Mechanical Wave Propagation in Solidifying Al-Cu-Mn-Ti Alloy and Its Effect on Solidification Feeding

Abstract

:1. Introduction

2. Experimental Process

2.1. Chemical Analysis of the Alloy

2.2. Casting Setup

2.3. Characterizations of Castings

3. Numerical Model and Process

3.1. Wave Equations

3.2. Boundary Conditions

3.3. Numerical Process

4. Results and Discussion

4.1. Shrinkage Defects

4.2. Temperature Field

4.3. Wave Field

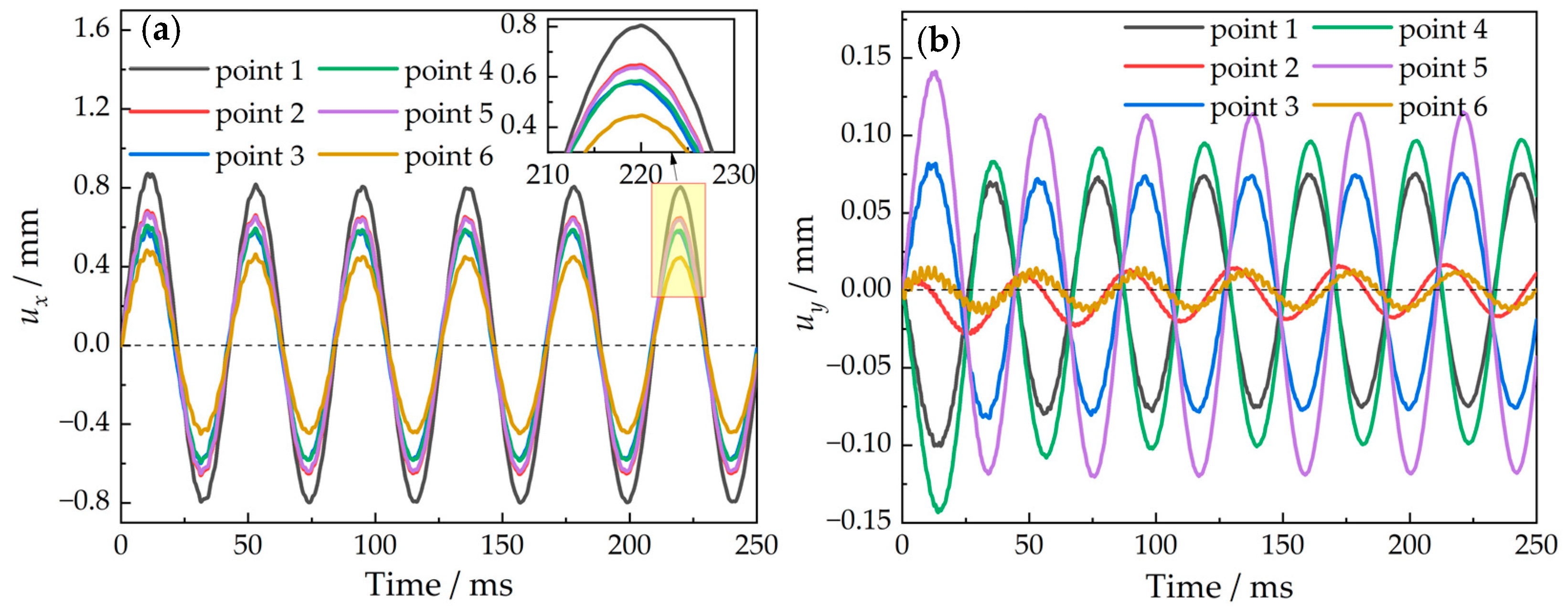

4.3.1. Evolution of the Wave Field with Time

4.3.2. Evolution of the Wave Field with Solidification

4.4. Effects of Mechanical Vibration on Solidification Feeding

4.4.1. Effect of Mechanical Vibration on Mass Feeding

4.4.2. Effect of Mechanical Vibration on Interdendritic Feeding

4.4.3. Effect of Mechanical Vibration on Burst Feeding

5. Conclusions

- (1)

- Applying vibration had a greater promotional effect on feeding than increasing the holding pressure.

- (2)

- The casting in solidification produced a stable harmonic vibration under the excitation of the continuous harmonic vibration source, and the vibration energy was mainly concentrated in the channel, causing cracks and shrinkage defects in the lower channel opposite the source, coinciding with the detections.

- (3)

- With solidification, the amplitude reduced rapidly after the dendrites overlapped when 27% < < 40%, and then it reduced slowly to a certain value; the amplitude reduced rapidly after the occurrence of a quasi-solid phase when 19.1% < < 30%, and it then reduced slowly to near zero.

- (4)

- The mechanical vibration produced a severe shear deformation in the quasi-liquid region—especially in the lower feeding channel—causing dendrites to be broken and remelted, reducing the grain size to promote the mass feeding.

- (5)

- The feeding pressure and gaps changed periodically under vibration, and the vibration-promoting interdendritic feeding rate fluctuated and eventually stabilized at about 13.4%.

