A Comprehensive Review of Secondary Carbon Bio-Carriers for Application in Metallurgical Processes: Utilization of Torrefied Biomass in Steel Production

Abstract

:1. Introduction

- -

- -

- Higher calorific value from 16–29 MJ kg−1 or energy density [37];

- -

ESTEP and Clean Steel Partnership to Decarbonize the EU Steel Sector

- -

- The decarbonization pathway SCU-PI is addressed by (i) the integration of carbonization, pyrolysis, and gasification processes for using secondary carbon bio-carriers as a substitute for fossil sources in existing iron and steelmaking process chains; (ii) the adaptation of grinding, drying, and pneumatic injection technologies to torrefied/carbonized bio-based sources in the BF and EAF; (iii) the design of new solid raw material injectors to use alternative material (i.e., the substitution of coal); (iv) use of auxiliary reducing agents and slag foaming materials (e.g., polymers from waste plastics, rubber form tires, biochar from agricultural/food residues).

- -

- The decarbonization pathway CDA is addressed by (i) replacing traditional carbons and hydrocarbons with secondary carbon bio-carriers in existing melting processes; (ii) preheating processes implementing multi-fuel burners for primary and secondary metallurgy with the use of secondary carbon bio-carriers as fuels.

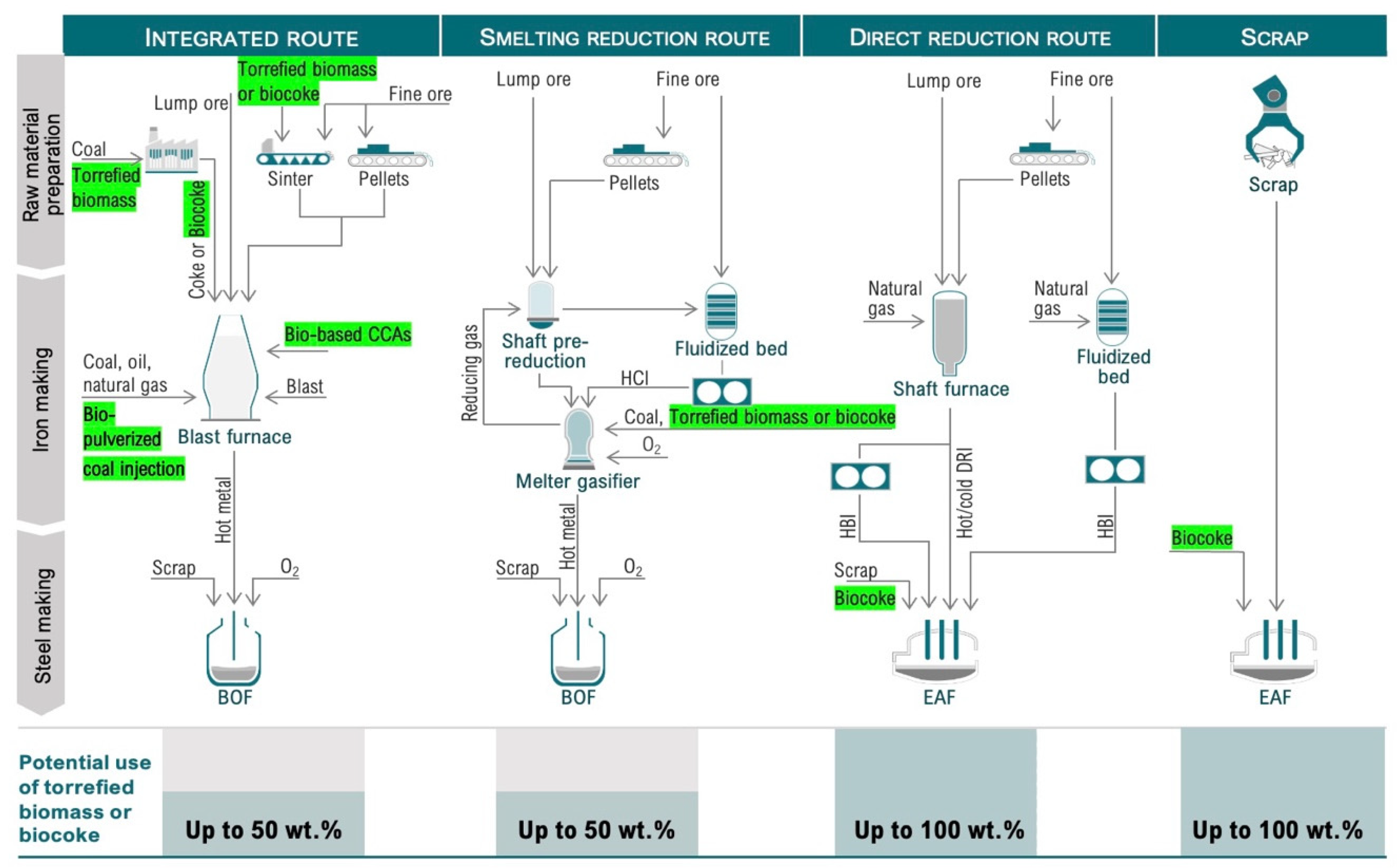

2. Pathways for the Use of Secondary Carbon Bio-Carriers in Metallurgical Processes

- -

- Sintering of iron ores to act as fuel;

- -

- BF to carry out functions as a fuel and reducing agent (delivers chemical energy to melt the burden and contributes to the reduction of iron oxide to metallic iron), as a filter for entrained particles from the raceway, and provides the carbon for the carburization (saturate hot metal with carbon);

- -

- EAF to enable carburizing and slag foaming;

- -

- Melter gasifier to generate heat, to act as a reducing agent, to produce a reducing gas, to ensure the permeability of the burden, and to carburize the hot metal.

2.1. Cokemaking

2.1.1. Features of the Process and Requirements for the Carbon-Bearing Material

2.1.2. Recommendations for the Use of Secondary Carbon Bio-Carriers

2.2. Iron Ore Sintering

2.2.1. Features of the Process and Requirements for the Carbon-Bearing Material

2.2.2. Recommendations for the Use of Secondary Carbon Bio-Carriers

2.3. Bio-Based Carbon Composite Agglomerates (CCAs)

2.3.1. Features of the Process and Requirements for the Carbon-Bearing Material

2.3.2. Recommendations for the Use of Secondary Carbon Bio-Carriers

2.4. Injection of Pulverized Secondary Carbon Bio-Carriers

Recommendations for the Use of Secondary Carbon Bio-Carriers

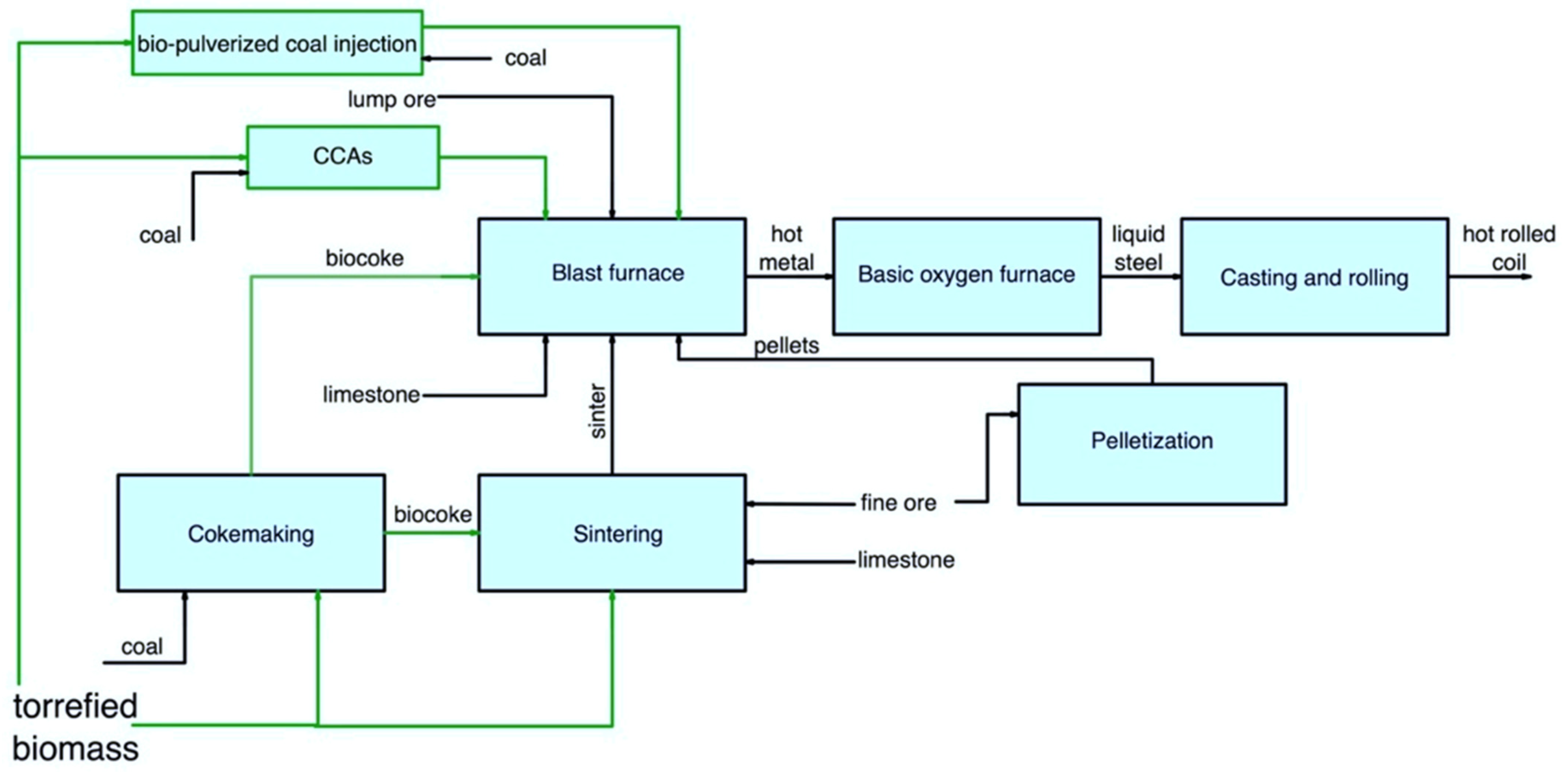

2.5. Blast Furnace Process

2.5.1. Features of the Process and Requirements for the Carbon-Bearing Material

2.5.2. Recommendations for the Use of Secondary Carbon Bio-Carriers

- -

- The use of biocoke produced with the addition of torrefied biomass, as discussed earlier in Section 2.1 Cokemaking;

- -

- The use of torrefied biomass or biocoke to produce sinter, which is afterwards used in the BF;

- -

- The use of bio-pulverized coal injection technology with partial replacement of coal with up to 50% torrefied biomass or full replacement of coal with a mixture of torrefied biomass and torrefied biomass after carbonization;

- -

- The use of torrefied biomass to produce CCAs, which are afterward used in the BF.

