Technological Insights into the Evolution of Bronze Bell Metal Casting on the Korean Peninsula

Abstract

1. Introduction

2. Historical Evolution of Casting Bell Technology in Asia

2.1. Appearance of Bells in Asia

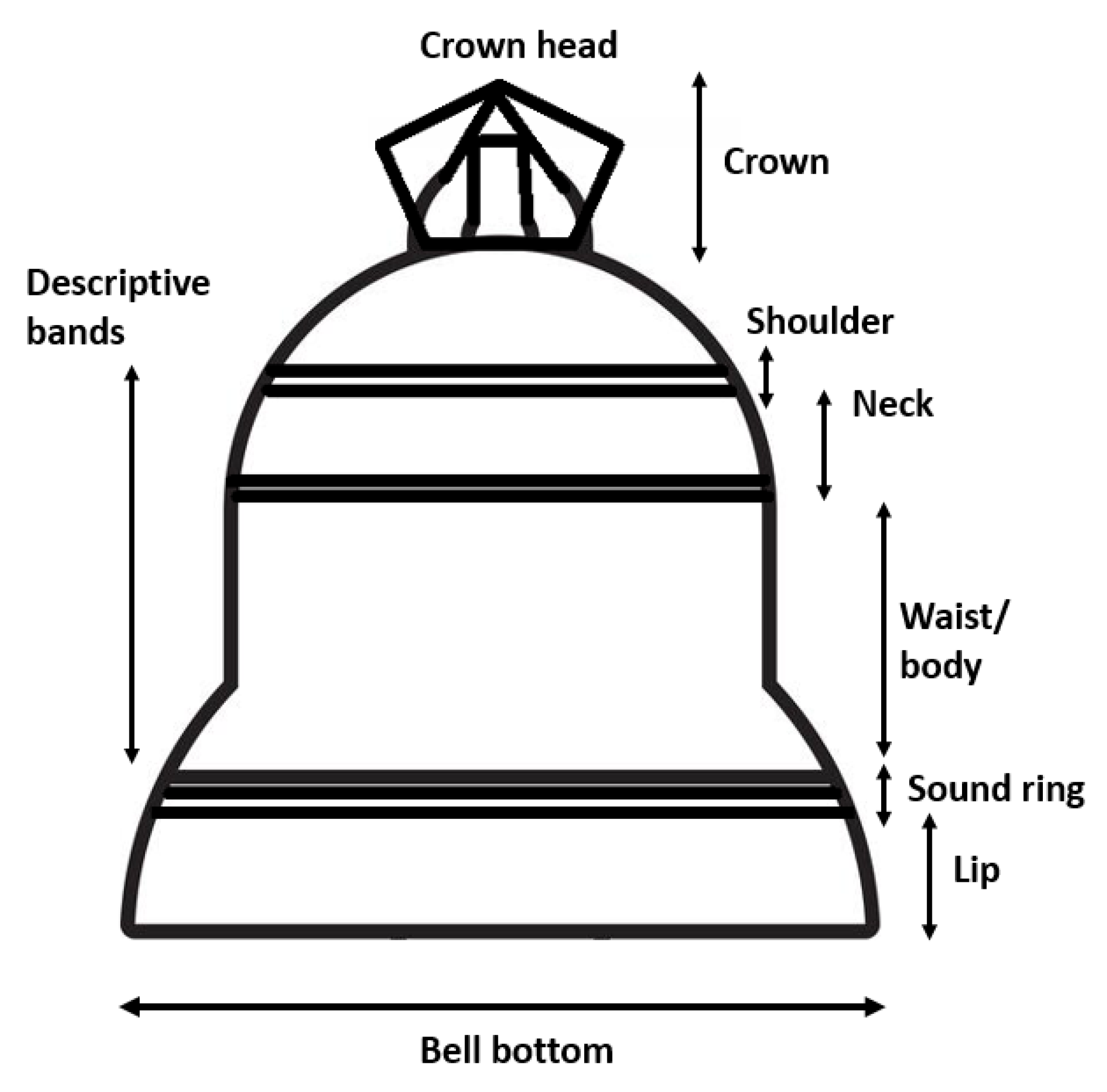

2.2. Types, Geographical Distribution, and Characteristics of Bronze Cast Bells

3. Bronze Alloys and Temple Bells

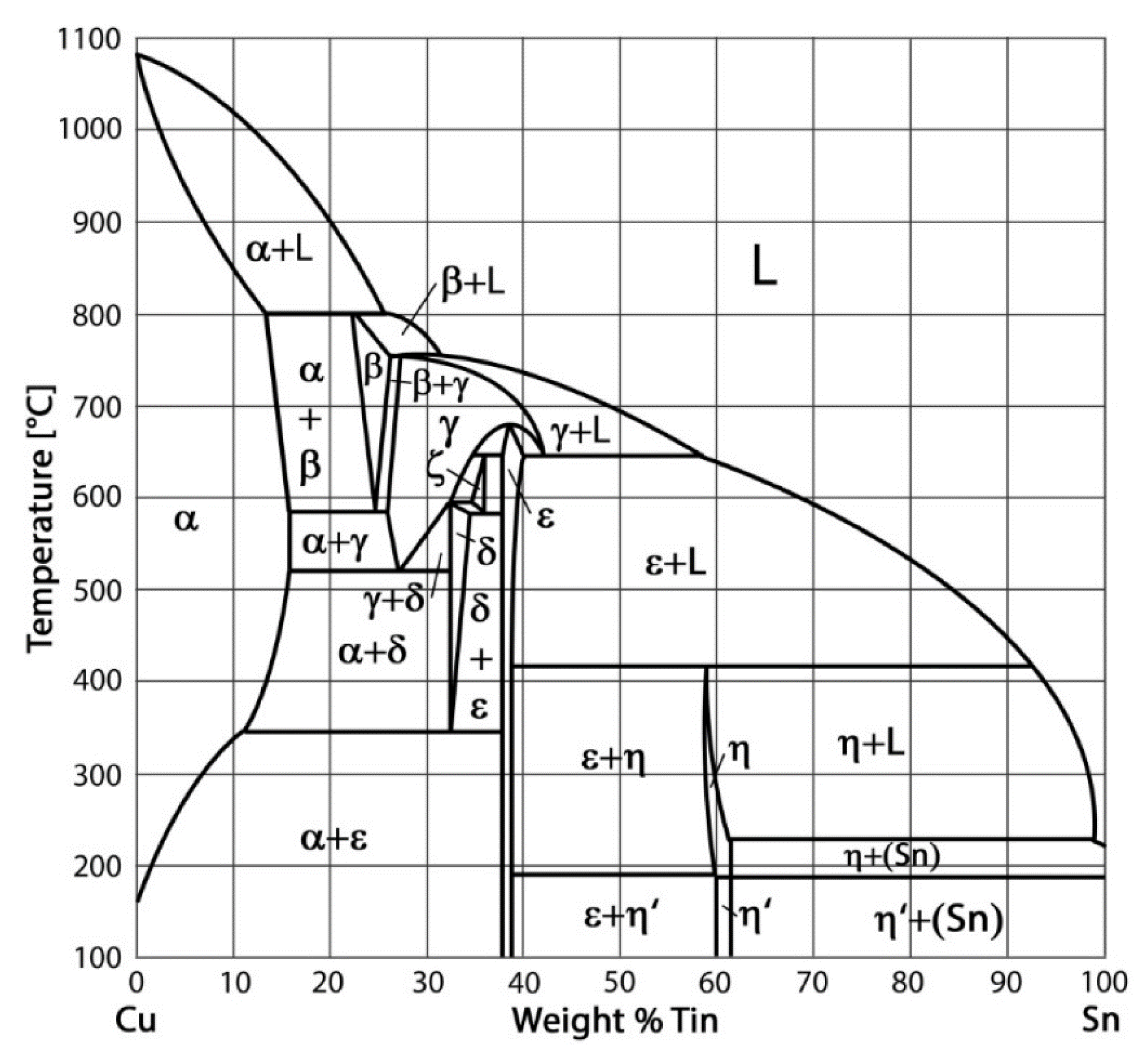

3.1. Composition of Bronze Bells

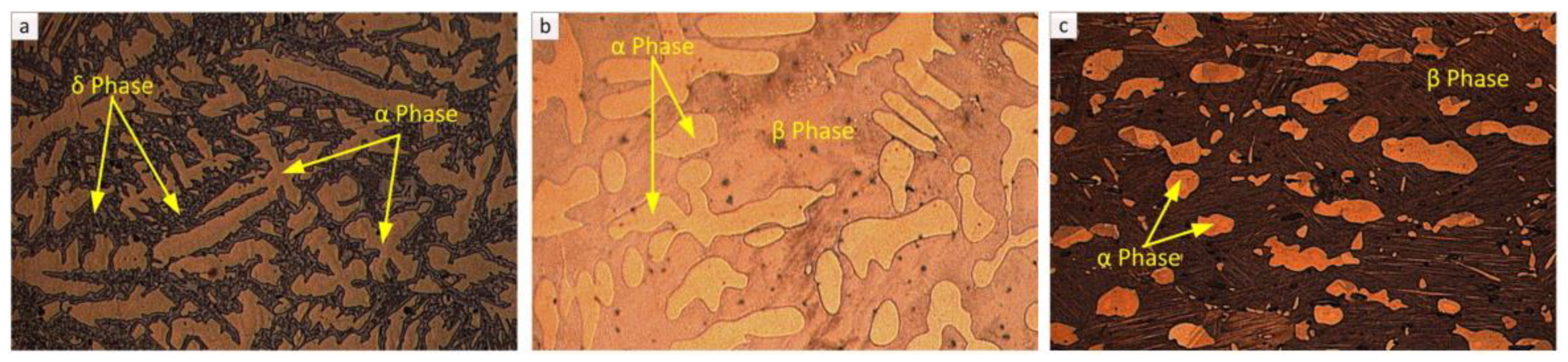

3.2. Microstructure of Bronze Bells

4. Metal Casting Technology

4.1. Traditional Bronze Casting Methods for Bells

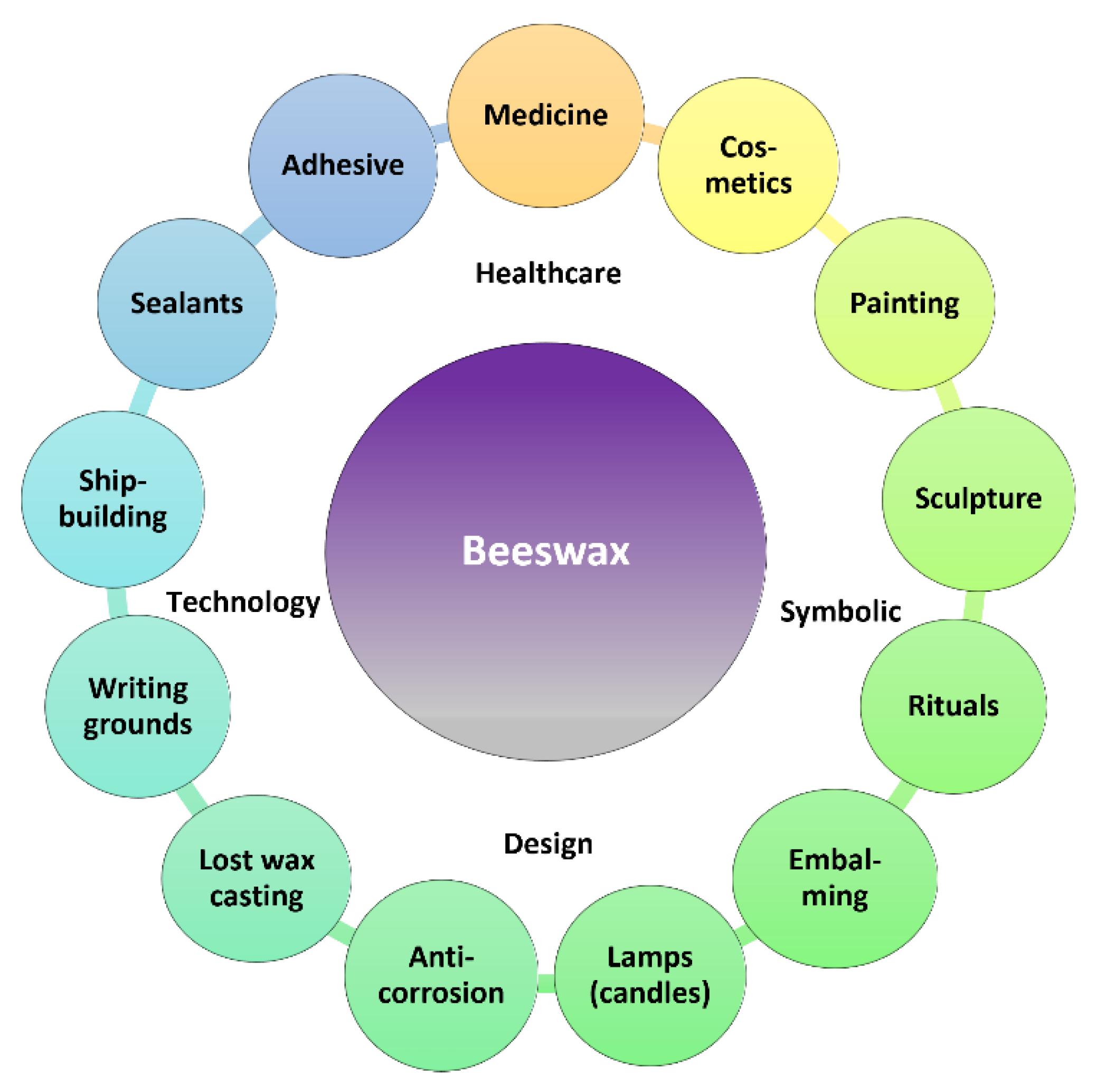

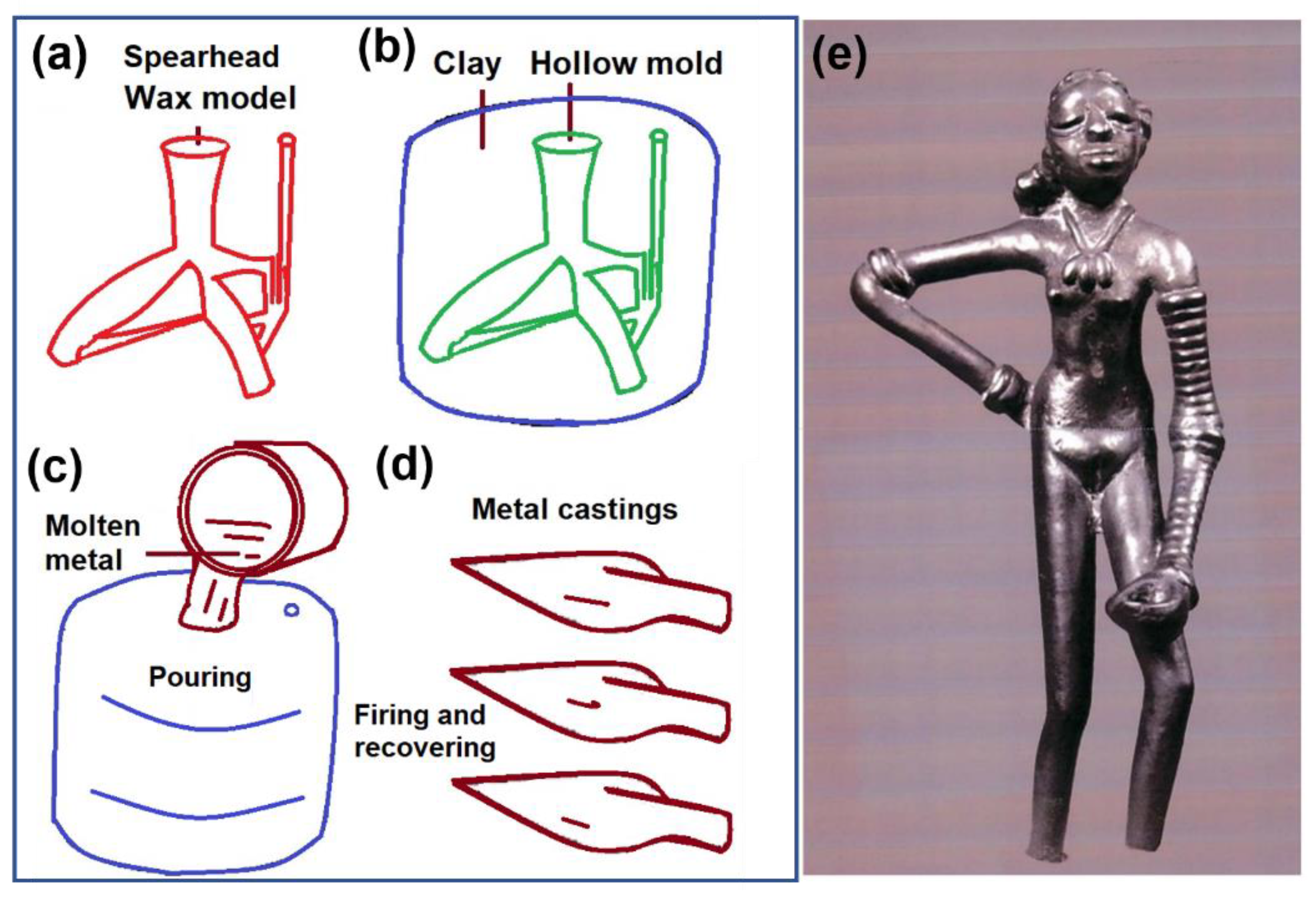

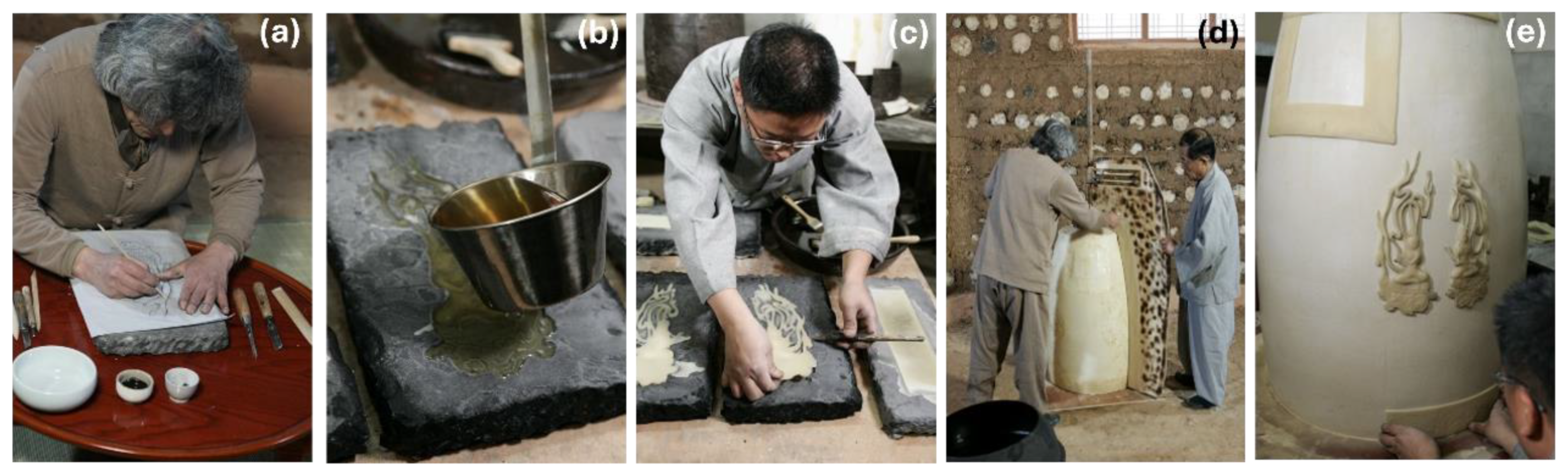

4.1.1. Importance of Beeswax in LWC

4.1.2. LWC Background

4.1.3. Merits and Drawbacks of LWC

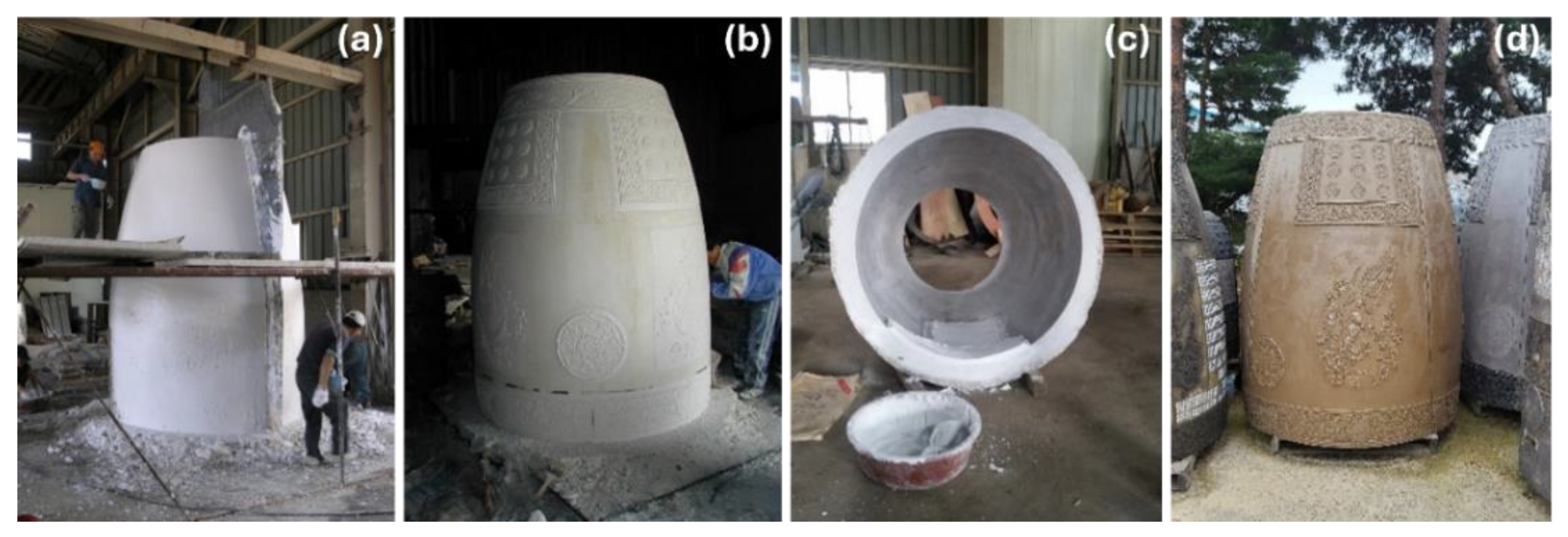

4.1.4. LWC for Bells

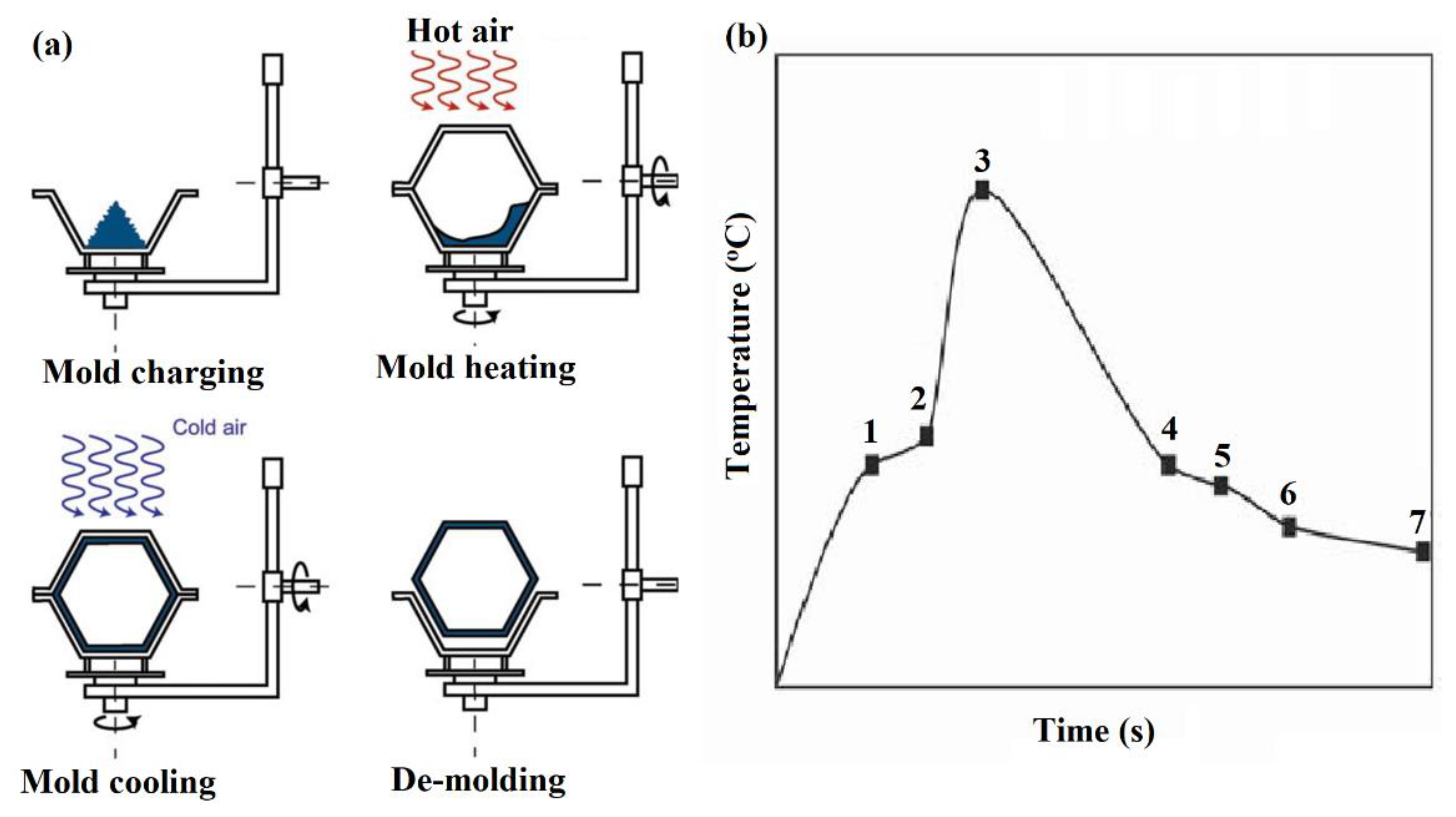

4.2. Rotational Molding Method

4.2.1. Rotomolding Process

4.2.2. Materials for Rotomolding

4.2.3. Major Applications of Rotomolding

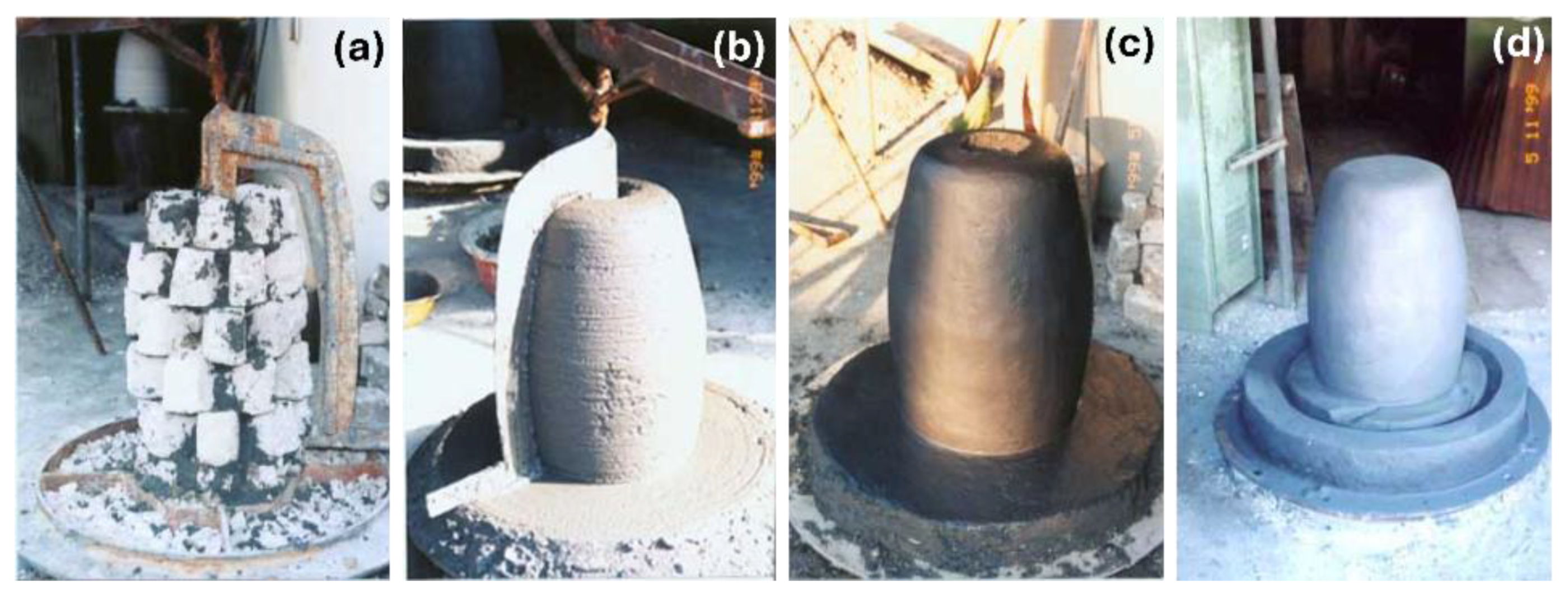

4.3. Pep-Set Casting Method

4.3.1. Pep-Set System

4.3.2. Background of Pep-Set Casting

4.3.3. Molding in Pep-Set

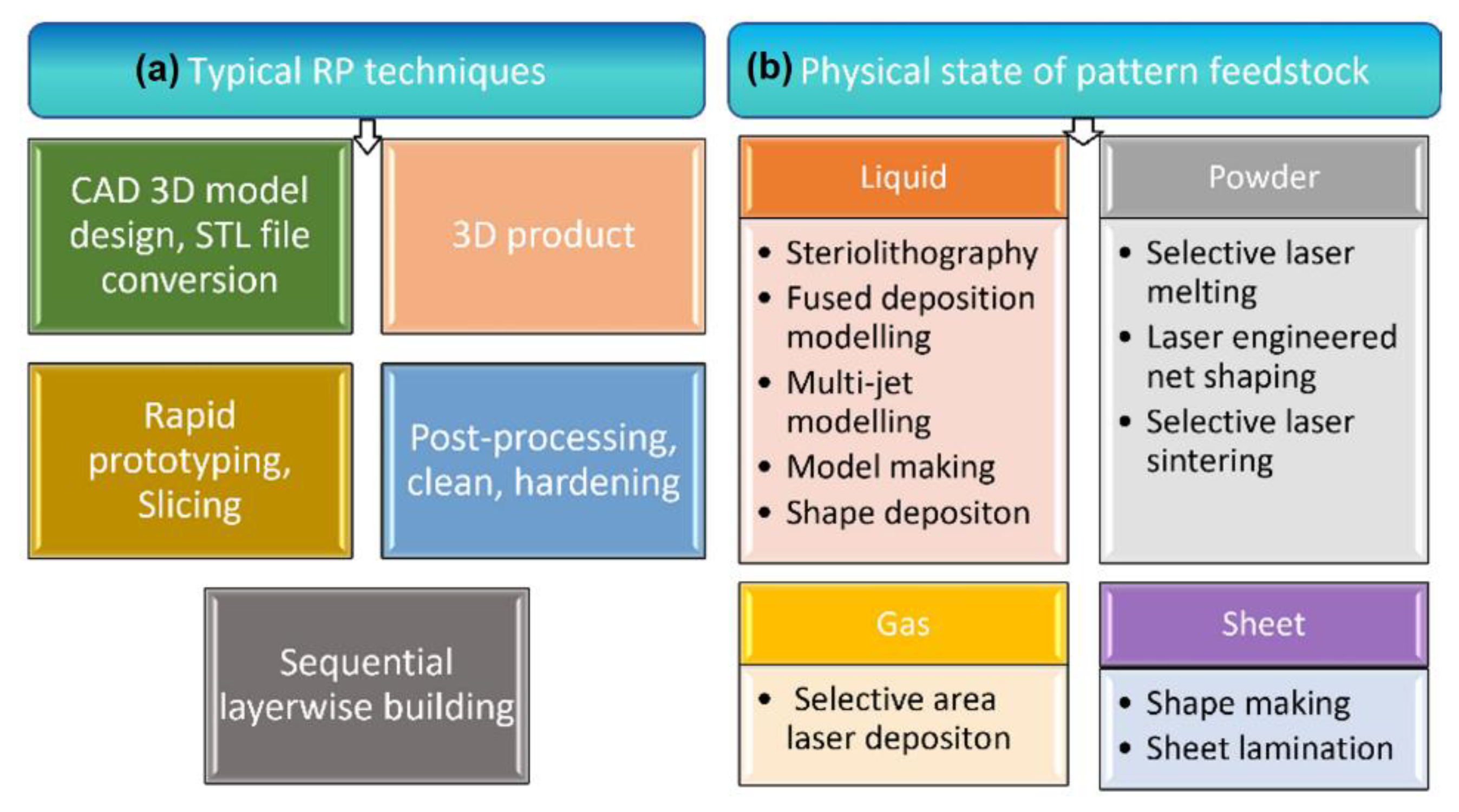

5. Advanced Rapid Prototyping Techniques in Investment Casting

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cebulak, M.; Kowalski, J.S.; Wojciechowski, W. Bell founding—The past and the present. Arch. Foundary Eng. 2010, 10, 167–170. [Google Scholar]

- DeSapio, V.; Fan, Q.; Fravel, D.; Houck, G.; Lenchitz, H.; Mapes, C.; Sykes, H.; Thomsen, C.; Treat, A.; Tsuji, K.; et al. Foundry Products—United States International Trade Commission Report. Investigation No. 332-USITC Publication May 2005; U.S. International Trade Commission: Washington, DC, USA, 2005. [Google Scholar]