- (6)

- The mechanical vibration can increase the feeding pressure difference and change the blockage structure simultaneously, increasing the formation probability of burst feeding.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mi, G.; Wang, K.; Gong, H.; Wang, H.; Zeng, S. Microstructure and Properties of ZL205 Alloy. China Foundry 2008, 5, 24–27. [Google Scholar]

- Luo, L.; Xia, H.Y.; Luo, L.S.; Su, Y.Q.; Cai, C.J.; Wang, L.; Guo, J.J.; Fu, H.Z. Eliminating Shrinkage Defects and Improving Mechanical Performance of Large Thin-Walled ZL205A Alloy Castings by Coupling Travelling Magnetic Fields with Sequential Solidification. Trans. Nonferrous Met. Soc. China 2021, 31, 865–877. [Google Scholar] [CrossRef]

- Wu, S.P.; Wang, R.J.; Wang, Y.; Chen, W.; Ji, Z.S. Reduction of Shrinkage Porosities in Aluminum Alloy Castings by External Pressure Fluctuation Under Gravity Field. China Foundry 2018, 15, 372–377. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Wu, S.P.; Niu, L.J.; Xue, X.; Zhang, J.B.; Xiao, W.F. Optimization of Low-Pressure Die Casting Process Parameters for Reduction of Shrinkage Porosity in ZL205A Alloy Casting Using Taguchi Method. Proc. Inst. Mech. Eng. Part B 2014, 228, 1508–1514. [Google Scholar]

- Yoshitake, Y.; Yamamoto, K.; Sasaguri, N.; Era, H. Refinement of Primary Si Grains of Al-21%Si Alloy Using Vibration Mold. Mater. Trans. 2020, 61, 355–360. [Google Scholar] [CrossRef]

- Promakhov, V.V.; Khmeleva, M.G.; Zhukov, I.A.; Platov, V.V.; Khrustalyov, A.P.; Vorozhtsov, A.B. Influence of Vibration Treatment and Modification of A356 Aluminum Alloy on Its Structure and Mechanical Properties. Metals 2019, 9, 87. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Qu, C.; Zheng, Y.; Du, F. Study on the Effect of Vibration on Solidification Structures in the Vibration Cast-Rolling Process. Mater. Und Werkst. 2021, 52, 452–459. [Google Scholar] [CrossRef]

- Xiao, B.; Fan, Z.; Jiang, W.; Xiang, J.; Yan, X. Effect of Vibration Frequency on Primary Phase and Properties of Grey Cast Iron Fabricated by Lost Foam Casting. China Foundry 2020, 17, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.L.; Chen, J.; Li, M.M.; Wang, A.L.; Su, M.Y. Numerical Simulation of Temperature and Fluid Fields in Solidification Process of Ferritic Stainless Steel Under Vibration Conditions. Crystals 2019, 9, 174. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.L.; Liu, Y.H.; Guo, L.T.; Wang, Y.L. Cellular Automaton Simulation of Dendrite Growth in Solidification Process of Cr17 Stainless Steel under Mechanical Vibration. Phys. Status Solidi A 2022, 219, 2100620. [Google Scholar] [CrossRef]

- Chai, G.C.; BÄckerud, L.; RØlland, T.; Arnberg, L. Dendrite Coherency During Equiaxed Solidification in Binary Aluminum Alloys. Metall. Mater. Trans. A 1995, 26, 965–970. [Google Scholar] [CrossRef]

- Pîrvulescu, C.M.; Bratu, C. Mechanic Vibrations Generation System and Effect on the Casting Alloys Solidification Process. UPB Sci. Bull. Ser. B 2010, 72, 219–232. [Google Scholar]

- Zhao, Z.; Fan, Z.T. Influence on the Microstructures and Properties of A356 with Vibration Pressure in Lost Form Casting. Appl. Mech. Mater. 2014, 685, 7–10. [Google Scholar] [CrossRef]

- Chen, W.; Wu, S.P.; Wang, R.J. Effect of Vibration on Interdendritic Feeding of Al–5%Cu–0.4%Mn Alloy. Int. J. Metalcast. 2019, 13, 969–978. [Google Scholar] [CrossRef]

- Tian, X.F.; Fan, Z.T.; Huang, N.Y. Effect of Mechanical Vibration on Microstructure and Mechanical Properties of Lost Foam Casting Magnesium Alloy. Chin. J. Nonferrous Met. 2006, 16, 1838–1844. [Google Scholar]

- Wang, R.J.; Wu, S.P.; Chen, W. Propagation of Thermoviscoelastic Wave in Inhomogeneous Alloy Melt with Varying Temperature. Acta Phys. Sin. 2019, 68, 048101. [Google Scholar] [CrossRef]

- Wu, S.P.; Wang, R.J.; Chen, W.; Dai, G.X. Progress on Numerical Simulation of Vibration in the Metal Solidification. Acta Metall. Sin. 2017, 54, 247–264. [Google Scholar]

