Experimental Investigation of Thrust Force in the Drilling of Titanium Alloy Using Different Machining Techniques

Abstract

1. Introduction

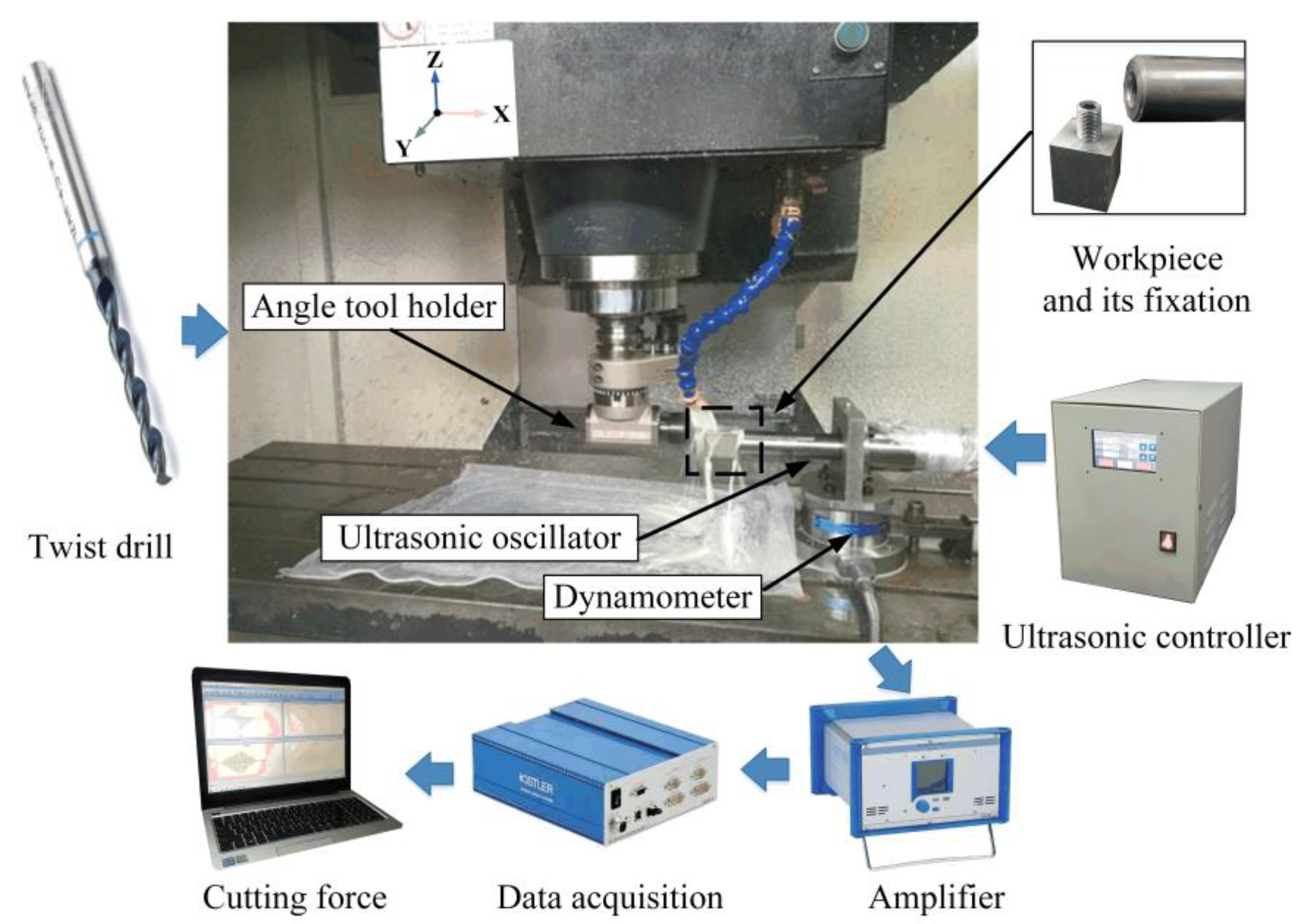

2. Materials and Methods

2.1. Experimental Methods and Materials

