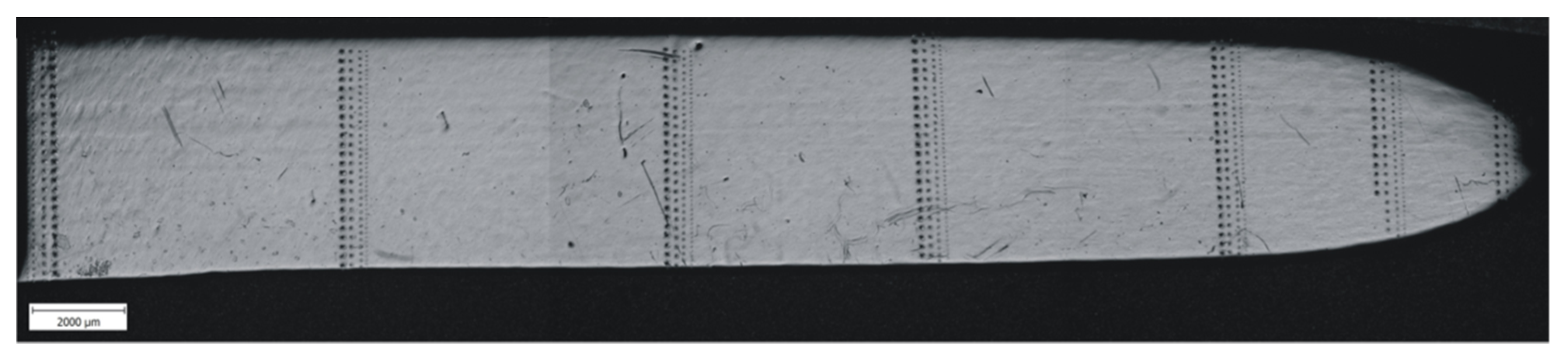

rel (k = 2) is 1.82% for YS and UTS and less than 1% for TE and Z. The micro-hardness was measured on a longer part of the fractured tensile piece, as shown in

Figure 2, and cut in the longitudinal axis by a water-cooled diamond saw. The method used for the measurement of micro-hardness is described in more detail in [

23]; some results are shown below for comparison.

The parameters of the tensile test are in

Table 1 and of the compression are given in

Table 2. The micro-hardness of the fractured tensile sample was measured with tester LECO 100 in individual areas between the neck (Z1) and the head (Z7). The relationship between the local reduction of the area and micro-hardness is shown in

Table 1.

The degree of the deformation ε (%) in the compression is a change in height, and the degree of the extension φ (%) is a change in the diameter. The samples were deformed without the lubricant. The accuracy in measurement of the dimensions was 0.001 mm. The deformed samples were cut parallel to the vertical axis at the maximum diameter with a water-cooled diamond saw; the starting, undeformed state was cut in planes both parallel and perpendicular to its axis.

Cut samples were fixed in the resin (dentacryl). For grinding silicon papers in sequence 80…3000ANSI/CAMI with water-cooling were used. The metallographic surface was polished with the water suspension of Al2O3 to a mirror finish. A water solution of 0.5% HF was used as the etching agent. The purpose of etching was to make visible hard intermetallic phases, firstly Al-Fe and Al-Fe-Mn. When measuring the micro-hardness, the area of their occurrence was missed.

For the nanoindentation testing, the sectioned pure aluminum rolls after different deformations were prepared using the fixation technique by cold resin, and then they were ground and polished—flat.

The nanoindentation measurement of the local hardness on the surface of the investigated sample was carried out with Agilent G200 indenter (Agilent Technologies, Inc., Chandler, AZ, USA) with a Berkovich tip perpendicular to the cutting surface mapping the matrix of points with 150 μm spacing. Single loading–unloading indentation was used. The indentation depth-controlled method was used with a maximum depth of 2000 nm was used in all cases.

The micro-hardness of compressed cylinders was measured with tester Hanemann, type Mod D32, part of the optical microscope Neophot-32. The tester’s optics enabled a magnification of 480×. The value of the smallest division of the scale (discrimination) of the device measuring indentations is 0.000313 mm. It ranged between 1.1% and 3.1% of the average diagonal, depending on the used load.

A reference block, –CRM (certified reference material) with specified hardness Hc = 195 HV0.05 and standard uncertainty u = 4.0 HV0.05, was used for the calibration of the tester.

According to the results of the calibration (repeatability r

rel, error of tester E

rel, and relative expanded uncertainty of calibration U

rel), which was done before each measurement, both testers meet the conditions of the standard ISO 6507-2 [

24].