- Legge, K.A.; Petrolito, J. Designing idiophones with tuned overtones. Acoust. Aust. 2007, 35, 47–50. [Google Scholar]

- Isogawa, S. Casting sites of bronze bell and iron kettle in ancient and medieval Japan. ISIJ Int. 2014, 54, 1123–1130. [Google Scholar] [CrossRef]

- Doney, L. Chapter 4—Bronze temple bells from the Tibetan imperial period: Buddhist material culture in context. In Beyond Boundaries; Willis, M., Schaik, S.V., Doney, L., Lucas, D.B., Elizabeth, A.C., Eds.; Walter de Gruyter GmbH: Berlin, Germany; Boston, MA, USA, 2020; Volume 2. [Google Scholar]

- The Beginning of the Country’s History, Prehistoric Times—Gojoseon, The Korean Cultural Center New York (KCCNY), 460 Park Avenue 6th Floor, New York, NY 10022. Available online: https://www.koreanculture.org/korea-information-history (accessed on 26 January 2022).

- When Nazis Took All the Bells; The National Bell Festival, Inc. and Bells.org.: Washington, DC, USA, 2022; Available online: https://www.bells.org/blog/when-nazis-took-all-bells (accessed on 26 January 2022).

- Bells and Clocks Since 1842, The Verdin Company, 444 Reading Road, Cincinnati, OH 45202. 2022. Available online: https://www.verdin.com/bells/history-of-bells/ (accessed on 26 January 2022).

- Xi’an Municipal Documents Repository. Xi’an City Archives Announces Historical Materials of the Anti-Japanese War. A Report; 31 August 2005; Xi’an Municipal Documents Repository: Xi’an, China, 2005. [Google Scholar]

- Zoom Korea, Meet the Master behind Korea’s Most Iconic Bell. Korea JungAng Daily in Association with The New York Times. 9 December 2021. Available online: https://koreajoongangdaily.joins.com/2021/12/09/culture/features/korean-bell-korean-temple-bell-Won-Kwangsik/20211209154758585.html (accessed on 26 January 2022).

- Yum, Y.H. Korean Bell; Seoul National University Press: Seoul, Korea, 1991; pp. 3–43. [Google Scholar]