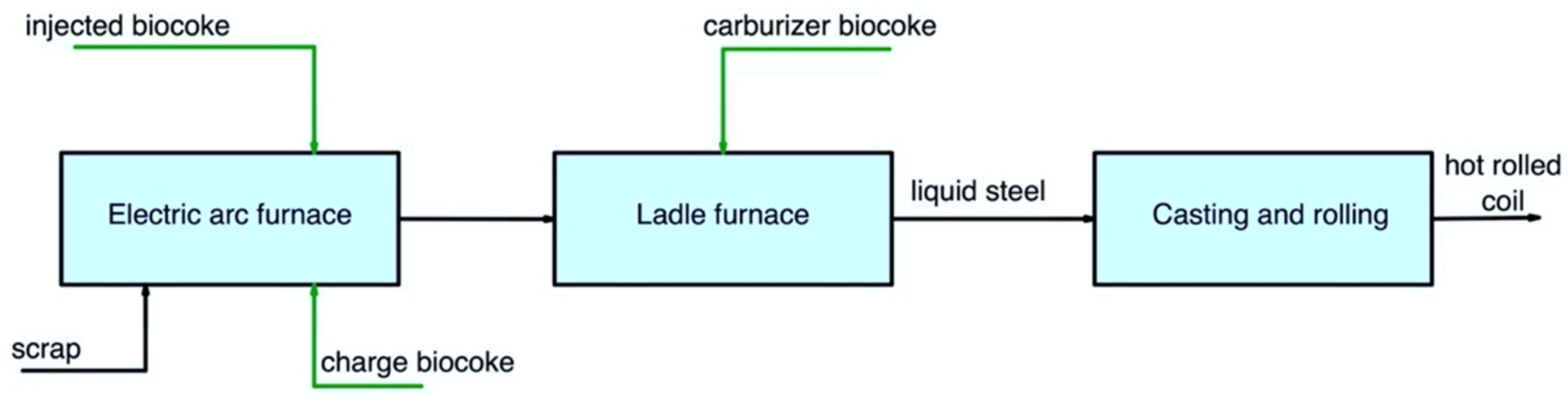

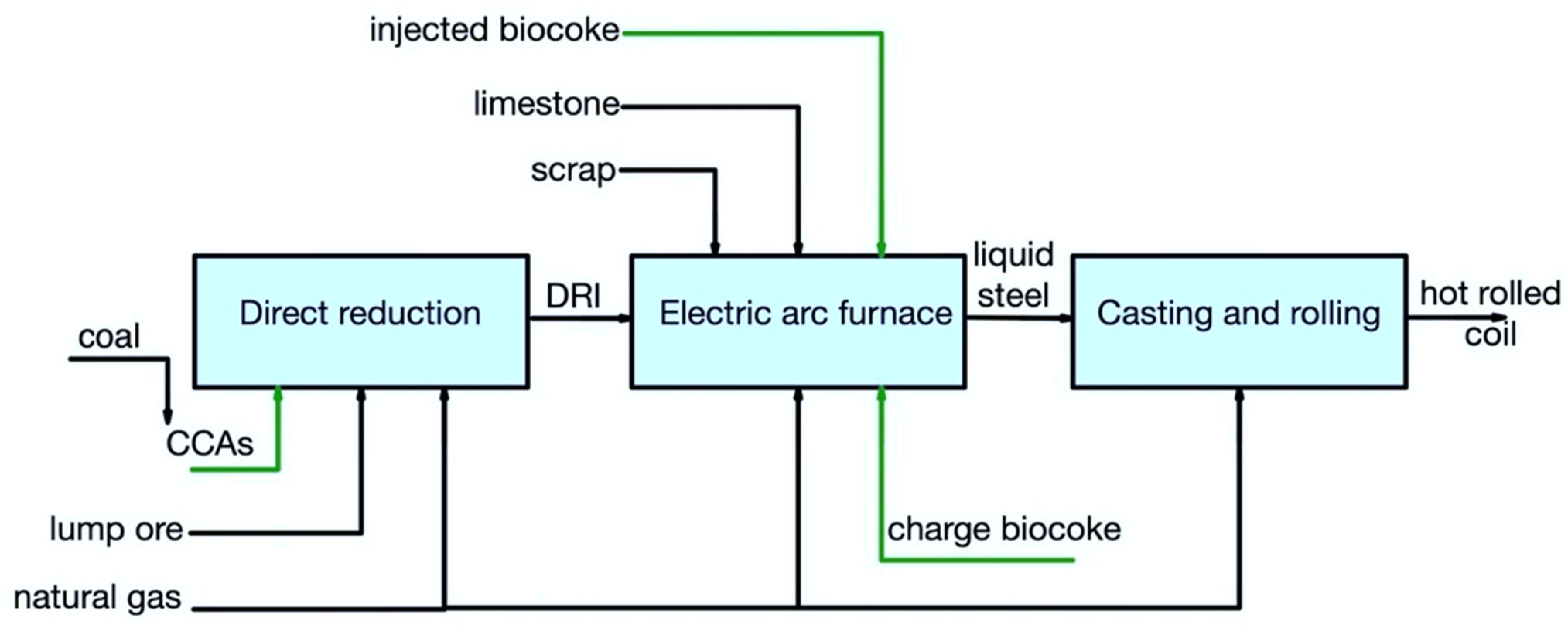

2.6. Electric Arc Furnace

2.6.1. Features of the Process and Requirements for the Carbon-Bearing Material

2.6.2. Recommendations for the Use of Secondary Carbon Bio-Carriers

- -

- a charge carbon in an EAF;

- -

- an injected carbon in an EAF;

- -

- a carburizer source in a ladle furnace.

2.7. Smelting Reduction Processes

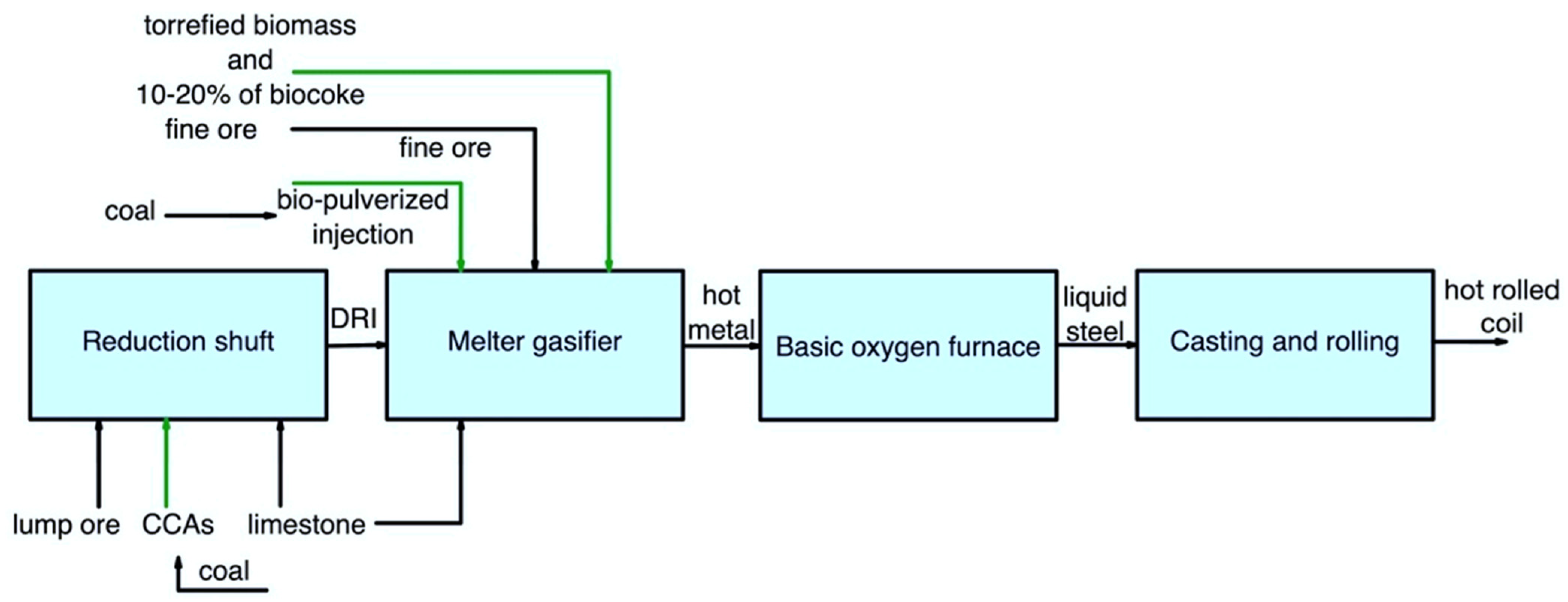

2.7.1. COREX Process

- -

- Biomass torrefied at the highest possible temperature can partially replace coal;

- -

- Biocoke for complete replacement of the conventional coke. At the same time, it is possible to consider using biocoke with a high amount of torrefied biomass as a substitute for coal.

