Process Optimization for Up-Facing Surface Finish of AlSi10Mg Alloy Produced by Laser Powder Bed Fusion

Abstract

1. Introduction

2. Experimental Procedures

2.1. Materials and LPBF Process

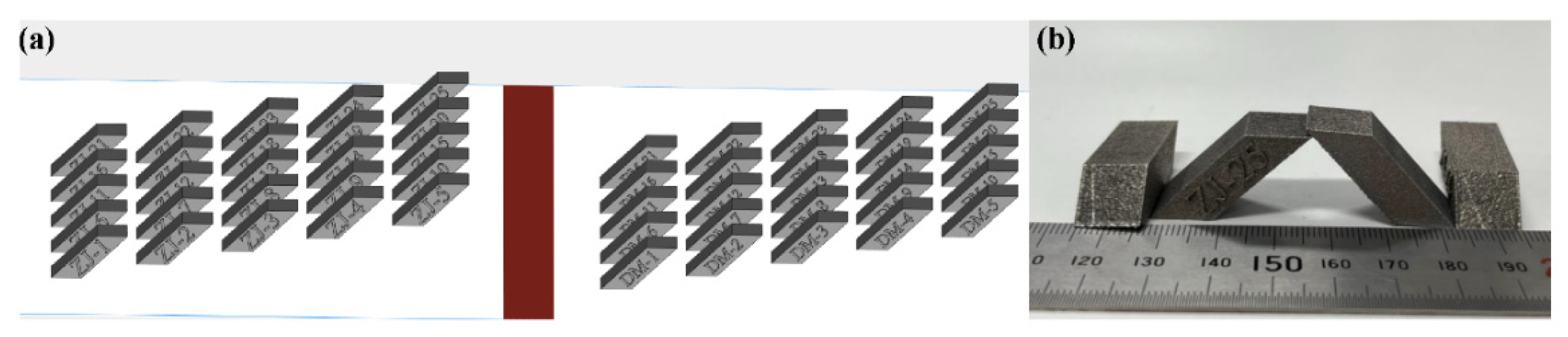

2.2. Design of Experiments

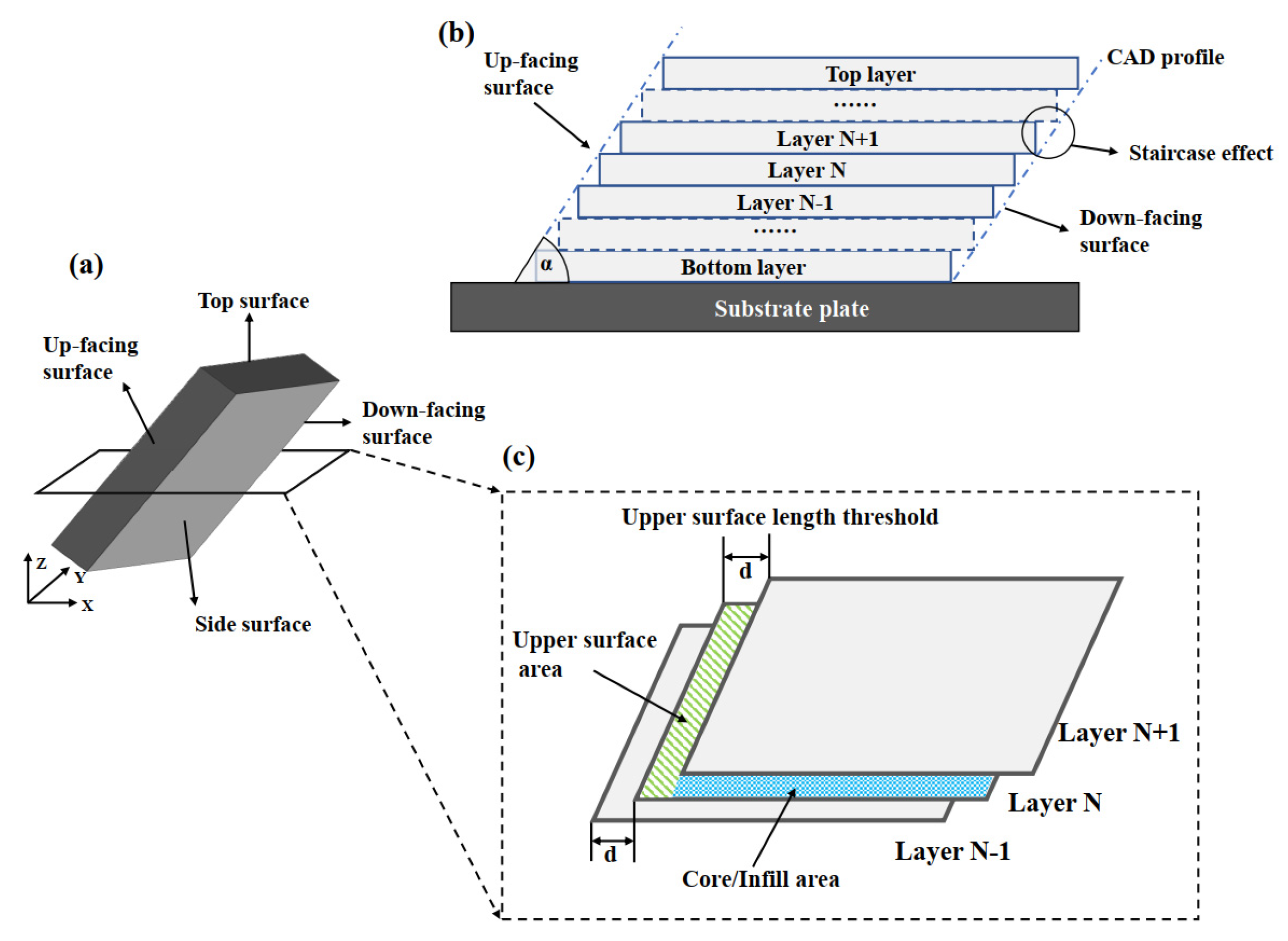

2.2.1. Up-Facing Parameters Optimization

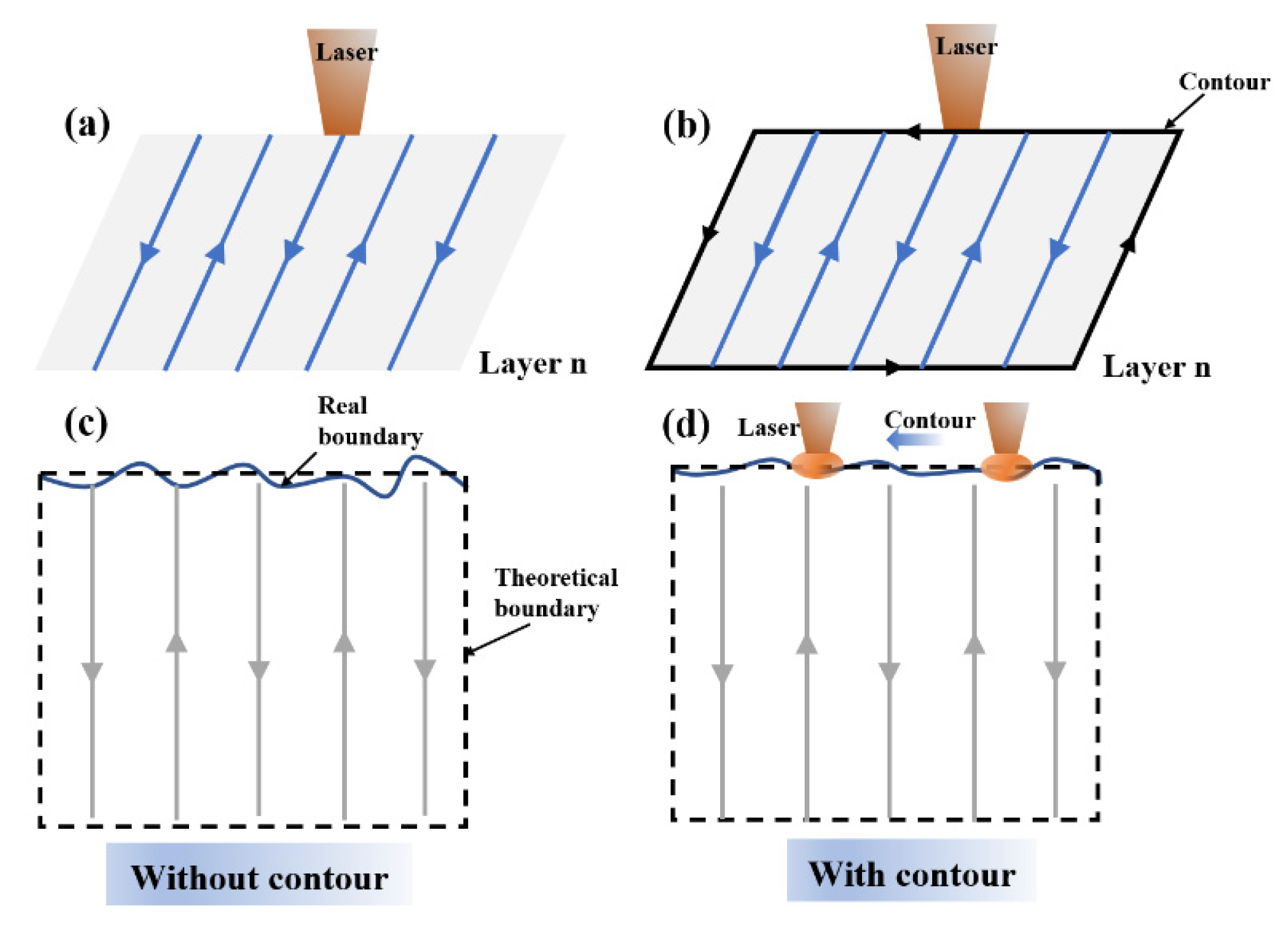

2.2.2. Contour Parameter Optimization

2.3. Surface Quality Characterization

