Mg-Ni-Nb2O5 Composite Produced by High-Pressure Torsion

Abstract

1. Introduction

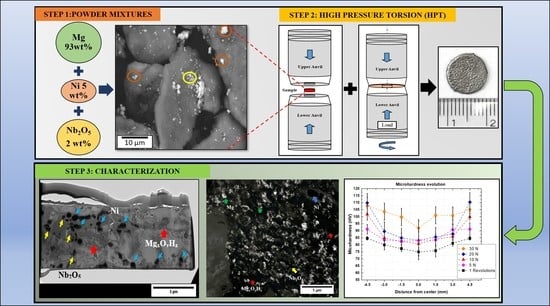

2. Materials and Methods

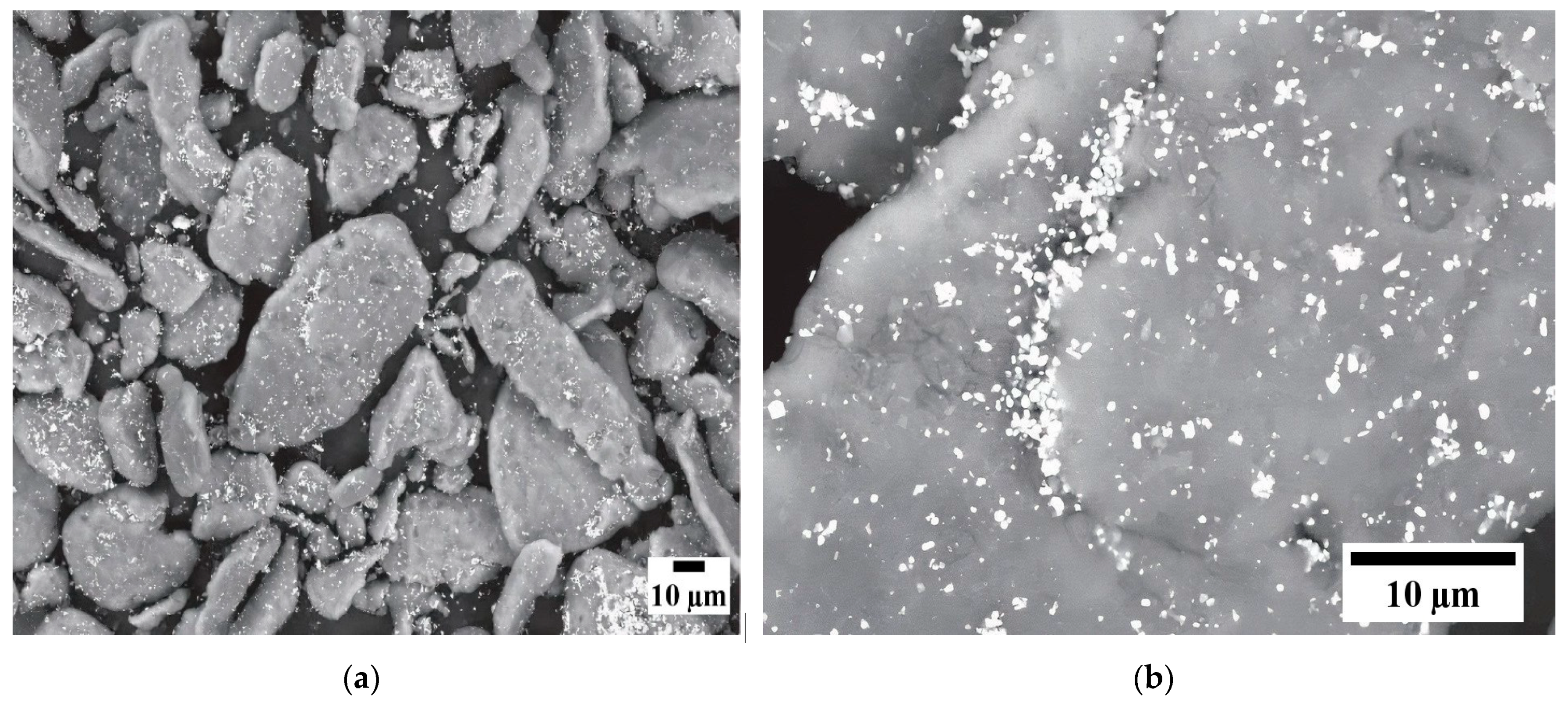

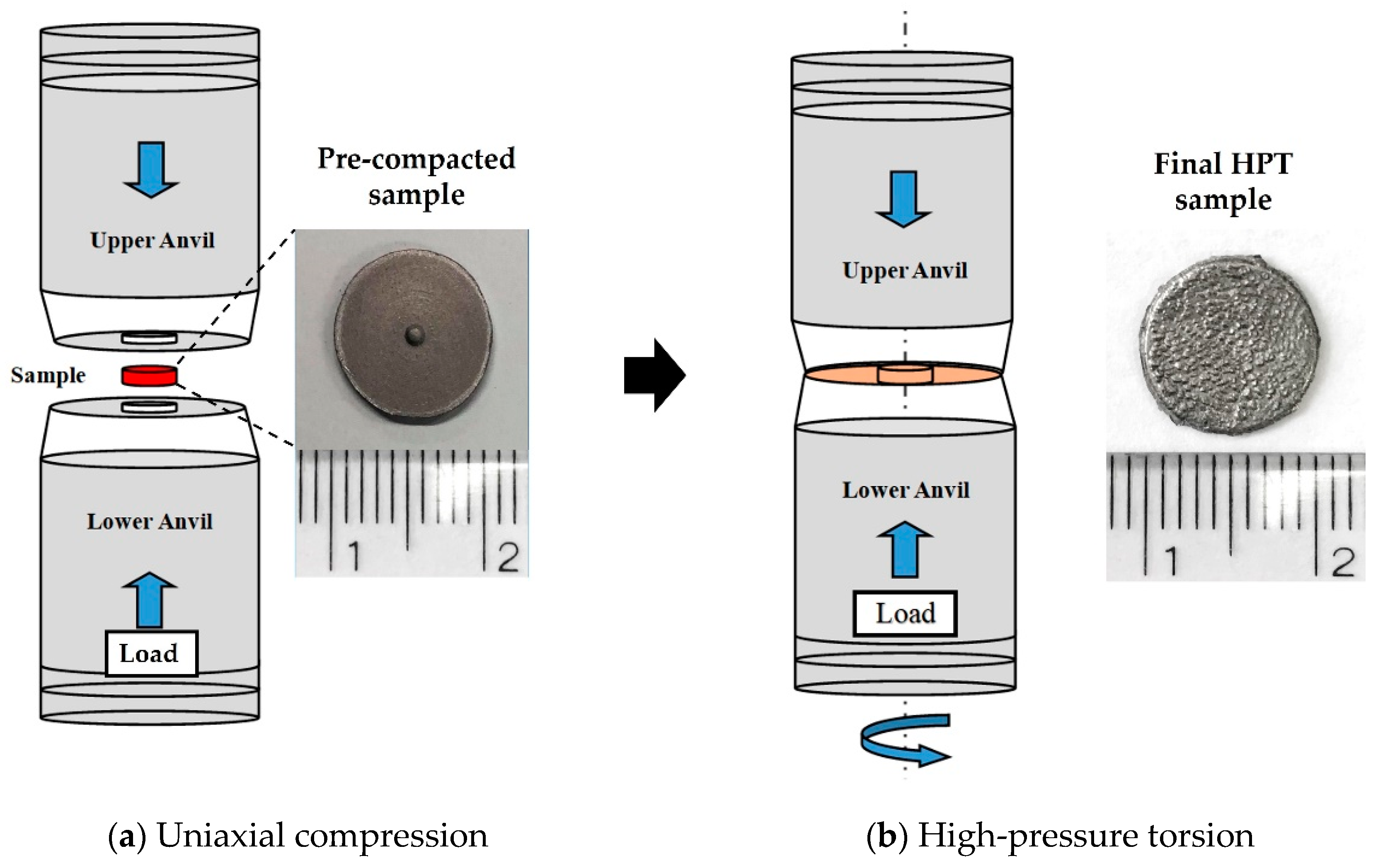

2.1. Sample Processing

2.2. Characterization

3. Results and Discussion

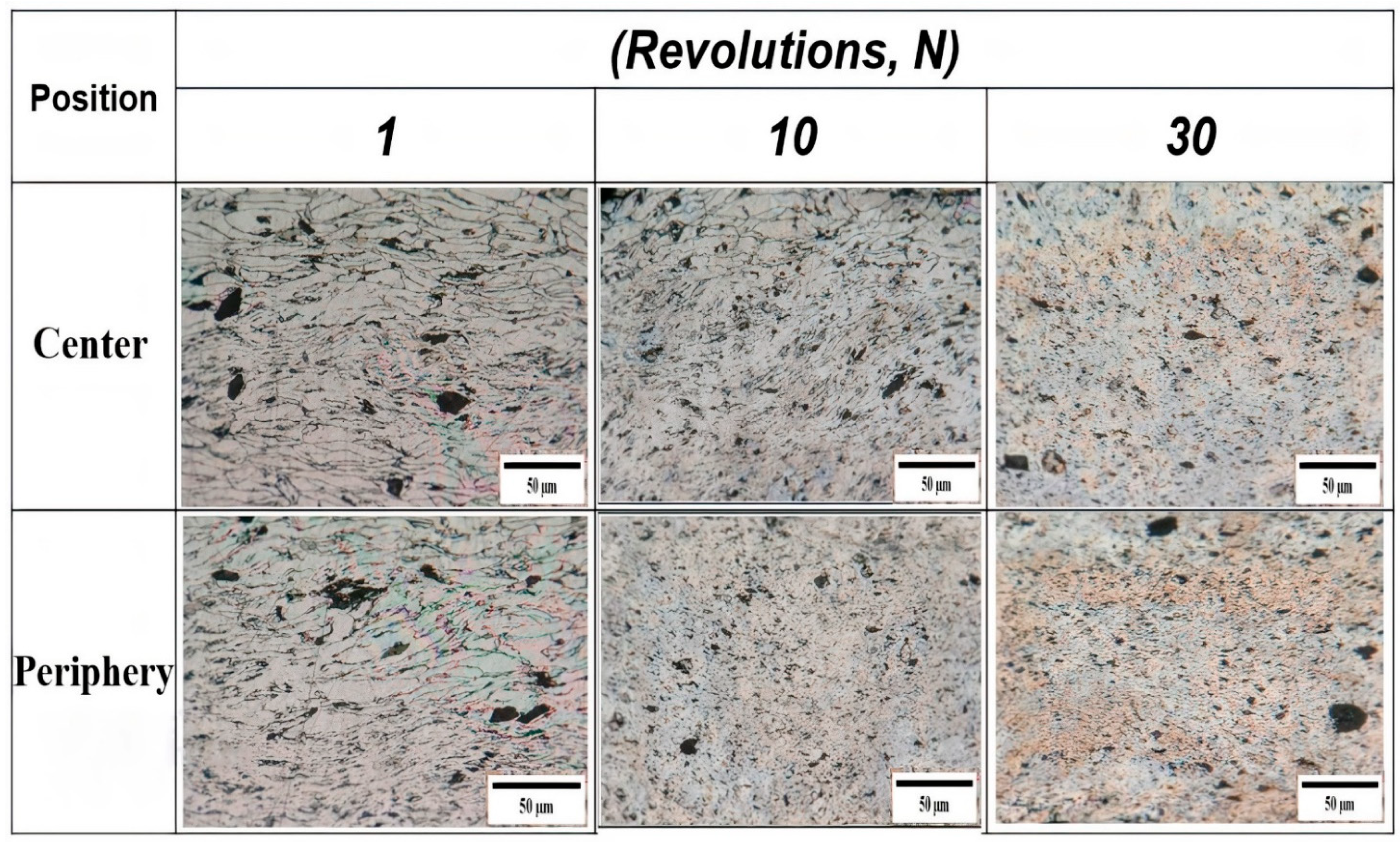

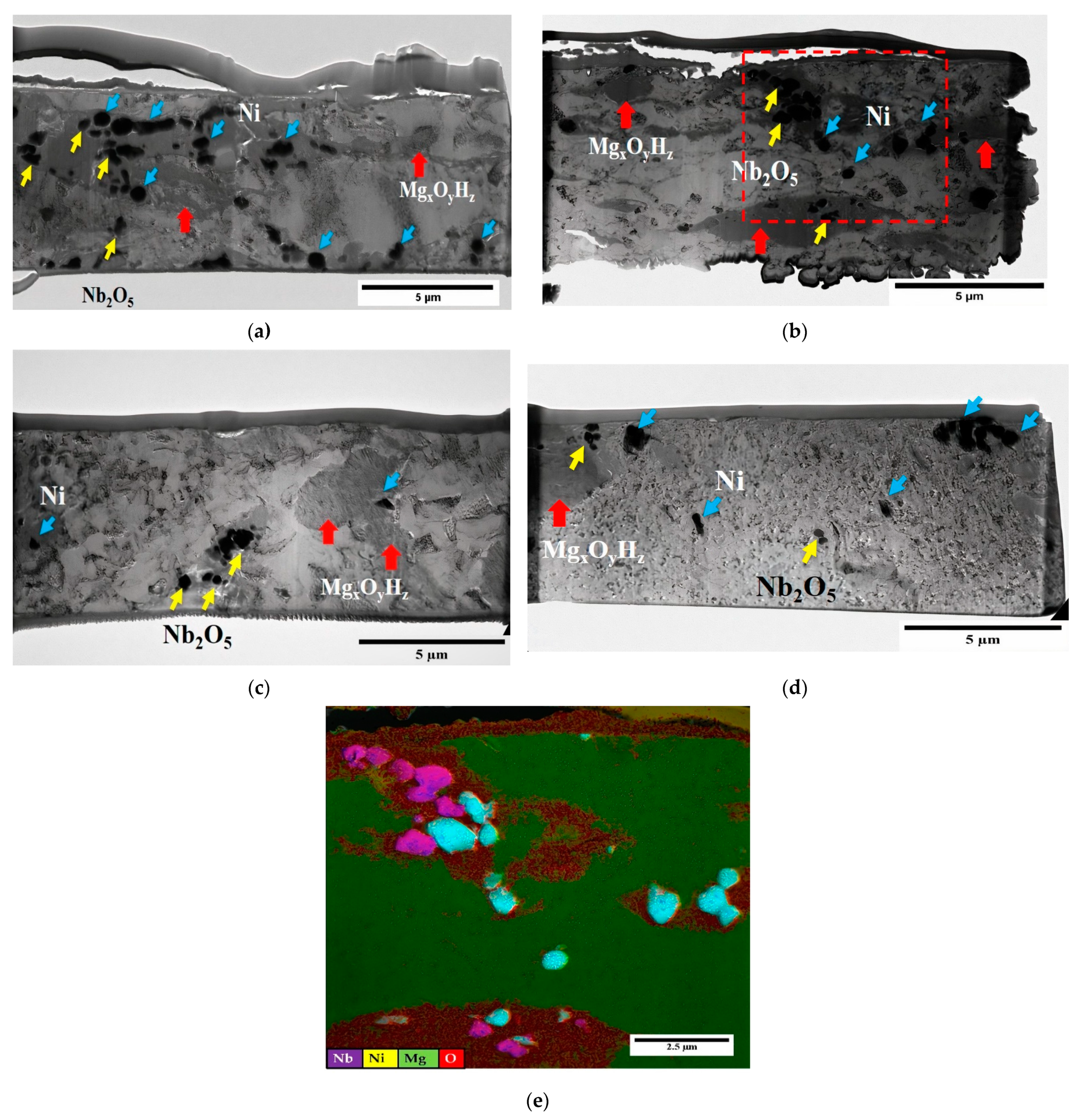

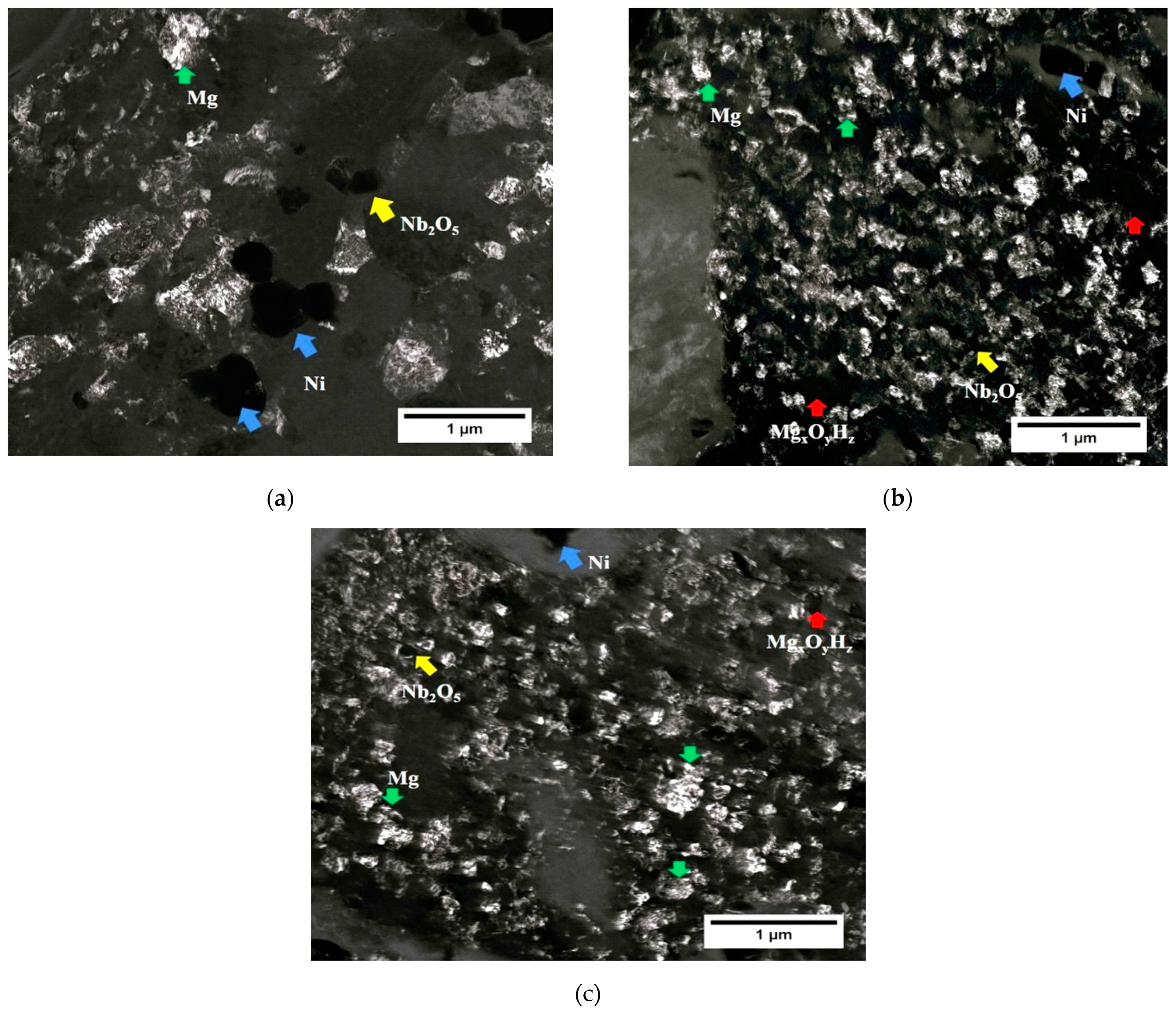

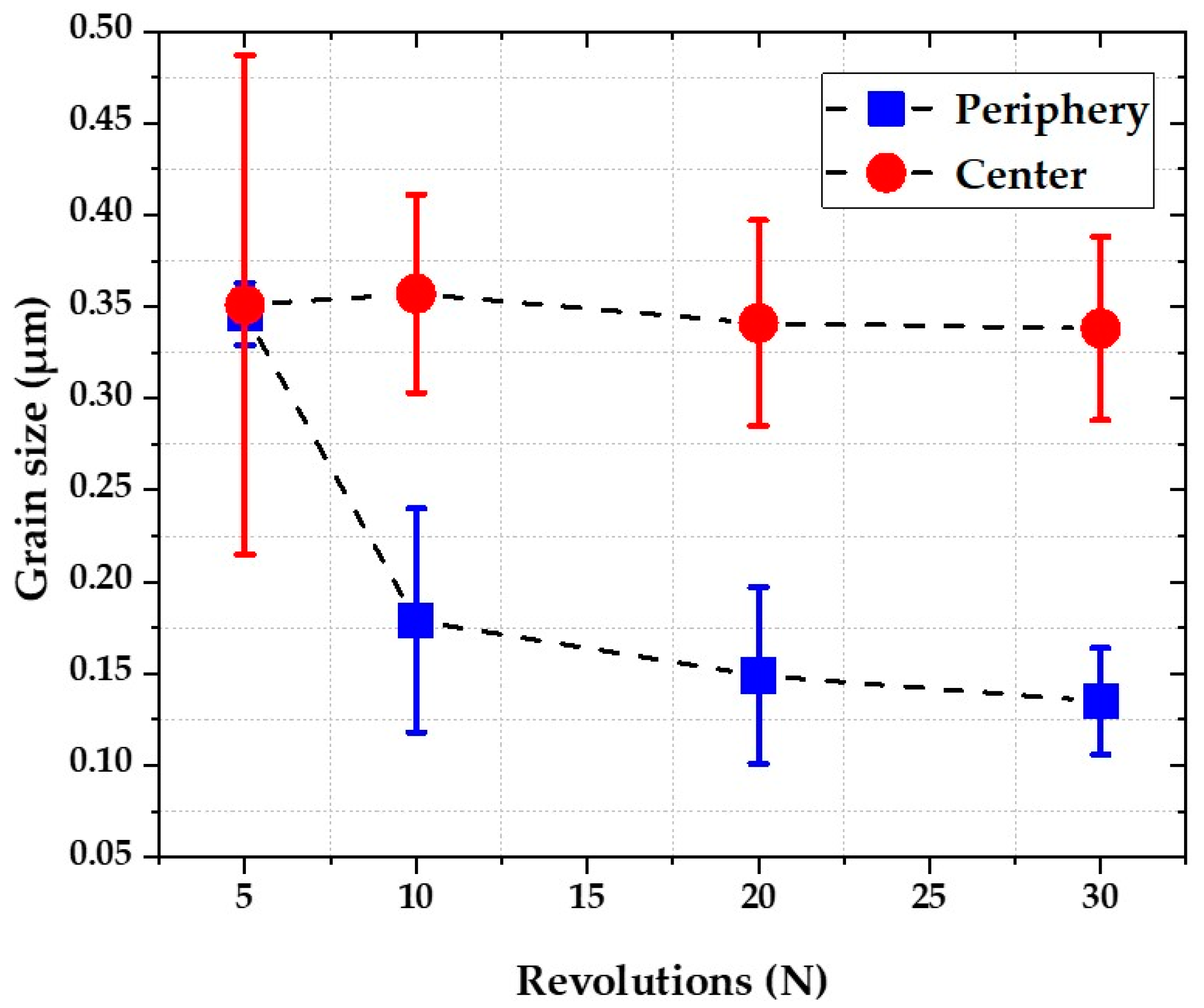