3. Results

The nano-hardness of the initial (starting, undeformed) state (the cut perpendicular to the axis), was measured in the axis of the sample over an area of 1.4 mm × 1.4 mm. The purpose was to evaluate the influence of the applied annealing process on the inhomogeneous distribution of hardness. As can be seen in

Figure 3, the difference in the nano-hardness is insignificant (between 0.380 and 0.436 GPa ≈ 38.0 and 43.6 HV).

The change of the nano-hardness of sample ε

6, in % (relative change of hardness obtained on the compressed samples in comparison with samples in the initial state without compression), can be seen in

Figure 4. The deformation is not homogeneous. At the bottom of the image can be seen an area with low deformation at the sample-anvil (die) contact. By contrast, the deformation in the upper part of the figure is significantly higher, and the arm of the X shape area or the “forging cross” is displayed.

The nano-hardness of sample ε

10 was measured to determine the influence of deformation on its value. Since the symmetrical distribution of deformation inhomogeneity is assumed, nano-hardness was measured only on half of the sample. In

Figure 5, the measured area is marked as J.

Figure 6 displays the change of the nano-hardness (in %), and inhomogeneous deformation is manifested by the formation of regions with different nano-hardness values. This fact was a guide for identifying areas for measuring the micro-hardness and determining its impact on ISE parameters.

One operator measured the micro-hardness according to ISO 6507-1:2004 [

25]. The applied loads P were 0.09807 N (10 g), 0.24518 N (25 g), 0.49035 N (50 g), and 0.9807 N (100 g). The duration of the load was 15 seconds. The values of the mean speed of the indenter’s penetration (v, in μm s

−1) into the volume of the sample at the load 0.49035 N are in

Table 2. The calculation of the speed is described in [

23].

First, an indentation of the load 50 g (0.49035 N) was applied. The indentations at the other loads were carried out; the distance between particular indentations meets the requirements of the standard ISO 6507-1 [

25]. At a distance of 1 mm, a further indentation was made at a load of 0.49035 N and indentations around it at other loads. The process was repeated until the opposite side of the sample was reached. Thus, the number of indentations was not the same and it increased with the degree (amount) of deformation and thus the sample diameter. For example, the arrangement of the indentations in the band is shown in detail in

Figure 7 (sample ε

10, area F in

Figure 5; the figure is illustrative to display the size of the indentations at different loads. Indentations whose dimensions were used to evaluate the ISE were at distances corresponding to the requirements of the standard).

For the compressed samples, the values of the relative expanded uncertainty Urel of the micro-hardness range between 29.4% and 61.7%. Its value is overestimated by the used CRM (iron) with a micro-hardness significantly higher than the hardness of the measured samples. Therefore, these values should only be considered indicative. The relationship (correlation) between the degree of deformation ε, and the uncertainty is strong (r2 = −0.9049), and the uncertainty decreases with increasing deformation.

The result of the micro-hardness measurement of compressed samples is “clusters” of 32–92 (depending on the degree of deformation) indentations for individual compressed samples. The average values of micro-hardness (HV) of each of the clusters, and the micro-hardness at individual loads are in

Table 1 for the fractured tensile piece, and in

Table 2 for compressed samples.

The influence of the local reduction of the area, load, and micro-hardness for compressed samples are shown in

Figure 8.

Anomalies in (

Figure 8) may be due to inhomogeneous deformation during the compression; the inhomogeneity is also increased by the absence of lubricant between the dies and the top or bottom contact face. They can also arise as a result of the presence of intermetallic phases, similar to tensile pieces [

23].

The result of the inhomogeneity of the deformation was the formation of three areas: an area without deformation at the sample-anvil (die) contact (above the top or the bottom contact face area H in

Table 3,

Figure 5), a slightly deformed area along the maximum circumference (edges, peripheries, sides of the sample—area A in Table 5,

Figure 4), and maximum deformed X shape area—the axisymmetric heterogeneity (barreling, zones of heterogeneity or the “forging cross”; D, E, and the first area I in Table 5,

Figure 4).

The relationship between the inhomogeneity of the deformation and the measured values of nano- and micro-hardness is demonstrated in sample ε

10. As expected, the locally increased degree of deformation was manifested by an increase in nano-hardness,

Figure 6, in the lower left, corresponding to the area I,

Figure 5. To investigate the influence of the local deformation (given by the area of the sample), the micro-hardness and the characteristics of ISE, the micro-hardness was measured in bands or in clusters (5 indentations per load, a total of 20 indentations per cluster).

The local degree of deformation could not be accurately measured. The use of the deformation of the originally equiaxed grains to determine the local deformation did not meet expectations. Even the deep etching did not make the grain boundaries clear enough. The selection of sites of the clusters or bands (A–I) was made based on the values of nano-hardness. The position of the clusters and bands is shown in

Figure 5 and the description in

Table 3, also with the values of the number of the indentations N, average micro-hardness, and Meyer’s indices n.