3. Results and Discussion

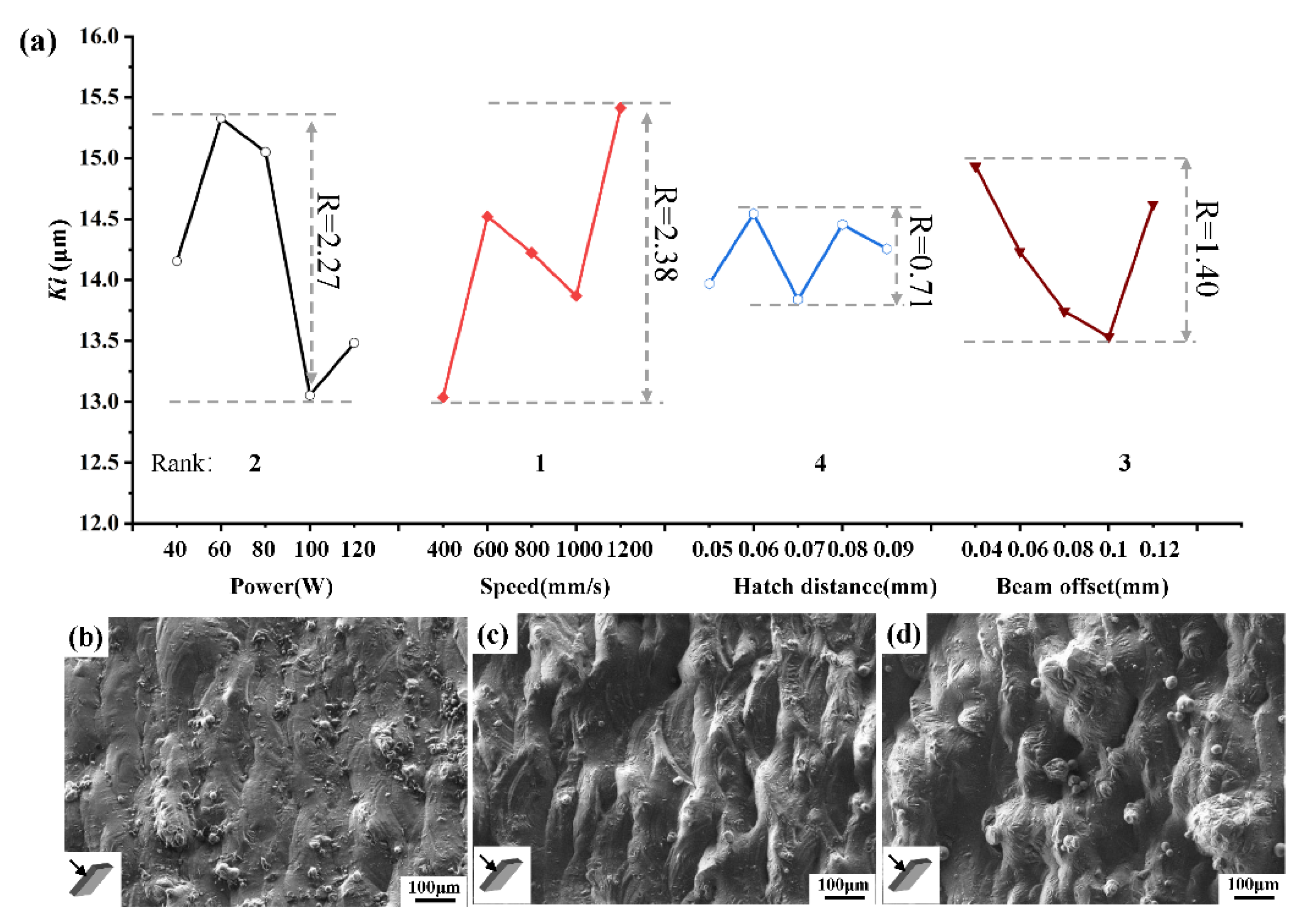

3.1. Optimization of Up-Facing Skin Parameter

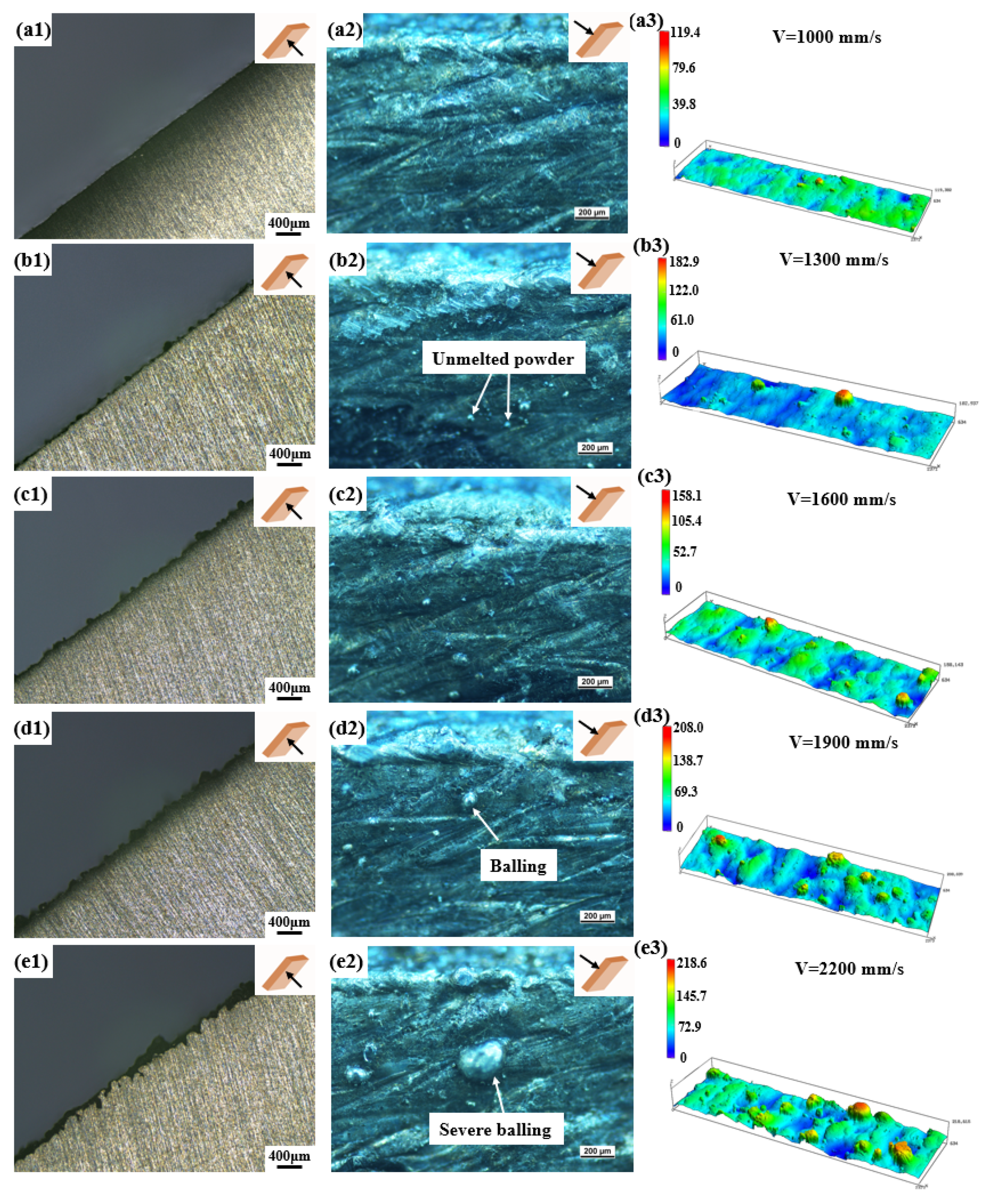

3.2. Contour Parameter Optimization

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Gao, C.; Wu, W.; Shi, J.; Xiao, Z.; Akbarzadeh, A.H. Simultaneous Enhancement of Strength, Ductility, and Hardness of TiN/AlSi10Mg Nanocomposites via Selective Laser Melting. Addit. Manuf. 2020, 34, 101378. [Google Scholar] [CrossRef]

- Charles, A.; Elkaseer, A.; Thijs, L.; Hagenmeyer, V.; Scholz, S. Effect of Process Parameters on the Generated Surface Roughness of Down-Facing Surfaces in Selective Laser Melting. Appl. Sci. 2019, 9, 1256. [Google Scholar] [CrossRef]

- Wang, W.; Garmestani, H.; Liang, S.Y. Prediction of Upper Surface Roughness in Laser Powder Bed Fusion. Metals 2021, 12, 11. [Google Scholar] [CrossRef]

- Metelkova, J.; Vanmunster, L.; Haitjema, H.; Van Hooreweder, B. Texture of inclined up-facing surfaces in laser powder bed fusion of metals. Addit. Manuf. 2021, 42, 101970. [Google Scholar] [CrossRef]

- Cabanettes, F.; Joubert, A.; Chardon, G.; Dumas, V.; Rech, J.; Grosjean, C.; Dimkovski, Z. Topography of as built surfaces generated in metal additive manufacturing: A multi scale analysis from form to roughness. Precis. Eng. 2018, 52, 249–265. [Google Scholar] [CrossRef]