- Patel, V.P.; Patel, J.V.; Patel, A.V.; Bhuva, B.V. A Review on Microstructure and Mechanical Properties of Aluminium Alloy Using Mold Vibration. Int. Res. J. Eng. Technol. 2019, 6, 1047–1051. [Google Scholar]

- Wang, R.J.; Wu, S.P.; Chen, W. Unified Wave Equation and Numerical Simulation of Mechanical Wave Propagation in Alloy Solidification. Simulation 2019, 95, 3–10. [Google Scholar] [CrossRef]

- Kong, W.; Cang, D.Q. Effects of Ultrasound on the Flow Field in Molten Steel and Solidification Structure. Simulation 2012, 88, 694–706. [Google Scholar] [CrossRef]

- Feng, X.H.; Zhao, F.Z.; Jia, H.M.; Li, Y.J.; Yang, Y.S. Numerical Simulation of Non-Dendritic Structure Formation in Mg-Al Alloy Solidified with Ultrasonic Field. Ultrason. Sonochem. 2018, 40, 113–119. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Jia, Y.; Le, Q.; Yu, F. Understanding the Influence of Ultrasonic Streaming on Solidification of AZ80 Magnesium Alloy During Direct-Chill Casting Using a Transient Coupling Modeling. J. Mater. Res. Technol. 2021, 14, 1154–1166. [Google Scholar] [CrossRef]

- Wang, R.J. Propagation of Mechanical Wave During Solidification of ZL205A Alloy and its Promoting Behavior on Feeding. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2021. [Google Scholar]

- Wang, R.J.; Wu, S.P.; Chen, W. Effect of Vibration on Seepage Feeding During Low-Pressure Casting of ZL205A Alloy. China Foundry 2019, 16, 40–45. [Google Scholar] [CrossRef] [Green Version]

- Chang, T.; Zou, C.M.; Wang, H.W.; Wei, Z.J.; Zhang, X.J. Optimization of the Interface Heat Transfer Coefficient Model Based on the Dynamic Thermo-Physical Parameters in the Pressure-Temperature Coupled Field. Int. Commun. Heat Mass 2020, 110, 104435. [Google Scholar] [CrossRef]

- Dahle, A.K.; StJohn, D.H. Rheological Behaviour of the Mushy Zone and its Effect on the Formation of Casting Defects During Solidification. Acta Mater. 1998, 47, 31–41. [Google Scholar] [CrossRef]

- Campbell, J. Castings, 2nd ed.; Butterworth-Heinemann: Oxford, UK, 1991; pp. 205–231. [Google Scholar]

- Ma, Z.; Zhang, H.; Zhang, X.; Wu, X.; Fu, H.; Jia, L.; Zhang, H. Rheological Behaviour of Partially Solidified A356 Alloy: Experimental Study and Constitutive Modelling. J. Alloy. Compd. 2019, 803, 1141–1154. [Google Scholar] [CrossRef]

- Ravi Narayan, L.; Hebert, R.J. Rheology of Partially Solidified Hypoeutectic Aluminum Copper Alloys. SN Appl. Sci. 2022, 4, 186. [Google Scholar] [CrossRef]

- Cornish, R.J. Flow in a Pipe of Rectangular Cross-Section. Proc. Roy. Soc. Lond. A 1928, 120, 691–700. [Google Scholar]

- Wang, R.J.; Wu, S.P.; Chen, W. Mechanism of Burst Feeding in ZL205A Casting Under Mechanical Vibration and Low Pressure. Trans. Nonferrous Met. Soc. China 2018, 28, 1514–1520. [Google Scholar] [CrossRef]

| Cu | Mn | Ti | Zr | B | Cr | V | Al |

|---|---|---|---|---|---|---|---|

| 5.0 | 0.4 | 0.2 | 0.15 | 0.03 | 0.15 | 0.08 | Bal. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, W.; Wu, S.; Wang, R. Mechanical Wave Propagation in Solidifying Al-Cu-Mn-Ti Alloy and Its Effect on Solidification Feeding. Metals 2022, 12, 2001. https://doi.org/10.3390/met12122001

Chen W, Wu S, Wang R. Mechanical Wave Propagation in Solidifying Al-Cu-Mn-Ti Alloy and Its Effect on Solidification Feeding. Metals. 2022; 12(12):2001. https://doi.org/10.3390/met12122001

Chicago/Turabian StyleChen, Wei, Shiping Wu, and Rujia Wang. 2022. "Mechanical Wave Propagation in Solidifying Al-Cu-Mn-Ti Alloy and Its Effect on Solidification Feeding" Metals 12, no. 12: 2001. https://doi.org/10.3390/met12122001

APA StyleChen, W., Wu, S., & Wang, R. (2022). Mechanical Wave Propagation in Solidifying Al-Cu-Mn-Ti Alloy and Its Effect on Solidification Feeding. Metals, 12(12), 2001. https://doi.org/10.3390/met12122001