Recrystallization Texture Analysis of FeCoNiCrMnAl0.5 High-Entropy Alloy Investigated by High-Energy X-ray Diffraction

Abstract

1. Introduction

2. Experimental

3. Results

4. Discussion

4.1. Orientation Correlation between the fcc and bcc Phases

4.2. Annealing Effects on the Cold-Rolled Texture

5. Conclusions

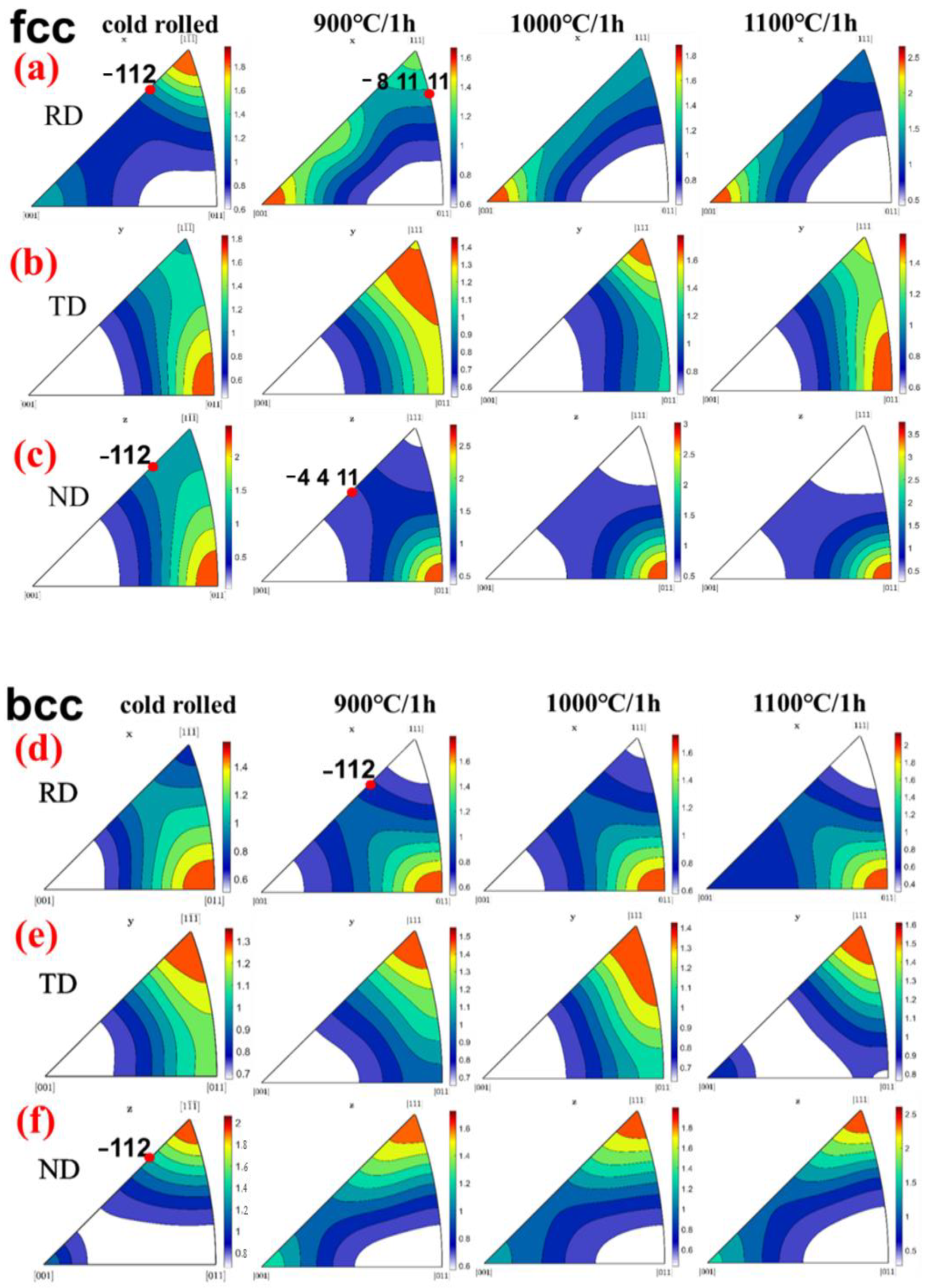