- Wang, D.; Liu, Y.; Yang, Y.; Xiao, D. Theoretical and experimental study on surface roughness of 316L stainless steel metal parts obtained through selective laser melting. Rapid. Prototyp. J. 2016, 22, 706–716. [Google Scholar] [CrossRef]

- Strano, G.; Hao, L.; Everson, R.M.; Evans, K.E. Surface roughness analysis, modelling and prediction in selective laser melting. J. Mater. Process. Technol. 2013, 213, 589–597. [Google Scholar] [CrossRef]

- Mumtaz, K.; Hopkinson, N. Top surface and side roughness of Inconel 625 parts processed using selective laser melting. Rapid. Prototyp. J. 2009, 15, 96–103. [Google Scholar] [CrossRef]

- Yan, X.; Gao, S.; Chang, C.; Huang, J.; Khanlari, K.; Dong, D.; Ma, W.; Fenineche, N.; Liao, H.; Liu, M. Effect of building directions on the surface roughness, microstructure, and tribological properties of selective laser melted Inconel 625. J. Mater. Process. Technol. 2021, 288, 116878. [Google Scholar] [CrossRef]

- Alghamdi, A.; Downing, D.; McMillan, M.; Brandt, M.; Qian, M.; Leary, M. Experimental and numerical assessment of surface roughness for Ti6Al4V lattice elements in selective laser melting. Int. J. Adv. Manuf. Technol. 2019, 105, 1275–1293. [Google Scholar] [CrossRef]

- Sadali, M.F.; Hassan, M.Z.; Ahmad, F.; Yahaya, H.; Rasid, Z.A. Influence of selective laser melting scanning speed parameter on the surface morphology, surface roughness, and micropores for manufactured Ti6Al4V parts. J. Mater. Res. 2020, 35, 2025–2035. [Google Scholar] [CrossRef]

- Vayssette, B.; Saintier, N.; Brugger, C.; Elmay, M.; Pessard, E. Surface roughness of Ti-6Al-4V parts obtained by SLM and EBM: Effect on the High Cycle Fatigue life. Procedia Eng. 2018, 213, 89–97. [Google Scholar] [CrossRef]

- Vayssette, B.; Saintier, N.; Brugger, C.; El May, M. Surface roughness effect of SLM and EBM Ti-6Al-4V on multiaxial high cycle fatigue. Theor. Appl. Fract. Mech. 2020, 108, 102581. [Google Scholar] [CrossRef]

- Yang, X.; Wang, F.H.; Wang, W.L.; Liu, S.F.; Chen, Y.Q.; Tang, H.P. Comparison of two-step surface treatment on surface roughness and corrosion resistance of TC4 alloy parts prepared by SLM and SEBM. J. Alloys Compd. 2022, 921, 165929. [Google Scholar] [CrossRef]

- Tian, Y.; Tomus, D.; Rometsch, P.; Wu, X. Influences of processing parameters on surface roughness of Hastelloy X produced by selective laser melting. Addit. Manuf. 2017, 13, 103–112. [Google Scholar] [CrossRef]

- Koutiri, I.; Pessard, E.; Peyre, P.; Amlou, O.; De Terris, T. Influence of SLM process parameters on the surface finish, porosity rate and fatigue behavior of as-built Inconel 625 parts. J. Mater. Process. Technol. 2018, 255, 536–546. [Google Scholar] [CrossRef]

- Boschetto, A.; Bottini, L.; Veniali, F. Roughness modeling of AlSi10Mg parts fabricated by selective laser melting. J. Mater. Process. Technol. 2017, 241, 154–163. [Google Scholar] [CrossRef]

- Hu, Z.; Qi, Y.; Nagarajan, B.; Nie, X.; Zhang, H.; Zhu, H.; Zeng, X. Top surface roughness evolution during selective laser melting of AlCu5MnCdVA aluminum alloy. J. Manuf. Process. 2021, 64, 1180–1195. [Google Scholar] [CrossRef]

- Masiagutova, E.; Cabanettes, F.; Sova, A.; Cici, M.; Bidron, G.; Bertrand, P. Side surface topography generation during laser powder bed fusion of AlSi10Mg. Addit. Manuf. 2021, 47, 102230. [Google Scholar] [CrossRef]

- Leon, A.; Aghion, E. Effect of surface roughness on corrosion fatigue performance of AlSi10Mg alloy produced by Selective Laser Melting (SLM). Mater. Charact. 2017, 131, 188–194. [Google Scholar] [CrossRef]

- Dai, D.; Gu, D. Tailoring surface quality through mass and momentum transfer modeling using a volume of fluid method in selective laser melting of TiC/AlSi10Mg powder. Int. J. Mach. Tools Manuf. 2015, 88, 95–107. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Krakhmalev, P.; Yadroitsava, I. Hierarchical design principles of selective laser melting for high quality metallic objects. Addit. Manuf. 2015, 7, 45–56. [Google Scholar] [CrossRef]

