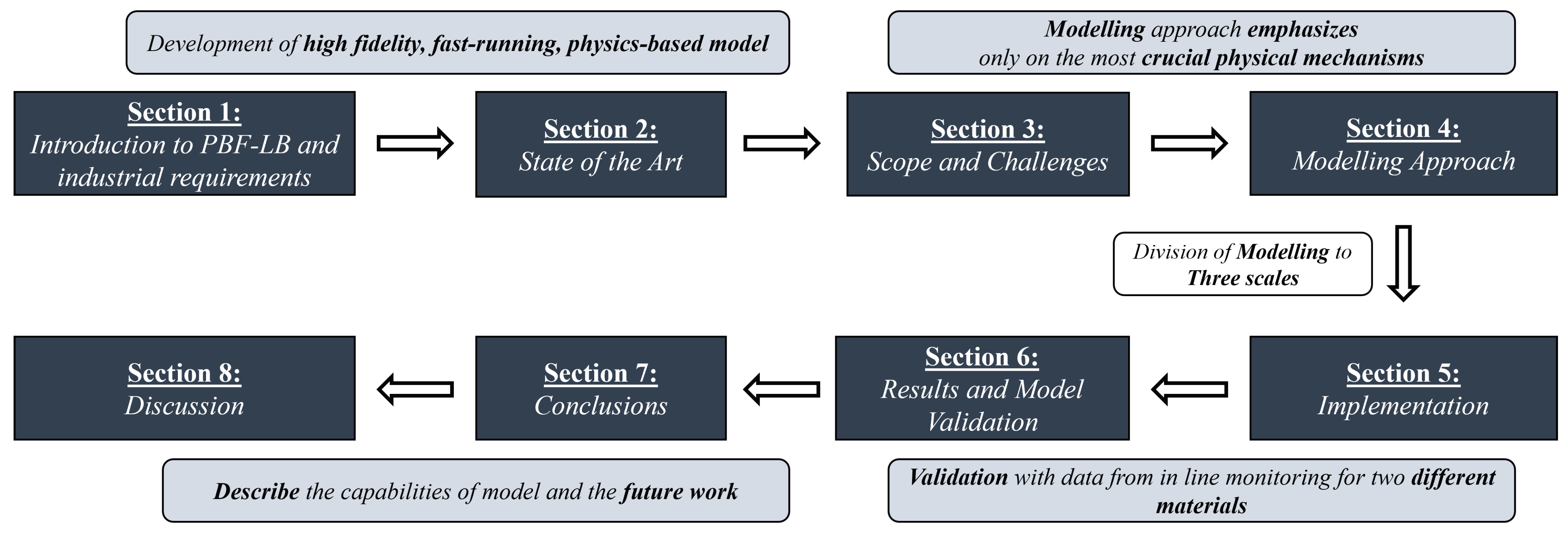

A Computationally Efficient Multi-Scale Thermal Modelling Approach for PBF-LB/M Based on the Enthalpy Method

Abstract

1. Introduction

2. State of the Art

3. Scope and Challenges

3.1. Scope

3.2. Challenges

3.2.1. Challenges Present in All Laser Processes

3.2.2. Particular Challenges in Additive Manufacturing Processes

- Due to the voids between the powder particles that are formed as the powder is packed on the powder bed, the average thermal conductivity of the powder is much smaller than the thermal conductivity of the raw solid phase of the same material. The difference may be as high as a factor of 10, 20, or even 100 [36,37], directly implying that the differentiation between the properties of the metal and the metal powder is a phenomenon that cannot be neglected.

- The same voids significantly alter the average mass density of the powder. It may differ from 30% to 70% to that of the solid material [38]. This is also a fact that cannot be neglected. The differentiation of the mass density generates a dynamical problem in the simulation algorithm; when powder melts, the density of the material changes drastically. This implies that it is difficult to define lattice elements of constant dimensions, which would significantly simplify simulation.

- The roughness of the surface of the powder is completely different from that of the solid material, due to the fine structure of the powder particles. This may induce an increase in the mean absorptivity of the surface up to 100% in comparison to the absorptivity of the raw metal [39].

- The powder phase is simulated by a randomly generated distribution of powder particles, following the distribution given by the powder manufacturer. This approach has the disadvantage that the precision of the lattice simulating the powder phase should be high enough to capture the fine details of the powder. Such an approach is completely impossible for the fast simulation of the whole workpiece, since it requires an enormous number of data.

- The powder phase is simulated by an effective material with the mean properties of the powder. This approach has the disadvantage that the mean properties of the powder, as well as their dependence on the temperature, are not usually given by the powder manufacturer. As a result, these properties have to be either calculated by a sophisticated model, or experimentally measured, or both.