- Nathaniel, S., Jr. Bell (Yongzhong) 5th–3rd century B.C, China. In A Treasury of Archaeological Bells; Hastings House Publishers: New York, NY, USA, 1978; Available online: https://www.metmuseum.org/art/collection/search/61053 (accessed on 1 February 2022).

- Kanzeon-ji Temple Bonsho Bell, Japan Heritage Dazaifu, Dazaifu City Japan Heritage Utilization Council. 2016. Available online: https://www.dazaifu-japan-heritage.jp/en/bunkazai/detail.php?cId=326 (accessed on 1 February 2022).

- Bronze Bell of Sangwonsa Temple. In Korea JungAng Daily in Association with The New York Times; 7 July 2013; Available online: https://koreajoongangdaily.joins.com/news/article/article.aspx?aid=2974158 (accessed on 1 February 2022).

- Catherine, S.J. Standing Waves and Musical Instruments, Connexions Module: m12413. pp. 1–10. Available online: http://cnx.org/content/m12413/latest/ (accessed on 1 February 2022).

- Jinpo, T.; Kobayashi, H.; Shigeo, T.; Tokihito, N. Papermaking Parts for Casting Production. Japanese Patent JP4002200B2, 31 October 2007. [Google Scholar]

- Cartwright, M. The Bronze Bells of Ancient Korea, World History Encyclopedia. Last Modified 18 October 2016. Available online: https://www.worldhistory.org/article/961/the-bronze-bells-of-ancient-korea/ (accessed on 1 February 2022).

- The Age-Old Chinese Bell Culture, China.org.cn. Available online: http://www.china.org.cn/features/fbich/2003–11/12/content_1078450.htm (accessed on 1 February 2022).

- The Story of Culture and Arts—Dongjong, Bronze Bells of Korea. Available online: http://contents.history.go.kr/mobile/tz/view.do?levelId=tz_b19 (accessed on 1 February 2022).

- Deep Echo of the Divine Bell; the New Beginning of the Silla Great Bell, Gyeonju City Council. 2017. Available online: https://www.gyeongju.go.kr/ (accessed on 1 February 2022).