- Jamshidinia, M.; Kovacevic, R. The influence of heat accumulation on the surface roughness in powder-bed additive manufacturing. Surf. Topogr. Metrol. Prop. 2015, 3, 14003. [Google Scholar] [CrossRef]

- Newton, L.; Senin, N.; Chatzivagiannis, E.; Smith, B.; Leach, R. Feature-based characterisation of Ti6Al4V electron beam powder bed fusion surfaces fabricated at different surface orientations. Addit. Manuf. 2020, 35, 101273. [Google Scholar] [CrossRef]

- Chen, Z.; Wu, X.; Tomus, D.; Davies, C.H.J. Surface roughness of Selective Laser Melted Ti-6Al-4V alloy components. Addit. Manuf. 2018, 21, 91–103. [Google Scholar] [CrossRef]

- Ferreira, S.L.; Dos Santos, W.N.; Quintella, C.M.; Neto, B.B.; Bosque-Sendra, J.M. Doehlert matrix: A chemometric tool for analytical chemistry-review. Talanta 2004, 63, 1061–1067. [Google Scholar] [CrossRef]

- Balaji, U.; Pradhan, S.K. Titanium anodisation designed for surface colouration—Systemisation of parametric interaction using response surface methodology. Mater. Des. 2018, 139, 409–418. [Google Scholar] [CrossRef]

- Doehlert, D.H. Uniform Shell Designs. Appl. Stat. 1970, 19, 231–239. [Google Scholar] [CrossRef]

- Calignano, F.; Manfredi, D.; Ambrosio, E.P.; Iuliano, L.; Fino, P. Influence of process parameters on surface roughness of aluminum parts produced by DMLS. Int. J. Adv. Manuf. Technol. 2012, 67, 2743–2751. [Google Scholar] [CrossRef]

- Li, J.; Hu, J.; Zhu, Y.; Yu, X.; Yu, M.; Yang, H. Surface roughness control of root analogue dental implants fabricated using selective laser melting. Addit. Manuf. 2020, 34, 101283. [Google Scholar] [CrossRef]

| Factors | Levels | ||||

|---|---|---|---|---|---|

| (Up-facing) laser power (W) | 40 | 60 | 80 | 100 | 120 |

| (Up-facing) scanning speed (mm/s) | 400 | 600 | 800 | 1000 | 1200 |

| (Up-facing) hatch distance (mm) | 0.05 | 0.06 | 0.07 | 0.08 | 0.09 |

| (Up-facing) beam offset (mm) | 0.04 | 0.06 | 0.08 | 0.1 | 0.12 |

| Independent Factors | Coded levels | ||||||

|---|---|---|---|---|---|---|---|

| Factor A coded | −1 | −0.5 | 0 | 0.5 | 1 | - | - |

| Factor B coded | −0.866 | −0.577 | −0.289 | 0 | 0.289 | 0.577 | 0.866 |

| Factor C coded | −0.817 | −0.613 | −0.204 | 0 | 0.204 | 0.613 | 0.817 |

| Factor D coded | −0.791 | 0 | 0.791 | - | - | - | - |

| Factors Contour | Levels | ||||

|---|---|---|---|---|---|

| (Contour) laser power (W) | 100 | 120 | 140 | 160 | 180 |

| (Contour) scanning speed (mm/s) | 1000 | 1300 | 1600 | 1900 | 2200 |

| (Contour) beam offset (mm) | 0.07 | 0.08 | 0.09 | 0.1 | 0.11 |

| Run | Factors: Up-Facing Skin Parameters | Results | |||

|---|---|---|---|---|---|

| Power (W) | Scanning Speed (mm/s) | Hatch Distance (mm) | Beam Offset (mm) | Surface Roughness (Ra, μm) | |