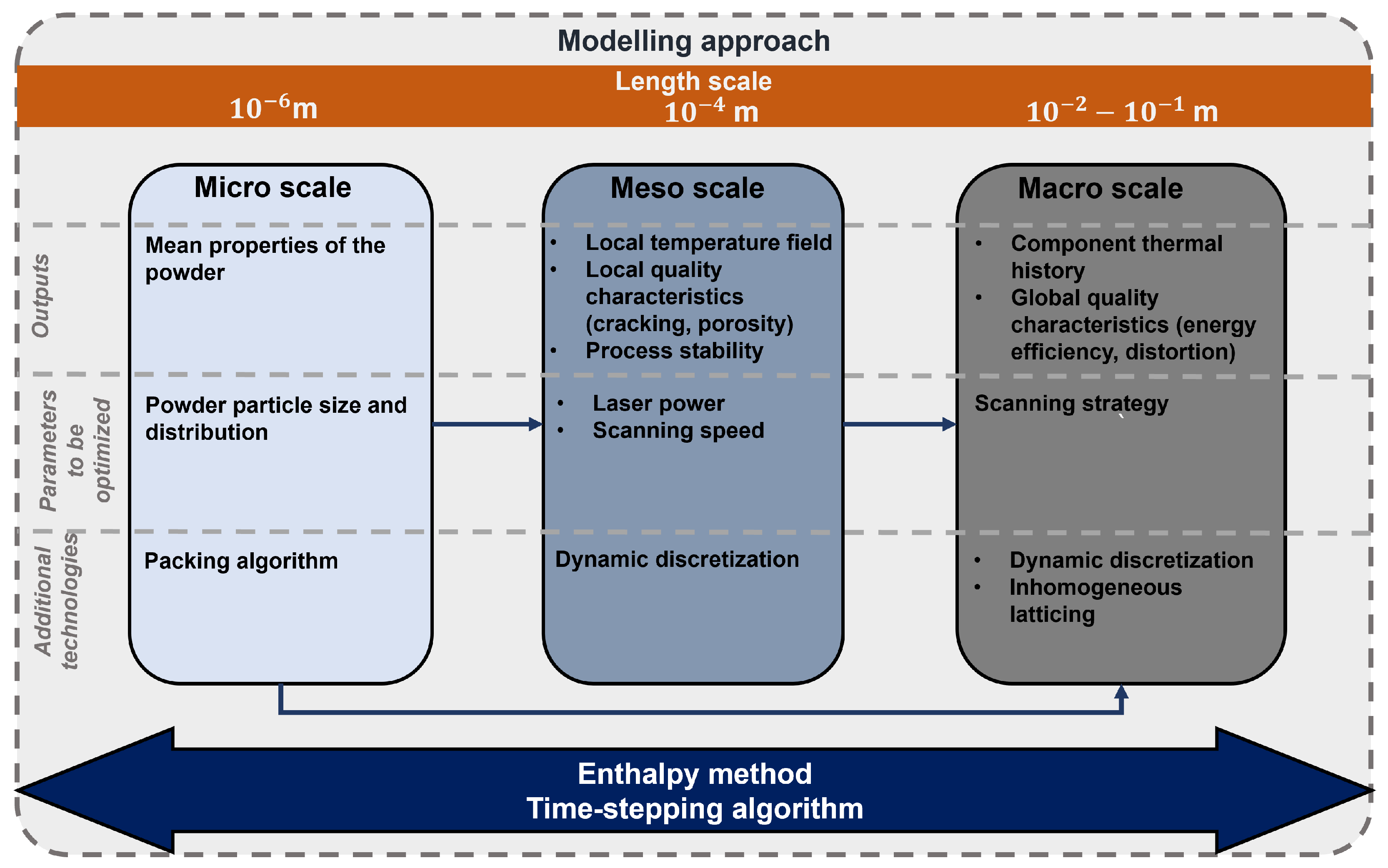

- There is a micro-scale, which is defined by the dimensions of the powder particles, namely dimensions of order m. The physics at this scale determines the mean behaviour of the powder, e.g., heat conduction within the powder phase of the material. It has to be noted that the latter is strongly related not only to the dimensions of the powder particles themselves, but also to the dimensions of the contact regions between the particles, which are actually one order of magnitude smaller ( m) [40]. Therefore, a model able to accurately predict the mean properties of the powder should work at least at this resolution. Furthermore, this scale is also related to several quality issues of the final workpiece, e.g., porosity, due to imperfect melting of the powder phase, since this kind of porosity is directly inherited from the voids due to the powder particle distribution [38].

- There is an intermediate meso-scale, which is defined by the melt pool dimensions, which is strongly related to the laser spot size. This characteristic scale defines the local heat-conduction mechanisms. At this length scale, the temperature gradient raises the temperature from the environment’s temperature to the melting temperature. This is caused by the laser power source and the physical properties of the material and typically is of order m. The physics at this scale determine local quality issues, e.g., porosity, because of fluxes of material due to excess of energy influx [26,35].

- Finally, there is the workpiece macro-scale, typically of order – m. This is determined by the global geometry of the workpiece. Quality issues, such as residual stresses, are relevant to this scale [41].

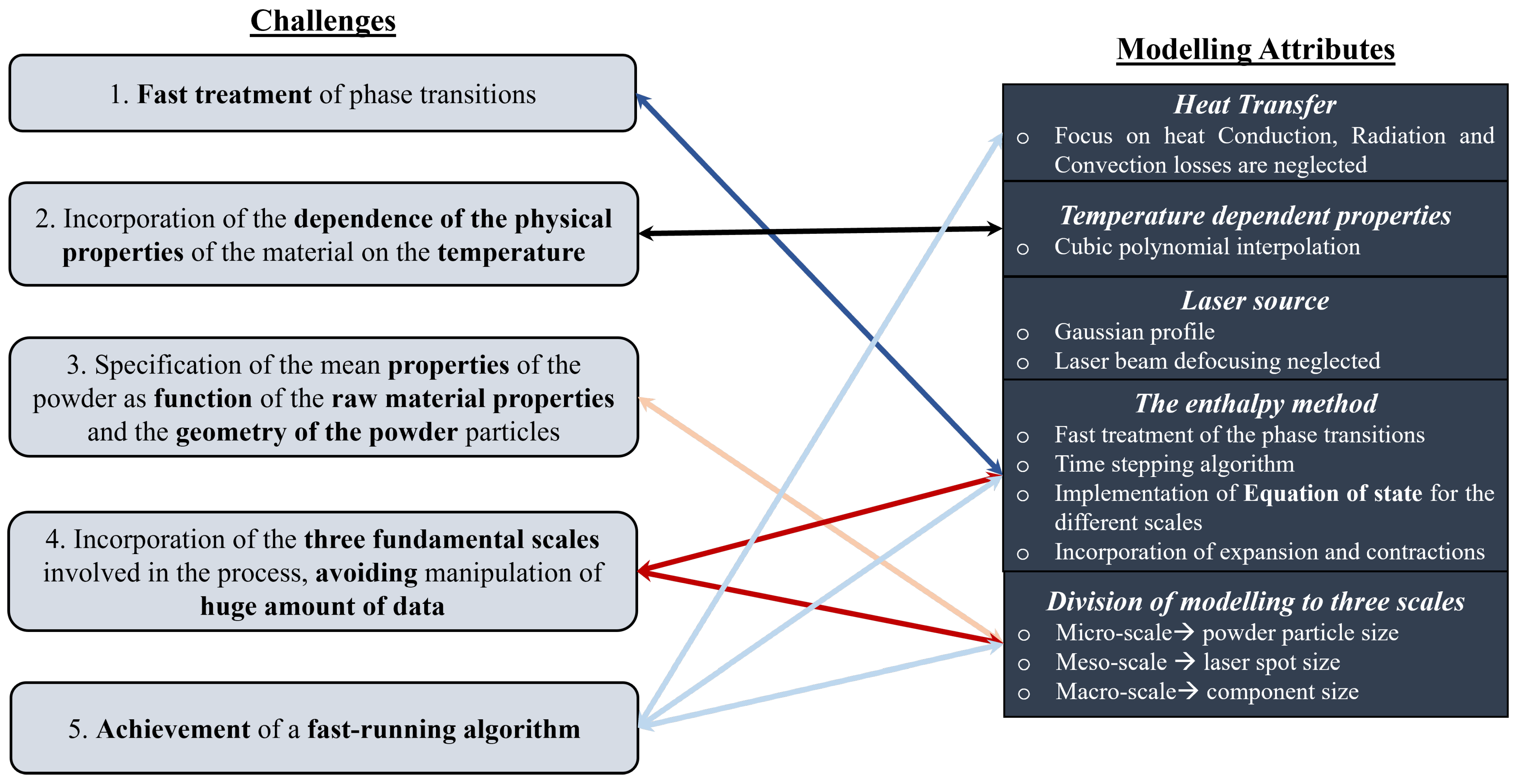

3.3. Summary of Challenges

- The fast treatment of phase transitions;

- The incorporation of the dependence of the physical properties of the material on the temperature;

- The specification of the mean thermophysical properties of the powder as a function of the properties of the raw material and the geometry of the powder particles;

- The incorporation of the three fundamental scales involved in the process without the need of manipulation of a huge number of data;

- The achievement of a fast-running algorithm.

