3.1. M23C6 Carbide Nucleation and Growth at Phase Boundary

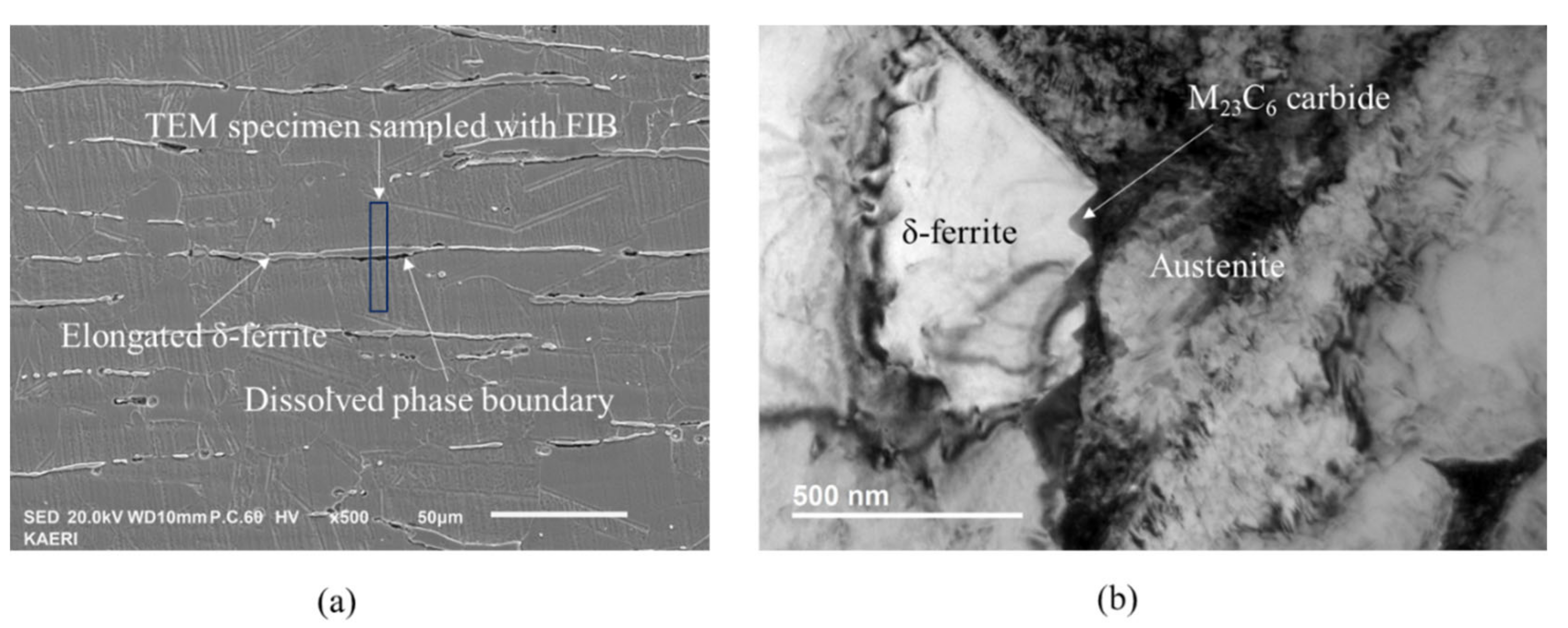

Figure 1a shows an SEM micrograph of the Type 304L stainless steel containing elongated δ ferrite. The specimen showed variation in the degree of sensitization from location to location, even in the same phase boundary between austenite and δ ferrite grains and from phase boundary to phase boundary, because the sensitization treatment time was not long enough. Some of the phase boundary dissolved because the phase boundary was sensitized with concomitant precipitation of M

23C

6 while most of the phase boundary was still immune to interphase corrosion during the DL-EPR test because the phase boundary was not sensitized. The grain boundary between austenite grains was not etched in the DL-EPR test because the grain boundary was almost free from M

23C

6 precipitation. M

23C

6 preferentially precipitated at the phase boundary compared to the grain boundary because chromium diffuses faster in ferrite than in austenite [

21].

The TEM specimen was harvested at the heavily dissolved phase boundary with FIB, as shown in

Figure 1a.

Figure 1b is a TEM micrograph showing parallel M

23C

6 carbides at the phase boundary between austenite and ferrite grains.