The statistical significance of the micro-hardness measured in individual areas (A–J) of sample ε

10 was obtained by unpaired

t-test. It is a statistical test that is used to compare the means of two groups. It is often used in hypothesis testing to determine whether a process or treatment has an effect on the population of interest, or whether two groups are different from one another. If the value of

p < α (significance level α = 0.05), the difference between average hardness is statistically significant (these values are in italics in

Table 4).

For the detection of outlier values Grubb’s test (significance level α = 0.05) was used. Statistical outliers indicate the measurement process that suffers from special disturbances and is out of statistical control. The Anderson – Darling test was applied to determine the normality of a “cluster” of measured values; the values in all “clusters” have normal distribution without outliers.

Meyer’s power law and proportional specimen resistance (PSR) are most often used to determine ISE characteristics [

20]:

Meyer’s Law can be expressed using Equation (1):

The parameters n and A are determined by exponential curve fitting to indentation diagonal d (mm) versus applied load P (N) or n and A

ln are determined by straight line fitting to ln (d) versus ln (P). The value d is the average value of the diagonals of all indentations in the band, done at one load. Meyer’s index n or work hardening coefficient is the slope, and coefficient A

ln is the y-intercept of the line. This relationship was derived for the ball indenter but it has become common practice to apply Tabor’s interpretation of the strain-hardening by pyramidal indenter and to derive a “work-hardening index” [

26]. The index n > 2 was used for reverse ISE, n < 2 was used for “normal” ISE. If n = 2, the micro-hardness is independent of the load and is given by Kick’s law.

The values of n and A

ln are in

Table 5. The relationship between deformation (Z for tensile test and ε for compressed samples) and Meyer’s index n is in

Figure 9. The ISE character (nature) changes from neutral (n = 2) to reverse for compressed samples and to “normal” for tensile test sample with an increase of deformation. As the deformation increases, the absolute value of the size of n also increases. The relationship between the amount of plastic deformation and Meyer’s index n is described by the polynomial 3rd degree with a strong correlation (Pearson’s coefficient r

2 = 0.8947; the coefficient of determination r

2 = 0.9291).

The dependence of the value of Meyer’s index on the position of the indentations and the degree of deformation for (a) the tensile piece and (b) the compressed samples can be seen in

Figure 10. In the case of a tensile piece and compressed samples, the values of the micro-hardness of the indentations in the bands were used to calculate the n index. In the case of the tensile sample, the indices are evaluated also in the bands, as shown in

Figure 2. The index was calculated from the values of the diagonals of the four nearest indents, the first of which was made at a load of 0.9807 N, the second 0.49035 N, the third 0.24518 N, and the fourth 0.09807 N.

The resistance model of Li and Bradt about proportional specimen PSR is considered a modified way of the Hays/Kendall coming nearer to the ISE [

2]. Many authors as [

1,

2,

20,

27,

28] have proposed that the ISE can be expressed by the Equation (2):

As stated by Li and Bradt [

21,

27], parameter a

1 (N mm

−1) is related to the elastic, and a

2 (N mm

−2) is related to the plastic properties of the material. We calculate both parameters using Equation (2). Both parameters can be obtained from the plots of P/d (N mm

−1) against d (mm).

Equation (3) can be regarded as a modified form of the PSR model. Parameter c

0 (N) is associated with residual surface stress, parameter c

1 (N mm

−1) is related to the elasticity, and parameter c

2 (N mm

−2) is related to the plastic properties of the material. Values of parameters can be obtained from the quadratic regressions of P (N) against d (mm), using Equation (5). Parameters c

1 and c

2 correspond to parameters a

1 and a

2 obtained by Hays/Kendall approach [

1,

2].

Parameter a

1 characterizes the load dependence of micro-hardness and describes the ISE in the PSR model. It consists of two components: the elastic resistance of the test sample and the friction resistance developed at the indenter facet/sample interface [

1,

20]. The harder material with a higher Young’s modulus has a higher value of a

1 [

29]. The parameter a

2 is related to load-independent micro-hardness, the “true hardness” HPSR, calculated by Equation (4) [

30].

The measure of the residual stress, the result of mechanical processing (preparation of the metallographic surface), is ratio c

1/c

2. According to [

1,

2], a relationship between c

0 and the ratio c

1/c

2 expressed by a linear dependence, is assumed. This fact confirms

Figure 11 for obtained data. The values of the parameters calculated using modified PSR are in

Table 5.