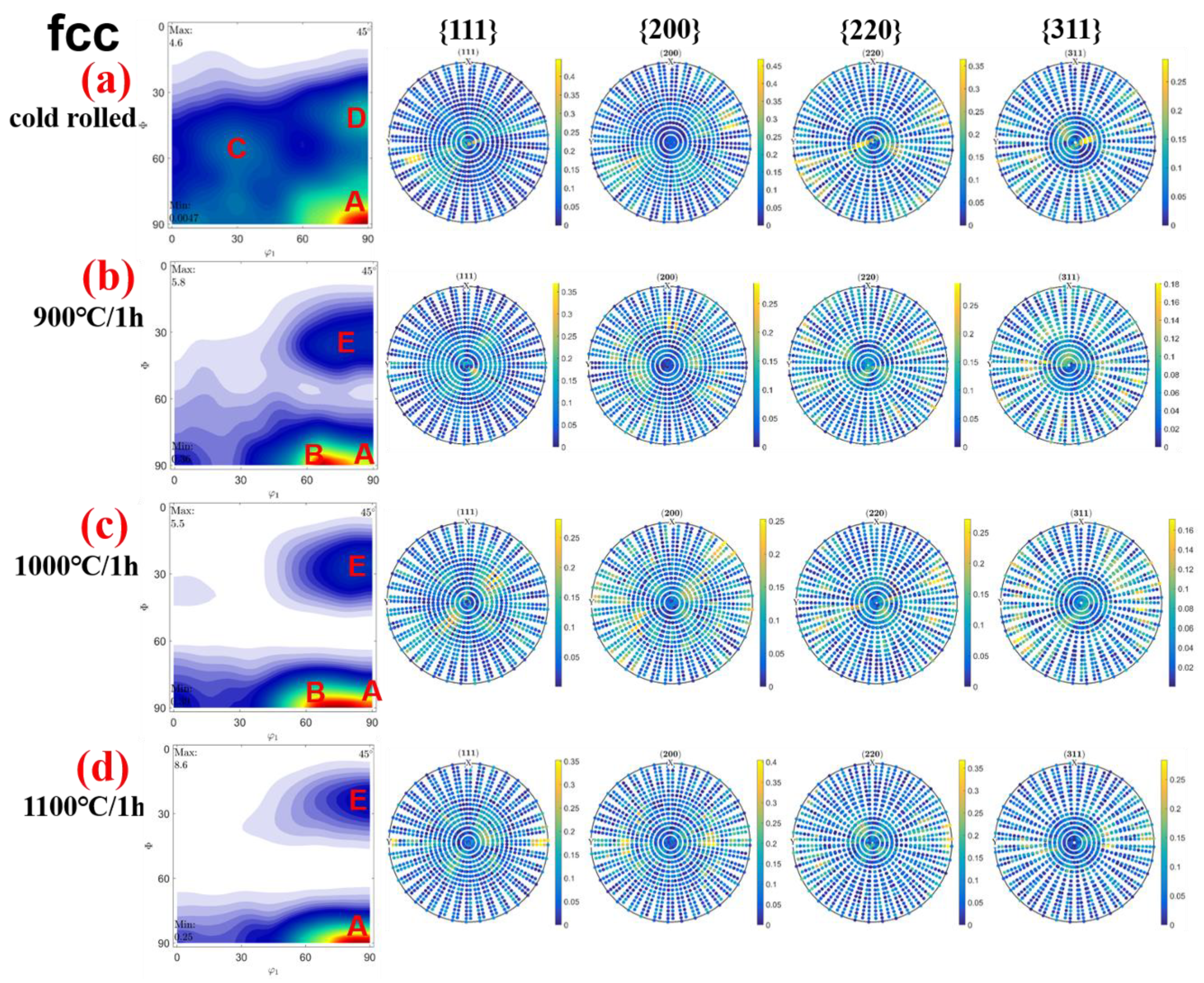

- In the fcc phase, the {1-1-1}//RD orientation decreased and then rotated toward {100}//RD with increasing annealing temperature. Here, <001>//ND is the dominant orientation in the cold-rolled and annealed states. A new texture component, {4 4 11}<-11 -11 8>, replaced {112}<111> after the annealing treatment.