Table 2 shows the chemical composition of major elements of ferrite, austenite and carbide measured with TEM-EDS. The Cr content is about 26 wt.% in ferrite and 18 wt.% in austenite, respectively. M in M

23C

6 is mainly composed of Cr and Fe. All the M

23C

6 carbides were nucleated at the phase boundary and grew into ferrite grain from the phase boundary. M

23C

6 carbides were not observed at the grain boundary between austenite grains in TEM, which is consistent with

Figure 1a. All M

23C

6 grew from phase boundary to ferrite grain.

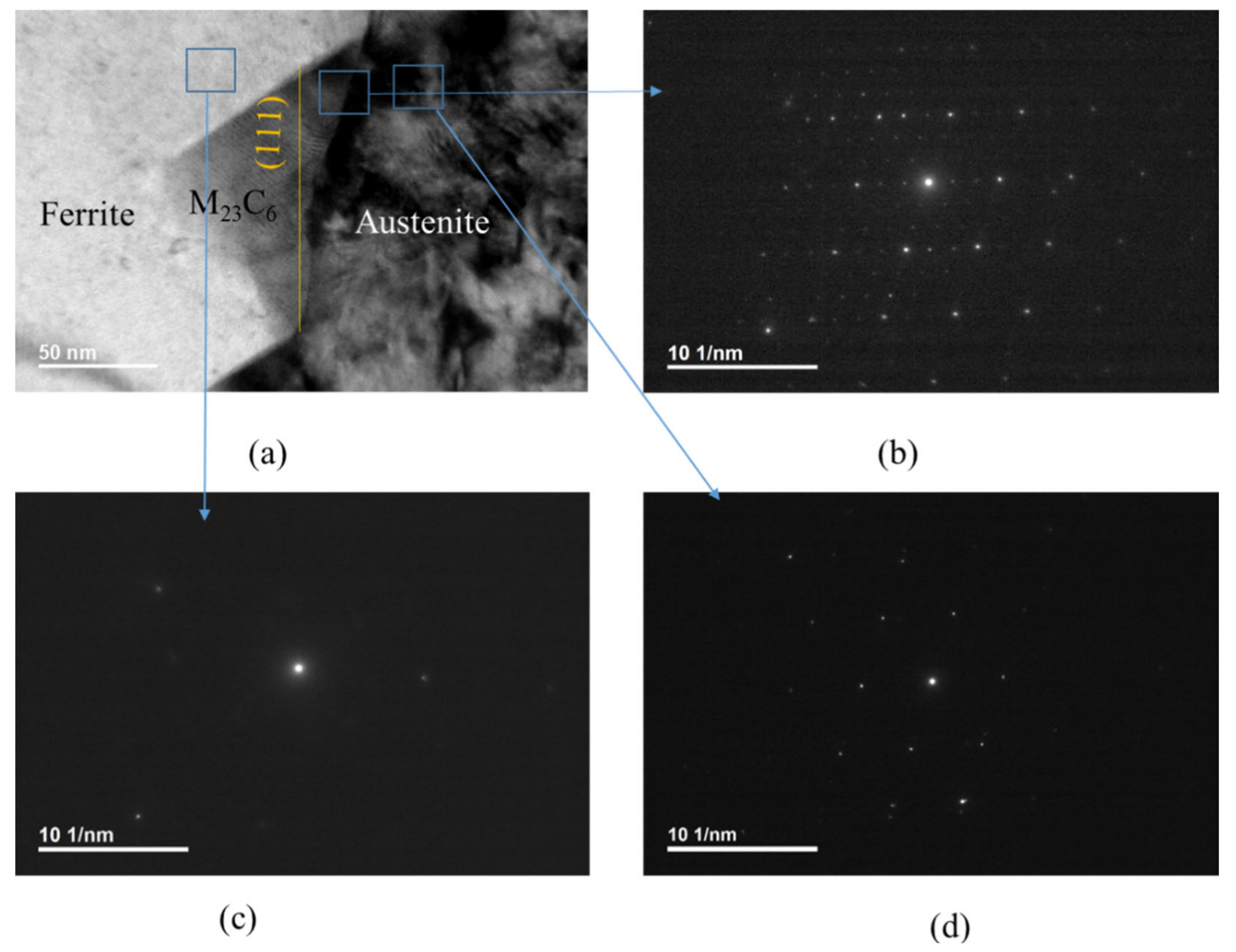

Figure 2a is a bright-field TEM image.

Figure 2b shows SAED patterns of M

23C

6 carbide together with austenite.