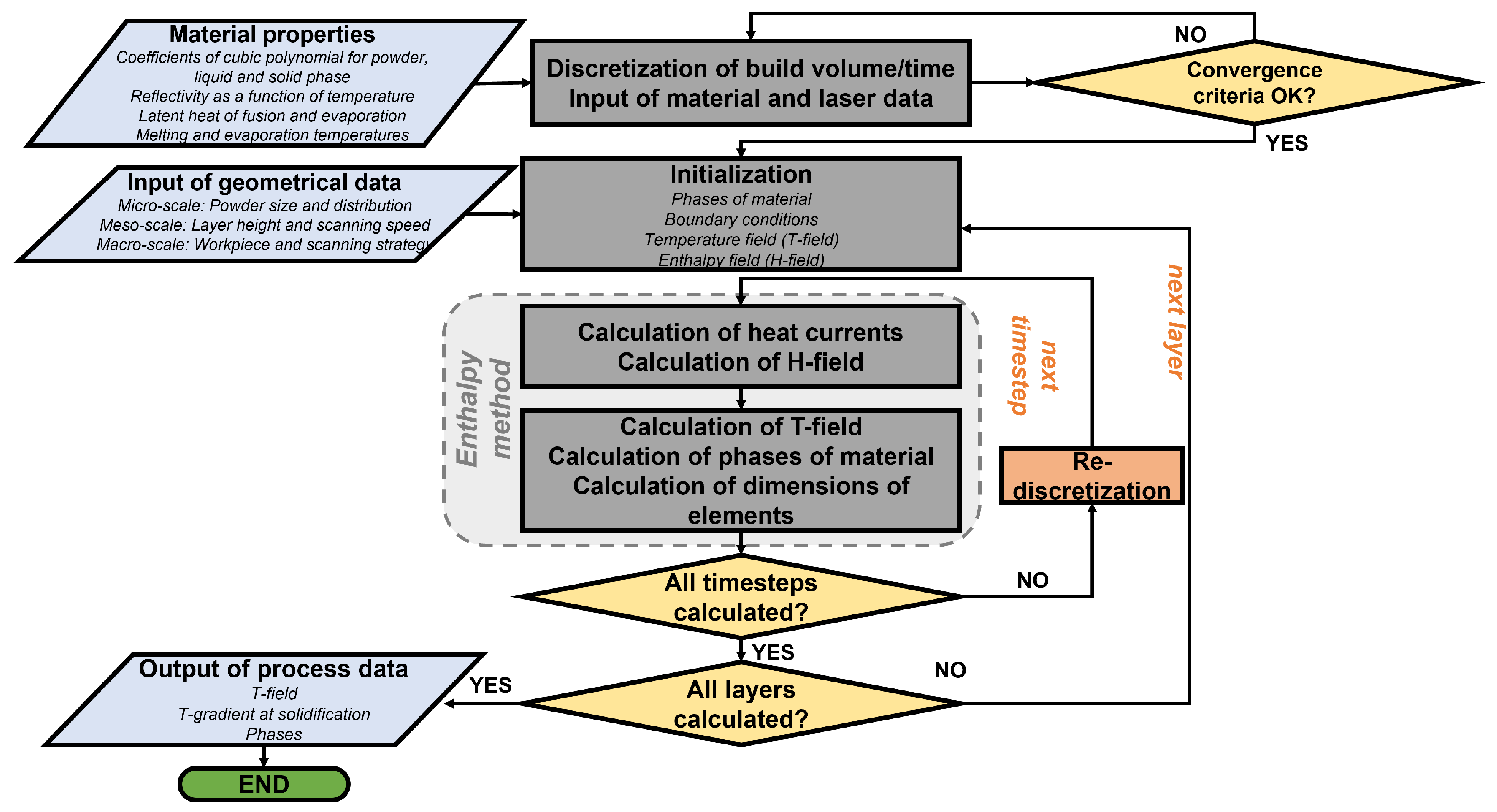

4. Modelling Approach

4.1. Heat Transfer

4.2. Modelling of the Material and Laser Source

4.2.1. Thermophysical Properties and Their Dependence on the Temperature

4.2.2. Laser Source

4.3. A Multi-Scale Enthalpy Method

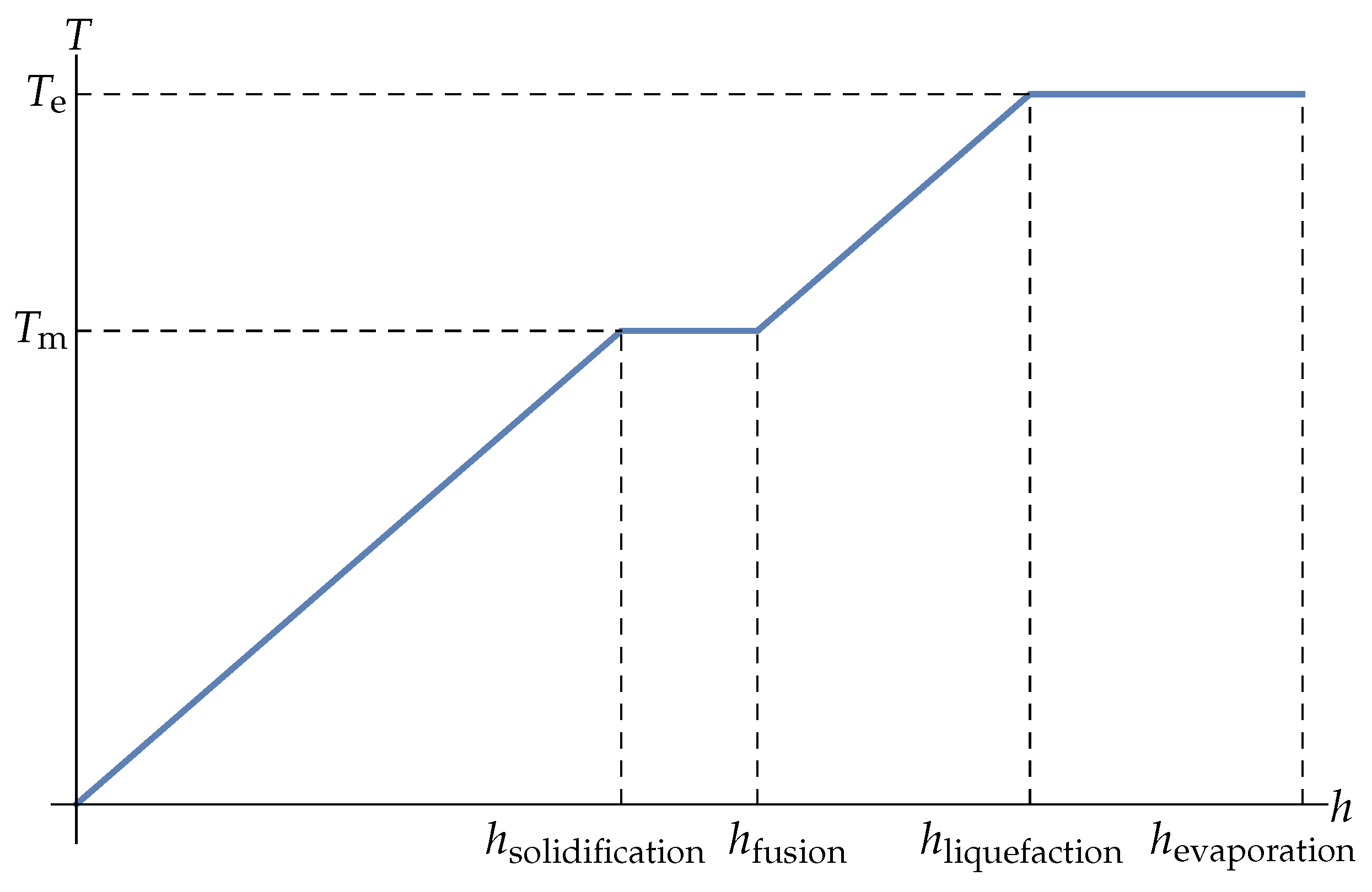

4.3.1. The Enthalpy Method

4.3.2. The Division of Modelling to Three Scales

4.3.3. The Equation of State

5. Implementation

5.1. Input Information and Data Structure

5.1.1. Simulation Lattice

- The maximum x-length XM

- the number of elements in the x-dimension Nx

- The maximum y-length YM

- the number of elements in the x-dimension Ny

- The maximum z-length ZM

- the number of elements in the x-dimension Nz

- The maximum time TM

- the number of time steps Nt

5.1.2. Data Structure

- A double precision three-dimensional array for the temperature, T(i,j,k), which takes values at each lattice cell;