2.2. Test Parameters

3. Results and Discussion

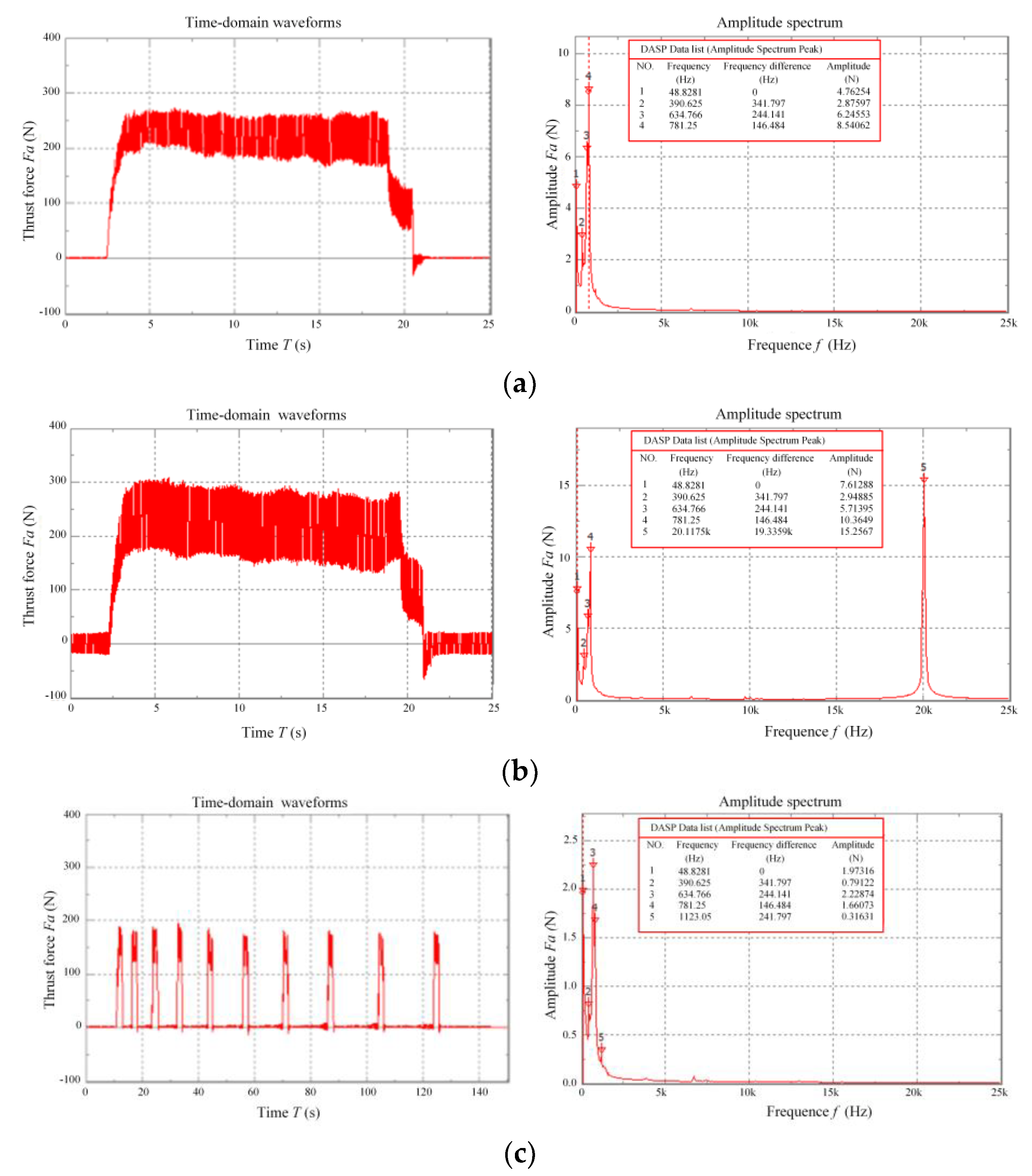

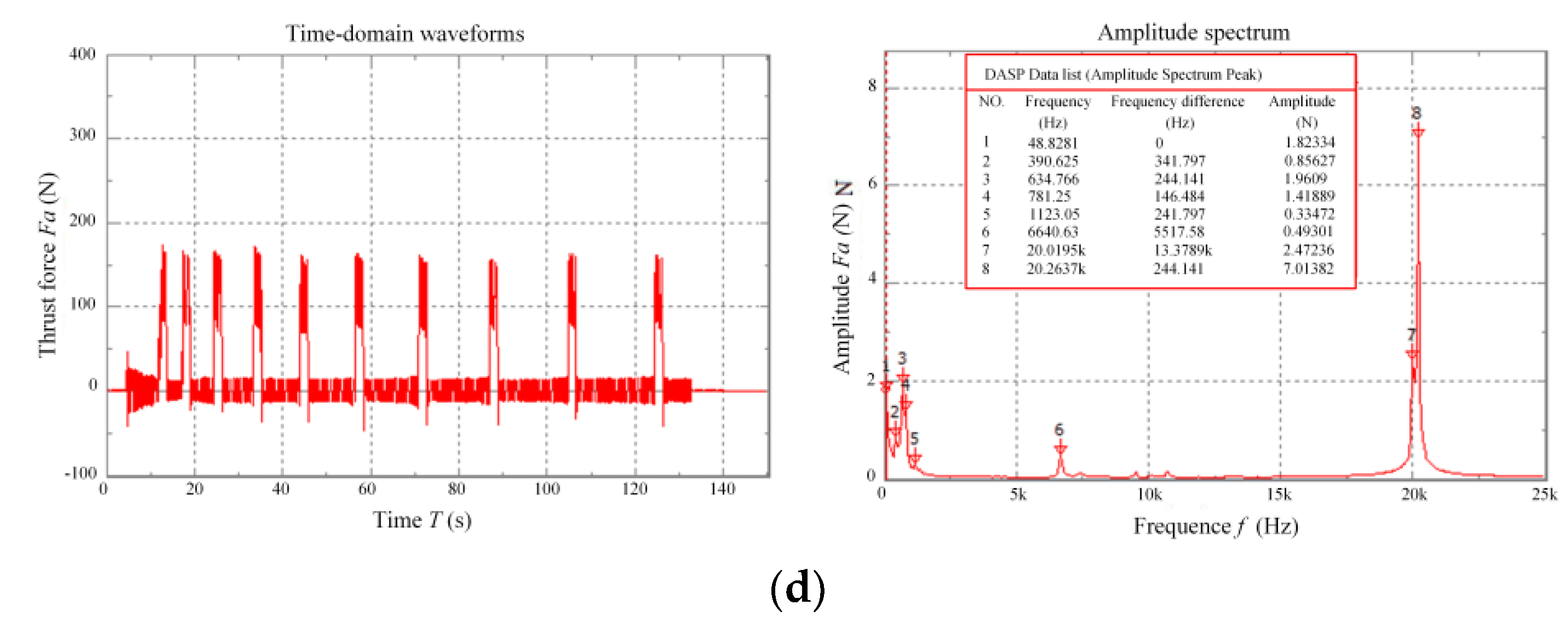

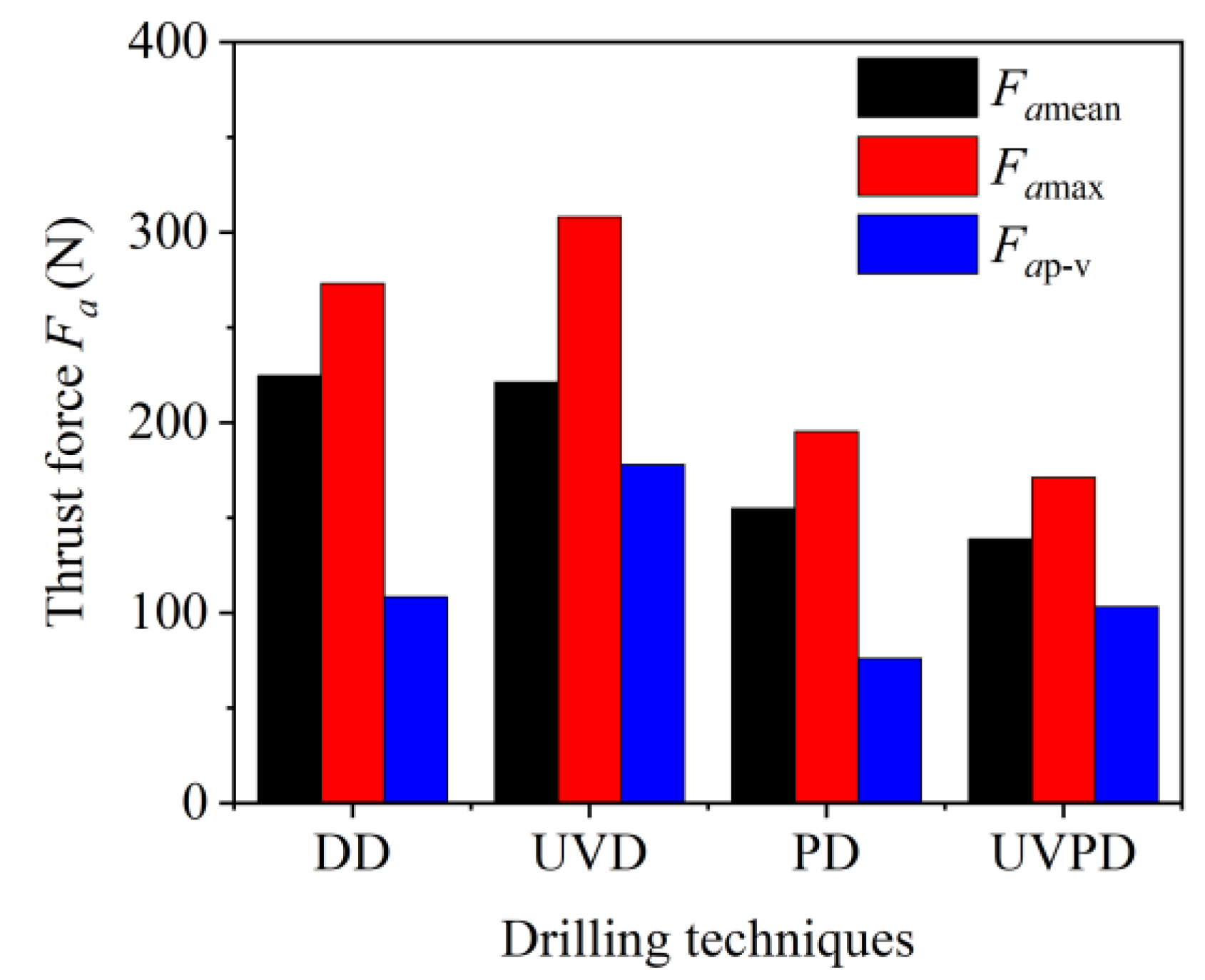

3.1. Comparison of Thrust Force under Different Drilling Techniques