3.1. Microstructural Characteristics after HPT

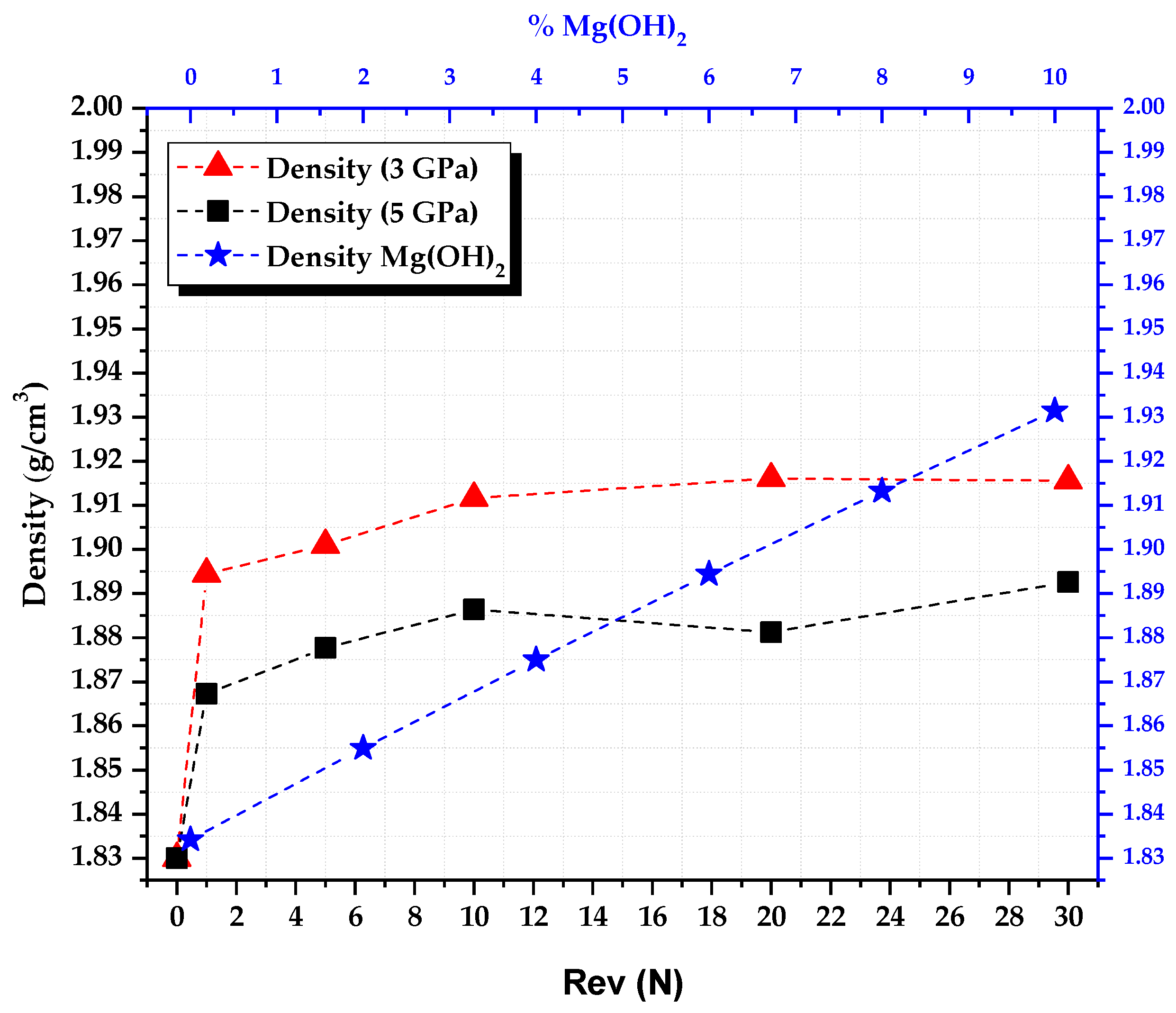

3.2. Density Measurements

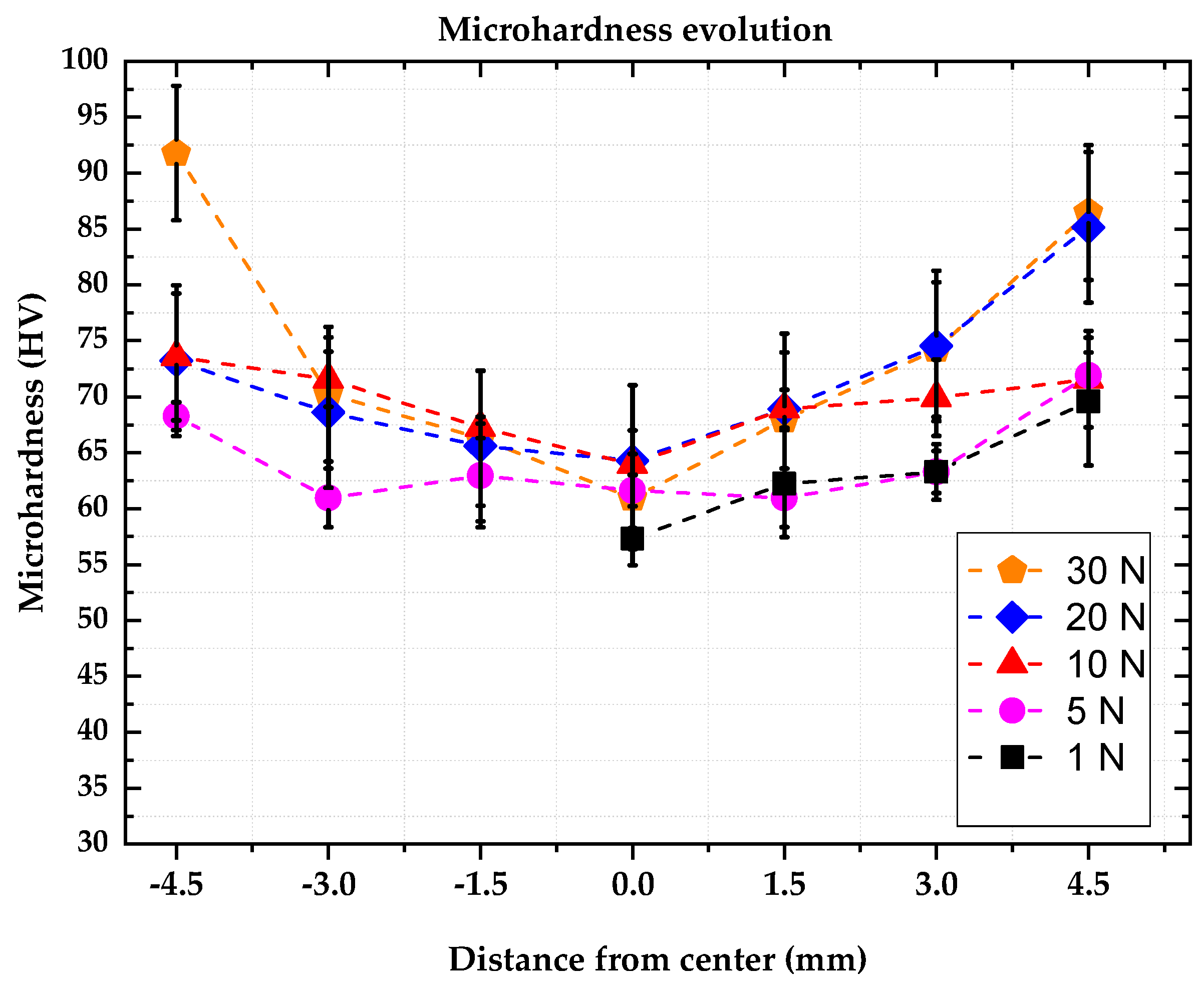

3.3. Microhardness Evolution

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kapoor, R. Severe Plastic Deformation of Materials. In Materials under Extreme Conditions: Recent Trends and Future Prospects; Chap. 20; Tyagi, A.K., Banerjee, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 717–754. [Google Scholar]