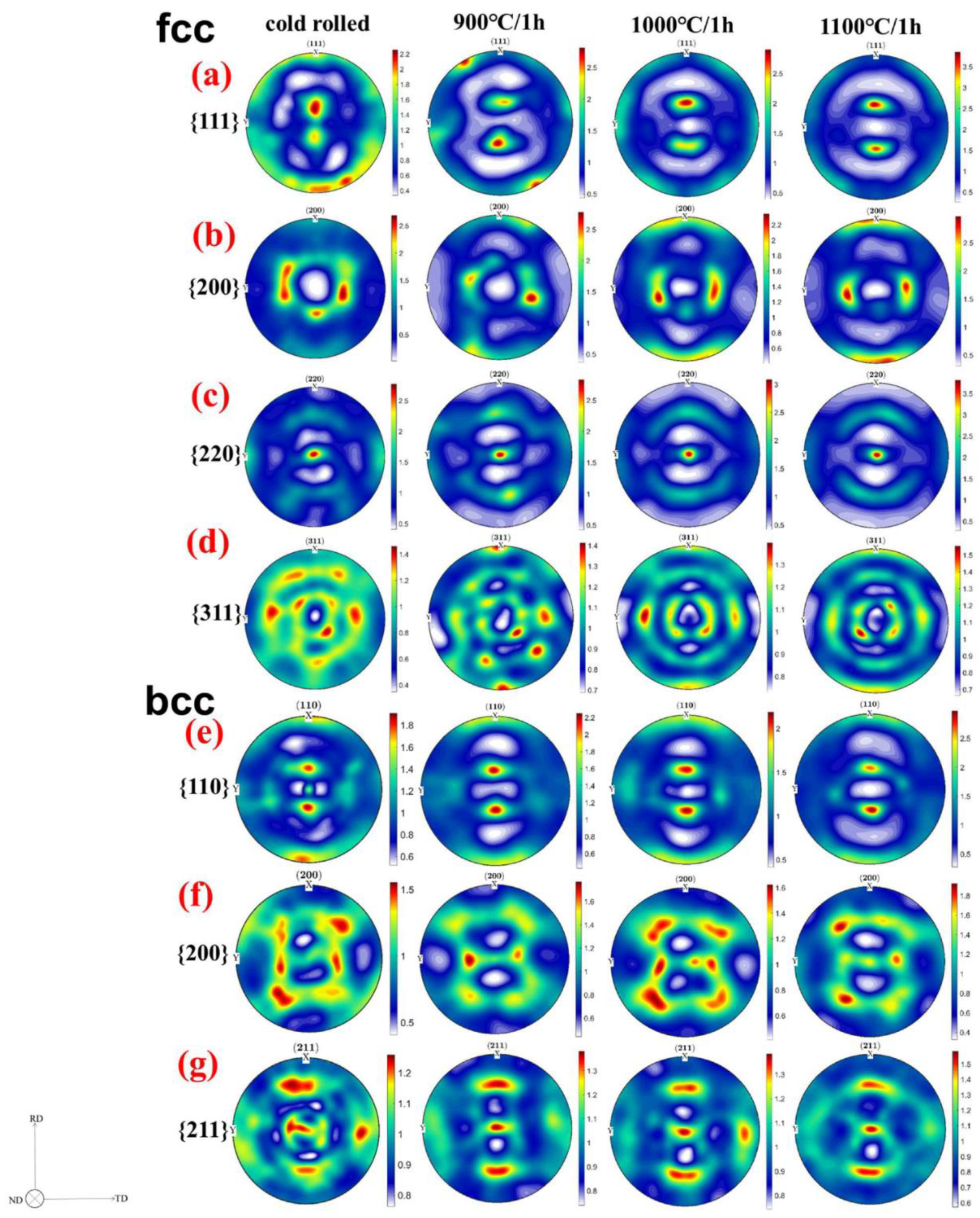

- The orientation relationships between {111}fcc//{110}bcc and <110>fcc//<111>bcc are observed in the FeCoNiCrMnAl0.5 HEA.