Figure 2c,d show ferrite and austenite, respectively. All of the micrographs in

Figure 2 were obtained at B = [01

] of M

23C

6 carbide. M

23C

6 has a face-centered cubic structure, as shown in

Figure 2b. Every third spot in

Figure 2b is very strong compared to the other spots and overlapping with that of austenite in

Figure 2d, indicating that an OR between the austenite and M

23C

6 carbide exists. The OR is (111)

a//(111)

c and [1

0]

a//[1

0]

c, as described in previous works [

7,

10,

22]. The lattice parameter of the carbide was about three-times that of the austenite. A comparison of

Figure 2c with

Figure 2d shows that the ferrite has no Kurjdjumov–Sachs (K–S) OR nor Nishiyama–Wassermann (N–W) OR with the austenite at the phase boundary. The K–S OR is (111)

a//(110)

f and [1

0]

a//[1

1]

f and the N–W OR is (111)

a//(110)

f and [10

]

a//[001]

f [

23]. SAED of ferrite (

Figure 2c) was not observed at the beam direction of [110] of austenite, which suggests that neither K–S OR nor N–W OR exists between the austenite and the ferrite.

The probability of the M

23C

6 establishing coherency with the ferrite is very low if the austenite has no coherency with the ferrite. A comparison of

Figure 2b with

Figure 2c shows that the δ ferrite has no OR with the M

23C

6 at the phase boundary, as expected from the absence of an OR between austenite and ferrite. The orange straight line in

Figure 2a is the (111) plane in carbide. For carbide nucleated at the phase boundary between the austenite and ferrite grains, the phase boundary between the M

23C

6 and austenite is not at the (111) plane, nor is it macroscopically straight, as shown in

Figure 2a, even though there is a coherency between austenite and the M

23C

6 grains. However, the edges of carbide nucleated at the phase boundary were parallel to those of the other carbides, as shown in

Figure 1b. Both the coherency between austenite and the M

23C

6 grains and same orientation of edges of the M

23C

6 carbides at the phase boundary suggest that M

23C

6 nucleates at the (111) plane of austenite grain at phase boundary in the same manner that it nucleates at the (111) plane of grain boundary in fully austenitic stainless steel.

Based on our findings, M

23C

6 nucleation and growth models at the grain boundary and phase boundary are presented schematically in

Figure 3.

Figure 3a is a schematic diagram showing carbide nucleation at the (111) plane of austenite grain at the phase boundary.

Figure 3b is a schematic diagram showing carbide growth at the phase boundary where the phase boundary between M

23C

6 and the austenite grains may change from the (111) plane of austenite to the other low-index plane of austenite with carbide growth. Apparently, the curved interphase interface between M

23C

6 and the austenite grain in

Figure 2a might be a faceted interface, as shown in

Figure 3b, on a smaller-length scale and consists of the (111) plane terrace connected by a low-index plane ledge, as suggested by previous works [

23,

24]. In fully austenitic stainless steel, M

23C

6 at the grain boundary has an OR with one of two austenite grains comprising the grain boundary and the coherent phase boundary between austenite and the M

23C

6 grains is the (111) plane because migration of the grain boundary just ahead of M

23C

6 takes places before M

23C

6 growth to minimize interfacial energy [

10]. The interphase boundary between the M

23C

6 and austenite grain in austenitic stainless steel containing delta ferrite is rather severely curved, as shown in

Figure 2a, whereas that in fully austenitic stainless steel is relatively straight [

10]. The difference in interphase appearance may be attributed to the size of the atomic rearrangement zone around the boundary just ahead of the M

23C

6. The size of the atomic rearrangement zone in austenitic stainless steel containing delta ferrite may be much smaller than that in fully austenitic stainless steel because the carbide growth rate in austenitic stainless steel containing delta ferrite is faster than that in fully austenitic stainless steel due to higher chromium diffusivity in ferrite [

21]. Carbide growth on the (111) plane of austenite grain in austenitic stainless steel containing delta ferrite may be most favorable if the other conditions are the same. However, if carbide growth on the (111) plane is not possible due to a smaller size of the rearrangement zone, then carbide growth may occur on the next favorable low-index plane, leading to a curved interphase boundary on the macro scale and faceted interphase boundary on the atomic scale.

3.2. M23C6 Carbide Morphology at Phase Boundary

To examine the early-stage M23C6 carbide morphology, the following four steps were employed. Firstly, TEM images of carbide were obtained at various beam directions and then the angle between edges of carbide in the TEM image was measured. Secondly, a presumed carbide morphology was established based on the characteristics of M23C6 carbide at the grain boundary and then the angle between the edge of the image of the presumed carbide morphology was calculated at a given projection direction. Thirdly, the angle measured in the TEM image was compared with that calculated from the presumed carbide morphology. Fourthly, the presumed carbide morphology was modified until the angle measured in the TEM image matched that calculated from the presumed carbide morphology.