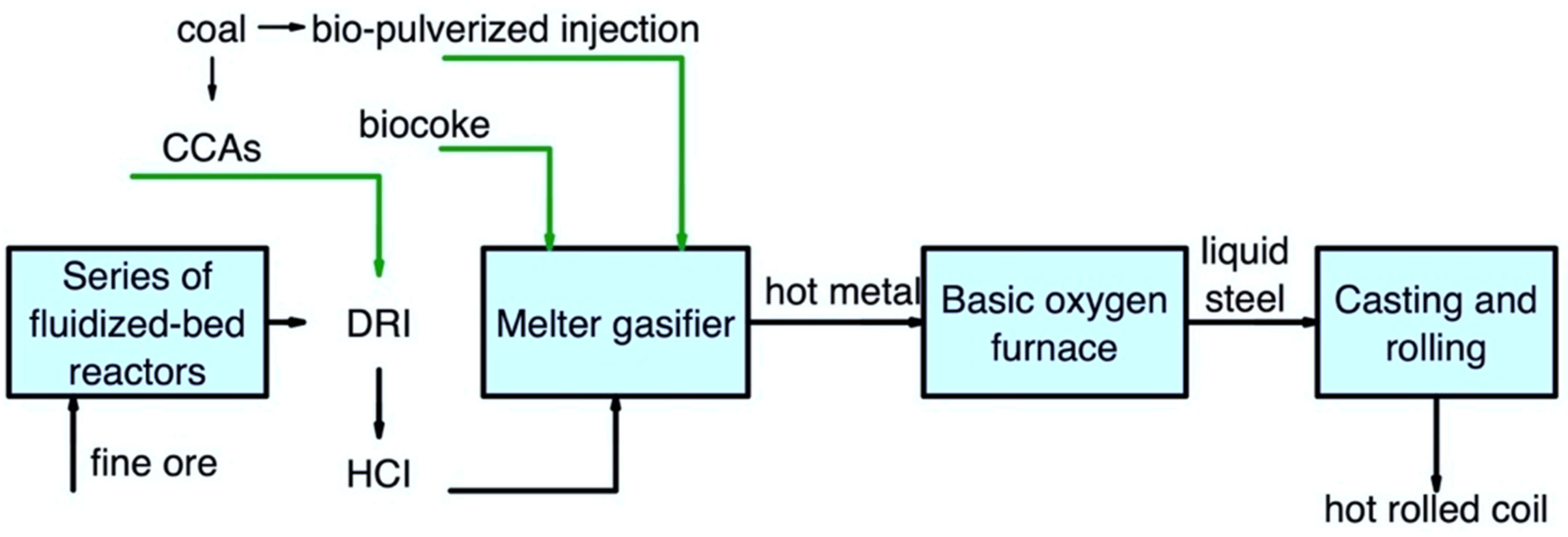

2.7.2. FINEX Process

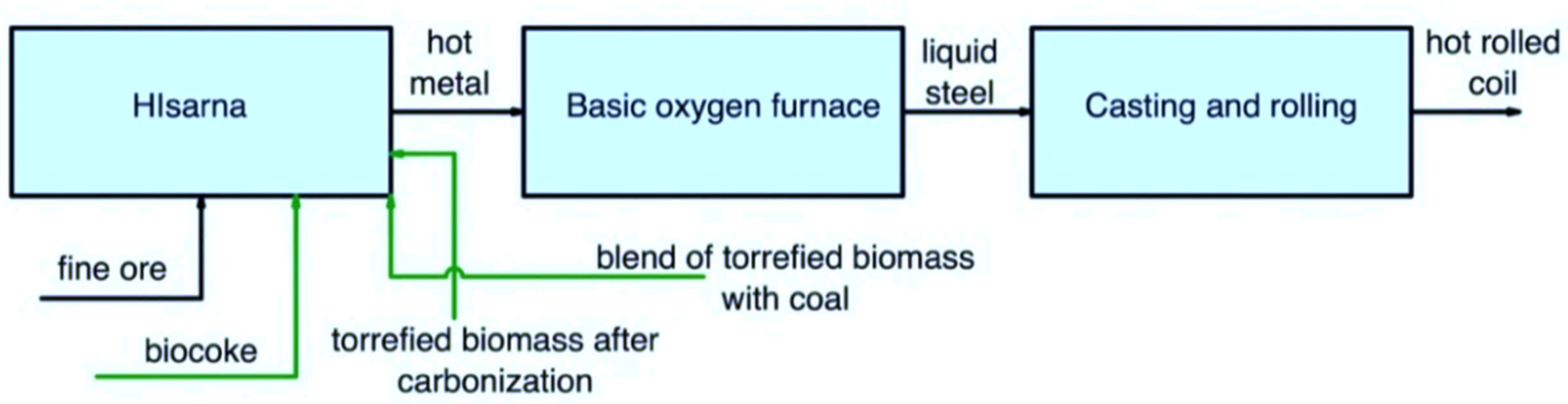

2.7.3. HIsarna and Hismelt Processes

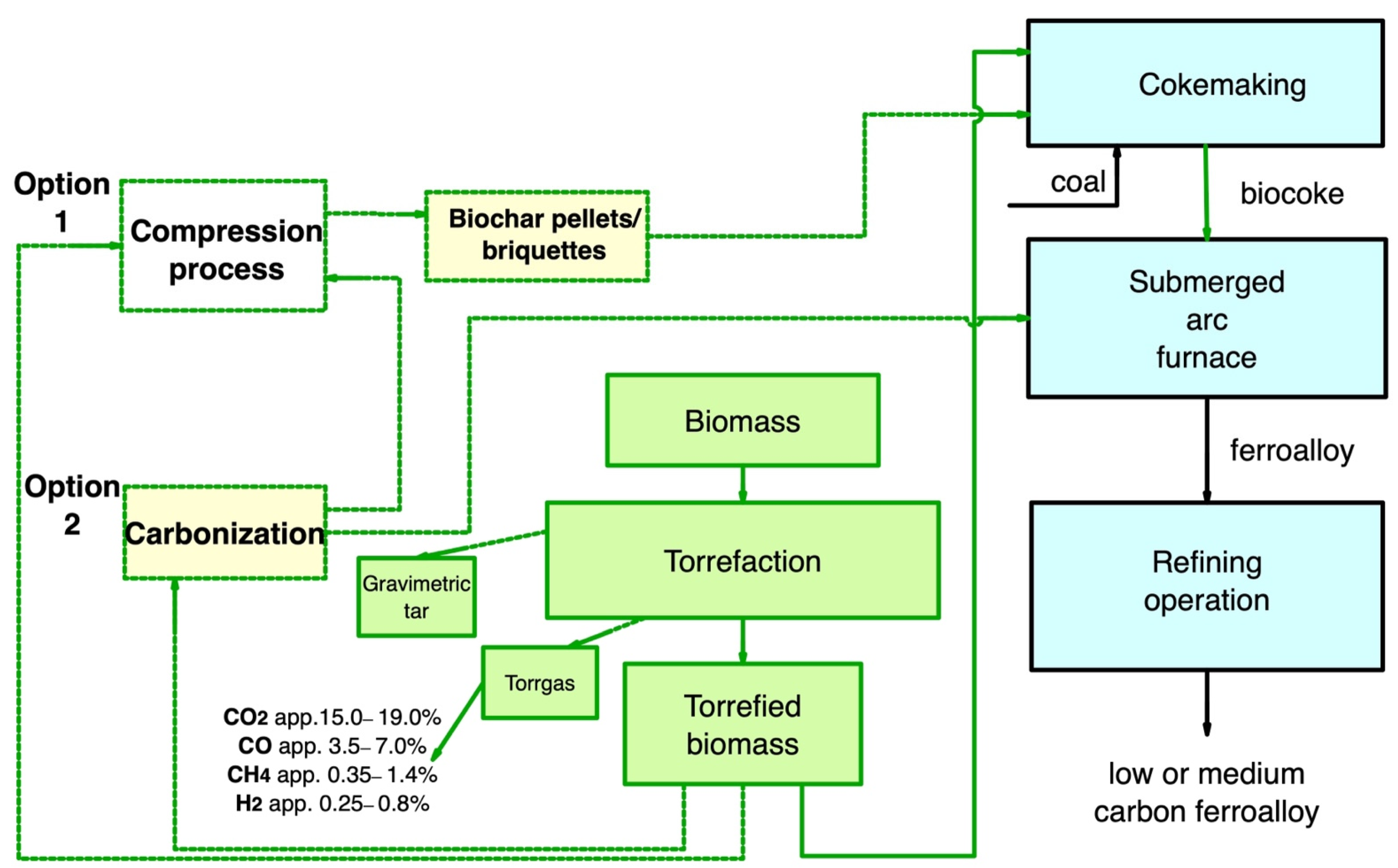

2.8. Ferroalloy Industry

2.8.1. Submerged Arc Furnace

2.8.2. Recommendations for the Use of Secondary Carbon Bio-Carriers

- -

- Torrefied biomass to produce biocoke and further use of biocoke to produce ferroalloys. At the same time, it is of interest to replace up to 50% of coal within the coal blend;

- -

- Subject torrefied biomass to carbonization to increase FC, reduce VM yield, and achieve the required electrical resistance values close to that of conventional fuel. Furthermore, after carbonization, secondary carbon bio-carriers can be used in the SAF;

- -

- Torrefied biomass, also after carbonization, can be subjected to subsequent compaction, and then the resulting briquettes can be used to produce biocoke.

3. Modification of the Properties of Secondary Carbon Bio-Carriers

3.1. Thermal Carbonization after Torrefaction

3.2. Compaction

3.3. Beneficiation of Secondary Carbon Bio-Carriers by Ash Removal

3.4. Utilization of Mineral Additives for Secondary Carbon Bio-Carriers

4. Research Activities within EU Projects for the Use of Secondary Carbon Bio-Carriers in Iron and Steelmaking

5. Aspects Being Considered for Evaluation of the Environmental Impacts Due to Substitution by Biomass

- -

- Firstly, a lifecycle perspective of the assessment should be ensured. This is generally accomplished by using the Life Cycle Assessment (LCA) methodology. Carbon footprints of biomass-based fuels are strongly sensitive to upstream processes: cultivation practices, transports, and further treatments (e.g., compaction, torrefaction, and the addition of mineral additives) [64]. These activities must be optimized as well to ensure a significant abatement of greenhouse gas emissions. In particular, cultivation practices are associated with the consumption of energy and materials (e.g., fertilizers may lead to an additional emission of 0.14–0.55 kg CO2-eq per kg of biofuel), and they may be associated with land use and carbon stock changes (direct and indirect) which may lead to a drastic increase of greenhouse gas emissions: 0.6–4.0 kg CO2-eq per kg of biofuel [203]. The production and processing of biomass feedstocks are associated with the variability of LCA results, both considering the only carbon footprint [75,195] and other impact categories [204]. In addition, the final applications of biomass-based fuels in steelmaking plants must be optimized as well, which has been the focus of several studies documented in the present paper. A comprehensive environmental analysis must account for possible adverse effects due to the introduction of biomass-based fuels: productivity decreases and an increase in total fuel consumption, as outlined in Section 2.2.1. These effects mean that a higher quantity of biofuel is necessary to replace 1 kg of fossil fuel. Therefore, a 1:1 substitution ratio should be adjusted according to the actual plant configuration.

- -

- Biomass may be obtained by either agricultural wastes or by cultivations. Norgate et al. [205] clarified that biochar is considered to be renewable due to the much shorter carbon cycle (5–10 years) with respect to fossil fuels (around 100 million years). Still, the biomass carbon cycle is not null; therefore, the availability of biomass needed for steelmaking plants should be considered for a correct evaluation. In addition, to minimize transport, biomass availability should be evaluated for specific regions. Kamal Baharin et al. [14] showed that Malaysia disposes of most of its biomass waste without using it as fuels, fertilizers, or animal feedstock; therefore, there is a potential to convert it into biocoke. National analyses for Sweden [28] and Finland [118] showed sufficient and available resources to cover the national demand for biomass use in steelmaking. Piketty et al. [206] reported that Brazil could be a remarkable actor in feeding the global supply chain for charcoal. Instead, Norgate et al. [119] performed an assessment and concluded that 50–150 Mha of land is required as biomass plantation areas to substitute 47% of the fossil carbon used to produce steel by the integrated route, through the use of charcoal. Comparing this value with the global productive forest plantation area (264 Mha), it emerges that an appreciable amount of land can be used for biomass cultivation. Finally, Mandova et al. [121] further led this kind of analysis by accounting for both resources and supportive policies to identify where a significant potential to harvest biomass sourced in a sustainable way is present. They found that Canada, Sweden, China, the USA, and France were the most suitable countries. It should be kept in mind that higher demand for crops may lead to indirect land use changes, e.g., deforestation, and intensification, which is linked to additional greenhouse gas emissions [207].

- -

- LCAs should also evaluate different potential impact categories to avoid burden-shifting risk, i.e., decreasing carbon footprint while increasing impacts in other categories. Bio-based processes are generally found to increase eutrophication and acidification impacts due to the agricultural phase [208]. Potential concerns are also related to water use for biomass cultivation [209].

- -

- Finally, linked to the matter of biomass availability, further environmental and societal aspects should be accounted for. If biomass is collected from dedicated cultivations, conflicts on land use for other uses (e.g., food and renewable energy production) should be accounted for [119]. If biomass is collected from agricultural wastes, the alternative fate of the waste is important to determine the net environmental impacts: e.g., if wastes would otherwise have been incinerated with energy recovery or used for landfill with large methane emissions. Consequential LCA approaches can account for counterfactual uses of different inputs from attributional models [210].

6. The Role of Digital Tools in Intensifying Use of Secondary Carbon Bio-Carriers

7. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Camia, A.; Robert, N.; Jonsson, K.; Pilli, R.; Garcia Condado, S.; Lopez Lozano, R.; Van Der Velde, M.; Ronzon, T.; Gurria Albusac, P.; M’barek, R.; et al. Biomass Production, Supply, Uses and Flows in the European Union: First Results from an Integrated Assessment; Publications Office of the European Union: Luxembourg, 2018. [Google Scholar]

- Zou, Y.; Wang, Y.; Liu, X.; Zhu, T.; Tian, M.; Cai, M. Simultaneous Removal of NOx and SO2 Using Two-Stage O3 Oxidation Combined with Ca(OH)2 Absorption. Korean J. Chem. Eng. 2020, 37, 1907–1914. [Google Scholar] [CrossRef]

- Zhu, T.; Wang, X.; Yu, Y.; Li, C.; Yao, Q.; Li, Y. Multi-Process and Multi-Pollutant Control Technology for Ultra-Low Emissions in the Iron and Steel Industry. J. Environ. Sci. 2022, S1001074222000572. [Google Scholar] [CrossRef]

- Suer, J.; Traverso, M.; Ahrenhold, F. Carbon Footprint of Scenarios towards Climate-Neutral Steel According to ISO 14067. J. Clean. Prod. 2021, 318, 128588. [Google Scholar] [CrossRef]

- Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions. The European Green Deal. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM:2019:640:FIN (accessed on 17 November 2022).

- Paris Agreement to the United Nations Framework Convention on Climate Change 2015. Available online: https://unfccc.int/sites/default/files/english_paris_agreement.pdf (accessed on 22 November 2022).

- Toktarova, A.; Karlsson, I.; Rootzén, J.; Göransson, L.; Odenberger, M.; Johnsson, F. Pathways for Low-Carbon Transition of the Steel Industry—A Swedish Case Study. Energies 2020, 13, 3840. [Google Scholar] [CrossRef]

- Fit for 55. Available online: https://www.consilium.europa.eu/en/policies/green-deal/fit-for-55-the-eu-plan-for-a-green-transition/ (accessed on 22 November 2022).

- Blengini, G.A.; El Latunussa, C.; Eynard, U.; Torres de Matos, C.; Wittmer, D.M.A.G.; Georgitzikis, K. Study on the EU’s List of Critical Raw Materials (2020): Final Report; Publications Office of the European Union: Luxembourg, 2020. [Google Scholar]

- Kieush, L.; Koveria, A.; Schenk, J.; Rysbekov, K.; Lozynskyi, V.; Zheng, H.; Matayev, A. Investigation into the Effect of Multi-Component Coal Blends on Properties of Metallurgical Coke via Petrographic Analysis under Industrial Conditions. Sustainability 2022, 14, 9947. [Google Scholar] [CrossRef]

- Kieush, L. Coal Pyrolysis Products Utilisation for Synthesis of Carbon Nanotubes. Pet. Coal 2019, 61, 461–466. [Google Scholar]

- Solar, J.; Hernandez, A.; Lopez-Urionabarrenechea, A.; de Marco, I.; Adrados, A.; Caballero, B.M.; Gastelu, N. From Woody Biomass Waste to Biocoke: Influence of the Proportion of Different Tree Components. Eur. J. Wood Prod. 2017, 75, 485–497. [Google Scholar] [CrossRef]

- Seo, M.W.; Jeong, H.M.; Lee, W.J.; Yoon, S.J.; Ra, H.W.; Kim, Y.K.; Lee, D.; Han, S.W.; Kim, S.D.; Lee, J.G.; et al. Carbonization Characteristics of Biomass/Coking Coal Blends for the Application of Bio-Coke. Chem. Eng. J. 2020, 394, 124943. [Google Scholar] [CrossRef]

- Kamal Baharin, N.S.; Koesoemadinata, V.C.; Nakamura, S.; Yahya, W.J.; Muhammad Yuzir, M.A.; Md Akhir, F.N.; Iwamoto, K.; Othman, N.; Ida, T.; Hara, H. Conversion and Characterization of Bio-Coke from Abundant Biomass Waste in Malaysia. Renew. Energy 2020, 162, 1017–1025. [Google Scholar] [CrossRef]

- Florentino-Madiedo, L.; Díaz-Faes, E.; Barriocanal, C. Mechanical Strength of Bio-Coke from Briquettes. Renew. Energy 2020, 146, 1717–1724. [Google Scholar] [CrossRef]

- Montiano, M.G.; Díaz-Faes, E.; Barriocanal, C.; Alvarez, R. Influence of Biomass on Metallurgical Coke Quality. Fuel 2014, 116, 175–182. [Google Scholar] [CrossRef]

- Rejdak, M.; Bigda, R.; Wojtaszek, M. Use of Alternative Raw Materials in Coke-Making: New Insights in the Use of Lignites for Blast Furnace Coke Production. Energies 2020, 13, 2832. [Google Scholar] [CrossRef]

- Ng, K.W.; MacPhee, J.A.; Giroux, L.; Todoschuk, T. Reactivity of Bio-Coke with CO2. Fuel Process. Technol. 2011, 92, 801–804. [Google Scholar] [CrossRef]

- Ueki, Y.; Nunome, Y.; Yoshiie, R.; Naruse, I.; Nishibata, Y.; Aizawa, S. Effect of Woody Biomass Addition on Coke Properties. ISIJ Int. 2014, 54, 2454–2460. [Google Scholar] [CrossRef] [Green Version]

- Rejdak, M.; Wojtaszek-Kalaitzidi, M.; Gałko, G.; Mertas, B.; Radko, T.; Baron, R.; Książek, M.; Yngve Larsen, S.; Sajdak, M.; Kalaitzidis, S. A Study on Bio-Coke Production—The Influence of Bio-Components Addition on Coke-Making Blend Properties. Energies 2022, 15, 6847. [Google Scholar] [CrossRef]

- Jha, G.; Soren, S. Study on Applicability of Biomass in Iron Ore Sintering Process. Renew. Sustain. Energy Rev. 2017, 80, 399–407. [Google Scholar] [CrossRef]

- Kawaguchi, T.; Hara, M. Utilization of Biomass for Iron Ore Sintering. ISIJ Int. 2013, 53, 1599–1606. [Google Scholar] [CrossRef] [Green Version]