| 1 | 40 | 400 | 0.05 | 0.04 | 13.25 |

| 2 | 40 | 600 | 0.06 | 0.06 | 13.60 |

| 3 | 40 | 800 | 0.07 | 0.08 | 14.73 |

| 4 | 40 | 1000 | 0.08 | 0.10 | 13.86 |

| 5 | 40 | 1200 | 0.09 | 0.12 | 15.34 |

| 6 | 60 | 400 | 0.06 | 0.08 | 13.82 |

| 7 | 60 | 600 | 0.07 | 0.10 | 14.26 |

| 8 | 60 | 800 | 0.08 | 0.12 | 16.26 |

| 9 | 60 | 1000 | 0.09 | 0.04 | 15.71 |

| 10 | 60 | 1200 | 0.05 | 0.06 | 16.57 |

| 11 | 80 | 400 | 0.07 | 0.12 | 13.86 |

| 12 | 80 | 600 | 0.08 | 0.04 | 15.92 |

| 13 | 80 | 800 | 0.09 | 0.06 | 15.69 |

| 14 | 80 | 1000 | 0.05 | 0.08 | 14.16 |

| 15 | 80 | 1200 | 0.06 | 0.10 | 15.63 |

| 16 | 100 | 400 | 0.08 | 0.06 | 11.75 |

| 17 | 100 | 600 | 0.09 | 0.08 | 12.65 |

| 18 | 100 | 800 | 0.05 | 0.10 | 11.42 |

| 19 | 100 | 1000 | 0.06 | 0.12 | 13.80 |

| 20 | 100 | 1200 | 0.07 | 0.04 | 15.65 |

| 21 | 120 | 400 | 0.09 | 0.10 | 12.51 |

| 22 | 120 | 600 | 0.05 | 0.12 | 14.45 |

| 23 | 120 | 800 | 0.06 | 0.04 | 14.14 |

| 24 | 120 | 1000 | 0.07 | 0.06 | 11.82 |

| 25 | 120 | 1200 | 0.08 | 0.08 | 14.49 |

| K | Factor: Up-Facing Skin Parameters | |||

|---|---|---|---|---|

| Power (W) | Scanning Speed (mm/s) | Hatch Distance (mm) | Beam Offset (mm) | |

| k1 | 14.15 | 13.04 | 13.97 | 14.93 |

| k2 | 15.33 | 14.52 | 14.55 | 14.23 |

| k3 | 15.05 | 14.22 | 13.84 | 13.74 |

| k4 | 13.05 | 13.87 | 14.46 | 13.53 |

| k5 | 13.48 | 15.41 | 14.26 | 14.62 |

| R = max(ki) − min(ki) | 2.27 | 2.38 | 0.71 | 1.40 |

| Order of factors | 2 | 1 | 4 | 3 |

| Run | Coded Levels | Uncoded Level: Up-Facing Parameters | Results | ||||||

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | Hatch Distance (mm) | Laser Power (W) | Scanning Speed (mm/s) | Beam Offset (mm) | Surface Roughness (Ra, μm) | |

| 1 | 0 | 0 | 0 | 0 | 0.07 | 150 | 700 | 0.08 | 9.41 |

| 2 | 1 | 0 | 0 | 0 | 0.09 | 150 | 700 | 0.08 | 9.09 |

| 3 | 0.5 | 0.866 | 0 | 0 | 0.08 | 193 | 700 | 0.08 | 6.92 |

| 4 | 0.5 | 0.289 | 0.817 | 0 | 0.08 | 164 | 945 | 0.08 | 9.33 |

| 5 | 0.5 | 0.289 | 0.204 | 0.791 | 0.08 | 164 | 761 | 0.11 | 9.51 |

| 6 | −1 | 0 | 0 | 0 | 0.05 | 150 | 700 | 0.08 | 10.85 |

| 7 | −0.5 | −0.866 | 0 | 0 | 0.06 | 107 | 700 | 0.08 | 12.70 |

| 8 | −0.5 | −0.289 | −0.817 | 0 | 0.06 | 136 | 455 | 0.08 | 10.48 |

| 9 | −0.5 | −0.289 | −0.204 | −0.791 | 0.06 | 136 | 639 | 0.05 | 11.28 |

| 10 | 0.5 | −0.866 | 0 | 0 | 0.08 | 107 | 700 | 0.08 | 12.69 |

| 11 | 0.5 | −0.289 | −0.817 | 0 | 0.08 | 136 | 455 | 0.08 | 11.02 |

| 12 | 0.5 | −0.289 | −0.204 | −0.791 | 0.08 | 136 | 639 | 0.05 | 12.28 |

| 13 | −0.5 | 0.866 | 0 | 0 | 0.06 | 193 | 700 | 0.08 | 7.84 |

| 14 | 0 | 0.577 | −0.817 | 0 | 0.07 | 179 | 455 | 0.08 | 9.15 |

| 15 | 0 | 0.577 | −0.204 | −0.791 | 0.07 | 179 | 639 | 0.05 | 9.46 |

| 16 | −0.5 | 0.289 | 0.817 | 0 | 0.06 | 164 | 945 | 0.08 | 10.02 |

| 17 | 0 | −0.577 | 0.817 | 0 | 0.07 | 121 | 945 | 0.08 | 12.03 |

| 18 | 0 | 0 | 0.613 | −0.791 | 0.07 | 150 | 884 | 0.05 | 11.13 |

| 19 | −0.5 | 0.289 | 0.204 | 0.791 | 0.06 | 164 | 761 | 0.11 | 10.13 |

| 20 | 0 | −0.577 | 0.204 | 0.791 | 0.07 | 121 | 761 | 0.11 | 12.78 |

| 21 | 0 | 0 | −0.613 | 0.791 | 0.07 | 150 | 516 | 0.11 | 10.46 |

| 22 | 0 | 0 | 0 | 0 | 0.07 | 150 | 700 | 0.08 | 10.71 |

| 23 | 0 | 0 | 0 | 0 | 0.07 | 150 | 700 | 0.08 | 10.31 |

| 24 | 0 | 0 | 0 | 0 | 0.07 | 150 | 700 | 0.08 | 10.17 |

| 25 | 0 | 0 | 0 | 0 | 0.07 | 150 | 700 | 0.08 | 10.75 |

| Headings | Factors: Contour Parameters | Results | ||

|---|---|---|---|---|

| Power (W) | Scanning Speed (mm/s) | Beam Offset (mm) | Surface Roughness (Ra, μm) | |