- Liu, D.X.; Pang, X.; Li, D.L.; Guo, C.G.; Wongsa-Ngam, J.; Langdon, T.G.; Meyers, M.A. Microstructural Evolution and Properties of a Hot Extruded and HPT-Processed Resorbable Magnesium WE43 Alloy. Adv. Eng. Mater. 2017, 19, 1600698. [Google Scholar] [CrossRef]

- Abdulov, R.Z.; Valiev, R.Z.; Krasilnikov, N.A. Formation of submicrometre-grained structure in magnesium alloy due to high plastic strains. J. Mater. Sci. Lett. 1990, 9, 1445–1447. [Google Scholar] [CrossRef]

- Alsubaie, S.A.; Bazarnik, P.; Lewandowska, M.; Huang, Y.; Langdon, T.G. Evolution of microstructure and hardness in an AZ80 magnesium alloy processed by high-pressure torsion. J. Mater. Res. Technol. 2016, 5, 152–158. [Google Scholar] [CrossRef]

- Figueiredo, R.B.; Aguilar, M.T.P.; Cetlin, P.R.; Langdon, T.G. Processing magnesium alloys by severe plastic deformation. IOP Conf. Ser. Mater. Sci. Eng. 2014, 63, 012171. [Google Scholar] [CrossRef]