- Kieush, L.; Koveria, A.; Zhu, Z.Q.; Boyko, M.; Sova, A.; Yefimenko, V. Application of Biomass Pellets for Iron Ore Sintering. MSF 2021, 1045, 17–31. [Google Scholar] [CrossRef]

- Kieush, L.; Koveria, A.; Boyko, M.; Yaholnyk, M.; Hrubiak, A.; Molchanov, L.; Moklyak, V. Influence of Biocoke on Iron Ore Sintering Performance and Strength Properties of Sinter. Min. Min. Depos. 2022, 16, 55–63. [Google Scholar] [CrossRef]

- Sefidari, H.; Ma, C.; Fredriksson, C.; Lindblom, B.; Wiinikka, H.; Nordin, L.O.; Wu, G.; Yazhenskikh, E.; Müller, M.; Öhman, M. The Effect of Co-Firing Coal and Woody Biomass upon the Slagging/Deposition Tendency in Iron-Ore Pelletizing Grate-Kiln Plants. Fuel Process. Technol. 2020, 199, 106254. [Google Scholar] [CrossRef]

- Babich, A.; Senk, D.; Fernandez, M. Charcoal Behaviour by Its Injection into the Modern Blast Furnace. ISIJ Int. 2010, 50, 81–88. [Google Scholar] [CrossRef]

- Hu, Z.W.; Zhang, J.L.; Zuo, H.B.; Tian, M.; Liu, Z.J.; Yang, T.J. Substitution of Biomass for Coal and Coke in Ironmaking Process. AMR 2011, 236–238, 77–82. [Google Scholar] [CrossRef]

- Wang, C.; Mellin, P.; Lövgren, J.; Nilsson, L.; Yang, W.; Salman, H.; Hultgren, A.; Larsson, M. Biomass as Blast Furnace Injectant—Considering Availability, Pretreatment and Deployment in the Swedish Steel Industry. Energy Convers. Manag. 2015, 102, 217–226. [Google Scholar] [CrossRef] [Green Version]

- Echterhof, T. Review on the Use of Alternative Carbon Sources in EAF Steelmaking. Metals 2021, 11, 222. [Google Scholar] [CrossRef]

- Bianco, L.; Baracchini, G.; Cirilli, F.; Sante, L.D.; Moriconi, A.; Moriconi, E.; Agorio, M.M.; Pfeifer, H.; Echterhof, T.; Demus, T.; et al. Sustainable Electric Arc Furnace Steel Production: GREENEAF. BHM Berg-Und Hüttenmännische Mon. 2013, 158, 17–23. [Google Scholar] [CrossRef]

- Han, H.; Duan, D.; Yuan, P.; Li, D. Biomass Reducing Agent Utilisation in Rotary Hearth Furnace Process for DRI Production. Ironmak. Steelmak. 2015, 42, 579–584. [Google Scholar] [CrossRef]

- Luo, S.; Zhou, Y.; Yi, C.; Yue, X.; Li, Z. Ironmaking by Direct Reduction of Iron Ore Biomass Composite Pellets Using Biomass Syngas. J. Univ. Sci. Technol. Beijing 2013, 35, 856–861. [Google Scholar]

- Yuan, P.; Shen, B.; Duan, D.; Adwek, G.; Mei, X.; Lu, F. Study on the Formation of Direct Reduced Iron by Using Biomass as Reductants of Carbon Containing Pellets in RHF Process. Energy 2017, 141, 472–482. [Google Scholar] [CrossRef]

- Sommerfeld, M.; Friedrich, B. Replacing Fossil Carbon in the Production of Ferroalloys with a Focus on Bio-Based Carbon: A Review. Minerals 2021, 11, 1286. [Google Scholar] [CrossRef]

- Surup, G.R.; Trubetskaya, A.; Tangstad, M. Charcoal as an Alternative Reductant in Ferroalloy Production: A Review. Processes 2020, 8, 1432. [Google Scholar] [CrossRef]

- Suer, J.; Ahrenhold, F.; Traverso, M. Carbon Footprint and Energy Transformation Analysis of Steel Produced via a Direct Reduction Plant with an Integrated Electric Melting Unit. J. Sustain. Metall. 2022, 1–14. [Google Scholar] [CrossRef]

- Chen, W.-H.; Peng, J.; Bi, X.T. A State-of-the-Art Review of Biomass Torrefaction, Densification and Applications. Renew. Sustain. Energy Rev. 2015, 44, 847–866. [Google Scholar] [CrossRef]

- Sarker, T.R.; Nanda, S.; Dalai, A.K.; Meda, V. A Review of Torrefaction Technology for Upgrading Lignocellulosic Biomass to Solid Biofuels. Bioenerg. Res. 2021, 14, 645–669. [Google Scholar] [CrossRef]

- Tekin, K.; Karagöz, S.; Bektaş, S. A Review of Hydrothermal Biomass Processing. Renew. Sustain. Energy Rev. 2014, 40, 673–687. [Google Scholar] [CrossRef]

- Valizadeh, S.; Hakimian, H.; Farooq, A.; Jeon, B.-H.; Chen, W.-H.; Hoon Lee, S.; Jung, S.-C.; Won Seo, M.; Park, Y.-K. Valorization of Biomass through Gasification for Green Hydrogen Generation: A Comprehensive Review. Bioresour. Technol. 2022, 365, 128143. [Google Scholar] [CrossRef] [PubMed]

- Fisher, E.M.; Dupont, C.; Darvell, L.I.; Commandré, J.-M.; Saddawi, A.; Jones, J.M.; Grateau, M.; Nocquet, T.; Salvador, S. Combustion and Gasification Characteristics of Chars from Raw and Torrefied Biomass. Bioresour. Technol. 2012, 119, 157–165. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hu, Q.; Yang, H.; Xu, H.; Wu, Z.; Lim, C.J.; Bi, X.T.; Chen, H. Thermal Behavior and Reaction Kinetics Analysis of Pyrolysis and Subsequent In-Situ Gasification of Torrefied Biomass Pellets. Energy Convers. Manag. 2018, 161, 205–214. [Google Scholar] [CrossRef]

- Sarker, T.R.; Nanda, S.; Meda, V.; Dalai, A.K. Pelletization of Torrefied Canola Residue: Effects of Microwave Power, Residence Time and Bio-Additives on Fuel Pellet Quality. Fuel 2022, 312, 122728. [Google Scholar] [CrossRef]

- Lin, Y.-L.; Zheng, N.-Y.; Hsu, C.-H. Torrefaction of Fruit Peel Waste to Produce Environmentally Friendly Biofuel. J. Clean. Prod. 2021, 284, 124676. [Google Scholar] [CrossRef]

- Wang, S.; Dai, G.; Ru, B.; Zhao, Y.; Wang, X.; Zhou, J.; Luo, Z.; Cen, K. Effects of Torrefaction on Hemicellulose Structural Characteristics and Pyrolysis Behaviors. Bioresour. Technol. 2016, 218, 1106–1114. [Google Scholar] [CrossRef]

- Tran, K.-Q.; Luo, X.; Seisenbaeva, G.; Jirjis, R. Stump Torrefaction for Bioenergy Application. Appl. Energy 2013, 112, 539–546. [Google Scholar] [CrossRef]

- Shang, L.; Nielsen, N.P.K.; Dahl, J.; Stelte, W.; Ahrenfeldt, J.; Holm, J.K.; Thomsen, T.; Henriksen, U.B. Quality Effects Caused by Torrefaction of Pellets Made from Scots Pine. Fuel Process. Technol. 2012, 101, 23–28. [Google Scholar] [CrossRef]

- White, J.E.; Catallo, W.J.; Legendre, B.L. Biomass Pyrolysis Kinetics: A Comparative Critical Review with Relevant Agricultural Residue Case Studies. J. Anal. Appl. Pyrolysis 2011, 91, 1–33. [Google Scholar] [CrossRef]

- Singh, A.K.; Singh, R.; Sinha, O.P. Characterization of Charcoals Produced from Acacia, Albizia and Leucaena for Application in Ironmaking. Fuel 2022, 320, 123991. [Google Scholar] [CrossRef]

- Koveria, A.; Kieush, L.; Svietkina, O.; Perkov, Y. Metallurgical Coke Production with Biomass Additives. Part 1. A Review of Existing Practices. Can. Metall. Q. 2020, 59, 417–429. [Google Scholar] [CrossRef]

- Kota, K.B.; Shenbagaraj, S.; Sharma, P.K.; Sharma, A.K.; Ghodke, P.K.; Chen, W.-H. Biomass Torrefaction: An Overview of Process and Technology Assessment Based on Global Readiness Level. Fuel 2022, 324, 124663. [Google Scholar] [CrossRef]

- Medic, D.; Darr, M.; Shah, A.; Potter, B.; Zimmerman, J. Effects of Torrefaction Process Parameters on Biomass Feedstock Upgrading. Fuel 2012, 91, 147–154. [Google Scholar] [CrossRef]

- Wiklund, C.M. Optimized of a Steel Plant Utilizing Converted Biomass. Doctor of. Technologies Thesis, Åbo Akademi University, Turku, Finland, 2016. [Google Scholar]

- Yang, H.; Yan, R.; Chen, H.; Zheng, C.; Lee, D.H.; Liang, D.T. In-Depth Investigation of Biomass Pyrolysis Based on Three Major Components: Hemicellulose, Cellulose and Lignin. Energy Fuels 2006, 20, 388–393. [Google Scholar] [CrossRef]

- Ong, H.C.; Yu, K.L.; Chen, W.-H.; Pillejera, M.K.; Bi, X.; Tran, K.-Q.; Pétrissans, A.; Pétrissans, M. Variation of Lignocellulosic Biomass Structure from Torrefaction: A Critical Review. Renew. Sustain. Energy Rev. 2021, 152, 111698. [Google Scholar] [CrossRef]

- Prins, M.J.; Ptasinski, K.J.; Janssen, F.J.J.G. More Efficient Biomass Gasification via Torrefaction. Energy 2006, 31, 3458–3470. [Google Scholar] [CrossRef]

- Strandberg, M.; Olofsson, I.; Pommer, L.; Wiklund-Lindström, S.; Åberg, K.; Nordin, A. Effects of Temperature and Residence Time on Continuous Torrefaction of Spruce Wood. Fuel Process. Technol. 2015, 134, 387–398. [Google Scholar] [CrossRef]

- Chen, C.; Qu, B.; Wang, W.; Wang, W.; Ji, G.; Li, A. Rice Husk and Rice Straw Torrefaction: Properties and Pyrolysis Kinetics of Raw and Torrefied Biomass. Environ. Technol. Innov. 2021, 24, 101872. [Google Scholar] [CrossRef]

- Ru, B.; Wang, S.; Dai, G.; Zhang, L. Effect of Torrefaction on Biomass Physicochemical Characteristics and the Resulting Pyrolysis Behavior. Energy Fuels 2015, 29, 5865–5874. [Google Scholar] [CrossRef]

- Wang, S.; Dai, G.; Yang, H.; Luo, Z. Lignocellulosic Biomass Pyrolysis Mechanism: A State-of-the-Art Review. Prog. Energy Combust. Sci. 2017, 62, 33–86. [Google Scholar] [CrossRef]

- Wei, R.; Zhang, L.; Cang, D.; Li, J.; Li, X.; Xu, C.C. Current Status and Potential of Biomass Utilization in Ferrous Metallurgical Industry. Renew. Sustain. Energy Rev. 2017, 68, 511–524. [Google Scholar] [CrossRef]

- Xie, Y.; Wang, L.; Li, H.; Westholm, L.J.; Carvalho, L.; Thorin, E.; Yu, Z.; Yu, X.; Skreiberg, Ø. A Critical Review on Production, Modification and Utilization of Biochar. J. Anal. Appl. Pyrolysis 2022, 161, 105405. [Google Scholar] [CrossRef]

- Chen, D.; Zheng, Z.; Fu, K.; Zeng, Z.; Wang, J.; Lu, M. Torrefaction of Biomass Stalk and Its Effect on the Yield and Quality of Pyrolysis Products. Fuel 2015, 159, 27–32. [Google Scholar] [CrossRef]

- Fan, Z.; Friedmann, S.J. Low-Carbon Production of Iron and Steel: Technology Options, Economic Assessment, and Policy. Joule 2021, 5, 829–862. [Google Scholar] [CrossRef]

- Mousa, E.; Wang, C.; Riesbeck, J.; Larsson, M. Biomass Applications in Iron and Steel Industry: An Overview of Challenges and Opportunities. Renew. Sustain. Energy Rev. 2016, 65, 1247–1266. [Google Scholar] [CrossRef]

- Wang, C.; Wei, W.; Mellin, P.; Yang, W.; Hultgren, A.; Salman, H. Utilization of Biomass for Blast Furnace in Sweden-Report I: Biomass Availability and Upgrading Technologies. KTH Royal Institute of Technology: Stockholm, Sweden, 2013; p. 97. [Google Scholar]

- TORrefying Wood with Ethanol as a Renewable Output: Large-Scale Demonstration. Periodic Reporting for Period 2—Torero (TORrefying Wood with Ethanol as a Renewable Output: Large-Scale Demonstration). Available online: https://cordis.europa.eu/project/id/745810/reportinghttp://www.torero.eu/ (accessed on 22 November 2022).