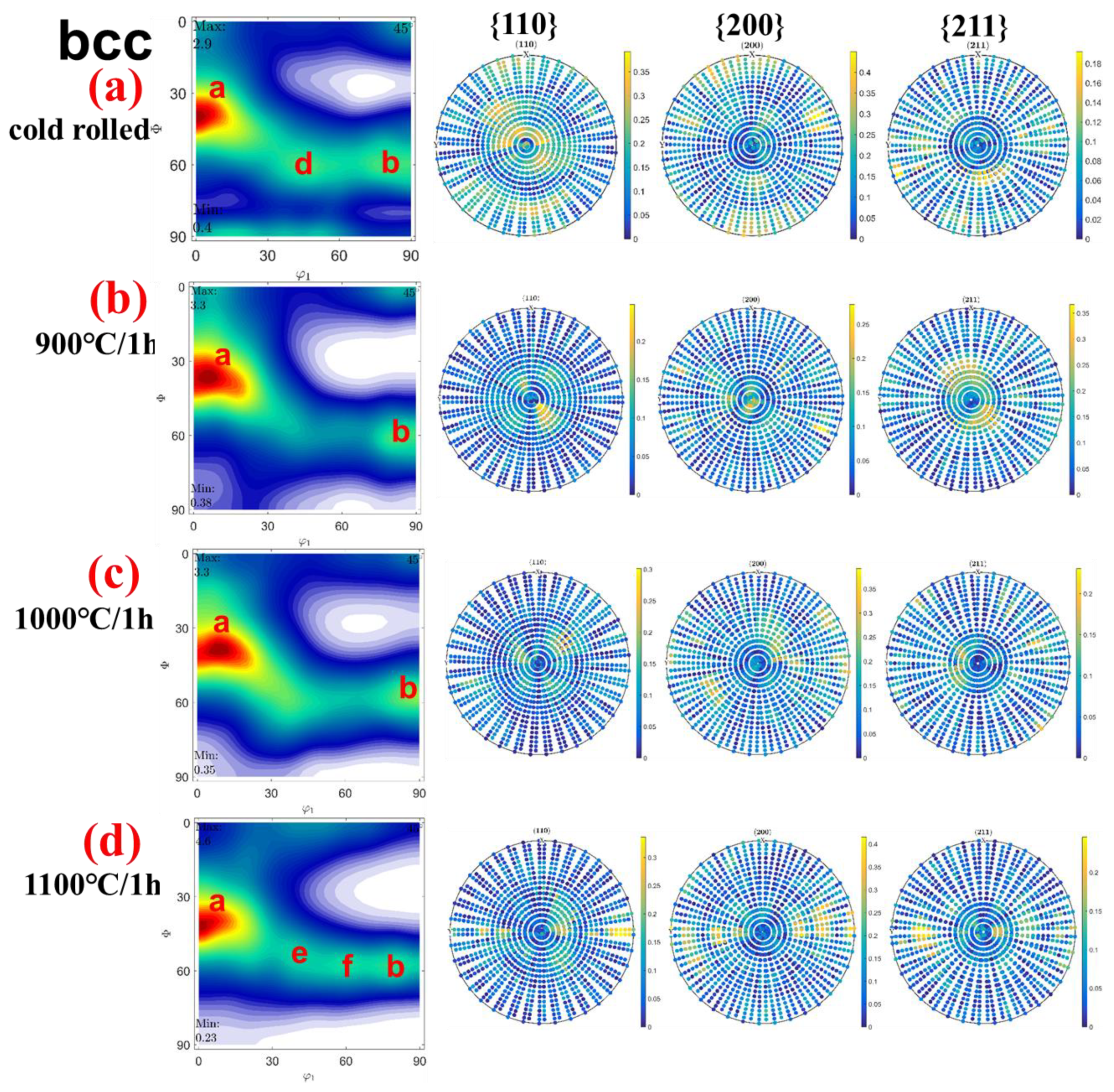

- The Goss texture component in the fcc phase and α{112}<110> texture component in the bcc phase exhibited similar trends. The major texture components in the bcc phase are confirmed as {112}<110> α and {111}<112> γ in four annealed states.