- A double precision three-dimensional array for the enthalpy density, H(i,j,k), which takes values at each lattice cell;

- A boolean three-dimensional array, IsSolid(i,j,k), providing the information of whether a specific cell is in the solid state, which takes values at each lattice cell;

- A boolean three-dimensional array, IsPowder(i,j,k), providing the information of whether a specific cell is in the powder state, which takes values at each lattice cell;

- A boolean three-dimensional array, IsLiquid(i,j,k), providing the information of whether a specific cell is in the liquid state, which takes values at each lattice cell;

- A boolean three-dimensional array, IsEmpty(i,j,k), providing the information of whether a specific cell is in the gaseous state or it is empty, which takes values at each lattice cell;

- Three double precision three dimensional arrays dx(i,j,k), dy(i,j,k) and dz(i,j,k) for the dimensions of the lattice cells, in order to take into account the phenomenon of expansion and contraction;

- A double precision three-dimensional array for the mass of each cell, m(i,j,k);

- An integer two-dimensional array, Top(i,j), which takes values at each x and y position of the lattice, which indicates the first cell at the corresponding vertical column of the lattice which is not empty, and, thus, the cell which is directly hit by the laser beam.

5.1.3. Material Properties

- The density ;

- The specific heat ;

- The thermal conductivity k.

- The melting temperature ;

- The latent heat of fusion ;

- The evaporation temperature ;

- The latent heat of evaporation .

5.1.4. Laser Beam Properties

- The laser beam power P;

- The radius of the laser spot ;

- The orbit of the laser beam spot, i.e., the two functions of time and .

5.1.5. Material–Laser Interaction

- Reflectivity as function of the angle of incidence

5.1.6. The Initial State of the Workpiece

- The initial temperature and the initial specific enthalpy field;

- The initial distribution of phases in the system.

- The initial temperature for the first layer is simply a homogeneous temperature field equal to the environment temperature ;

- The initial temperature for the next layers can be simply the output of the previous layer and a cooling/powder reloading phase.

- In the case of meso and macro configurations, for the first layer, the initial configuration is rather trivial, as only a single, constant-depth layer of powder exists. For the next layers, the initial configuration is simply the outcome of the previous layer and a cooling/powder reloading phase.

- In the case of micro configurations, this kind of data can be quite complicated, since they should simulate the shape, distribution, and size of the powder particles. In these cases, though the initial configuration contains only two phases, the solid and the empty, unlike the macro configurations, where in general three phases may be present, the phases can be solid, powder, and empty.

5.2. Boundary Conditions

- Dirichlet conditions: The whole lattice box is considered to be in contact with an environment with a large heat capacity, which completely sets the temperature of the boundary.

- Neumann conditions: the whole lattice box is considered to be thermally isolated from its environment.

5.3. The Time-Stepping Algorithm

- Initiate a loop for time starting from t = 1;

- Initiate a loop for x from i = 1, initiate a loop for y from j = 1 and finally initiate a loop for z from k = Top(i,j), i.e., initiate each vertical column from its top element to its depths;

- Use Formula (6) to calculate the heat current from the left, right, front, back, top and bottom. For example, the incoming heat current from the left isand from the right isThe conductivity in the above example should be taken as the conductivity of the neighbouring lattice element, that is to say the conductivity referring to the phase of the neighbouring element at the temperature of this neighbouring element. For example, in the above formula for the left current, k should be considered the conductivity of the element (i − 1,j,k). This ensures that to heat current is going to be calculated when the neighbouring element is empty.Notice also that since the lattice elements may have different dimensions, the variable dx in the above formulae should be calculated as the average of the parameter dx for the two involved lattice cells.

- In an obvious manner the formula for the left current is problematic when i = 1. This specific left current is calculated via the boundary conditions. If Neumann conditions are applied, then this left current vanishes. If Dirichlet boundary conditions are applied, then it is considered that the element to the left lies at the environment temperature T0 and thereforeIn the more generic case of intermediate boundary conditions it holds thatSimilar care should be taken for the right current when i = XM, the front current when j = 1, the back current when j = YM and the bottom current when k = ZM.

- from the currents calculate the influx of energy from each direction. For example, the influx from the left will beNotice that since the lattice elements may have different dimensions, the variables dy and dz in the above formulae should be calculated as the average of the corresponding parameters for the two involved lattice cells.

- If k = Top(i,j) calculate the top influx from the laser power function reduced by the reflectivity factor

- Recalculate the enthalpy ingredient of the element (i,j,k), using the formula

- Advance z loop, advance y loop, advance x loop.

- Initiate a loop for x from i = 1, initiate a loop for y from j = 1 and finally initiate a loop for z from k = Top(i,j).

- If the enthalpy density is larger than the value HEvap, we should give to IsEmpty(i,j,k) the value True, and we should give to the rest of the Boolean variables at (i,j,k) the value False and add one to the Top(i,j).

- Else If the enthalpy density is larger than the value HFusion and IsPowder(i,j,k) is True, then, give the value False to IsPowder(i,j,k), the value True to IsLiquid(i,j,k).

- Else If the enthalpy density is larger than the value HFusion and IsSolid(i,j,k) is True, then, give the value False to IsSolid(i,j,k), the value True to IsLiquid(i,j,k).

- Else If the enthalpy density is smaller than the value HSolid and IsLiquid(i,j,k) is True, then, give the value False to IsLiquid(i,j,k), the value True to IsSolid(i,j,k).

- Recalculate the temperature of the element from its enthalpy density using the function TofH

- Recalculate the dimensions of the element using the function of the mass density.

- Advance z loop, advance y loop, advance x loop.

- Advance the time loop.