- POLTORR—Biomass Thermal Processing. Available online: https://www.tkisrus.com/assets/pdf/brochures/pyroprocessing/en/POLTORR.pdf (accessed on 22 November 2022).

- European Steel Technology Platform (ESTEP): Clean Steel Partnership Roadmap. Available online: https://www.estep.eu/assets/Uploads/CSP-SRIA-Oct2021-clean.pdf (accessed on 22 November 2022).

- European Steel Technology Platform ESTEP. Available online: https://www.estep.eu/ (accessed on 22 November 2022).

- Colla, V.; Pietrosanti, C.; Malfa, E.; Peters, K. Environment 4.0: How Digitalization and Machine Learning Can Improve the Environmental Footprint of the Steel Production Processes. Matériaux Tech. 2020, 108, 507. [Google Scholar] [CrossRef]

- Rovelli, D.; Brondi, C.; Andreotti, M.; Abbate, E.; Zanforlin, M.; Ballarino, A. A Modular Tool to Support Data Management for LCA in Industry: Methodology, Application and Potentialities. Sustainability 2022, 14, 3746. [Google Scholar] [CrossRef]

- Kim, G.-M.; Lisandy, K.Y.; Isworo, Y.Y.; Kim, J.-H.; Jeon, C.-H. Investigation into the Effects of Ash-Free Coal Binder and Torrefied Biomass Addition on Coke Strength and Reactivity. Fuel 2018, 212, 487–497. [Google Scholar] [CrossRef]

- Sun, W.; Wang, Q.; Zheng, Z.; Cai, J. Material–Energy–Emission Nexus in the Integrated Iron and Steel Industry. Energy Convers. Manag. 2020, 213, 112828. [Google Scholar] [CrossRef]

- Suopajärvi, H.; Umeki, K.; Mousa, E.; Hedayati, A.; Romar, H.; Kemppainen, A.; Wang, C.; Phounglamcheik, A.; Tuomikoski, S.; Norberg, N.; et al. Use of Biomass in Integrated Steelmaking—Status Quo, Future Needs and Comparison to Other Low-CO2 Steel Production Technologies. Appl. Energy 2018, 213, 384–407. [Google Scholar] [CrossRef] [Green Version]

- Ghosh, B.; Sahoo, B.K.; Chakraborty, B.; Manjhi, K.K.; Das, S.K.; Sahu, J.N.; Varma, A.K. Influence of Coke Structure on Coke Quality Using Image Analysis Method. Int. J. Coal Sci. Technol. 2018, 5, 473–485. [Google Scholar] [CrossRef]

- Janhsen, U.; Sante, L.; Steiler, J.M.; Sert, D.; Negro, P.; Wilmers, R.R.; Bennington, C.R.; Hitchenson, C. Reduction of Iron Ores. In Coke Quality for Blast Furnace Operation with High Levels of Coal/Oil Injection; European Commission, Directorate-General for Research and Innovation: Luxembourg, 2002; p. 205. [Google Scholar]

- Bazaluk, O.; Kieush, L.; Koveria, A.; Schenk, J.; Pfeiffer, A.; Zheng, H.; Lozynskyi, V. Metallurgical Coke Production with Biomass Additives: Study of Biocoke Properties for Blast Furnace and Submerged Arc Furnace Purposes. Materials 2022, 15, 1147. [Google Scholar] [CrossRef]

- Mansor, A.M.; Theo, W.L.; Lim, J.S.; Ani, F.N.; Hashim, H.; Ho, W.S. Potential Commercialisation of Biocoke Production in Malaysia—A Best Evidence Review. Renew. Sustain. Energy Rev. 2018, 90, 636–649. [Google Scholar] [CrossRef]

- Castro-Díaz, M.; Vega, M.F.; Díaz-Faes, E.; Barriocanal, C.; Musa, U.; Snape, C. Evaluation of Demineralized Lignin and Lignin-Phenolic Resin Blends to Produce Biocoke Suitable for Blast Furnace Operation. Fuel 2019, 258, 116125. [Google Scholar] [CrossRef]

- Tsalidis, G.A.; Di Marcello, M.; Spinelli, G.; de Jong, W.; Kiel, J.H.A. The Effect of Torrefaction on the Process Performance of Oxygen-Steam Blown CFB Gasification of Hardwood and Softwood. Biomass Bioenergy 2017, 106, 155–165. [Google Scholar] [CrossRef]

- Kieush, L.; Schenk, J.; Pfeiffer, A.; Koveria, A.; Rantitsch, G.; Hopfinger, H. Investigation on the Influence of Wood Pellets on the Reactivity of Coke with CO2 and Its Microstructure Properties. Fuel 2022, 309, 122151. [Google Scholar] [CrossRef]

- Chen, W.-H.; Lin, B.-J.; Lin, Y.-Y.; Chu, Y.-S.; Ubando, A.T.; Show, P.L.; Ong, H.C.; Chang, J.-S.; Ho, S.-H.; Culaba, A.B.; et al. Progress in Biomass Torrefaction: Principles, Applications and Challenges. Prog. Energy Combust. Sci. 2021, 82, 100887. [Google Scholar] [CrossRef]

- MacPhee, J.A.; Gransden, J.F.; Giroux, L.; Price, J.T. Possible CO2 Mitigation via Addition of Charcoal to Coking Coal Blends. Fuel Process. Technol. 2009, 90, 16–20. [Google Scholar] [CrossRef]

- Babich, A.; Senk, D. Coke in the Iron and Steel Industry. In New Trends in Coal Conversion; Woodhead Publishing: Sawston, UK, 2019; pp. 367–404. ISBN 978-0-08-102201-6. [Google Scholar]

- MacPhee, J.A.; Grandsen, J.F.; Giroux, L.; Price, J.T. CO2 Mitigation via Addition of Charcoal to Coking Coal Blends. In Proceedings of the International Conference on Coal Science and Technology, Nottingham, UK, 28–31August 2007. [Google Scholar]

- Guerrero, A.; Diez, M.A.; Borrego, A.G. Influence of Charcoal Fines on the Thermoplastic Properties of Coking Coals and the Optical Properties of the Semicoke. Int. J. Coal Geol. 2015, 147–148, 105–114. [Google Scholar] [CrossRef] [Green Version]

- Kudo, S.; Mori, A.; Soejima, R.; Murayama, F.; Karnowo; Nomura, S.; Dohi, Y.; Norinaga, K.; Hayashi, J. Preparation of Coke from Hydrothermally Treated Biomass in Sequence of Hot Briquetting and Carbonization. ISIJ Int. 2014, 54, 2461–2469. [Google Scholar] [CrossRef] [Green Version]

- Castro-Díaz, M.; Uguna, C.N.; Florentino, L.; Díaz-Faes, E.; Stevens, L.A.; Barriocanal, C.; Snape, C.E. Evaluation of Hydrochars from Lignin Hydrous Pyrolysis to Produce Biocokes after Carbonization. J. Anal. Appl. Pyrolysis 2017, 124, 742–751. [Google Scholar] [CrossRef]

- Fick, G.; Mirgaux, O.; Neau, P.; Patisson, F. Using Biomass for Pig Iron Production: A Technical, Environmental and Economical Assessment. Waste Biomass Valor 2014, 5, 43–55. [Google Scholar] [CrossRef] [Green Version]

- Lu, L.; Ishiyama, O. Iron Ore Sintering. In Iron Ore; Elsevier: Amsterdam, The Netherlands, 2015; pp. 395–433. ISBN 978-1-78242-156-6. [Google Scholar]

- Luengen, H.B.; Endemann, G.; Schmoele, P. Measures to Reduce CO2 and Other Emissions in the Steel Industry in Germany and Europe. World Iron Steel 2013, 1, 8–15. [Google Scholar]

- Forsmo, S.P.E.; Forsmo, S.-E.; Samskog, P.-O.; Björkman, B.M.T. Mechanisms in Oxidation and Sintering of Magnetite Iron Ore Green Pellets. Powder Technol. 2008, 183, 247–259. [Google Scholar] [CrossRef]

- Ooi, T.C.; Aries, E.; Ewan, B.C.R.; Thompson, D.; Anderson, D.R.; Fisher, R.; Fray, T.; Tognarelli, D. The Study of Sunflower Seed Husks as a Fuel in the Iron Ore Sintering Process. Miner. Eng. 2008, 21, 167–177. [Google Scholar] [CrossRef]

- Xiong, L.; Peng, Z.; Gu, F.; Ye, L.; Wang, L.; Rao, M.; Zhang, Y.; Li, G.; Jiang, T. Combustion Behavior of Granulated Coke Breeze in Iron Ore Sintering. Powder Technol. 2018, 340, 131–138. [Google Scholar] [CrossRef]

- Khanna, R.; Li, K.; Wang, Z.; Sun, M.; Zhang, J.; Mukherjee, P.S. Biochars in Iron and Steel Industries. In Char and Carbon Materials Derived from Biomass; Elsevier: Amsterdam, The Netherlands, 2019; pp. 429–446. ISBN 978-0-12-814893-8. [Google Scholar]

- Okimori, Y.; Ogawa, M.; Takahashi, F. Potential of Co 2 Emission Reductions by Carbonizing Biomass Waste from Industrial Tree Plantation in South Sumatra, Indonesia. Mitig. Adapt. Strateg. Glob. Chang. 2003, 8, 261–280. [Google Scholar] [CrossRef]

- Zandi, M.; Martinez-Pacheco, M.; Fray, T.A.T. Biomass for Iron Ore Sintering. Miner. Eng. 2010, 23, 1139–1145. [Google Scholar] [CrossRef]

- Ooi, T.C.; Thompson, D.; Anderson, D.R.; Fisher, R.; Fray, T.; Zandi, M. The Effect of Charcoal Combustion on Iron-Ore Sintering Performance and Emission of Persistent Organic Pollutants. Combust. Flame 2011, 158, 979–987. [Google Scholar] [CrossRef]

- Jha, G.; Soren, S.; Mehta, K.D. Life Cycle Assessment of Sintering Process for Carbon Footprint and Cost Reduction: A Comparative Study for Coke and Biomass-Derived Sintering Process. J. Clean. Prod. 2020, 259, 120889. [Google Scholar] [CrossRef]

- Lovel, R.; Vining, K.; Dell’Amico, M. Iron Ore Sintering with Charcoal. Miner. Process. Extr. Metall. 2007, 116, 85–92. [Google Scholar] [CrossRef]

- Abreu, G.C.; de Carvalho, J.A.; da Silva, B.E.C.; Pedrini, R.H. Operational and Environmental Assessment on the Use of Charcoal in Iron Ore Sinter Production. J. Clean. Prod. 2015, 101, 387–394. [Google Scholar] [CrossRef]

- Ji, Z.; Fan, X.; Gan, M.; Chen, X.; Li, Q.; Jiang, T. Assessment on the Application of Commercial Medium-Grade Charcoal as a Substitute for Coke Breeze in Iron Ore Sintering. Energy Fuels 2016, 30, 10448–10457. [Google Scholar] [CrossRef]

- Gan, M.; Li, Q.; Ji, Z.; Fan, X.; Lv, W.; Chen, X.; Tian, Y.; Jiang, T. Influence of Surface Modification on Combustion Characteristics of Charcoal and Its Performance on Emissions Reduction in Iron Ore Sintering. ISIJ Int. 2017, 57, 420–428. [Google Scholar] [CrossRef] [Green Version]

- Cheng, Z.; Yang, J.; Zhou, L.; Liu, Y.; Wang, Q. Characteristics of Charcoal Combustion and Its Effects on Iron-Ore Sintering Performance. Appl. Energy 2016, 161, 364–374. [Google Scholar] [CrossRef]

- Niesler, M.; Stecko, J.; Stelmach, S.; Kwiecińska-Mydlak, A. Biochars in Iron Ores Sintering Process: Effect on Sinter Quality and Emission. Energies 2021, 14, 3749. [Google Scholar] [CrossRef]

- Wiinikka, H.; Sepman, A.; Ögren, Y.; Lindblom, B.; Nordin, L.-O. Combustion Evaluation of Renewable Fuels for Iron-Ore Pellet Induration. Energy Fuels 2019, 33, 7819–7829. [Google Scholar] [CrossRef]

- Mousa, A.; Ahmed, H.; Viswanathan, N.; Larsson, M. Recent Trends in Ironmaking Blast Furnace Technology to Mitigate CO2 Emissions: Tuyeres Injection. In Ironmaking and Steelmaking Processes: Greenhouse Emissions, Control and Reduction; Springer International Publishing: Cham, Switzerland, 2016; pp. 173–197. [Google Scholar]

- Ahmed, H.M.; Viswanathan, N.; Bjorkman, B. Composite Pellets—A Potential Raw Material for Iron-Making. Steel Res. Int. 2014, 85, 293–306. [Google Scholar] [CrossRef]

- Ueki, Y.; Yoshiie, R.; Naruse, I.; Ohno, K.; Maeda, T.; Nishioka, K.; Shimizu, M. Reaction Behavior during Heating Biomass Materials and Iron Oxide Composites. Fuel 2013, 104, 58–61. [Google Scholar] [CrossRef]

- Hu, Q.; Yao, D.; Xie, Y.; Zhu, Y.; Yang, H.; Chen, Y.; Chen, H. Study on Intrinsic Reaction Behavior and Kinetics during Reduction of Iron Ore Pellets by Utilization of Biochar. Energy Convers. Manag. 2018, 158, 1–8. [Google Scholar] [CrossRef]