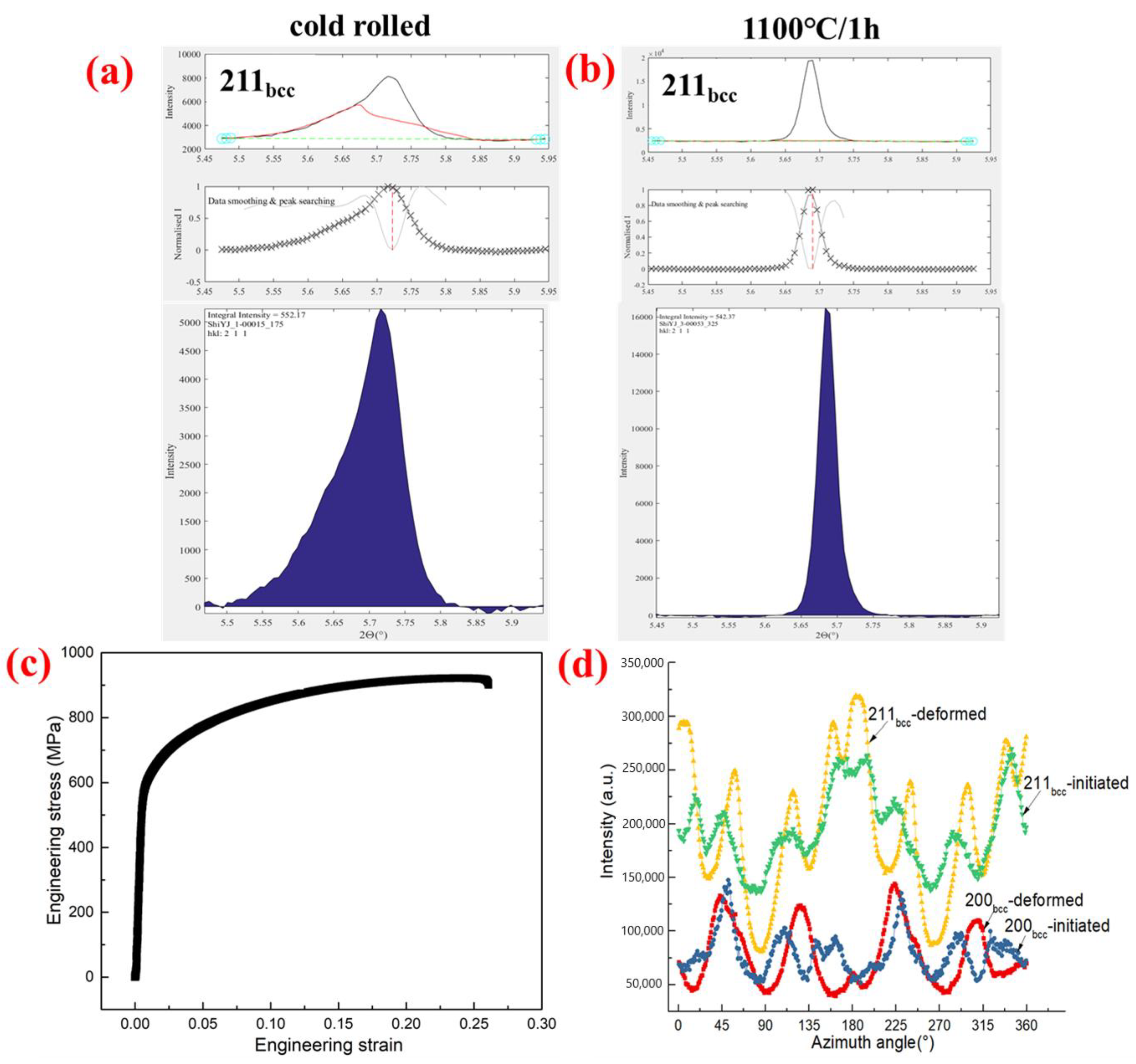

- The {200} and {211} peaks exhibited asymmetry in the bcc phase, resulting from the residual stress during cold rolling. The asymmetry was eliminated after annealing at temperatures of 900 °C/h~1100 °C/h with recrystallization and relaxation of the stress.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hoseini-Athar, M.M.; Mahmudi, R.; Prasath Babu, R.; Hedström, P. Tailoring the texture of an extruded Mg sheet through constrained groove pressing for achieving low mechanical anisotropy and high yield strength. Scr. Mater. 2020, 186, 253–258. [Google Scholar] [CrossRef]

- Hamad, K.; Chung, B.K.; Ko, Y.G. Effect of deformation path on microstructure, microhardness and texture evolution of interstitial free steel fabricated by differential speed rolling. Mater. Charact. 2014, 94, 203–214. [Google Scholar] [CrossRef]

- Lobanov, M.L.; Loginov, Y.N.; Danilov, S.V.; Golovin, M.A.; Karabanalov, M.S. Effect of Hot Rolling Rate on the Structure and Texture Condition of Plates of the Al–Si–Mg Alloy System. Met. Sci. Heat Treat. 2018, 60, 322–328. [Google Scholar] [CrossRef]

- Sathiaraj, G.D.; Pukenas, A.; Skrotzki, W. Texture formation in face-centered cubic high-entropy alloys. J. Alloy. Compd. 2020, 826, 154183. [Google Scholar] [CrossRef]

- Tazuddin; Biswas, K.; Gurao, N.P. Deciphering micro-mechanisms of plastic deformation in a novel single phase fcc-based MnFeCoNiCu high entropy alloy using crystallographic texture. Mat. Sci. Eng. A Struct. 2016, 657, 224–233. [Google Scholar] [CrossRef]