3.1.1. Time-Domain Waveforms and Frequency Spectrum

3.1.2. Comparison of Characteristic Values of Thrust Force

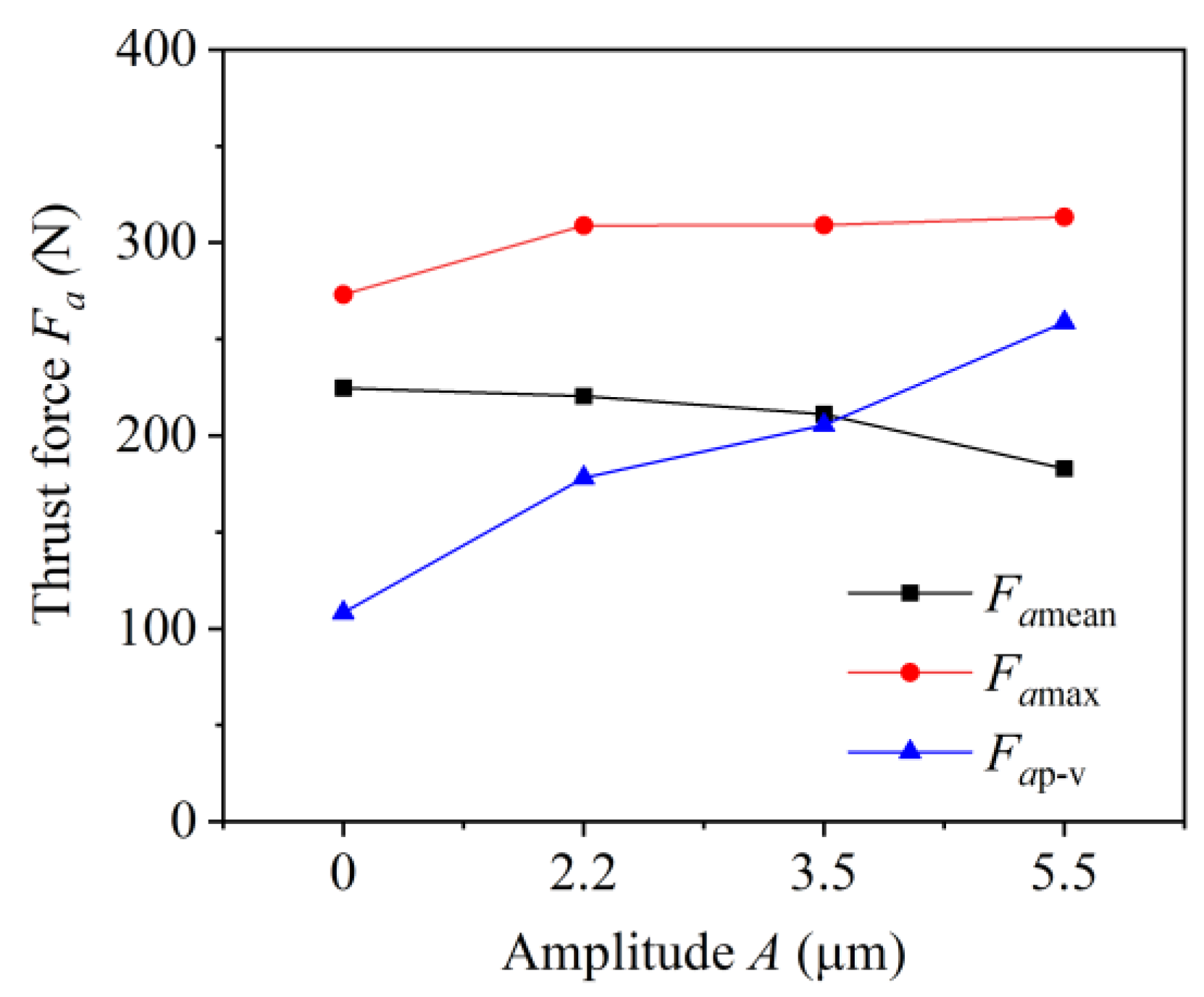

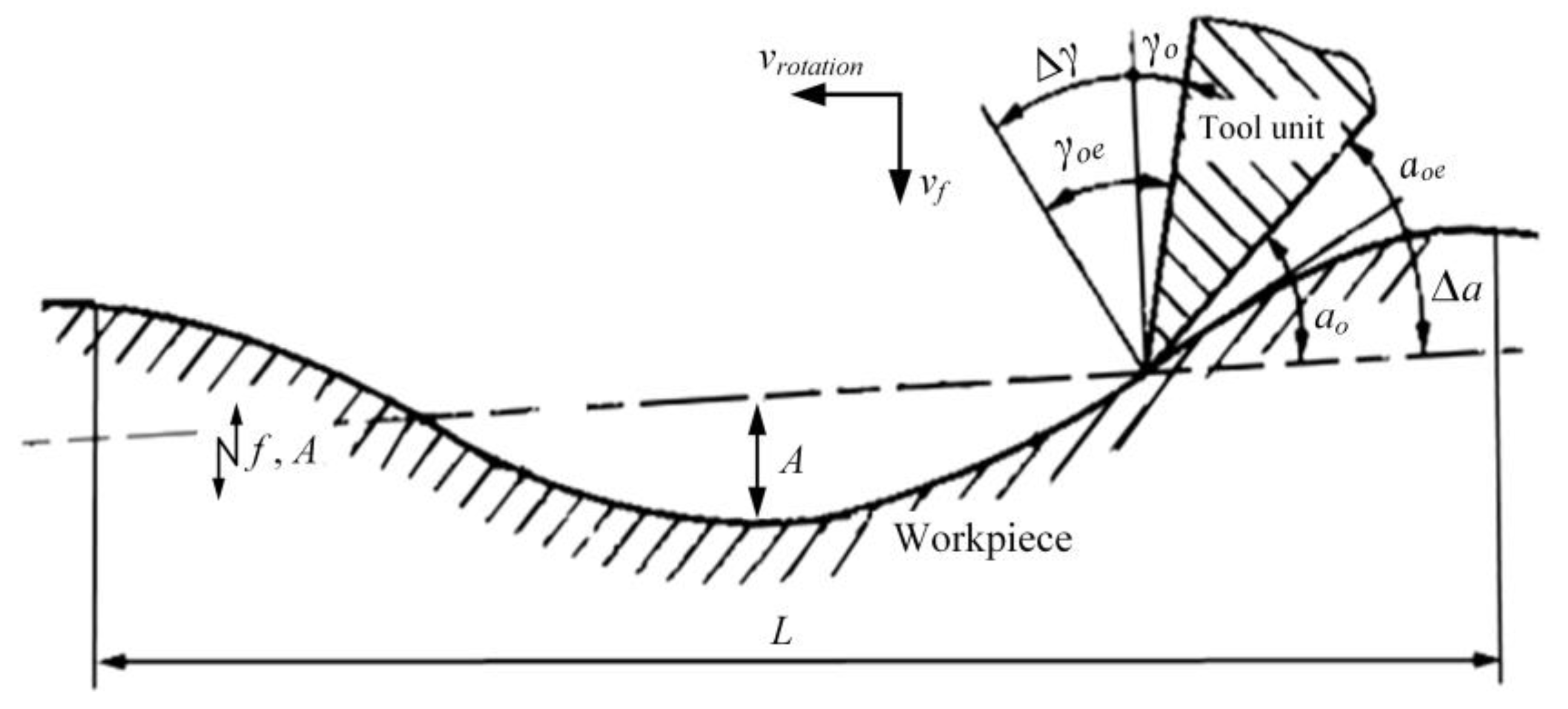

3.2. Effect of Vibration Amplitude on Thrust Force of UVD

3.2.1. Thrust Force at Various Amplitudes

3.2.2. Reasons for Thrust Force Changes in UVD

- (1)

- High-frequency impact effect of ultrasonic vibration

- (2)

- Variable velocity cutting characteristic of UVD

- (3)