- Kim, S.; Lee, J.H.; Byeon, J.H. Vibration and Sound of Silla Great Bell. J. Acoust. Soc. Kor. 2017, 36, 186–193. (In Korean) [Google Scholar] [CrossRef][Green Version]

- Park, S.H.; Lee, M.; Hahn, N.; Sung, K.M. Acoustic characteristics and timbre preferences of Korean bells. J. Korean Acoust. Soc. 2011, 30, 273–280. [Google Scholar] [CrossRef]

- Jincheon Bell Museum, Jincheon-Gun, Korea. Available online: https://www.jincheon.go.kr/site/eng/sub.do?menukey=2687 (accessed on 1 February 2022).

- Jang, I.N.; Cho, N.C. A study on archaeological production sites of South Korean bronze bells through slag and soil analysis. Archaeol. Anthropol. Sci. 2022, 14, 3. [Google Scholar] [CrossRef]

- Na, D.K. Korean Bells—Design and Characteristics. In Proceedings of the Ninth International Conference on the Beginnings of the Use of Metals and Alloys, Busan, Korea, 16–19 October 2017; The Korean Institute of Metals and Materials: Seoul, Korea, 2018; Volume 1, pp. 1–11. [Google Scholar]

- Steve46814. Korean Buddhist ’Emille’ Bell. World History Encyclopedia. Last Modified 5 October 2016. Available online: https://www.worldhistory.org/image/5838/korean-buddhist-emille-bell/ (accessed on 1 February 2022).

- Dae, C.C. Sacred Spirit of Emille Bell, The Korea Times, 14 January 2013. Available online: https://www.koreatimes.co.kr/www/opinion/2018/06/162_128814.html (accessed on 20 March 2022).

- Gyeongju Hwangnyongsa Temple Site, Current Status—Historic Site No. 6 (Designated on 21 January 1963). Available online: http://www.gyeongju.go.kr/tour (accessed on 20 March 2022).

- Lee, J.; Kim, C. A study on formative style of Silla bell. J. Korea Multimed. Soc. 2013, 16, 1214–1229. [Google Scholar] [CrossRef][Green Version]

- Landers, J. A Rare Collection of Bronze Age Chinese Bells Tells a Story of Ancient Innovation. Smithsonian Magazine. 5 October 2017. Available online: https://www.smithsonianmag.com/ (accessed on 20 March 2022).