- Osorio-García, M.; Suárez-Alcántara, K.; Todaka, Y.; Tejeda-Ochoa, A.; Herrera-Ramírez, M.; Hernández-Silva, O.; Cruz-Gandarilla, F.; Cabañas-Moreno, J.G. Low-temperature hydrogenation of Mg-Ni-Nb2O5 alloy processed by high-pressure torsion. J. Alloys Compd. 2021, 878, 160309. [Google Scholar] [CrossRef]

- Varin, R.A.; Czujko, T.; Wronski, Z.S. Nanomaterials for Solid State Hydrogen Storage; Chap. 2; Springer Science+Business Media: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Aguey-Zinsou, K.-F.; Fernandez, J.R.A.; Klassen, T.; Bormann, R. Effect of Nb2O5 on MgH2 properties during mechanical milling. Int. J. Hydrogen Energy 2007, 32, 2400–2407. [Google Scholar] [CrossRef]

- Edalati, K.; Kitabayashi, K.; Ikeda, Y.; Matsuda, J.; Li, H.W.; Tanaka, I.; Akiba, E.; Horita, Z. Bulk nanocrystalline gamma magnesium hydride with low dehydrogenation temperature stabilized by plastic straining via high-pressure torsion. Scr. Mater. 2018, 157, 54–57. [Google Scholar] [CrossRef]

- Leiva, D.R.; Jorge, A.M.; Ishikawa, T.T.; Botta, W.J. Hydrogen storage in Mg and Mg-based alloys and composites processed by severe plastic deformation. Mater. Trans. 2019, 60, 1561–1570. [Google Scholar] [CrossRef]

- Skripnyuk, V.M.; Rabkin, E.; Estrin, Y.; Lapovok, R. The effect of ball milling and equal channel angular pressing on the hydrogen absorption/desorption properties of Mg-4.95 wt% Zn-0.71 wt% Zr (ZK60) alloy. Acta Mater. 2004, 52, 405–414. [Google Scholar] [CrossRef]