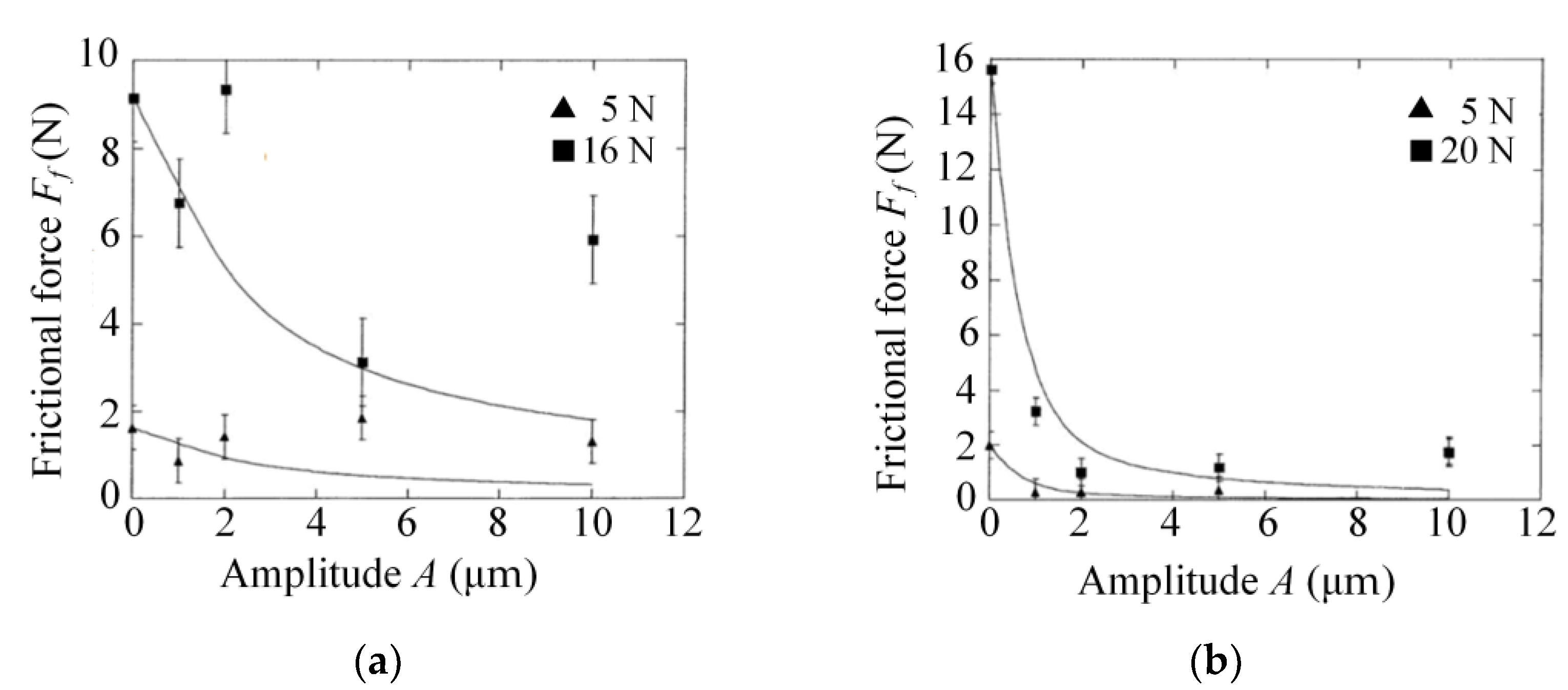

- Antifriction effect of UVD

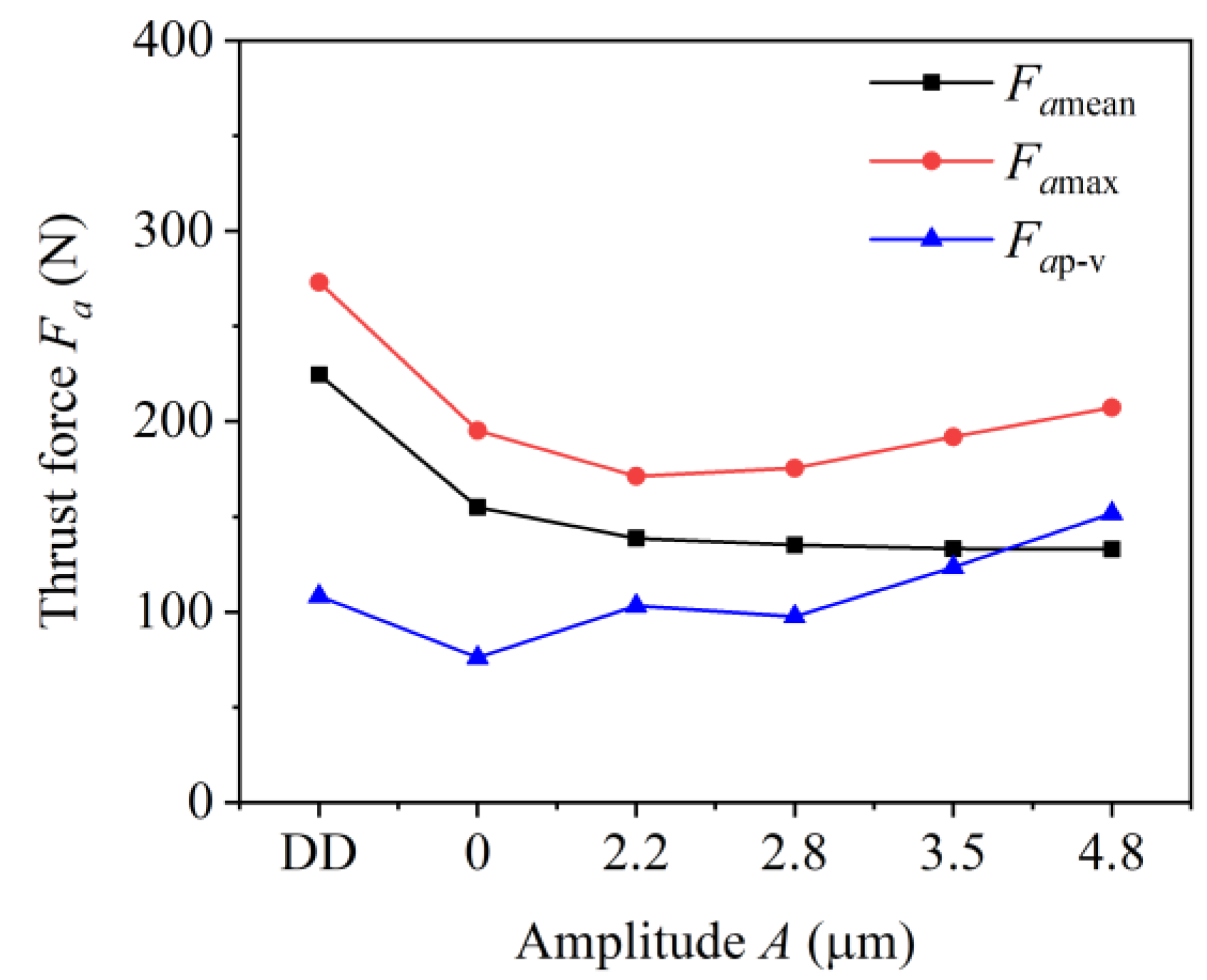

3.3. Effect of Vibration Amplitude on Thrust Force of UVPD

3.3.1. Thrust Force at Various Amplitudes

3.3.2. Reasons for Reducing Thrust Force by UVPD

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| DD | Direct drilling |

| PD | Peck drilling |

| VD | Vibration drilling |

| LFVD | Low-frequency vibration drilling |

| UVD | Ultrasonic vibration drilling |

| UVPD | Ultrasonic vibration peck drilling |

| CFRP | Carbon fiber-reinforced plastic |

| PCD | Polycrystalline diamond |

| n | Rotation speed of main spindle or drill bit |

| fr | Feed per revolution |

| vf | Feed rate |

| f | Frequency of ultrasonic vibration |

| A | Amplitude of ultrasonic vibration |

| Q | Pecking depth or one-step feed length |

| α | Instantaneous acceleration of ultrasonic vibration |

| vr | Synthetic cutting velocity of the unit tool edge with distance r from the drill axis during UVD |

| Fa | Thrust force of drilling |

| Famean | Mean thrust force |

| Famax | Maximum thrust force |

| Fap-v | Peak-to-valley value of thrust force |

References

- Batista Ponce, M.; Vazquez-Martinez, J.M.; Davim, J.P.; Salguero Gomez, J. Analysis of secondary adhesion wear mechanism on hard machining of titanium aerospace alloy. Materials 2019, 12, 2015. [Google Scholar] [CrossRef] [PubMed]

- Festas, A.; Ramos, A.; Davim, J.P. Machining of titanium alloys for medical application—A review. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2021, 236, 309–318. [Google Scholar] [CrossRef]

- Gaur, B.; Soman, D.; Ghyar, R.; Bhallamudi, R. Ti6Al4V scaffolds fabricated by laser powder bed fusion with hybrid volumetric energy density. Rapid Prototyp. J. 2022. ahead of print. [Google Scholar] [CrossRef]

- Wang, B.; Liu, Z.Q. Influences of tool structure, tool material and tool wear on machined surface integrity during turning and milling of titanium and nickel alloys: A review. Int. J. Adv. Manuf. Technol. 2018, 98, 1925–1975. [Google Scholar] [CrossRef]