- Praes, G.E.; de Arruda, J.D.; Lemos, L.R.; Tavares, R.P. Assessment of Iron Ore Pellets Production Using Two Charcoals with Different Content of Materials Volatile Replacing Partially Anthracite Fines. J. Mater. Res. Technol. 2019, 8, 1150–1160. [Google Scholar] [CrossRef]

- Abd Rashid, R.Z.; Salleh, H.M.; Ani, M.H.; Yunus, N.A.; Akiyama, T.; Purwanto, H. Reduction of Low Grade Iron Ore Pellet Using Palm Kernel Shell. Renew. Energy 2014, 63, 617–623. [Google Scholar] [CrossRef]

- Srivastava, U.; Kawatra, S.K.; Eisele, T.C. Production of Pig Iron by Utilizing Biomass as a Reducing Agent. Int. J. Miner. Process. 2013, 119, 51–57. [Google Scholar] [CrossRef]

- Toloue Farrokh, N.; Suopajärvi, H.; Mattila, O.; Sulasalmi, P.; Fabritius, T. Characteristics of Wood-Based Biochars for Pulverized Coal Injection. Fuel 2020, 265, 117017. [Google Scholar] [CrossRef]

- Knepper, M.; Babich, A.; Senk, D.; Buergler, T.; Feilmayr, C.; Kieberger, N. Waste Plastics Injection: Reaction Kinetics and Effect on the Blast Furnace Process. In Proceedings of the 6th International Congress on the Science and Technology of Ironmaking-ICSTI, Rio de Janeiro, RJ, Brazil, 14–18 October 2012; pp. 798–810. [Google Scholar]

- de Castro, J.A.; de Mattos Araújo, G.; da Mota ID, O.; Sasaki, Y.; Yagi, J.I. Analysis of the Combined Injection of Pulverized Coal and Charcoal into Large Blast Furnaces. J. Mater. Res. Technol. 2013, 2, 308–314. [Google Scholar] [CrossRef] [Green Version]

- Suopajärvi, H.; Fabritius, T. Towards More Sustainable Ironmaking—An Analysis of Energy Wood Availability in Finland and the Economics of Charcoal Production. Sustainability 2013, 5, 1188–1207. [Google Scholar] [CrossRef] [Green Version]

- Norgate, T.; Haque, N.; Somerville, M.; Jahanshahi, S. Biomass as a Source of Renewable Carbon for Iron and Steelmaking. ISIJ Int. 2012, 52, 1472–1481. [Google Scholar] [CrossRef] [Green Version]

- Proskurina, S.; Heinimö, J.; Schipfer, F.; Vakkilainen, E. Biomass for Industrial Applications: The Role of Torrefaction. Renew. Energy 2017, 111, 265–274. [Google Scholar] [CrossRef]

- Mandova, H.; Leduc, S.; Wang, C.; Wetterlund, E.; Patrizio, P.; Gale, W.; Kraxner, F. Possibilities for CO2 Emission Reduction Using Biomass in European Integrated Steel Plants. Biomass Bioenergy 2018, 115, 231–243. [Google Scholar] [CrossRef]

- Mattila, O.; Vuorenmaa, V.; Paananen, T. Grinding and Transport Properties of Wood Char Together with Blast Furnace PCI. In Proceedings of the 5th International Conference on Process Development in Iron and Steelmaking (SCANMET V), Luleå, Sweden, 12–15 June 2016. [Google Scholar]

- Du, S.-W.; Chen, W.-H.; Lucas, J.A. Pretreatment of Biomass by Torrefaction and Carbonization for Coal Blend Used in Pulverized Coal Injection. Bioresour. Technol. 2014, 161, 333–339. [Google Scholar] [CrossRef] [PubMed]

- Phanphanich, M.; Mani, S. Impact of Torrefaction on the Grindability and Fuel Characteristics of Forest Biomass. Bioresour. Technol. 2011, 102, 1246–1253. [Google Scholar] [CrossRef]

- Chen, W.-H.; Cheng, W.-Y.; Lu, K.-M.; Huang, Y.-P. An Evaluation on Improvement of Pulverized Biomass Property for Solid Fuel through Torrefaction. Appl. Energy 2011, 88, 3636–3644. [Google Scholar] [CrossRef]

- Chen, W.-H.; Du, S.-W.; Tsai, C.-H.; Wang, Z.-Y. Torrefied Biomasses in a Drop Tube Furnace to Evaluate Their Utility in Blast Furnaces. Bioresour. Technol. 2012, 111, 433–438. [Google Scholar] [CrossRef] [PubMed]

- Suopajärvi, H.; Pongrácz, E.; Fabritius, T. The Potential of Using Biomass-Based Reducing Agents in the Blast Furnace: A Review of Thermochemical Conversion Technologies and Assessments Related to Sustainability. Renew. Sustain. Energy Rev. 2013, 25, 511–528. [Google Scholar] [CrossRef]

- Großpietsch, K.H.; Lüngen, H.B.; Dauwels, G.; Ferstl, A.; Karjalahti, T.; Negro, P.; van der Velden, B.; Willmers, R. Coke Quality Requirements by European Blast Furnace Operators on the Turn of the Millennium. In Proceedings of the 4th European Coke and Ironmaking Congress, Paris, France, 19–21 June 2000; Volume 1, pp. 2–11. [Google Scholar]

- Álvarez, R.; Díez, M.A.; Barriocanal, C.; Díaz-Faes, E.; Cimadevilla, J.L.G. An Approach to Blast Furnace Coke Quality Prediction. Fuel 2007, 86, 2159–2166. [Google Scholar] [CrossRef]

- Babich, A.; Senk, D.; Gudenau, H.W. Ironmaking; Mainz GmbH Aachen: Aachen, Germany, 2008. [Google Scholar]

- Scarpinella, C.A.; Cyro, T.; Tagusagawa, S.Y.; Mourao, M.B.; Lenz e Silva, F.B. Charcoal ironmaking: A contribution for CO2 mitigation. In Proceedings of the Fray International Syymposium, Cancun, Mexico, 27 November–1 December 2011; Metals and Materials Processing in a Clean Environment. pp. 109–121. [Google Scholar]

- Adilson de Castro, J.; de Medeiros, G.A.; de Oliveira, E.M.; de Campos, M.F.; Nogami, H. The Mini Blast Furnace Process: An Efficient Reactor for Green Pig Iron Production Using Charcoal and Hydrogen-Rich Gas: A Study of Cases. Metals 2020, 10, 1501. [Google Scholar] [CrossRef]

- Hanrot, F.; Sert, D.; Delinchant, J.; Pietruck, R.; Bürgler, T.; Babich, A.; Fernández, M.; Alvarez, R.; Diez, M.A. CO2 Mitigation for Steelmaking Using Charcoal and Plastics Wastes as Reducing Agents and Secondary Raw Materials. In Proceedings of the 1st Spanish National Conference on Advances in Materials Recycling and Eco—Energy, Madrid, Spain, 12–13 November 2009; pp. 181–184. [Google Scholar]

- Steel Statistical Yearbook 2019. Available online: https://worldsteel.org/wp-content/uploads/Steel-Statistical-Yearbook-2019-concise-version.pdf (accessed on 22 November 2022).

- Rehfeldt, M.; Worrell, E.; Eichhammer, W.; Fleiter, T. A Review of the Emission Reduction Potential of Fuel Switch towards Biomass and Electricity in European Basic Materials Industry until 2030. Renew. Sustain. Energy Rev. 2020, 120, 109672. [Google Scholar] [CrossRef]

- Yunos, N.F.M.; Zaharia, M.; Idris, M.A.; Nath, D.; Khanna, R.; Sahajwalla, V. Recycling Agricultural Waste from Palm Shells during Electric Arc Furnace Steelmaking. Energy Fuels 2012, 26, 278–286. [Google Scholar] [CrossRef]

- Huang, X.-A.; Ng, K.W.; Giroux, L.; Duchesne, M. Carbonaceous Material Properties and Their Interactions with Slag During Electric Arc Furnace Steelmaking. Met. Mater. Trans. B 2019, 50, 1387–1398. [Google Scholar] [CrossRef]

- Fidalgo, B.; Berrueco, C.; Millan, M. Chars from Agricultural Wastes as Greener Fuels for Electric Arc Furnaces. J. Anal. Appl. Pyrolysis 2015, 113, 274–280. [Google Scholar] [CrossRef]

- Meier, T.; Hay, T.; Echterhof, T.; Pfeifer, H.; Rekersdrees, T.; Schlinge, L.; Elsabagh, S.; Schliephake, H. Process Modeling and Simulation of Biochar Usage in an Electric Arc Furnace as a Substitute for Fossil Coal. Steel Res. Int. 2017, 88, 1600458. [Google Scholar] [CrossRef]

- Nwachukwu, C.M.; Wang, C.; Wetterlund, E. Exploring the Role of Forest Biomass in Abating Fossil CO2 Emissions in the Iron and Steel Industry—The Case of Sweden. Appl. Energy 2021, 288, 116558. [Google Scholar] [CrossRef]

- Wieder, K.; Böhm, C.; Wurm, J.; Vuletic, B. Confronting the Coke Shortage with the COREX and FINEX Technology. BHM Berg- Und Hüttenmännische Mon. 2004, 149, 379–384. [Google Scholar]

- Rammer, B.; Millner, R.; Boehm, C. Comparing the CO2 Emissions of Different Steelmaking Routes. BHM Berg- Und Hüttenmännische Mon. 2017, 162, 7–13. [Google Scholar] [CrossRef]

- Hammerschmid, M.; Müller, S.; Fuchs, J.; Hofbauer, H. Evaluation of Biomass-Based Production of below Zero Emission Reducing Gas for the Iron and Steel Industry. Biomass Conv. Bioref. 2021, 11, 169–187. [Google Scholar] [CrossRef]

- Mahi, F.T.; Nassaralla, C.L. Iron Production. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2016; p. B9780128035818035000. ISBN 978-0-12-803581-8. [Google Scholar]

- Prachethan Kumar, P.; Raju, B.S.L.; Ranjan, M. Characteristics of Coal Required for Superior Performance of Corex Ironmaking. Ironmak. Steelmak. 2011, 38, 412–416. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Arens, M.; Price, L. Alternative Emerging Ironmaking Technologies for Energy-Efficiency and Carbon Dioxide Emissions Reduction: A Technical Review. Renew. Sustain. Energy Rev. 2014, 33, 645–658. [Google Scholar] [CrossRef]

- Adeleke, A.A.; Odusote, J.K.; Lasode, O.A.; Ikubanni, P.P.; Malathi, M.; Paswan, D. Densification of Coal Fines and Mildly Torrefied Biomass into Composite Fuel Using Different Organic Binders. Heliyon 2019, 5, e02160. [Google Scholar] [CrossRef] [Green Version]

- Yang, F.; Meerman, H.; Faaij, A. Harmonized Comparison of Virgin Steel Production Using Biomass with Carbon Capture and Storage for Negative Emissions. Int. J. Greenh. Gas Control 2021, 112, 103519. [Google Scholar] [CrossRef]

- THE FINEX® Process Economical and Environmentally Safe Ironmaking. Available online: https://www.primetals.com/fileadmin/user_upload/content/01_portfolio/1_ironmaking/finex/THE_FINEX_R__PROCESS.pdf (accessed on 17 November 2022).