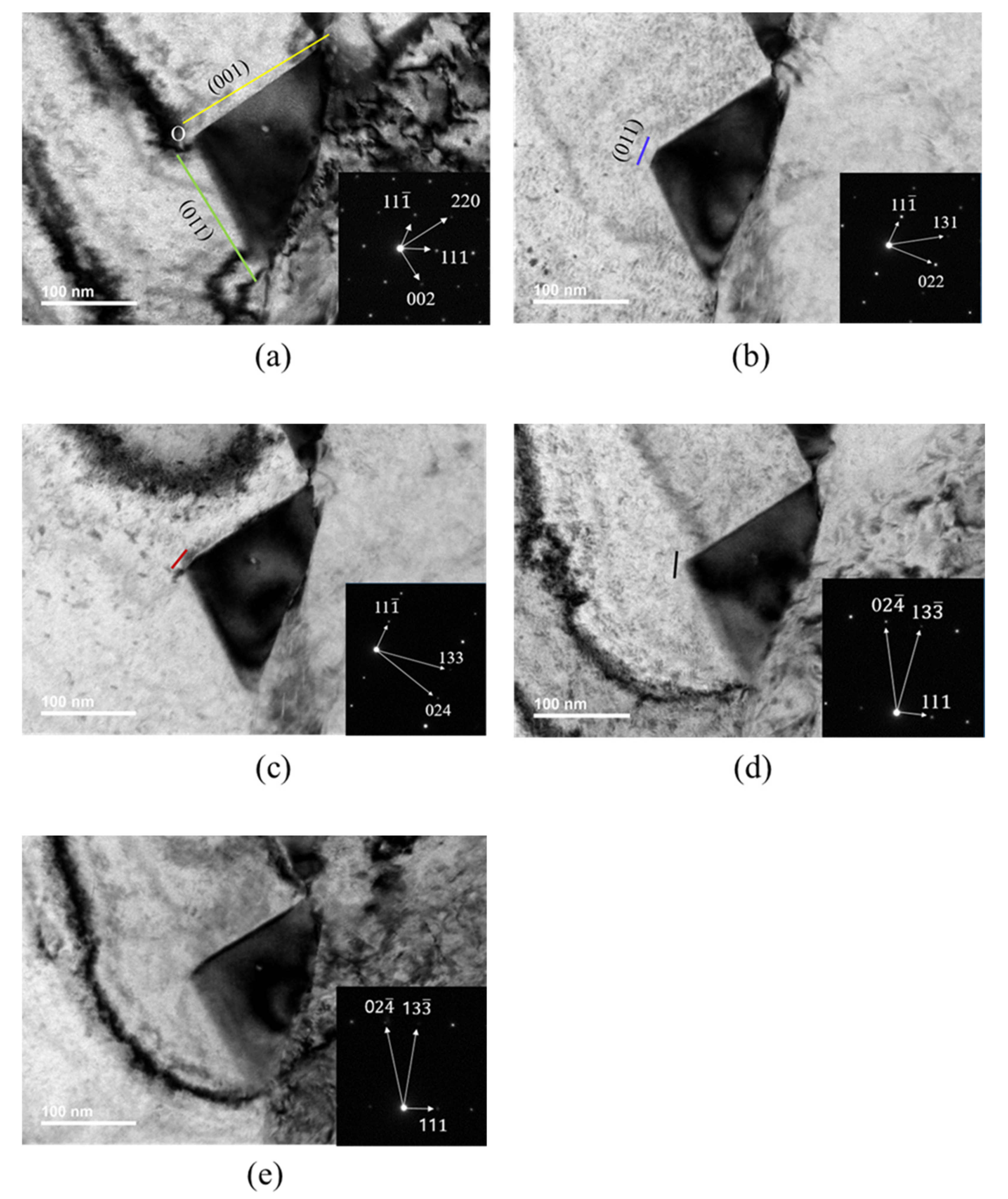

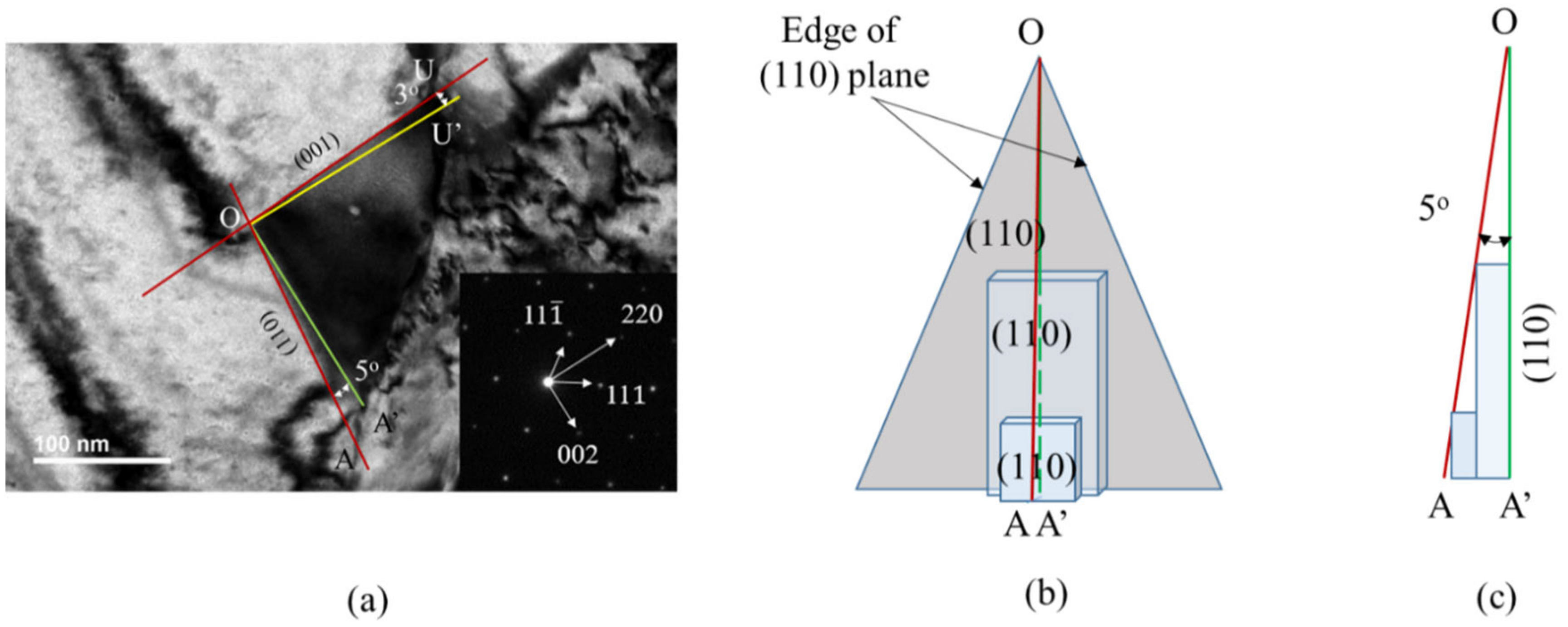

TEM images were taken at various rotation angles of the TEM specimen.

Figure 4 shows TEM images and diffraction patterns obtained at B[1

0] (

Figure 4a), B[2

1] (

Figure 4b), B[3

1] (

Figure 4c), B[2

1] (

Figure 4d) and B[3

] (

Figure 4e). Diffraction patterns and TEM images at B[1

0] (

Figure 4a) were obtained during rotation, either around the [111] pole or around [11

]. The short red line in

Figure 4c and short black line in

Figure 4d were explained later in relation to carbide morphology.

The M

23C

6 carbide at the grain boundary in fully austenitic stainless steel has the following characteristics. An OR exists between one of two austenite grains comprising the grain boundary and carbide, as in the matrix, i.e., (111)

a//(111)

c and [01

]

a//[01

]

c [

7,

10]. M

23C

6 carbide is partially bound by <110> segments on the (111) plane in the grain boundary [

7], which is consistent with the OR between austenite and M

23C

6 carbide. The angle at the apex of the TEM carbide image is almost 90° in many cases when the TEM image is obtained at the <110> beam direction [

10]. Faces of M

23C

6 carbide at the early stage are composed of low-index planes, as in type-3 incoherent boundaries [

24]. The characteristics of the M

23C

6 carbide at the grain boundary in fully austenitic stainless steel may be applicable to those at the phase boundary between austenite and ferrite grains.