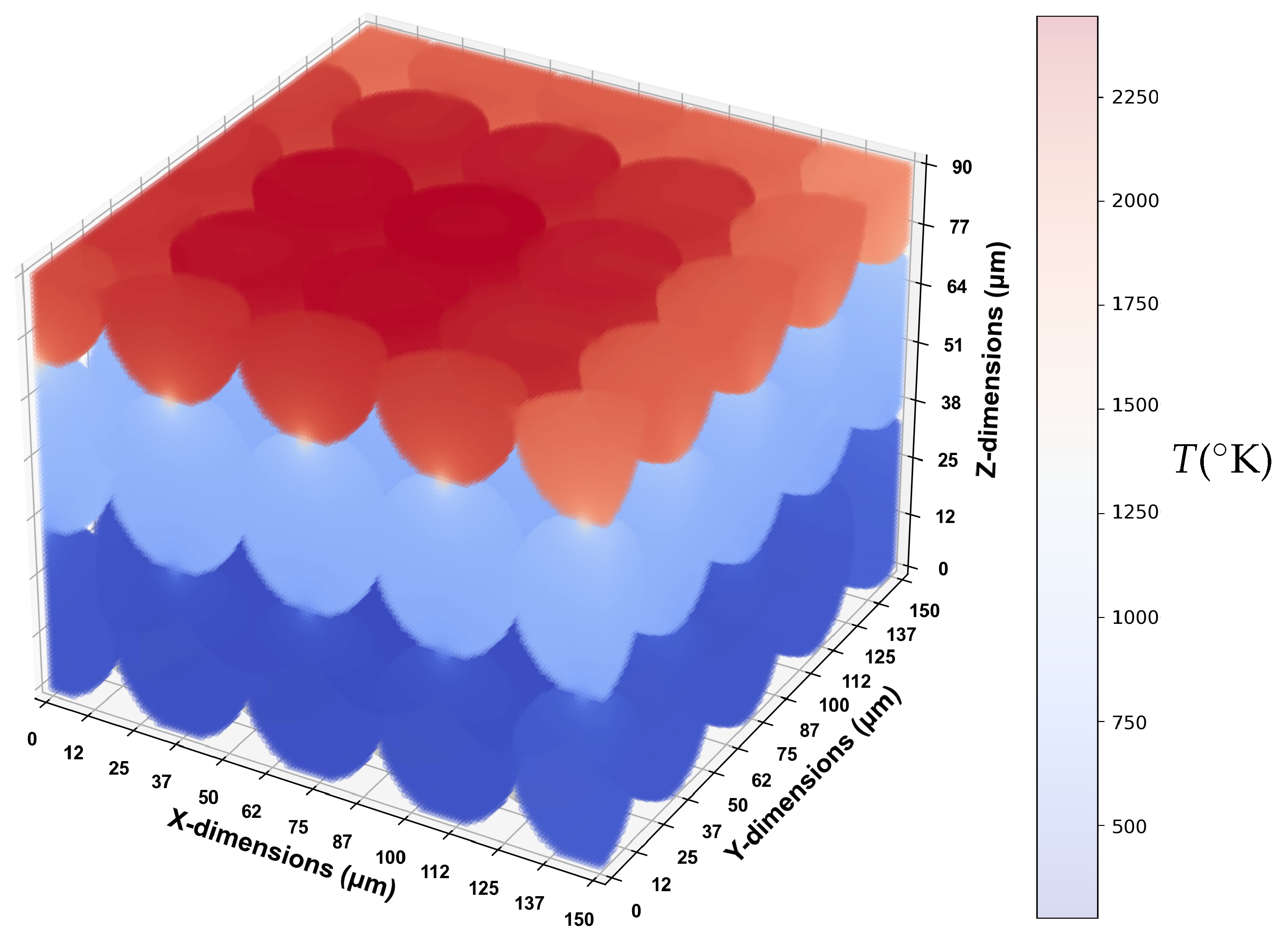

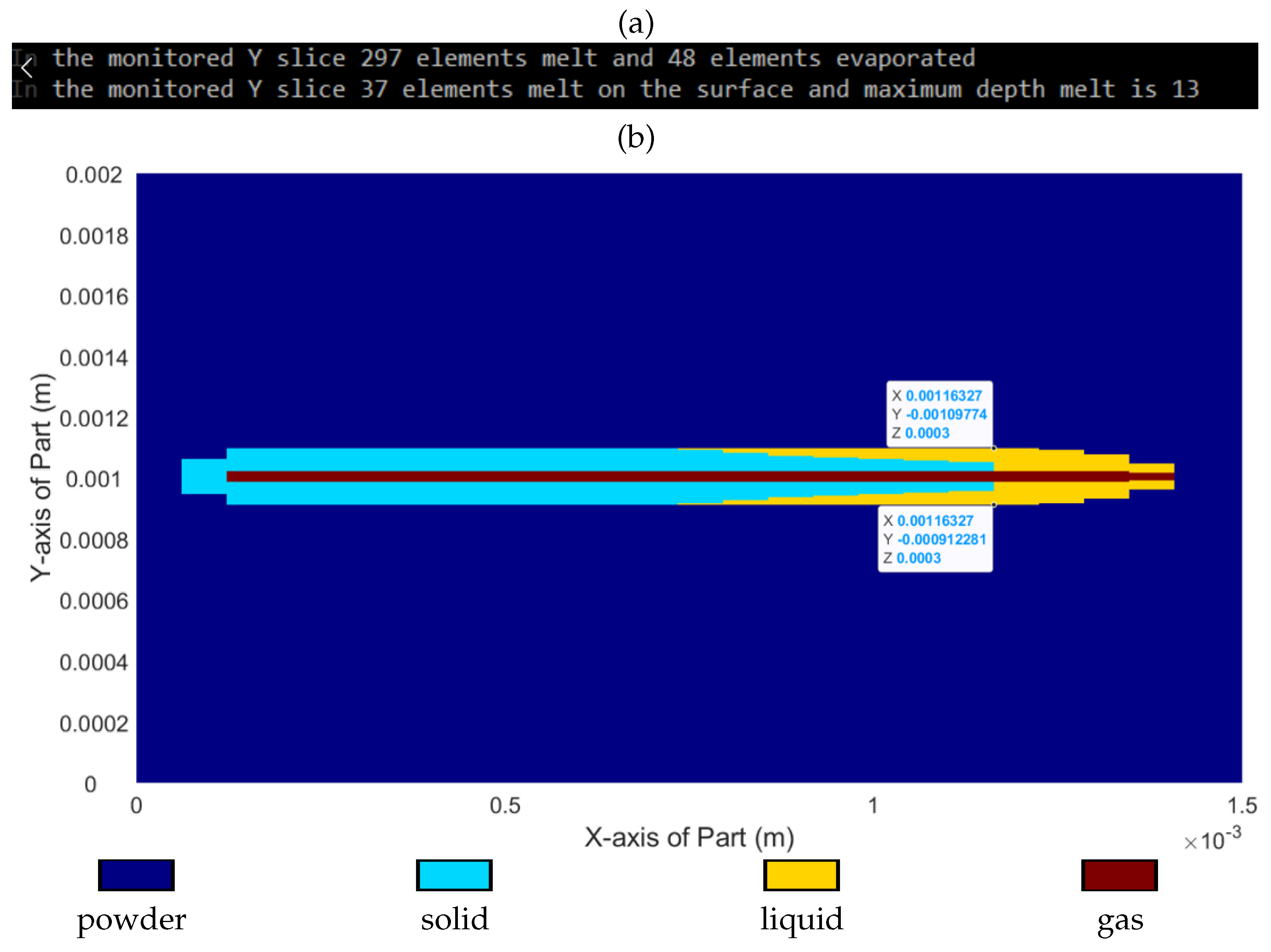

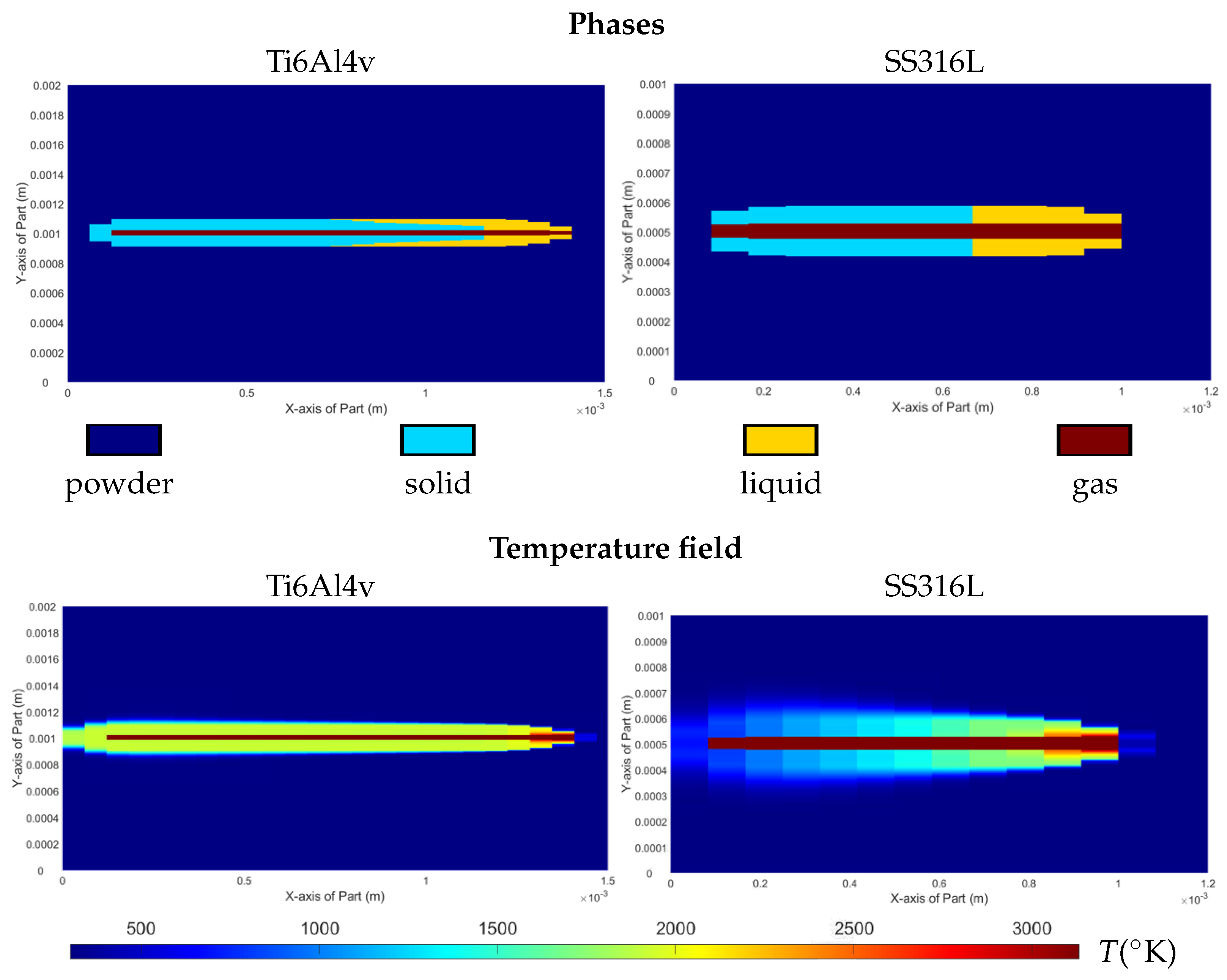

6. Model Validation and Results

7. Conclusions

8. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ISO/ASTM 52911-1; Additive Manufacturing—Design—Part 1: Laser-Based Powder Bed Fusion of Metals. International Organization for Standardization: Geneva, Switzerland, 2019.

- Stavropoulos, P.; Foteinopoulos, P. Modelling of additive manufacturing processes: A review and classification. Manuf. Rev. 2018, 5, 26. [Google Scholar] [CrossRef]

- AMPOWER Report 2022. Available online: https://additive-manufacturing-report.com/ (accessed on 2 August 2022).

- Schmidt, M.; Merklein, M.; Bourell, D.; Dimitrov, D.; Hausotte, T.; Wegener, K.; Overmeyer, L.; Vollertsen, F.; Levy, G.N. Laser based additive manufacturing in industry and academia. CIRP Ann. 2017, 66, 561–583. [Google Scholar] [CrossRef]

- HUBS. Additive Manufacturing Trend Report 2021. 2021. Available online: https://www.hubs.com/get/trends/ (accessed on 8 April 2022).

- Stavropoulos, P.; Papacharalampopoulos, A.; Michail, C.K.; Chryssolouris, G. Robust additive manufacturing performance through a control oriented digital twin. Metals 2021, 11, 708. [Google Scholar] [CrossRef]

- Sanaei, N.; Fatemi, A. Defects in additive manufactured metals and their effect on fatigue performance: A state-of-the-art review. Prog. Mater. Sci. 2021, 117, 100724. [Google Scholar] [CrossRef]

- Gunasegaram, D.R.; Murphy, A.B.; Barnard, A.; DebRoy, T.; Matthews, M.J.; Ladani, L.; Gu, D. Towards developing multiscale-multiphysics models and their surrogates for digital twins of metal additive manufacturing. Addit. Manuf. 2021, 46, 102089. [Google Scholar] [CrossRef]