- Khasraw, D.; Spooner, S.; Hage, H.; Meijer, K.; Li, Z. Devolatilisation Characteristics of Coal and Biomass with Respect to Temperature and Heating Rate for HIsarna Alternative Ironmaking Process. Fuel 2021, 284, 119101. [Google Scholar] [CrossRef]

- Abdul Quader, M.; Ahmed, S.; Dawal, S.Z.; Nukman, Y. Present Needs, Recent Progress and Future Trends of Energy-Efficient Ultra-Low Carbon Dioxide (CO2) Steelmaking (ULCOS) Program. Renew. Sustain. Energy Rev. 2016, 55, 537–549. [Google Scholar] [CrossRef]

- Zhang, X.; Jiao, K.; Zhang, J.; Guo, Z. A Review on Low Carbon Emissions Projects of Steel Industry in the World. J. Clean. Prod. 2021, 306, 127259. [Google Scholar] [CrossRef]

- Khasraw, D.; Theint Htet, T.; Yang, X.; Degirmenci, V.; Hage, H.; Meijer, K.; Li, Z. Gasification and Structural Behaviour of Different Carbon Sources and Resultant Chars from Rapid Devolatilization for HIsarna Alternative Ironmaking Process. Fuel 2022, 309, 122210. [Google Scholar] [CrossRef]

- Htet, T.T.; Yan, Z.; Spooner, S.; Degirmenci, V.; Meijer, K.; Li, Z. Gasification and Physical-Chemical Characteristics of Carbonaceous Materials in Relation to HIsarna Ironmaking Process. Fuel 2021, 289, 119890. [Google Scholar] [CrossRef]

- Surup, G.; Vehus, T.; Eidem, P.-A.; Trubetskaya, A.; Nielsen, H.K. Characterization of Renewable Reductants and Charcoal-Based Pellets for the Use in Ferroalloy Industries. Energy 2019, 167, 337–345. [Google Scholar] [CrossRef]

- Monsen, B.; Tangstad, M.; Solheim, I.; Syvertsen, M.; Ishak, R.; Midtgaard, M. Charcoal for Manganese Alloy Production. In Proceedings of the 11th International Ferroalloys Congress, New Delhi, India, 18–21 February 2007; pp. 297–310. [Google Scholar]

- Surup, G.R.; Foppe, M.; Schubert, D.; Deike, R.; Heidelmann, M.; Timko, M.T.; Trubetskaya, A. The Effect of Feedstock Origin and Temperature on the Structure and Reactivity of Char from Pyrolysis at 1300–2800 °C. Fuel 2019, 235, 306–316. [Google Scholar] [CrossRef]

- Surup, G.; Kaffash, H.; Ma, Y.; Trubetskaya, A.; Pettersen, J.; Tangstad, M. Life Cycle Based Climate Emissions of Charcoal Conditioning Routes for the Use in the Ferro-Alloy Production. Energies 2022, 15, 3933. [Google Scholar] [CrossRef]

- Wannapeera, J.; Worasuwannarak, N. Examinations of Chemical Properties and Pyrolysis Behaviors of Torrefied Woody Biomass Prepared at the Same Torrefaction Mass Yields. J. Anal. Appl. Pyrolysis 2015, 115, 279–287. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, M.; Jiang, E.; Wang, D.; Zhang, K.; Ren, Y.; Jiang, Y. Pyrolysis of Torrefied Biomass. Trends Biotechnol. 2018, 36, 1287–1298. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, R.; Wu, C.; Zhu, L.; Hu, Z.; Xu, J.; Yang, Y.; Yang, F.; Ma, Z. Regulation of the Elemental Distribution in Biomass by the Torrefaction Pretreatment Using Different Atmospheres and Its Influence on the Subsequent Pyrolysis Behaviors. Fuel Process. Technol. 2021, 222, 106983. [Google Scholar] [CrossRef]

- Louwes, A.C.; Basile, L.; Yukananto, R.; Bhagwandas, J.C.; Bramer, E.A.; Brem, G. Torrefied Biomass as Feed for Fast Pyrolysis: An Experimental Study and Chain Analysis. Biomass Bioenergy 2017, 105, 116–126. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Wright, C.T.; Hess, J.R.; Kenney, K.L. A Review of Biomass Densification Systems to Develop Uniform Feedstock Commodities for Bioenergy Application. Biofuels Bioprod. Bioref. 2011, 5, 683–707. [Google Scholar] [CrossRef]

- Sarker, T.R.; Azargohar, R.; Stobbs, J.; Karunakaran, C.; Meda, V.; Dalai, A.K. Complementary Effects of Torrefaction and Pelletization for the Production of Fuel Pellets from Agricultural Residues: A Comparative Study. Ind. Crops Prod. 2022, 181, 114740. [Google Scholar] [CrossRef]

- Peng, J.H.; Bi, H.T.; Lim, C.J.; Sokhansanj, S. Study on Density, Hardness, and Moisture Uptake of Torrefied Wood Pellets. Energy Fuels 2013, 27, 967–974. [Google Scholar] [CrossRef]

- Manouchehrinejad, M.; Mani, S. Torrefaction after Pelletization (TAP): Analysis of Torrefied Pellet Quality and Co-Products. Biomass Bioenergy 2018, 118, 93–104. [Google Scholar] [CrossRef]

- Sarker, T.R.; Azargohar, R.; Dalai, A.K.; Meda, V. Characteristics of Torrefied Fuel Pellets Obtained from Co-Pelletization of Agriculture Residues with Pyrolysis Oil. Biomass Bioenergy 2021, 150, 106139. [Google Scholar] [CrossRef]

- Peng, J.; Bi, X.T.; Lim, C.J.; Peng, H.; Kim, C.S.; Jia, D.; Zuo, H. Sawdust as an Effective Binder for Making Torrefied Pellets. Appl. Energy 2015, 157, 491–498. [Google Scholar] [CrossRef]

- Matsumura, T.; Ichida, M.; Nagasaka, T.; Kato, K. Carbonization Behaviour of Woody Biomass and Resulting Metallurgical Coke Properties. ISIJ Int. 2008, 48, 572–577. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Liu, X.; Legros, R.; Bi, X.T.; Jim Lim, C.; Sokhansanj, S. Pelletization of Torrefied Sawdust and Properties of Torrefied Pellets. Appl. Energy 2012, 93, 680–685. [Google Scholar] [CrossRef]

- Manouchehrinejad, M.; Bilek, E.M.T.; Mani, S. Techno-Economic Analysis of Integrated Torrefaction and Pelletization Systems to Produce Torrefied Wood Pellets. Renew. Energy 2021, 178, 483–493. [Google Scholar] [CrossRef]

- Rahman, M.; Pudasainee, D.; Gupta, R. Review on Chemical Upgrading of Coal: Production Processes, Potential Applications and Recent Developments. Fuel Process. Technol. 2017, 158, 35–56. [Google Scholar] [CrossRef]

- Dhawan, H.; Sharma, D.K. Advances in the Chemical Leaching (Inorgano-Leaching), Bio-Leaching and Desulphurisation of Coals. Int. J. Coal Sci. Technol. 2019, 6, 169–183. [Google Scholar] [CrossRef] [Green Version]

- Iniesta, E.; Sánchez, F.; García, A.N.; Marcilla, A. Yields and CO2 Reactivity of Chars from Almond Shells Obtained by a Two Heating Step Carbonisation Process. Effect of Different Chemical Pre-Treatments and Ash Content. J. Anal. Appl. Pyrolysis 2001, 58–59, 983–994. [Google Scholar] [CrossRef]

- Das, P.; Ganesh, A.; Wangikar, P. Influence of Pretreatment for Deashing of Sugarcane Bagasse on Pyrolysis Products. Biomass Bioenergy 2004, 27, 445–457. [Google Scholar] [CrossRef]

- Hussein, A.; Larachi, F.; Ziegler, D.; Alamdari, H. Effects of Heat Treatment and Acid Washing on Properties and Reactivity of Charcoal. Biomass Bioenergy 2016, 90, 101–113. [Google Scholar] [CrossRef]

- Oudenhoven, S.R.G.; van der Ham, A.G.J.; van den Berg, H.; Westerhof, R.J.M.; Kersten, S.R.A. Using Pyrolytic Acid Leaching as a Pretreatment Step in a Biomass Fast Pyrolysis Plant: Process Design and Economic Evaluation. Biomass Bioenergy 2016, 95, 388–404. [Google Scholar] [CrossRef] [Green Version]

- Vamvuka, D.; Sfakiotakis, S. Effects of Heating Rate and Water Leaching of Perennial Energy Crops on Pyrolysis Characteristics and Kinetics. Renew. Energy 2011, 36, 2433–2439. [Google Scholar] [CrossRef]

- Deng, L.; Zhang, T.; Che, D. Effect of Water Washing on Fuel Properties, Pyrolysis and Combustion Characteristics, and Ash Fusibility of Biomass. Fuel Process. Technol. 2013, 106, 712–720. [Google Scholar] [CrossRef]

- Xia, D.; Tan, F.; Zhang, C.; Jiang, X.; Chen, Z.; Li, H.; Zheng, Y.; Li, Q.; Wang, Y. ZnCl 2 -Activated Biochar from Biogas Residue Facilitates Aqueous As(III) Removal. Appl. Surf. Sci. 2016, 377, 361–369. [Google Scholar] [CrossRef]

- Mu, L.; Zheng, H.; Wei, G.; Shen, F. Effect of Znic on Strength of Coke. J. Iron Steel Res. 2011, 23, 10–22. [Google Scholar]

- Li, K.; Zhang, J.; Liu, Z.; Wang, T.; Ning, X.; Zhong, J.; Xu, R.; Wang, G.; Ren, S.; Yang, T. Zinc Accumulation and Behavior in Tuyere Coke. Met. Mater. Trans. B 2014, 45, 1581–1588. [Google Scholar] [CrossRef]

- Wang, Z.; Pang, K.; Li, K.; Zhang, J.; Sun, M.; Han, B.; Jiang, C.; Li, H. Positive Catalytic Effect and Mechanism of Iron on the Gasification Reactivity of Coke Using Thermogravimetry and Density Functional Theory. ISIJ Int. 2021, 61, 773–781. [Google Scholar] [CrossRef]

- Babich, A.; Senk, D.; Gudenau, H.W. Effect of Coke Reactivity and Nut Coke on Blast Furnace Operation. Ironmak. Steelmak. 2009, 36, 222–229. [Google Scholar] [CrossRef] [Green Version]

- Iguchi, Y.; Takada, Y. Rate of Direct Reactions Measured in Vacuum of Iron Ore-Carbon Composite Pellets Heated at High Temperatures: Influence of Carbonaceous Materials, Oxidation Degree of Iron Oxides and Temperature. ISIJ Int. 2004, 44, 673–681. [Google Scholar] [CrossRef]

- Nomura, S.; Ayukawa, H.; Kitaguchi, H.; Tahara, T.; Matsuzaki, S.; Naito, M.; Koizumi, S.; Ogata, Y.; Nakayama, T.; Abe, T. Improvement in Blast Furnace Reaction Efficiency through the Use of Highly Reactive Calcium Rich Coke. ISIJ Int. 2005, 45, 316–324. [Google Scholar] [CrossRef] [Green Version]

- Ueda, S.; Watanabe, K.; Yanagiya, K.; Inoue, R.; Ariyama, T. Improvement of Reactivity of Carbon Iron Ore Composite with Biomass Char for Blast Furnace. ISIJ Int. 2009, 49, 1505–1512. [Google Scholar] [CrossRef] [Green Version]

- Bhattacharyya, A. Characterization of Cokes and Chars for Optimized Use in Ironmaking Processes. Ph.D. Thesis, Montanuniversität Leoben, Leoben, Austria, 2017. [Google Scholar]

- Li, W.; Shen, Y.; Guo, J.; Kong, J.; Wang, M.; Chang, L. Effect of Flotation Fractions of Long-Flame Coal on Regulation of Sulfur and Coke Reactivity during Pyrolysis of High-Sulfur Coking Coal. J. Fuel Chem. Technol. 2021, 49, 881–889. [Google Scholar] [CrossRef]

- Dai, X.; Theppitak, S.; Yoshikawa, K. Pelletization of Carbonized Wood Using Organic Binders with Biomass Gasification Residue as an Additive. Energy Fuels 2019, 33, 323–329. [Google Scholar] [CrossRef]

- Meijer, K.; Denys, M.; Lasar, J.; Birat, J.-P.; Still, G.; Overmaat, B. ULCOS: Ultra-Low CO 2 Steelmaking. Ironmak. Steelmak. 2009, 36, 249–251. [Google Scholar] [CrossRef]

- Birat, J.P. Global Technology Roadmap for CCS in Industry. Steel Sectoral Report; Contribution to the UNIDO Roadmap on CCS1—Fifth Draft. 2010. Available online: https://www.globalccsinstitute.com/archive/hub/publications/15671/global-technology-roadmap-ccs-industry-steel-sectoral-report (accessed on 17 November 2022).

- Development of a Low CO2 Iron and Steelmaking Integrated Process Route for a Sustainable European Steel Industry. Available online: https://cordis.europa.eu/project/id/654013/reporting (accessed on 17 November 2022).

- Carbo, M. The SECTOR Project: Production of Solid Sustainable Energy Carriers. In Proceedings of the International Conference of the Cluster of Excellence Tailor-Made Fuels from Biomass 2015, Aachen, Germany, 15 April 2015. [Google Scholar]

- Thrän, D. Production of Solid Sustainable Energy Carriers from Biomass by Means of Torrefaction; DBFZ Deutsches Biomasseforschungszentrum Gemeinnützige GmbH: 2016. Available online: https://cordis.europa.eu/project/id/282826/reporting (accessed on 17 November 2022).

- Sundqvist Ökvist, L.; From, L.; Lagerwall, P. Improved Coal Combustion under Variable BF Conditions (IMPCO): Final Report; European Commission, Directorate-General for Research and Innovation: Publications Office: 2019. Available online: https://op.europa.eu/en/publication-detail/-/publication/d26e2b93-22ae-11e9-8d04-01aa75ed71a1/language-en/format-PDF/source-95172924 (accessed on 22 November 2022).

- Unland, E.; Ventrella, G.; Janz, J. Alternate Carbon Sources for Sintering of Iron Ore (Acasos); Publications Office: European Commission, Directorate-General for Research and Innovation: 2013. Available online: https://op.europa.eu/en/publication-detail/-/publication/a3b3e8a0-01c6-4451-8945-1919162f2cb8 (accessed on 22 November 2022).

- Synopsis of RFCS Projects 2016–2019. Full List of Projects Co-financed by the Research Fund for Coal and Steel of the European Union; European Commission, Directorate-General for Research and Innovation: 2020. p. 52. Available online: https://ec.europa.eu/info/sites/default/files/research_and_innovation/funding/documents/synopsis_of_rfcs_projects_2016-2019.pdf (accessed on 17 November 2022).

- Alexis, J.; Heintz, I.; Björkvall, J. Recycling of Industrial and Municipal Waste as Slag Foaming Agent in EAF (RIMFOAM); European Commission, Directorate-General for Research and Innovation: 2021. Available online: https://www.cde.ual.es/ficha/recycling-of-industrial-and-municipal-waste-as-slag-foaming-agent-in-eaf-rimfoam-final-report/ (accessed on 17 November 2022).