- Iron Bell of Jeondeungsa Temple; Cultural Heritage Administration: Daejeon, Korea, 1963; Available online: https://english.cha.go.kr/html/HtmlPage.do?pg=/contact/contactsEng.jsp&mn=EN_05_03 (accessed on 20 March 2022).

- Fletcher, N.H. The nonlinear physics of musical instruments. Rep. Prog. Phys. 1999, 62, 723–764. [Google Scholar] [CrossRef]

- Schilling, M. Bells. Shape, Sound and Ornament; Verlag der Kunst: Dresden, Germany, 1988. [Google Scholar]

- Audy, J.; Audy, K. Analysis of bell materials: Tin bronzes. China Foundry 2009, 58, 77–81. [Google Scholar]

- Bartocha, D.; Baron, C.; Suchon, J. The influence of solidification rate on high-tin bronze microstructure. Arch. Foundry Eng. 2019, 19, 89–97. [Google Scholar]

- Cekus, D.; Kwiaton, P.; Nadolski, M.; Sokół, K. Quality assessment of a manufactured bell using a 3D scanning process. Sensors 2020, 20, 7057. [Google Scholar] [CrossRef] [PubMed]

- Strafford, K.N.; Newell, R.; Audy, K.; Audy, J. Analysis of bell material from the Middle Ages to the Recent Time. Endeavour 1996, 20, 22–27. [Google Scholar] [CrossRef]

- Cheng, C.F.; Schwitter, C.M. Nickel in Ancient Bronzes. Am. J. Archaeol. 1957, 61, 351–365. [Google Scholar] [CrossRef]

- Rosenfield, A.R. The crack in the liberty bell. Int. J. Fract. 1976, 12, 791–797. [Google Scholar] [CrossRef]

- Rainio, R. Classifying iron age bells, pellet bells and bell pendants. In Studies in Music Archeology; German Archeological Institute: Berlin, Germany, 2008; Volume VI. (In German) [Google Scholar]

- Yun, Y.H.; Cho, N.C.; Doh, J.M. Experimental research of lost-wax casting: Gilt-Bronze Pensive Bodhisattva. J. Conserv. Sci. 2020, 36, 123–142. [Google Scholar] [CrossRef]

- Vináš, J.; Vrabel, M.; Greš, M.; Brezina, J.; Sabadka, D.; Fedorko, G.; Molnár, V. Restoration of worn movable bridge props with use of bronze claddings. Materials 2018, 11, 459. [Google Scholar] [CrossRef]

- Audy, K. The Metallurgy of Ancient Artefacts. Ph.D Thesis, University of South Australia, Adelaide, Australia, 1999. [Google Scholar]

- Audy, J. Bells Evaluation from Buchner Workshop from Casting Point of View. Bachelor’s/Master’s Eng Thesis, The Technical University in Kosice City, Kosice, Czechoslovakia, June 1988. [Google Scholar]

- Audy, J.; Cech, J.; Beno, J. Composition and microstructure of medieval bells. Pract. Metallogr. 1992, 29, 74–84. [Google Scholar] [CrossRef]

- Audy, K.; Audy, J. Analysis of bell-making process from the middle ages to recent times. Pract. Metallogr. 2006, 43, 271–291. [Google Scholar] [CrossRef]

- Buchner, A. Workshop Diary and Recipes (1884–1975); Item Number HU 1384/193/84; A Report on Collection of Slovak Technical Museum (STM): Kosice City, Slovakia, 1984. [Google Scholar]

- Sarudyova, M. Work of A. Buchner—The Bell-Maker and Art Black-Smith (1884–1975); Brochure of Permanent Museum Exhibition; A Report on Collection of Slovak Technical Museum (STM): Kosice City, Slovakia, 1987. [Google Scholar]

- Grigerova, T. Metallurgy of Casting Alloys of Nonferrous Materials; Technical University (VST): Kosice City, Slovakia, 1986. [Google Scholar]

- Vilcko, J.; Slovak, S. Casting Technology; SNTL: Bratislava, Slovakia, 1987. [Google Scholar]

- American Society for Metals. Casting Design Handbook; McGraw Hill Inc.: Columbus, OH, USA, 1958. [Google Scholar]

- American Foundrymen’s Society. Pattern-Makers’ Manual; McGraw Hill Inc.: Columbus, OH, USA, 1953. [Google Scholar]

- Schubert, R.; D’ Egidio, S.M. The surface composition of copper with indoor exposures ranging from 3 to 47 years. Corr. Sci. 1990, 30, 999–1008. [Google Scholar] [CrossRef]

- Borland, D.W. The Structure of Materials. In The University of Melbourne Handbook; University of Melbourne: Melbourne, Australia, 1989; pp. 24–25. [Google Scholar]

- Heine, R.W.; Loper, C.R.; Rosenthal, P.C. Principles of Metal Casting; McGraw Hill Inc.: Columbus, OH, USA, 1967. [Google Scholar]

- Zeuner, F. Dating the Past; Methuen & Co. Ltd.: London, UK, 1970. [Google Scholar]

- Shim, J.-H.; Oh, C.-S.; Lee, B.-J.; Lee, D.N.Z. Thermodynamic assessment of the Cu-Sn system. Metallkde 1996, 87, 205–212. [Google Scholar] [CrossRef]

- Pillai, R.M.; Pillai, S.G.K.; Damodaran, A.D. Shaping of High Bronze in Ancient Kerala and the Metallurgy Behind. Met. Mater. Process. 2002, 13, 291–300. [Google Scholar]

- Manu, K.; Abhinav, J.; Shankar, K.V. Morphological and Mechanical Behaviour of Cu–Sn Alloys—A review. Met. Metal Int. 2021, 27, 1915–1946. [Google Scholar]

- Paul, C.; Sellamuthu, R. The effect of Sn content on the properties of surface refined Cu-Sn bronze alloys. Procedia Eng. 2014, 97, 1341–1347. [Google Scholar] [CrossRef]

- Nadolski, M. The evaluation of mechanical properties of high-tin bronzes. Arch. Foundry Eng. 2017, 17, 127–130. [Google Scholar] [CrossRef][Green Version]

- Cekus, D.; Nadolski, M. Assessment of the change in the tin concentration in bronzes to the basic components of the sound of bells. Arch. Metall. Mater. 2021, 66, 531–535. [Google Scholar]

- Debuta, V.; Carvalho, M.; Figueiredo, E.; Antunes, J.; Silva, R. The sound of bronze: Virtual resurrection of a broken medieval bell. J. Cult. Herit. 2016, 19, 544–554. [Google Scholar] [CrossRef]

- Slamet, S.; Suyitno, S.; Kusumaningtyas, I.; Miasa, I.M. Effect of high-tin bronze composition on physical, mechanical, and acoustic properties of Gamelan materials. Arch. Foundry Eng. 2021, 21, 137–145. [Google Scholar]

- Abdulhussaien kadhim, H.; Abed, I.J. Investigation wear behaviour of tin bronze alloy prepared by different casting techniques. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1094, 012126. [Google Scholar] [CrossRef]

- Quaranta, M.; Catelli, E.; Prati, S.; Sciutto, G.; Mazzeo, R. Chinese archaeological artefacts: Microstructure and corrosion behaviour of high-leaded bronzes. J. Cult. Herit. 2014, 15, 283–291. [Google Scholar] [CrossRef]

- Vazdirvanidis, A.; Pantazopoulos, G. Metallographic study of great anthony historical bronze bells of apostle Andrew Skete in Mount Athos, Greece. Metallogr. Microstruct. Anal. 2017, 6, 340–351. [Google Scholar] [CrossRef]

- Sarkar, P.K.; Kakoty, S.K. Effect of quenching parameters on mechanical properties of bell metal. Mater. Today Proc. 2021, 44, 4179–4183. [Google Scholar] [CrossRef]

- Srinivasan, S. Iron Age beta (23% tin) bronze: Peninsular Indian bowls of Adichanallur, Nilgiris, and Boregaon. Mater. Manuf. Process. 2016, 32, 807–812. [Google Scholar] [CrossRef]

- Liu, J.; Zheng, W.; Yin, H. Effect of heat treatment temperature on the spinning structure and properties of a Cu–Sn alloy. Microsc. Microanal. 2020, 26, 29–35. [Google Scholar] [CrossRef] [PubMed]

- Pillai, R.M.; Pillai, S.G.K.; Damodaran, A.D. The lost-wax casting of icons, utensils, bells, and other items in South India. JOM 2002, 54, 12–16. [Google Scholar] [CrossRef]

- Park, J.S.; Park, C.W.; Lee, K.J. Implication of peritectic composition in historical high-tin bronze metallurgy. Mater. Char. 2009, 60, 1268–1275. [Google Scholar] [CrossRef]

- ASM Handbook, Volume 3: Phase Diagrams; ASM International: Materials Park, OH, USA, 1992.

- ASM Specialty Handbook, Copper and Copper Alloys; ASM International: Materials Park, OH, USA, 2001.