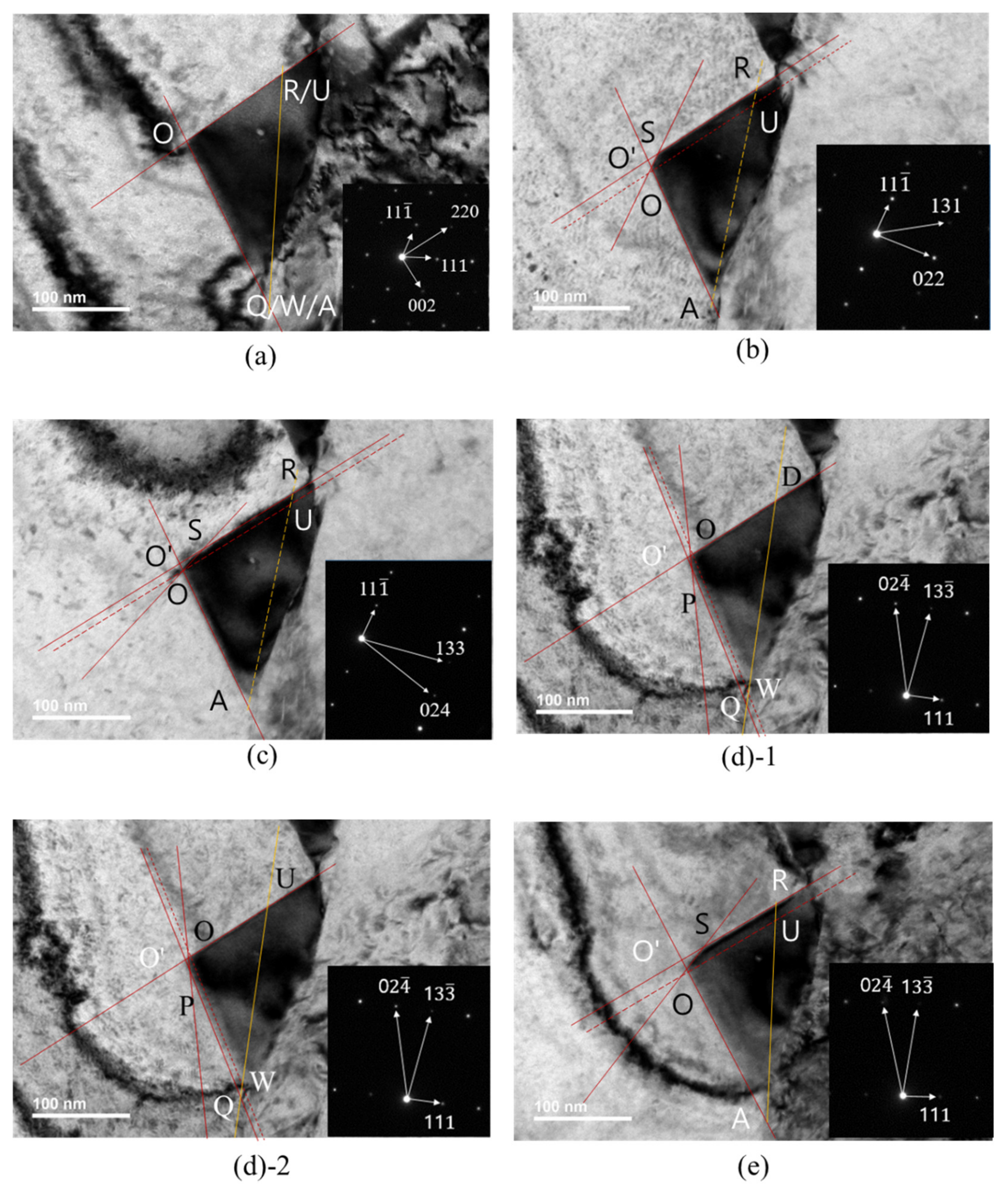

Figure 5 shows that M

23C

6 carbide morphology developed from (

Figure 5a) to (

Figure 5b) and finally to (

Figure 5c). All capital letters except W in

Figure 5 indicate vertex positions on carbide. W is a position on carbide such that WO parallels to QP.

Figure 5a is an initially presumed M

23C

6 carbide morphology at the phase boundary because it has the characteristics of M

23C

6 carbide at the grain boundary in fully austenitic stainless steel. That is, the angle between edges of the image expected from

Figure 5a is 90° for the <110> zone axis and the interfaces of

Figure 5a are composed of low-index planes and carbide on the (111) basal plane is bound by the <110> segment. The fact that

Figure 5a includes characteristics of M

23C

6 carbide at the phase boundary may not guarantee that

Figure 5a is the real carbide morphology at the phase boundary. The feasibility of

Figure 5a being the carbide morphology at the phase boundary was confirmed by comparing the angle measured between the edge in the TEM image and that calculated between edges in the image in

Figure 5a in the beam direction.