- Madhavan, R.; Ray, R.K.; Suwas, S. New insights into the development of microstructure and deformation texture in nickel–60 wt.% cobalt alloy. Acta Mater. 2014, 78, 222–235. [Google Scholar] [CrossRef]

- Kalsar, R.; Ray, R.K.; Suwas, S. Effects of alloying addition on deformation mechanisms, microstructure, texture and mechanical properties in Fe-12Mn-0.5C austenitic steel. Mater. Sci. Eng. A 2018, 729, 385–397. [Google Scholar] [CrossRef]

- Gottstein, G. Physical Foundations of Materials Science. Mater. Today 2004, 7, 197–302. [Google Scholar]

- Kestens, L.A.I.; Pirgazi, H. Texture formation in metal alloys with cubic crystal structures. Mater. Sci. Tech. Lond. 2016, 32, 1303–1315. [Google Scholar] [CrossRef]

- Sathiaraj, G.D.; Bhattacharjee, P.P.; Tsai, C.W.; Yeh, J.W. Effect of heavy cryo-rolling on the evolution of microstructure and texture during annealing of equiatomic CoCrFeMnNi high entropy alloy. Intermetallics 2016, 69, 1–9. [Google Scholar] [CrossRef]

- Shafiei, E.; Dehghani, K.; Ostovan, F.; Toozandehjani, M. Effect of Microstructure and Texture Evolution During Variable Gauge Rolling on Mechanical Properties of Tailor Rolled Blanks. Met. Mater. Int. 2019, 25, 1378–1387. [Google Scholar] [CrossRef]

- Bhattacharjee, P.P.; Sathiaraj, G.D.; Zaid, M.; Gatti, J.R.; Lee, C.; Tsai, C.W.; Yeh, J.W. Microstructure and texture evolution during annealing of equiatomic CoCrFeMnNi high-entropy alloy. J. Alloy. Compd. 2014, 587, 544–552. [Google Scholar] [CrossRef]

- Kalidindi, S.R. modeling anisotropic strain hardening and deformation textures in low stacking fault enegy fcc metals. Int. J. Plast. 2001, 17, 837–860. [Google Scholar] [CrossRef]