- Higgins, R.A. Engineering Metallurgy, 6th ed.; Arnold: London, UK, 1993. [Google Scholar]

- Pantazopoulos, G.; Preka-Alexandri, K.; Varoufakis, G. Metallurgical investigation of bronze urns found at Corfu Island, Greece. Rev. Min. Geotech. Metall. Eng. 2010, 20, 123–139. (In Greek) [Google Scholar]

- Cekus, D.; Kwiaton, P.; Nadolski, M.; Sokół, K. Effect of material-technological properties on the reconstruction of utility parameters of bells. Eng. Sci. Technol. Int. J. 2021, 24, 1042–1048. [Google Scholar] [CrossRef]

- Pantazopoulos, G.; Vazdirvanidis, A. Characterization of the microstructural aspects of machinable α-β phase brass. Microsc. Anal. 2008, 22, 13–16. [Google Scholar]

- Rzadkosz, S.; Garbacz-Klempka, A.; Kozana, J.; Piękoś, M.; Czekaj, E.; Perek-Nowak, M. Research of aluminium influence on tin bronzes. Arch. Foundry Eng. 2015, 15, 93–98. [Google Scholar]

- Campbell, J. Perspective Chapter: A Personal Overview of Casting Processes. In Casting Processes and Modelling of Metallic Materials; Abdallah, Z., Aldoumani, N., Eds.; IntechOpen: London, UK, 2020. [Google Scholar]

- Nadolski, M.; Cekus, D. The influence of casting parameters on the sound of a bell. In Proceedings of the 26th International Conference on Metallurgy and Materials, Brno, Czech Republic, 24–26 May 2017; pp. 1893–1898. [Google Scholar]

- Lee, W. The Casting Method of a Temple Bell Using Beeswax. Korean Patent KR100952444B1, 12 April 2010. [Google Scholar]

- Greco, A.; Maffezzoli, A.; Vlachopoulos, J. Simulation of Heat Transfer During Rotational Molding. Adv. Polym. Technol. 2003, 22, 271–279. [Google Scholar] [CrossRef]

- Holtzer, M.; Bobrowski, A.; Dro ˙zy ´nski, D.; Makselon, J.; Isendorf, B. Investigations of Properties of Moulding Sands with Resins Applied in the Alphaset Technology. Arch. Found. Eng. 2013, 13, 31–37. [Google Scholar]

- Bell, K. Lost Wax: An Exploration of Bronze Sculpture in Senegal. In Independent Study Project (ISP) Collection; University of Denver: Denver, CO, USA, 2009; Volume 735. [Google Scholar]

- Heron, C.; Nemcek, N.; Bonfield, K.M.; Dixon, D.; Ottaway, B.S. The chemistry of Neolithic beeswax. Naturwissenschaften 1994, 81, 266–269. [Google Scholar] [CrossRef]

- Frade, J.C.; Monge Soares, A.M.; Candeias, A.; Ribeiro, M.I.M.; Nunes da Ponte, T.; Serra, M.; Porfírio, E. Beeswax and propolis as sealants of funerary chambers during the Middle Bronze Age in the South-Western Iberian Peninsula. In Proceedings of the 39th International Symposium for Archaeometry, Leuven, Belgium, 28 May–1 June 2012; Scott, R.B., Braekmans, D., Carremans, M., Degryse, P., Eds.; Centre for Archaeological Science Leuven: Leuven, Belgium, 2014; pp. 141–145. [Google Scholar]

- Hung, W. A sampan shan chariot ornament and the Xiangrui design in Western Han art. Arch. Asian Art. 1984, 37, 38–59. [Google Scholar]

- Kim, H.Y. Korea’s Movable Metal Type Opens the Era of Modern Civilization. Koreana 2005, 19, 60–65. [Google Scholar]

- Shin, S. Artistic Achievements and International Exchange of Metalwork of the Unified Silla Period: Gilt-bronze Candlesticks with Inlaid Crystal Ornaments; Art History Research No. 290/291; National Treasure No. 174: Seoul, South Korea, 2016; Volume 9, pp. 43–66. [Google Scholar]

- Tulloch, P. Composition of some natural waxes. Cosmet. Perfumery 1974, 89, 53–54. [Google Scholar]

- Jiménez, J.J.; Bernal, J.L.; del Nozal, M.J.; Martín, M.T.; Bernal, J. Sample preparation methods for beeswax characterization by gas chromatography with flame ionization detection. J. Chromatogr. A 2006, 1129, 262–272. [Google Scholar] [CrossRef]

- Aichholz, R.; Lorbeer, E. Investigation of combwax of honeybees with high temperature gas chromatography and high-temperature gas chromatography– chemical ionization mass spectrometry. I. High-temperature gas chromatography. J. Chromatogr. A 1999, 855, 601–615. [Google Scholar] [CrossRef]

- Evershed, R.P.; Vaughan, S.J.; Dudd, S.N.; Soles, J.S. Fuel for thought? Beeswax in lamps and conical cups from late Minoan Crete. Antiquity 1997, 71, 979–985. [Google Scholar] [CrossRef]

- Tulloch, P.; Hoffman, L.L. Canadian beeswax: Analytical values and composition of hydrocarbons, free acids and long chain esters. J. Am. Oil Chem. Soc. 1972, 49, 696–699. [Google Scholar] [CrossRef]

- Maia, M.; Nunes, F.M. Authentification of beeswax (Apis mellifera) by hightemperature gas chromatography and chemometric analysis. Food Chem. 2013, 136, 961–968. [Google Scholar] [CrossRef]

- Regert, M.; Colinart, S.; Degrand, L.; Decavallas, O. Chemical alteration and use of beeswax through time: Accelerated ageing tests and analysis of archaeological samples from various environmental contexts. Archaeometry 2001, 43, 549–569. [Google Scholar] [CrossRef]

- Daniels, V. Analyses of copper- and beeswax-containing green paint on Egyptian antiquities. Stud. Conserv. 2007, 52, 13–18. [Google Scholar] [CrossRef]

- Garnier, N.; Cren-Olivé, C.; Rolando, C.; Regert, M. Characterization of archaeological beeswax by electron ionization and electrospray ionization mass spectrometry. Anal. Chem. 2002, 74, 4868–4877. [Google Scholar] [CrossRef] [PubMed]

- Regert, M.; Vacher, C.S.; Moulherat, C.; Decavallas, O. Adhesive production and pottery function during the Iron Age at the site of Grand Aunay. Archaeometry 2003, 45, 101–120. [Google Scholar] [CrossRef]

- Luo, W.; Li, T.; Wang, C.; Huang, F. Discovery of beeswax as binding agent on a 6th-century BC Chinese turquoise-inlaid bronze sword. J. Archaeol. Sci. 2012, 39, 1227–1237. [Google Scholar] [CrossRef]

- Regert, M.; Rolando, C. Identification of archaeological adhesives using direct inlet electron ionization mass spectrometry. Anal. Chem. 2002, 74, 965–975. [Google Scholar] [CrossRef]

- Amir, A.; Gadot, Y.; Weitzel, J.; Finkelstein, I.; Neumann, R.; Bezzel, H.; Covello-Paran, K.; Sergi, O. Heated beeswax usage in mortuary practices: The case of Ḥorvat Tevet (Jezreel Valley, Israel) ca. 1000 BCE. J. Archaeol. Sci. Rep. 2021, 36, 102904. [Google Scholar] [CrossRef]

- Davey, C.J. The early history of lost-wax casting. In Metallurgy and Civilisation: Eurasia and Beyond; Mei, J., Rehren, T., Eds.; Archetype: London, UK, 2009; pp. 147–154. [Google Scholar]

- Bernardini, F.; Tuniz, C.; Coppa, A.; Mancini, L.; Dreossi, D.; Eichert, D.; Turco, G.; Biasotto, M.; Terrasi, F.; de Cesare, N.; et al. Beeswax as dental filling on a Neolithic human tooth. PLoS ONE 2012, 7, e44904. [Google Scholar] [CrossRef]

- Kimpe, K.; Jacobs, P.A.; Waelkens, M. Mass spectrometric methods prove the use of beeswax and ruminant fat in late Roman cooking pots. J. Chromatogr. A 2002, 968, 151–160. [Google Scholar] [CrossRef]

- Zografou, A. Magic lamps, luminous dreams: Lamp in PGM recipes. In Light and Darkness in Ancient Greek Myth and Religion; Christopoulos, M., Karakantza, E.D., Levaniouk, O., Eds.; Lexington Books: Plymouth, UK, 2010; pp. 276–294. [Google Scholar]

- Ma, S.P. Study of Lamp in Han Dynasty. Ph.D. Thesis, Fudan University, Shanghai, China, 2012. [Google Scholar]

- Taylor, P.R. An illustrated history of lost wax casting. In Proceedings of the 17th Annual BICTA Conference, Stratford-upon-Avon, UK, 4–7 September 1983. [Google Scholar]

- Kotzin, E.L. Metal Casting and Moulding Processes; American Foundrymen Society Inc.: Schaumburg, IL, USA, 1981. [Google Scholar]

- Eddy, W.P.; Barbero, R.J.; Dieters, W.I.; Esarey, B.J.; Frey, L.; Gros, J.R.; Lyman, T. (Eds.) Investment Casting; American Society for Metals: Materials Park, OH, USA, 1974; pp. 237–261. [Google Scholar]

- Craig, R.G.; Eick, J.D.; Peyton, F.A. Properties of natural waxes used in dentistry. J. Dental Res. 1965, 44, 1308–1316. [Google Scholar] [CrossRef]

- Craig, R.G.; Eick, J.D.; Peyton, F.A. Strength properties of waxes at various temperatures and their practical application. J. Dental Res. 1967, 46, 300–305. [Google Scholar] [CrossRef] [PubMed]

- Won, K.S. The Beeswax Casting Method for a Big Size Temple Bell. Korean Patent KR101487449B1, 3 February 2015. [Google Scholar]

- Kissi, B.S. Evaluation of beeswax and core materials for lost wax casting. Ph.D. Thesis, Faculty of Art, College of Art and Social Sciences, KNUST, Kumasi, Ghana, 2011. [Google Scholar]

- Hossain, E.M.; Ketata, C.; Islam, R. Experimental study of physical and mechanical properties of natural and synthetic waxes using uniaxial compressive strength test. In Proceedings of the Third International Conference on Modeling, Simulation and Applied Optimization, Sharjah, United Arab Emirates, 20–22 January 2009. [Google Scholar]

- Giuseppe, C.; Giuseppe, L.; Milioto, S.; Parisi, F.; Sparacino, V. Thermal and dynamic mechanical properties of beeswax-halloysite nano composites for consolidating waterlogged archaeological woods. Polym. Degrad. Stab. 2015, 120, 220–225. [Google Scholar]

- Zhang, H.; Feng, Y.; Li, K.; Zhang, W. Thermal analysis of four insect waxes based on differential scanning calorimetry (DSC). Procedia Eng. 2011, 18, 101–106. [Google Scholar]

- Dong-Joo, L.; Ick-Jae, S. Effects of vacuum, mold temperature and cooling rate on mechanical properties of press consolidated glass fiber/PET composite. Compos. Part A Appl. Sci. Manuf. 2002, 33, 1107–1114. [Google Scholar]

- Park, M.Y. An experimental study on the restoration of beeswax casting method. J. Stud. Bibliograph. 2006, 33, 79–106. [Google Scholar]

- Sohn, J.W.; Park, J.H.; Choi, S.B. Vibration characteristics of high speed rotary bell cup. Trans. Korean Soc. Noise Vibr. Eng. 2015, 25, 771–778. [Google Scholar] [CrossRef][Green Version]

- Won, K.S. Lost Wax Casting Method of the Temple Bell. Korean Patent KR-10–0587775B1, 14 June 2006. [Google Scholar]

- Hossain, M.A.; Khan, S.A.R.; Kaiser, M.S.; Nur, M.A. Experimental Analysis on the Physical Manners of Thermally Affected Bell Metal. In Proceedings of the International Conference on Mechanical, Industrial and Energy Engineering 2020, Khulna, Bangladesh, 19–21 December 2020. [Google Scholar]

- Mukherjee, D. Investigating the technological aspects of bell metal with special reference to West Bengal Heritage. J. Multidisciplinary Stud. Archaeol. 2018, 6, 1004–1012. [Google Scholar]

- Lee, J.M.; Kim, S.H.; Lee, S.J.; Jeong, J.D.; Choi, H.G. A study on the vibration characteristics of a large size Korean bell. J. Sound Vibr. 2002, 257, 779–790. [Google Scholar] [CrossRef]

- Lisovskii, V.A.; Lisovskaya, O.B.; Kochetkova, L.P.; Favstov, Y.K. Sparingly Alloy. Bell bronzes with elevated parameters of mechanical properties. Metal Sci. Heat Treat. 2007, 49, 232–235. [Google Scholar] [CrossRef]

- Nevworldwonders. Pingdingshan and Spring Temple. Available online: http://www.nevworldwonders.com/2012/04/day-214-pingdingshan-and-spring-temple.html (accessed on 20 March 2022).