- ElMaraghy, H.; Monostori, L.; Schuh, G.; ElMaraghy, W. Evolution and future of manufacturing systems. CIRP Ann. 2021, 70, 635–658. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Gerontas, C.; Bikas, H.; Souflas, T. Multi-Body dynamic simulation of a machining robot driven by CAM. Procedia CIRP 2022, 107, 764–769. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing; Springer: New York, NY, USA, 2015. [Google Scholar]

- Foteinopoulos, P.; Papacharalampopoulos, A.; Angelopoulos, K.; Stavropoulos, P. Development of a simulation approach for laser powder bed fusion based on scanning strategy selection. Int. J. Adv. Manuf. Technol. 2020, 108, 3085–3100. [Google Scholar] [CrossRef]

- Clare, A.; Gullane, A.; Hyde, C.; Murray, J.W.; Sankare, S.; Wits, W.W. Interlaced layer thicknesses within single laser powder bed fusion geometries. CIRP Ann. 2021, 70, 203–206. [Google Scholar] [CrossRef]

- Jackson, M.A.; Van Asten, A.; Morrow, J.D.; Min, S.; Pfefferkorn, F.E. A Comparison of Energy Consumption in Wire-based and Powder-based Additive-subtractive Manufacturing. Procedia Manuf. 2016, 5, 989–1005. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Foteinopoulos, P.; Papapacharalampopoulos, A. On the impact of additive manufacturing processes complexity on modelling. Appl. Sci. 2021, 11, 7743. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Panagiotopoulou, V.C. Developing a Framework for Using Molecular Dynamics in Additive Manufacturing Process Modelling. Modelling 2022, 3, 189–200. [Google Scholar] [CrossRef]

- Tan, J.H.; Wong, W.L.E.; Dalgarno, K.W. An overview of powder granulometry on feedstock and part performance in the selective laser melting process. Addit. Manuf. 2017, 18, 228–255. [Google Scholar] [CrossRef]