- Gupta, K.; Laubscher, R.F. Sustainable machining of titanium alloys: A critical review. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 231, 2543–2560. [Google Scholar] [CrossRef]

- Agarwal, R.; Singh, R.P.; Gupta, V.; Singh, J. Influence of cutting force on temperature, microcracks and chip morphology during rotary ultrasonic bone drilling: An in-vitro study. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 301. [Google Scholar] [CrossRef]

- Mahdi, A.; Turki, Y.; Habak, M.; Salem, M.; Bouaziz, Z. Experimental study of thrust force and surface quality when drilling hybrid stacks. Int. J. Adv. Manuf. Technol. 2020, 107, 3981–3994. [Google Scholar] [CrossRef]

- Han, C.W.; Kim, K.B.; Lee, S.W.; Jun, M.B.-G.; Jeong, Y.H. Thrust force-based tool wear estimation using discrete wavelet transformation and artificial neural network in CFRP drilling. Int. J. Precis. Eng. Manuf. 2021, 22, 1527–1536. [Google Scholar] [CrossRef]

- Niketh, S.; Samuel, G.L. Surface textured drill tools—An effective approach for minimizing chip evacuation force and burr formation during high aspect ratio machining of titanium alloy. J. Manuf. Sci. Eng. 2021, 143, 041005. [Google Scholar] [CrossRef]

- Qi, Z.C.; Zhang, K.F.; Li, Y.; Liu, S.; Cheng, H. Critical thrust force predicting modeling for delamination-free drilling of metal-FRP stacks. Compos. Struct. 2014, 107, 604–609. [Google Scholar] [CrossRef]

- Liu, L.P.; Qi, C.L.; Wu, F.; Xu, J.; Zhu, X. Experimental thrust forces and delamination analysis of GFRP laminates using candlestick drills. Mater. Manuf. Processes 2017, 33, 695–708. [Google Scholar] [CrossRef]

- Kim, D.; Ramulu, M. Study on the drilling of titanium graphite hybrid composites. J. Eng. Mater. Technol. 2005, 100, 99–106. [Google Scholar] [CrossRef]

- Li, R.; Hegde, P.; Shih, A.J. High-throughput drilling of titanium alloys. Int. J. Mach. Tools Manuf. 2007, 47, 63–74. [Google Scholar] [CrossRef]

- Wei, Y.Y.; An, Q.L.; Ming, W.W.; Chen, M. Effect of drilling parameters and tool geometry on drilling performance in drilling carbon fiber–reinforced plastic/titanium alloy stacks. Adv. Mech. Eng. 2016, 8. [Google Scholar] [CrossRef]

- Park, K.-H.; Beal, A.; Kim, D.; Kwon, P.; Lantrip, J. Tool wear in drilling of composite/titanium stacks using carbide and polycrystalline diamond tools. Wear 2011, 271, 2826–2835. [Google Scholar] [CrossRef]

- Eltaggaz, A.; Deiab, I. Comparison of between direct and peck drilling for large aspect ratio in Ti-6Al-4V alloy. Int. J. Adv. Manuf. Technol. 2019, 102, 2797–2805. [Google Scholar] [CrossRef]

- Kuo, C.L.; Soo, S.L.; Aspinwall, D.K.; Thomas, W.; Carr, C.; Pearson, D.; M’Saoubi, R.; Leahy, W. Performance of multi-margin coated tools in one-shot drilling of metallic-composite stack materials under varying feed rate and pecking conditions. In Proceedings of the 38th International MATADOR Conference, Huwei, Taiwan, 28–31 March 2022; pp. 295–312. [Google Scholar]

- Jiménez, A.; Arizmendi, M.; Sánchez, J.M. Extraction of tool wear indicators in peck-drilling of Inconel 718. Int. J. Adv. Manuf. Technol. 2021, 114, 2711–2720. [Google Scholar] [CrossRef]

- Patra, K.; Jha, A.K.; Szalay, T.; Ranjan, J.; Monostori, L. Artificial neural network based tool condition monitoring in micro mechanical peck drilling using thrust force signals. Precis. Eng. 2017, 48, 279–291. [Google Scholar] [CrossRef]

- Kim, D.W.; Lee, Y.S.; Park, M.S.; Chu, C.N. Tool life improvement by peck drilling and thrust force monitoring during deep-micro-hole drilling of steel. Int. J. Mach. Tools Manuf. 2009, 49, 246–255. [Google Scholar] [CrossRef]

- Okamura, K.; Sasahara, H.; Segawa, T.; Tsutsumi, M. Low-frequency vibration drilling of titanium alloy. JSME Int. J. Ser. C 2006, 49, 76–82. [Google Scholar] [CrossRef]

- Li, S.M.; Zhang, D.Y.; Liu, C.J.; Shao, Z.Y.; Ren, L.L. Influence of dynamic angles and cutting strain on chip morphology and cutting forces during titanium alloy Ti-6Al-4 V vibration-assisted drilling. J. Mater. Processing Technol. 2021, 288, 116898. [Google Scholar] [CrossRef]

- Churi, N.J.; Pei, Z.J.; Treadwell, C. Rotary ultrasonic machining of titanium alloy (Ti-6Al-4V) effects of tool variables. Int. J. Precis. Technol. 2007, 1, 85–96. [Google Scholar] [CrossRef]