- Gierlotka, S. Bells, History, Technique of Production, and Driving Mechanisms; Edycja—Książki Naukowe i Specjalistyczne: Katowice, Poland, 2013; p. 17. ISBN 978-83-935389-9-7. (In Polish) [Google Scholar]

- Piaskowski, J. Technology of Ancient Artistic Castings; Foundry Institute: Krakow, Poland, 1981. (In Polish) [Google Scholar]

- Merechal, K. Bell Casting Technology; Przegląd Odlewnictwa: Krakow, Poland, 1974; pp. 269–273. (In Polish) [Google Scholar]

- Hua, J. The sound of chime bells of 2400 years ago. Endeavour 1993, 17, 32–37. [Google Scholar]

- Saraiva, A.S.; Figueiredo, E.; Águas, H.; Silva, R.J.C. Characterisation of archaeological high-tin bronze corrosion structures. Stud. Conserv. 2022, 67, 222–236. [Google Scholar] [CrossRef]

- Audy, J.; Audy, K. Effects of microstructure and chemical composition on strength and impact toughness of tin bronzes. MM Sci. J. 2009, 6, 124–129. [Google Scholar] [CrossRef]

- Orr, S.A. In situ acoustic analysis of two twentieth-century heritage carillons. Herit. Sci. 2021, 9, 16. [Google Scholar] [CrossRef]

- Swadowski, J. Some problems concerning the acoustic analysis of bells. In Bellfounding in Poland; District Museum in Toruń: Toruń, Poland, 2003; p. 119. (In Polish) [Google Scholar]

- A Guide to Rotational Molding; LyondellBasell Industries: Houston, TX, USA, 2000.

- Sarrabi, S.; Lacrampe, M.-F.; Krawczak, P. Phosphorous Antioxidants against Polypropylene Thermal Degradation during Rotational Molding-kinetic Modeling. J. Appl. Polym. Sci. 2015, 132, 41285. [Google Scholar] [CrossRef]

- Kontopoulou, M.; Vlachopoulos, J. Bubble dissolution in molten polymers and its role in rotational molding. Polym. Eng. Sci. 1999, 39, 1189–1198. [Google Scholar] [CrossRef]

- Shan, T.K.; Chen, C.T.; Huang, J.D. Design of a plastic auto’s door based on the rotational molding process. Key Eng. Mater. 2016, 717, 79–85. [Google Scholar] [CrossRef]

- Löhner, M.; Drummer, D. Experimental studies on the bonding strength and fracture behavior of incompatible materials bonded by mechanical adhesion in multilayer rotational molding. J. Polym. 2016, 2016, 5768453. [Google Scholar] [CrossRef]

- Ogila, K.O.; Shao, M.; Yang, W.; Tan, J. Rotational molding: A review of the models and materials. Express Polym. Lett. 2017, 11, 778–798. [Google Scholar] [CrossRef]

- Rotational Moulding Technology Handbook; Engineers India Research Institute, EIRI Consultants and Engineers: New Delhi, India, 2009.

- Gupta, M.; Ramkumar, P.L.; Sangani, V. An approach toward augmenting materials, additives, processability and parameterization in rotational molding: A review. Mater. Manuf. Process 2020, 35, 1539–1556. [Google Scholar] [CrossRef]

- Yeom, Y.H. Internationalization of Korean Traditional Technology-Bronze Age; National Science Foundation: Daejeon, Korea, 1995. [Google Scholar]

- Lee, W.H.; Wu, Y.F.; Ding, Y.C.; Cheng, T.W. Fabrication of ceramic moulds using recycled shell powder and sand with geopolymer technology in investment casting. Appl. Sci. 2020, 10, 4577. [Google Scholar] [CrossRef]

- Carey, P.R.; Swartzlander, M. Sand Binder Systems. Technical Paper, Part-2; Ask Chemicals: Hilden, Germany, 2022; pp. 1–9. [Google Scholar]

- Callister, W.D. Fundamentals of Materials Science and Engineering; John Wiley and Sons: New York, NY, USA, 2001. [Google Scholar]

- Balasubramanian, A. Classification of Materials; University of Mysore: Mysore, India, 2017. [Google Scholar] [CrossRef]

- Drouet, C.; Leriche, A.; Hampshire, S.; Kashani, M.; Stamboulis, A.; Iafisco, M.; Tampieri, A. Types of ceramics: Material class. In Advances in Ceramic Biomaterials; Elsevier: Amsterdam, The Netherlands, 2017; pp. 21–82. [Google Scholar]

- Bagherpour, E.; Pardis, N.; Reihanian, M.; Ebrahimi, R. An overview on severe plastic deformation: Research status, techniques classification, microstructure evolution, and applications. Int. J. Adv. Manuf. Technol. 2019, 100, 1647–1694. [Google Scholar] [CrossRef]

- Ramkumar, P.L.; Kulkarni, D.M.; Abhijit, V.V.R.; Cherukumudi, A. Investigation of melt flow index and impact strength of foamed LLDPE for rotational moulding process. Procedia Mater. Sci. 2014, 6, 361–367. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Wang, F.; Shi, M.; Tian, W. Mechanical behavior of polyurethane polymer materials under triaxial cyclic loading: A particle flow code approach. J. Wuhan Univ. Technol. Sci. Ed. 2018, 33, 980–986. [Google Scholar] [CrossRef]

- Jia, Z.; Xia, X.; Wang, X.; Wang, T.; Xu, G.; Liu, B.; Zhou, J.; Li, F. All-conjugated amphiphilic diblock copolymers for improving morphology and thermal stability of polymer/nanocrystals hybrid solar cells. Front. Mater. Sci. 2018, 12, 225–238. [Google Scholar] [CrossRef]

- Crawford, R.J. Plastics Engineering; Pergamon Press: Oxford, UK, 1987. [Google Scholar]

- Liu, G.; Park, C.B.; Lefas, J.A. Production of low-density LLDPE foams in rotational molding. Polym. Eng. Sci. 1998, 38, 1997–2009. [Google Scholar] [CrossRef]

- Wang, B.; Panigrahi, S.; Tabil, L.; Crerar, W. Pre-treatment of flax fibers for use in rotationally molded biocomposites. J. Reinf. Plast. Compos. 2007, 26, 447–463. [Google Scholar] [CrossRef]

- Pal, R.; Narasimha Murthy, H.N.; Sreejith, M.; Vishnu Mahesh, K.R.; Krishna, M.; Sharma, S.C. Effect of laminate thickness on moisture diffusion of polymer matrix composites in artificial seawater ageing. Front. Mater. Sci. 2012, 6, 225–235. [Google Scholar] [CrossRef]

- Bart, J.C.J. Additives in Polymers: Industrial Analysis and Applications; John Wiley & Sons Ltd.: West Sussex, UK, 2005. [Google Scholar]

- Alshabanat, M. Morphological, thermal, and biodegradation properties of LLDPE/treated date palm waste composite buried in a soil environment. J. Saudi Chem. Soc. 2019, 23, 355–364. [Google Scholar] [CrossRef]

- Nugent, P. Rotational Molding. In Applied Plastics Engineering Handbook; Elsevier: Amsterdam, The Netherlands, 2011; pp. 311–332. [Google Scholar]

- Ramkumar, P.L.; Kulkarni, D.M. Impact strength investigation of foamed linear low density polyethylene in rotational moulding process. Int. J. Mater. Eng. Innov. 2016, 7, 159. [Google Scholar] [CrossRef]

- Liu, S.-J.; Fu, K.-H. Effect of enhancing fins on the heating/cooling efficiency of rotational molding and the molded product qualities. Polym. Test. 2008, 27, 209–220. [Google Scholar] [CrossRef]

- Torres, F.G.; Aragon, C.L. Final Product Testing of Rotational Moulded Natural Fibre-reinforced Polyethylene. Polym. Test. 2006, 25, 568–577. [Google Scholar] [CrossRef]

- Crawford, R.J.; Spence, A.G.; Cramez, M.C.; Oliveira, M.J. Mould pressure control in rotational moulding. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2004, 218, 1683–1693. [Google Scholar] [CrossRef]

- Spence, A.G.; Crawford, R.J. Removal of pinholes and bubbles from rotationally moulded products. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 1996, 210, 521–533. [Google Scholar] [CrossRef]

- Gogos, G. Bubble removal in rotational molding. Polym. Eng. Sci. 2004, 44, 388–394. [Google Scholar] [CrossRef]

- Qin, L.; Ding, Y.-M.; Zhu, G.-C.; Yu, H.-C.; Yang, W.-M. Heat flow analysis and efficiency optimization of rotational molding equipment for large plastic products. Int. Polym. Process. 2015, 30, 194–201. [Google Scholar] [CrossRef]

- Kunzler, W.F.; Coombs, W.F. Rotational Molding of Contact Lenses. U.S. Patent US4555372A, 26 November 1985. [Google Scholar]

- De Donno, G. Pep Set, an Efficient and Environmentally Friendly Binder System. Posted on 8 November 2016. Available online: https://www.metalworkingworldmagazine.com/7239-2/ (accessed on 20 March 2022).