The TEM image in

Figure 4a was obtained at a beam direction of [1

0]. By comparing the diffraction pattern and carbide image in

Figure 4a, the lower-side edge is almost parallel to the green line and the green line is perpendicular to the [220] direction in the SAED. The upper-side edge is almost parallel to the yellow line and the yellow line is perpendicular to the [002] direction in the SAED. Therefore, the lower-side edge almost parallel to the green line and the upper-side edge almost parallel to the yellow line were assigned to the (110) plane and the (001) plane, respectively. Then, the green line and yellow line in the TEM image in

Figure 4a are consistent with the images generated by the BOA and COD interface in

Figure 5a, respectively, at the beam direction of [1

0].

The TEM image in

Figure 4b obtained at the [2

1] beam direction is a trapezoid. The edge of the TEM image parallel to the blue line in

Figure 4b is perpendicular to the [022] direction of SAED at the [2

1] beam direction. Therefore, the edge parallel to the blue line was assigned to the (011) plane and is produced by BOC (011) in

Figure 5a. However, the image expected from the carbide morphology in

Figure 5a at the [2

1] beam direction is a triangular shape because the image is produced by the AOC in

Figure 5a. The discrepancy between the TEM image in

Figure 4b and the image expected from

Figure 5a implies that the carbide morphology in

Figure 5a is not valid. To obtain the trapezoid TEM image in

Figure 4b, the carbide morphology was modified from

Figure 5a to

Figure 5b, where the QPSR (

11) plane below the POS (011) plane in

Figure 5b was additionally introduced because the QPSR (

11) plane satisfies the characteristic of the M

23C

6. In this case, the edge of carbide parallel to the blue line in

Figure 4b is produced by POS (011) in

Figure 5b. Then, the image expected from the carbide morphology in

Figure 5b at the [2

1] beam direction is a trapezoid and consistent with the TEM image in

Figure 4b.

If we assign coordinates to the two vertex positions in

Figure 5b, for example, O(111) and R(

1), then the coordinates of the other vertex positions are determined as shown in

Table 3.

Figure 6 is a duplication of

Figure 4, with additional positions and lines corresponding to those in the carbide morphology in

Figure 5 to avoid confusion in viewing the TEM carbide image in

Figure 4. The position marked with a letter (for example, O) in the TEM image in

Figure 6 corresponds to the position with the same letter (O) in the carbide morphology in

Figure 5. Q, W and A coordinates in

Figure 5c are given by one point in the TEM image of

Figure 6a because the [1

0] beam direction is parallel to an edge, including Q, W and A coordinates in

Figure 5c. R and U coordinates in

Figure 5c are also given by one point in

Figure 6a. Both

Figure 6(d1,d2) corresponding to

Figure 4d are the same, except the position mark D (

Figure 6(d1)) and U (

Figure 6(d2)). In

Figure 6, the solid orange line is the (111) plane but the dotted orange line is not the (111) plane. The dotted orange line was drawn only to indicate coordinates of the position, where the (111) plane meets the other interfaces. ∠OSR in the TEM image in

Figure 6b was measured and ∠OSR in the image expected from the carbide morphology in

Figure 5b was calculated at the [2

1] beam direction. Both the angle measured and that calculated were 149°, which proves that the QPSR plane below the POS (011) plane in

Figure 5b is the (

11) plane. The trapezium TEM image in

Figure 4c at the [3

1] beam direction is also generated by the AOSR of the carbide morphology in

Figure 5b. The edge parallel to the short red line in

Figure 4c is generated by the OS line in

Figure 6b. O’ in

Figure 6b corresponds to a position where extrapolation of AO and RS meet together in the TEM image.

TEM images and SAED of carbide in

Figure 4d,e were obtained at the [2

1] and [3

1] beam directions during rotation about the (111) pole, respectively. The edge parallel to the short black line in

Figure 4d corresponds to

of the carbide morphology in

Figure 5b at the [2

1] beam direction. The TEM image of QPOD in

Figure 6(d1) corresponds to the QPOD of carbide morphology in

Figure 5b at the [2

1] beam direction.