- Skrotzki, W.; Pukenas, A.; Odor, E.; Joni, B.; Ungar, T.; Völker, B.; Hohenwarter, A.; Pippan, R.; George, E.P. Microstructure, Texture, and Strength Development during High-Pressure Torsion of CrMnFeCoNi High-Entropy Alloy. Crystals 2020, 10, 336. [Google Scholar] [CrossRef]

- Bonis, L.J.; Duga, J.J.; Gilman, J.J. Fracture of Metals, Polymers, and Glasses: Proceedings. Fundam. Phenom. Mater. Sci. 1967, 10, 139–146. [Google Scholar]

- He, Y.; Godet, S.; Jacques, P.J.; Jonas, J.J. Crystallographic relations between face- and body-centred cubic crystals formed under near-equilibrium conditions: Observations from the Gibeon meteorite. Acta Mater. 2006, 54, 1323–1334. [Google Scholar] [CrossRef]

- Shi, Y.J.; Li, S.L.; Tung, L.L.; Hui, X.D.; Zhang, Z.; Li, R.; Zhang, M.; Kabra, S.; Wang, Y.-D. In situ neutron diffraction study of a new type of stress-induced confined martensitic transformation in Fe22Co20Ni19Cr20Mn12Al7 high-entropy alloy. Mater. Sci. Eng. A 2020, 771, 138555. [Google Scholar] [CrossRef]

- He, J.Y.; Liu, W.H.; Wang, H.; Wu, Y.; Liu, X.J.; Nieh, T.G.; Lu, Z.P. Effects of Al addition on structural evolution and tensile properties of the FeCoNiCrMn high-entropy alloy system. Acta Mater. 2014, 62, 105–113. [Google Scholar] [CrossRef]

- McChesney, J.L.; Reininger, R.; Ramanathan, M.; Benson, C.; Srajer, G.; Abbamonte, P.; Campuzano, J.C. The intermediate energy X-ray beamline at the APS. Nucl. Instrum. Meth. A 2014, 746, 98–105. [Google Scholar] [CrossRef]

- Chen, S.F.; Song, H.W.; Zhang, S.H.; Cheng, M.; Lee, M.G. Effect of shear deformation on plasticity, recrystallization mechanism and texture evolution of Mg–3Al–1Zn alloy sheet: Experiment and coupled finite element-VPSC simulation. J. Alloy. Compd. 2019, 805, 138–152. [Google Scholar] [CrossRef]

- Harris, K.E.; Ebrahimi, F.; Garmestani, H. Texture evolution in NiAl. Mater. Sci. Eng. A 1998, 247, 187–194. [Google Scholar] [CrossRef]

- Sathiaraj, G.D.; Ahmed, M.Z.; Bhattacharjee, P.P. Microstructure and texture of heavily cold-rolled and annealed fcc equiatomic medium to high entropy alloys. J. Alloy. Compd. 2016, 664, 109–119. [Google Scholar] [CrossRef]

- Haase, C.; Barrales-Mora, L.A. Influence of deformation and annealing twinning on the microstructure and texture evolution of face-centered cubic high-entropy alloys. Acta Mater. 2018, 150, 88–103. [Google Scholar] [CrossRef]

- Reddy, S.R.; Ahmed, M.Z.; Sathiaraj, G.D.; Bhattacharjee, P.P. Effect of strain path on microstructure and texture formation in cold-rolled and annealed fcc equiatomic CoCrFeMnNi high entropy alloy. Intermetallics 2017, 87, 94–103. [Google Scholar] [CrossRef]

- Kim, W.J.; Jeong, H.T.; Park, H.K.; Park, K.; Na, T.W.; Choi, E. The effect of Al to high-temperature deformation mechanisms and processing maps of Al0.5CoCrFeMnNi high entropy alloy. J. Alloy. Compd. 2019, 802, 152–165. [Google Scholar] [CrossRef]

- Inagak, H. Fundamental aspect of texture formation in Low carbon steel. ISIJ Int. 1994, 34, 313–321. [Google Scholar] [CrossRef]

- Lucke, R.K. Rabbe Texture and microstructure of hot rolled steel. Scr. Metal. 1992, 26, 1221–1226. [Google Scholar]