- Choi, C.; Kim, C. Technological trends for special casting systems and environmental improvement in foundries. J. Korean Soc. Cast. Eng. 2017, 37, 2. [Google Scholar]

- Zhao, X.; Ning, Z.; Li, Z.; Zou, W.; Li, B.; Huang, Y.; Cao, F.; Sun, J. Evolved gas analysis of PEP-SET sand by TG and FTIR. J. Anal. Appl. Pyrol. 2017, 127, 490–495. [Google Scholar] [CrossRef]

- Kyung-Jun, R.A.; Kim, H.Y.; Won, K.S. Restoration of “JikJi” movable metal type and the related issues. J. Hist. Sci. Korea 2006, 28, 139–160. [Google Scholar]

- Kienlin, T.L. Traditions and Transformations: Approaches to Eneolithic (Copper Age) and Bronze Age metalworking and Society in Eastern Central Europe and the Carpathian Basin; BAR Int Series; Archaeopress: Oxford, UK, 2010. [Google Scholar]

- Baron, J.; Miazga, B.; Ntaflos, T.; Puziewicz, J.; Szumny, A. Beeswax remnants, phase and major element chemical composition of the bronze age mould from Gaj Oławski (SW Poland). Archaeol. Anthropol. Sci. 2016, 8, 187–196. [Google Scholar] [CrossRef][Green Version]

- History of Casting, Bernier Cast Metals, Inc. 2018. Available online: https://bernierinc.com/history-of-casting (accessed on 20 March 2022).

- Vidale, M.; Melucco Vaccaro, A.; Salvatore, M.R.; Micheli, M.; Balista, C. From Theophilus to C. S. Smith: Discovery of an eleventh century AD bell-casting mold from venosa (Southern Italy). Mat. Res. Soc. Symp. Proc. 1992, 267, 757–779. [Google Scholar] [CrossRef]

- Drescher, H. Eine technische Betrachtung bronzezeitlicher Halskragen. Offa 1953, 12, 67–72. [Google Scholar]

- Rønne, P. Early Bronze Age Spiral Ornament–The technical Background. J. Dan. Archaeol. 1989, 8, 126–143. [Google Scholar] [CrossRef]

- Rønne, P. Forsogarkaeologi og Bronzealderens Ornamentik; Historical-Archaeological Research Centre, Experimental Archaeology, Studies in Technology and Culture: Lejre, Denmark, 1991. [Google Scholar]

- Cheah, C.M.; Chua, C.K.; Lee, C.W.; Feng, C.; Totong, K. Rapid prototyping and tooling techniques: A review of applications for rapid investment casting. Int. J. Adv. Manuf. Technol. 2005, 25, 308–320. [Google Scholar] [CrossRef]

- Liu, Q.; Sui, G.; Leu, M.C. Experimental study on the ice pattern fabrication for the investment casting by rapid freeze prototyping. Comput. Ind. 2002, 48, 181–197. [Google Scholar] [CrossRef]

| Bell Name | Period | Remarks |

|---|---|---|

| Silla bells | 57 BCE to 935 CE | Silla art, gold crowns, tombs, Buddhist temples |

| Sangwonsa bell | 725 CE | Mount Odaesan near Pyeongchang |

| Songdok bell | 771 CE | Gyeongju National Museum, Korea |

| Hwangnyong-sa bell | 553-645 CE | Gyeonju, Korea |

| Goryeo bell | 963 CE | Toksu Palace Museum of Fine Arts, Seoul, Korea |

| Kasagi bell | 1196 CE | Kyoto, Japan |

| Name of Bell | Chemical Composition (wt.%) | Impurity | |||||

|---|---|---|---|---|---|---|---|

| Cu | Sn | Pb | Au | Zn | Ag | S | |

| Sangwonsa bell | 83.87 | 13.26 | 2.12 | - | 0.32 | - | - |

| Seonrimwon bell | 80.2 | 12.2 | - | - | 2.2 | - | 0.1 |

| Silsangsa bell | 75.7 | 18.0 | 0.31 | - | - | - | - |

| Bell of the Joseon dynasty | 80.1 | 12.2 | - | - | - | - | - |

| Japanese bell | 82.1 | 9~13 | - | - | 1~1.7 | - | - |

| Alloying Constituents (wt.%) | Properties | Ref. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sn | Pb | Zn | Bi | Ag | Sb | As | Ni | Fe | S | P | ||

| 10–20 | - | ≈5 | - | - | - | - | - | - | - | - | High tensile strength | [37,44,45,46,47,48,49] |

| 10–20 | ✓ | - | ✓ | - | - | ✓ | - | - | - | - | Reduced tensile strength | [44,45,46,47,49] |

| <23 | - | <5 | - | - | ≈1 | - | - | ✓ | ✓ | - | High hardness | [44,45,46,49] |

| >23 | - | - | ✓ | - | >1 | ✓ | - | - | - | - | High brittleness | [44,45,46,49] |

| - | ✓ | - | - | - | - | - | ✓ | ✓ | - | - | High wear resistance | [49] |

| - | - | <5 | - | - | - | - | - | - | - | - | High elongation | [37,44,45,49] |

| <5 | - | - | - | - | - | - | - | - | - | - | Reduced elongation | [43,44] |

| ≈20 | - | - | - | - | - | - | - | - | - | - | High elastic limit | [43,44,46,48] |

| >23 | - | - | - | - | - | - | - | - | - | - | Low elastic limit | [43,44,46,48] |

| - | - | - | - | - | - | - | - | ✓ | - | - | Abrasion resistant | [50] |

| ✓ | - | - | - | - | - | - | - | - | - | - | High toughness | [21,22,24] |

| - | - | - | - | - | - | - | - | ✓ | - | - | Low toughness | [43,44,46] |

| - | - | - | - | - | - | - | ✓ | - | - | - | Fatigue resistant | [51] |

| ✓ | ✓ | - | - | - | - | - | - | - | - | - | High fluidity | [11,22,43] |

| - | - | - | - | - | - | - | >2 | - | - | - | Low fluidity | [5,43,49] |

| - | - | - | - | - | ≈1 | - | - | - | - | 0.01 | Deoxidizing | [43] |

| - | - | - | - | - | - | - | ✓ | - | - | - | Reduced deformability | [52] |

| - | - | - | - | - | - | - | - | ✓ | - | - | Poor rusting resistance | [44,45,53] |

| >15 | - | - | - | - | - | - | - | - | - | - | Poor crack resistance | [43,44] |

| ✓ | - | - | - | - | - | - | - | - | - | - | Change in cast color | [33,43,44,45] |

| - | - | ✓ | - | - | - | - | - | - | - | - | Reduced crystallization gap | [42,43,44,49,54] |

| - | - | - | ✓ | - | - | ✓ | - | - | - | - | Poor castability | [43,44,45,49,54] |

| ✓ | ✓ | - | - | - | - | - | - | - | ✓ | - | High machinability | [43,44,45,46,49,54] |

| - | - | - | - | - | - | - | - | ✓ | - | - | Poor machinability | [3,5,11,44] |

| <10 | - | - | - | - | - | - | - | - | - | - | Highly porous | [2,44,45,54] |

| - | - | - | - | - | - | - | 0.4–5 | - | - | - | Reduced porosity | [55,56] |

| - | - | - | - | - | - | - | 0.5–2 | - | - | - | Softening increased | [45,55] |

| - | - | - | - | - | - | - | 2–4 | - | - | - | Structure stabilizes | [45,55,56] |

| 20–23 | - | - | - | - | ≈1 | - | - | - | - | - | Good sound quality | [37,44,45,46] |

| - | >1.5 | >1.5 | - | ✓ | - | - | - | - | - | - | Poor sound quality | [37,44,45,46] |

| ✓ | ✓ | ✓ | - | - | - | - | - | - | - | - | Reduced melting point | [37,43,44,45,47,48] |

| ✓ | - | - | - | ✓ | - | - | - | - | - | - | Expensive | [37,43,44,45,46] |

| - | ✓ | - | - | - | - | - | - | - | - | - | Cost-effective | [37,43,44,45,46] |

| Polymer | Moldability | Impact Strength | Advantage | Limitations |

|---|---|---|---|---|

| Polyethylene | Excellent | Good | Low cost | Lower strength |

| Polypropylene | Good | Poor | Better stiffness | Low strength at cryo temperatures, costly than polyethylene |

| Polystyrene | Good | Poor | Minimum shrinkage | Poor strength |

| Polyether ether ketone | Moderate | Poor | Rigid, fire safety | Expensive compared to polyethylene |

| Polyvinyl chloride | Good | Good | Easily paintable | costly than polyethylene, lower stiffness than polyethylene |

| Acrylonitrile butadiene styrene | Moderate | Good | Rigid and paintable | costly than polyethylene |

| Ethylene butyl acetate | Good | Good | Stretchable | Powder form |

| Epoxy | Moderate | Poor | Thick and rigid, high impact strength | Highly expensive |

| Fluropolymers | Good | Good | Chemical resistant | toxic |

| Nylon | Good | Good | Heat resistance, better impact resistance | Expensive |

| Polycarbonate | Good | Good | Transparent, tough | Harder moldability compared to polyethylene |

| Polyurethane | Good | Good | Wear resistant | Higher cost than polyethylene |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Won, C.-S.; Jung, J.P.; Won, K.-S.; Sharma, A. Technological Insights into the Evolution of Bronze Bell Metal Casting on the Korean Peninsula. Metals 2022, 12, 1776. https://doi.org/10.3390/met12111776

Won C-S, Jung JP, Won K-S, Sharma A. Technological Insights into the Evolution of Bronze Bell Metal Casting on the Korean Peninsula. Metals. 2022; 12(11):1776. https://doi.org/10.3390/met12111776

Chicago/Turabian StyleWon, Chun-Soo, Jae Pil Jung, Kwang-Sik Won, and Ashutosh Sharma. 2022. "Technological Insights into the Evolution of Bronze Bell Metal Casting on the Korean Peninsula" Metals 12, no. 11: 1776. https://doi.org/10.3390/met12111776

APA StyleWon, C.-S., Jung, J. P., Won, K.-S., & Sharma, A. (2022). Technological Insights into the Evolution of Bronze Bell Metal Casting on the Korean Peninsula. Metals, 12(11), 1776. https://doi.org/10.3390/met12111776