- Churi, N.J.; Pei, Z.J.; Treadwell, C. Rotary Ultrasonic Machining of Titanium Alloy: Effects of Machining Variables. Mach. Sci. Technol. 2007, 10, 301–321. [Google Scholar] [CrossRef]

- Gao, G.F.; Yuan, Z.J.; Xia, Z.W.; Fu, Z.X.; Xiang, D.H.; Zhao, B. Study on thrust force of ultrasonic-assisted vibration micro-hole drilling of titanium alloy. Int. J. Adv. Manuf. Technol. 2021, 112, 3399–3413. [Google Scholar] [CrossRef]

- Hsu, I.; Tsao, C.C. Study on the effect of frequency tracing in ultrasonic-assisted drilling of titanium alloy. Int. J. Adv. Manuf. Technol. 2008, 43, 127–135. [Google Scholar] [CrossRef]

- Jain, A.K.; Pandey, P.M. Study of Peck drilling of borosilicate glass with μRUM process for MEMS. J. Manuf. Processes 2016, 22, 134–150. [Google Scholar] [CrossRef]

- Isobe, H.; Uehara, Y.; Okada, M.; Horiuchi, T.; Hara, K. Visualization of Stress Distribution on Ultrasonic Vibration Aided Drilling Process. J. Adv. Mech. Des. Syst. Manuf. 2012, 6, 771–780. [Google Scholar] [CrossRef][Green Version]

- Jeon, S.; Thundat, T.; Braiman, Y. Effect of normal vibration on friction in the atomic force microscopy experiment. Appl. Phys. Lett. 2006, 88. [Google Scholar] [CrossRef]

- Kumar, V.C.; Hutchings, I.M. Reduction of the sliding friction of metals by the application of longitudinal or transverse ultrasonic vibration. Tribol. Int. 2004, 37, 833–840. [Google Scholar] [CrossRef]

- Ying, S.S.; Zhang, S.Q.; Lin, L.G.; Wang, Y.; Schmidt, R. Experimental investigation on reduction of broaching forces by active external vibrations. Mach. Sci. Technol. 2021, 25, 438–454. [Google Scholar] [CrossRef]

- Yang, H.J.; Chen, Y.; Xu, J.H.; Ladonne, M.; Lonfier, J.; Ding, W. Chip control analysis in low-frequency vibration-assisted drilling of Ti–6Al–4V titanium alloys. Int. J. Precis. Eng. Manuf. 2019, 21, 565–584. [Google Scholar] [CrossRef]

- Ge, J.; Reji, R.; Feist, T.; Elmore, A.; McClelland, J.; Higgins, C.; McLaughlin, B.; Jin, Y.; Sun, D. Investigating hole making performance of Al 2024-T3/Ti-6Al-4V alloy stacks: A comparative study of conventional drilling, peck drilling and helical milling. Int. J. Adv. Manuf. Technol. 2022, 120, 5027–5040. [Google Scholar] [CrossRef]

- Bleicher, F.; Reiter, M.; Brier, J. Increase of chip removal rate in single-lip deep hole drilling at small diameters by low-frequency vibration support. CIRP Annals 2019, 68, 93–96. [Google Scholar] [CrossRef]

| Properties | Values |

|---|---|

| Tensile strength σb (MPa) | ≥895 |

| Residual tensile stress σr0.2 (MPa) | ≥825 |

| Elongation δ5 (%) | ≥10 |

| Cross-sectional shrinkage Ψ (%) | ≥10 |

| Density β (N/m2) | 4.4 × 103 |

| Thermal conductivity K (W/m·K) | 7.955 |

| Elastic modulus E (GPa) | 110 |

| Parameter | DD | PD | UVD | UVPD |

|---|---|---|---|---|

| Rotation speed n (r/min) | 1200 | |||

| Feed per revolution fr (mm/r) | 0.01, 0.03 | |||

| Feed rate vf (mm/min) | 12, 36 | |||

| Vibration frequency f (KHz) | / | / | 20 | |

| Amplitude A (μm) | 0, 2.2, 2.8, 3.5, 4.8, 5.5 | |||

| Pecking depth Q (mm) | 1 | 1 | ||

| Amplitude A (μm) | 0 | 2.2 | 2.8 |

|---|---|---|---|

| UVD (Q = 0) |  |  |  |

| UVPD (Q = 1 mm) |  |  |  |

| UVPD (Q = 1.5 mm) |  |  |  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, L.; Ma, Z.; Yu, H.; Li, S.; Pang, M.; Wang, Z. Experimental Investigation of Thrust Force in the Drilling of Titanium Alloy Using Different Machining Techniques. Metals 2022, 12, 1905. https://doi.org/10.3390/met12111905

Ma L, Ma Z, Yu H, Li S, Pang M, Wang Z. Experimental Investigation of Thrust Force in the Drilling of Titanium Alloy Using Different Machining Techniques. Metals. 2022; 12(11):1905. https://doi.org/10.3390/met12111905

Chicago/Turabian StyleMa, Lijie, Zunyan Ma, Hui Yu, Shenwang Li, Minghua Pang, and Zhankui Wang. 2022. "Experimental Investigation of Thrust Force in the Drilling of Titanium Alloy Using Different Machining Techniques" Metals 12, no. 11: 1905. https://doi.org/10.3390/met12111905

APA StyleMa, L., Ma, Z., Yu, H., Li, S., Pang, M., & Wang, Z. (2022). Experimental Investigation of Thrust Force in the Drilling of Titanium Alloy Using Different Machining Techniques. Metals, 12(11), 1905. https://doi.org/10.3390/met12111905