- Groarke, R.; Danilenkoff, C.; Karam, S.; McCarthy, E.; Michel, B.; Mussatto, A.; Sloane, J.; O’ Neill, A.; Raghavendra, R.; Brabazon, D. 316L Stainless Steel Powders for Additive Manufacturing: Relationships of Powder Rheology, Size, Size Distribution to Part Properties. Materials 2020, 13, 5537. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.; Zhang, Y.; Chen, J. Numerical simulation of random packing of spherical particles for powder-based additive manufacturing. J. Manuf. Sci. Eng. 2009, 131, 031004. [Google Scholar] [CrossRef]

- Meakin, P.; Jullien, R. Restructuring effects in the rain model for random deposition. J. Phys. Fr. 1987, 48, 1651–1662. [Google Scholar] [CrossRef]

- Parteli, E.J.; Poschel, T. Particle-based simulation of powder application in additive manufacturing. Powder Technol. 2016, 288, 96–102. [Google Scholar] [CrossRef]

- Xiang, Z.; Yin, M.; Deng, Z.; Mei, X.; Yin, G. Simulation of Forming Process of Powder Bed for Additive Manufacturing. J. Manuf. Sci. Eng. 2016, 138, 081002. [Google Scholar] [CrossRef]

- Dou, X.; Mao, Y.; Zhang, Y. Effects of Contact Force Model and Size Distribution on Microsized Granular Packing. J. Manuf. Sci. Eng. 2014, 136, 021003. [Google Scholar] [CrossRef]

- Roberts, I.A.; Wang, C.J.; Esterlein, R.; Standford, M.; Mynors, D.J. A three-dimensional finite element analysis of the temperature field during laser melting of metal powders in additive layer manufacturing. Int. J. Mach. Tools Manuf. 2009, 49, 916–923. [Google Scholar] [CrossRef]

- Foteinopoulos, P.; Papacharalampopoulos, A.; Stavropoulos, P. On thermal modeling of Additive Manufacturing processes. CIRP J. Manuf. Sci. Technol. 2018, 20, 66–83. [Google Scholar] [CrossRef]

- Bayat, M.; Thanki, A.; Mohanty, S.; Witvrouw, A.; Yang, S.; Thorborg, J.; Tiedje, N.S.; Hattel, J.H. Keyhole-induced porosities in Laser-based Powder Bed Fusion (L-PBF) of Ti6Al4V: High-fidelity modelling and experimental validation. Addit. Manuf. 2019, 30, 100835. [Google Scholar] [CrossRef]

- Panwisawas, C.; Qiu, C.; Anderson, M.J.; Sovani, Y.; Turner, R.P.; Atallah, M.M.; Brooks, J.W.; Basoalto, H.C. Mesoscale modelling of selective laser melting: Thermal fluid dynamics and microstructural evolution. Comput. Mater. Sci. 2017, 126, 479–490. [Google Scholar] [CrossRef]

- Luo, Z.; Zhao, Y. A survey of finite element analysis of temperature and thermal stress fields in powder bed fusion additive manufacture. Addit. Manuf. 2018, 21, 318–332. [Google Scholar] [CrossRef]

- Bourell, D.; Kruth, J.P.; Leu, M.; Levy, G.; Rosen, D.; Beese, A.M.; Clare, A. Materials for additive manufacturing. CIRP Ann. 2017, 66, 659–681. [Google Scholar] [CrossRef]

- Li, C.; Guo, Y.; Fang, X.; Fang, F. A scalable predictive model and validation for residual stress and distortion in selective laser melting. CIRP Ann. 2018, 67, 249–252. [Google Scholar] [CrossRef]

- Yang, Y.; Knol, M.; Van Keulen, F.; Ayas, C. A semi-analytical thermal modelling approach for selective laser melting. Addit. Manuf. 2018, 21, 284–297. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Foteinopoulos, P.; Papacharalampopoulos, A.; Tsoukantas, G. Warping in SLM additive manufacturing processes: Estimation through thermo-mechanical analysis. Int. J. Adv. Manuf. Technol. 2019, 104, 1571–1580. [Google Scholar] [CrossRef]

- Bompos, D.; Chaves-Jacob, J.; Sprauel, J.M. Shape distortion prediction in complex 3D parts induced during the selective laser melting process. CIRP Ann. 2020, 69, 517–520. [Google Scholar] [CrossRef]

- Voller, V.R.; Cross, M. Accurate solutions of moving boundary problems using the enthalpy method. Int. J. Heat Mass Transf. 1981, 24, 545–556. [Google Scholar] [CrossRef]

- Coen, V.; Goossens, L.; van Hooreweder, B. Methodology and experimental validation of analytical melt pool models for laser powder bed fusion. J. Mater. Process. Technol. 2022, 304, 117547. [Google Scholar] [CrossRef]

- Yang, H.; Li, Z.; Wang, S. The Analytical Prediction of Thermal Distribution and Defect Generation of Inconel 718 by Selective Laser Melting. Appl. Sci. 2020, 10, 7300. [Google Scholar] [CrossRef]

- Cheng, B.; Lane, B.; Whiting, J.; Chou, K. A Combined Experimental-Numerical Method to Evaluate Powder Thermal Properties in Laser Powder Bed Fusion. J. Manuf. Sci. Eng. 2018, 140, 111008. [Google Scholar] [CrossRef] [PubMed]

- Yang, D.; Xinyu, Y.; Fengbin, Q.; Lijie, G.; Zhengwu, L. A model for predicting the temperature field during selective laser melting. Results Phys. 2019, 12, 52–60. [Google Scholar] [CrossRef]

- Gunenthiram, V.; Peyre, P.; Schneider, M.; Dal, M.; Coste, F. Analysis of laser–melt pool–powder bed interaction during the selective laser melting of a stainless steel. J. Laser Appl. Laser Inst. Am. 2017, 29, 022303. [Google Scholar] [CrossRef]

- Gusarov, A.; Kovalev, E.P. Model of thermal conductivity in powder beds. Phys. Rev. B 2009, 80, 024202. [Google Scholar] [CrossRef]

- Xiao, X.; Lu, C.; Fu, Y.; Ye, X.; Song, L. Progress on Experimental Study of Melt Pool Flow Dynamics in Laser Material Processing. In Liquid Metals; Chelladurai, J.S., Gnanasekaran, S., Mayilswamy, S., Eds.; Intech Open: London, UK, 2021. [Google Scholar] [CrossRef]

- Ranjan, R.; Ayas, C.; Langelaar, M.; van Keulen, F. Fast Detection of Heat Accumulation in Powder Bed Fusion Using Computationally Efficient Thermal Models. Materials 2020, 13, 4576. [Google Scholar] [CrossRef]

- Ahsan, F.; Razmi, R.; Ladani, L. Experimental measurement of thermal diffusivity, conductivity and specific heat capacity of metallic powders at room and high temperatures. Powder Technol. 2020, 374, 648–657. [Google Scholar] [CrossRef]

- Pastras, G.; Fysikopoulos, A.; Stavropoulos, P.; Chryssolouris, G. An approach to modelling evaporation pulsed laser drilling and its energy efficiency. Int. J. Adv. Manuf. Technol. 2014, 72, 1227–1241. [Google Scholar] [CrossRef]

- Pastras, G.; Fysikopoulos, A.; Giannoulis, C.; Chryssolouris, G. A numerical approach to modeling keyhole laser welding. Int. J. Adv. Manuf. Technol. 2015, 78, 723–736. [Google Scholar] [CrossRef]