- Tóth, L.S.; Jonas, J.J.; Daniei, D.; Ray, R.K. Development of ferrite rolling textures in low- and extra low-carbon steels. Met. Trans. A 1990, 21, 2985–3000. [Google Scholar] [CrossRef]

- Inagaki, H.; Suda, T. The development of rolling textures in low-carbon steels. Texture Stress Microstruct. 1972, 1, 129–140. [Google Scholar] [CrossRef]

- El-Danaf, E.; Kalidindi, S.R.; Doherty, R.D.; Necker, C. Deformation texture transition in brass: Critical role of micro-scale shear bands. Acta Mater. 2000, 48, 2665–2673. [Google Scholar] [CrossRef]

- Haase, C.; Chowdhury, S.G.; Barrales-Mora, L.A.; Molodov, D.A.; Gottstein, G. On the Relation of Microstructure and Texture Evolution in an Austenitic Fe-28Mn-0.28C TWIP Steel During Cold Rolling. Metall. Mater. Trans. A 2012, 44, 911–922. [Google Scholar] [CrossRef]

- Sakata, T.; Yasuda, H.Y.; Umakoshi, Y. Control of microstructure and orientation distribution in Ni-Al-based β/γ’two phase alloys by thermomechanical processing. Acta Mater. 2001, 49, 4231–4239. [Google Scholar] [CrossRef]

- Moravcik, I.; Cizek, J.; Zapletal, J.; Kovacova, Z.; Vesely, J.; Minarik, P.; Kitzmantel, M.; Neubauer, E.; Dlouhy, I. Microstructure and mechanical properties of Ni1,5Co1,5CrFeTi0,5 high entropy alloy fabricated by mechanical alloying and spark plasma sintering. Mater. Des. 2017, 119, 141–150. [Google Scholar] [CrossRef]

| Component | Miller Indices | Euler Angles (φ1, Φ, φ2) | Symbol |

|---|---|---|---|

| Goss | {110}<001> | 90°, 90°, 45° | ζ (A) |

| Brass | {110}<1-12> | 60°, 90°, 45° | (B) |

| Brass | {111}<1-21> | 30°, 60°, 45° | ε (C) |

| Copper | {112}<-1-11> | 90°, 45°, 45° | (D) |

| Dillamore | {4 4 11}<-11 -11 8> | 90°, 30°, 45° | (E) |

| Cube | {112}<1-10> | 0°, 30°, 45° | α(a) |

| Cube | {111}<112> | 90°, 60°, 45° | γ(b) |

| Cube | {111}<0-11> | 60°, 60°, 45° | γ(f) |

| Cube | {111}<1-21> | 30°, 60°, 45° | γ(e) |

| Cube | {111}<1-32> | 45°, 60°, 45° | Γ(d) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, Y.; Wang, Y.; Li, S.; Li, R.; Cui, Y.; Wang, Y.-D. Recrystallization Texture Analysis of FeCoNiCrMnAl0.5 High-Entropy Alloy Investigated by High-Energy X-ray Diffraction. Metals 2022, 12, 1674. https://doi.org/10.3390/met12101674

Shi Y, Wang Y, Li S, Li R, Cui Y, Wang Y-D. Recrystallization Texture Analysis of FeCoNiCrMnAl0.5 High-Entropy Alloy Investigated by High-Energy X-ray Diffraction. Metals. 2022; 12(10):1674. https://doi.org/10.3390/met12101674

Chicago/Turabian StyleShi, Yajuan, Youkang Wang, Shilei Li, Runguang Li, Yimin Cui, and Yan-Dong Wang. 2022. "Recrystallization Texture Analysis of FeCoNiCrMnAl0.5 High-Entropy Alloy Investigated by High-Energy X-ray Diffraction" Metals 12, no. 10: 1674. https://doi.org/10.3390/met12101674

APA StyleShi, Y., Wang, Y., Li, S., Li, R., Cui, Y., & Wang, Y.-D. (2022). Recrystallization Texture Analysis of FeCoNiCrMnAl0.5 High-Entropy Alloy Investigated by High-Energy X-ray Diffraction. Metals, 12(10), 1674. https://doi.org/10.3390/met12101674