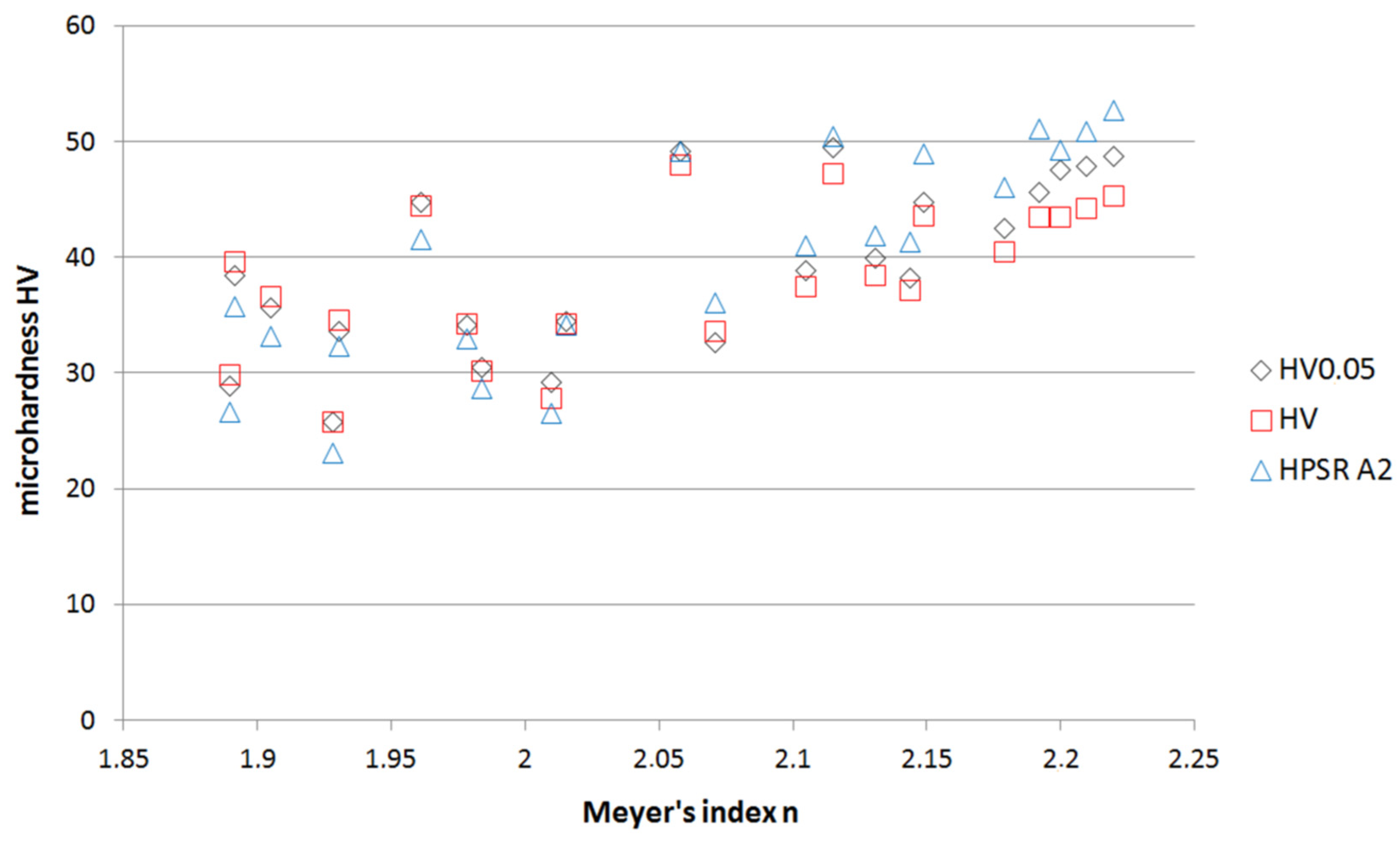

The value of Meyer’s index n increases with increasing micro-hardness, as shown in

Figure 12, for both tensile and pressure deformations. A similar ratio between the micro-hardness and Meyer’s index n was observed for iron-based CRMs with micro-hardness between 195 and 519 HV0.05, heat-treated carbon steel, aluminum alloy EN 6082, and technically pure metals (Al, Zn, Cu, Fe, Ni, Co), all with reverse ISE [

31,

32]. The mentioned samples were not deformed, except for surface treatment by grinding and polishing. The “true hardness” by analogy to a

2 can be calculated as H

PSRc2 using c

2 instead of a

2 in Equation (4).

Test load W (N) is the load necessary to initiate plastic deformation with a visible indentation; only elastic deformation occurs below it. In that event, the load dependence of hardness is expressed by Equation (5):

Parameter A

1 (N mm

−2) is independent of load. W and A

1 may be obtained from the regressions of P (N) against d

2 (mm) [

1], their values are in

Table 5.

By analogy to a

2, the “true hardness” H

PSRA

1 can be calculated by Equation (4). The values of “true hardness” are in

Table 6.