| 1 | 100 | 1000 | 0.07 | 5.49 |

| 2 | 100 | 1300 | 0.08 | 5.82 |

| 3 | 100 | 1600 | 0.09 | 8.18 |

| 4 | 100 | 1900 | 0.1 | 12.20 |

| 5 | 100 | 2200 | 0.11 | 16.77 |

| 6 | 120 | 1000 | 0.08 | 6.22 |

| 7 | 120 | 1300 | 0.09 | 6.48 |

| 8 | 120 | 1600 | 0.1 | 7.10 |

| 9 | 120 | 1900 | 0.11 | 17.52 |

| 10 | 120 | 2200 | 0.07 | 14.55 |

| 11 | 140 | 1000 | 0.09 | 7.51 |

| 12 | 140 | 1300 | 0.1 | 7.92 |

| 13 | 140 | 1600 | 0.11 | 9.80 |

| 14 | 140 | 1900 | 0.07 | 11.26 |

| 15 | 140 | 2200 | 0.08 | 12.98 |

| 16 | 160 | 1000 | 0.1 | 6.91 |

| 17 | 160 | 1300 | 0.11 | 9.03 |

| 18 | 160 | 1600 | 0.07 | 9.25 |

| 19 | 160 | 1900 | 0.08 | 10.43 |

| 20 | 160 | 2200 | 0.09 | 12.92 |

| 21 | 180 | 1000 | 0.11 | 7.53 |

| 22 | 180 | 1300 | 0.07 | 9.47 |

| 23 | 180 | 1600 | 0.08 | 9.91 |

| 24 | 180 | 1900 | 0.09 | 10.53 |

| 25 | 180 | 2200 | 0.1 | 11.78 |

| Source | A | B | C | AB | AC | BC | A2 | B2 | C2 |

|---|---|---|---|---|---|---|---|---|---|

| p-value | 0.453 | 0.000 | 0.462 | 0.005 | 0.008 | / | 0.818 | 0.000 | 0.015 |

| Source | Degrees of Freedom | Sum of Squares | Mean Square | F Value | p Value | Heading |

|---|---|---|---|---|---|---|

| Model | 7 | 188.65 | 26.95 | 72.61 | 0.000 | Significant |

| A-Laser power | 1 | 0.233 | 0.233 | 0.63 | 0.440 | |

| B-Scanning speed | 1 | 107.32 | 107.32 | 289.12 | 0.000 | |

| C-Beam offset | 1 | 0.223 | 0.223 | 0.60 | 0.449 | |

| B2 | 1 | 9.488 | 9.488 | 25.56 | 0.000 | |

| C2 | 1 | 2.933 | 2.933 | 7.90 | 0.012 | |

| AB | 1 | 4.092 | 4.092 | 11.02 | 0.004 | |

| AC | 1 | 3.542 | 3.542 | 9.54 | 0.007 | |

| Error | 17 | 6.310 | 0.371 | |||

| Total | 24 | 194.96 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, C.; Tang, H.; Zhang, S.; Ma, Z.; Bi, Y.; Rao, J.-H. Process Optimization for Up-Facing Surface Finish of AlSi10Mg Alloy Produced by Laser Powder Bed Fusion. Metals 2022, 12, 2053. https://doi.org/10.3390/met12122053

Gao C, Tang H, Zhang S, Ma Z, Bi Y, Rao J-H. Process Optimization for Up-Facing Surface Finish of AlSi10Mg Alloy Produced by Laser Powder Bed Fusion. Metals. 2022; 12(12):2053. https://doi.org/10.3390/met12122053

Chicago/Turabian StyleGao, Chaofeng, Huaping Tang, Shiheng Zhang, Zhibo Ma, Yunjie Bi, and Jeremy-Heng Rao. 2022. "Process Optimization for Up-Facing Surface Finish of AlSi10Mg Alloy Produced by Laser Powder Bed Fusion" Metals 12, no. 12: 2053. https://doi.org/10.3390/met12122053

APA StyleGao, C., Tang, H., Zhang, S., Ma, Z., Bi, Y., & Rao, J.-H. (2022). Process Optimization for Up-Facing Surface Finish of AlSi10Mg Alloy Produced by Laser Powder Bed Fusion. Metals, 12(12), 2053. https://doi.org/10.3390/met12122053