and

are parallel to

and

, respectively, in

Figure 5b. ∠QPO, ∠POD and ∠WOD in the TEM image in

Figure 6(d1) correspond to ∠QPO, ∠POD and ∠WOD in the carbide morphology of

Figure 5b at the [2

1] beam direction, respectively. ∠QPO, ∠POD and ∠WOD in the TEM image in

Figure 6(d1) were measured and those for the carbide morphology in

Figure 5b were calculated at the [2

1] beam direction. The results are listed in

Table 4. ∠WOD is the same with ∠QO’D in the TEM image at the [2

1] beam direction in

Figure 6(d1). ∠QPO measured in the TEM image in

Figure 6(d1) closely matched that calculated from the carbide morphology in

Figure 5b. However, ∠POD and ∠WOD measured in the TEM image in

Figure 6(d1) deviate substantially from those calculated from the carbide morphology in

Figure 5b, as shown in

Table 4. The deviation in both ∠POD and ∠WOD measured in the TEM image from that calculated from the carbide morphology in

Figure 5b means that

Figure 5b is not real carbide morphology. If ∠POU and ∠WOU of the TEM image of carbide in

Figure 6(d2) are generated by those of the carbide morphology in

Figure 5c, then ∠POU and ∠WOU measured in the TEM image of carbide in

Figure 6(d2) perfectly matches those calculated from the carbide morphology in

Figure 5c, as shown in

Table 4. Therefore, the initially presumed OSRD (001) plane in

Figure 5b should be split to the (001) plane of OSRU and the unknown plane containing

edge. Accordingly, the AOD (100) plane in

Figure 5b should split to the (100) plane and the unknown plane. The unknown plane split from the OSRD (001) plane and that from the AOD (100) plane may be the same plane.

Now, the carbide morphology at the right side of AOU in

Figure 5c is identified completely but that at the left side of AOU remains. Interfaces of the carbide morphology at the left side of AOU may be assumed as low-index planes as in interfaces of the carbide morphology at the right side of AOU. Low-index planes with a

[110] edge are the (1

1), (1

0), (001) and (

11) planes. The (

11) plane was excluded because the (

11) plane with the

[110] edge can not include the

edge. The (001) plane was also excluded because the (001) plane was already there and could not make the

[110] edge. The (1

0) plane was also excluded because the presence of the (1

0) plane does not allow for the (100) plane in

Figure 5c. If the (1

0) plane exists, the (1

0) plane with

edge also includes

edge, that is, the (1

0) plane is AOV in

Figure 5c. The (100) plane in contact with the OSP (011) plane in

Figure 5c was confirmed in previous work [

10]. Therefore, the possible unknown plane is the (1

1) plane. VOU (1

1) plane was introduced in

Figure 5c. The (1

1) plane in

Figure 5c is a reasonable choice in terms of a low-index plane and volume to surface energy ratio.

The presence of the

edge in

Figure 5c was not confirmed through a comparison of the angle measured with that calculated because TEM specimen rotation is limited. ∠WOV from the carbide morphology in

Figure 5c for the beam direction of [10

] was calculated to be 100°. The entire boundary at the basal plane of carbide is enclosed by <110> segments, which is consistent with the OR between austenite and carbide. Angles measured in the TEM image of

Figure 6, except

Figure 6(d1), closely match those calculated from the carbide morphology in

Figure 5c at various beam directions, as shown in

Table 5. Based on the findings and reasoning on the carbide morphology, the early-stage M

23C

6 carbide morphology is identified to be a complex pyramid shape in

Figure 5c and is composed of low-index planes of {001}, {011} and {111} planes. Variants of

Figure 5c produced by symmetry operations may be a morphology of the M

23C

6 at the phase boundary.

TEM images of intergranular M

23C

6 carbide were reported to be triangular and trapezoidal shapes in fully austenitic stainless steel [

6]. These TEM images can be generated from just one kind of morphology, such as in

Figure 5c. Care should be taken in inferring carbide morphology from TEM images because many TEM images can be generated by observing one kind of carbide morphology in different directions. However, the presence of other carbide morphology at the phase boundary cannot be ruled out. A prismatic morphology with a scalene quadrilateral cross-section was suggested as the carbide morphology, where the quadrilateral facets are the (11

), (1

1), (02

) and (200) planes, but the two end facets of the prismatic morphology were not identified [

10]. If the M

23C

6 carbide morphology is a prismatic shape with a scalene quadrilateral cross-section and has the (111) basal plane, the TEM image will be changed from a triangle to a trapezoidal square when the beam direction is changed from B = [1

0] to B = [2

1] or to B = [3

] for rotation around the [111] pole. However, the TEM image was not changed in that way in this work, as shown in

Figure 4d,e. However, the presence of elongated pyramid morphology with a scalene quadrilateral cross-section may be possible in a later stage through preferential growth to the [01

] direction in

Figure 5c or coalescence of closely spaced carbides in

Figure 5c.