- Jacob, G.; Donmez, A.; Slotwiski, J.; Moylan, S. Measurement of powder bed density in powder bed fusion additive manufacturing processes. Meas. Sci. Technol. 2016, 27, 115601. [Google Scholar] [CrossRef]

- Thanki, A.; Goossens, L.; Ompusunggu, A.P.; Bayat, M.; Bey-Temsamani, A.; Van Hooreweder, B.; Kruth, J.-P.; Witvrouw, A. Melt pool feature analysis using a high-speed coaxial monitoring system for laser powder bed fusion of Ti-6Al-4 V grade 23. Int. J. Adv. Manuf. Technol. 2022, 120, 6497–6514. [Google Scholar] [CrossRef]

- Goossens, L.R.; Van Hooreweder, B. A virtual sensing approach for monitoring melt-pool dimensions using high speed coaxial imaging during laser powder bed fusion of metals. Addit. Manuf. 2021, 40, 101923. [Google Scholar] [CrossRef]

- Valencia, J.J.; Quested, P.N. Thermophysical Properties. In Volume 15—Casting; Viswanathan, S., Apelian, D., Donahue, R.J., DasGupta, B., Gywn, M., Jorstad, J.L., Monroe, R.W., Sahoo, M., Prucha, T.E., Twarog, D., Eds.; ASM Handbook; ASM International: Materials Park, OH, USA, 2008; pp. 468–481. [Google Scholar] [CrossRef]

- Dai, K.; Shaw, L. Thermal and mechanical finite element modeling of laser forming from metal and ceramic powders. Acta Mater. 2004, 52, 69–80. [Google Scholar] [CrossRef]

- Tang, C.; Tan, J.L.; Wong, C.H. A numerical investigation on the physical mechanisms of single-track defects in selective laser melting. Int. J. Heat Mass Transf. 2018, 126, 957–968. [Google Scholar] [CrossRef]

- Bartsch, K.; Herzog, D.; Bossen, B.; Emmelmann, C. Material modeling of Ti–6Al–4V alloy processed by laser powder bed fusion for application in macro-scale process simulation. Mater. Sci. Eng. A 2021, 814, 141237. [Google Scholar] [CrossRef]

- Khorasani, M.; Ghasemi, A.; Leary, M.; Cordova, L.; Sharabian, E.; Farabi, E.; Gibson, I.; Brandt, M.; Rolfe, B. A comprehensive study on meltpool depth in laser-based powder bed fusion of Inconel 718. Int. J. Adv. Manuf. Technol. 2022, 120, 2345–2362. [Google Scholar] [CrossRef]

- Li, Z.; Yu, G.; He, X.; Li, S.; Shu, Z. Surface Tension-Driven Flow and Its Correlation with Mass Transfer during L-DED of Co-Based Powders. Metals 2022, 12, 842. [Google Scholar] [CrossRef]

- Mukherjee, T.; Wei, H.L.; De, A.; DebRoy, T. Heat and fluid flow in additive manufacturing—Part II: Powder bed fusion of stainless steel, and titanium, nickel and aluminum base alloys. Comput. Mater. Sci. 2018, 150, 369–380. [Google Scholar] [CrossRef]

- Zalameda, J.N.; Hocker, S.J.A.; Fody, J.M.; Tayon, W.A. Melt pool imaging using a configurable architecture additive testbed system. In Proceedings of the Thermosense: Thermal Infrared Applications XLIII, Online, 12–17 April 2021. [Google Scholar] [CrossRef]

- Zeng, K.; Pal, D.; Stucker, B. A review of thermal analysis methods in laser sintering and selective laser melting. In Proceedings of the 2012 Solid Freeform Fabrication Symposium, Austin, TX, USA, 6–8 August 2012; pp. 796–814. [Google Scholar]

- Yang, Y.; Keulen, F.; Ayas, C. A computationally efficient thermal model for selective laser melting. Addit. Manuf. 2020, 31, 100955. [Google Scholar] [CrossRef]

- Averardi, A.; Cola, C.; Zeltmann, S.E.; Gupta, N. Effect of particle size distribution on the packing of powder beds: A critical discussion relevant to additive manufacturing. Mater. Today Commun. 2020, 24, 100964. [Google Scholar] [CrossRef]

- Lozanovski, B.; Downing, D.; Tran, P.; Shidid, D.; Qian, M.; Choong, P.; Brandt, M.; Leary, M. A Monte Carlo simulation-based approach to realistic modelling of additively manufactured lattice structures. Addit. Manuf. 2020, 32, 101092. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Gusarov, A.V.; Metel, A.S.; Tarasova, T.V.; Volosova, M.A.; Okunkova, A.A.; Gusev, A.S. Beam Shaping in Laser Powder Bed Fusion: Péclet Number and Dynamic Simulation. Metals 2022, 12, 722. [Google Scholar] [CrossRef]

- Leis, A.; Weber, R.; Graf, T. Process Window for Highly Efficient Laser-Based Powder Bed Fusion of AlSi10Mg with Reduced Pore Formation. Materials 2021, 14, 5255. [Google Scholar] [CrossRef] [PubMed]

| Parameter | Ti6Al4v | SS316L | Units |

|---|---|---|---|

| Power | 170 | 500 | |

| Speed | 1000 | 600 | |

| Laser spot size | 37.5 | 19.5 | |

| Layer thickness | 30 | 30 | |

| Substrate material | Ti6Al4v | SS316L | |

| Reflectivity of powder | 0.3 | 0.24 | - |

| Reflectivity of solid | 0.7 | 0.58 | - |

| Reflectivity of liquid | 0.6 | 0.38 | - |

| Melting temperature | 1660 | 1400 | |

| Evaporation temperature | 2860 | 2800 | |

| Latent heat of fusion | 286 | 260 | |

| Latent heat of evaporation | 9830 | 7450 |

| Parameter | Ti6Al4v |

| / | |

| Parameter | SS316L |

| / | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stavropoulos, P.; Pastras, G.; Souflas, T.; Tzimanis, K.; Bikas, H. A Computationally Efficient Multi-Scale Thermal Modelling Approach for PBF-LB/M Based on the Enthalpy Method. Metals 2022, 12, 1853. https://doi.org/10.3390/met12111853

Stavropoulos P, Pastras G, Souflas T, Tzimanis K, Bikas H. A Computationally Efficient Multi-Scale Thermal Modelling Approach for PBF-LB/M Based on the Enthalpy Method. Metals. 2022; 12(11):1853. https://doi.org/10.3390/met12111853

Chicago/Turabian StyleStavropoulos, Panagiotis, Georgios Pastras, Thanassis Souflas, Konstantinos Tzimanis, and Harry Bikas. 2022. "A Computationally Efficient Multi-Scale Thermal Modelling Approach for PBF-LB/M Based on the Enthalpy Method" Metals 12, no. 11: 1853. https://doi.org/10.3390/met12111853

APA StyleStavropoulos, P., Pastras, G., Souflas, T., Tzimanis, K., & Bikas, H. (2022). A Computationally Efficient Multi-Scale Thermal Modelling Approach for PBF-LB/M Based on the Enthalpy Method. Metals, 12(11), 1853. https://doi.org/10.3390/met12111853

_Bikas.png)