- Implementation of a Smart RETROfitting Framework in the Process Industry towards Its Operation with Variable, Biobased and Circular FEEDstock; Spain. 2021. Available online: https://cordis.europa.eu/project/id/869939/results (accessed on 17 November 2022).

- Rejdak, M.; Pawłowski, P.; Mertas, B.; Gałko, G.; Wojtaszek –Kalaitzidi, M.; Książek, M.; Larsen, S.Y.; Baron, R. Bio-Coke for Ferroalloys Industry Production: The Influence of Charcoal Addition to Coking Blend on Mechanical Strength of Stamped Coal Cakes. Available online: https://biocoke4fai.pl/wp-content/uploads/2021/11/MEC_2021_abstract.pdf (accessed on 17 November 2022).

- Johnson, E. Goodbye to Carbon Neutral: Getting Biomass Footprints Right. Environ. Impact Assess. Rev. 2009, 29, 165–168. [Google Scholar] [CrossRef]

- Suopajärvi, H.; Pongrácz, E.; Fabritius, T. Bioreducer Use in Finnish Blast Furnace Ironmaking—Analysis of CO2 Emission Reduction Potential and Mitigation Cost. Appl. Energy 2014, 124, 82–93. [Google Scholar] [CrossRef]

- Abbate, E.; Rovelli, D.; Andreotti, M.; Brondi, C.; Ballarino, A. Plastic Packaging Substitution in Industry: Variability of LCA Due to Manufacturing Countries. Procedia CIRP 2022, 105, 392–397. [Google Scholar] [CrossRef]

- Norgate, T.; Jahanshahi, S. Assessing the Energy and Greenhouse Gas Footprints of Nickel Laterite Processing. Miner. Eng. 2011, 24, 698–707. [Google Scholar] [CrossRef]

- Piketty, M.-G.; Wichert, M.; Fallot, A.; Aimola, L. Assessing Land Availability to Produce Biomass for Energy: The Case of Brazilian Charcoal for Steel Making. Biomass Bioenergy 2009, 33, 180–190. [Google Scholar] [CrossRef]

- Schmidt, J.H.; Weidema, B.P.; Brandão, M. A Framework for Modelling Indirect Land Use Changes in Life Cycle Assessment. J. Clean. Prod. 2015, 99, 230–238. [Google Scholar] [CrossRef]

- Winter, B.; Meys, R.; Bardow, A. Towards Aromatics from Biomass: Prospective Life Cycle Assessment of Bio-Based Aniline. J. Clean. Prod. 2021, 290, 125818. [Google Scholar] [CrossRef]

- Pawelzik, P.; Carus, M.; Hotchkiss, J.; Narayan, R.; Selke, S.; Wellisch, M.; Weiss, M.; Wicke, B.; Patel, M.K. Critical Aspects in the Life Cycle Assessment (LCA) of Bio-Based Materials—Reviewing Methodologies and Deriving Recommendations. Resour. Conserv. Recycl. 2013, 73, 211–228. [Google Scholar] [CrossRef]

- Plevin, R.J.; Delucchi, M.A.; Creutzig, F. Using Attributional Life Cycle Assessment to Estimate Climate-Change Mitigation Benefits Misleads Policy Makers: Attributional LCA Can Mislead Policy Makers. J. Ind. Ecol. 2014, 18, 73–83. [Google Scholar] [CrossRef]

- Wang, P.; Ryberg, M.; Yang, Y.; Feng, K.; Kara, S.; Hauschild, M.; Chen, W.-Q. Efficiency Stagnation in Global Steel Production Urges Joint Supply- and Demand-Side Mitigation Efforts. Nat. Commun. 2021, 12, 2066. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Z.; Tan, Z.; Guo, Z.; Yang, J.; Wang, Q. Recent Progress in Sustainable and Energy-Efficient Technologies for Sinter Production in the Iron and Steel Industry. Renew. Sustain. Energy Rev. 2020, 131, 110034. [Google Scholar] [CrossRef]

- Son, K.; Lee, J.; Hwang, H.; Jeon, W.; Yang, H.; Sohn, I.; Kim, Y.; Um, H. Slag Foaming Estimation in the Electric Arc Furnace Using Machine Learning Based Long Short-Term Memory Networks. J. Mater. Res. Technol. 2021, 12, 555–568. [Google Scholar] [CrossRef]

- Matino, I.; Colla, V.; Baragiola, S. Quantification of Energy and Environmental Impacts in Uncommon Electric Steelmaking Scenarios to Improve Process Sustainability. Appl. Energy 2017, 207, 543–552. [Google Scholar] [CrossRef]

- Karpatne, A.; Atluri, G.; Faghmous, J.H.; Steinbach, M.; Banerjee, A.; Ganguly, A.; Shekhar, S.; Samatova, N.; Kumar, V. Theory-Guided Data Science: A New Paradigm for Scientific Discovery from Data. IEEE Trans. Knowl. Data Eng. 2017, 29, 2318–2331. [Google Scholar] [CrossRef]

- Colla, V. A Big Step Ahead in Metal Science and Technology through the Application of Artificial Intelligence. IFAC-PapersOnLine 2022, 55, 1–6. [Google Scholar] [CrossRef]

| Parameters | Conventional Coke | References |

|---|---|---|

| Ash, wt.% | <11 | [76] |

| Volatile matters, wt.% | <1.1 | [76,77] |

| Moisture by dry quenching, wt.% | <0.7 | [76] |

| Moisture by wet quenching, wt.% | <5 | [76] |

| C, wt.% | 96.5–97.5 | [76] |

| Fixed carbon, wt.% | 88.8 | [77] |

| H, wt.% | <0.8 | [76] |

| O, wt.% | <0.4 | [76] |

| N, wt.% | <1.3 | [76] |

| S, wt.% | 0.5–1.2 | [76] |

| Coke reactivity index, wt.% | <30 | [76] |

| Coke strength after reaction with CO2, wt.% | <65 | [76] |

| Structural strength, wt.% | <80 | [78] |

| Size distribution, mm | 40–80 | [76] |

| Bulk density, kg/m3 | 430–500 | [76] |

| Porosity, % | 45.0–55.0 | [76] |

| Electric resistivity, mΩ·m | 10–12 | [78] |

| Calorific value (MJ/kg) | app. 29.0 | [79] |

| Parameters | Torrefied Biomass | Biocoke |

|---|---|---|

| Moisture, wt.% | 4.8 | 0.65 or 1.35 |

| Volatile matters, wt.% | 34–85 | 1.4–2.7 |

| Ash, wt.% | 0.4 | 5.8–10.8 |

| Fixed carbon, wt.% | 13–45 | 87.8–92.4 |

| C, wt.% | 45–68 | 86.38–91.65 |

| S, wt.% | traces | 0.22–0.23 |

| Coke reactivity index, wt.% | n/a | app. 25–50 |

| Strength after reaction with CO2, wt.% | n/a | app. 65–20 |

| Calorific value, (MJ/kg) | 16–29 | app. 18–32 |

| Source | Amount of Required Biomass (kt/Year) | |

|---|---|---|

| 20 wt.% | 50 wt.% | |

| Raw biomass | 192.5 | 481.3 |

| Torrefied biomass | 77.0 | 192.5 |

| Parameters | Values | References |

|---|---|---|

| Moisture, wt.% | <15 | [50,95] |

| Volatile matters, wt.% | <3 | [96] |

| Ash, wt.% | <12 | [50,95] |

| Density, kg/m3 | >700 | [96] |

| Size, mm | 0.3–3 | [96] |

| Total sulfur, wt.% | <2 | [50,95] |

| Fixed carbon, wt.% | <76 | [97] |

| Component (wt.%) | C | H | O | N | S | Ash | Volatile Matters | Moisture |

|---|---|---|---|---|---|---|---|---|

| 80.6 | 4.35 | 5.35 | 1.65 | 0.45 | 10.89 | 19.50 | 0.01 | |

| References | [26] | [26] | [26] | [26] | [26] | [26] | [117] | [117] |

| Parameters | Values |

|---|---|

| Moisture, wt.% | <4 |

| Ash, wt.% | <12 |

| Volatile matters, wt.% | 25–27 |

| Sulfur, wt.% | <0.6 |

| Fixed carbon, wt.% | 55–70 |

| Calorific value, kJ kg−1 | >27,000 |

| Parameters | Values |

|---|---|

| Coke reactivity index, wt.% | <35 |

| Coke strength after reaction, wt.% | >55 |

| Volatile matters, wt.% | app. 25 |

| Ash, wt.% | <15 |

| Sulfur, wt.% | <1 |

| Grain size, mm | 10–15 |

| Fixed Carbon, wt.% | Ash, wt.% | Volatile Matters, wt.% | Sulfur, wt.% | Reference |

|---|---|---|---|---|

| min. 55 | up to 25 | <35 | <1 | [149] |

| Parameters | Conventional Coke |

|---|---|

| Fixed carbon, wt.% | 86–88 |

| Volatile matter, wt.% | ≤1 |

| Ash, wt.% | 10–12 |

| Reactivity with CO2 at 1060 °C, %C/s | (0.2–0.5)10−2 |

| Thermal cohesion strength, % | 93–97 |

| Thermal abrasion strength, % | 82–89 |

| Electrical resistance for carbon material with size, mm: | 10–20 |

| Electrical resistance at 1000 °C, U∙m | 0.003–0.008 |

| Electrical resistance at 1400 °C, U∙m | 0.003–0.009 |

| Parameters | Sources | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| CWT | CWC | TCR (Before Compaction) | TCR (After Compaction) | Bch285 (WAT), [174] | Bch285 (AAT), [174] | Switchgrass (Unwashed), [178] | Switchgrass (Washed), [178] | Coke | CRC10 | CRC20 | |

| Carbonization [190] | Compaction [43] | Beneficiation | Mineral additives [186] | ||||||||

| C (wt.%) | 72.85 | 84.74 | 48.3 | 42.8 | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. |

| H (wt.%) | 4.56 | 3.18 | 5.5 | 5.9 | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. |

| N (wt.%) | 0.27 | 0.39 | 2.3 | 2.2 | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. |

| S (wt.%) | 0.14 | 0.1 | 1.0 | 0.8 | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. |

| O (wt.%) | 18.95 | 9.45 | 33.0 | 38.7 | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. |

| Ash (wt.%) | 0.4 | 0.7 | 9.9 | 9.6 | n.a. | n.a. | 8.5 | 2.9 | n.a. | n.a. | n.a. |

| HHV (MJ/kg) | 28.83 | 32.32 | n.a. | 19.3 | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. |

| R | n.a. | n.a. | n.a. | n.a. | 4.9 | 2.0 | n.a. | n.a. | n.a. | n.a. | n.a. |

| DI150 15 | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | 84.5 | 84.0 | 81.8 |

| CRI, % | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | 23.3 | 24.8 | 33.2 |

| CSR, % | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | 66.8 | 68.0 | 58.6 |

| JIS ReI | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | 6.6 | 39.0 | 41.8 |

| Inorganics (%): | |||||||||||

| K2O | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | 11.9 | 0.86 | n.a. | n.a. | n.a. |

| P2O5 | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | 4.5 | 1.0 | n.a. | n.a. | n.a. |

| SO3 | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | 0.17 | 0.11 | n.a. | n.a. | n.a. |

| Cl (ppm) | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | 70 | 18 | n.a. | n.a. | n.a. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kieush, L.; Rieger, J.; Schenk, J.; Brondi, C.; Rovelli, D.; Echterhof, T.; Cirilli, F.; Thaler, C.; Jaeger, N.; Snaet, D.; et al. A Comprehensive Review of Secondary Carbon Bio-Carriers for Application in Metallurgical Processes: Utilization of Torrefied Biomass in Steel Production. Metals 2022, 12, 2005. https://doi.org/10.3390/met12122005

Kieush L, Rieger J, Schenk J, Brondi C, Rovelli D, Echterhof T, Cirilli F, Thaler C, Jaeger N, Snaet D, et al. A Comprehensive Review of Secondary Carbon Bio-Carriers for Application in Metallurgical Processes: Utilization of Torrefied Biomass in Steel Production. Metals. 2022; 12(12):2005. https://doi.org/10.3390/met12122005

Chicago/Turabian StyleKieush, Lina, Johannes Rieger, Johannes Schenk, Carlo Brondi, Davide Rovelli, Thomas Echterhof, Filippo Cirilli, Christoph Thaler, Nils Jaeger, Delphine Snaet, and et al. 2022. "A Comprehensive Review of Secondary Carbon Bio-Carriers for Application in Metallurgical Processes: Utilization of Torrefied Biomass in Steel Production" Metals 12, no. 12: 2005. https://doi.org/10.3390/met12122005

APA StyleKieush, L., Rieger, J., Schenk, J., Brondi, C., Rovelli, D., Echterhof, T., Cirilli, F., Thaler, C., Jaeger, N., Snaet, D., Peters, K., & Colla, V. (2022). A Comprehensive Review of Secondary Carbon Bio-Carriers for Application in Metallurgical Processes: Utilization of Torrefied Biomass in Steel Production. Metals, 12(12), 2005. https://doi.org/10.3390/met12122005