- Grill, A.; Horky, J.; Panigrahi, A.; Krexner, G.; Zehetbauer, M. Long-term hydrogen storage in Mg and ZK60 after Severe Plastic Deformation. Int. J. Hydrogen Energy 2015, 40, 17144–17152. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Estrin, Y.; Horita, Z.; Langdon, T.G.; Zehetbauer, M.J.; Zhu, Y. Producing Bulk Ultrafine-Grained Materials by Severe Plastic Deformation. JOM 2006, 58, 33–39. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Estrin, Y.; Horita, Z.; Langdon, T.G.; Zehetbauer, M.J.; Zhu, Y. Producing Bulk Ultrafine-Grained Materials by Severe Plastic Deformation: Ten Years Later. JOM 2016, 68, 1216–1226. [Google Scholar] [CrossRef]

- Moss, M.; Lapovok, R.; Bettles, C.J. The Equal Channel Angular Pressing of Magnesium and Magnesium Alloy Powders. JOM 2007, 59, 54–57. [Google Scholar] [CrossRef]

- Alexandrov, I.V.; Zhu, Y.T.; Lowe, T.C.; Islamgaliev, R.K.; Valiev, R.Z. Microstructures and properties of nanocomposites obtained through SPTS consolidation of powders. Metall. Mater. Trans. A 1998, 29, 2253–2260. [Google Scholar] [CrossRef]

- Xia, K. Consolidation of particles by severe plastic deformation: Mechanism and applications in processing bulk ultrafine and nanostructured alloys and composites. Adv. Eng. Mater. 2010, 12, 724–729. [Google Scholar] [CrossRef]

- ASTM-B962-08; Standard Test Methods for Density of Compacted or Sintered Powder Metallurgy Products Using Archimedes’ Principle. ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- Kondoh, K.; Funatsu, K.; Takahashi, M.; Li, S.; Akamatsu, F.; Umeda, J. Understanding Corrosion Behavior of Magnesium Surface by x-Ray Irradiation for Improved Surface Design and Applications. JOM 2020, 72, 4657–4664. [Google Scholar] [CrossRef]

- Ahmadkhaniha, D.; Huang, Y.; Jaskari, M.; Järvenpää, A.; Sohi, M.H.; Zanella, C.; Karjalainen, L.P.; Langdon, T.G. Effect of high-pressure torsion on microstructure, mechanical properties and corrosion resistance of cast pure Mg. J. Mater. Sci. 2018, 53, 16585–16597. [Google Scholar] [CrossRef]

- Lindstrom, R.; Johansson, L.-G.; Thompson, G.E.; Skeldon, P.; Svensson, J. Corrosion of magnesium in humid air. Corros. Sci. 2004, 46, 1141–1158. [Google Scholar] [CrossRef]

- Mansoor, P.; Dasharath, S.M. Microstructural and mechanical properties of magnesium alloy processed by severe plastic deformation (SPD)–A review. Mater. Today Proc. 2019, 20, 145–154. [Google Scholar] [CrossRef]

- Harai, Y.; Kai, M.; Kaneko, K.; Horita, Z.; Langdon, T.G. Microstructural and mechanical characteristics of AZ61 magnesium alloy processed by high-pressure torsion. Mater. Trans. 2008, 49, 76–83. [Google Scholar] [CrossRef]

- Figueiredo, R.B.; Langdon, T.G. Processing Magnesium and Its Alloys by High-Pressure Torsion: An Overview. Adv. Eng. Mater. 2019, 21, 1801039. [Google Scholar] [CrossRef]

- Pippan, R.; Scheriau, S.; Taylor, A.; Hafok, M.; Hohenwarter, A.; Bachmaier, A. Saturation of Fragmentation during Severe Plastic Deformation. Annu. Rev. Mater. Res. 2010, 40, 319–343. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fibela-Esparza, M.; Salinas-Rodriguez, A.; Méndez-Nonell, J.; Herrera-Ramirez, J.M.; Todaka, Y.; Cabañas-Moreno, J.G. Mg-Ni-Nb2O5 Composite Produced by High-Pressure Torsion. Metals 2022, 12, 1684. https://doi.org/10.3390/met12101684

Fibela-Esparza M, Salinas-Rodriguez A, Méndez-Nonell J, Herrera-Ramirez JM, Todaka Y, Cabañas-Moreno JG. Mg-Ni-Nb2O5 Composite Produced by High-Pressure Torsion. Metals. 2022; 12(10):1684. https://doi.org/10.3390/met12101684

Chicago/Turabian StyleFibela-Esparza, Martin, Armando Salinas-Rodriguez, Juan Méndez-Nonell, José Martin Herrera-Ramirez, Yoshikazu Todaka, and José Gerardo Cabañas-Moreno. 2022. "Mg-Ni-Nb2O5 Composite Produced by High-Pressure Torsion" Metals 12, no. 10: 1684. https://doi.org/10.3390/met12101684

APA StyleFibela-Esparza, M., Salinas-Rodriguez, A., Méndez-Nonell, J., Herrera-Ramirez, J. M., Todaka, Y., & Cabañas-Moreno, J. G. (2022). Mg-Ni-Nb2O5 Composite Produced by High-Pressure Torsion. Metals, 12(10), 1684. https://doi.org/10.3390/met12101684